Trenton TPLP104MAS1, TPLP209MAS1, TPLP107MAS1, TPLP106MAS1, TPLP211MAS1 Installation Instructions Manual

...Page 1

PRODUCT DATA &

29/11/18

INSTALLATION

Bulletin T30-TPLP-PDI-14

Part #1087152

PRODUCT SUPPORT

web: t-rp.com/tplp

email: evaps@t-rp.com

call: 1-844-893-3222 x520

scan:

TPLP Pre-Assembled

Low Prole

Evaporators

Air & Electric Defrost

Medium T emperature Applications: 35°F

Low T emperature Applications: -10°F

Electrical: 115/1/60, 208-230/1/60, 208-230/3/60, 460/1/60

See Page 16 for details

see page 20 for details

CONTENTS

Page

Nomenclature................................................................................................................. 2

Standard Features (All Models)...................................................................................... 2

Available Congurations................................................................................................. 3

Capacity Data................................................................................................................. 4

Electrical Data................................................................................................................. 5 - 7

Wiring Diagrams - Models with PSC motors .................................................................. 8 - 15

Wiring Diagrams - Models with EC Motors / ............................................ 16 - 19

Wiring Diagrams - Models with ......................................................................... 20 - 25

Shipping Weights............................................................................................................ 26

Dimensional Data............................................................................................................ 27

Expansion Valve Selections - Electro-Mechanical Models............................................. 28 - 29

Expansion Valve Selections - Models with ....................................................... 30

Installation Instructions................................................................................................... 31 -32

Project Information........................................................................................................... 34

Product Support Resources: Service Parts, Troubleshooting, Warranty, etc................... 35

“As Built” Service Parts.................................................................................................... Back

Page 2

NOMENCLATURE

29/11/18

T30-TPLP-PDI-14

- 2 -

T P LP 3 14 L E S2 B R6 - ESPE

T = Trenton

Pre-Assembled

Low Prole Evaporator

Number of Fans

Nominal Capacity:

x 1000 @ 10°F TD, Btu/H, R404A

Application Range:

M = Medium to High Temp 6 FPI (25°F / -4°C) Evap T emp)

L = Low Temp 6 FPI (-20°F / -29°C) Evap Temp)

V = Low Temp 4 FPI (-20°F / -29°C) Evap T emp)

Defrost*:

A = Air E = Electric

STANDARD FEATURES (ALL MODELS)

Designation:

Mechanical:

if blank = PSC Motor

EC2 = SmartSpeed EC Motor

Electronic:

ESPP = ESP+ w/ PSC Motor

ESPE = ESP+ w/ EC Motor

Refrigerant Designation:

R2 = R407A / R407C / R22 / R448A

R6 = R404A

R8 = R407A / R407C / R22 / R448A, R404A

(R8 applies to ESP+ models only)

Generation: B = 2

Voltage:

S1 = 115/1/60 (air defrost models only)

S2 = 208-230/1/60

S4 = 460/1/60 (2 to 6 fan models only)

T3 = 208-230/3/60

nd

• Compatible with Low GWP Refrigerants

• High eciency and high strength fan guard

• Front access

• Internally enhanced tubing

• Convenient mounting brackets

• Ample electrical and header compartments

• Positive slope, hinged drain pan

• Centrally located, universal drain connection

• Large 3/4” ID (3/4” MPT) drain hole

• Schrader valve on suction header, located

outside of cabinet

Page 3

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 3 -

PRE-ASSEMBLED CONFIGURATIONS

(R8) MODELS

Include factory installed:

• ESP+ Adaptive Defrost Control

• ESP+ Remote Display

• EEV Electronic Expansion Valve

• Solenoid Valve

ELECTRO-MECHANICAL

(R2 and R6) MODELS

Include factory installed:

• TX Valve

• Solenoid Valve

• Thermostat

ALL CONFIGURATIONS AVAILABLE WITH:

OR

PSC MOTORS

Page 4

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 4 -

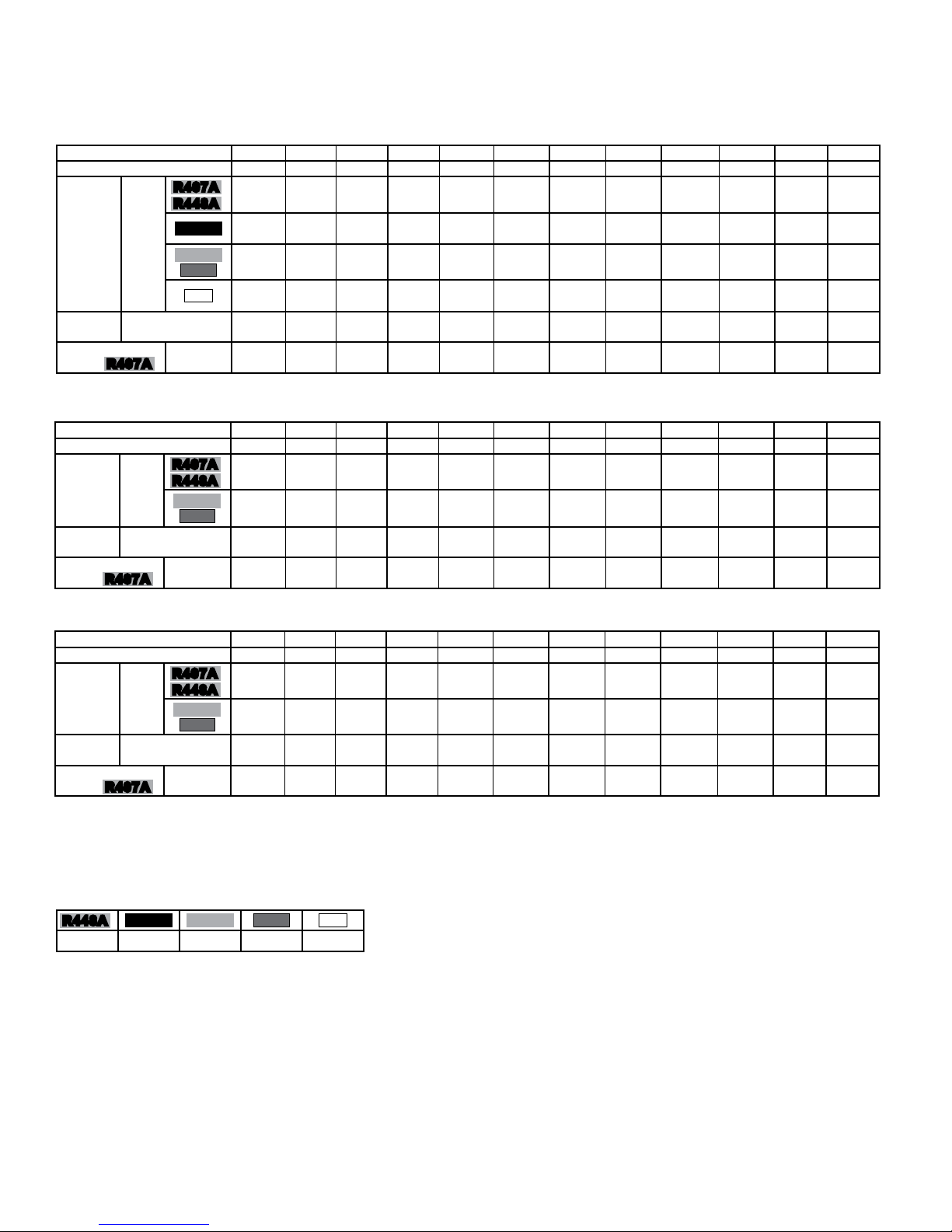

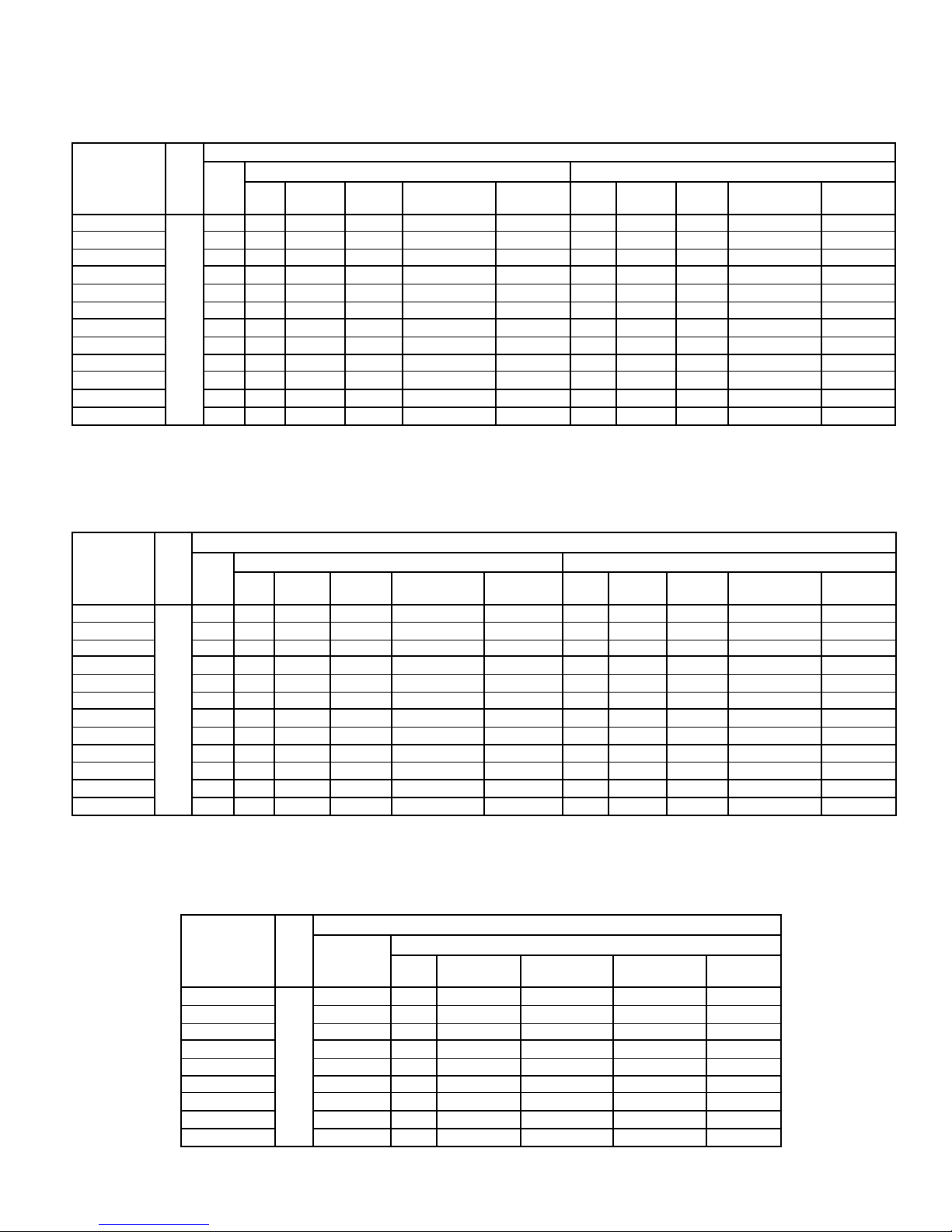

CAPACITY DATA - ALL MODELS

Medium Temperature Models - Capacity @ 6 F.P.I.

Medium Temp. Models TPLP 104M 106M 107M 209M 211M 214M 317M 320M 423M 426M 532M 639M

Number Of Fans 1 1 1 2 2 2 3 3 4 4 5 6

4090 5230 6460 8170 10450 13300 16200 19000 21900 24700 30400 37100

(1197) (1530) (1891) (2394) (3059) (3895) (4731) (5567) (6403) (7230) (8902) (10830)

3870 4950 6120 7740 9900 12600 15400 18100 20800 23500 28900 35200

(1134) (1449) (1791) (2268) (2898) (3690) (4482) (5274) (6066) (6849) (8433) (10260)

4300 5500 6800 8600 11000 14000 17000 20000 23000 26000 32000 39000

(1260) (1610) (1990) (2520) (3220) (4100) (4980) (5860) (6740) (7610) (9370) (11400)

4090 5230 6460 8170 10500 13300 16200 19000 21900 24700 30400 37100

(1197) (1530) (1891) (2394) (3059) (3895) (4731) (5567) (6403) (7230) (8902) (10830)

1010

(477)

0.7

(0.3)

950

(458)

1.1

(0.5)

900

(425)

1.5

(0.7)

2020

(953)

1.3

(0.6)

1910

(901)

1.4

(0.6)

1800

(850)

2.0

(0.9)

2860

(1350)

3.0

(1.4)

2700

(1274)

4.0

(1.8)

3810

(1798)

3.9

(1.8)

3600

(1699)

3.3

(1.5)

4500

(2124)

6.5

(2.9)

5400

(2549)

7.8

(3.5)

Capacity

BTUH

(WATTS)

Air Flow CFM (L/S)

Refrigerant **

Charge

Evap

Temp.

