Trenton TTM105LE-S2 Installation Manual

PRODUCT DATA &

15/08/16

INSTALLATION

Bulletin T30-TTM-PDI-7

1087841

TTM Two-Way

Medium Prole

Evaporators

High, Medium and Low

T emperature Applications

-10°F (-23.3 °C) or Above

Box Temperature

Air, Electric or Hot Gas

Defrost (Reverse Cycle)

See Page 11 for details

INCLUDES RATINGS FOR

?

Questions about this product?

Email: evaps@t-rp.com

Call: 1-844-893-3222 x520

?

CONTENTS

Page

Nomenclature..................................................................................................................... 2

Features.............................................................................................................................. 2

Capacity Data (Imperial and Metric).................................................................................... 3

Electrical Data.................................................................................................................. 4 - 5

Wiring Diagrams............................................................................................................... 6 - 10

Wiring Diagrams - Models with optional EC Motors / ............................... 11 -15

Mechanical Data................................................................................................................. 16

Dimensional Data............................................................................................................... 17

Installation Clearances....................................................................................................... 18

TXV Selection.................................................................................................................. 19 - 21

Installation Instructions.................................................................................................... 22 - 23

Service Parts..................................................................................................................... 24

Warranty............................................................................................................................. 27

Project Information............................................................................................................. 27

“As Built” Service Parts List............................................................................................. BACK

T TM 2 9 5 M A - S1 A - T

15/08/16

T30-TTM-PDI-7

- 2 -

Model Name

T = Trenton

Product Name

TM = Two Way Medium Prole Unit Cooler

X 100 = Nominal Capacity

(10°F TD, 60Hz), Btu/H

Evap Temp Range

M = Medium Temp (10 - 45°F), 6 FPI.

L = Low Temp (-20 - 0°F), 6 FPI.

STANDARD FEATURES

NOMENCLATURE

Motor

C = PSC

T = ECM

Design Version

Unit Electrical Designaton

S1 = 115/1/60 (air defrost models only)

S2 = 208-230/1/60 S6 = 200-220/1/50

S4 = 460/1/60 S9 = 380-400/1/50

Defrost Type

A = Air Defrost

E = Electric Defrost

G = Reverse Cycle w/ Electric Heater Pan

• Compatable with Low GWP Refrigerants

• Heavy gauge textured aluminum cabinet

construction resists scratches/corrosion and

minimizes weight for shipment, installation and

service.

• Capacity up to 29,500 BTUH nominal @ 10F TD.

• Dual refrigeration coils with two-way air

distribution reduces air velocities to minimize

product dehydration.

• Air enters through fan and discharges two ways

out of each coil side.

• Low height compact size useable storage space.

OPTIONAL FEATURES

• Factory mounted solenoid valve, TXV and

Thermostat on air and electric defrost models.

• Internally enhanced tube.

• Attractive and durable high - density

polyethylene fan guards.

• Standard PSC motors

• Hinged drain pan provides convenient access

for cleaning.

• Terminal board allows for easy electrical

connections.

• Reduced operating charge with 3/8” OD tubing

• Refrigerants R407A, R407C, R404A/R507,

R22 and R134a.

• EC motors with patented SmartSpeed®

Technology. See page 11

• Fin material and special coatings.

• Other options available - consult factory.

