Treston 14-C12049206, 14-C12041204, 14-C12049205, 14-C12049204, 14-C12041205 User Manual

...

ASSEMBLY INSTRUCTIONS

Cornerstone Bench

905998

10/17/19

1 (7)

Treston • 156 Bluffs Court, Canton, GA 30114

Tel. 800.437.6772 • Fax 770.720.6584 • infousa@treston.com • www.treston.us

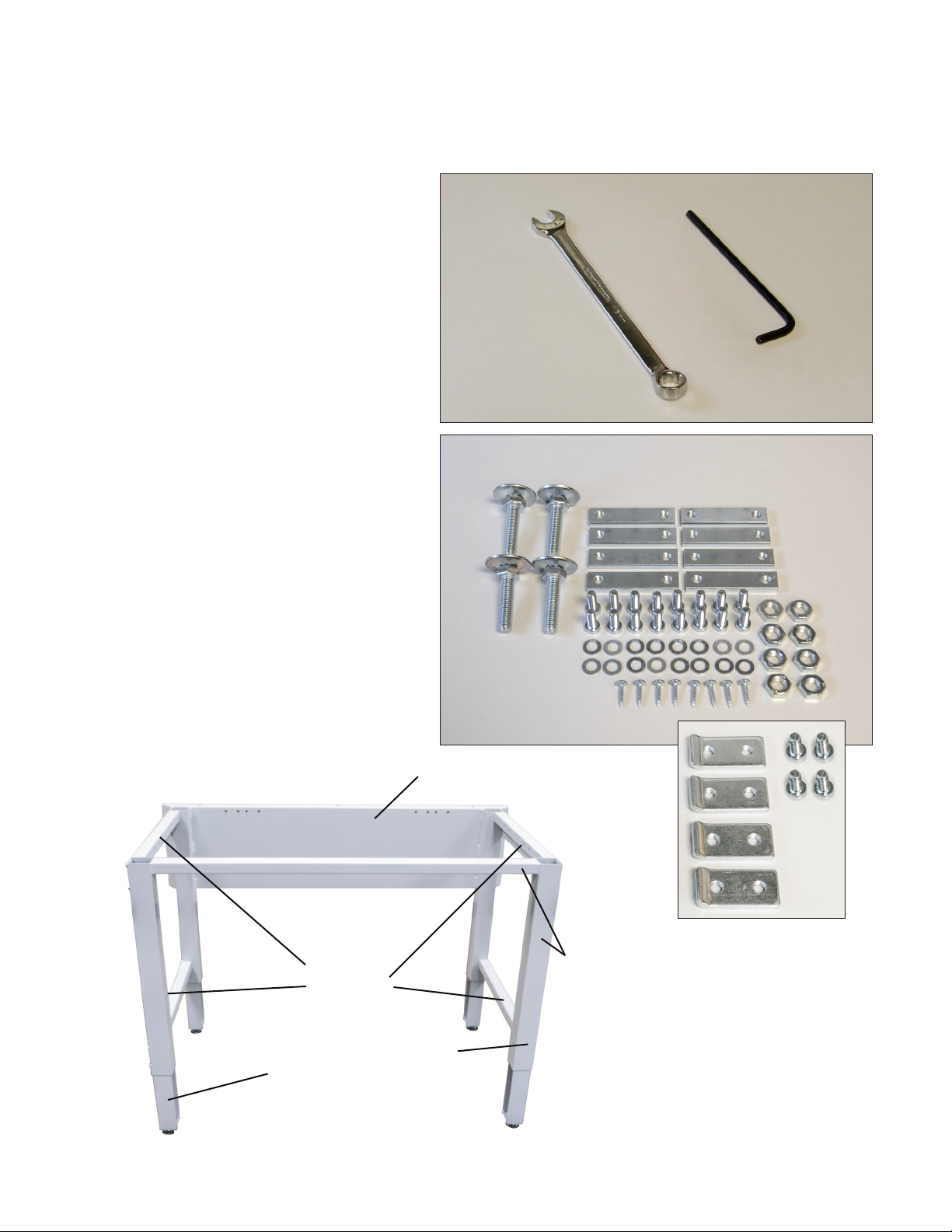

TOOLS REQUIRED FOR INSTALLATION:

• 5mm hex key

• 19mm wrench

HARDWARE INCLUDED:

• (4) 12mm foot glides

• (8) threaded nut plates

• (16) M8 x 20 bolts

• (16) M8 washers

• (8) 12mm nuts

• (8) wood screws

ASSEMBLY INSTRUCTIONS

Cornerstone Bench

905998

10/17/19

2 (7)

