Page 1

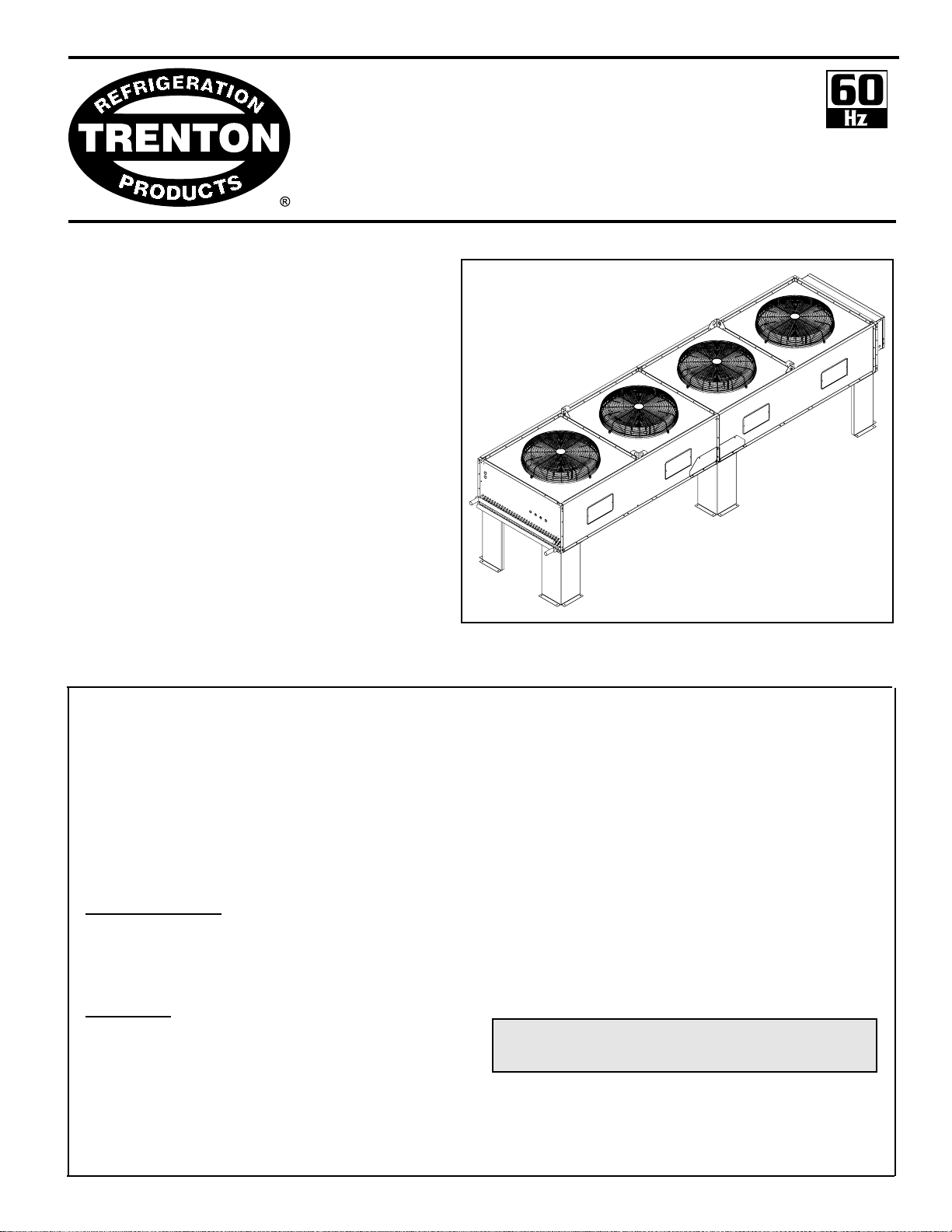

PRODUCT DATA &

01/16/11

INSTALLATION

ONE TO FOUR FAN MODELS

ELECTRICAL POWER:

208-230/1/60, 208-230/3/60,

460/1/60, 460/3/60,

575/1/60, 575/3/60

TFM-LINE

FLUID

COOLERS

Bulletin T60-TFM-PDI

1090825

CONTENTS

Page

Nomenclature............................................. 2

Features & Options.................................... 2

Fluid Cooler Selection................................ 3

Typical Applications.................................... 4

Physical/Mechanical Data (All Models)...... 5

Standard Motors

Electrical Data............................................ 5

Low Ambient Operation.............................. 6

Wiring Diagrams......................................... 7 - 8

EC Motors

About EC Motors........................................ 9

Electrical Data............................................ 9

Wiring Diagram........................................... 10

EC Motor Application Data......................... 11 - 12

Page

Header Sizes (All Models).................. 13

Dimensional Data (All Models)........... 14 - 15

Installation........................................... 16 - 18

Hydronic System Components........... 18 - 19

Pump Package System Parameters... 20

Generic Service Parts......................... 21

Warranty.............................................. 23

Project Information.............................. 23

“As Built” Service Parts List................. BACK

For the latest product updates and further

information, visit www.trentonrefrigeration.com

Page 2

Brand Name:

T60-TFL-PDI

- 2 -

01/16/11

T = Trenton

Product Name

FM = Medium Sized Fluid Cooler

Fans Wide

1 = Inline (Double wide not available)

Fans Deep

Motor

A = 1075 RPM, 3/4 HP Motor

E = ECM Motor

Coil Rows Deep

2, 3, or 4

Coil Fins Per Inch

08 = 8 fpi 10 = 10 fpi 12 = 12 fpi

NOMENCLATURE

T FM 1 3 A - 4 08 V - T5 A - XXXX

Optional Sufx

Does Not Affect Design

Design Version

Voltage

S2 = 208-230/1/60 T3 = 208-230/3/60

S4 = 460/1/60 T4 = 460/3/60

S5 = 575/1/60 T5 = 575/3/60

Application

V = Vertical Air Discharge

H = Horizontal Air Discharge

STANDARD FEATURES INCLUDE

• Heavy-gauge galvanized steel cabinet construction

• Energy efcient PSC and 3 phase fan motors

with internal overload protection

• Quiet “swept wing” fan blade for quiet operation and

optimal efciency

• Heavy duty 24” legs

OPTIONAL FEATURES

• Fan Cycling – Ambient thermostat / fan row

with contactors

• Fan Cycling – Aquastat thermostat fan cycling

control / outlet uid temperature

• Individual fan motor fusing

• Non-fused disconnect

• Horizontal air discharge conguration

• All fan sections individually bafed with

clean-out panels.

• Zinc plated huck bolts

• Control circuit voltage – 230 V

• Variable Speed EC Motor which provides optimum

efciency and sound levels (see pg. 9-12 for details)

• Extended leg kits (36” or 48”) with cross bracing for

extra rigidity

• Optional n materials

• Optional coil coating

• Voltages available for 60Hz or 50Hz

Page 3

FLUID COOLER SELECTION

SAMPLE

T60-TFL-PDI

- 3 -

01/16/11

TFM 60Hz

Previously, the selection of a uid cooler involved using charts, correction factors and hand calculations to

determine the capacity and make the selection.

We have simplied the selection process. Our engineering department has created a computer program.

This provides exibility and streamlines the selection process

TEMPERATURE LIMITATIONS

Fluid Coolers are suitable for leaving air temperatures up to a maximum of 130°F (54°C). Fluid temperature

up to an average of 150°F (66°C ) may be used at ambient temperatures up to 90°F (32°C ). Entering uid

conditions should not exceed 200°F (93°C ).

PARAMETERS FOR SELECTION OF A FLUID COOLER

Fluid Type: □ Water □ Ethylene Glycol / Water

□ Propylene Glycol / Water

Elevation: ___________ Feet Above Sea Level

Fluid Concentration: ___________%Water ___________%Glycol

Air Inlet (ambient temp.) __________ ºF

Three of the four following parameters must be specied:

1. Required Capacity __________ Btu/h 2. Fluid Inlet Temperature __________ ºF

3. Fluid Flow Rate __________ GPM 4. Fluid Outlet Temperature __________ ºF

Other Items To Specify:

1. Voltage (S2 = 208-230/1/60 S4 = 460/1/60 S5 = 575/1/60

T3 = 208-230/3/60 T4 = 460/3/60 T5 = 575/3/60) ______Specify S2,S4, S5,T3,T4 or T5

2. Please Specify (Check Box) Options Required:

Control Voltage 240V (Standard) Variable Speed EC Motor

Control Voltage 120V Extended leg kits 36”

Control Voltage 24V Extended leg kits 48”

Fan Cycling Ambient Thermostat Gold Coat Fin

Fan Cycling Aquastat Thermostat Copper Fin

Fan Cycling Control by Others Heresite Coating

Non-fused disconnect 50 Hz

Horizontal air discharge conguration

Customer Info:

Name: ______________________ Telephone Number: _____________________

Fax: ______________________ Email: ______________________

Fax or email completed sheet to your sales representative.