25°F

(-4°C)

R407A

LB. (KG)

R407A

R448A

R407C

R404A

R507

R22

Low Temperature Models - Capacity @ 6 F.P.I.

Low Temp. Models TPLP 104L 105L 106L 207L 209L 211L 314L 317L 419L 422L 527L 631L

Number Of Fans 1 1 1 2 2 2 3 3 4 4 5 6

Capacity

BTUH

(WATTS)

Air Flow CFM (L/S)

Refrigerant **

Charge

Evap

Temp.

-20°F

(-29°C)

R407A

LB. (KG)

R407A

R448A

R404A

R507

3610 4560 5510 7030 8550 10500 13300 16200 18100 20900 25700 29500

(1055) (1340) (1615) (2062) (2508) (3059) (3895) (4731) (5292) (6118) (7515) (8626)

3800 4800 5800 7400 9000 11000 14000 17000 19000 22000 27000 31000

(1110) (1410) (1700) (2170) (2640) (3220) (4100) (4980) (5570) (6440) (7910) (9080)

1010

(477)

0.7

(0.3)

950

(458)

1.1

(0.5)

900

(425)

1.5

(0.7)

2020

(953)

1.3

(0.6)

1910

(901)

1.4

(0.6)

1800

(850)

2.0

(0.9)

2860

(1350)

3.0

(1.4)

2700

(1274)

4.0

(1.8)

3810

(1798)

3.9

(1.8)

3600

(1699)

3.3

(1.5)

4500

(2124)

6.5

(2.9)

5400

(2549)

7.8

(3.5)

Low Temperature Models - Capacity @ 4 F.P.I.

Low Temp. 4 FPI Models TPLP 103V 104V 105V 206V 208V 209V 312V 315V 416V 419V 523V 627V

Number Of Fans 1 1 1 2 2 2 3 3 4 4 5 6

R407A

Capacity

BTUH

(WATTS)

Air Flow CFM (L/S)

Refrigerant **

Charge

Capacities rated using 10°F (5.6°C) TD & 100°F (38°C) liquid temperature.

Capacities at other TD within a range of 8 to 15 °F (4.4 to 8.3°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

Capacities for R448A, R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated suction

temperature and the temperature feeding the evaporator. For dew point ratings, consult factory.

For R449A, use R448A data.

** REFRIGERANT CHARGE CONVERSION FACTORS

R448A

0.96 0.99 0.92 0.93 1.02

Evap

Temp.

-20°F

(-29°C)

R407A

LB. (KG)

R407C R404A

R448A

R404A

R507

2850 3900 4750 6080 7410 8840 11400 14300 15200 18100 21900 25700

(836) (1140) (1397) (1786) (2176) (2584) (3344) (4171) (4456) (5292) (6403) (7515)

3000 4100 5000 6400 7800 9300 12000 15000 16000 19000 23000 27000

(880) (1200) (1470) (1880) (2290) (2720) (3520) (4390) (4690) (5570) (6740) (7910)

1010

(477)

0.7

(0.3)

R507

950

(458)

1.1

(0.5)

R22

900

(425)

1.5

(0.7)

2020

(953)

1.3

(0.6)

1910

(901)

1.4

(0.6)

1800

(850)

2.0

(0.9)

2860

(1350)

3.0

(1.4)

2700

(1274)

4.0

(1.8)

3810

(1798)

3.9

(1.8)

3600

(1699)

3.3

(1.5)

4500

(2124)

6.5

(2.9)

5400

(2549)

7.8

(3.5)

Page 5

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 5 -

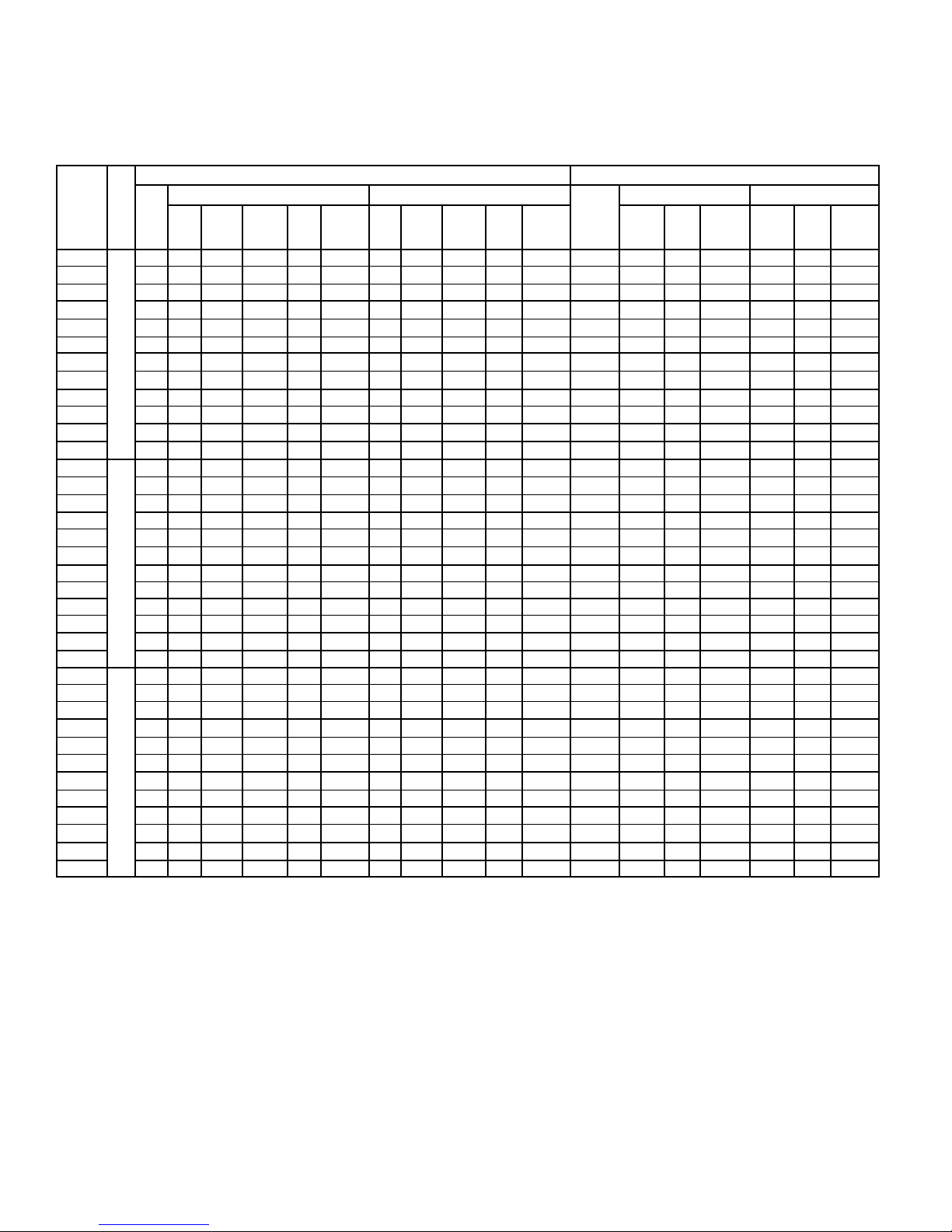

ELECTRICAL DATA

115/1/60 - AIR DEFROST MODELS

MODEL

TPLP

104MAS1

106MAS1 1 1/15 1.0 100 1.3 15 1/15 1.0 60 1.3 15

107MAS1 1 1/15 1.0 100 1.3 15 1/15 1.0 60 1.3 15

209MAS1 2 1/15 2.0 200 2.3 15 1/15 2.0 120 2.3 15

211MAS1 2 1/15 2.0 200 2.3 15 1/15 2.0 120 2.3 15

214MAS1 2 1/15 2.0 200 2.3 15 1/15 2.0 120 2.3 15

317MAS1 3 1/15 3.0 300 3.3 15 1/15 3.0 180 3.3 15

320MAS1 3 1/15 3.0 300 3.3 15 1/15 3.0 180 3.3 15

423MAS1 4 1/15 4.0 400 4.3 15 1/15 4.0 240 4.3 15

426MAS1 4 1/15 4.0 400 4.3 15 1/15 4.0 240 4.3 15

532MAS1 5 1/15 5.0 500 5.3 15 1/15 5.0 300 5.3 15

639MAS1 6 1/15 6.0 600 6.3 15 1/15 6.0 360 6.3 15

FPI

QTY.

1 1/15 1.0 100 1.3 15 1/15 1.0 60 1.3 15

6

HP

FLA

TOTAL

PSC MOTORS EC MOTORS

WATTS

MIN. CIRC.

AMPACITY (A)

FAN MOTORS

MAX. FUSE

(AMPS)

HP

FLA

TOTAL

WATTS

MIN. CIRC.

AMPACITY (A)

MAX. FUSE

(AMPS)

ELECTRICAL DATA

208-230/1/60 - AIR DEFROST MODELS

MODEL

TPLP

104MAS2

106MAS2 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.8 15

107MAS2 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.8 15

209MAS2 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15

211MAS2 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15

214MAS2 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15

317MAS2 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15

320MAS2 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15

423MAS2 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15

426MAS2 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15

532MAS2 5 1/15 2.5 500 2.6 15 1/15 3.0 300 3.2 15

639MAS2 6 1/15 3.0 600 3.1 15 1/15 3.6 360 3.8 15

FPI

QTY.

1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.8 15

6

HP

FLA

TOTAL

PSC MOTORS EC MOTORS

WATTS

MIN. CIRC.

AMPACITY (A)

FAN MOTORS

MAX. FUSE

(AMPS)

HP

FLA

TOTAL

WATTS

MIN. CIRC.

AMPACITY (A)

MAX. FUSE

(AMPS)

460/1/60 - AIR DEFROST MODELS

MODEL

TPLP

209MAS4

211MAS4 2 1/15 0.8 200 0.9 15

214MAS4 2 1/15 0.8 200 0.9 15

317MAS4 3 1/15 1.2 300 1.3 15

320MAS4 3 1/15 1.2 300 1.3 15

423MAS4 4 1/15 1.6 400 1.7 15

426MAS4 4 1/15 1.6 400 1.7 15

532MAS4 5 1/15 2.0 500 2.1 15

639MAS4 6 1/15 2.4 600 2.5 15

FPI

6

ELECTRICAL DATA

FAN MOTORS

PSC MOTORS

QUANTITY

2 1/15 0.8 200 0.9 15

HP

FLA

TOTAL

WATTS

MIN. CIRC.

AMPACITY (A)

MAX. FUSE

(AMPS)

Page 6

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 6 -

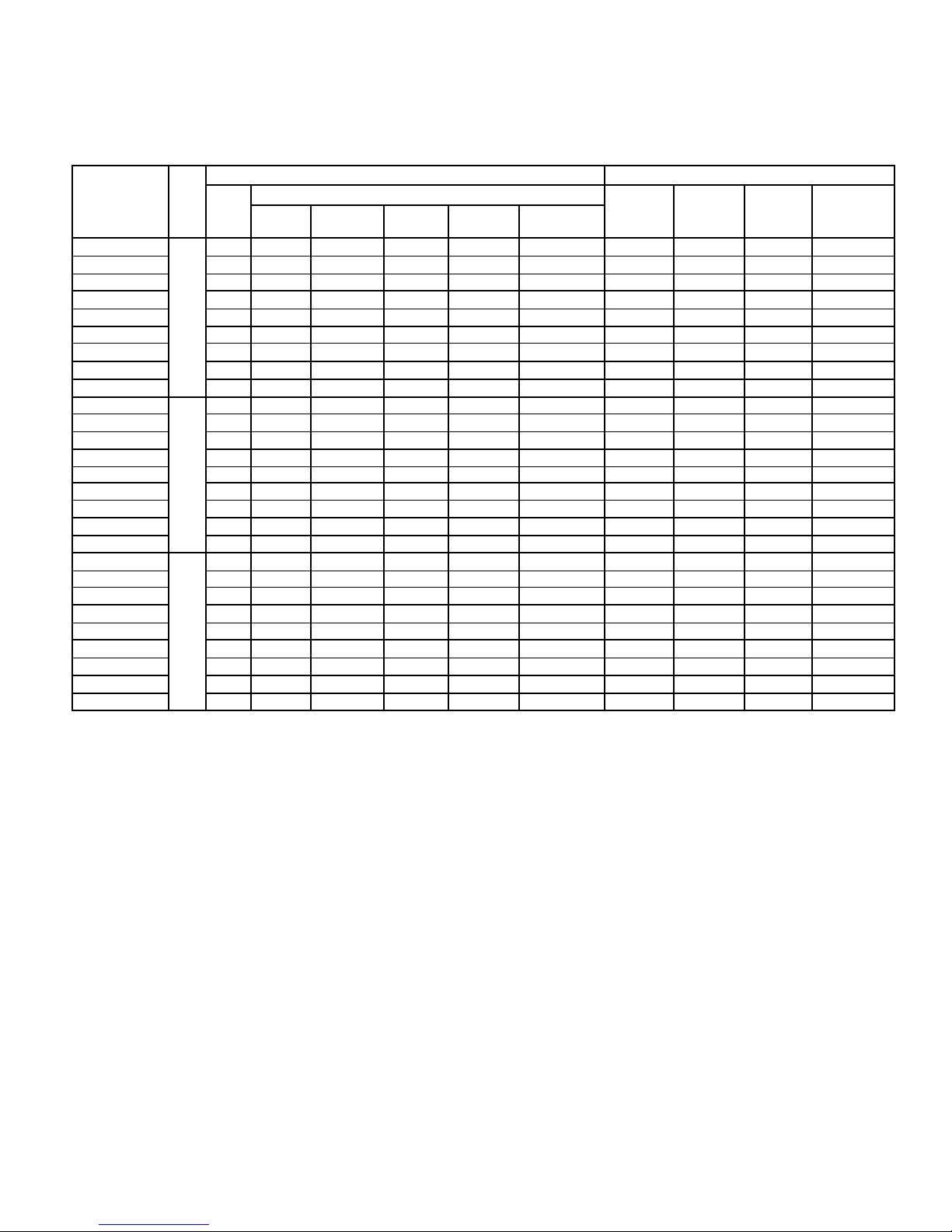

ELECTRICAL DATA -

208-230/1/60 & 208-230/3/60

ELECTRIC DEFROST MODELS

FAN MOTORS DEFROST HEATERS

MODEL

TPLP

104ME*

106ME* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.8 15 1060 4.6 5.8 15 3.0 3.8 15