Hardware for optional upright attachment:

• (4) upright tabs

• (4) M8 x 16 bolts

depth kit

rails

telescoping legs

rear case assembly

front leg assembly

leg tubes

Treston • 156 Bluffs Court, Canton, GA 30114

Tel. 800.437.6772 • Fax 770.720.6584 • infousa@treston.com • www.treston.us

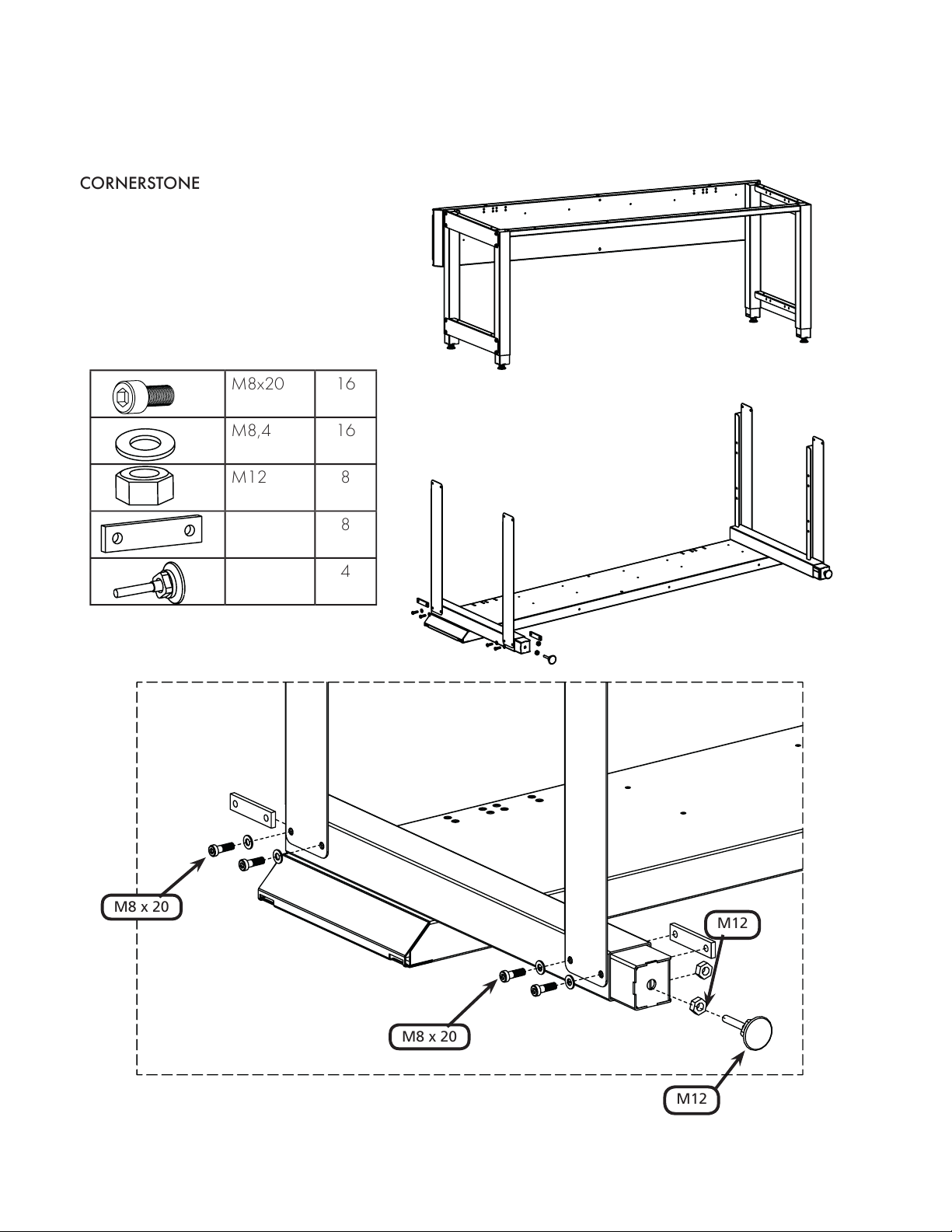

CORNERSTONE

M8x20 16

M8,4 16

M12 8

8

4

M8 x 20

M12

M12

M8 x 20

ASSEMBLY INSTRUCTION

905998

2019-11-07

1 (3)

ASSEMBLY INSTRUCTIONS

Cornerstone Bench

905998

10/17/19

3 (7)

Tel. 800.437.6772 • Fax 770.720.6584 • infousa@treston.com • www.treston.us

Treston • 156 Bluffs Court, Canton, GA 30114

ASSEMBLY INSTRUCTIONS

M8 x 20

M8 x 20

M12

M12

ASSEMBLY INSTRUCTION

905998

2019-11-07

2 (3)