TTM 60Hz

15/08/16

T30-TTM-PDI-7

- 3 -

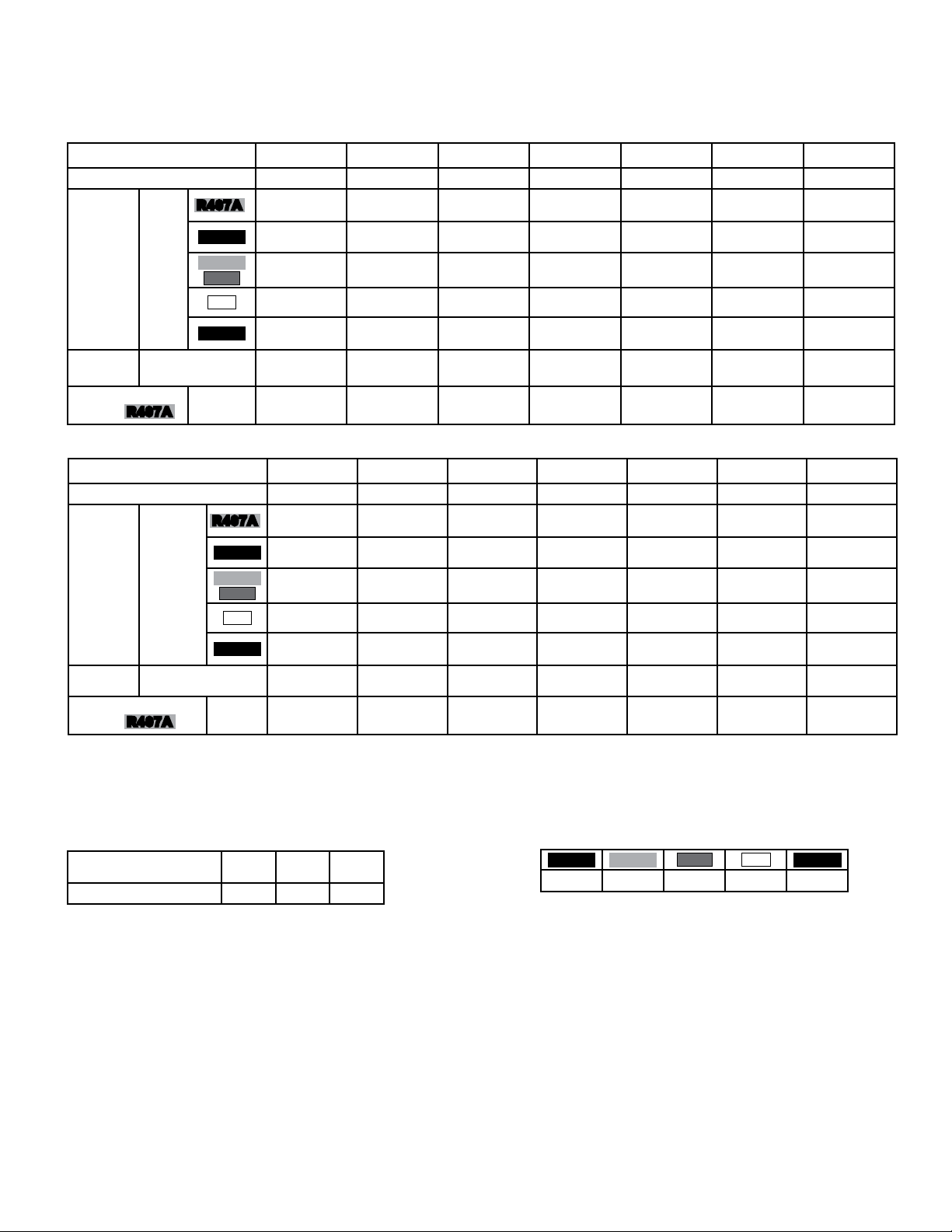

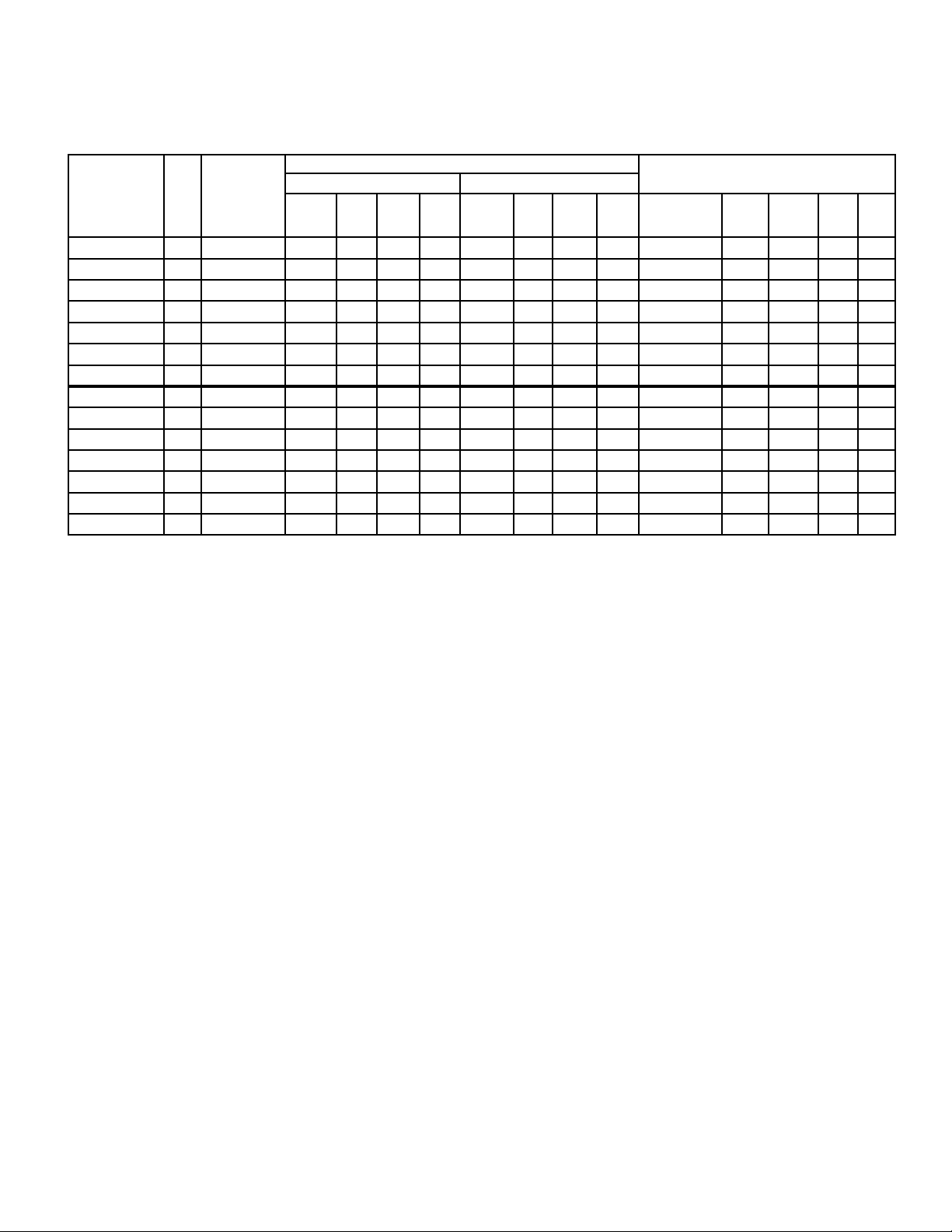

CAPACITY DATA - ALL MODELS

MEDIUM TEMPERATURE MODELS - CAPACITY

Medium Temp. Models TTM115M TTM139M TTM172M TTM208M TTM236M TTM260M TTM295M

Number of Fans 2 2 3 3 4 4 5

10930 13210 16340 19760 22420 24700 28000

(3202) (3870) (4789) (5791) (6570) (7239) (8214)