107ME* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.8 15 1060 4.6 5.8 15 3.0 3.8 15

209ME* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

211ME* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

214ME* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

317ME* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

320ME* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

423ME* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

426ME* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

532ME* 5 1/15 2.5 500 2.6 15 1/15 3.0 300 3.2 15 4400 19.1 23.9 25 12 15.1 20

639ME* 6 1/15 3.0 600 3.1 15 1/15 3.6 360 3.8 15 5230 22.7 28.4 30 15 18 20

104LE*

105LE* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

106LE* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

207LE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

209LE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

211LE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

314LE* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15

317LE* 3 1/15 1.5 300 1.6

419LE* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

422LE* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

527LE* 5 1/15 2.5 500 2.6 15 1/15 3.0 300 3.2 15 4400 19.1 23.9 25 12 15.1 20

631LE* 6 1/15 3.0 600 3.1 15 1/15 3.6 360 3.8 15 5230 22.7 28.4 30 15 18 20

103VE*

104VE* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

105VE* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

206VE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

208VE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

209VE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

312VE* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

315VE* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

416VE* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

419VE* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

523VE* 5 1/15 2.5 500 2.6 15 1/15 3.0 300 3.2 15 4400 19.1 23.9 25 12 15.1 20

627VE* 6 1/15 3.0 600 3.1 15 1/15 3.6 360 3.8 15 5230 22.7 28.4 30 15 18 20

* = S2 or T3. Refer to Nomenclature for details

FPI

QTY.

HP

1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.8 15 1060 4.6 5.8 15 3.0 3.8 15

6

1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

6

1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

4

PSC MOTORS EC MOTORS

FLA

TOTAL

WATTS

MCA

(A)

MAX.

FUSE

(AMPS)

15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

HP

FLA

TOTAL

WATTS

MCA

(A)

MAX.

FUSE

(AMPS)

TOTAL

WATTS

2730 11.9 14.8 15 7.7 10 15

208-230/1/60 208-230/3/60

MCA

(A)

MAX.

FUSE

(AMPS)

TOTAL

AMPS

TOTAL

AMPS

MCA

(A)

(AMPS)

MAX.

FUSE

Page 7

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 7 -

ELECTRICAL DATA - 460/1/60

ELECTRIC DEFROST MODELS

MODEL

TPLP

209MES4

211MES4 2 1/15 0.8 200 0.9 15 1890 4.1 5.1 15

214MES4 2 1/15 0.8 200 0.9 15

317MES4 3 1/15 1.2 300 1.3 15

320MES4 3 1/15 1.2 300 1.3 15

423MES4 4 1/15 1.6 400 1.7 15

426MES4 4 1/15 1.6 400 1.7 15

532MES4 5 1/15 2.0 500 2.1 15 4400 9.6 12.0 15

639MES4 6 1/15 2.4 600 2.5 15 5230 11.4 14.2 15

207LES4

209LES4 2 1/15 0.8 200 0.9 15 1890 4.1 5.1 15

211LES4 2 1/15 0.8 200 0.9 15

314LES4 3 1/15 1.2 300 1.3 15

317LES4 3 1/15 1.2 300 1.3 15

419LES4 4 1/15 1.6 400 1.7 15

422LES4 4 1/15 1.6 400 1.7 15

527LES4 5 1/15 2.0 500 2.1 15 4400 9.6 12.0 15

631LES4 6 1/15 2.4 600 2.5 15 5230 11.4 14.2 15

206VES4

208VES4 2 1/15 0.8 200 0.9 15 1890 4.1 5.1 15

209VES4 2 1/15 0.8 200 0.9 15

312VES4 3 1/15 1.2 300 1.3 15

315VES4 3 1/15 1.2 300 1.3 15

416VES4 4 1/15 1.6 400 1.7 15

419VES4 4 1/15 1.6 400 1.7 15

523VES4 5 1/15 2.0 500 2.1 15 4400 9.6 12.0 15

627VES4 6 1/15 2.4 600 2.5 15 5230 11.4 14.2 15

FPI

6

6

4

QTY.

HP

2 1/15 0.8 200 0.9 15

2 1/15 0.8 200 0.9 15

2 1/15 0.8 200 0.9 15

FAN MOTORS DEFROST HEATERS

FLA

TOTAL

PSC MOTORS

WATTS

MCA

(A)

MAX. FUSE

(AMPS)

TOTAL

WATTS

1890 4.1 5.1 15

1890 4.1 5.1 15

2730 5.9 7.4 15

2730 5.9 7.4 15

3560 7.7 9.7 15

3560 7.7 9.7 15

1890 4.1 5.1 15

1890 4.1 5.1 15

2730 5.9 7.4 15

2730 5.9 7.4 15

3560 7.7 9.7 15

3560 7.7 9.7 15

1890 4.1 5.1 15

1890 4.1 5.1 15

2730 5.9 7.4 15

2730 5.9 7.4 15

3560 7.7 9.7 15

3560 7.7 9.7 15

TOTAL

AMPS

MCA

(A)

MAX. FUSE

(AMPS)

Page 8

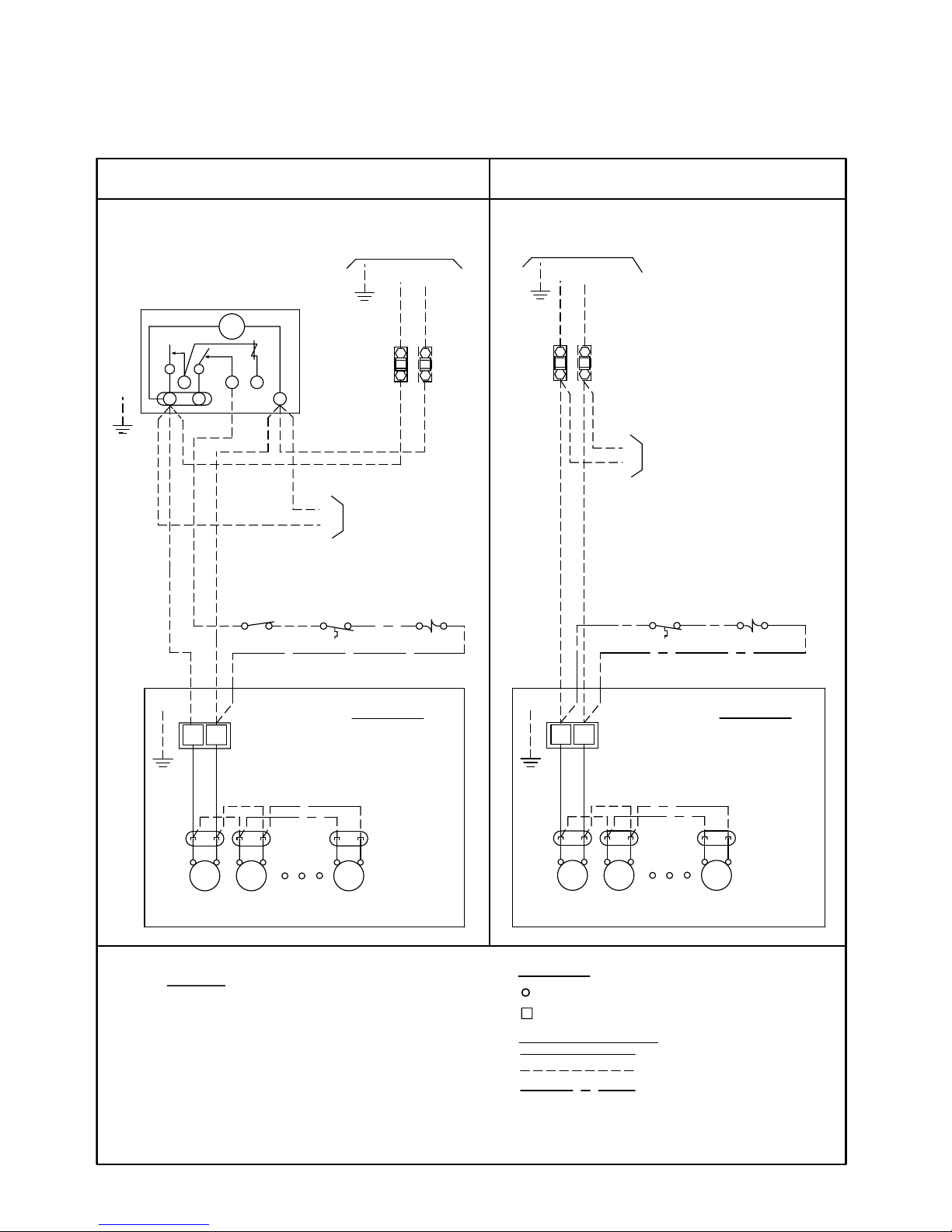

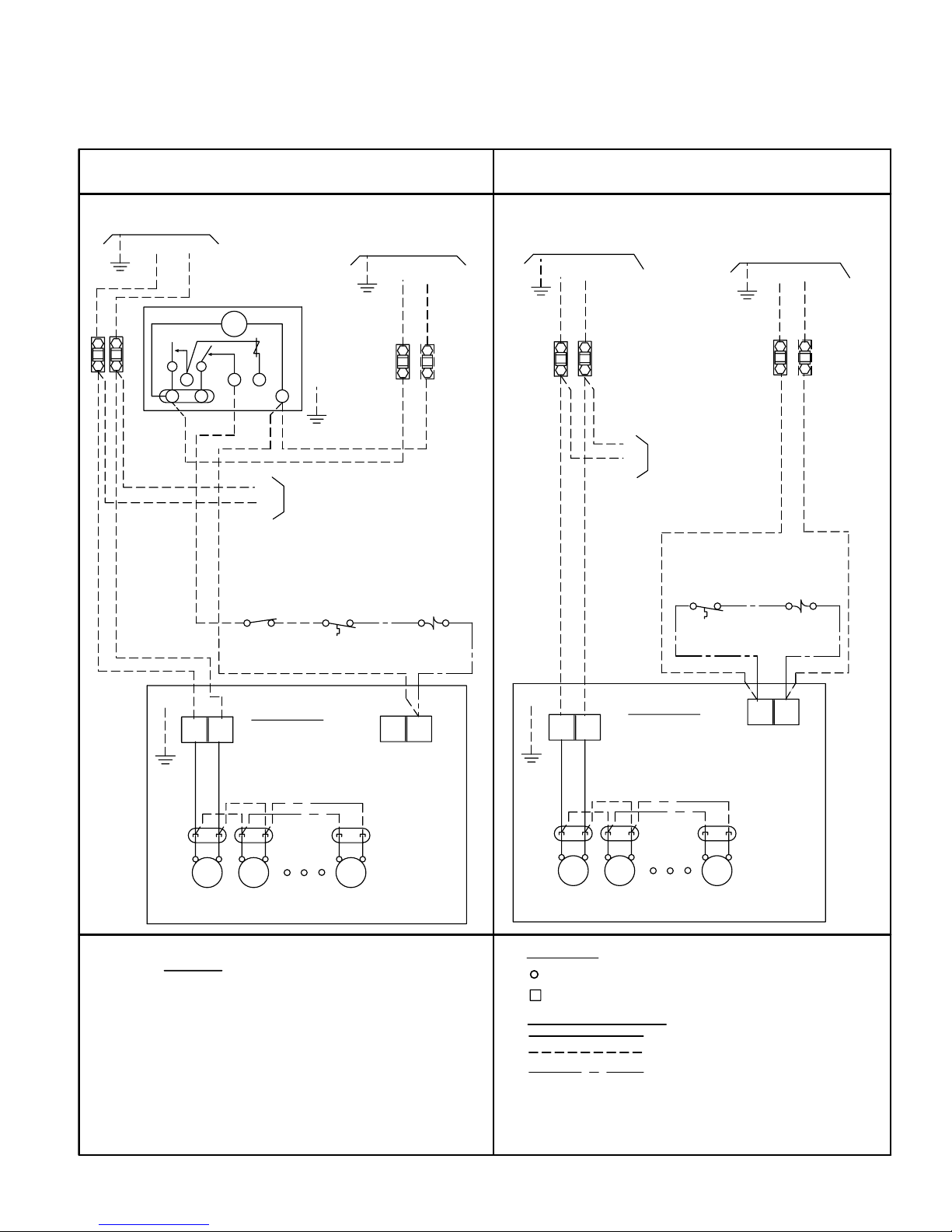

CONDUCTORS/WIRING

AND NATIONAL CODES.

