Trenton TTL025MA-S1A, TTL010MA-S1A, TTL015MA-S1A, TTL038MA-S1A, TTL032MA-S1A Installation Instructions Manual

...Page 1

PRODUCT DATA &

23/06/17

INSTALLATION

Bulletin T30-TTL-PDI-16

Part #

1087831

PRODUCT SUPPORT

web: t-rp.com/ttl

email: evaps@t-rp.com

call: 1-844-893-3222 x520

scan:

TTL Two-Way

Low Prole

Evaporators

High, Medium and Low

T emperature Applications

-10°F (-23.3 °C) or Above

Box Temperature

Air, Electric or Hot Gas

Defrost (Reverse Cycle)

INCLUDES RATINGS FOR

CONTENTS

Nomenclature.................................................................................................................. 2

Features........................................................................................................................... 2

Capacity Data (Imperial and Metric)................................................................................ 3

Electrical Data................................................................................................................. 4 - 5

Wiring Diagrams.............................................................................................................. 6 - 8

Dimensional Data........................................................................................................... 9 - 10

TXV Selection................................................................................................................. 11 - 12

Installation Instructions................................................................................................... 13 - 14

Project Information......................................................................................................... 14

Product Support Resources: Service Parts, Troubleshooting, Warranty, etc................. 15

“As Built” Service Parts List............................................................................................ BACK

Page

Page 2

Model Name

23/06/17

T30-TTL-PDI-16

- 2 -

T = Trenton

NOMENCLATURE

T TL 1 1 5 M A - S1 A

Design Version

Product Name

TL = Two Way Low Prole Evaporator

X 100 = Nominal Capacity

(10°F TD, 60Hz), Btu/H

Evap Temp Range

M = Medium Temp (10 - 45°F), 8 FPI.

L = Low Temp(-20 - 0°F), 8 FPI.

STANDARD FEATURES

• Compatable with Low GWP Refrigerants

• Low height compact size maximizes useable

storage space

• Dual refrigeration coils and two-way air

distribution reduces air velocities to minimize

product dehydration

• Air enters through fan and discharges two ways

out of each coil side

Unit Electrical Designaton.

S1 = 115/1/60

S2 = 208-230/1/60

S6 = 200-220/1/50

Defrost Type.

A = Air Defrost

E = Electric Defrost

• Rugged heavy duty motor mount reduces

vibration and noise

• Electric defrost models include factory installed

defrost termination and fan delay thermostat

• NSF approved “ush to ceiling mount”

• Internally enhanced tube

• PSC Motors available on all models

• EC Motors available for Medium Temperature

models 038, 060, 077 & 115 and

Low Temperature models 033, 052, 066 & 099

AVAILABLE OPTIONS

• Additional options available, please contact

factory

Page 3

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 3 -

CAPACITY DATA - ALL MODELS

MEDIUM TEMPERATURE MODELS - CAPACITY *

Model TTL 010M 015M 020M 025M 032M 038M 060M 077M 115M

Number of Fans 1 1 1 1 1 1 2 2 3

900 1380 1900 2380 3040 3600 5700 7300 10900

(264) (404) (557) (696) (891) (1058) (1670) (2144) (3202)

860 1305 1800 2250 2880 3420 5400 6900 10400

(250) (383) (527) (660) (844) (1003) (1582) (2031) (3033)

950 1450 2000 2500 3200 3800 6000 7700 11500

(278) (425) (586) (733) (938) (1114) (1758) (2257) (3370)

900 1380 1900 2380 3000 3600 5700 7300 10900

(264) (404) (557) (696) (891) (1058) (1670) (2144) (3202)

855 1305 1800 2250 2880 3420 5400 6930 10350

(250) (383) (527) (660) (844) (1003) (1582) (2031) (3033)

130 180 237 270 440 440 928 807 1242

(61) (85) (112) (127) (208) (208) (438) (381) (586)

0.4 0.5 0.7 0.8 0.9 1.2 1.4 2.3 3.4

(0.2) (0.2) (0.3) (0.4) (0.4) (0.5) (0.6) (1.0) (1.5)

Capacity

BTUH

(WATTS)

Air Flow CFM (L/s)

Refrigerant **

Charge

Evap

Temp.

25°F

(-4°C)

R407A

R407A

R448A

R407C

R404A

R507

R22

R134a

Lbs (Kg)

LOW TEMPERATURE MODELS - CAPACITY *

Model TTL 009L 013L 017L 021L 028L 033L 052L 066L 099L

Number of Fans 1 1 1 1 1 1 2 2 3

810 1190 1620 2000 2660 3100 4900 6300 9400

(237) (348) (473) (584) (780) (919) (1448) (1837) (2756)

770 1125 1530 1890 2520 2970 4700 6000 8900

(224) (329) (448) (554) (739) (870) (1372) (1741) (2611)

850 1250 1700 2100 2800 3300 5200 6600 9900

(249) (366) (498) (615) (821) (967) (1524) (1934) (2901)

810 1190 1620 2000 2700 3100 4900 6300 9400

(237) (348) (473) (584) (780) (919) (1448) (1837) (2756)

765 1125 1530 1890 2520 2970 4680 5940 8910

(224) (329) (448) (554) (739) (870) (1372) (1741) (2611)

130 180 237 270 440 440 928 807 1242

(61) (85) (112) (127) (208) (208) (438) (381) (586)

0.4 0.5 0.7 0.8 0.9 1.2 1.4 2.3 3.4

(0.2) (0.2) (0.3) (0.4) (0.4) (0.5) (0.6) (1.0) (1.5)

Capacity

BTUH

(WATTS)

Air Flow CFM (L/s)

Refrigerant **

Charge

Evap

Temp.

-20°F

(-28.9°C)

R407A

R407A

R448A

R407C

R404A

R507

R22

R134a

Lbs

(Kg)

* Derate capacity by 5% when using EC Motors

Capacities rated using 10°F (5.6°C) TD & 100°F (38°C) liquid temperature.

Capacities at other TD within a range of 8 to 15 °F (4.4 to 8.3°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

For capacities at TD outside of range 8 to 15 °F (4.4 to 8.3°C), or liquid temperature lower than 75°F (24°), consult factory .

Capacities for R448A, R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated suction

temperature and the temperature feeding the evaporator. For dew point ratings, consult factory.

For R449A, use R448A data.