10350 12510 15480 18720 21240 23400 26600

(3033) (3667) (4537) (5486) (6224) (6858) (7781)

11500 13900 17200 20800 23600 26000 29500

(3370) (4074) (5041) (6096) (6916) (7620) (8646)

10930 13210 16340 19760 22400 24700 28000

(3202) (3870) (4789) (5791) (6570) (7239) (8214)

10350 12510 15480 18720 21240 23400 26550

(3033) (3667) (4537) (5486) (6224) (6858) (7781)

2020 1900 3030 2850 3700 3780 4630

(953) (897) (1430) (1345) (1746) (1760) (2185)

2.3

(1.1)

3.1

(1.4)

3.4

(1.5)

4.6

(2.1)

4.6

(2.1)

5.7

(2.6)

5.7

(2.6)

Capacity

BTUH

(WATTS)

Air Flow CFM (L/s)

Refrigerant **

Charge

Evap

Temp.

25°F

(-4°C)

R407A

R407A

R407C

R404A

R507

R22

R134a

Lbs (Kg)

LOW TEMPERATURE MODELS - CAPACITY *

Low Temp. Models TTM105L TTM124L TTM153L TTM188L TTM210L TTM235L TTM265L

Number of Fans 2 2 3 3 4 4 5

9980 11780 14540 17860 19950 22300 25200

(2923) (3452) (4260) (5235) (5846) (6543) (7378)

9450 11160 13770 16920 18900 21150 23900

(2769) (3271) (4036) (4959) (5539) (6198) (6989)

10500 12400 15300 18800 21000 23500 26500

(3077) (3634) (4484) (5510) (6154) (6887) (7766)

9980 11780 14540 17860 20000 22300 25200

(2923) (3452) (4260) (5235) (5846) (6543) (7378)

9450 11160 13770 16920 18900 21150 23850

(2769) (3271) (4036) (4959) (5539) (6198) (6989)

2020 1900 3030 2850 3700 3780 4630

(953) (897) (1430) (1345) (1746) (1760) (2185)

2.3

(1.1)

3.1

(1.4)

3.4

(1.5)

4.6

(2.1)

4.6

(2.1)

5.7

(2.6)

5.7

(2.6)

Capacity

BTUH

(WATTS)

Air Flow CFM (L/s)

Refrigerant **

Charge

Evap

Temp.

-20°F

(-28.9°C)

R407A

R407A

R407C

R404A

R507

R22

R134a

Lbs

(Kg)

Capacities rated using 10°F (5.6°C) TD & 100°F (38°C) liquid temperature.

Capacities at other TD within a range of 8 to 15 °F (4.4 to 8.3°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

For capacities at TD outside of range 8 to 15 °F (4.4 to 8.3°C), or liquid temperature lower than 75°F (24°), consult factory .

Capacities for R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated suction

temperature and the temperature feeding the evaporator. For dew point ratings, consult factory.

* CAPACITY CORRECTION FACTORS FOR LOW TEMPERATURE UNITS

SATURATED SUCTION

TEMPERATURE °F (°C)0 (-17.8)

FACTOR 1.06 1.03 1.0

NO CORRECTION FACTOR REQUIRED FOR MEDIUM TEMP. UNITS

-10

(23.3)

-20

(-28.9)