-TERMINAL BLOCK TERMINAL

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

-COMPONENT TERMINAL

4). MAY BE FACTORY INSTALLED-MOUNTED AND

3). OVERCURRENT PROTECTION FOR

1). USE COPPER CONDUCTORS ONLY

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

HEATERS MUST NOT EXCEED MAXIMUM

EVAPORATOR FAN MOTORS AND DEFROST

2). USE 75°C WIRE (OR HIGHER)

WIRED ON EVAPORATOR .

NOTES

TERMINALS

OPTIONAL FACTORY OR

1-LP AIR 09/06

BY OTHERS

WIRING BY OTHERS

FACTORY WIRING

WITHOUT DEFROST TIME CLOCK

REQUIREMENTS

REFER TO EVAPORATOR

NAMEPLATE FOR ELECTRICAL

L1

PARAGON # 8145

DEFROST CLOCK

OR EQUIVALENT

THERMOSTAT

CIRCUIT

FUSE OR

NOTE #3

BREAKER

SWITCH

PUMP DOWN

(IF USED)

NOTE #4

SPACE

LIQUID LINE

SOLENOID VALVE

NOTE #4

N.C.

WITH DEFROST TIME CLOCK

GND

L1

GND

SOLENOID VALVE

THERMOSTAT

BREAKER

NOTE #3

FUSE OR

CIRCUIT

SPACE

NOTE #4

IF(N)

2ND FUSE

OMIT

LIQUID LINE

NOTE #4

N.C.

L2(N)

1

TM

3

2

4X

N

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

GND.

FAN

MTR

FAN

MTR

FAN

MTR

EVAPORATOR

TERMINAL BOARD

F

4

FAN MOTOR

POWER

PLUGS

FAN

MTR

FAN

MTR

FAN

MTR

F

GND.

4

TERMINAL BOARD

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

FAN MOTOR

POWER

PLUGS

EVAPORATOR

IF(N)

OMIT 2ND

L2(N)

4

F

TO MULTIPLE EVAPS

(IF APPLIC)

4

F

EVAPORATORS (IF APPLIC)

TO MULTIPLE

FUSE

GND

REQUIREMENTS

REFER TO EVAPORATOR

NAMEPLATE FOR ELECTRICAL

TPLP

29/11/18

T30-TPLP-PDI-14

- 8 -

WIRING DIAGRAM - 115/1/60, 208-230/1/60

STANDARD PSC MOTORS

AIR DEFROST MODELS

PSC

60Hz

Page 9

CONDUCTORS/WIRING

AND NATIONAL CODES.

-TERMINAL BLOCK TERMINAL

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

-COMPONENT TERMINAL

4). MAY BE FACTORY INSTALLED-MOUNTED AND

3). OVERCURRENT PROTECTION FOR

1). USE COPPER CONDUCTORS ONLY

VALUE SHOWN ON EVAPORATOR NAMEPLATE.

HEATERS MUST NOT EXCEED MAXIMUM

EVAPORATOR FAN MOTORS AND DEFROST

2). USE 75°C WIRE (OR HIGHER)

WIRED ON EVAPORATOR .

NOTES

TERMINALS

OPTIONAL FACTORY OR

6-LP 460 AIR 09/06

BY OTHERS

WIRING BY OTHERS

FACTORY WIRING

WITHOUT DEFROST TIME CLOCK

L1

PARAGON # 8145

DEFROST CLOCK

OR EQUIVALENT

THERMOSTAT

CIRCUIT

FUSE OR

NOTE #3

BREAKER

SWITCH

PUMP DOWN

(IF USED)

NOTE #4

SPACE

LIQUID LINE

SOLENOID VALVE

NOTE #4

N.C.

WITH DEFROST TIME CLOCK

380/400-1-50Hz

CONTROL VOLTAGE

GND

L1

GND

IF(N)

2ND FUSE

OMIT

L2

1

TM

3

2

4X

N

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

GND.

FAN

MTR

FAN

MTR

FAN

MTR

EVAPORATOR

FAN MOTOR

POWER

PLUGS

FAN

MTR

FAN

MTR

FAN

MTR

M2

GND.

M1

TERMINAL BOARD

REFER TO

EVAPORATOR

DATA PLATE

FOR MOTOR

QUANTITY

FAN MOTOR

POWER

PLUGS

EVAPORATOR

IF(N)

OMIT 2ND

L2

TO MULTIPLE

EVAPORATORS (IF APPLIC)

M1

M2

EVAPORATORS (IF APPLIC)

TO MULTIPLE

FUSE

GND

4

N

GND

L2(N)

L1

460-1-60 Hz

M2

M1

TERMINAL BOARD

N

4

THERMOSTAT

NOTE #4

N.C.

SOLENOID VALVE

SPACE

LIQUID LINE

NOTE #4

GND

L1

L2(N)

460-1-60 Hz

380/400-1-50Hz

CONTROL VOLTAGE

M1

M2

NOTE #3

CIRCUIT

BREAKER

FUSE OR

TPLP

29/11/18

T30-TPLP-PDI-14

- 9 -

WIRING DIAGRAM - 460/1/60

STANDARD PSC MOTORS

AIR DEFROST MODELS

PSC

60Hz

Page 10

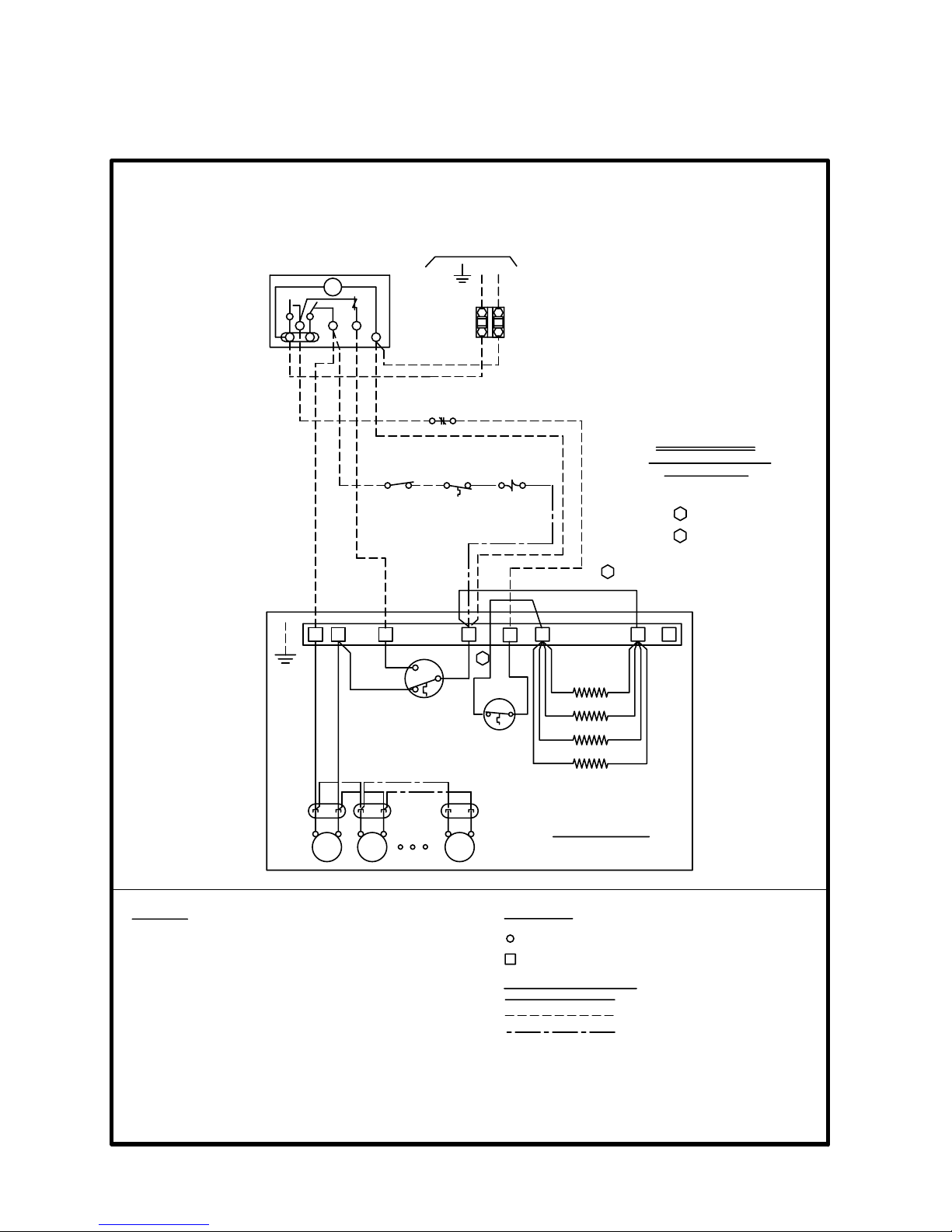

WARNING

EVAP FIELD MODIFICATION

MUST BE MADE

REFER TO EVAPORATOR

COMPR INTERLOCK

FOR ALL MODELS WITHOUT DEFROST HEATER CONTACTOR

THERMOSTAT

NOTE #4

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

NOTES

2). USE 75°C WIRE (OR HIGHER)

FAN

MTR

DEFROST TERMINATION

CONTROL

(10.0A MAX.)

& FAN DELAY

FD-FAN DELAY

DT-DEFROST TERM

X

F

4

BK

GND.

C

FD

DT

BN

RD

(IF USED)

SWITCH

OR EQUIVALENT

PUMP DOWN

SPACE

(IF USED)

21

N

TM

4X

3

DEFROST CLOCK

PARAGON # 8145

EVAPORATOR

OPTIONAL FACTORY

FACTORY WIRING

WIRING BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

2-LP ED 12/07

-TERMINAL BLOCK TERMINAL

-COMPONENT TERMINAL

CONDUCTORS/WIRING

TERMINALS

DATA PLATE FOR

MOTOR QUANTITY

EVAPORATOR

REFER TO

POWER PLUGS

FAN MOTOR

H2

H1

NOTE #4

SOL VALVE

L2L1

N.C.

LIQUID LINE

GND

NAMEPLATE FOR ELECTRICAL

REQUIREMENTS

OR BY OTHERS

AND WIRED ON EVAPORATOR

4.) MAY BE FACTORY INSTALLED-MOUNTED

DEFROST HEATERS

CIRCUIT

BREAKER

FUSE OR

USING MAXIMUM 15A HEATER OVERCURRENT PROTECTION

15A

N

1

FAN

MTR

2

FAN

MTR

6

H3

3

WH

YL

ORANGE JUMPER

SWITCH

LIMIT

HEATER

(10.0A MAX.)

1

2

FROM H2 TO N

INSTALL ORANGE JUMPER

(SUPPLIED LOOSE)

N TO H1 AS SHOWN

RELOCATE WHITE WIRE FROM

2

1

SEE NOTE:

TPLP

29/11/18

T30-TPLP-PDI-14

- 10 -

WIRING DIAGRAM - 208-230/1/60

PSC

60Hz

STANDARD PSC MOTORS

ELECTRIC DEFROST MODELS - SINGLE EVAPORATOR 10A MAX.

