Page 1

PRODUCT DATA &PRODUCT DATA &

PRODUCT DATA &

PRODUCT DATA &PRODUCT DATA &

SPECIFICATIONSSPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONSSPECIFICATIONS

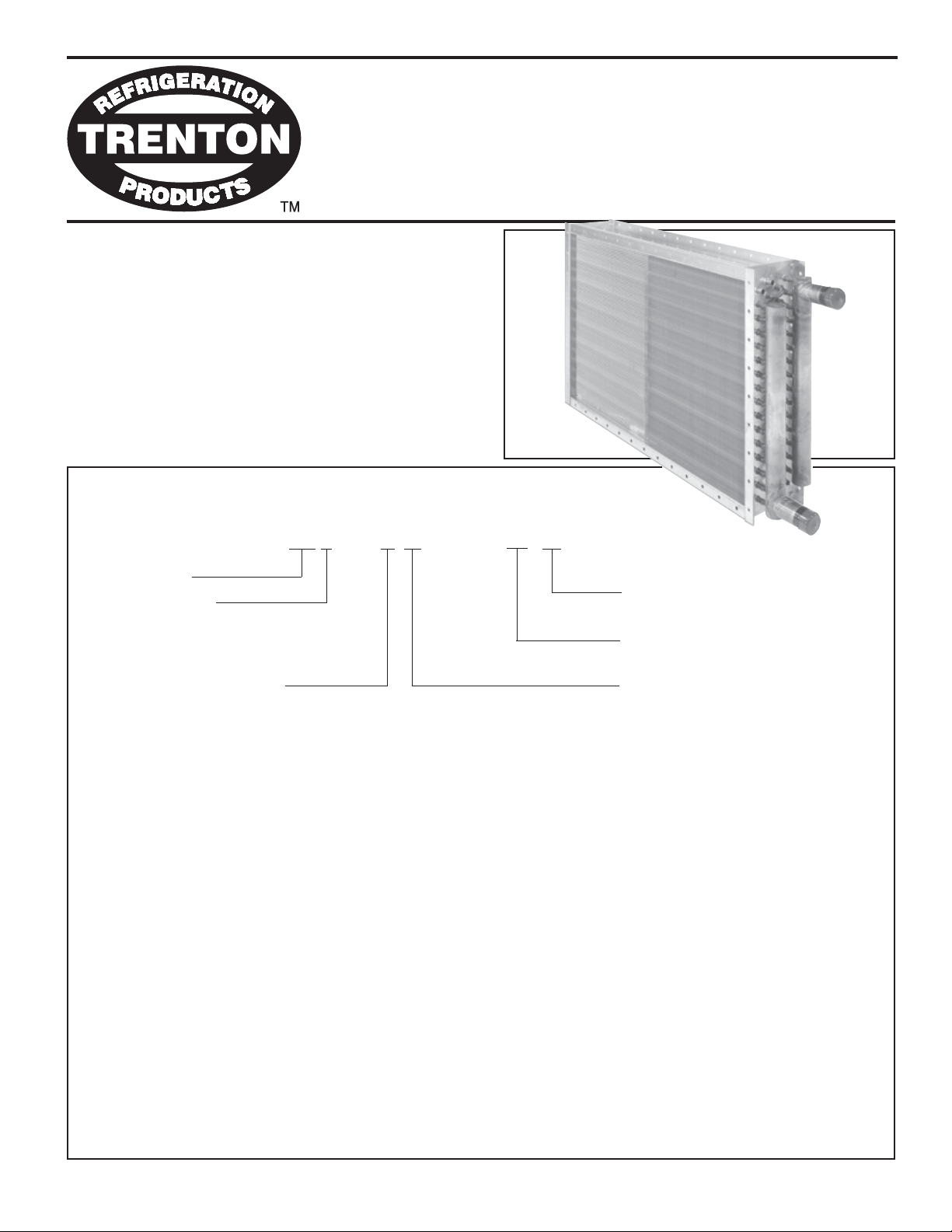

TYPES TWS, TWD, TWH &

TYPE TB BOOSTER COILS

BULLETIN: T70-TWSH-PDS-11

1064630

NOMENCLATURE

TYPE MODEL FACE DIMENSIONS

TW

Coil Type

CIRCUITING:

S = Single Serpentine

D = Double Serpentine

H = Half Serpentine

Fin Series (60, 80, 100

or 120) (100 shown)

S

- 1 0 5 - 18 x 45

D

H

WW

AA

W

WW

COILSCOILS

COILS

COILSCOILS

TER HEATER HEA

A

TER HEA

AA

TER HEATER HEA

TINGTING

TING

TINGTING

Nominal Tube Length (inches)

“W” Dimensions (inches)

Rows Deep

CONTENTS P AGE

Nomenclature.............................................................................................................................. Cover

Water Heater Coils...................................................................................................................... 2

Type TWS and TWD Coils........................................................................................................... 3

Type TWH and Booster Coils....................................................................................................... 3

Coil Selection - Size - Table 1....................................................................................................... 3

General Information...................................................................................................................... 4

Conversion of Air Volume to Standard Air....................................................................................... 5

Example Coil Selection No. 1 and 2..............................................................................................6

Example Coil Selection No. 3...................................................................................................... 7

Example Coil Selection No. 4....................................................................................................... 8

Booster Coil Table No. 2............................................................................................................... 9 to 14

One Row TW Coils Table No. 3.................................................................................................... 15 to 17

Two Row TW Coils Table No. 3..................................................................................................... 18 to 19

Three Row TW Coils Table No. 3................................................................................................... 20 to 21

Four Row TW Coils Table No. 3.................................................................................................... 22 to 23

Entering Air Correction Table No. 4................................................................................................ 23

Coil Selection Using Heat Transfer Curve....................................................................................... 24

Heat Transfer Curve Fig. 3............................................................................................................ 25

M.E.D. Tables Fig. 4.................................................................................................................... 26 to 27

Air Friction Curves Fig. 5.............................................................................................................. 28

Coil Circulating Table No. 5........................................................................................................... 28

Water Pressure Drop Curve Fig. 6................................................................................................. 29

Water Pressure Drop, Row-Length Correction Factor Table Nos 6 & 7.............................................. 30

TW Dimensional Drawings........................................................................................................... 31

Booster Dimensional Drawings...................................................................................................... 32

Engineering Specifications............................................................................................................ 32

We are on the InternetWe are on the Internet

We are on the Internet

We are on the InternetWe are on the Internet

www.trentonrefrigeration.com

Page 2

WATER HEATING COILS

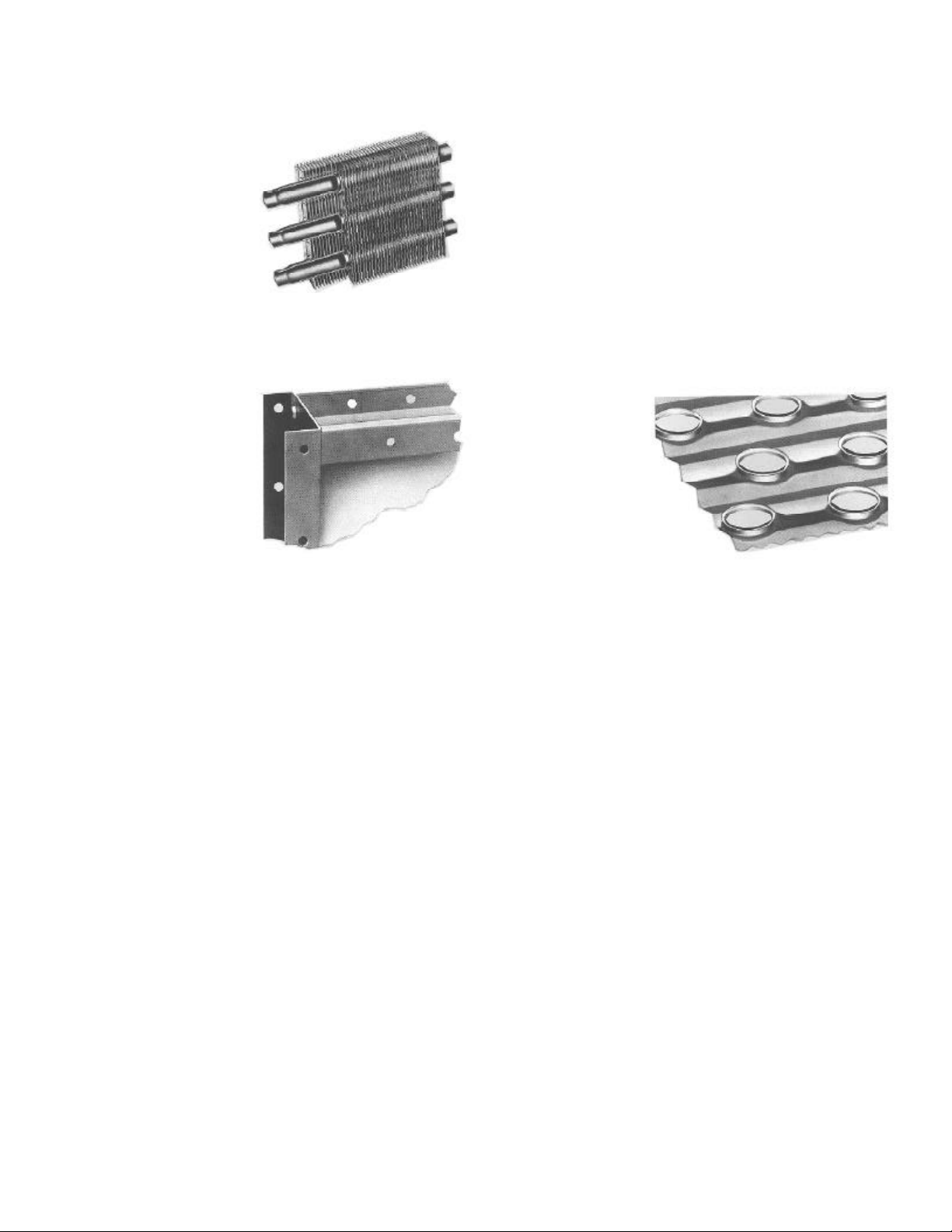

MECHANICAL

PRESSURE BOND

Trenton Mechanical

Pressure Bond guarantees

that each tube and fin collar

make positive permanent

metal to metal contact.

No need for using low

conductivity metals or alloys,

FLANGED CASINGS

Double flanged galvanized

steel casings on all

Trenton Water Heating

Coils provide greater

strength - better support

for easier coil stacking.

Simplifies moving and handling operations.

Top and bottom casing flanges are turned back to

form two channel sections in a “box shape”.

Provides maximum strength and durability.

Standard casings are continuous galvanized steel.

Copper and aluminum casings available.

COPPER TUBE HEADERS

Made from heavy gauge seamless drawn copper

tube, Trenton designed headers lengthen coil life provide necessary header flexibility to compansate

for expansion and contraction during operation.

Header flexibility also reduces coil core “strains”

during start up. Further proof that Trenton

design means long life and top performance.

FULL FIN

COLLARS

Efficient Trenton

fin presses perform

multi - stage operations

to draw full fin collars

with wide, smooth surfaces

that completely cover coil

tubes - actually form a tube within a tube for

greater strength and maximum heat transfer.

Lack of sharp collar edges make Trenton Coils

easier to clean - smoother Trenton Collars

retard lint and dirt accumulation.