Extra copies of this form available on page 22

Page 4

TYPICAL APPLICATIONS

p

y

p

T60-TFL-PDI

- 4 -

01/16/11

TFM 60Hz

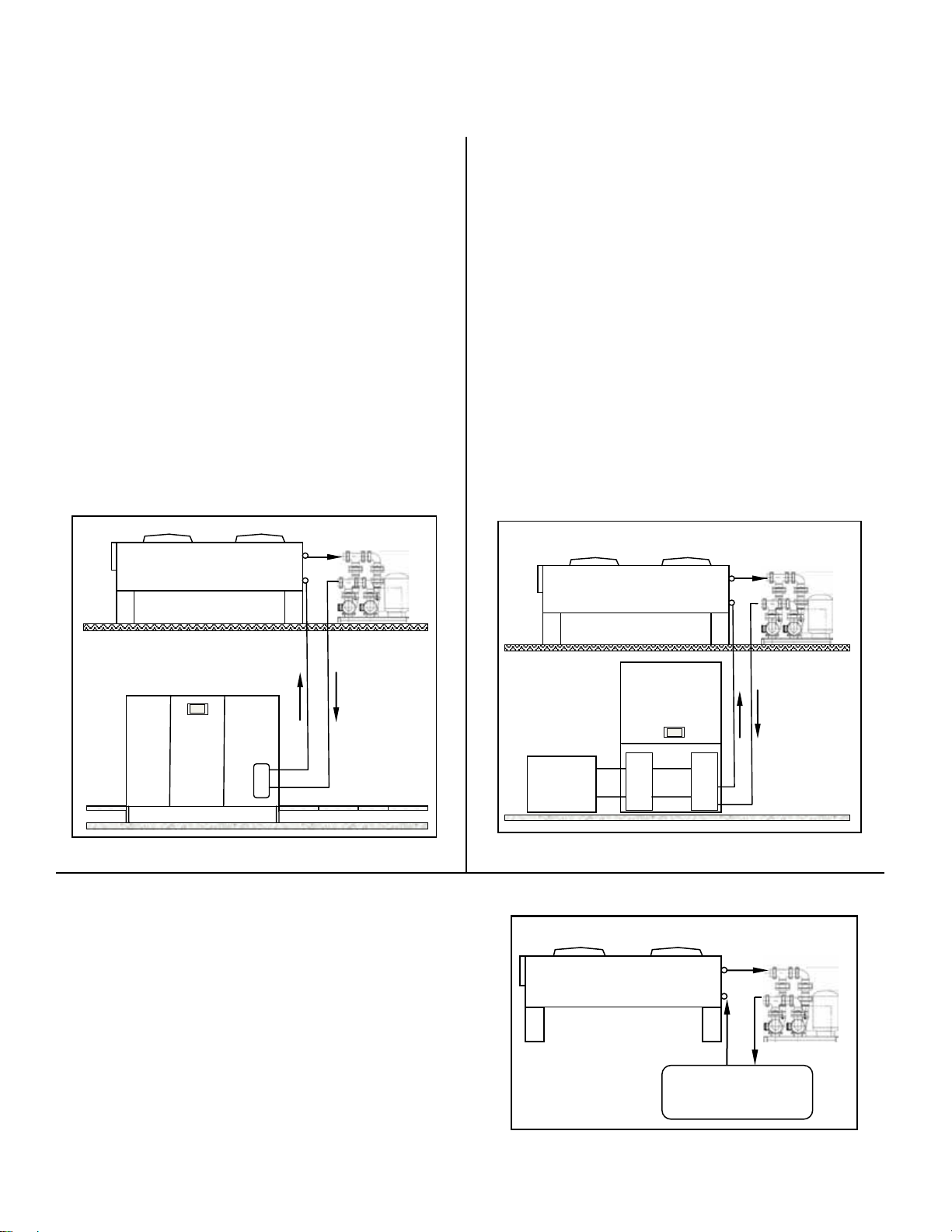

Data Center / Computer Rooms

Fluid Coolers are suitable for use with Computer Room

Air Conditioning (CRAC) Units. (see Illustration below)

Dry Type Fluid Coolers are particularly suitable for applications where long pipe runs of refrigerant piping to

an air cooled condenser are not practical. Cooling Tower

maintenance and winter operation issues are eliminated.