Page 11

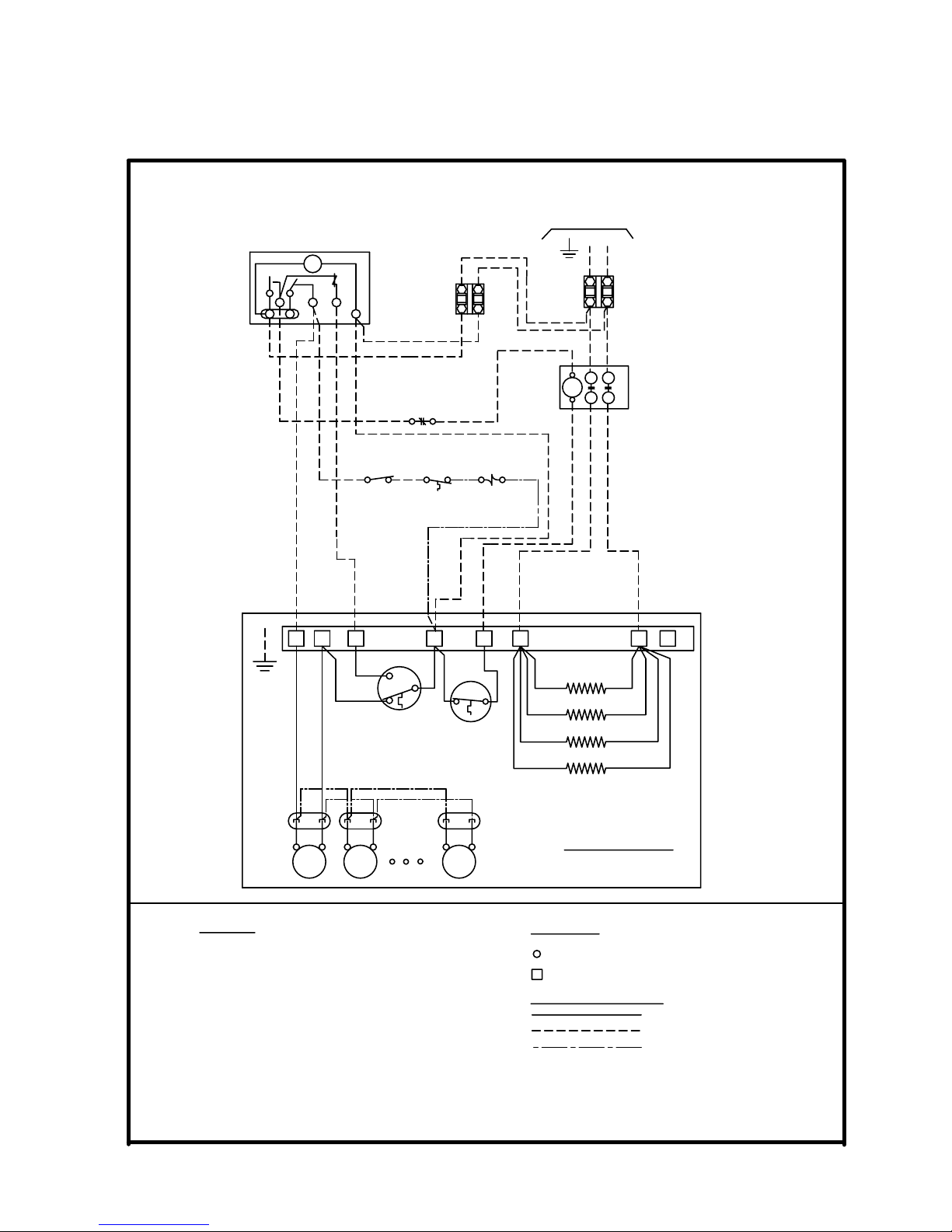

COMPR INTERLOCK

FOR ALL MODELS USING DEFROST HEATER CONTACTOR

THERMOSTAT

NOTE #4

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

NOTES

2). USE 75°C WIRE (OR HIGHER)

(IF USED)

SWITCH

OR EQUIVALENT

PUMP DOWN

SPACE

(IF USED)

21

N

TM

4X

3

DEFROST CLOCK

PARAGON # 8145

OPTIONAL FACTORY

FACTORY WIRING

WIRING BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

3-LP ED CONTACTOR SINGLE 12/07

-TERMINAL BLOCK TERMINAL

-COMPONENT TERMINAL

CONDUCTORS/WIRING

TERMINALS

NOTE #4

SOL VALVE

N.C.

LIQUID LINE

OR BY OTHERS

AND WIRED ON EVAPORATOR

4.) MAY BE FACTORY INSTALLED-MOUNTED

CIRCUIT

BREAKER

NOTE #3

FUSE OR

CONTACTOR

DEFROST HEATER

T2

T1

C

L2

L1

NOTE #3

BREAKER

FUSE OR

CIRCUIT

GND

L2L1

YL

(10.0A MAX.)

REFER TO

POWER PLUGS

MOTOR QUANTITY

DATA PLATE FOR

EVAPORATOR

FAN MOTOR

N

3

X

F

4

621

DEFROST TERMINATION

FD-FAN DELAY

DT-DEFROST TERM

FAN

MTR

GND.

BK

FAN

MTRMTR

FAN

RD

C

(10.0A MAX.)

CONTROL

& FAN DELAY

FD

DT

BN

LIMIT

SWITCH

HEATER

WH

H3

H2

H1

EVAPORATOR

DEFROST HEATERS

REFER TO EVAPORATOR NAMEPLATE

FOR ELECTRICAL REQUIREMENTS

TPLP

29/11/18

T30-TPLP-PDI-14

- 11 -

WIRING DIAGRAM - 208-230/1/60

STANDARD PSC MOTORS

ELECTRIC DEFROST MODELS - SINGLE EVAPORATOR

PSC

60Hz

Page 12

COMPR INTERLOCK

FOR ALL MODELS USING 3 PHASE DEFROST HEATER CONTACTOR

THERMOSTAT

NOTE #4

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

NOTES

2). USE 75°C WIRE (OR HIGHER)

(IF USED)

SWITCH

OR EQUIVALENT

PUMP DOWN

SPACE

(IF USED)

21

N

TM

4X

3

DEFROST CLOCK

PARAGON # 8145

OPTIONAL FACTORY

FACTORY WIRING

WIRING BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

3A-LP ED 3ph.CONTACTOR SINGLE 12/07

-TERMINAL BLOCK TERMINAL

-COMPONENT TERMINAL

CONDUCTORS/WIRING

TERMINALS

NOTE #4

SOL VALVE

N.C.

LIQUID LINE

OR BY OTHERS

AND WIRED ON EVAPORATOR

4.) MAY BE FACTORY INSTALLED-MOUNTED

CIRCUIT

BREAKER

NOTE #3

FUSE OR

CONTACTOR

DEFROST HEATER

T2

T1

C

L2

L1

NOTE #3

BREAKER

FUSE OR

CIRCUIT

GND

L2L1

L3

T3

L3

DEFROST HEATERS

H1

H2 H3

DATA PLATE FOR

MOTOR QUANTITY

12 6

3

N

F

4

X

DT

CONTROL

(10.0A MAX.)

FD

& FAN DELAY

DT-DEFROST TERM

DEFROST TERMINATION

FD-FAN DELAY

MTR

FAN

MTR

FAN

GND.

BK

BN

SWITCH

(10.0A MAX.)

MTR

FAN

FAN MOTOR

REFER TO

EVAPORATOR

POWER PLUGS

HEATER

LIMIT

RD

WH

C

YL

EVAPORATOR

REFER TO EVAPORATOR NAMEPLATE

FOR ELECTRICAL REQUIREMENTS

TPLP

29/11/18

T30-TPLP-PDI-14

- 12 -

WIRING DIAGRAM - 208-230/3/60

STANDARD PSC MOTORS

ELECTRIC DEFROST MODELS - SINGLE EVAPORATOR

PSC

60Hz

Page 13

REFER TO EVAPORATOR NAMEPLATE

FOR ELECTRICAL REQUIREMENTS

COMPR INTERLOCK

FOR ALL 460V MODELS USING DEFROST HEATER AND FAN CONTACTORS

THERMOSTAT

NOTE #4

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

NOTES

2). USE 75°C WIRE (OR HIGHER)

MTR

FANFAN

MTR

FAN

MTR

M2

M1

GND.

(IF USED)

SWITCH

OR EQUIVALENT

PUMP DOWN

SPACE

(IF USED)

BREAKER

21

N

NOTE #3

TM

4X

3

CIRCUIT

FUSE OR

DEFROST CLOCK

PARAGON # 8145

EVAPORATOR

OPTIONAL FACTORY

FACTORY WIRING

WIRING BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

7-LP ED CONTACTOR SINGLE 12/07

-TERMINAL BLOCK TERMINAL

-COMPONENT TERMINAL

CONDUCTORS/WIRING

TERMINALS

DATA PLATE FOR

MOTOR QUANTITY

EVAPORTOR

REFER TO

POWER PLUGS

FAN MOTOR

NOTE #4

SOL VALVE

L2L1

N.C.

LIQUID LINE

L2

T2

L1

C

T1

GND

OR BY OTHERS

AND WIRED ON EVAPORATOR

4.) MAY BE FACTORY INSTALLED-MOUNTED

CIRCUIT

BREAKER

NOTE #3

FUSE OR

GND

L2(N)

L1

CONTACTOR

DEFROST HEATER

EVAP FAN

C

CONTACTOR

T2

T1

L2

L1

COIL DEFROST HEATERS

H1 H2

DEFROST TERMINATION

CONTROL

& FAN DELAY

(10.0A MAX.)

FD-FAN DELAY

DT-DEFROST TERM

BK

FD

BN

DT

C

RD

3

X

N

4

F

YL

(10.0A MAX.)

LIMIT

SWITCH

HEATER

WH

TPLP

29/11/18

T30-TPLP-PDI-14

- 13 -

WIRING DIAGRAM - 460/1/60

STANDARD PSC MOTORS

ELECTRIC DEFROST MODELS - SINGLE EVAPORATOR

PSC

60Hz

Page 14

MUST BE MADE

EVAP#2 FIELD MODIFICATION

WARNING

COMPR INTERLOCK

FOR ALL MODELS USING DEFROST HEATER CONTACTOR

THERMOSTAT

NOTE #4

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

NOTES

2). USE 75°C WIRE (OR HIGHER)

MTR

FANFAN

MTR

FAN

MTR

DEFROST TERMINATION

CONTROL

(10.0A MAX.)

& FAN DELAY

FD-FAN DELAY

DT-DEFROST TERM

X

F

4

BK

GND.

C

FD

DT

BN

RD

(IF USED)

SWITCH

OR EQUIVALENT

PUMP DOWN

SPACE

(IF USED)

BREAKER

21

N

NOTE #3

TM

4X

3

CIRCUIT

FUSE OR

DEFROST CLOCK

PARAGON # 8145

EVAPORATOR

OPTIONAL FACTORY

FACTORY WIRING

WIRING BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

4-LP ED CONTACTOR MULTI 12/07

-TERMINAL BLOCK TERMINAL

-COMPONENT TERMINAL

CONDUCTORS/WIRING

TERMINALS

DATA PLATE FOR

MOTOR QUANTITY

EVAPORATOR

REFER TO

POWER PLUGS

FAN MOTOR

H2

NOTE #4

SOL VALVE

L2

L1

N.C.

LIQUID LINE

L2

T2

L1

C

T1

GND

OR BY OTHERS

AND WIRED ON EVAPORATOR

4.) MAY BE FACTORY INSTALLED-MOUNTED

DEFROST HEATERS

CIRCUIT

BREAKER

NOTE #3

FUSE OR

DEFROST HEATER

CONTACTOR

EVAPORATOR

MTR

FAN

MTR

FANFAN

MTR

FAN MOTOR

POWER PLUGS

EVAPORATOR

MOTOR QUANTITY

DATA PLATE FOR

REFER TO

GND.

4

DT

RD

DEFROST TERMINATION

DT-DEFROST TERM

FD-FAN DELAY

(10.0A MAX.)

CONTROL

& FAN DELAY

BK

FD

C

DEFROST HEATERS

F

X

BN

* Remove & Insulate

* Fan delay not used on second evap / use fan contactor if total fan amps exceeds 10A

PRIMARY

SECONDARY

FUSE OR

BREAKER

NOTE #3

CIRCUIT

H1NH2

H1N

LIMIT

YL

3

(10.0A MAX.)

SWITCH

HEATER

WH

LIMIT

YL

3

(10.0A MAX.)

SWITCH

HEATER

WH

REFER TO EVAPORATOR NAMEPLATE

FOR ELECTRICAL REQUIREMENTS

RELOCATE WHITE WIRE FROM

N AS SHOWN

SEE NOTE:

1

1

REMOVE AND INSULATE

2

AS SHOWN

2

TPLP

29/11/18

T30-TPLP-PDI-14

- 14 -

WIRING DIAGRAM - 208-230/1/60

STANDARD PSC MOTORS

ELECTRIC DEFROST MODELS - MULTIPLE EVAPORATORS

PSC

60Hz

Page 15

WARNING

EVAP#2 FIELD MODIFI-

CATION MUST BE MADE

COMPR INTERLOCK

FOR ALL 460V MODELS USING DEFROST HEATER AND FAN CONTACTORS

THERMOSTAT

NOTE #4

EVAPORATOR FAN MOTORS AND

DEFROST HEATERS MUST NOT EXCEED

1). USE COPPER CONDUCTORS ONLY

3). OVERCURRENT PROTECTION FOR

MAXIMUM VALUE SHOWN ON

EVAPORATOR NAMEPLATE.