** REFRIGERANT CHARGE CONVERSION FACTORS

R407C R404A

0.99 0.92 0.93 1.02 1.03

R507

R22

R134a

TTM 60Hz

15/08/16

T30-TTM-PDI-7

- 4 -

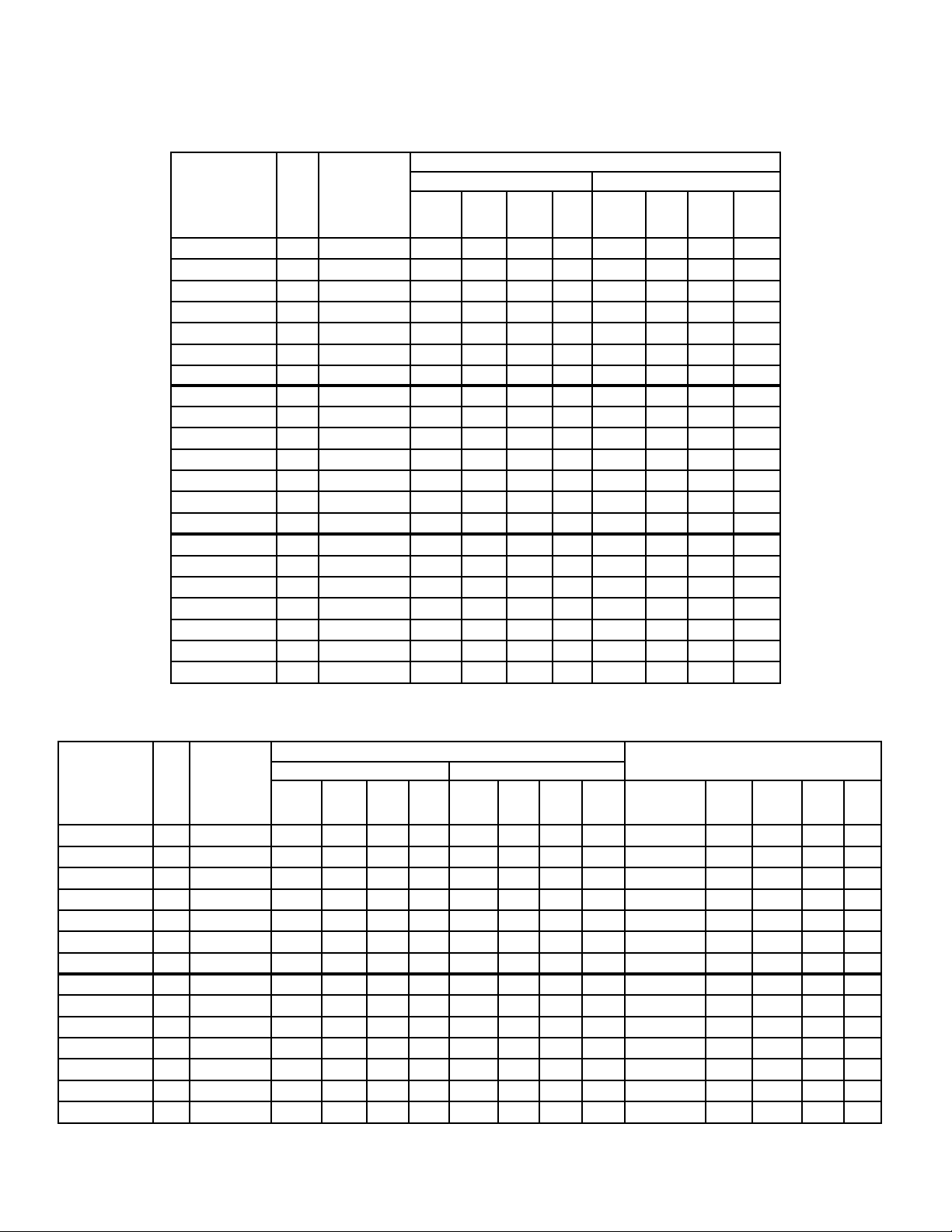

ELECTRICAL DATA

AIR DEFROST

FAN MOTOR(S)

MODEL

TTM115MA-S1 2 115/1/60 2.2 2.5 200 15 3 3.4 104 15

TTM139MA-S1 2 115/1/60 2.2 2.5 200 15 3 3.4 104 15

TTM172MA-S1 3 115/1/60 3.3 3.6 300 15 4.5 4.9 156 15

TTM208MA-S1 3 115/1/60 3.3 3.6 300 15 4.5 4.9 156 15

TTM236MA-S1 4 115/1/60 4.4 4.7 400 15 6 6.4 208 15

TTM260MA-S1 4 115/1/60 4.4 4.7 400 15 6 6.4 208 15

TTM295MA-S1 5 115/1/60 5.5 5.8 500 15 7.5 7.9 260 15

TTM115MA-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15

TTM139MA-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15

TTM172MA-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15

TTM208MA-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15

TTM236MA-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15

TTM260MA-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15

TTM295MA-S2 5 208-230/1/60 2.5 2.6 500 15 5.0 5.3 260 15

TTM115MA-S4 2 460/1/60 0.6 0.7 200 15

TTM139MA-S4 2 460/1/60 0.6 0.7 200 15

TTM172MA-S4 3 460/1/60 0.9 1.0 300 15

TTM208MA-S4 3 460/1/60 0.9 1.0 300 15

TTM236MA-S4 4 460/1/60 1.2 1.3 400 15

TTM260MA-S4 4 460/1/60 1.2 1.3 400 15

TTM295MA-S4 5 460/1/60 1.5 1.6 500 15

No.

of

FANS

POWER

SUPPLY

PSC-Standard ECM-Optional

TOTAL

MOTOR

FLA

M.C.A. WATTS M.O.P

TOTAL

MOTOR

FLA

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

- - - -

M.C.A. WATTS M.O.P

ELECTRIC DEFROST

FAN MOTOR(S)

No.

MODEL

TTM115ME-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 2600 11.3 14.1 15

TTM139ME-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 2600 11.3 14.1 15

TTM172ME-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 3720 16.2 20.3 25

TTM208ME-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 3720 16.2 20.3 25

TTM236ME-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 3720 16.2 20.3 25

TTM260ME-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 4560 19.8 24.8 25

TTM295ME-S2 5 208-230/1/60 2.5 2.6 500 15 5.0 5.3 260 15 208-230/1/60 4560 19.8 24.8 25

TTM105LE-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 2600 11.3 14.1 15

TTM124LE-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 2600 11.3 14.1 15

TTM153LE-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 3720 16.2 20.3 25

TTM188LE-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 3720 16.2 20.3 25

TTM210LE-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 3720 16.2 20.3 25

TTM235LE-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 4560 19.8 24.8 25

TTM265LE-S2 5 208-230/1/60 2.5 2.6 500 15 5.0 5.3 260 15 208-230/1/60 4560 19.8 24.8 25

FANS

of

POWER

SUPPLY

PSC-Standard ECM-Optional

TOTAL

MOTOR

FLA

M.C.A. WATTS M.O.P

TOTAL

MOTOR

FLA

M.C.A. WATTS M.O.P

POWER

SUPPLY

DEFROST HEATERS

TOTAL

WATTS

TOTAL

MOTOR

FLA

M.C.A. M.O.P

TTM 60Hz

15/08/16

T30-TTM-PDI-7

- 5 -

ELECTRICAL DATA

HOT GAS DEFROST

FAN MOTOR(S)