- 2 -

Page 3

WATER HEATING COILS

TYPE “TWS” COILS

Type “TWS” Coils are specifically designed and

engineered to meet most applications requiring normal

water quantities and normal water pressure drop.

Type “TWS” Coils are counterflow, single serpentine

circuited to deliver absolute maximum performance.

With single serpentine coils every tube in the first row is

fed.

Type “TWS” Coils of two and four rows deep are

furnished with the supply and return connections on the

same and of the coil. Intermediate drain headers are

TYPE “TWD” COILS

Type “TWD” Coils are designed for use in applications that

require high water quantities and low water pressure drop.

“TWD” Coils are counterflow, double serpentine circuited

to maintain normal water velocities and low water

pressure drops. With double serpentine coils every tube in

the first and second rows are fed. “TWD” coils are 2 row or

4 row. Four row coils have the supply and return connections on the same end of the coil. Intermediate drain

headers can be furnished to permit draining of coils that

cannot be installed level.

available to permit draining of coils which cannot be

installed level.

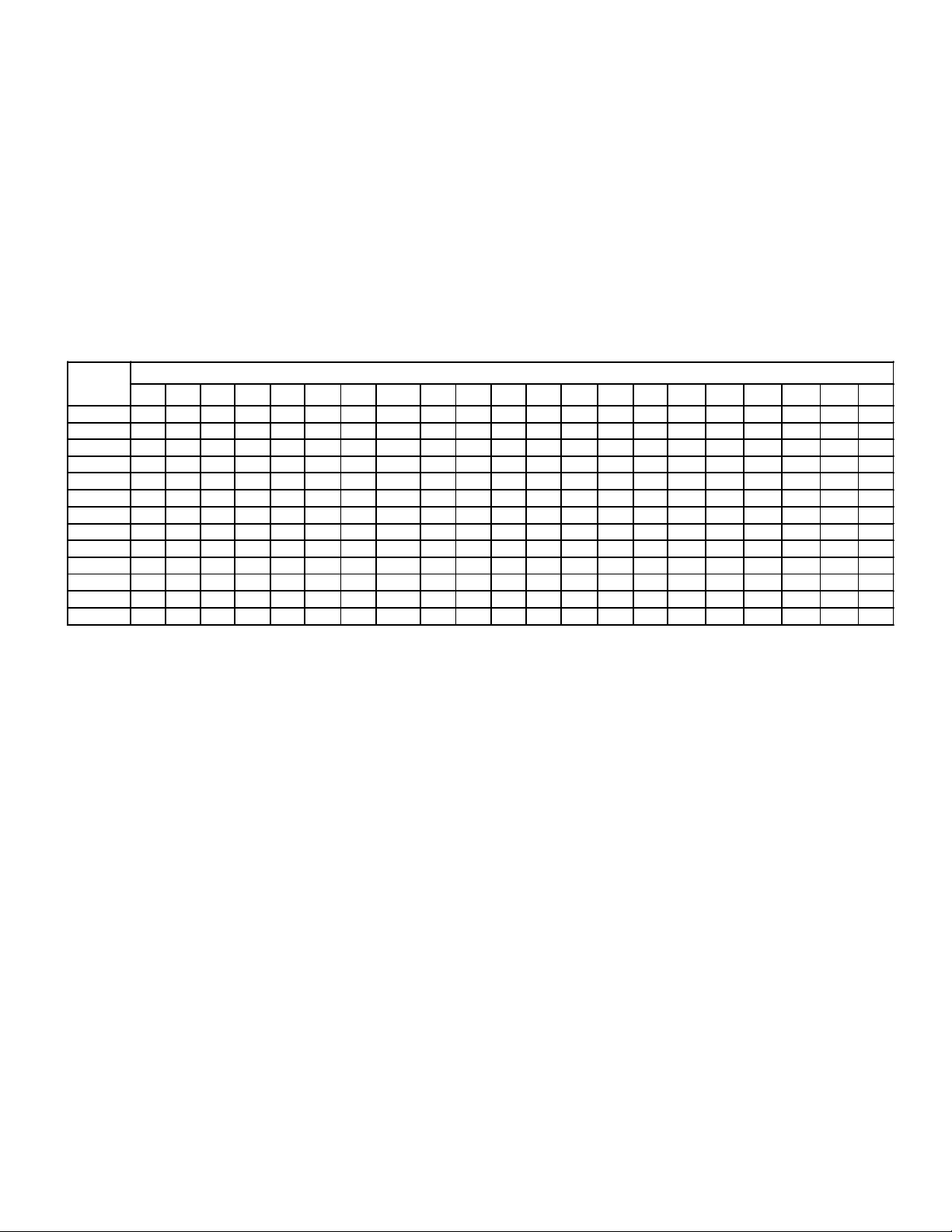

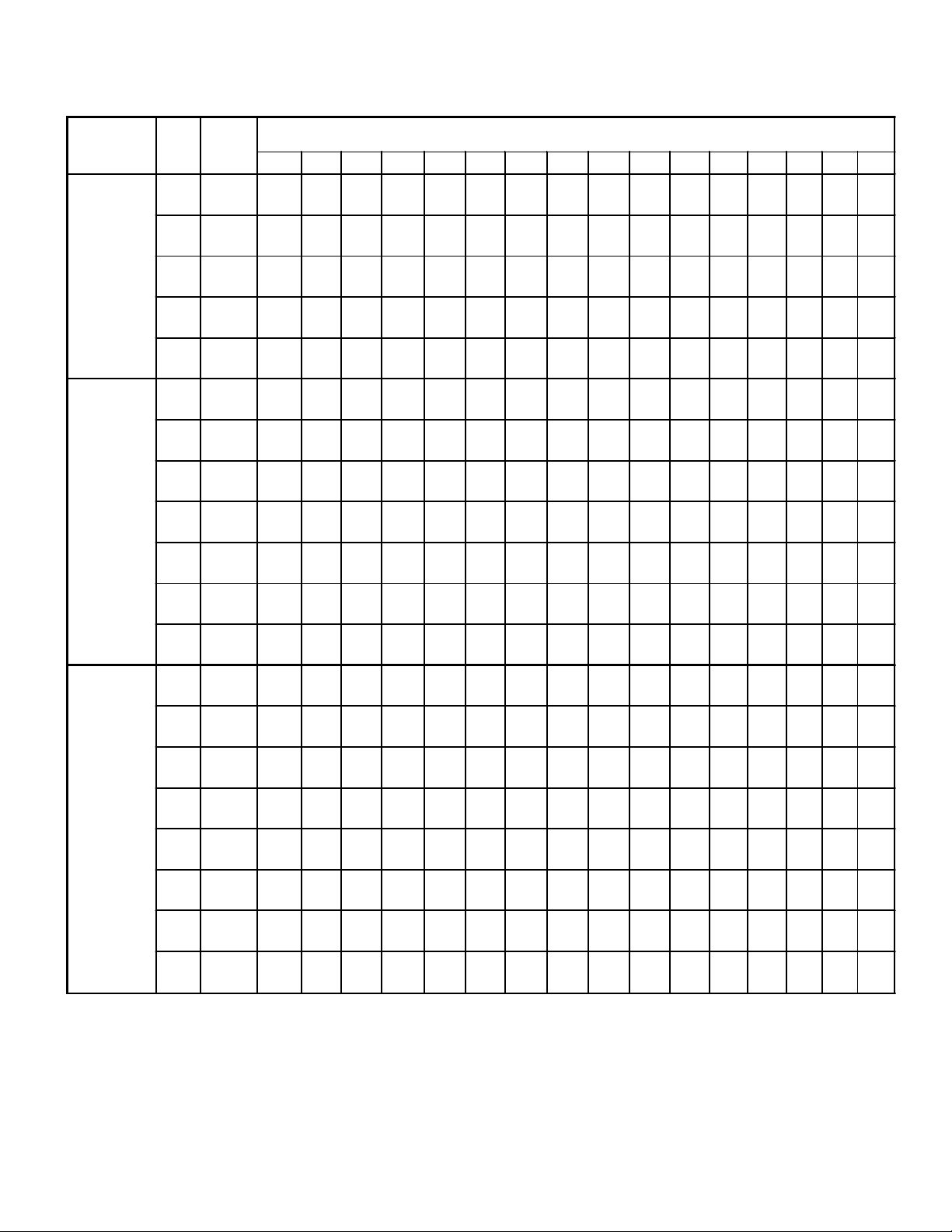

TABLE No. 1 COIL SIZES - NOMINAL FACE AREA SQ. FT.

"W"

INCHES

12

15

18

21

24

27

30

33

36

39

42

In addition to the Standard sizes listed above, Trenton can furnish coils having an NTL up to 144 inches and a “W” dimension up to 72 inches.

Type “B” coils available in sizes listed in BOLD only.

12 15 18 21 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

6

.50 .62 .75 .87 1.00 1.25 1.50 1.75 2.0 2.2 2.5 2.7 3.0

9

.75 .94 1.12 1.31 1.50 1.87 2.25 2.62 3.0 3.4 3.7 4.1 4.5

1.00 1.25 1.50 1.75 2.00 2.50 3.00 3.50 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0

1.56 1.87 2.19 2.50 3.12 3.75 4.37 5.0 5.6 6.2 6.9 7.5 8.1 8.7 9.4 10.0 10.6 11.2 11.9 12.5

2.25 2.62 3.00 3.75 4.50 5.25 6.0 6.7 7.5 8.2 9.0 9.7 10.5 11.2 12.0 12.7 13.5 14.2 15.0

3.06 3.50 4.37 5.25 6.12 7.0 7.9 8.7 9.6 10.5 11.4 12.2 13.1 14.0 14.9 15.7 16.6 17.5

4.00 5.00 6.00 7.00 8.0 9.0 10.0 11.0 12.0 13.0 14.0 15.0 16.0 17.0 18.0 19.0 20.0

5.62 6.75 7.87 9.0 10.1 11.2 12.4 13.5 14.6 15.7 16.9 18.0 19.0 20.2 21.4 22.5

6.25 7.50 8.75 10.0 11.2 12.5 13.7 15.0 16.2 17.5 18.7 20.0 21.2 22.5 23.7 25.0

NOMINAL TUBE LENGTH - NTL - (INCHES)

8.25 9.62 11.0 12.4 13.7 15.1 16.5 17.9 19.2 20.6 22.0 23.4 24.7 26.1 27.5

9.00 10.50 12.0 13.5 15.0 16.5 18.0 19.5 21.0 22.5 24.0 25.5 27.0 28.5 30.0

11.37 13.0 14.6 16.2 17.9 19.5 20.1 22.7 24.4 26.0 27.6 29.2 30.9 32.5

12.25 14.0 15.7 17.5 19.2 21.0 22.7 24.5 26.2 28.0 29.7 31.5 33.2 35.0

TYPE “TWH” COILS

Type “TWH” Coils are designed to produce high

capacity with limited water quantity. High capacity is

obtained from the counterflow half serpentine water

circuiting which gives higher water velocities.

With half serpentine coils every other tube in the first

row is fed. All Type “TWH” Coils, regardless of row

depth, have both the supply and return connections on

the same end of the coil. Intermediate drain headers are

not available on “TWH” coils.

TYPE “TB” COILS

Type “TB” standard drainable single and double circuit

return bend booster water heating coils are specifically

made for reheat zone applications. These coils will give

high capacity with a normal water temperature drop. In

many instances a two row booster coil will do a better

heating job that would require a three row standard coil.

Single circuit one and two row and two circuit two row

coils are available. The fin, tube and return bend

construction is the same as for standard “TWS” coils, and

casing is designed for easy installation in confined

spaces.