* CAPACITY CORRECTION FACTORS FOR LOW TEMPERATURE UNITS

SATURATED SUCTION

TEMPERATURE °F (°C)0 (-17.8)

FACTOR 1.06 1.03 1.0

NO CORRECTION FACTOR REQUIRED FOR MEDIUM TEMP. UNITS

-10

(23.3)

-20

(-28.9)

** REFRIGERANT CHARGE CONVERSION FACTORS

R448A

0.96 0.99 0.92 0.93 1.02 1.03

R407C R404A

R507

R22

R134a

Page 4

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 4 -

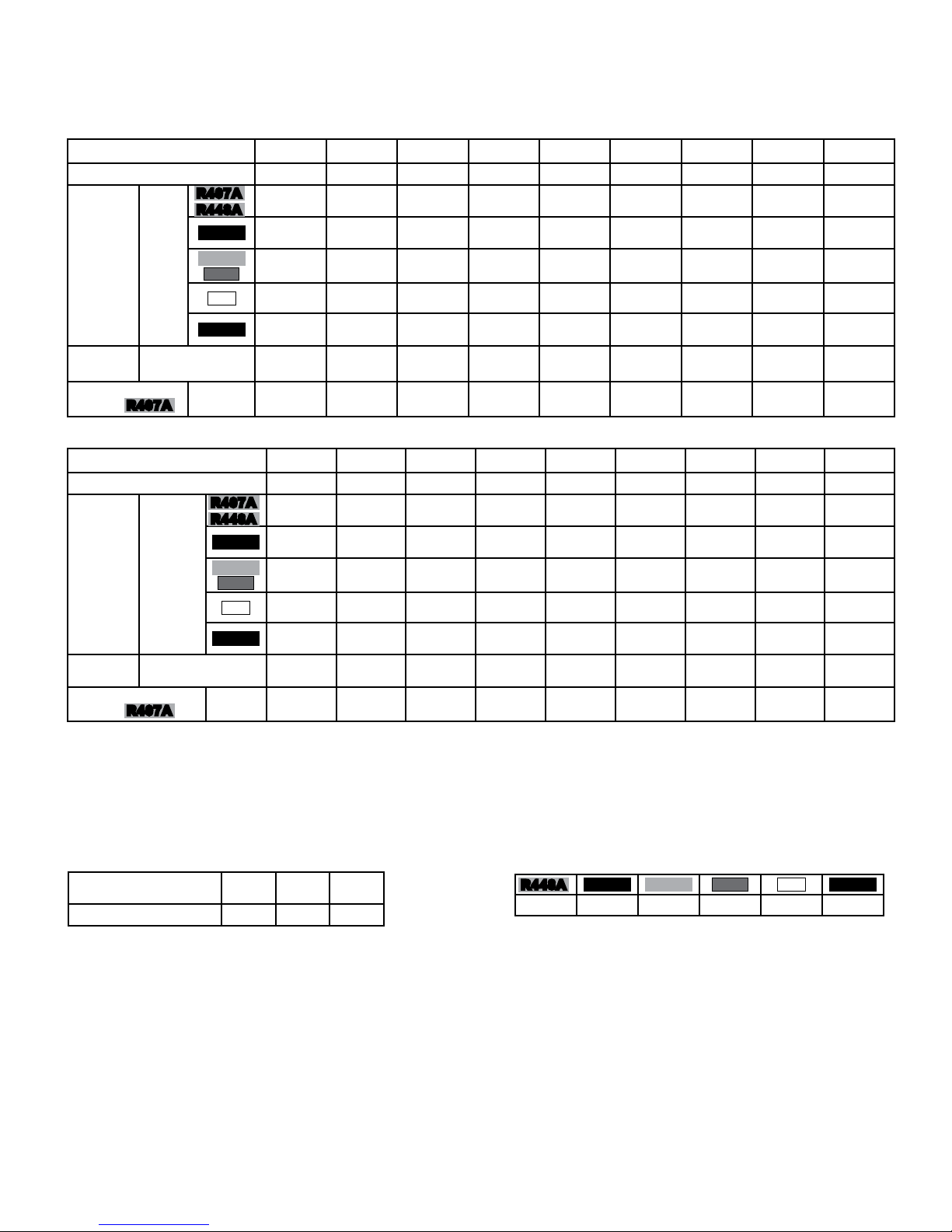

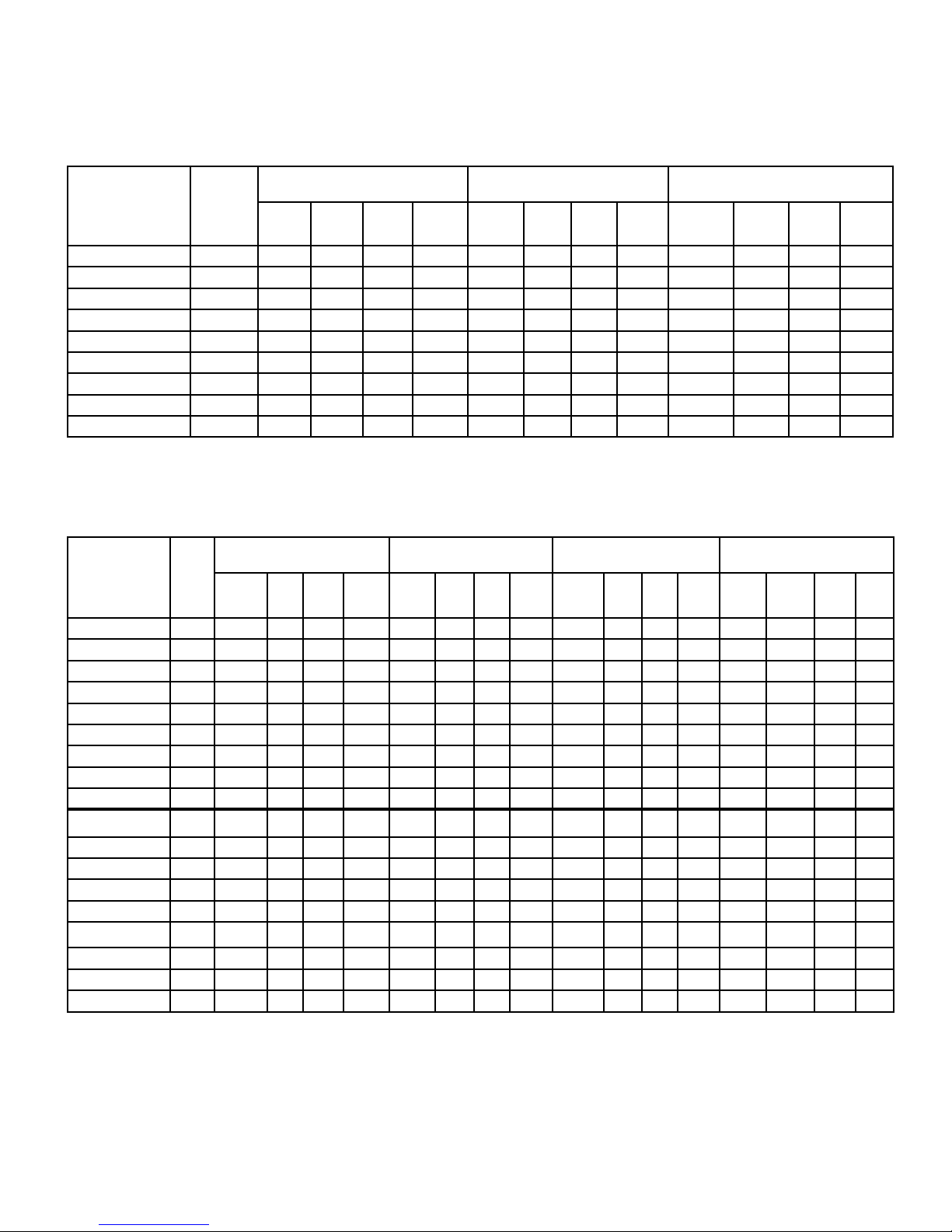

ELECTRICAL DATA

115/1/60

AIR DEFROST

MODEL

TTL

010MA-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - -

015MA-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - -

020MA-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - -

025MA-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - -

032MA-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 0.60 0.75 15 30

038MA-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 0.60 0.75 15 30

060MA-S1A 2 2.4 2.7 15 140 1.30 1.46 15 120 1.20 1.35 15 60

077MA-S1A 2 2.4 2.7 15 140 1.30 1.46 15 120 1.20 1.35 15 60

115MA-S1A 3 3.6 3.9 15 210 1.95 2.11 15 180 1.80 1.95 15 90

No.

of

FANS

TOTAL

MOTOR

FAN MOTOR(S) -

SHADED POLE (STANDARD)

M.C.A. M.O.P WATTS

FLA

MOTOR

ELECTRIC DEFROST

MODEL

TTL

010ME-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - - 206 1.8 2.2 15

015ME-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - - 530 4.6 5.8 15

020ME-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - - 530 4.6 5.8 15

025ME-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - - 530 4.6 5.8 15

032ME-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 0.60 0.75 15 30 750 6.5 8.2 15

038ME-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 0.60 0.75 15 30 750 6.5 8.2 15

060ME-S1A 2 2.4 2.7 15 140 1.30 1.46 15 120 1.20 1.35 15 60 1100 9.6 12.0 15

077ME-S1A 2 2.4 2.7 15 140 1.30 1.46 15 120 1.20 1.35 15 60 1540 13.4 16.8 20

115ME-S1A 3 3.6 3.9 15 210 1.95 2.11 15 180 1.80 1.95 15 90 2270 19.7 24.6 25

009LE-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - - 206 1.8 2.2 15

013LE-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - - 530 4.6 5.8 15

017LE-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - - 530 4.6 5.8 15