Piping can be easily installed and low ambient control

can be used using water regulating valves. Fluid cooler

can be easily connected to city water for emergency use.

The glycol loop is sometimes connected to a “Free-Cooling” Economizer Coil within the CRAC unit, which allows

for partial free-cooling when the glycol loop temperature

is below the CRAC units return air temperature.

Dual Pump Pkg c/w

ansion Tank

Ex

Dry Fluid Cooler

Industrial Glycol /Water Cooling Systems

Water pollution issues and water conservation have

become critical in recent years. The “Once-Only” use of

water for industrial process cooling has been wasteful

and often unnecessary. By using a dry type Fluid Cooler,

glycol/water for industrial process cooling applications

can be cooled to within 10°F (6°C) of the ambient dry

bulb temperature. The water is continuously re-circulated

and remains in a closed system so reducing the problem

of corrosion normally encountered in non re-circulated

systems.

Considerable savings can be affected by using a Dry

Type Fluid Cooler. Many industrial applications have

seen water consumption being reduced by millions of gallons and reduced maintenance costs to a fraction of that

experienced prior to the use of a closed non re-circulated

system. (see illustration below)

Dual Pump Pkg c/w

ansion Tank

Ex

Dry Fluid Cooler

Computer Room Air

Conditioner( CRAC)U nit

Glycol /

Water

Cooled

Cond.

Computer

Room AC

(CRAC)

Unit

Secondary

Heat

Exchanger

Remote Radiators for Diesel and Gas Engines

A remote radiator is usually required with the larger style

of diesel engine. The Fluid Cooler is suitable for this type

of application. Designed to give the customer trouble free

operation, the multiple fan arrangement reduces the possibility of down time. Units are completely pre-assembled

and require only piping and electrical connections. (see

illustration to the right)

Glycol/Water

Cooled

Cooling

S

stem

Process

Heat

Load

Glycol/Water

Cooled

Chiller

E

V

A

P

C

O

N

D

Cooler

Glycol/Water

Cooled

Cooling

System

Dual Pump Pkg c/w

Dry Fluid Cooler

Expansion Tank

Remote

Radiator

for

Engine

Diesel Engine

for

Page 5

TFM

T60-TFL-PDI

- 5 -

01/16/11

PHYSICAL / MECHANICAL DATA

60Hz

1075 RPM (A) ECM (E)

MODEL

NO.

TFM 11*-310 10 1 x 1 6870

TFM 11*-312 12 1 x 1 6640

TFM 11*-410 10 1 x 1 6620

TFM 11*-412 12 1 x 1 6400

TFM 12*-208 8 1 x 2 14800

TFM 12*-210 10 1 x 2 14400

TFM 12*-212 12 1 x 2 13900

TFM 12*-308 8 1 x 2 14200

TFM 12*-310 10 1 x 2 13700

TFM 12*-312 12 1 x 2 13300

TFM 12*-408 8 1 x 2 13700

TFM 12*-410 10 1 x 2 13200

TFM 12*-412 12 1 x 2 12800

TFM 13*-308 8 1 x 3 21300

TFM 13*-310 10 1 x 3 20600

TFM 13*-312 12 1 x 3 19900

TFM 13*-408 8 1 x 3 20500

TFM 13*-410 10 1 x 3 19900

TFM 13*-412 12 1 x 3 19200

TFM 14*-308 8 1 x 4 28400

TFM 14*-310 10 1 x 4 27500

TFM 14*-312 12 1 x 4 26600

TFM 14*-408 8 1 x 4 27400

TFM 14*-410 10 1 x 4 26500

TFM 14*-412 12 1 x 4 25600

NOTES:

* Insert voltage code (see Nomenclature, page 2)

(1) For 50 HZ fan data, use 60 Hz CFM (m3/h) x 0.83

(2) Sound level pressure at 30 ft (10m)

(3) Not including headers.

FPI

FAN

AIR FLOW

(1)

CONFIG.

RATE

CFM (m3/h) dBA CFM (m3/h) dBA US (LITRES) LBS. (kg.)