NOTES

2). USE 75°C WIRE (OR HIGHER)

MTR

FANFAN

MTR

FAN

MTR

M2

M1

GND.

(IF USED)

SWITCH

OR EQUIVALENT

PUMP DOWN

SPACE

(IF USED)

BREAKER

21

N

NOTE #3

TM

4X

3

CIRCUIT

FUSE OR

DEFROST CLOCK

PARAGON # 8145

EVAPORATOR

OPTIONAL FACTORY

FACTORY WIRING

WIRING BY OTHERS

ALL FIELD WIRING MUST BE DONE IN

COMPLIANCE WITH ALL APPLICABLE LOCAL

AND NATIONAL CODES.

8-LP 460v ED CONTACTOR MULTI 09/06

-TERMINAL BLOCK TERMINAL

-COMPONENT TERMINAL

CONDUCTORS/WIRING

TERMINALS

DATA PLATE FOR

MOTOR QUANTITY

EVAPORATOR

REFER TO

POWER PLUGS

FAN MOTOR

NOTE #4

SOL VALVE

L2

L1

N.C.

LIQUID LINE

L2

T2

L1

C

T1

GND

OR BY OTHERS

AND WIRED ON EVAPORATOR

4.) MAY BE FACTORY INSTALLED-MOUNTED

CIRCUIT

BREAKER

NOTE #3

FUSE OR

GND

L2(N)

L1

CONTACTOR

DEFROST HEATER

EVAP FAN

C

CONTACTOR

T2

T1

L2

L1

MTR

FAN

MTR

FAN

GND.

M1

M2

EVAPORATOR

REFER TO

EVAPORATOR

MOTOR QUANTITY

DATA PLATE FOR

MTR

FAN

POWER PLUGS

FAN MOTOR

NOTE #3

FUSE OR

CIRCUIT

BREAKER

PRIMARY

SECONDARY

* Note: Fan Delay not used on second evap

DEFROST HEATERS

H1 H2

DEFROST TERMINATION

DT-DEFROST TERM

FD-FAN DELAY

CONTROL

(10.0A MAX.)

BK

FD

& FAN DELAY

C

RD

X

4

BN

DT

N

DEFROST TERMINATION

DT-DEFROST TERM

FD-FAN DELAY

CONTROL

(10.0A MAX.)

BK

FD

& FAN DELAY

C

RD

X

4

BN

DT

N

DEFROST HEATERS

H1 H2

*

HEATER

SWITCH

LIMIT

(10.0A MAX.)

YL

WH

3

3

F

F

(10.0A MAX.)

LIMIT

SWITCH

HEATER

YL

WH

N AS SHOWN

RELOCATE WHITE WIRE FROM

1

1

REFER TO EVAPORATOR NAMEPLATE

FOR ELECTRICAL REQUIREMENTS

TPLP

29/11/18

T30-TPLP-PDI-14

- 15 -

WIRING DIAGRAM - 460/1/60

STANDARD PSC MOTORS

ELECTRIC DEFROST MODELS - MULTIPLE EVAPORATORS

PSC

60Hz

Page 16

SmartSpeed

Evaporators

EVAP w/ PSC

EVAP with SmartSpeed

REFRIGERATION = FULL SPEED = 60W PER MOTOR

OFF CYCLE = LOW SPEED = 13W PER MOTOR

40 % EXTRA ENERGY SAVINGS vs. FIXED SPEED EC MOTOR ON EVAPORATOR

10 % EXTRA ENERGY SAVINGS ON COMPRESSOR WHEN USING SMARTSPEED EVAPORATOR

DESIGN HIGHLIGHTS

NO COMPLEX CONTROLS, NO COST ADDER, SIMPLE TO UNDERSTAND

PATENT

PENDING

TPLP

29/11/18

T30-TPLP-PDI-14

- 16 -

ECM

60Hz

US Patents Nos.

8,635,883

DESIGN FEATURES

• Standard on all EC Motors

& 9,151,525

• Refrigeration mode – EC motor operates at full speed.

• O Cycle mode – EC motor operates at reduced speed.

• NO special controls required.

Consumption 60 W per motor

Consumption 13 W per motor.

• Energy saving benet on motor and compressor wattage consumption:

20000

18000

16000

14000

12000

with PSC vs ECM vs SmartSpeed Evaporator Fan Motors

ENERGY CONSUMPTION COMPA RISON:

Compressor w/ PSC

Compressor w/ ECM

Compressor w/ SmartSpeed

10000

8000

ADDITIONAL ENERGY SAVINGS WHEN

USING SMARTSPEED EVAPS

6000

4000

Energy Consumption (Watt-Hours)

2000

0

0 50 100 150 200 250 300 350 400 450 500

Time (minutes)

Note: Data collected on a typical freezer application with a 3HP low temp condensing unit and a 4 fan TPLP evaporator

EVAP w/ ECM

INSTALLATION NOTES

EC motors are factory wired for SmartSpeed operation on evaporators equipped with

a factory installed thermostat.

Page 17

TPLP

29/11/18

T30-TPLP-PDI-14

- 17 -

WIRING DIAGRAM - 115/1/60, 208-230/1/60

OPTIONAL EC MOTORS with

AIR DEFROST MODELS

ECM

60Hz

Page 18

TPLP

29/11/18

T30-TPLP-PDI-14

- 18 -

WIRING DIAGRAM - 208-230/1/60

OPTIONAL EC MOTORS with

ELECTRIC DEFROST MODELS

ECM

60Hz

Page 19

TPLP

29/11/18

T30-TPLP-PDI-14

- 19 -

WIRING DIAGRAM - 208-230/1/60

OPTIONAL EC MOTORS with

ELECTRIC DEFROST MODELS - MULTIPLE EVAPORATORS

ECM

60Hz

Page 20

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 20 -

INTUITIVE EVAPORA T OR CONTROL TECHNOLOGY

What is ESP+?

Trenton Refrigeration's ESP+ intuitive evaporator control technology is designed to replace traditional electromechanical refrigeration controls typically used on medium and low temperature applications. By combining award

winning adaptive technology along with an electronic expansion valve, Trenton Refrigeration continues Leading

The Way with innovative, state-of-the-art designs.

Installing an evaporator utilizing the ESP+ intuitive evaporator control technology is simple. Two pipes, two wires

and you’re done. No interconnecting control wiring between the evaporator and the condensing unit is required.

• Quick simple installation

• Improved evaporator performance by minimizing excessive frost on the evaporator

• Eliminates ice build up on surfaces and product

• Energy savings through evaporator fan management

• Energy savings with reduction in the number of defrost cycles

• Defrost heater management

• Improved system diagnostics and service through advanced alarm notication text/email

• Remote monitoring & system control

• User friendly interface

• Precise temperature control for prolonged product shelf life

• Improved product integrity with less potential for spoilage

• Downloadable data provides system history for prior 30 days

• Remotely view and change system parameters and alarm settings

• Manually control system

• Easily troubleshoot issues

ESP+ controls:

- Box Temperature - Superheat

- Defrost Initiation - Defrost Termination - Fan Motors

- Defrost Heater (Electric Defrost Models)

Plus - User can access operating data directly from the system interface

15-20% System Energy Savings

over a Properly Commissioned System!

86% Fewer Defrost Cycles*

• Enhanced system performance

• Energy Savings

• Improved product integrity

* Data may vary depending on application

Visit t-rp.com/esp for details

Page 21

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 21 -

WIRING DIAGRAM - 115/1/60

AIR DEFROST MODELS w/

Page 22

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 22 -

WIRING DIAGRAM - 208-230/1/60

AIR DEFROST MODELS w/

Page 23

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 23 -

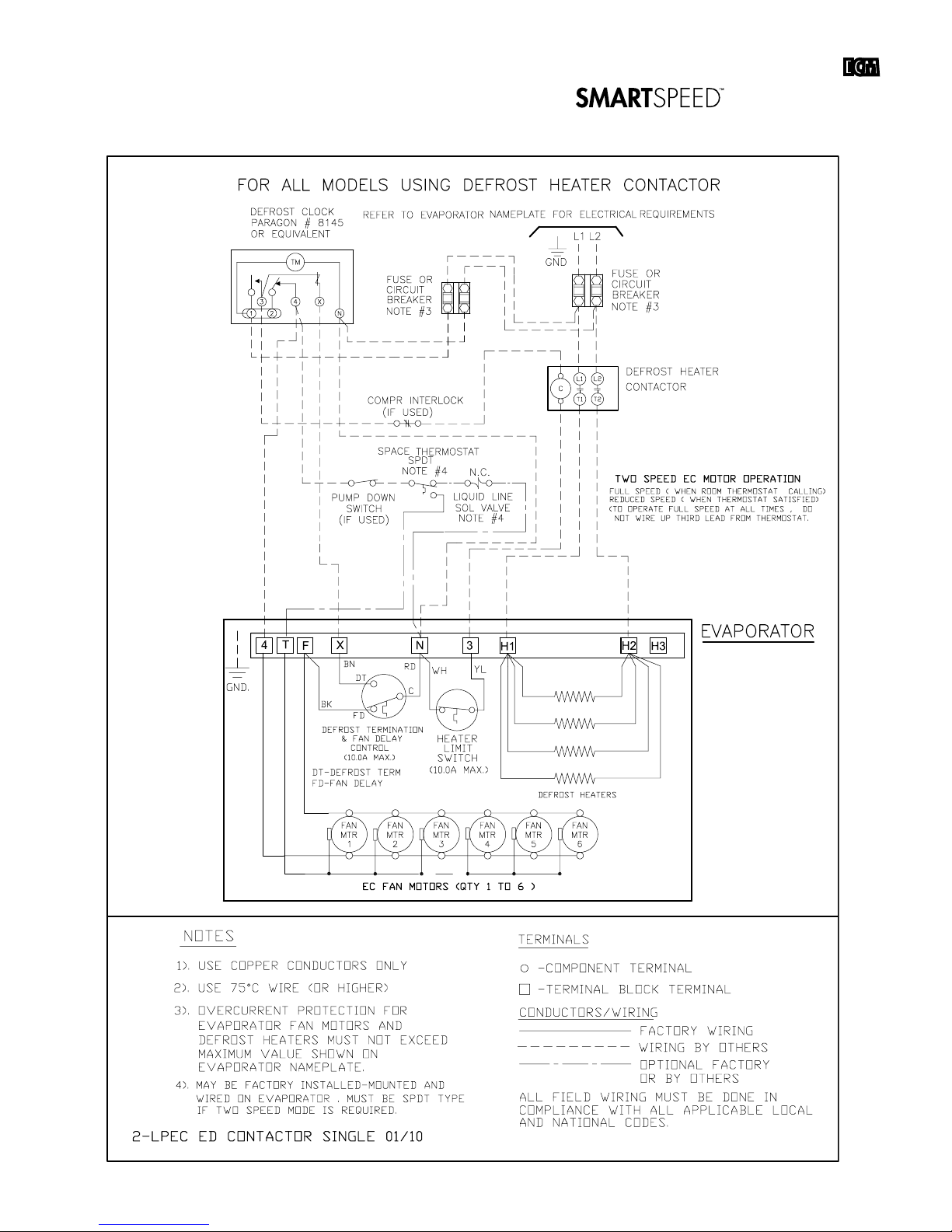

WIRING DIAGRAM - 208-230/1/60

1-3 FAN ELECTRIC DEFROST MODELS

w/ MAX. 12A

Page 24

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 24 -

WIRING DIAGRAM - 208-230/1/60

4-5 FAN ELECTRIC DEFROST MODELS

w/ 16A TO 20A

Page 25

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 25 -

WIRING DIAGRAM - 208-230/1/60

6 FAN ELECTRIC DEFROST MODELS

w/ 24A

Page 26

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 26 -

SHIPPING WEIGHTS

Air Defrost Models

MODEL

TPLP

104MA 45 (20)

106MA 47 (21)

107MA 49 (22)

209MA 70 (32)

211MA 74 (33)

214MA 78 (35)

317MA 101 (46)

320MA 107 (48)

423MA 117 (53)

426MA 135 (61)

532MA 163 (74)

639MA 192 (87)

SHIPPING WEIGHT

LB. (kg)

Electric Defrost Models

MODEL

TPLP

104ME 104LE 103VE 49 (22)

106ME 105LE 104VE 51 (23)

107ME 106LE 105VE 53 (24)

209ME 207LE 206VE 76 (34)

211ME 209LE 208VE 80 (36)

214ME 211LE 209VE 84 (38)

317ME 314LE 312VE 109 (49)

320ME 317LE 315VE 115 (52)

423ME 419LE 416VE 127 (58)

426ME 422LE 419VE 145 (66)

532ME 527LE 523VE 176 (80)

639ME 631LE 627VE 207 (94)

SHIPPING WEIGHT

LB. (kg)

Page 27

.438 SLOTS IN

MOUNTING BRACKETS

AIR THROW

APPROX 35'

IN OPEN

SPACE

12

MINIMUM

11 7/83 1/8

3

[305][302] [79]

[76]

[403]

15 7/8

[35]

1 3/8

3/4 MPT / 3/4 FLARE

DRAIN CONNECTION

4, 5 AND 6 FAN

MODELS.