MODEL

TTM115MG-S1 2 115/1/60 2.2 2.5 200 15 3.0 3.4 104 15 115/1/60 1300 11.3 14.1 15

TTM139MG-S1 2 115/1/60 2.2 2.5 200 15 3.0 3.4 104 15 115/1/60 1300 11.3 14.1 15

TTM172MG-S1 3 115/1/60 3.3 3.6 300 15 4.5 4.9 156 15 115/1/60 1860 16.2 20.3 25

TTM208MG-S1 3 115/1/60 3.3 3.6 300 15 4.5 4.9 156 15 115/1/60 1860 16.2 20.3 25

TTM236MG-S1 4 115/1/60 4.4 4.7 400 15 6.0 6.4 208 15 115/1/60 1860 16.2 20.3 25

TTM260MG-S1 4 115/1/60 4.4 4.7 400 15 6.0 6.4 208 15 115/1/60 2280 19.8 24.8 25

TTM295MG-S1 5 115/1/60 5.5 5.8 500 15 7.5 7.9 260 15 115/1/60 2280 19.8 24.8 25

TTM115MG-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 1300 5.7 7.1 15

TTM139MG-S2 2 208-230/1/60 1.0 1.1 200 15 2.0 2.3 104 15 208-230/1/60 1300 5.7 7.1 15

TTM172MG-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 1860 8.1 10.1 15

TTM208MG-S2 3 208-230/1/60 1.5 1.6 300 15 3.0 3.3 156 15 208-230/1/60 1860 8.1 10.1 15

TTM236MG-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 1860 8.1 10.1 15

TTM260MG-S2 4 208-230/1/60 2.0 2.1 400 15 4.0 4.3 208 15 208-230/1/60 2280 9.9 12.4 15

TTM295MG-S2 5 208-230/1/60 2.5 2.6 500 15 5.0 5.3 260 15 208-230/1/60 2280 9.9 12.4 15

No.

FANS

of

POWER

SUPPLY

PSC-Standard ECM-Optional

TOTAL

MOTOR

FLA

M.C.A. WATTS M.O.P

TOTAL

MOTOR

FLA

M.C.A. WATTS M.O.P

DRAIN PAN HEATERS

POWER

SUPPLY

TOTAL

WATTS

TOTAL

MOTOR

FLA

M.C.A. M.O.P

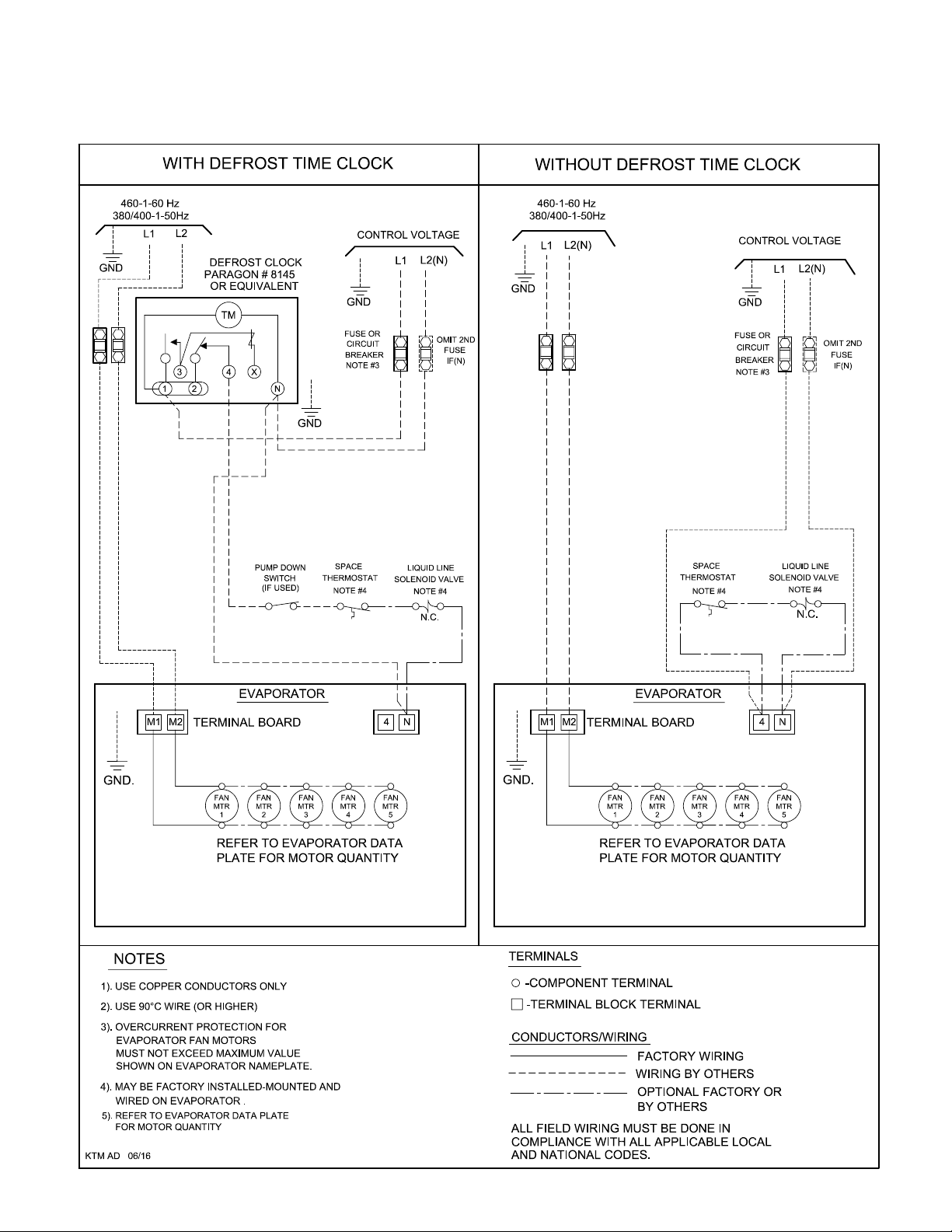

1-TM AD 03/08

TERMINAL BOARD

PUMP DOWN

WIRED ON EVAPORATOR .