11670

11280

11250

10870

25150

24470

23620

24130

23280

22600

23280

22430

21750

36190

35000

33810

34830

33810

32620

48250

46720

45190

46550

45020

43490

SOUND

LEVEL

51 6180

51 5980

51 5960

51 5760

53 13320

53 12960

53 12510

53 12780

53 12330

53 11970

53 12330

53 11880

53 11520

54 19170

54 18540

54 17910

54 18450

54 17910

54 17280

55 25560

55 24750

55 23940

55 24660

55 23850

55 23040

APPROX. DRY

(3)

SHIPPING

WEIGHT

AIR FLOW

(2)

RATE

(1)

10500

10160

10130

9790

22630

22020

21250

21710

20950

20340

20950

20180

19570

32570

31500

30430

31350

30430

29360

43430

42050

40670

41900

40520

39140

SOUND

LEVEL

50 1.9 7.2 245 111

50 1.9 7.2 250 114

50 2.5 9.5 265 120

50 2.5 9.5 270 123

52 2.4 9.1 410 186

52 2.4 9.1 415 189

52 2.4 9.1 420 191

52 3.6 13.6 450 205

52 3.6 13.6 455 207

52 3.6 13.6 460 209

52 4.8 18.2 480 218

52 4.8 18.2 490 223

52 4.8 18.2 500 227

53 5.4 20.4 630 286

53 5.4 20.4 640 291

53 5.4 20.4 650 295

53 7.2 27.3 680 309

53 7.2 27.3 695 316

53 7.2 27.3 710 323

54 7.1 26.9 810 368

54 7.1 26.9 825 375

54 7.1 26.9 840 382

54 9.5 36.0 880 400

54 9.5 36.0 900 409

54 9.5 36.0 920 418

(2)