021LE-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 - - - - 530 4.6 5.8 15

028LE-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 0.60 0.75 15 30 750 6.5 8.2 15

033LE-S1A 1 1.2 1.5 15 70 0.65 0.81 15 60 0.60 0.75 15 30 750 6.5 8.2 15

052LE-S1A 2 2.4 2.7 15 140 1.30 1.46 15 120 1.20 1.35 15 60 1100 9.6 12.0 15

066LE-S1A 2 2.4 2.7 15 140 1.30 1.46 15 120 1.20 1.35 15 60 1540 13.4 16.8 20

099LE-S1A 3 3.6 3.9 15 210 1.95 2.11 15 180 1.80 1.95 15 90 2270 19.7 24.6 25

No.

of

FANS

FAN MOTOR(S) -

SHADED POLE (STANDARD)

TOTAL

MOTOR

M.C.A. M.O.P WATTS

FLA

FAN MOTOR(S) PSC (OPTIONAL)

TOTAL

MOTOR

M.C.A. M.O.P WATTS

FLA

TOTAL

FLA

FAN MOTOR(S) PSC (OPTIONAL)

M.C.A. M.O.P WATTS

FAN MOTOR(S)-

EC (OPTIONAL)

TOTAL

MOTOR

M.C.A. M.O.P WATTS

FLA

TOTAL

MOTOR

FLA

TOTAL

WATTS

FAN MOTOR(S)-

EC (OPTIONAL)

M.C.A. M.O.P WATTS

DEFROST HEATERS

TOTAL

M.C.A. M.O.P

AMPS

Page 5

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 5 -

ELECTRICAL DATA

208-230/1/60

AIR DEFROST

TOTAL

MOTOR

FLA

FAN MOTOR(S) PSC (OPTIONAL)

M.C.A. M.O.P WATTS

TOTAL

MOTOR

MODEL

TTL

010MA-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - -

015MA-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - -

020MA-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - -

025MA-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - -

032MA-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 0.30 0.40 15 30

038MA-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 0.30 0.40 15 30

060MA-S2A 2 1.4 1.6 15 120 0.48 0.54 15 100 0.60 0.70 15 60

077MA-S2A 2 1.4 1.6 15 120 0.48 0.54 15 100 0.60 0.70 15 60

115MA-S2A 3 2.1 2.3 15 180 0.72 0.78 15 150 0.90 1.00 15 90

No.

of

FANS

TOTAL

MOTOR

FAN MOTOR(S) -

SHADED POLE

M.C.A. M.O.P WATTS

FLA

(STANDARD)

ELECTRIC DEFROST

FAN MOTOR(S)-

EC (OPTIONAL)

M.C.A. M.O.P WATTS

FLA

MODEL

TTL

010ME-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - - 206 0.9 1.1 15

015ME-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - - 530 2.3 2.9 15

020ME-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - - 530 2.3 2.9 15

025ME-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - - 530 2.3 2.9 15

032ME-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 0.30 0.40 15 30 750 3.3 4.1 15