- 3 -

Page 4

GENERAL INFORMATION

DETERMINATION OF AIR MIXTURE TEMPERATURE

Frequently return air at different temperatures or fresh air

and return air are mixed before entering a heating coil. To

determine the performance of a heating coil the

SPECIFIED:

Return air temperature = 51 OF cfm (return air) = 5100

Fresh air temperature = 20 OF cfm (fresh air) = 1200

SOLUTION:

MIxed air temperature =

Total cfm mixture

Mixed air temperature =

For best coil performance, the water flow rate should be

between 3.0 and 6.0 gpm per feed. For normal

applications it is recommended that 3 gpm per feed be

assumed in the calculations, and that the coil most

closely meeting this requirement be checked first. For the

majority of applications this will be a “TWH” Coil. If a

“TWH” exceeds the 3 gpm per feed, then check a “TWS’

or “TWD” Coil.

cfm (return air) X (temp of return air) + cfm (fresh air) X (temp of fresh air)

5100 X 51 + 1200 X 20 = 260,100 + 24,000 = 284,100

6300

6300

GPM PER FEED RECOMMENDATIONS

mixture air temperature entering the coil is required.

Determine mixture air temperature as follows:

6300

“TBS” and “TBD2” Coils should be checked when the flow

rate falls below 3 gpm per feed and the face dimensions

fall within the booster coil sizes. If a low water pressure

drop is desired, it is recommended that 3 gpm per feed

be assumed in the calculations. In all selections the

maximum allowable gpm per feed should be used to

obtain the most economical coil.

= 45.1OF

RECOMMENDED FACE VELOCITY AND PRELIMINARY COIL SIZE SELECTION

Desired face velocity must be assumed if not specified.

For normal heating applications face velocities from 500 to

800 fpm are recommended. Higher face velocities are

used on some industrial and process installations.

Occasionally lower face velocities are employed when the

allowable air friction is extremely low.

For hot water applications, coils are normally selected

which have a tube length 2 to 3 times the “W” dimension.

PROCESS APPLICATIONS AND COILS IN SERIES

Occasionally, it may be necessary or desirable to use two

or more coils in series in order to obtain the final

temperature required, although one coil of the proper

depth is usally used on hot water installations. If row

SERPENTINE

The word serpentine has often been used in explaining or

classifying circuiting of coils. A single serpentine coil has

all the tubes in a row supplied in parallel. On a multi-row

single serpentine coil the tubes of the second and

subsequent rows are fed by return bends from the first

row. A single serpentine coil with 8 tubes in the face all

the tubes in the first two rows. A one-half serpentine

Square face dimension water coils are rarely selected

because of the low water velocities that result. Coils of

several different dimensions are usally available to

choose from. Select the most desirable. If the required

face area is not listed in a size to fit the space available

in Table 1 select a coil which will fit the space and

divide the face area of this coil into the cfm to

determine the coil face velocity.

control is required, individual coils would be necessary.

In calculating the temperature rise through a second coil,

the leaving air temperature from the first is used as the

entering air temperature to the second coil.

coil has 1/2 as many circuits as there are tubes in the

face. As a result the liquid passing through a 1/2

serpentine coil, travels through two tubes in every row.

Trenton standard “TWS” one, two, three and four row coils

are single serpentine. Standard “TWD” four row

coils are double serpentine. “TWH” one, two, three and

four row coils are 1/2 serpentine.

- 4 -

Page 5

CONVERSION OF AIR VOLUME TO STANDARD AIR

When the specified air volume (cfm) is given at any temperature other than 70 OF or at any altitude

other than sea level, these charts should be used for correction before using the following capacity

and friction tables (which are based on cfm at standard air conditions).

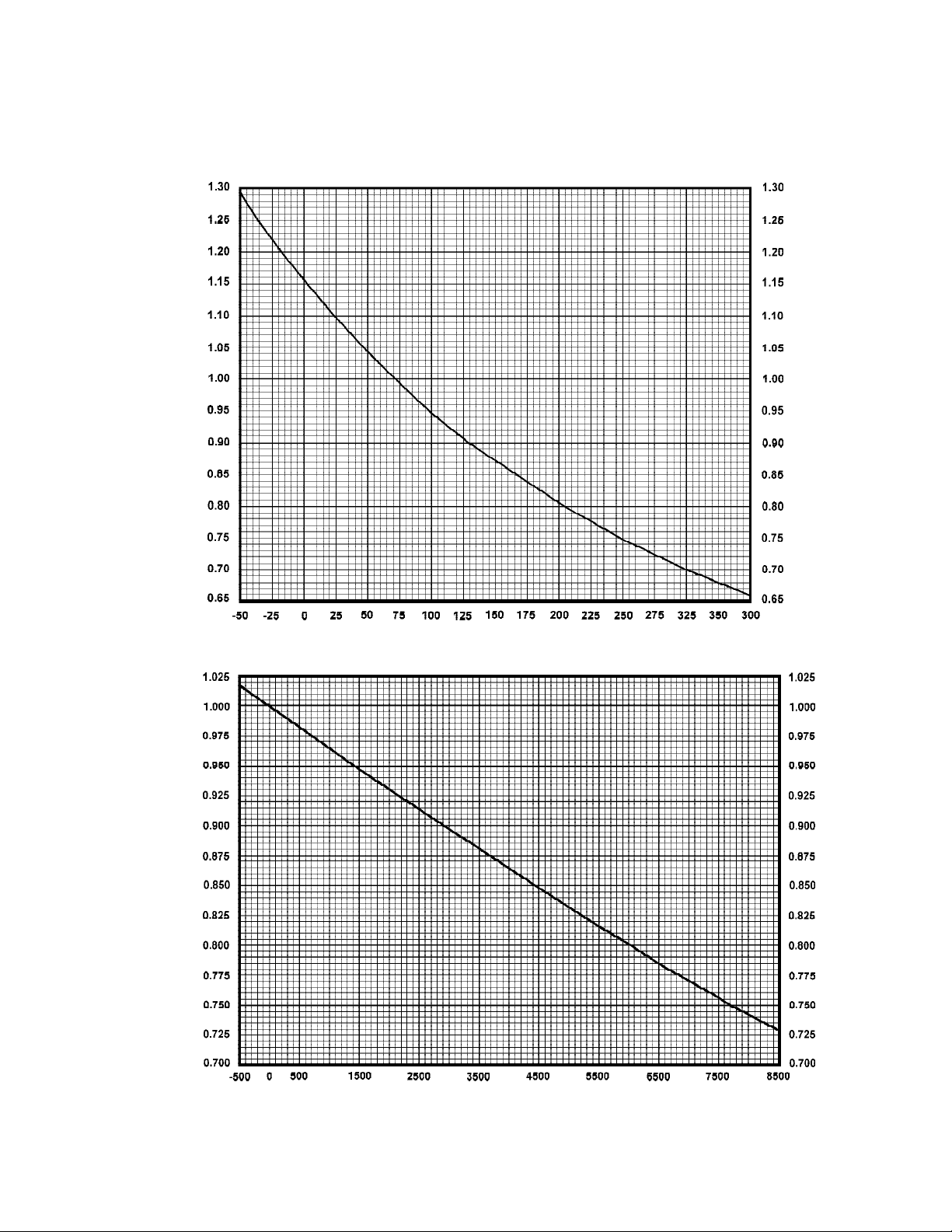

TEMPERATURE CONVERSION FACTOR

Figure No. 1

Figure No. 2

)ALTITUDE CONVERSION FACTOR (F

1

TEMPERATURE CONVERSION FACTOR (F

ALTITUDE CONVERSION FACTOR

)

1

)

2

EXAMPLE: To convert 15,900 cfm of air at 94 OF and at 3,000 ft altitude to standard conditions:

SOLUTION: cfm of std air= cfm of specified air X F1 XF2 = 15,900 X .955 X .896 = 13,600

WHERE: F1 = Temperature conversion factor from Figure 1.

F2 = Altitude conversion factor from Figure 2.

- 5 -

) TEMPERATURE CONVERSION FACTOR (F

2

ALTITUDE CONVERSION FACTOR (F

Page 6

COIL SELECTION

EXAMPLE PROBLEM No. 1

(Showing Use of Direct Selection Table No. 2)

GIVEN:

CFM (Std. Air)...................................................................................................675

Entering Air Temperature...............................................................................80 OF

Leaving Air Temperature..............................................................................120 OF

Entering Water Temperature........................................................................230 OF

Desired Water Temperature Drop..................................................................25 OF

Required Face Dimensions......................................................................12” X 18”

1. FACE AREA

FA = 1.5 sq. ft. (Table 1, Page 3)

2. FACE VELOCITY

cfm

FV =

3. BTUH REQUIRED

Btuh = 1.09 X cfm X (lvg air temp - ent air temp)

= 1.09 X 675 X (120 - 80) = 29,430

4. GALLONS PER MINUTE REQIUIRED

gpm =

5. BASE TEMPERATURE RISE REQUIRED

Base temp rise =

=

Where: 1.07 = Fe corr fact. for 230 ºF ent. water and 80 ºF

ent. air temp (Table 4, Page 23)

face area 1.5

500 X water temp. drop 500 X 25

675

=

= 450 fpm

Btuh

lvg. air temp - ent. air temp

F

1.07

e

= 37.4 OF

120 - 80

=

29,430

= 2.35

SOLUTION

6. APPR0XIMATE NUMBER OF FEEDS REQUIRED

No. feed =

Turn to the coil Circuiting Tables (Table 5, Page 28).

Select a Type “TBS1” Booster Coil which has 1 feed.

7. GPM PER FEED

gpm/feed =

8. ROWS DEEP AND FIN SERIES

From Table 2, Page 10 select a Type “TBS1” model “101” Booster

Coil. At 1.5 sg. ft. of face area, 2.35 gpm/feed (by interpolation)

and 450 fpm this coil has a base temp of 40.9 OF. This meets the

required base temp rise of 37.4 OF.

9. FINAL COIL SELECTION

The final selection is a “TBS1 101 - 12 X 18” Coil

10. ACTUAL CAPACITY

Btuh = 1.09 X cfm X Air Temp. rise

= 1.09 X 675 X 40.9 = 30,092 Btuh.

gpm

gpm/feed

gpm

no. feeds

=

=

2.35

1

2.35

1

= .8

= 2.35

EXAMPLE PROBLEM No. 2

(Showing Use of Direct Selection Table No. 2)

GIVEN:

CFM (Std. Air)................................................................................................. 1,000

Maximum face Velocity............................................................................. 400 FPM

Entering Air Temperature................................................................................70 OF

Leaving Air Temperature..............................................................................125 OF

Entering Water Temperature........................................................................180 OF

Gallons Per Minute.................................................................................... 3.3 GPM

1. MINIMUM FACE AREA REQUIRED

cfm

FA =

2. BASE TEMPERATURE REQUIRED

Base temp rise =

where : .79 = Fe corr fact. for 180 OF ent. water and 70 OF

ent. air temp (Table 4, Page 23)

3. APPROXIMATE NUMBER OF FEEDS REQUIRED

No. feeds =

Turn to the Coil Circuiting Tables (Table 5, Page 28).

Select a Type “TBS1” Booster Coil which has a 1 feed.

4. GPM PER FEED

gpm/feed =

face velocity 400

gpm/feed

gpm

no. feeds

1000

=

Ivg air temp - ent air temp

gpm

=

=

= 2.5 sq. ft.