2). USE 90°C WIRE (OR HIGHER)

EVAPORATOR FAN MOTORS AND DEFROST

HEATERS MUST NOT EXCEED MAXIMUM

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

4). MAY BE FACTORY INSTALLED-MOUNTED AND

NOTES

MTR

FAN

MTR

FAN

4

GND.

F

(IF USED)

SWITCH

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

BY OTHERS

OPTIONAL FACTORY OR

COMPLIANCE WITH ALL APPLICABLE LOCAL

ALL FIELD WIRING MUST BE DONE IN

AND NATIONAL CODES.

TERMINAL BOARD

NOTE #4

SPACE

THERMOSTAT

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

FAN MOTOR

POWER

PLUGS

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

MTR

FAN

TERMINALS

MTR

FAN

MTR

FAN

SOLENOID VALVE

EVAPORATOR

NOTE #4

SPACE

THERMOSTAT

N.C.

NOTE #4

LIQUID LINE

4

GND.

F

FAN MOTOR

POWER

PLUGS

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

MTR

FAN

EVAPORATOR

N.C.

NOTE #4

LIQUID LINE

SOLENOID VALVE

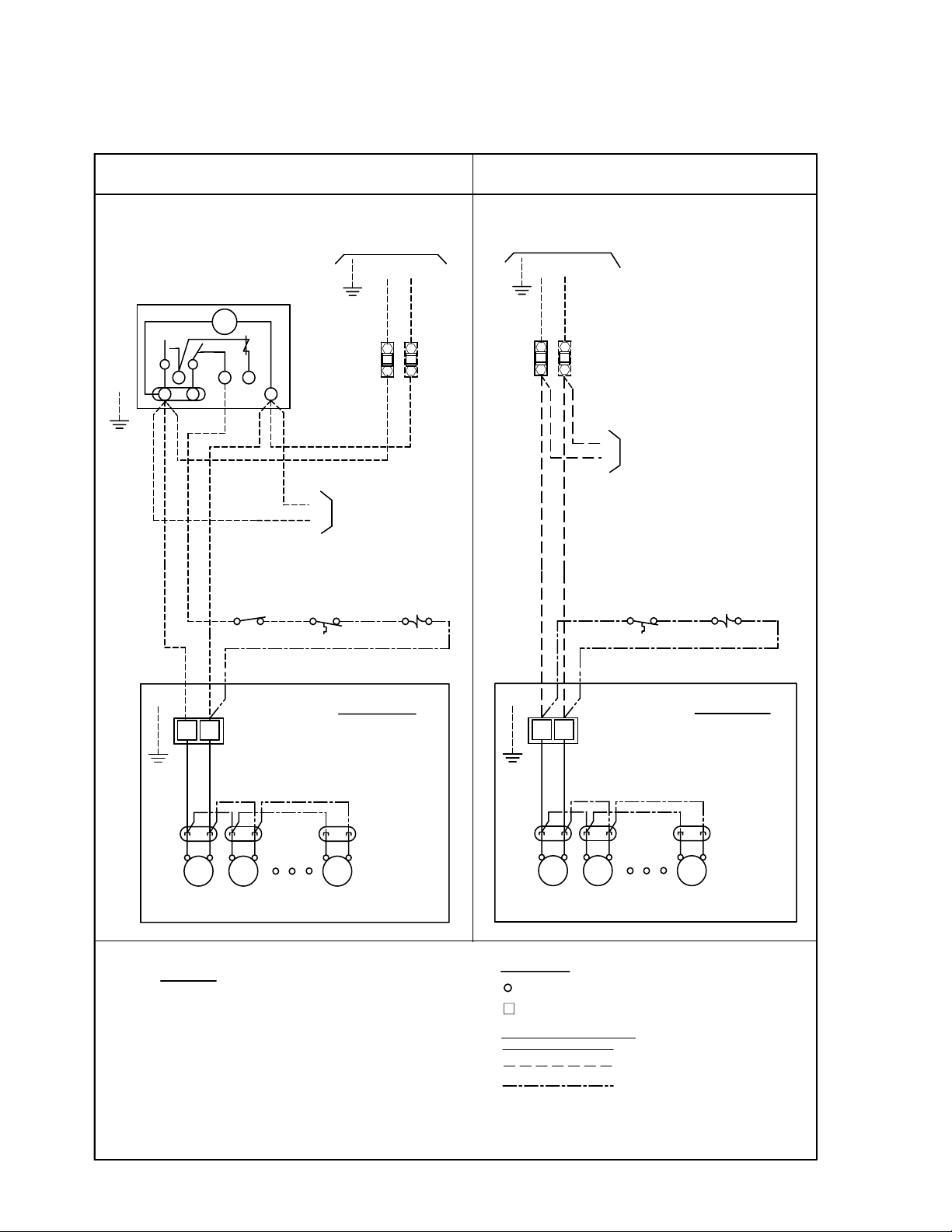

WITH DEFROST TIME CLOCK

GND

132

4NX

TM

OR EQUIVALENT

DEFROST CLOCK

PARAGON # 8145

EVAPORATORS (IF APPLIC)

NAMEPLATE FOR ELECTRICAL

REFER TO EVAPORATOR

WITHOUT DEFROST TIME CLOCK

GND

IF(N)

TO MULTIPLE EVAPS

F

4

(IF APPLIC)

OMIT 2ND

BREAKER

NOTE #3

FUSE OR

FUSE

CIRCUIT

4

F

BREAKER

NOTE #3

CIRCUIT

FUSE OR

NAMEPLATE FOR ELECTRICAL

REFER TO EVAPORATOR

REQUIREMENTS

L2(N)

L1

REQUIREMENTS

GND

L1

L2(N)

TO MULTIPLE

IF(N)