038ME-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 0.30 0.40 15 30 750 3.3 4.1 15

060ME-S2A 2 1.4 1.6 15 120 0.48 0.54 15 100 0.60 0.70 15 60 1100 4.8 6.0 15

077ME-S2A 2 1.4 1.6 15 120 0.48 0.54 15 100 0.60 0.70 15 60 1540 6.7 8.4 15

115ME-S2A 3 2.1 2.3 15 180 0.72 0.78 15 150 0.90 1.00 15 90 2270 9.9 12.4 15

009LE-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - - 206 0.9 1.1 15

013LE-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - - 530 2.3 2.9 15

017LE-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - - 530 2.3 2.9 15

021LE-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 - - - - 530 2.3 2.9 15

028LE-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 0.30 0.40 15 30 750 3.3 4.1 15

033LE-S2A 1 0.7 0.9 15 60 0.24 0.30 15 50 0.30 0.40 15 30 750 3.3 4.1 15

052LE-S2A 2 1.4 1.6 15 120 0.48 0.54 15 100 0.60 0.70 15 60 1100 4.8 6.0 15

066LE-S2A 2 1.4 1.6 15 120 0.48 0.54 15 100 0.60 0.70 15 60 1540 6.7 8.4 15

099LE-S2A 3 2.1 2.3 15 180 0.72 0.78 15 150 0.90 1.00 15 90 2270 9.9 12.4 15

No. of

FANS

FAN MOTOR(S) -

SHADED POLE(STANDARD)

TOTAL

MOTOR

M.C.A. M.O.P WATTS

FLA

FAN MOTOR(S) PSC (OPTIONAL)

TOTAL

MOTOR

M.C.A. M.O.P WATTS

FLA

FAN MOTOR(S)-

EC (OPTIONAL)

TOTAL

MOTOR

M.C.A. M.O.P WATTS

FLA

DEFROST HEATERS

TOTAL

WATTS

TOTAL

AMPS

M.C.A. M.O.P

Page 6

1-TL AD 03/08

TERMINAL BOARD

PUMP DOWN

WIRED ON EVAPORATOR .

2). USE 75°C WIRE (OR HIGHER)

EVAPORATOR FAN MOTORS AND DEFROST

HEATERS MUST NOT EXCEED MAXIMUM

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

4). MAY BE FACTORY INSTALLED-MOUNTED AND

NOTES

MTR

FAN

MTR

FAN

4

GND.

F

(IF USED)

SWITCH

CONDUCTORS/WIRING

FACTORY WIRING

WIRING BY OTHERS

BY OTHERS

OPTIONAL FACTORY OR

COMPLIANCE WITH ALL APPLICABLE LOCAL

ALL FIELD WIRING MUST BE DONE IN

AND NATIONAL CODES.

TERMINAL BOARD

NOTE #4

SPACE

THERMOSTAT

-COMPONENT TERMINAL

-TERMINAL BLOCK TERMINAL

FAN MOTOR

POWER

PLUGS

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

MTR

FAN

TERMINALS

MTR

FAN

MTR

FAN

SOLENOID VALVE

EVAPORATOR

NOTE #4

SPACE

THERMOSTAT

N.C.

NOTE #4

LIQUID LINE

4

GND.

F

FAN MOTOR

POWER

PLUGS

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

MTR

FAN

EVAPORATOR

N.C.

NOTE #4

LIQUID LINE

SOLENOID VALVE

WITH DEFROST TIME CLOCK

GND

132

4NX

TM

OR EQUIVALENT

DEFROST CLOCK

PARAGON # 8145

EVAPORATORS (IF APPLIC)

NAMEPLATE FOR ELECTRICAL

REFER TO EVAPORATOR

WITHOUT DEFROST TIME CLOCK

GND

IF(N)

TO MULTIPLE EVAPS

F

4

(IF APPLIC)

OMIT 2ND

BREAKER

NOTE #3

FUSE OR

FUSE

CIRCUIT

4

F

BREAKER

NOTE #3

CIRCUIT

FUSE OR

NAMEPLATE FOR ELECTRICAL

REFER TO EVAPORATOR

REQUIREMENTS

L2(N)

L1

REQUIREMENTS

GND

L1

L2(N)

TO MULTIPLE

IF(N)

2ND FUSE

OMIT

(SUPPLIED ON MULTIPLE

FAN MODELS ONLY)

(SUPPLIED ON MULTIPLE

FAN MODELS ONLY)

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 6 -

WIRING DIAGRAM

AIR DEFROST - ALL VOLTAGES

Page 7

FAN

MTR

FAN

MTR

FAN

MTR

DATA PLATE FOR

MOTOR QUANTITY

EVAPORATOR

REFER TO

EVAPORATOR

FAN MOTOR

POWER PLUGS

RD

DEFROST TERMINATION

FD-FAN DELAY

DT-DEFROST TERM

& FAN DELAY

(10.0A MAX.)

CONTROL

FD

BK

FAN MOTOR

POWER PLUGS

REFER TO

DATA PLATE FOR

MOTOR QUANTITY

EVAPORATOR

MTRMTRMTR

FANFAN FAN

(10.0A MAX.)

DT-DEFROST TERM

FD-FAN DELAY

& FAN DELAY

CONTROL

DEFROST TERMINATION

FD

BK

EVAPORATOR

PARAGON # 8145

MUST BE MADE

EVAP FIELD MODIFICATION

WARNING

SEE NOTE:

SPACE

GND.

F

4

DT

BN

C

X

3

N

H1

H3H2

ORANGE JUMPER

THERMOSTAT

NOTE #4

SWITCH

(IF USED)

PUMP DOWN

NOTE #4

SOL VALVE

1

N.C.

LIQUID LINE

BREAKER

(IF USED)

COMPR INTERLOCK

12

N

NAMEPLATE FOR ELECTRICAL

REFER TO EVAPORATOR

GND

REQUIREMENTS

3

4

TM

X

FUSE OR

CIRCUIT

PARAGON # 8145

DEFROST CLOCK

OR EQUIVALENT

15A

N

L1

N.C.

LIQUID LINE

SOL VALVE

NOTE #4

GND.