F

e

3.3

= 1.1

3

3.3

= 3.3

1

=

125 -70

.79

= 69.6 OF

SOLUTION

5. PHYSICAL SIZE

From table 1, Page 3 select a coil that has a face area equal to,

or greater than the minimum face area , and with face

dimensions that will meet the application.

For this example problem assume that a 15 X 24 Coil with 2.5 sq.

ft. of face area is the best selection.

6. ROWS DEEP AND FIN SERIES

From Table 2, Page 14 select a Type “TBS2” Model “122” Booster

Coil. 2.5 sq. ft. of face area, 3.3 gpm/feed (by interpolation) and

400 fpm this coil has a base temp. rise of 70.2 OF. This meets the

required base temp rise of 69.6 OF.

7. FINAL COIL SELECTION

The final selection is “TBS2 122 - 15 X 24” Coil.

8. ACTUAL PERFORMANCE

The actual performance, if required, may be obtained as

outlined in Problem 1, item 10 above.

- 6 -

Page 7

COIL SELECTION

EXAMPLE PROBLEM No. 3

(Showing Use of Direct Selection Table No. 3)

GIVEN:

CFM (Std. Air)................................................................................................. 6,000

Entering Air Temperature................................................................................45 OF

Required BTUH..........................................................................................480,000

Entering Water Temperature........................................................................180 OF

Gallons Per Minute.................................................................................. 48.0 GPM

Face Dimensions...................................................................................... 24” X 72”

Maximum Water Pressure...... Drop.......................................................3.0 Ft H2O

Maximum Air Pressure Drop...............................................................0.25 In. H2O

1. FACE AREA

FA = 12 sq. ft. (Table 1, Page 3)

2. FACE VELOCITY

FV =

3. AIR TEMPERATURE RISE REQUIRED

Air temp. rise =

Lvg air temp req’d = ent air temp + air temp rise

= 45 + 73.4 = 118.4 OF

4. BASE TEMPERATURE RISE REQUIRED

Base temp.rise =

CFM

face area

Where: .96 = Fe corr fact. for 180 OF ent water and 45 OF

ent air temp (Table 4, Page 23)

5. WATER TEMPERATURE DROP

Water temp. drop =

Lvg water temp. desired = ent water temp - water temp. drop

= 180 - 20 = 160 OF

6. APPROXIMATE NUMBER OF FEEDS REQUIRED

Assume 3 gpm/feed - see gpm per feed recommendations.

No. feed =

Turn to the Coil Circuiting Tables (Table 5, Page 28).

Under the 24” “W” dimension column, note that the 1, 2, 3 and 4

row Type “TWS” Coils have 16 feeds.

=

1.09 X cfm

air temp. rise

gpm

=

gpm/feed

6,000

= 500 FPM

12

Btuh

=

F

e

.

Btuh

=

500 X gpm

48.0

3

480,000

1.09 X 6,000

73.4

=

96

480.00

500 X 48.0

= 16.0

= 73.4 OF

= 76.5 OF

= 20.0 OF

Start with the Type “TWS” 2 row section (Table 3, Page 18).

A check of all four coil models (62, 82, 102 and 122) shows that a

2 row coil will not meet the required base temp. rise of 76.5 OF.

Turn to the Type “TWS” 3 row section (Table 3, Page 20).

A 3 row Model “63” Coil is still too small.

A 3 row Model “83” Coil has a base temp rise of 77.6 OF which is

slightly above the required base temp. rise.

Select a “TWS83-24 X 72” Coil.

9. AIR TEMPERATURE RISE ACTUAL

Air temp. rise = base air temp rise X F

= 77.6 X .96 = 74.5 OF

Where: .96 = F

ent air temp (Table 4, Page 23)

Lvg air temp actual = ent air temp + air temp. rise

= 45 + 74.5 = 119.5 OF

10. BTYUH (TOTAL LOAD) ACTUAL

Btuh = 1.09 X cfm X air temp. rise

= 1.09 X 6,000 X 74.5 = 4876.000

11. WATER TEMPERATURE DROP ACTUAL

Water temp. drop =

Lvg water temp. actual = ent water temp - water temp. drop

= 180 - 20.3 = 159.7 OF

12. WATER PRESSURE DROP

Water pressure drop = base water pressure drop X row-length

corr. fact.

= 2.09 X 1.00 = 2.09 ft. H2O

Where: 2.09 = base water pressure drop for 3.00 gpm/feed and 3

rows (Figure 6, Page 29)

1.00 = row-length corr. fact. for 2 rows, Type “TWS” and

72” NTL (Table 6, Page 30)

corr fact. for 180

e

Btuh

500 X gpm

e

O

F ent water and 45 OF

487,000

=

500 X 48.0

= 20.3 OF

7. GPM PER FEED

gpm/feed =

8. COIL SELECTION - ROWS DEEP AND FIN SERIES REQUIRED

Enter base temp. rise tables at:

Type “TWS”

72” NTL

3 gpm/feed

500 coil face velocity (fpm)

gpm

no. feeds

=

48.0

16

= 3.00

13. AIR PRESSURE DROP

Air pressure drop = base air prtessure drop X F

= .20 X 1.00 = .20 in H2O

Where: .20 = base air pressure drop for 3 rows deep and 500 fpm

(Figure 5, Page 28)

1.00 = 80 fin series corr. fact. F

fr

fr

(Insert Fig. 5, Page 28)

- 7 -

Page 8

COIL SELECTION

EXAMPLE PROBLEM No. 4

(Showing Use of Direct Selection Table No. 3)

GIVEN:

CFM (Std. Air)................................................................................................... 4,800

Maximum Face Velocity............................................................................. 600 FPM

Entering Air Temperature................................................................................ 70 OF

Leaving Air Temperature.............................................................................. 120 OF

Entering Water Temperature........................................................................190 OF

Desired Water Temperature Drop..................................................................20 OF

Maximum Water Pressure drop.............................................................4.0 Ft H2O

Maximum Air Pressure drop................................................................0.26 In. H2O

SOLUTION

1. MINIMUM FACE AREA REQUIRED

cfm

FA =

2. BTUH REQUIRED

Btuh = 1.09 M cfm X (lvg air temp - ent. air temp)

= 1.09 X 4,800 X (120 - 70) = 261,600

3. GALLONS PER MINUTE REQUIRED

gpm =

4. BASE AIR TEMPERATURE RISE REQUIRED

Base temp. rise =

=

Where: .86 = F

temp. (Table 4, Page 23)

5. PHYSICAL SIZE

From Table 1, Page 3 select a coil that has a face area equal to, or

greater than the minimum face area, and with face dimensions that

will meet the application. For this example problem assume that a

24 X 48 Coil with 8.0 sq. ft. of face area is the best selection.

6. APPRIXIMATE NUMBER OF FEEDS REQUIRED

No. feeds =

A quick check of the Base Temp Rise tables indicates that at least

a two row coil is required.

Turn to the Coil Circuiting Tables (Table 5, Page 28). Under the

24” “W” dimension column, note that the 1, 2, 3 and 4 row.

Type “TWH” high capacity coils have 8 feeds.

Therefore, start selection using 8 feeds.

7. GPM PER FEED

gpm/feed =

8. ROWS DEEP AND FIN SERIES

From Table 3, Page 18 select a Type “TWH” Model “102” Coil.

face velocity

500 X water temp. drop

gpm/feed

no. feeds

4,800

=

Btuh

lvg air temp - ent air temp.

120 - 70

corr. fact for 190

e

gpm

=

gpm

= 8.0 sg. ft

600

=

= 58.1 OF

.86

26.16

3

26.16

=

8

F

e

= 8.7

= 3.27

261,600

500 X 20

O

F ent water and 70 OF ent air

= 26.16

At 3 gpm/feed, 600 fpm and 48” NTL this coil has a base temp rise

of 59.4 OF. This meets the required base temp rise of 58.1 OF.

9. ACTUAL BASE TEMPERATURE RISE

Return to Table 3, Page 18 to the 600 fpm, 48” NTL, Type “TWH”,

Model “102” section.

at 3 gpm/feed - base temp. rise = 59.4 OF

at 4 gpm/feed - base temp. rise = 62.0 OF

By interpolation:

at 3.27 gpm/feed - base temp. rise = 60.1 OF

10. ACTUAL LEAVING AIR TEMPERATURE

Actual temp. rise = base temp. rise X F

= 60.1 X .86 = 51.7 OF

Where: .86 = F

temp. (Table 4, Page 23).

Actual lvg air temp. = ent air temp. + temp. rise

= 70 + 51.7 = 121.7 OF

11. BTUH ACTUAL

Btuh = 1.09 X cfm X (lvg air temp. - ent. air temp.)

= 1.09 X 4,800 X (121.7 - 70) = 270,500

12. WATER TEMPERATURE DROP ACTUAL

Water temp. drop =

13. WATER PRESSURE DROP

Water pressure drop = base water pressure drop X row-length

corr. fact.

= 2.00 X 1.31 = 2.62 ft. H2O

Where: 2.00 = base water pressure drop for 3.27 gpm/feed and

2 rows (Figure 6, Page 29)

1.31 = row-length corr. fact. for 2 rows, Type “TWH” and

48” NT (Table6, Page 30)

14. AIR PRESSURE DROP

Air pressure drop = base pressure drop X F

= .19 X 1.16 = .22 in. H2O

Where: .19 = base air pressure drop for 2 rows, 600 fpm

(Figure 5, Page 28)

1.16 = 100 fin series corr fact. Ffr (Figure 5, Page 28 inset)