INTERNAL

VOLUME

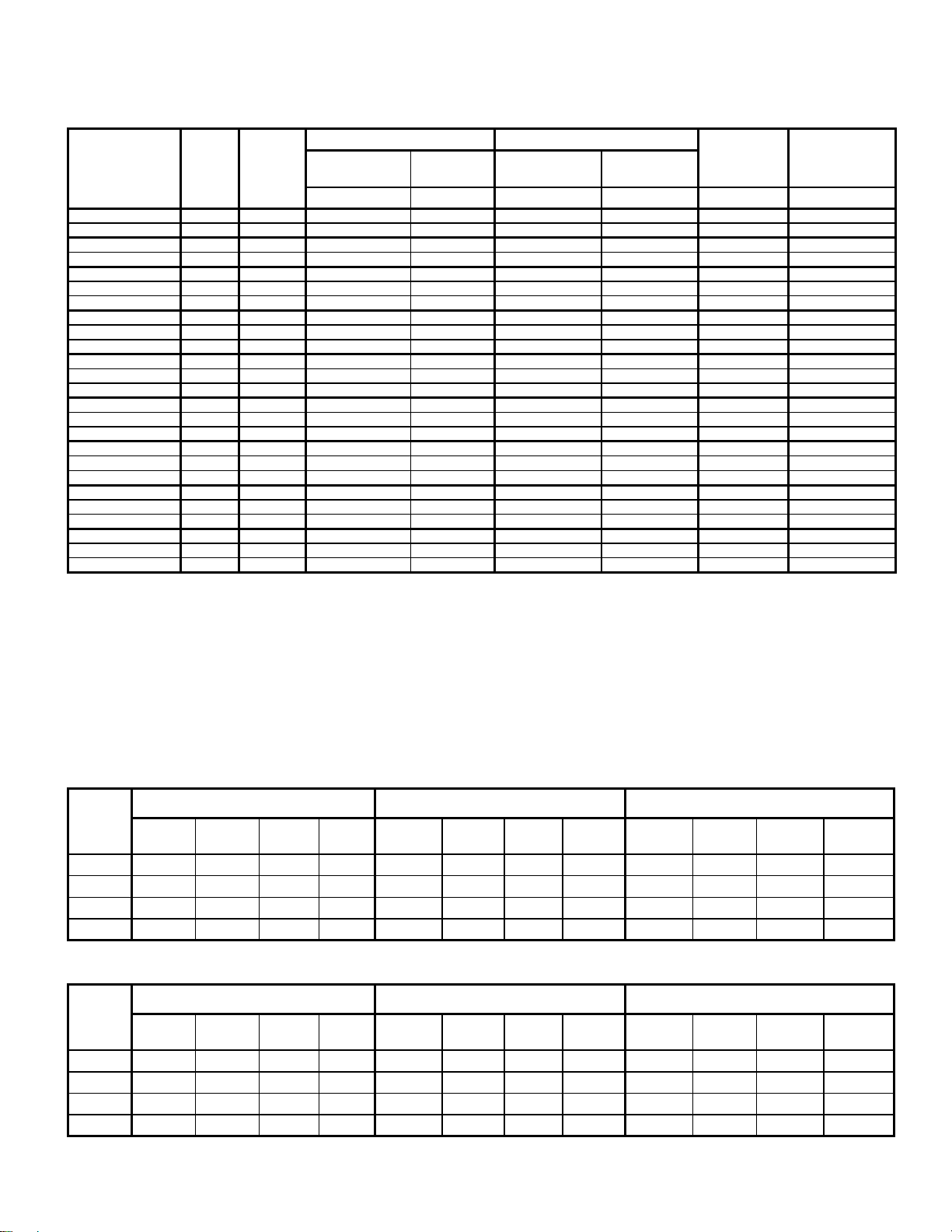

ELECTRICAL DATA

1075 RPM MODELS - SINGLE PHASE

NO. OF

FAN

MOTORS

1 3.6 4.5 15.0 790 1.7 2.1 15 810 1.4 1.8 15.0 830

2 7.2 8.1 15.0 1580 3.4 3.8 15 1620 2.8 3.2 15.0 1660

3 10.8 15.1 20.0 2370 5.1 5.5 15 2430 4.2 4.6 15.0 2490

4 14.4 15.3 20.0 3160 6.8 7.2 15 3240 5.6 6.0 15.0 3320

NO. OF

FAN

MOTORS

1 2.3 2.9 15.0 720 1.2 1.4 15 720 0.9 1.1 15.0 720

2 4.6 5.2 15.0 1440 2.3 2.6 15 1440 1.8 2.0 15.0 1440

3 6.9 7.5 15.0 2160 3.5 3.7 15 2160 2.7 2.9 15.0 2160

4 9.2 9.8 15.0 2880 4.6 4.9 15 2880 3.6 3.8 15.0 2880

TOTAL

TOTAL

208-230/1/60 460/1/60 575/1/60

FLA

MCA MOP WATTS

TOTAL

FLA

MCA MOP WATTS

TOTAL

FLA

1075 RPM MODELS - THREE PHASE

208-230/3/60 460/3/60 575/3/60

FLA

MCA MOP WATTS

TOTAL

FLA

MCA MOP WATTS

TOTAL

FLA

MCA MOP WATTS

MCA MOP WATTS

Page 6

TFM

T60-TFL-PDI

- 6 -

01/16/11

LOW AMBIENT OPERATION

60Hz

Fan Cycling Control

When a remote air cooled Fluid Cooler is installed outdoors, it will be subjected to varying temperatures. Within

many areas, winter to summer annual temperature swings

can be as high as 120°F (48.9°C) or so. This will have a

major impact on the performance of the Fluid Cooler. As

the ambient temperature drops, the Fluid Cooler capacity

increases due to a wider temperature difference between

ambient air and entering uid temperature. As this happens, the leaving uid temperature drops as well.

Cycling of the Fluid Cooler fans helps control the leaving

uid temperature. With this approach to solving low ambient problems, fans are taken off-line one at a time. It is not

recommended that multiple fan Fluid Coolers cycle more

than two (2) fans per step. The reason for this is that the

uid temperature will change drastically as several fans

are taken off-line at the same time. This could result in

excessive tube stress within the unit, due to rapid expansion and contraction of the coil which could lead to needless tube failure.

Fan Cycling Control Schedule

Fans closest to the inlet header should be set to run whenever the uid circulating pump is running.

Substantial fan motor power savings can be realized as

well using this method.

For low ambient conditions, optional

Aquastats (Fluid Temperature

Controllers) are used to cycle fans

on and off as required to maintain

constant leaving glycol/water

temperature as per the schedules below.