3

N

X

4

F

DT

BN

RD

C

FROM H2 TO N

REMOVE ORANGE JUMPER

(IF USED)

SWITCH

PUMP DOWN

NOTE #4

H2

H3

H1

SPACE

THERMOSTAT

(IF USED)

COMPR INTERLOCK

OR EQUIVALENT

1

CIRCUIT

4

2

3

X

N

NOTE #3

BREAKER

TM

FUSE OR

DEFROST HEATER

L1

C

T1

CONTACTOR

CIRCUIT

BREAKER

NOTE #3

N

GND

L1

FUSE OR

USING MAXIMUM 15A HEATER OVERCURRENT PROTECTION

FOR ALL MODELS WITHOUT DEFROST HEATER CONTACTOR

FOR ALL MODELS USING DEFROST HEATER CONTACTOR

REFER TO EVAPORATOR

DEFROST CLOCK

REQUIREMENTS

NAMEPLATE FOR ELECTRICAL

FAN MODELS ONLY)

(SUPPLIED ON MULTIPLE

TERMINAL BOARD

BK

BK

DEFROST HEATERS

BOTTOM

BK

BOTTOM

L.H. COIL

BK

R.H. COIL

ORANGE

JUMPER

DEFROST HEATERS

L.H. COIL

BOTTOM

BK

R.H. COIL

BOTTOM

BK

BK

BK

ORANGE

JUMPER

T2

L2

ORANGE JUMPER

1

SEE NOTE:

TERMINAL BOARD

(SUPPLIED ON MULTIPLE

FAN MODELS ONLY)

DEFROST HEATERS MUST NOT EXCEED

4.) MAY BE FACTORY INSTALLED-MOUNTED

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

EVAPORATOR FAN MOTORS AND

AND WIRED ON EVAPORATOR

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

2). USE 75°C WIRE (OR HIGHER)

NOTES

FACTORY WIRING

OPTIONAL FACTORY

WIRING BY OTHERS

OR BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

TERMINALS

-TERMINAL BLOCK TERMINAL

-COMPONENT TERMINAL

CONDUCTORS/WIRING

2-TL ED1 03/08

(IF APPLIC.)

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 7 -

WIRING DIAGRAM

ELECTRIC DEFROST - 115V

Page 8

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 8 -

WIRING DIAGRAM

ELECTRIC DEFROST - 230V

Page 9

BOTTOM VIEW

Connection

CONNECTION END VIEW

TXV

Connection

AIR

OUT

AIR IN

with electric defrost heaters

splice box and defrost control

NOTE: Dimensional views shown

Suction

OUT

AIR

mounted.

7/8 (22 mm) dia.

2 each side

9/16 (14 mm) dia.

2 each side

1/2 (12 mm) dia.

aluminum drain.

2 connection end

7/8 (22 mm) dia.

knockouts

knockouts

knockouts

SIDE VIEW

PIPING CONNECTION

1-3/8"

(35 mm)

3"

(76 mm)

9/16"

(14 mm)

Splice box.

electric defrost models

Defrost control

4 Mounting holes

7/32 (6 mm) dia.

E

D

B

A

C

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 9 -

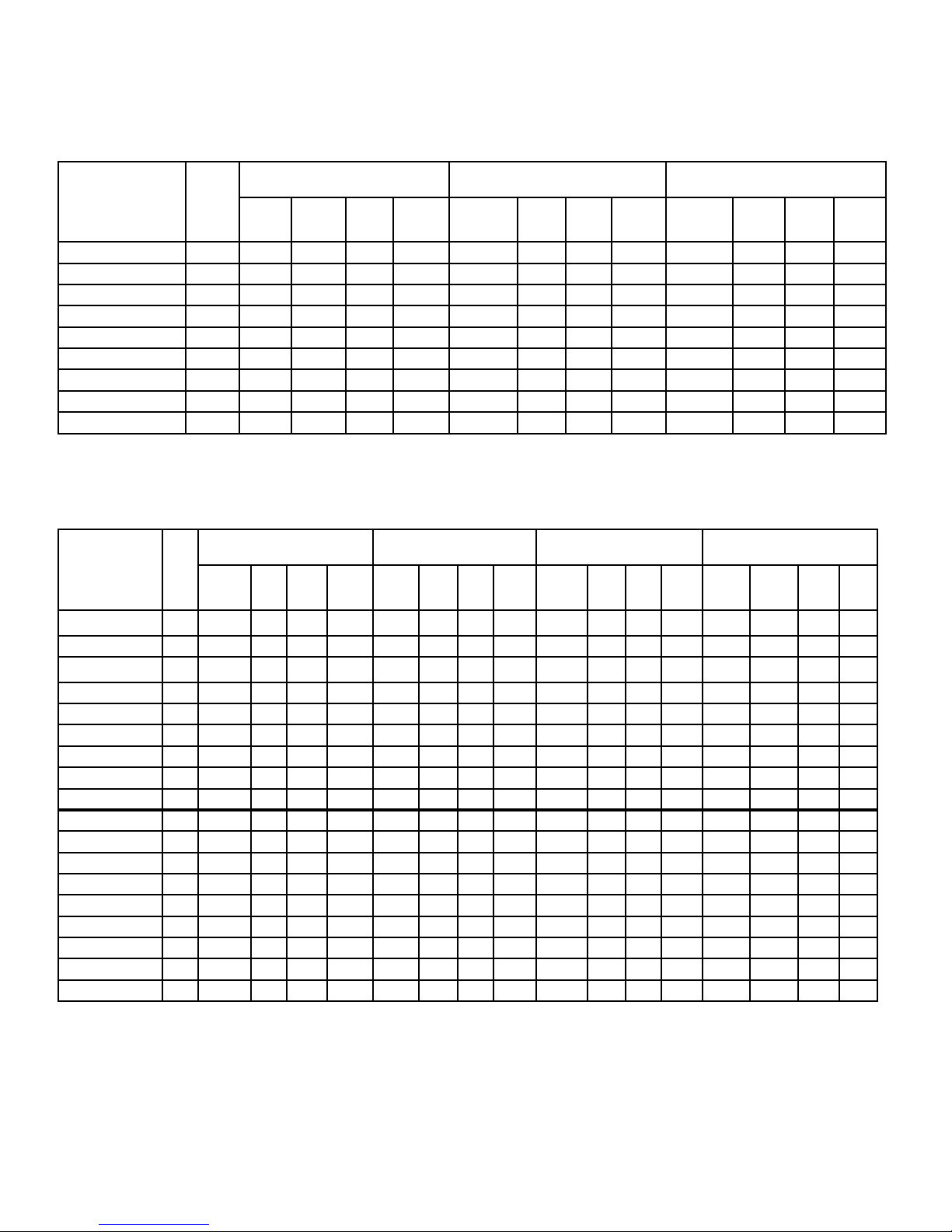

DIMENSIONAL DATA - 1 FAN

Inches (mm)