15. FINAL COIL SELECTION

corr. fact. for 190

e

Btuh

500 X gpm

=

e

O

F ent. water and 70 OF ent. air

270,500

= 20.7 OF

fr

500 X 26.16

The final selection is a “TWH 102 - 24 X 48” Coil. OF

- 8 -

Page 9

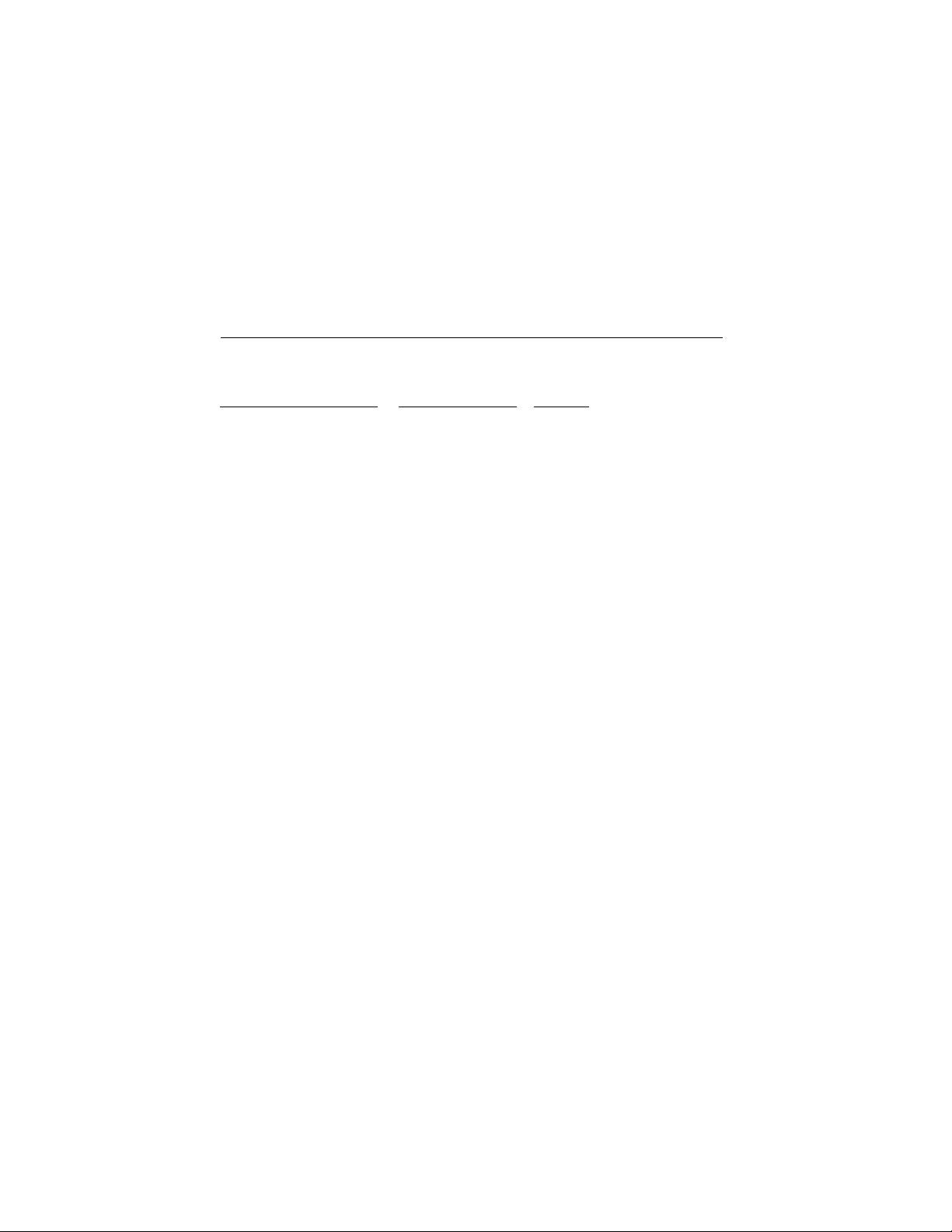

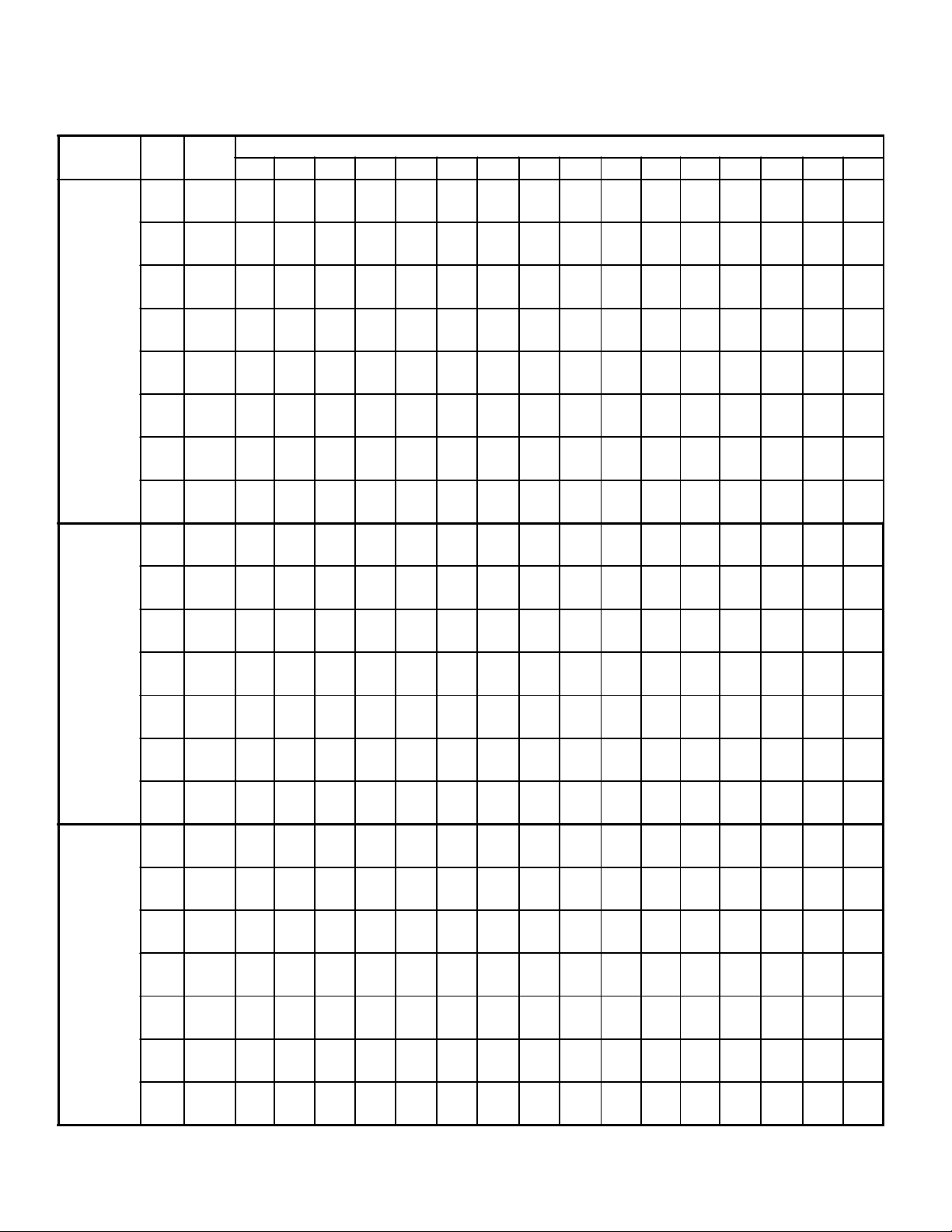

BOOSTER COIL BASE TEMPERATURE RISE OF

SINGLE CIRCUIT ONE ROW COILS - 200 OF ENTERING WATER AND 60 OF ENTERING AIR

Table No. 2

FACE AREA

SQ. FEET

TYPE TBS1

.25

.50

.75

1. Table base temperature rise values have been tabulated for 200 OF entering water and 60 OF entering air. At entering

conditions other than the base use the Fe entering conditions correction factors in Table 4 on Page 23.

2. In general the table values have been tabulated for a range of 5 OF to 55 OF water temperature drop. Water

temperature drop outside of the above range is perfectly satisfactory.

3. Table values have been tabulated for a maximum water pressure drop of 20 feet of water.

4. Interpolation between base temperature rise values is permissable for face velocities, face areas, and gpm per feeds.

In the base temperature rise value for a higher face velocity, larger face area or smaller gpm per feed satisfies the

required final air temperature condition, interpolation is not necessary unless the actual leaving air temperature is

desired.

5. For values not listed in the table, coils may be selected as shown on pages 24 and 25.

GPM

PER

FEED

.50

.75

1.00

1.50

2.00

.50

.75

1.00

1.50

2.00

3.00

4.00

.50

.75

1.00

1.50

2.00

3.00

4.00

6.00

COIL

MODEL

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

COIL FACE VELOCITY - FPM (STANDARD AIR)