6 1/2

C

A

B

[165]

MTG SLOTS

13 7/16

[341]

(TOP VIEW)

REFRIGERATION

CONNECTIONS.

SUCTION & LIQUID.

ELECTRICAL

CONNECTIONS.

A

B

13 7/16

MTG SLOTS

[165]

[165]

6 1/26 1/2

4

TYP

[102]

[341]

1, 2 AND 3 FAN

MODELS.

(TOP VIEW)

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 27 -

DIMENSIONAL DATA

MODEL

TPLP

NO. OF

FANS

A B C

IN (mm) IN (mm) IN (mm)

104M^ 1 30 1/4 (768) 17 1/4 (438) N/A N/A 5/8 3/8 3/8 3/8

106M^ 1 30 1/4 (768) 17 1/4 (438) N/A N/A 5/8 3/8 3/8 3/8

107M^ 1 30 1/4 (768) 17 1/4 (438) N/A N/A 5/8 3/8 3/8 3/8

209M^ 2 46 1/4 (1175) 33 1/4 (845) N/A N/A 7/8 3/8 3/8 3/8

211M^ 2 46 1/4 (1175) 33 1/4 (845) N/A N/A 7/8 3/8 3/8 3/8

214M^ 2 46 1/4 (1175) 33 1/4 (845) N/A N/A 7/8 3/8 3/8 3/8

317M^ 3 62 1/4 (1581) 49 1/4 (1251) N/A N/A 7/8 3/8 3/8 3/8

320M^ 3 62 1/4 (1581) 49 1/4 (1251) N/A N/A 7/8 3/8 3/8 3/8

423M^ 4 78 1/4 (1988) 32 5/8 (829) 32 5/8 (829) 1 1/8 3/8 3/8 3/8

426M^ 4 78 1/4 (1988) 32 5/8 (829) 32 5/8 (829) 1 1/8 3/8 1/2 3/8

532M^ 5 94 1/4 (2394) 32 5/8 (829) 48 5/8 (1235) 1 3/8 1/2 1/2 1/2

639M^ 6 110 1/4 (2800) 48 5/8 (1235) 48 5/8 (1235) 1 3/8 1/2 1/2 1/2

104L^ 1 30 1/4 (768) 17 1/4 (438) N/A N/A 5/8 3/8 3/8 3/8

105L^ 1 30 1/4 (768) 17 1/4 (438) N/A N/A 5/8 3/8 3/8 3/8

106L^ 1 30 1/4 (768) 17 1/4 (438) N/A N/A 5/8 3/8 3/8 3/8

207L^ 2 46 1/4 (1175) 33 1/4 (845) N/A N/A 7/8 3/8 3/8 3/8

209L^ 2 46 1/4 (1175) 33 1/4 (845) N/A N/A 7/8 3/8 3/8 3/8

211L^ 2 46 1/4 (1175) 33 1/4 (845) N/A N/A 7/8 3/8 3/8 3/8

314L^ 3 62 1/4 (1581) 49 1/4 (1251) N/A N/A 7/8 3/8 3/8 3/8

317L^ 3 62 1/4 (1581) 49 1/4 (1251) N/A N/A 1 1/8 3/8 3/8 3/8

419L^ 4 78 1/4 (1988) 32 5/8 (829) 32 5/8 (829) 1 1/8 3/8 3/8 3/8

422L^ 4 78 1/4 (1988) 32 5/8 (829) 32 5/8 (829) 1 1/8 3/8 3/8 3/8

527L^ 5 94 1/4 (2394) 32 5/8 (829) 48 5/8 (1235) 1 3/8 3/8 1/2 1/2

631L^ 6 110 1/4 (2800) 48 5/8 (1235) 48 5/8 (1235) 1 3/8 1/2 1/2 1/2

103V^ 1 30 1/4 (768) 17 1/4 (438) N/A N/A 5/8 3/8 3/8 3/8

104V^ 1 30 1/4 (768) 17 1/4 (438) N/A N/A 5/8 3/8 3/8 3/8

105V^ 1 30 1/4 (768) 17 1/4 (438) N/A N/A 5/8 3/8 3/8 3/8

206V^ 2 46 1/4 (1175) 33 1/4 (845) N/A N/A 7/8 3/8 3/8 3/8

208V^ 2 46 1/4 (1175) 33 1/4 (845) N/A N/A 7/8 3/8 3/8 3/8

209V^ 2 46 1/4 (1175) 33 1/4 (845) N/A N/A 7/8 3/8 3/8 3/8

312V^ 3 62 1/4 (1581) 49 1/4 (1251) N/A N/A 7/8 3/8 3/8 3/8

315V^ 3 62 1/4 (1581) 49 1/4 (1251) N/A N/A 1 1/8 3/8 3/8 3/8

416V^ 4 78 1/4 (1988) 32 5/8 (829) 32 5/8 (829) 1 1/8 3/8 3/8 3/8

419V^ 4 78 1/4 (1988)

523V^ 5 94 1/4 (2394) 32 5/8 (829) 48 5/8 (1235) 1 3/8 3/8 1/2 1/2

627V^ 6 110 1/4 (2800) 48 5/8 (1235) 48 5/8 (1235) 1 3/8 3/8 1/2 1/2

A or E. Refer to Nomenclature for details

^ =

SUCTION

LIQUID CONNECTION (ID) SWEAT

CONNECTION

(ID) SWEAT

32 5/8 (829) 32 5/8 (829) 1 1/8 3/8 3/8 3/8

R407A

R22

R404A

Page 28

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 28 -

F ACT ORY INST ALLED

EXPANSION V ALVE SELECTIONS -

MEDIUM TEMP. MODELS (MECHANICAL)

MEDIUM TEMPERATURE

R404A

AIR OR ELECTRIC DEFROST

MODEL

TPLP

104M***BR6 N/A EBQE-AA-SC E3 MKC-1

106M***BR6 L-1/2 EBQE-A-SC E3 MKC-1

107M***BR6 L-1/2 EBQE-A-SC E3 MKC-1

209M***BR6 L-3/4 EBQE-A-SC E3 MKC-1

211M***BR6 L-1 EBQE-A-SC E3 MKC-1

214M***BR6 L-1 EBQE-B-SC E5 MKC-1

317M***BR6 L-1 1/2 EBQE-B-SC E5 MKC-1

320M***BR6 L-1 1/2 EBQE-B-SC E5 MKC-1

423M***BR6 L-2 EBQE-C-SC E6 MKC-1

426M***BR6 L-2 EBQE-C-SC E6 MKC-1

532M***BR6 L-2 1/2 EBSSE-6-SC E6 MKC-1

639M***BR6 G-3 EBSSE-6-SC E6 MKC-1

*** Insert defrost and voltage type. See nomenclature for details

FACTORY

INSTALLED

NOZZLE

FACTORY

INSTALLED

EXPANSION

VALVE

FACTORY

INSTALLED

LIQUID LINE

SOLENOID

VALVE

FACTORY

INSTALLED

SOLENOID

COIL

MEDIUM TEMPERATURE

R448A

R407A

R407C

R22

AIR OR ELECTRIC DEFROST

MODEL

TPLP

104M***BR2 N/A EBQE-AAA-VC E3 MKC-1

106M***BR2 L-1/2 EBQE-AA-VC E3 MKC-1

107M***BR2 L-1/2 EBQE-AA-VC E3 MKC-1

209M***BR2 L-3/4 EBQE-A-VC E3 MKC-1

211M***BR2 L-1 EBQE-A-VC E3 MKC-1

214M***BR2 L-1 EBQE-A-VC E3 MKC-1

317M***BR2 L-1 1/2 EBQE-A-VC E3 MKC-1

320M***BR2 L-1 1/2 EBQE-B-VC E5 MKC-1

423M***BR2 L-2 EBQE-B-VC E5 MKC-1

426M***BR2 L-2 EBQE-B-VC E5 MKC-1

532M***BR2 L-2 1/2 EBQE-C-VC E6 MKC-1

639M***BR2 G-3 EBQE-C-VC E6 MKC-1

*** Insert defrost and voltage type. See nomenclature for details

FACTORY

INSTALLED

NOZZLE

FACTORY

INSTALLED

EXPANSION

VALVE

FACTORY

INSTALLED

LIQUID LINE

SOLENOID

VALVE

FACTORY

INSTALLED

SOLENOID

COIL

Page 29

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 29 -

F ACT ORY INST ALLED

EXPANSION V ALVE SELECTIONS -

LOW TEMP. MODELS (MECHANICAL)