MODEL

TTL

010M* 3/8 1/2” Flare 18 7/8 479 4 1/2 114 14 1/8 359 17 3/4 451 9 3/4 248 11.6 5.3

015M* 3/8 1/2” Flare 18 7/8 479 4 1/2 114 14 1/8 359 17 3/4 451 9 3/4 248 12.6 5.7

Suc. Conn. TXV A B C D E

(ID) Sweat Inlet Size Inches mm Inches mm Inches mm Inches mm Inches mm Lbs. Kgs

020M* 3/8 1/2” Flare 18 7/8 479 5 1/2 140 14 1/8 359 17 3/4 451 9 3/4 248 13.7 6.2

025M* 3/8 1/2” Flare 18 7/8 479 5 1/2 140 14 1/8 359 17 3/4 451 9 3/4 248 14.7 6.7

032M* 3/8 1/2” ODS 21 7/8 556 5 1/2 140 19 1/8 486 20 3/4 527 14 3/4 375 18.9 8.6

038M* 3/8 1/2” ODS 21 7/8 556 5 1/2 140 19 1/8 486 20 3/4 527 14 3/4 375 20.0 9.1

009LE 3/8 1/2” Flare 18 7/8 479 4 1/2 114 14 1/8 359 17 3/4 451 9 3/4 248 11.6 5.3

013LE 3/8 1/2” Flare 18 7/8 479 4 1/2 114 14 1/8 359 17 3/4 451 9 3/4 248 12.6 5.7

017LE 3/8 1/2” ODS 18 7/8 479 5 1/2 140 14 1/8 359 17 3/4 451 9 3/4 248 13.7 6.2

021LE 3/8 1/2” ODS 18 7/8 479 5 1/2 140 14 1/8 359 17 3/4 451 9 3/4 248 14.7 6.7

028LE 1/2 1/2” ODS 21 7/8 556 5 1/2 140 19 1/8 486 20 3/4 527 14 3/4 375 18.9 8.6

033LE 1/2 1/2” ODS 21 7/8 556 5 1/2 140 19 1/8 486 20 3/4 527 14 3/4 375 20.0 9.1

* - A (AIR DEFROST) OR E (ELECTRIC DEFROST)

APPROX.

WEIGHT

Page 10

compartment

Electrical

OUT

AIR

AIR

PIPING CONNECTION

END VIEW

AIR IN

2 each side

knockouts

7/8 (22 mm) dia

knockouts

9/16 (14 mm) dia

2 each side

2). Electrical connection end is

opposite the piping end on

NOTES: 1). Electric defrost views shown.

Air defrost models have identical

BOTTOM VIEW

AIR

SIDE VIEW

AIR

OUT

1-1/8 (28 mm) dia

knockouts

1 each side

1" FPT. Aluminum

drain fitting.

dimensioning.

multiple fan models.

1 each side

knockouts

7/8 (22 mm) dia

TXV Connection 1/2"(13) ODS.

33

5/16 (9 mm)

Mounting holes.

22-1/4

(565)

ED F

23-5/8

(600)

C

7-5/8

(194)

23-3/4 (603)

23/06/17

T30-TTL-PDI-16

- 10 -

TTL 60Hz

DIMENSIONAL DATA - 2 & 3 FAN

Inches (mm)

3/4” MPT / 3/4 are

drain connection

MODEL

TTL

Suc. Conn. TXV C D E F APPROX. WEIGHT

(ID) Sweat Inlet Size Inches mm Inches mm Inches mm Inches mm Lbs. Kgs

060M 1/2 1/2” ODS 42 3/4 1086 4 holes @ 8” 203 7 11/16 195 10 15/16 278 37.8 17.1

077M 5/8 1/2” ODS 42 3/4 1086 4 holes @ 8” 203 7 11/16 195 10 15/16 278 39.9 18.1

115M 5/8 1/2” ODS 59 1/2 1511 6 holes @ 8” 203 8 203 11 7/16 291 59.9 27.2

052LE 5/8 1/2” ODS 42 3/4 1086 4 holes @ 8” 203 7 11/16 195 10 15/16 278 37.8 17.1

066LE 5/8 1/2” ODS 42 3/4 1086 4 holes @ 8” 203 7 11/16 195 10 15/16 278 39.9 18.1

099LE 7/8 1/2” ODS 59 1/2 1511 6 holes @ 8” 203 8 203 11 7/16 291 59.9 27.2

Page 11

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 11 -

NOZZLE SELECTIONS

(FACTORY INSTALLED)

For all applications and refrigerants

Model TTL Nozzle

010MA/ME NA

015MA/ME NA

020MA/ME NA

025MA/ME NA

032MA/ME L-1/4

038MA/ME L-1/3

060MA/ME L-1/2

077MA/ME L-3/4

115MA/ME L-1

Model TTL Nozzle

009LE NA

013LE NA

017LE L-1/4

021LE L-1/3

028LE L-1/2

033LE L-1/2

052LE L-1

066LE L-1

099LE L-1 1/2

RECOMMENDED EXPANSION VALVE SELECTION

MEDIUM TEMPERATURE MODELS

SPORLAN

MODEL

TTL

010M

015M

020M

025M

032M

038M

060M

077M

115M

For medium temp. R-507, refrigerant designation changes from ‘S’ to ‘P’.

For R449A, use R448A data.

TD

10

15

10

15

10 EGS-1/6-C EGV-1/5-C

15 EGS-1/6-C EGV-1/3-C

10

15 EGV-1/3-C

10

15 SBFVE-AA-C

10 SBFSE-AA-C SBFVE-AAA-C

15 SBFSE-A-C SBFVE-AA-C

10

15

10

15 SBFVE-A-C

10 SBFSE-A-C

15 SBFSE-B-C

R404A

R507

EGS-1/8-C EGV-1/5-C

EGS-1/6-C EGV-1/5-C

EGS-1/6-C

SBFSE-AA-C

SBFSE-A-C SBFVE-AA-C

SBFSE-A-C

R448A

R407A

R407C

EGV-1/5-C

SBFVE-AAA-C

SBFVE-AA-C

SBFVE-A-C

R22

ALCO

ALL TXV Selections based on 90-100°F liquid.