200 250 300 350 400 450 500 550 600 650 700 750 800

40.3

35.8

32.4

29.7

27.5

25.6

24.0

22.7

21.5

20.4

19.4

47.5

53.4

58.3

42.5

50.5

57.2

62.9

43.8

52.3

59.5

65.7

45.2

54.4

62.2

68.9

46.0

55.6

63.7

70.8

39.1

45.7

51.2

55.7

41.6

49.2

55.5

60.9

43.0

51.3

58.2

64.0

44.7

53.6

61.2

67.7

45.6

55.0

63.0

69.8

46.6

56.4

64.8

72.1

47.2

57.2

65.9

73.5

37.9

44.1

49.1

53.2

40.7

47.9

53.9

58.9

42.3

50.2

56.8

62.4

44.2

52.9

60.2

66.5

45.2

54.4

62.2

68.9

46.3

56.0

64.3

71.5

47.0

56.9

65.5

72.9

47.6

57.9

66.7

74.5

42.2

47.4

51.8

37.9

45.2

51.2

56.4

39.2

47.0

53.6

59.2

40.7

49.1

56.3

62.6

41.5

50.3

57.9

64.5

34.5

40.4

45.2

49.2

37.0

43.8

49.5

54.3

38.5

45.9

52.2

57.5

40.2

48.3

55.3

61.3

41.1

49.7

57.1

63.5

42.1

51.2

59.0

65.9

42.7

52.0

60.1

67.3

33.4

38.8

43.1

46.7

36.1

42.6

47.9

52.4

37.8

44.9

50.8

55.9

39.6

47.5

54.3

60.1

40.7

49.1

56.3

62.5

41.8

50.7

58.4

65.2

42.5

51.7

59.7

66.7

43.1

52.7

61.0

68.4

38.2

42.9

46.8

34.6

41.2

46.7

51.4

35.9

43.0

49.0

54.3

37.3

45.1

51.8

57.7

38.2

46.3

53.4

59.7

31.2

36.5

40.7

44.3

33.7

39.8

45.0

49.3

35.1

41.9

47.6

52.5

36.8

44.3

50.8

56.4

37.8

45.7

52.6

58.6

38.8

47.2

54.6

61.1

39.4

48.1

55.8

62.6

30.0

34.9

38.7

41.9

32.8

38.6

43.4

47.4

34.4

40.9

46.3

50.9

36.3

43.6

49.8

55.1

37.3

45.1

51.8

57.6

38.5

46.8

54.0

60.4

39.1

47.8

55.3

62.0

39.8

48.8

56.7

63.7

34.9

32.3

36.2

39.5

29.6

35.2

39.9

43.9

30.8

34.7

42.2

46.7

32.3

39.1

45.0

50.1

33.1

40.3

46.6

52.2

26.3

30.7

34.2

37.1

28.7

33.9

38.2

41.9

30.1

35.9

40.8

45.0

31.8

38.3

43.9

48.8

32.7

39.7

45.8

51.1

33.8

41.2

47.8

53.7

34.4

42.1

49.0

55.2

25.2

29.2

32.3

34.8

27.8

32.7

36.7

40.0

29.4

34.9

39.5

43.4

31.2

37.5

42.9

47.6

32.3

39.1

45.0

50.1

33.5

40.8

47.2

52.9

34.1

41.8

48.6

54.6

34.8

42.8

50.0

56.4

30.0

33.7

36.7

27.7

32.9

37.3

41.0

28.9

37.0

39.5

43.8

30.4

36.8

42.3

47.2

31.2

38.0

43.9

49.2

24.5

28.5

31.7

34.3

26.8

31.6

35.6

39.0

28.2

33.6

38.2

42.1

29.8

36.0

41.3

45.9

30.8

37.4

43.1

48.2

31.8

38.9

45.1

50.7

32.4

39.8

46.3

52.2

23.4

27.0

29.8

32.2

25.9

30.4

34.1

37.2

27.5

32.6

36.9

40.5

29.3

35.2

40.2

44.6

30.3

36.7

42.3

47.1

31.5

38.4

44.5

50.0

32.2

39.4

45.9

51.6

32.9

40.5

47.3

53.5

39.2

42.8

31.8

37.9

43.0

47.3

33.1

39.7

45.3

50.2

34.8

41.8

48.1

53.6

35.4

43.1

49.7

55.6

28.5

33.3

37.1

40.3

30.9

36.6

41.3

45.3

32.4

38.6

43.9

48.4

34.0

41.0

47.0

52.3

35.0

42.4

48.9

54.6

36.0

44.0

50.9

57.1

36.6

44.8

52.1

58.6

27.4

31.7

35.2

38.0

30.0

35.3

39.7

43.4

31.6

37.6

42.6

46.8

33.5

40.3

46.0

51.0

34.6

41.8

48.1

53.5

35.7

43.5

50.3

56.3

36.4

44.5

51.6

58.0

37.1

45.5

53.0

59.8

Table No. 2 NOTES

- 9 -

28.1

31.5

34.3

26.0

30.9

35.0

38.5

27.2

32.6

37.2

41.2

28.6

34.7

39.9

44.6

29.5

35.9

41.6

46.6

22.9

26.6

29.5

32.0

25.1

29.6

33.4

36.5

26.5

31.6

35.9

39.5

28.1

33.9

38.9

43.3

29.0

35.3

40.7

45.5

30.1

36.8

42.8

48.1

30.7

37.7

44.0

49.6

21.8

25.1

27.8

29.9

24.3

28.5

31.9

34.8

25.8

30.6

34.6

38.0

27.6

33.2

37.9

42.0

28.6

34.7

39.9

44.5

29.8

36.4

42.2

47.3

30.4

37.4

43.5

49.0

31.1

38.4

44.9

50.8

26.5

29.6

32.3

24.6

29.2

33.1

36.4

25.8

31.0

35.5

39.1

27.3

33.0

38.0

42.4

28.1

34.2

39.6

44.4

21.6

25.0

27.6

30.0

23.8

28.0

31.5

34.5

25.1

29.9

34.0

37.4

26.7

32.2

37.0

41.1

27.7

33.6

38.8

43.4

28.7

35.1

40.9

46.0

29.3

36.0

42.1

47.2

20.5

23.6

26.0

28.0

22.9

26.9

30.1

32.7

24.4

28.9

32.7

35.9

26.2

31.5

36.0

39.9

27.3

33.0

38.0

42.4

28.4

34.7

40.3

45.2

29.1

35.7

41.6

46.9

29.8

36.8

43.0

48.7

25.1

28.0

30.4

23.4

27.7

31.4

34.5

24.6

29.4

33.5

37.1

26.0

31.5

36.2

40.4

26.8

32.7

37.8

42.4

20.4

23.6

26.2

28.3

22.5

26.5

29.8

32.6

23.9

28.4

32.2

35.5

25.5

30.7

35.2

39.1

26.4

32.1

37.0

41.4

27.4

33.6

39.1

44.0

28.0

34.5

40.3

45.5

19.4

22.2

24.5

26.3

21.7

25.4

28.4

30.9

23.2

27.4

31.0

34.0

24.9

30.0

34.2

37.9

26.0

31.5

36.2

40.4

27.1

33.1

38.5

43.2

27.8

34.1

39.8

44.9

28.5

35.2

41.2

46.7

23.9

26.6

28.9

22.3

26.5

29.9

32.8

23.5

28.2

32.1

35.5

24.9

30.2

34.7

38.7

25.8

31.4

36.4

40.8

19.4

22.4

24.8

26.8

21.5

25.3

28.4

31.0

22.8

27.1

30.8

33.9

24.4

29.4

33.7

37.5

25.3

30.8

35.5

39.7

26.4

32.3

37.6

42.3

27.0

33.2

38.8

43.8

18.4

21.1

23.2

24.9

20.7

24.2

27.0

29.3

22.2

26.2

29.5

32.4

23.9

28.7

32.7

36.3

24.9

30.2

34.7

38.7

26.1

31.8

37.0

41.5

26.7

32.8

38.3

43.2

27.4

33.9

39.8

45.1

22.7

25.3

27.4

21.3

25.2

28.5

31.3

22.4

26.8

30.6

33.8

23.8

26.8

33.2

37.0

24.6

30.0

34.8

39.0

18.4

21.3

23.5

25.4

20.5

24.1

27.0

29.5

21.8

25.9

29.3

32.3

23.3

28.1

32.2

35.8

24.2

29.4

34.0

38.0

25.2

30.9

36.0

40.5

25.6

31.8

37.2

42.0

17.4

20.0

21.9

23.5

19.7

23.0

25.6

27.8

21.1

24.9

28.1

30.8

22.8

27.4

31.2

34.6

23.8

28.8

33.2

37.0

24.9

30.5

35.4

39.8

25.6

31.5

36.7

41.4

26.3

32.5

38.2

43.3

18.6

21.6

24.1

26.1

20.4

24.1

27.2

29.9

21.5

25.7

29.3

32.4

22.9

27.7

31.9

35.6

23.7

28.9

33.4

37.5

17.6

20.3

22.4

24.1

19.6

23.0

25.8

28.1

20.8

24.8

28.0

30.8

22.5

27.0

30.9

34.3

23.3

28.3

32.6

36.5

24.3

29.8

34.6

39.0

24.9

30.6

35.8

40.5

16.6

19.0

20.9

22.3

18.8

21.9

24.4

26.5

20.2

23.8

26.9

29.4

21.9

26.2

29.9

33.2

22.9

27.7

31.8

35.5

24.0

29.3

34.0

38.3

24.6

30.3

35.4

39.9

25.3

31.3

36.8

41.8

100-0120-0150-

17.8

15.3

20.7

17.1

23.0

19.6

25.0

21.2

19.6

16.9

23.1

20.0

26.1

22.5

28.6

24.6

20.7

18.0

24.7

21.5

28.1

24.4

31.1

26.9

22.0

19.3

26.7

23.3

30.7

36.8

34.2

29.8

22.8

20.0

27.9

24.4

32.3

28.3

36.2

31.7

16.8

14.4

19.4

16.5

21.4

18.1

23.0

19.5

18.8

16.2

22.0

18.9

24.7

21.2

26.9

23.0

20.0

17.4

23.8

20.6

26.9

23.2

29.6

25.5

21.5

18.8

25.9

22.6

29.7

25.8

33.0

28.7

22.4

19.6

27.2

23.8

31.4

27.5

35.2

30.7

23.4

20.6

28.7

25.3

33.4

29.4

37.7

33.1

24.0

21.2

29.6

26.1

34.6

30.6

39.2

34.6

15.9

13.5

18.1

15.4

19.9

16.8

21.3

17.9

18.0

15.5

21.0

18.0

23.4

19.9

25.4

21.6

19.4

16.8

22.9

19.7

25.8

22.1

28.2

24.2

21.1

18.3

25.2

21.9

28.8

25.0

31.9

27.6

22.0

19.3

26.7

23.3

30.7

26.7

34.2

29.8

23.1

20.3

28.3

24.8

32.8

28.8

36.9

32.4

23.8

20.9

29.3

25.8

34.1

30.1

38.6

34.0

24.5

21.6

30.3

26.8

35.6

31.5

40.4

35.8

13.4

15.5

17.1

18.5

14.9

17.6

19.7

21.6

15.9

19.0

21.5

23.7

17.2

20.7

23.8

26.5

17.9

21.8

25.2

28.3

12.6

14.4

15.8

16.9

14.3

16.6

18.5

20.1

15.3

18.1

20.4

22.4

16.7

20.0

22.9

25.4

17.5

21.2

24.5

27.3

18.4

22.6

26.3

29.6

19.0

23.4

27.4

31.1

11.8

13.4

14.5

15.5

13.6

15.7

17.4

18.8

14.8

17.3

19.4

21.2

16.3

19.4

22.1

24.4

17.1

20.7

23.8

26.4

18.2

22.2

25.8

28.9

18.8

23.1

27.0

30.5

19.4

24.1

28.3

32.2

0

11.4

13.1

14.4

15.5

12.8

15.0

16.8

18.3

13.7

16.2

18.4

20.2

14.8

17.8

20.4

22.7

15.5

18.8

21.8

24.4

10.6

12.1

13.2

14.1

12.1

14.1

15.7

17.0

13.1

15.5

17.4

19.0

14.4

17.2

19.6

21.7

15.1

18.3

21.1

23.5

16.0

19.6

22.8

25.7

16.5

20.3

23.8

27.0

9.9

11.2

12.1

12.9

11.5

13.3

14.7

15.8

12.6

14.7

16.5

17.9

14.0

16.6

18.9

20.8

14.8

17.8

20.4

22.7

15.7

19.2

22.3

25.0

16.3

20.0

23.4

26.5

16.9

21.0

24.7

28.1

Page 10

Table No. 2

BOOSTER COIL BASE TEMPERATURE RISE OF

SINGLE CIRCUIT ONE ROW COILS - 200 OF ENTERING WATER AND 60 OF ENTERING AIR

FACE AREA

SQ. FEET

TYPE TBS1

1.00

1.50

2.00

GPM

PER

FEED

.50

.75

1.00

1.50

2.00

3.00

4.00

6.00

.75

1.00

1.50

2.00

3.00

4.00

6.00

.75

1.00

1.50

2.00

3.00

4.00

6.00

COIL

MODEL

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

COIL FACE VELOCITY - FPM (STANDARD AIR)