Cornerstone Bench

905998

10/17/19

4 (7)

Treston • 156 Bluffs Court, Canton, GA 30114

Tel. 800.437.6772 • Fax 770.720.6584 • infousa@treston.com • www.treston.us

ASSEMBLY INSTRUCTIONS

4,5 x 20

4,5x20 8

ASSEMBLY INSTRUCTION

905998

2019-11-07

3 (3)

Cornerstone Bench

905998

10/17/19

5 (7)

LAMINATE

Treston laminate tops assembled with wood screws provided.

PHENOLIC

DO NOT USE provided screws from the hardware pack provided with the table. These screws are for

laimate work surfaces only.

Treston phenolic tops can be assembled in 2 ways:

• Mechanical fasteners - Screws to be provided by the installer. Pre-drill a pilot hole in the bottom of the work

surface, taking care to keep from penetrating through the top. The pre-drilled hole should be the same length as

the screw shaft. The screw should be slightly larger in diameter than the pilot hole. Use a coarse threaded screw,

wood or machine.

• Adhesive - Provided by the installer. Use 100% silicon. Apply several “spots” or a continuous bead to the top of

the table frame. Position the work surface as centered on the frame and let cure for 12 hrs at room temp.

Treston • 156 Bluffs Court, Canton, GA 30114

Tel. 800.437.6772 • Fax 770.720.6584 • infousa@treston.com • www.treston.us

work surface

support lip

ASSEMBLY INSTRUCTIONS

Cornerstone Bench

905998

10/17/19

6 (7)

STEP ONE: Lay rear case assembly with back side

down. Attach depth kit rails to the legs with the work

surface support lips facing up, flush with the inside of the

leg. Attach the depth kit rail using M8 hardware, inserting

threaded nut plate into legs.

NOTE: Wait to attach lower depth kit rails until step 3,

after telescoping legs have been inserted.

STEP THREE: Attach lower depth kit rails to legs

using M8 hardware. Insert the threaded nut plate into

telescoping leg. M8 bolts with washers will hold depth kit

rail, leg tube and telescoping leg together.

STEP TWO: Insert telescoping legs into leg tubes. Align

holes with outer side of the leg tubes. Set to desired

position/height of the table.

STEP FOUR: With rear case still laying flat on the floor,

lay front leg and front rail assembly onto depth kit rails,

keeping the depth kit rails flush with the outsides of the

front assembly.

STEP FIVE: Attach front leg/front rail assembly to the

rest of the frame with M8 hardware and nut plates. Insert

telescoping legs into leg tubes before attaching lower

depth kit rails. (see steps 1-3). Tighten all bolts.

NOTE: If adding a bottom shelf, depth kit rails should be

mounted with lip facing out to support shelf brackets.

Tel. 800.437.6772 • Fax 770.720.6584 • infousa@treston.com • www.treston.us

STEP SIX: Floor glides will each require 2 nuts for

mounting. Before attaching floor glides to legs, place first

nut on bolt in desired location.

Treston • 156 Bluffs Court, Canton, GA 30114

ASSEMBLY INSTRUCTIONS

Cornerstone Bench

905998

10/17/19

7 (7)

STEP SEVEN: Insert glide into bottom of telescoping leg

tubes. Attach second nut to glide stem and tighten. (In the

above photo, the glide is placed in the shortest position.)

STEP NINE: Attach laminate work surface using

provided hardware. For phenolic tops, please refer to

work surface instructions, right.

STEP EIGHT: Rotate table into upright position.

LAMINATE

Treston laminate tops assembled with wood screws

provided.

PHENOLIC

DO NOT USE provided screws from the hardware

pack provided with the table. These screws are for

laimate work surfaces only.

Treston phenolic tops can be assembled in 2 ways:

• Mechanical fasteners - Screws to be provided by the

installer. Pre-drill a pilot hole in the bottom of the work

surface, taking care to keep from penetrating through

the top. The pre-drilled hole should be the same length

as the screw shaft. The screw should be slightly larger

in diameter than the pilot hole. Use a coarse threaded

screw, wood or machine.

• Adhesive - Provided by the installer. Use 100% silicon.

Apply several “spots” or a continuous bead to the top of

the table frame. Position the work surface as centered on

the frame and let cure for 12 hrs at room temp.

Treston • 156 Bluffs Court, Canton, GA 30114

Tel. 800.437.6772 • Fax 770.720.6584 • infousa@treston.com • www.treston.us

Loading...

Loading...