For R449A, use R448A data.

DANFOSS

MODEL

TTL

010M

015M

020M

025M

032M

038M

060M

077M

115M

For R449A, use R448A data.

TD

10 TUA-R404A-0-N

15 TUA-R404A-1-N

10 TUA-R404A-1-N TUA-R22-0-N

15 TUA-R404A-2-N TUA-R22-1-N

10 TUA-R404A-2-N TUA-R22-1-N

15 TUAE-R404A-3-N TUAE-R22-2-N

10 TUA-R404A-2-N TUA-R22-1-N

15 TUAE-R404A-3-N TUAE-R22-2-N

10 TUAE-R404A-3-N TUAE-R22-2-N

15 TUAE-R404A-4-N TUAE-R22-3-N

10 TUAE-R404A-3-N TUAE-R22-3-N

15 TUAE-R404A-4-N TUAE-R22-4-N

10 TUAE-R404A-5-N TUAE-R22-4-N

15 TUAE-R404A-6-N TUAE-R22-5-N

10 TUAE-R404A-5-N TUAE-R22-5-N

15 TUAE-R404A-6-N TUAE-R22-6-N

10 TUAE-R404A-6-N TUAE-R22-6-N

15 TUAE-R404A-8-N TUAE-R22-7-N

R404A

R507

R448A

R407C

TUA-R22-0-N

R407A

R22

MODEL

TTL

010M

015M

020M

025M

032M

038M

060M

077M

115M

TD

10

15

10

15

10 HF-1/8-SC

15 HF-1/4-SC

10

15

10 HFESC-1/4-SC HFESC-1/4-HC

15 HFESC-1/2-SC HFESC-1/2-HC

10 HFESC-1/4-SC

15 HFESC-1/2-SC

10 HFESC-1/2-SC HFESC-1/2-HC

15 HFESC-1-SC HFESC-1-HC

10 HFESC-1/2-SC

15 HFESC-1-SC

10 HFESC-1-SC HFESC-1-HC

15 HFESC-1 1/4-SC HFESC-1 1/2-HC

R404A

R507

HF-1/8-SC HF-1/4-HC

HF-1/8-SC HF-1/4-HC

HF-1/4-SC HF-1/4-HC

R448A

HFESC-1/2-HC

R407A

R407C

HFESC-1-HC

R22

HF-1/4-HC

Page 12

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 12 -

RECOMMENDED EXPANSION VALVE

SELECTION -

MEDIUM TEMPERATURE MODELS

SPORLAN -

MODEL

TTL

0 865 EGV-1/5-C 1,273 EGV-1/5-C 1,729 EGVE-1/5-C 2,138 SBFVE-AAA-C 2,850 SBFVE-AAA-C

EVAP

TEMP.

EVAP

TEMP.

°F

Selections based on 90-100°F liquid.

For R407A valves operating below 0F, the pressure limiting charge ‘ZP40’ may be substituted for the ‘Z’ charge.

R407A derated by .95 factor

For R449A, use R448A data.

-10 836

-15 827 1,216 1,644 2,033 2,717

°F

-20 808 1,188 1,615 1,995 2,660

MODEL

TTL

0 3,354 SBFVE-AAA-C 5,282 SBFVE-AA-C 6,707 SBFVE-AA-C 10,061 SBFVE-A-C

-10 3,259

-20 3,135 4,940 6,270 9,405

SPORLAN -

MODEL

TTL

0 910 EGS-1/8-C 1,340 EGS-1/8-C 1,820 SBFSE-AAA-C 2,250 SBFSE-AAA-C 3,000 SBFSE-AA-C

EVAP

TEMP.

EVAP

TEMP.

°F

-10 880

-15 870 1,280 1,730 2,140 2,860

°F

-20 850 1,250 1,700 2,100 2,800

MODEL

TTL

0 3,530 SBFSE-AA-C 5,560 SBFSE-AA-C 7,060 SBFSE-A-C 10,590 SBFSE-A-C

-10 3,430

-20 3,300 5,200 6,600 9,900

R407A

009L 013L 017L 021L 028L

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

EGV-1/5-Z

033L 052L 066L 099L

BTUH VALVE # BTUH VALVE BTUH VALVE # BTUH VALVE #

SBFVE-AA-Z

R404A

009L 013L 017L 021L 028L

BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE # BTUH VALVE #

EGS-1/8-Z

033L 052L 066L 099L

BTUH VALVE # BTUH VALVE BTUH VALVE # BTUH VALVE #

SBFSE-AA-Z

R448A

1,235

5,140

1,300

5,410

EGV-1/5-Z

SBFVE-AA-Z

EGS-1/8-Z

SBFSE-A-Z

1,682

6,517

1,770

6,860

SBFVE-AAA-Z

SBFVE-AA-Z

SBFSE-AAA-Z

SBFSE-A-Z

2,071

SBFVE-AAA-Z

9,785

2,180

SBFSE-AAA-Z

10,300

2,765

SBFVE-AAA-Z

SBFVE-A-Z-15 3,202 5,035 6,394 9,595

2,910

SBFSE-AA-Z

SBFSE-A-Z-15 3,370 5,300 6,730 10,100

Selections based on 90-100°F liquid.

For medium temp. R-507, refrigerant designation changes from ‘S’ to ‘P’.

For R404A/R507 valves operating below 0F, the pressure limiting charge ‘ZP’ may be substituted for the ‘Z’ charge.

For R449A, use R448A data.

Page 13

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 13 -

INSTALLATION INSTRUCTIONS

INSPECTION

Careful inspection of all parts when received for loss

or damage in transit is very important Remember, you, the consignee, must make any

claim necessary against the transportation company.

Shipping damage or missing parts, when discovered

at the outset, will prevent later unnecessary and

costly delays.

Electrical characteristics should also be checked at

this time to ensure that they are as ordered.