LOW TEMPERATURE

R404A

ELECTRIC DEFROST

MODEL

TPLP

104LE**BR6 L-1/2 EBQE-AA-ZP E3 MKC-1

105LE**BR6 L-3/4 EBQE-AA-ZP E3 MKC-1

106LE**BR6 L-1 EBQE-A-ZP E3 MKC-1

207LE**BR6 L-1 EBQE-A-ZP E3 MKC-1

209LE**BR6 L-1 1/2 EBQE-A-ZP E3 MKC-1

211LE**BR6 L-2 EBQE-B-ZP E3 MKC-1

314LE**BR6 L-2 EBQE-B-ZP E5 MKC-1

317LE**BR6 L-3 EBQE-C-ZP E5 MKC-1

419LE**BR6 L-3 EBQE-C-ZP E5 MKC-1

422LE**BR6 G-4 EBQE-C-ZP E6 MKC-1

527LE**BR6 G-4 EBSSE-6-ZP E6 MKC-1

631LE**BR6 G-5 EBSSE-6-ZP E6 MKC-1

*** Insert voltage type. See nomenclature for details

FACTORY

INSTALLED

NOZZLE

FACTORY

INSTALLED

EXPANSION

VALVE

FACTORY

INSTALLED

LIQUID LINE

SOLENOID

VALVE

FACTORY

INSTALLED

SOLENOID

COIL

LOW TEMPERATURE

R404A

ELECTRIC DEFROST 4 FPI

MODEL

TPLP

103VE**BR6 L-1/2 EBQE-AA-ZP E3 MKC-1

104VE**BR6 L-3/4 EBQE-AA-ZP E3 MKC-1

105VE**BR6 L-1 EBQE-A-ZP E3 MKC-1

206VE**BR6 L-1 EBQE-A-ZP E3 MKC-1

208VE**BR6 L-1 1/2 EBQE-A-ZP E3 MKC-1

209VE**BR6 L-2 EBQE-B-ZP E3 MKC-1

312VE**BR6 L-2 EBQE-B-ZP E5 MKC-1

315VE**BR6 L-3 EBQE-C-ZP E5 MKC-1

416VE**BR6 L-3 EBQE-C-ZP E5 MKC-1

419VE**BR6 G-4 EBQE-C-ZP E6 MKC-1

523VE**BR6 G-4 EBQE-C-ZP E6 MKC-1

627VE**BR6 G-5 EBSSE-6-ZP E6 MKC-1

*** Insert voltage type. See nomenclature for details

FACTORY

INSTALLED

NOZZLE

FACTORY

INSTALLED

EXPANSION

VALVE

FACTORY

INSTALLED

LIQUID LINE

SOLENOID

VALVE

FACTORY

INSTALLED

SOLENOID

COIL

LOW TEMPERATURE

R448A

R407A

R22

ELECTRIC DEFROST

MODEL

TPLP

104LE**BR2 L-1/2 EBQE-AA-VZ E3 MKC-1

105LE**BR2 L-3/4 EBQE-AA-VZ E3 MKC-1

106LE**BR2 L-1 EBQE-AA-VZ E3 MKC-1

207LE**BR2 L-1 EBQE-A-VZ E3 MKC-1

209LE**BR2 L-1 1/2 EBQE-A-VZ E3 MKC-1

211LE**BR2 L-2 EBQE-A-VZ E3 MKC-1

314LE**BR2 L-2 EBQE-B-VZ E3 MKC-1

317LE**BR2 L-3 EBQE-B-VZ E5 MKC-1

419LE**BR2 L-3 EBQE-B-VZ E5 MKC-1

422LE**BR2 G-4 EBQE-C-VZ E5 MKC-1

527LE**BR2 G-4 EBQE-C-VZ E5 MKC-1

631LE**BR2 G-5 EBQE-C-VZ E6 MKC-1

*** Insert voltage type. See nomenclature for details

FACTORY

INSTALLED

NOZZLE

FACTORY

INSTALLED

EXPANSION

VALVE

FACTORY

INSTALLED

LIQUID LINE

SOLENOID

VALVE

FACTORY

INSTALLED

SOLENOID

COIL

LOW TEMPERATURE

R448A

R407A

R22

ELECTRIC DEFROST 4 FPI

MODEL

TPLP

103VE**BR2 L-1/2 EBQE-AAA-VZ E3 MKC-1

104VE**BR2 L-3/4 EBQE-AA-VZ E3 MKC-1

105VE**BR2 L-1 EBQE-AA-VZ E3 MKC-1

206VE**BR2 L-1 EBQE-A-VZ E3 MKC-1

208VE**BR2 L-1 1/2 EBQE-A-VZ E3 MKC-1

209VE**BR2 L-2 EBQE-A-VZ E3 MKC-1

312VE**BR2 L-2 EBQE-B-VZ E3 MKC-1

315VE**BR2 L-3 EBQE-B-VZ E5 MKC-1

416VE**BR2 L-3 EBQE-B-VZ E5 MKC-1

419VE**BR2 G-4 EBQE-C-VZ E5 MKC-1

523VE**BR2 G-4 EBQE-C-VZ E5 MKC-1

627VE**BR2 G-5 EBQE-C-VZ E6 MKC-1

*** Insert voltage type. See nomenclature for details

FACTORY

INSTALLED

NOZZLE

FACTORY

INSTALLED

EXPANSION

VALVE

FACTORY

INSTALLED

LIQUID LINE

SOLENOID

VALVE

FACTORY

INSTALLED

SOLENOID

COIL

Page 30

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 30 -

F ACT ORY INST ALLED

EXPANSION V ALVE SELECTIONS -

MODELS w/

MEDIUM TEMPERATURE

R448A

R407A

AIR OR ELECTRIC DEFROST

MODEL

TPLP

104M***BR8-ESP N/A 9 E3

106M***BR8-ESP L1/2 11 E3

107M***BR8-ESP L1/2 14 E3

209M***BR8-ESP L3/4 14 E3

211M***BR8-ESP L1 14 E3

214M***BR8-ESP L1 18 E3

317M***BR8-ESP L1-1/2 18 E5

320M***BR8-ESP L1-1/2 24 E5

423M***BR8-ESP L2 24 E5

426M***BR8-ESP L2 24 E5

532M***BR8-ESP L2-1/2 35 E6

639M***BR8-ESP G3 35 E6

*** Insert defrost and voltage type. See nomenclature for details

FACTORY

INSTALLED

NOZZLE

R407C R404A

FACTORY

INSTALLED

E2V EXPANSION

VALVE

R22

FACTORY

INSTALLED

LIQUID LINE

SOLENOID VALVE

LOW TEMPERATURE

R448A

R407A

R404A

R22

ELECTRIC DEFROST

MODEL

TPLP

104LE**BR8-ESP L1/2 9 E3

105LE**BR8-ESP L3/4 9 E3

106LE**BR8-ESP L1 11 E3

207LE**BR8-ESP L1 11 E3

209LE**BR8-ESP L1-1/2 11 E3

211LE**BR8-ESP L2 14 E3

314LE**BR8-ESP L2 14 E5

317LE**BR8-ESP L3 18 E5

419LE**BR8-ESP L3 18 E5

422LE**BR8-ESP G4 24 E5

527LE**BR8-ESP G4 24 E6

631LE**BR8-ESP G5 24 E6

** Insert voltage type. See nomenclature for details

FACTORY

INSTALLED

NOZZLE

FACTORY

INSTALLED

E2V EXPANSION

VALVE

FACTORY

INSTALLED

LIQUID LINE

SOLENOID VALVE

LOW TEMPERATURE

R448A

R407A

R404A

R22

ELECTRIC DEFROST 4 FPI

MODEL

TPLP

103VE**BR8-ESP L1/2 9 E3

104VE**BR8-ESP L3/4 9 E3

105VE**BR8-ESP L1 9 E3

206VE**BR8-ESP L1 11 E3

208VE**BR8-ESP L1-1/2 11 E3

209VE**BR8-ESP L2 11 E3

312VE**BR8-ESP L2 14 E3

315VE**BR8-ESP L2-1/2 14 E5

416VE**BR8-ESP J2-1/2 18 E5

419VE**BR8-ESP G3 18 E5

523VE**BR8-ESP G4 24 E5

627VE**BR8-ESP G5 24 E6

** Insert voltage type. See nomenclature for details

FACTORY

INSTALLED

NOZZLE

FACTORY

INSTALLED

E2V EXPANSION

VALVE

FACTORY

INSTALLED

LIQUID LINE

SOLENOID VALVE

Page 31

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 31 -

INSTALLATION INSTRUCTIONS

INSTALLATION

The installation and start-up of evaporators should only

be performed by qualied refrigeration mechanics.

This equipment should be installed in accordance with

all applicable codes, ordinances and local by-laws.

INSPECTION

Inspect all equipment before unpacking for visible signs

of damage or loss. Check shipping list against material

received to ensure shipment is complete.

IMPORTANT: Remember, you, the consignee, must

make any claim necessary against the transportation

company. Shipping damage or missing parts, when

discovered at the outset, will prevent later unnecessary

and costly delays.

If damage or loss during transport is evident, make

claim to carrier, as this will be their responsibility,

not the manufacturer’s.

Should carton be damaged, but damage to equipment is

not obvious, a claim should be led for “concealed

damage” with the carrier.

IMPORTANT: The electrical characteristics of the unit

should be checked at this time to make sure they

correspond to those ordered and to electrical power

available at the job site.

Save all shipping papers, tags and instruction sheets for

reference by installer and owner.

APPLICATION

TPLP evaporators are designed for walker-in cooler and

freezer applications used with a wide range of refrigerants. For room temperatures above 35°F (2°C) AND

evaporating temperatures above 26°F (-3°C), positive

defrosting means (electric) may not be required,

otherwise, electric defrost defrost models should be

used. Electric defrost models come with defrost

termination and fan delay as standard to control the

defrost cycle termination and fan delay, while defrost

initiation means (e.g. defrost timer) is not included.

The coil must not be exposed to any abnormal

atmospheric or acidic environments. This may result in

corrosion to the cabinet and possible coil failure (leaks).

LOCATION

The unit location in the room should be selected to ensure uniform air distribution throughout the entire space

to be refrigerated. Be sure that the product does not

obstruct the free circulation of air. Allow a minimum of

24” clearance at each end. Do not locate evaporators

over doors. Consideration should be given to the coil

location in order to minimize the piping run length to the

condensing unit and oor drain.

EXPANSION VALVE (TXV) PRE-SELECTED

Locate the expansion valve bulb on a horizontal

length of suction line preferably 3 to 6 inches

from the suction header. Locate the bulb at 4 or

8 clock position and insulate with a waterproof

type of insulation. Clamp the bulb to ensure

100% contact of the bulb with the suction line.

After following the manufacturer’s installation instructions

and after the room has reached the desired

temperature the valve superheat should be checked.

This will conrm that the evaporator is operating

properly and performing to maximum eciency. The

superheat should be around 6 (3.3°C) to 8°F (4.4°C) for

a 10 to 12°F T.D (5.6 to 6.7°C). Too high or low a super

heat will result in unsatisfactory system

performance and possible compressor problems.

MOUNTING

Refer to dimensional drawing for recommended

mounting arrangements. Ensure adequate clearance

is provided behind the coil as well as each end. The

evaporators may be mounted ush with ceiling with

bolts, or hanging down with rod hangers. When using

rod hangers, allow adequate space between the top of

the unit and the ceiling for cleaning to comply with NSF

Standard 7.

Ensure that the ceiling is level since the drain pan

has been sloped for drainage during the defrost

cycle.

DRAIN LINE

The drain line should be run from the drain connection,

sloping at least 1” (25 mm) per foot and should have

the size at least as large as the drain connection. A

P-Trap in a warm area outside the room must be

provided to allow proper draining through the tubing.

Connection should be made to proper drainage facilities

that comply with local regulations.

To prevent freeze-up when the temperature of the

refrigerated space is 35°F (2°C) or lower, the drain line

should be heated along its run inside the cold room.

The heated drain line should be insulated. It is recommended that the heater be energized at all times. A

heat input of 20 watts per foot in a 28°F (-2°C) room

and 30 watts per foot for -20°F (-29°C) rooms, is

satisfactory. Drain line heaters are not required for

constant room temperature above 35°F (2°C).

Always trap evaporator drain line individually to prevent

vapor migration.

Ensure that the drain line has sucient slope for

proper drainage (prevention of ice build up/blockage in pan).

Page 32

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 32 -

INSTALLATION INSTRUCTIONS (cont’d)

PIPING

Refrigeration grade piping must be used for all eld

refrigeration piping. Refrigerant line sizes are important

and may not be the same size as the coil connections.

Consult ASHRAE handbook or other similar reference

book for proper line sizing.

Refrigerant piping and control system should be designed

to prevent possible liquid slugging (from oil or refrigerant)

of the compressors on start-up after the defrost cycle.

Also, it should prevent oil logging and minimize refrigerant

pressure drop.

WIRING

Wire system in accordance with governing standards and

local codes. See data and wiring diagrams on pages 4 to

20 for typical wiring arrangement. Electrical wiring is to be

sized in accordance with minimum circuit ampacity rating

(MCA). Size fuses used must not exceed the Maximum

Fuse Size ratings.

For ease of identifying the proper wiring terminal, unit

wiring is color coded and terminal block connections are

identied.

When fan delay thermostats (combination fan delay and

defrost termination) are installed, on start-up, the fans

do not operate until the coil temperature is reduced to

approximately 25oF (-4°C). It is normal for the fans to

cycle a few times until the room temperature is brought

down. At higher evaporating temperatures this control

may not close and therefore should either be by-passed

temporarily or replaced with an adjustable type. (set for a

higher temperature cut-in point).

MAINTENANCE

The unit should be periodically inspected for any dirt or ice

build-up on the n surface and cleaned if necessary with

a soft whisk or brush. Also ensure coils inner (and outer)

drain pans do not have any ice build-up from improper

defrost operation. When replacing heater elements rst

remove heater retainer brackets and heater clips.

SYSTEM CHECK

Before Start-Up:

1. All wiring should be in accordance with local

codes.

2. Refrigerant lines should be properly sized.

3. Thorough evacuation and dehydration has been

performed.

4. The suction, discharge, and receiver service

valves must be open.

5. The system preferably include a liquid line lter

drier moisture indicator and suction lter.

6. Pour enough water into the drain pan to allow a

good check on drainage and seal the trap.

After Start-Up:

1. Check the oil level to be sure the oil charge is

correct.

2. On initial start up the fans do not start until coil

temperature is pulled down to approximately 25°F

(-4°C) on the coil. Also, it is normal for the fan to

cycle a few times until the room temperature is

pulled down.

3. If necessary, temporarily by-pass fan delay control

(to run fans until room temp is lowered).

4. Be sure that the expansion valve is properly set to

provide the correct amount of superheat.

5. After the box temperature is close to reaching the

desired temperature, the evaporator superheat

must be checked and adjustment made if

necessary. In general, evaporators running with

a TD of 10°F (5.6°C ) should have a superheat

reading of 6° to 8°F (3.3°C to 4.4°C). For

evaporators with another T.D., the general rule is

that the superheat should be around 60 to

80% of T .D.

6. Heavy moisture loads are usually encountered

when starting the system for the rst time.

This may cause a rapid build-up of frost on the

evaporator. During the initial pull down, we

suggest that the frost build-up be watched and

defrosted manually as required.

7. Observe that the system goes through at least

one complete DEFROST CYCLE.

Visit

t-rp.com/esp

for Quick Start Guide, Operation Manual, etc

Page 33

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 33 -

NOTES

Page 34

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 34 -

System

Model Number Date of Start-Up

Serial Number Service Contractor

Refrigerant Phone

Electrical Supply E-Mail

PROJECT INFORMATION

Page 35

TPLP 60Hz

29/11/18

T30-TPLP-PDI-14

- 35 -

PRODUCT SUPPORT RESOURCES

web: t-rp.com/tplp

email: evaps@t-rp.com

call: 1-844-893-3222 x520

email: troubleshooting@t-rp.com

call: 1-844-893-3222 x529

web: t-rp.com/parts

email: parts@t-rp.com

call: 1-844-893-3222 x520

web: t-rp.com/warranty

email: warranty@t-rp.com

call: 1-844-893-3222 ext. 501

email: orders@t-rp.com

call: 1-844-893-3222 x501

email: shipping@t-rp.com

call: 1-844-893-3222 x503

Page 36

“AS BUILT” SERVICE PARTS LIST

29/11/18

Service Parts List

Label

To Be Attached

HERE

Trenton Refrigeration

Brantford, ON • Longview, TX

1-800-463-9517 info@t-rp.com www.t-rp.com

Due to the manufacturer’s policy of continuous product improvement, we reserve the right to make changes without notice.

Loading...

Loading...