200 250 300 350 400 450 500 550 600 650 700 750 800 1000 1200 1500

36.7

32.2

28.9

26.3

24.2

22.4

20.8

19.6

18.4

17.5

16.6

15.8

15.0

12.8

11.1

42.5

47.1

50.8

39.8

46.7

52.3

57.0

41.6

49.2

55.5

60.8

43.7

52.1

59.3

65.3

44.8

53.8

61.4

67.9

46.1

55.6

63.7

70.8

46.8

56.6

65.1

72.4

47.5

57.5

66.5

74.1

38.1

44.4

49.4

53.5

40.2

47.3

53.1

57.9

42.7

50.7

57.4

63.1

44.0

52.7

59.9

66.1

45.5

54.8

62.7

69.5

46.3

56.0

64.2

71.4

47.2

57.2

65.9

73.4

36.5

42.2

46.6

50.3

38.9

45.5

50.7

55.1

41.7

49.3

55.6

60.9

43.3

51.5

58.5

64.3

45.0

54.0

61.6

68.2

45.9

55.3

63.4

70.4

46.9

56.8

65.3

72.7

37.2

41.2

44.5

35.2

41.3

46.3

50.5

37.0

43.9

49.5

54.3

39.1

46.8

53.3

58.8

40.3

48.5

55.5

61.5

41.5

50.3

57.9

64.5

42.2

51.3

59.2

66.2

43.0

52.4

60.7

68.0

33.6

39.0

43.4

47.0

35.7

41.9

47.0

51.3

38.1

45.3

51.4

56.5

39.5

47.3

53.9

59.6

41.0

49.5

56.8

63.1

41.8

50.7

58.4

65.1

42.7

52.0

60.1

67.2

32.0

36.9

40.8

43.9

34.4

40.1

44.7

48.6

37.1

44.0

49.6

54.4

38.7

46.2

52.5

57.8

40.4

48.7

55.7

61.8

41.4

50.1

57.5

64.1

42.4

51.5

59.5

66.5

33.4

36.9

39.7

31.9

37.4

41.8

45.6

33.7

39.9

45.0

49.3

35.7

42.8

48.8

53.9

36.9

44.5

51.0

56.6

38.2

46.4

53.4

59.7

38.9

47.4

54.9

61.4

39.7

48.5

56.4

63.3

30.2

35.1

39.0

42.2

32.3

37.9

42.5

46.4

34.7

41.3

46.9

51.6

36.1

43.3

49.4

54.7

37.6

45.5

52.3

58.3

38.5

46.8

54.0

60.3

39.4

48.1

55.7

62.5

28.7

33.0

36.4

39.1

31.0

36.2

40.3

43.6

33.8

39.9

45.1

49.4

35.3

42.2

47.9

52.9

37.1

44.7

51.2

56.9

38.0

46.1

53.1

59.2

39.1

47.6

55.1

61.8

30.3

33.4

35.9

29.2

34.2

38.2

41.6

30.9

36.6

41.3

45.2

33.0

39.5

45.0

49.8

34.2

41.2

47.3

52.5

35.4

43.1

49.7

55.6

36.2

44.2

51.2

57.4

38.9

45.3

52.7

59.3

27.6

31.9

35.4

38.2

29.6

34.7

38.9

42.3

32.0

38.1

43.1

47.5

33.4

40.0

45.7

50.6

34.9

42.2

48.6

54.2

35.7

43.5

50.3

56.3

36.6

44.8

52.1

58.5

26.1

29.9

32.9

35.3

28.3

32.9

36.6

39.7

31.0

36.7

41.4

45.3

32.6

28.9

44.2

48.8

34.3

41.4

47.5

52.8

35.3

42.8

49.4

55.2

36.3

44.4

51.5

57.7

27.7

30.5

32.3

27.0

31.5

35.2

38.3

28.7

33.9

38.2

41.9

30.7

36.8

41.9

46.4

31.9

38.5

44.1

49.1

33.2

40.4

46.6

52.2

33.9

41.4

48.1

54.0

34.7

42.6

49.7

56.0

25.4

29.4

32.5

35.0

27.4

32.0

35.9

39.0

29.7

35.3

40.0

44.1

31.1

37.3

42.6

47.2

32.6

39.5

45.5

50.8

33.4

40.8

47.2

52.9

34.4

42.1

49.0

55.2

23.9

27.4

30.1

32.2

26.1

30.3

33.7

36.4

28.8

34.0

38.3

41.9

30.3

36.2

41.1

45.3

32.0

38.7

44.4

49.4

33.0

40.1

46.3

51.7

34.0

41.7

48.4

54.4

25.6

28.2

30.2

25.1

29.3

32.7

35.5

26.8

31.6

35.6

39.0

28.8

34.5

39.3

43.4

29.9

36.1

41.5

46.1

31.2

38.0

44.0

49.2

31.9

39.1

45.4

51.1

32.7

40.2

47.0

53.0

23.6

27.2

30.0

32.4

25.5

29.8

33.3

36.2

27.8

33.0

37.4

41.1

29.1

35.0

39.9

44.2

30.6

37.2

42.8

47.8

31.5

38.4

44.5

49.9

32.4

39.8

46.3

52.2

22.1

25.3

27.7

29.6

24.3

28.1

31.2

33.7

26.8

31.7

35.7

39.0

28.4

33.8

38.5

42.4

30.1

36.3

41.7

46.4

31.0

37.7

43.6

48.8

32.1

39.3

45.7

51.4

23.8

26.1

28.0

23.5

27.4

30.5

33.1

25.1

29.6

33.4

36.5

27.1

32.4

36.9

40.8

28.2

34.1

39.1

43.5

29.5

35.9

41.6

46.6

30.2

37.0

43.0

48.4

31.0

38.2

44.6

50.4

22.0

25.3

27.9

30.1

23.8

27.9

31.1

33.8

26.1

31.0

35.1

38.6

27.4

32.9

37.6

41.6

28.9

35.1

40.4

45.2

29.8

36.3

42.1

47.3

30.7

37.7

44.0

49.6

20.6

23.5

25.7

27.4

22.7

28.2

29.0

31.3

25.2

29.7

33.4

36.5

26.7

31.8

36.1

39.8

28.4

34.3

39.3

43.8

29.3

35.7

41.2

46.1

30.4

37.2

43.3

48.8

22.3

24.5

26.2

22.1

25.8

28.7

31.1

23.8

28.0

31.5

34.4

25.7

30.8

35.0

38.7

26.9

32.4

37.2

41.4

28.1

34.3

39.7

44.5

28.8

35.3

41.1

46.3

29.6

36.5

42.7

48.3

20.7

23.8

26.2

28.1

22.5

26.3

29.3

31.8

24.7

29.4

33.2

36.5

26.1

31.3

35.7

39.5

27.5

33.4

38.5

43.0

28.4

34.7

40.2

45.1

29.3

36.0

42.0

47.5

19.3

22.0

24.0

25.6

21.4

24.7

27.3

29.4

23.8

28.1

31.5

34.4

25.3

30.2

34.2

37.7

27.0

32.6

37.4

41.6

27.9

34.0

39.3

44.0

29.0

35.6

41.4

46.6

21.0

23.0

24.5

20.9

24.3

27.1

29.3

22.5

26.5

29.8

32.6

24.5

29.2

33.3

36.8

25.6

30.9

35.4

39.4

26.8

32.7

37.9

42.4

27.5

33.8

39.3

44.3

28.3

34.9

40.9

46.3

19.5

22.4

24.6

26.4

21.3

24.8

27.6

29.9

23.5

27.9

31.5

34.6

24.8

29.7

33.9

37.5

26.3

31.9

36.7

41.0

27.1

33.1

38.4

43.1

28.0

34.5

40.2

45.5

18.2

20.7

22.5

24.0

20.2

23.2

25.7

27.6

22.6

26.6

29.8

32.6

24.0

28.5

32.5

35.8

25.7

31.0

35.6

39.6

26.7

32.4

37.5

42.0

27.7

34.0

39.6

44.6

19.9

21.7

23.2

19.9

23.1

25.7

27.8

21.5

25.3

28.4

31.0

23.4

28.0

31.8

35.1

24.5

29.6

33.9

37.7

25.8

31.4

36.4

40.8

26.5

32.5

37.8

42.6

27.3

33.7

39.4

44.6

18.5

21.2

23.3

25.0

20.3

23.5

26.2

28.4

22.5

26.6

30.0

32.9

23.7

28.4

32.4

35.9

25.2

30.6

35.2

39.3

26.0

31.8

36.9

41.4

26.9

33.2

38.8

54.8

17.3

19.5

21.2

22.6

19.2

22.0

24.3

26.1

21.6

25.3

28.4

31.0

23.0

27.4

31.0

34.1

24.7

29.7

34.1

38.0

25.6

31.2

36.0

40.3

26.6

32.7

38.1

43.0

18.8

20.5

21.9

18.9

22.0

24.3

26.3

20.5

24.0

27.0

29.4

22.3

26.7

30.3

33.5

23.4

28.2

32.4

36.0

24.7

30.1

34.8

39.0

25.4

31.1

36.2

40.8

26.1

32.3

37.8

42.9

17.6

20.1

22.0

23.6

19.3

22.4

24.9

26.9

21.4

25.3

28.6

31.3

22.7

27.1

30.9

34.2

24.1

29.2

33.7

37.6

24.9

30.4

53.3

39.7

25.8

31.8

37.2

42.0

16.3

18.4

20.0

21.3

18.2

20.9

23.0

24.7

20.5

24.1

27.0

29.4

21.9

26.1

29.5

32.5

23.5

28.4

32.6

36.3

24.6

29.8

34.5

38.6

25.5

31.3

36.5

41.2

17.9

19.5

20.7

18.1

20.9

23.2

25.0

19.6

23.0

25.7

28.1

21.4

25.5

39.0

32.0

22.5

27.1

31.1

34.6

23.7

28.9

33.5

37.5

24.4

30.0

34.9

39.3

25.2

31.1

36.5

41.3

16.7

19.1

21.0

22.4

18.4

21.4

23.7

25.6

20.5

24.2

27.3

29.9

21.7

26.0

29.6

32.7

23.1

28.1

32.4

36.1

24.0

29.3

34.0

38.2

24.9

30.6

35.8

40.5

15.5

17.5

19.0

20.2

17.3

19.9

21.9

23.5

19.5

23.0

25.7

28.0

21.0

25.0

28.3

31.1

22.6

27.3

31.3

34.8

23.5

28.6

33.1

37.1

24.5

30.2

35.2

39.7

17.0

18.5

19.7

17.3

20.0

22.2

23.9

18.8

22.0

24.7

26.9

20.6

24.5

27.9

30.8

21.7

26.1

29.9

33.2

22.9

27.9

32.3

36.2

23.6

28.9

33.7

38.0

24.3

30.1

35.3

40.0

16.0

18.2

20.0

21.4

17.6

20.4

22.7

24.5

19.7

23.2

26.2

28.7

20.9

25.0

28.5

31.5

22.3

27.0

31.2

34.8

23.1

28.3

32.8

36.8

24.0

29.6

34.6

39.1

14.8

16.7

18.1

19.2

16.6

19.0

20.9

22.4

18.8

22.0

24.7

26.8

20.2

24.0

27.1

29.8

21.8

26.3

30.1

33.5

22.7

27.6

31.9

35.7

23.7

29.1

34.0

38.3

14.4

15.5

18.5

14.3

17.1

18.8

20.3

16.2

18.9

21.1

23.0

17.9

21.3

24.1

26.6

18.9

22.7

26.0

28.9

20.0

24.4

28.3

31.7

20.7

25.4

29.7

33.4

21.5

26.6

31.2

35.4

13.6

15.5

16.9

18.0

15.1

17.4

19.3

20.8

17.0

20.0

22.5

24.6

18.2

21.7

24.7

27.2

19.5

23.6

27.2

30.4

20.3

24.8

28.8

32.3

21.2

26.1

30.5

34.6

12.5

14.0

15.2

16.0

14.1

16.1

17.6

18.8

16.2

18.9

21.1

22.9

17.5

20.7

23.4

25.6

19.0

22.9

26.2

29.1

19.9

24.2

27.9

31.3

20.9

25.6

29.9

33.8

12.4

12.4

14.2

13.0

14.9

16.4

17.6

14.2

16.6

18.5

20.1

15.8

18.8

21.3

23.4

16.8

20.2

23.1

25.6

17.9

21.8

25.2

28.3

18.5

22.8

26.5

29.9

19.3

23.8

28.0

31.8

11.9

13.4

14.6

15.5

13.3

15.2

16.8

18.0

15.0

17.6

19.8

21.6

16.1

19.2

21.8

24.0

17.4

21.0

24.2

27.0

18.1

22.1

25.7

38.9

19.0

23.4

27.4

31.0

10.9

12.1

13.0

13.7

12.4

14.0

15.3

16.3

14.3

16.6

18.5

20.0

15.5

18.3

20.6

22.5

16.9

20.3

23.2

25.8

17.7

21.6

24.9

27.8

18.7

23.0

26.8

30.2

9.3

10.4

11.2

11.8

11.0

12.5

13.8

14.7

12.1

14.1

15.6

16.9

13.6

16.1

18.1

19.9

14.4

17.3

19.8

21.9

15.5

18.8

21.8

24.4

16.1

19.7

23.0

25.9

16.8

20.8

24.4

27.7

10.0

11.2

12.2

12.9

11.2

12.8

14.1

15.1

12.8

15.0

16.8

18.3

13.8

16.4

18.6

20.4

15.0

18.1

20.8

23.2

15.7

19.2

22.2

24.9

16.5

20.3

23.8

27.0

9.1

10.1

10.8

11.4

10.4

11.8

12.8

13.6

12.1

14.4

16.6

16.8

13.2

15.6

17.5

19.1

14.5

17.5

19.9

22.1

15.3

18.6

21.5

24.0

16.2

19.9

23.2

26.2

- 10 -

Page 11

Table No. 2

BOOSTER COIL BASE TEMPERATURE RISE OF

SINGLE CIRCUIT ONE ROW COILS - 200 OF ENTERING WATER AND 60 OF ENTERING AIR

FACE AREA

SQ. FEET

TYPE TBS1

2.50

3.00

4.00

5.00

6.00

GPM

PER

FEED

1.00

1.50

2.00

3.00

4.00

6.00

1.50

2.00

3.00

4.00

6.00

2.00

3.00

4.00

6.00

2.00

3.00

4.00

6.00

3.00

4.00

6.00

COIL

MODEL

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

61

81

101

121

COIL FACE VELOCITY FPM (STANDARD AIR)