APPLICATION

Two-Way evaporators are designed for use in coolers and freezers such as reach in boxes, display

cases, back bars, walk-in rooms and any other

cooler applications where a low velocity, uniform air

ow is required. The compact and low height unit

provides maximum useable product storage space.

o

At room temperatures above 34°F (1.1

C) and evap-

orating temperatures no lower than 27°F (-2.8°C)

the air owing through the coil will accomplish the

defrost (Air Defrost).

o

At room temperatures 34

F and below (to -10oF)

positive defrosting is required (Electric defrost).

These will require the use of:

1. Time Clock (to initiate and terminate the defrost

cycle),

2. Defrost termination thermostat (to prevent

unnecessary prolonged heating and steaming of the

coil once all the frost and ice has melted). And if a

freezer,

3. Fan delay thermostat (to prevent evaporator fans

starting up right away and blowing water on to the

fan blades, guards and oor).

This evaporator coil must not be exposed to any

abnormal environments (acidic or caustic) that can

result in coil corrosion and leaks. Consult factory

for optional baked on phenolic protective coatings.

These evaporators are for use primarily on R448A/

R407A/R407C/R404A/R507/R22 and R134a refrigerants and their approved alternatives / replace-

ments.

INSTALLATION

The installation and start up of evaporators should

only be performed by qualied refrigeration

mechanics. This equipment should be installed in

accordance with all applicable codes, ordinances,

and local by-laws.

LOCATION

The evaporator is designed to be mounted to the

ceiling of the box or cabinet. Refrigeration piping and

electrical connections are routed to the rear sides

(through the knock-outs). The unit must be mounted

to a level ceiling to ensure complete drainage from

the condensate pan to the drain tting. Refer to the

dimensional drawings for the drain tting and

mounting location details.

On freezer applications it is important that warm, hu-

mid inltrated air is not drawn directly towards the

evaporator. Keeping the evaporator away from the

door, using strip curtains, and using door switches

to lock out and de-energize the liquid solenoid valve

are all eective methods to minimize any unnecessary frost build -up of the fan guard. (Air enters the

fan and discharges out each side of the coil).

TXV SELECTION (thermostatic expansion valve)

For normal operating conditions refer to the TXV

selection chart. When selecting valves ensure they

are sized to meet the capacity at the actual evaporating temperature, liquid temperature and operating

TD of the system . All these conditions can greatly

aect the size and selection. Consult the factory or

valve manufacturer for assistance. All models that

use a distributor (larger models) must use a nozzle.

Smaller models do not have distributors or nozzles.

The TXV superheat setting should NOT be initially

adjusted . After the room has reached or is close to

the required operating temperature the TXV superheat should then be checked and only adjusted if

necessary. Refer to Section on SYSTEM CHECK.

To avoid overheating the valve or distributor

wrap a wet cloth around the valve diaphragm

and body.

MOUNTING

Mounting brackets with 7/32 - 5/16” diameter holes

are provided for ush mounting to the ceiling.

Ensure the evaporator is located correctly with

the air owing in the two desired directions. Avoid

discharging the air directly on to glass doors or door

openings.

After mounting the coil check the slope of the drain

pan with a level. If the ceiling is not level the drain

pan slope may not be correct which can result in

defrosting (ice-up) problems.

Page 14

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 14 -

INSTALLATION INSTRUCTIONS (CONT’D)

DRAIN LINE

The drain line should be run from the drain

connection, sloping at least 4” vertical drop for

every foot of horizontal distance . A trap outside

the room will allow proper draining throughout the

line. Connection should be made to proper drainage

facilities that comply with local codes and regulations.

In freezers, to prevent drain line freeze up problems, the line must be heated and insulated. A heat

input of 20 W per foot in a 0°F room and 30 W

per foot in a -20°F room is usually satisfactory.

Once the line has been completed , double check

the slope in the drain pan to ensure proper drainage

(prevention of ice build-up on pan).

PIPING

Refrigerant line sizes are important and are not

necessarily the same size as the connections at the

condensing unit or evaporator. If in doubt refer to

a recognized source. (Manufacturer’s Engineering

Manual, Ashrae Manuals, etc.)

WIRING

Wire system in accordance with local codes and

regulations. A 36” cord is provided for single fan air

defrost models (AD). Multiple fans have a junction

terminal box for conduit connections.

When fan delay thermostats are installed the fans

may not start up until the coil temperature

reaches approximately 26°F. On initial start up it may

be necessary to bypass (jumper) this control

temporarily until the coil is cold enough.

SYSTEM CHECK

Before Start Up:

1. Ensure wiring is in accordance with codes.

2. Refrigerant lines are properly sized and routed.

3. Thorough leak check, evacuation and dehydration

has been performed.

4. Drain line has been checked for free ow.

After Start Up:

1. Fan has been checked for correct air ow and no

obstructions.

2. Expansion valve superheat has been checked for

proper operation. (Superheat of the coil should be

around 5 to 6°F for a 10°F TD.)

MAINTENANCE

The unit should be periodically inspected for any dirt

or build up on the n surface and cleaned if

necessary with a soft whisk or brush.

The fan motor is permanently lubricated and should

not require service.

PROJECT INFORMATION

System

Model Number Date of Start-Up

Serial Number Service Contractor

Refrigerant Phone

Electrical Supply E-Mail

Page 15

TTL 60Hz

23/06/17

T30-TTL-PDI-16

- 15 -

PRODUCT SUPPORT RESOURCES

web: t-rp.com/ttl

email: evaps@t-rp.com

call: 1-844-893-3222 x520

email: troubleshooting@t-rp.com

call: 1-844-893-3222 x529

web: t-rp.com/parts

email: parts@t-rp.com

call: 1-844-893-3222 x501

web: t-rp.com/warranty

email: warranty@t-rp.com

call: 1-844-893-3222 ext. 501

email: orders@t-rp.com

call: 1-844-893-3222 x501

email: shipping@t-rp.com

call: 1-844-893-3222 x503

Page 16

“AS BUILT” SERVICE PARTS LIST

23/06/17

Service Parts List

Label

To Be Attached

HERE

NATIONAL REFRIGERATION &

AIR CONDITIONING CANADA CORP.

159 Roy Blvd.

Brantford Ontario Canada N3R 7K1

PHONE: (519) 751-0444 800-463-9517

FAX (519) 753-1140 www.t-rp.com

Due to the manufacturer’s policy of continuous product improvement, we reserve the right to make changes without notice.

Loading...

Loading...