2ND FUSE

OMIT

TTM 60Hz

15/08/16

T30-TTM-PDI-7

- 6 -

WIRING DIAGRAM

AIR DEFROST - 120V & 208-230V

TTM 60Hz

15/08/16

T30-TTM-PDI-7

- 7 -

WIRING DIAGRAM

AIR DEFROST - 460V

TTM 60Hz

15/08/16

T30-TTM-PDI-7

- 8 -

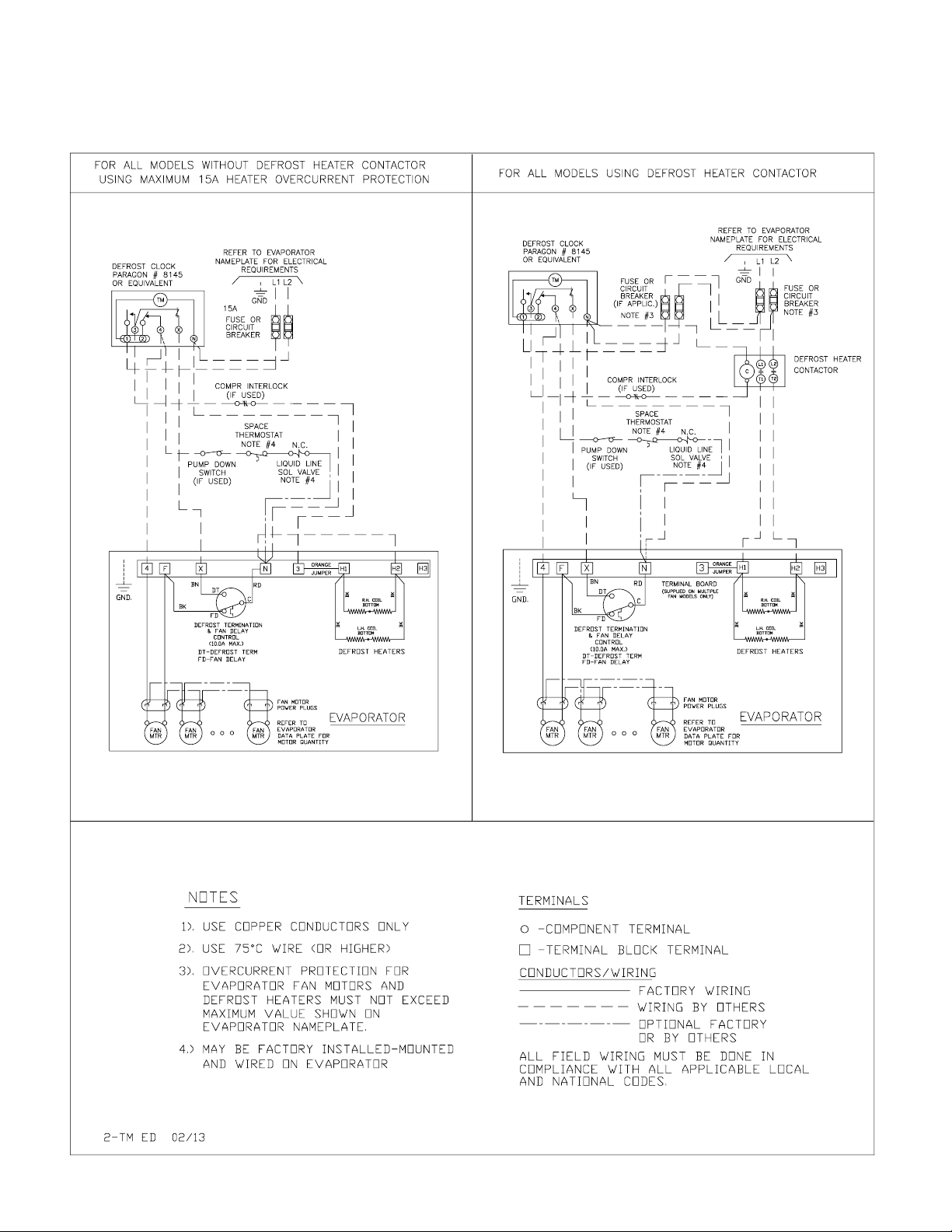

WIRING DIAGRAM

ELECTRIC DEFROST -

208-230V (SINGLE EVAPORATOR)