200 250 300 350 400 450 500 550 600 650 700 750 800 1000 1200 1500

37.6

33.1

29.8

27.1

25.0

23.1

21.6

20.3

19.1

18.1

17.2

16.4

15.6

13.3

11.5

43.7

48.5

52.5

40.7

48.0

53.9

58.8

42.5

50.5

57.1

62.6

44.4

53.2

60.6

66.9

45.5

54.7

62.6

69.4

46.6

56.4

64.7

72.0

39.8

46.7

52.3

56.9

41.8

49.4

55.7

61.0

43.9

52.4

59.6

65.7

45.1

54.1

61.8

68.4

46.3

55.9

64.2

71.3

40.3

47.4

53.1

57.9

42.9

51.0

57.7

63.4

44.3

53.0

60.3

66.5

45.8

55.1

63.1

70.0

39.0

45.5

50.7

55.0

41.9

49.5

55.8

61.1

43.5

51.8

58.8

64.7

45.2

54.3

62.0

68.6

40.9

48.2

54.1

59.0

42.7

50.7

57.4

62.9

44.6

53.5

61.0

67.4

38.4

42.6

46.0

36.2

42.6

47.9

52.3

37.9

45.1

51.1

56.1

39.9

47.9

54.7

60.5

40.9

49.4

56.7

63.0

42.1

51.1

58.9

65.8

35.3

41.3

46.3

50.3

37.2

44.0

49.7

54.4

39.3

47.1

53.6

59.2

40.5

48.8

55.9

62.0

41.8

50.7

58.3

65.0

35.8

42.0

47.1

51.3

38.3

45.6

51.7

56.8

39.7

47.6

54.3

60.1

41.2

49.8

57.2

63.6

34.4

40.2

44.7

48.4

37.3

44.2

49.8

54.6

38.9

46.5

52.8

58.2

40.7

49.0

56.1

62.3

36.3

42.8

48.0

52.4

38.1

45.3

51.3

56.4

40.1

48.2

550

60.9

34.5

38.2

41.1

32.8

38.6

43.4

47.3

34.6

41.1

46.5

51.1

36.5

43.9

50.2

55.6

37.6

45.5

52.2

58.2

38.8

47.2

54.5

61.0

31.9

37.3

41.7

45.4

33.8

40.0

45.2

49.5

36.0

43.1

49.1

54.3

37.2

44.8

51.4

57.1

38.5

46.7

53.9

60.2

32.4

38.0

42.6

46.3

34.9

41.6

47.1

51.9

39.3

43.6

49.8

55.1

37.9

45.9

52.8

58.8

31.1

36.2

40.2

43.5

33.9

40.1

45.3

49.6

35.5

42.5

48.3

53.2

37.3

45.0

51.6

57.4

33.0

38.8

43.5

47.4

34.8

41.3

46.8

51.4

36.7

44.2

50.5

56.0

31.3

34.6

37.2

30.1

35.4

39.7

43.2

31.8

37.8

42.8

47.0

33.8

40.6

46.2

51.5

34.8

42.2

48.5

54.1

36.0

43.9

50.8

57.0

29.2

34.1

38.1

41.3

31.1

36.8

41.4

45.4

33.2

39.8

45.4

50.2

34.4

41.6

47.7

53.0

35.7

43.5

50.2

56.2

29.7

34.8

38.9

42.3

32.2

38.3

43.4

47.7

33.6

40.3

46.1

51.0

35.1

42.6

49.1

54.7

28.4

32.9

36.6

39.5

31.2

36.9

41.5

45.5

32.8

39.2

44.5

49.1

34.5

41.7

47.9

53.3

30.2

35.5

39.8

43.3

32.0

38.0

43.0

47.3

34.0

40.9

46.8

51.9

28.7

31.7

34.1

27.8

32.7

36.6

39.9

29.6

35.1

39.7

43.6

31.5

37.9

43.3

48.0

32.6

39.5

45.4

50.6

33.7

41.2

47.7

53.6

27.0

31.5

35.1

38.0

28.8

34.1

38.4

42.0

30.9

37.1

42.3

46.7

32.1

38.8

44.6

49.6

33.4

40.7

47.1

52.8

27.4

32.1

35.8

38.9

29.9

35.6

40.3

44.3

31.3

37.6

42.9

47.6

32.8

39.9

45.9

51.3

26.2

30.3

33.4

36.2

28.9

34.1

38.4

42.0

30.5

38.4

41.4

45.7

32.3

39.0

44.8

49.8

28.0

32.8

36.7

39.9

29.7

35.3

39.9

43.8

31.7

38.2

43.7

48.5

26.6

29.2

31.4

25.9

30.4

34.0

37.0

27.6

32.8

37.1

40.7

29.5

35.5

40.6

45.1

30.6

37.1

42.7

47.7

31.8

38.8

45.1

50.6

25.1

29.2

32.5

35.2

26.9

31.8

35.7

39.1

29.0

34.7

39.6

43.8

30.2

36.5

41.9

46.6

31.5

38.4

44.5

49.8

25.5

29.8

33.3

36.1

28.0

33.2

37.6

41.4

29.4

35.3

40.3

44.6

30.9

37.5

43.3

48.3

24.3

28.1

31.0

33.4

27.0

31.8

35.8

39.1

28.6

34.1

38.7

42.7

30.3

36.6

42.1

46.9

26.0

30.5

34.1

37.1

27.8

33.0

37.3

40.9

29.7

35.8

41.0

45.5

24.7

27.2

29.1

24.3

28.4

31.8

34.5

25.9

30.8

34.8

38.1

27.8

33.5

38.3

42.5

28.9

35.0

40.4

45.1

30.1

36.8

42.7

48.0

23.5

27.3

30.3

32.8

25.2

29.8

33.5

36.6

27.3

32.7

37.3

41.2

28.5

34.4

39.5

44.0

29.8

36.3

42.1

47.2

23.9

27.9

31.1

33.7

26.3

31.2

35.3

38.8

27.6

33.2

37.9

42.0

29.2

35.4

40.9

45.7

22.7

26.2

28.9

29.1

25.3

29.8

33.5

36.6

26.9

32.0

36.4

40.1

28.6

34.6

39.7

44.2

24.4

28.5

31.9

34.6

26.1

31.0

35.0

38.3

28.0

33.7

38.6

42.9

23.2

25.4

27.2

23.0

26.8

30.0

32.5

24.6

29.1

32.9

36.0

26.4

31.8

36.4

40.3

27.5

33.4

38.4

42.9

28.7

35.1

40.8

45.8

22.1

25.7

28.5

30.8

23.9

28.1

31.6

34.5

25.9

31.0

35.3

39.1

27.1

32.7

37.6

41.8

28.4

34.6

40.2

45.0

22.6

26.3

29.2

31.6

24.9

29.6

33.4

36.7

26.3

31.5

36.0

39.8

27.8

33.8

39.0

43.5

21.3

24.6

27.1

31.1

23.9

28.2

31.6

34.5

25.5

30.4

34.5

38.0

27.2

32.9

37.8

42.1

23.0

26.9

30.0

32.5

24.7

29.3

33.1

36.2

26.7

32.1

36.7

40.7

21.8

23.9

25.5

21.7

25.4

28.3

30.7

23.3

27.6

31.1

34.1

25.2

30.2

34.6

38.3

26.2

31.8

36.6

40.9

27.4

33.5

39.0

43.8

20.9

24.2

26.9

29.0

22.6

26.6

29.9

32.6

24.6

29.5

33.6

37.1

25.8

31.2

35.8

39.9

27.1

33.1

38.3

43.0

21.3

22.4

27.6

29.8

23.6

28.0

32.7

34.7

25.0

30.0

34.2

37.9

26.5

32.2

37.2

41.5

20.2

23.2

25.5

27.3

22.7

26.7

29.9

32.6

24.2

28.9

32.7

36.0

25.9

31.3

36.0

40.1

21.8

25.4

28.3

30.7

23.5

27.8

31.3

34.3

25.4

30.5

34.9

38.7

20.6

22.6

24.1

20.7

24.1

26.9

29.1

22.3

26.3

29.7

32.5

24.1

29.0

33.1

36.7

25.2

30.5

35.1

39.2

26.3

32.2

37.5

42.1

19.9

23.0

25.5

27.5

21.6

25.4

28.4

31.0

23.6

28.2

32.1

35.4

24.8

29.9

34.3

38.2

26.0

31.8

36.9

41.4

20.3

23.6

26.1

28.2

22.6

26.8

31.2

33.1

23.9

28.7

32.7

36.2

25.4

30.9

35.7

39.8

19.1

22.0

24.1

25.8

21.7

25.4

28.5

31.0

23.2

27.6

31.2

34.4

24.9

30.0

34.5

38.4

20.8

24.2

26.9

29.1

22.4

26.5

29.8

32.6

24.3

29.2

33.4

37.0

19.5

21.3

22.7

19.7

22.9

25.5

27.6

21.2

25.1

28.2

30.9

23.0

27.6

31.6

35.0

24.1

29.2

33.6

37.5

25.2

30.9

35.9

40.4

18.9

21.8

24.1

26.0

20.6

24.1

27.0

29.4

22.5

26.9

30.6

33.8

23.7

28.6

32.8

36.5

24.9

30.4

35.3

39.6

19.3

22.4

24.8

26.7

21.5

25.5

28.7

31.5

22.9

27.4

31.2

34.5

24.3

29.5

34.1

38.1

18.2

20.8

22.8

24.4

20.6

24.2

27.0

29.4

22.1

26.3

29.8

32.7

23.8

28.7

33.0

36.7

19.7

23.0

25.5

27.5

21.4

25.2

28.4

31.0

23.2

27.9

31.9

35.3

18.6

20.2

21.6

18.8

21.9

24.3

26.3

20.3

24.0

27.0

29.5

22.1

26.5

30.3

33.5

23.1

28.0

32.3

36.0

24.2

29.7

34.5

38.9

18.0

20.8

23.0

24.7

19.7

23.0

25.8

28.0

21.6

25.8

29.3

32.3

22.7

27.4

31.5

35.0

24.0

29.3

33.9

38.1

18.4

21.3

23.6

25.4

20.6

24.4

27.5

30.1

21.9

26.2

29.9

33.1

23.4

28.4

32.8

36.6

17.3

19.8

21.7

23.2

19.7

23.1

25.8

28.1

21.2

25.2

28.5

31.3

22.8

27.6

31.6

35.2

18.9

21.9

24.3

26.2

20.4

24.1

27.1

29.6

22.3

26.8

30.6

33.9

17.7

19.3

20.5

18.0

20.9

23.2

25.1

19.5

23.0

25.9

28.3

21.3

25.5

29.1

32.2

22.3

27.0

31.1

34.7

23.4

28.7

33.3

37.5

17.3

19.9

21.9

23.6

18.9

22.1

24.7

26.8

20.8

24.8

28.1