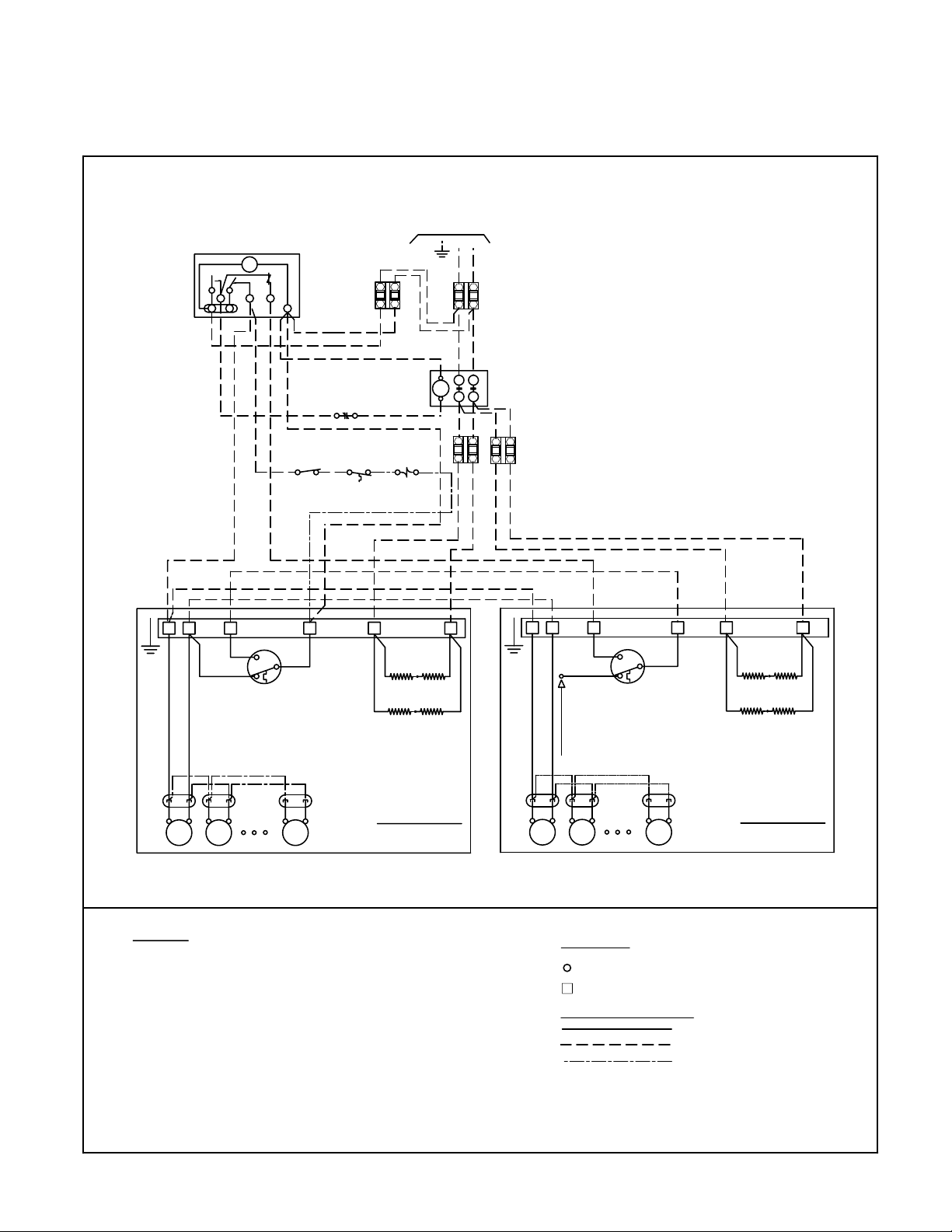

* Fan delay not used on second evap / use fan contactor if total fan amps exceeds 10A

4.) MAY BE FACTORY INSTALLED-MOUNTED

FAN MOTOR

POWER PLUGS

REFER TO

EVAPORATOR

MOTOR QUANTITY

DATA PLATE FOR

3-TM ED CONTACTOR MULTI 03/08

3). OVERCURRENT PROTECTION FOR

1). USE COPPER CONDUCTORS ONLY

DEFROST HEATERS MUST NOT EXCEED

EVAPORATOR FAN MOTORS AND

AND WIRED ON EVAPORATOR

EVAPORATOR NAMEPLATE.

MAXIMUM VALUE SHOWN ON

2). USE 90°C WIRE (OR HIGHER)

NOTES

MTR

FANFAN

MTR MTR

FAN

DT-DEFROST TERM

FD-FAN DELAY

& FAN DELAY

(10.0A MAX.)

DEFROST TERMINATION

BK

GND.

4

BN

F

X

CONTROL

FD

RD

DT

C

N

COMPLIANCE WITH ALL APPLICABLE LOCAL

ALL FIELD WIRING MUST BE DONE IN

WIRING BY OTHERS

FACTORY WIRING

OPTIONAL FACTORY

AND NATIONAL CODES.

TERMINALS

CONDUCTORS/WIRING

OR BY OTHERS

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

SECONDARY

EVAPORATOR

* Remove & Insulate

EVAPORATOR

FAN

MTR

PRIMARY

MTR

FANFAN

MTR

DATA PLATE FOR

MOTOR QUANTITY

REFER TO

EVAPORATOR

FD-FAN DELAY

DT-DEFROST TERM

POWER PLUGS

FAN MOTOR

H1

H2

GND.

4

F

N

BK

& FAN DELAY

CONTROL

(10.0A MAX.)

DEFROST TERMINATION

FD

RD

BN

DT

X

C

H1 H2

FUSE OR

NOTE #3

BREAKER

CIRCUIT

(IF USED)

SPACE

NOTE #4

THERMOSTAT

FOR ALL MODELS USING DEFROST HEATER CONTACTOR

COMPR INTERLOCK

REFER TO EVAPORATOR

PUMP DOWN

(IF USED)

SWITCH

DEFROST CLOCK

PARAGON # 8145

OR EQUIVALENT

3

12

X4

N

TM

DEFROST HEATER

LIQUID LINE

SOL VALVE

NOTE #4

N.C.

NOTE #3

BREAKER

CIRCUIT

FUSE OR

T1

L1

C

CONTACTOR

T2

L2

REQUIREMENTS

L1

GND

FUSE OR

CIRCUIT

NOTE #3

BREAKER

L2

NAMEPLATE FOR ELECTRICAL

DEFROST HEATERS

L.H. COIL

BK

BOTTOM

BK

R.H. COIL

BOTTOM

BK

BK

DEFROST HEATERS

BK

BOTTOM

L.H. COIL

BK

BK

BK

BOTTOM

R.H. COIL

TTM 60Hz

15/08/16

T30-TTM-PDI-7

- 9 -

WIRING DIAGRAM

ELECTRIC DEFROST -

230V (MULTI EVAPORATOR)

Loading...

Loading...