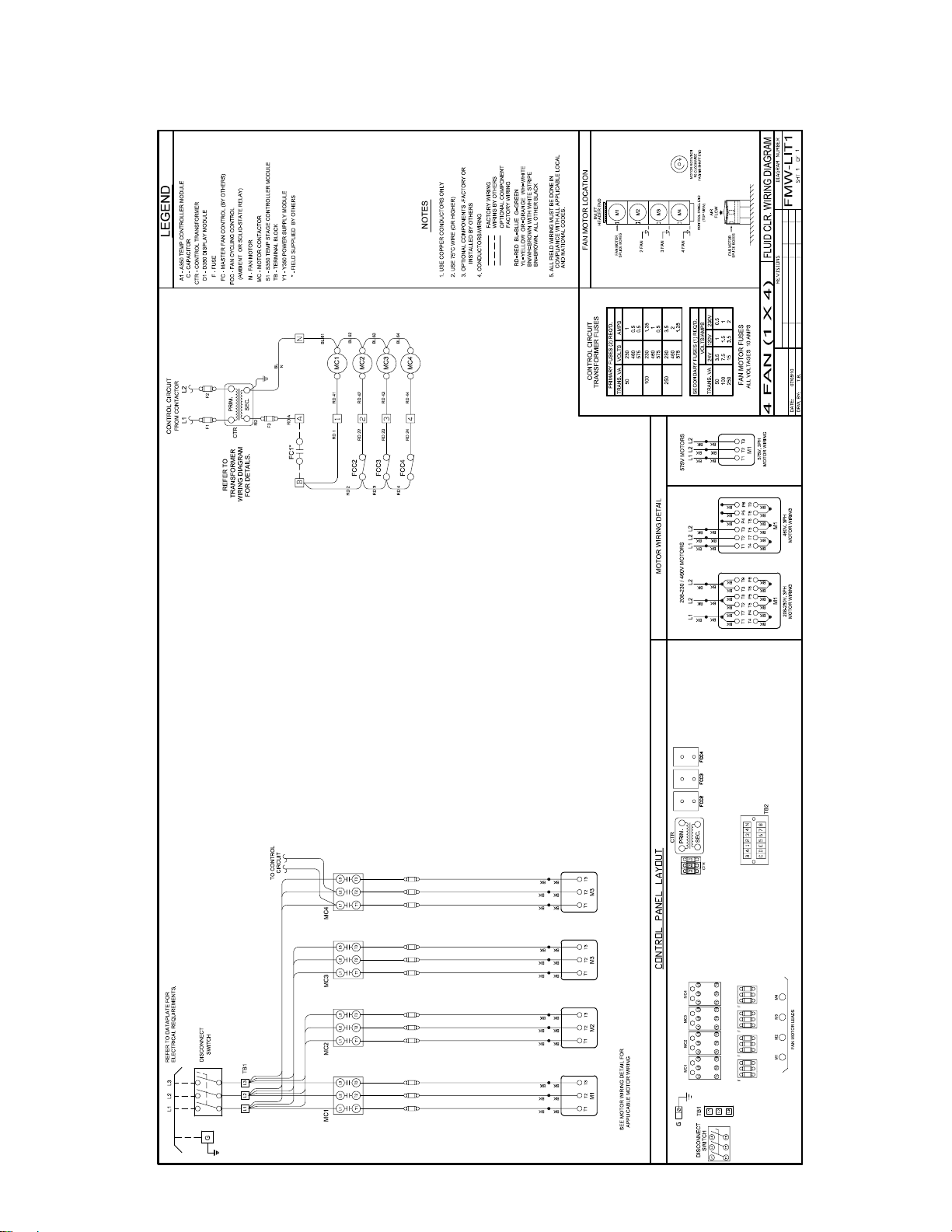

Page 7

TFM

T60-TFL-PDI

- 7 -

01/16/11

WIRING DIAGRAM

AMBIENT FAN CYCLING

1075 RPM

60Hz

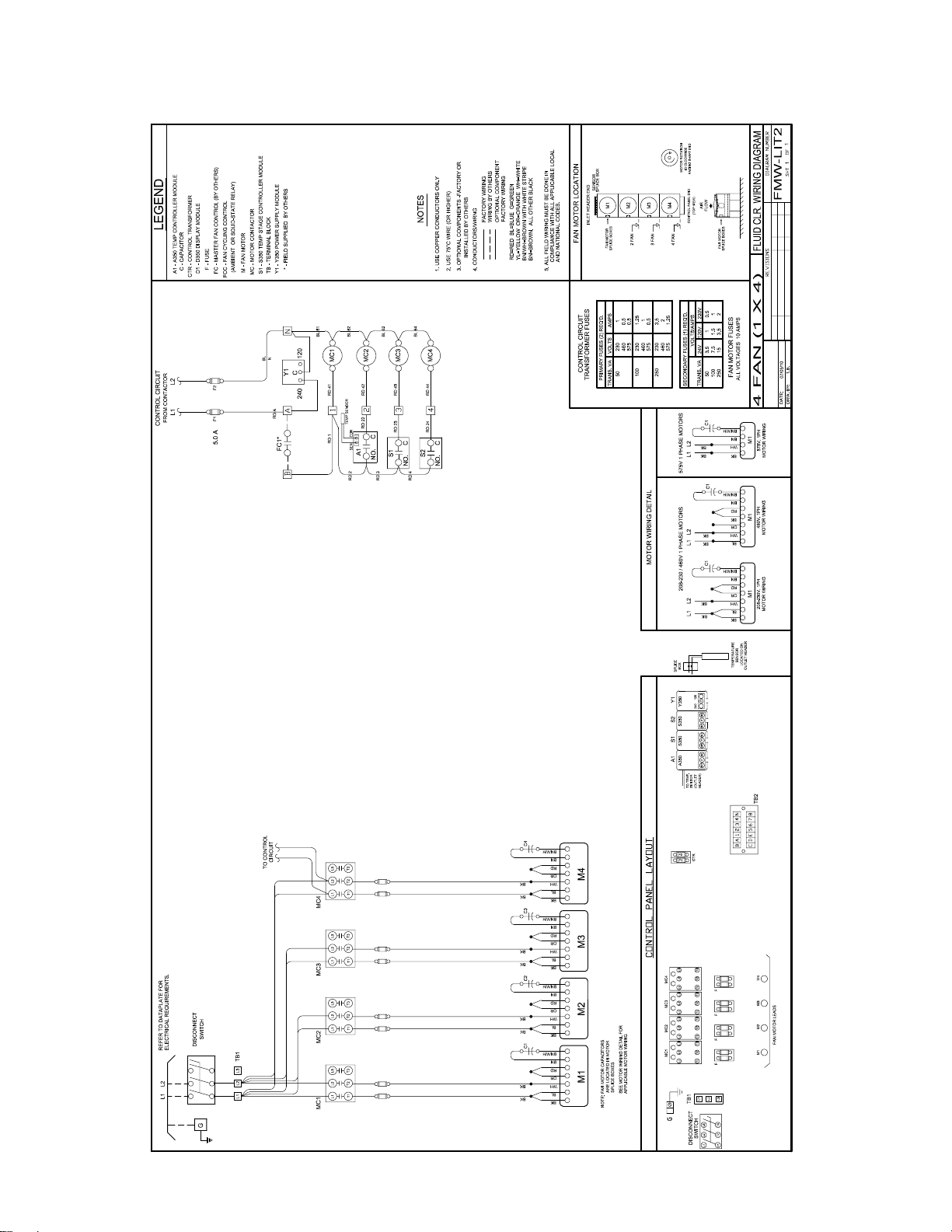

Page 8

TFM

T60-TFL-PDI

- 8 -

01/16/11

WIRING DIAGRAM

AQUASTAT FAN CYCLING

1075 RPM

60Hz

Page 9

TFM

T60-TFL-PDI

- 9 -

01/16/11

ABOUT EC MOTORS

EC MOTORS

60Hz

Fluid coolers utilizing electrically commutated motor

(EC motor) technology offer many benets; Improved

Efciency, Reduced Sound Levels, Speed Control,

Simplicity and Reliability

Efciency

The speed control function of an EC motor allows the

condenser to run at optimized energy levels at different operating conditions. Up to 75% in energy savings can be realized when comparing the EC motor

speed control method to a conventional fan cycling

method.

ELECTRICAL DATA

ECM 1075 RPM MODELS - SINGLE PHASE

Sound

As EC motor speeds vary for different operating

conditions they also offer reduced sound levels when

compared to conventional motor running full speed.

Sound levels are reduced on cooler days and in

evenings.

Simplicity and Reliability

The installation and control of EC motors is very

simple compared to other methods of speed control

used on conventional AC motors. Lower running operating temperatures and smooth transitional speed

changes make EC motors durable and reliable.

NO. OF

FAN

MOTORS

1 6.3 7.9 15 560

2 12.6 14.2 15 1120

3 18.9 20.5 25 1680

4 25.2 26.8 30 2240

TOTAL

208-230/1/60

FLA

MCA MOP WATTS

Page 10

TFM

T60-TFL-PDI

- 10 -

01/16/11

WIRING DIAGRAM

MODELS WITH EC MOTORS

EC MOTORS

60Hz

Page 11

TFM

T60-TFL-PDI

- 11 -

01/16/11

EC MOTOR APPLICATION

EC MOTORS

60Hz

Motors With Built-in Variable Speed –

Optional “E” Fan/motor Code

Units with an E (in nomenclature) motor designation use

an EC (electronically commutated) motor / fan combination to provide variable speed fan motor control. ECM fan/

motor combinations use DC motors with integral AC to DC

conversion allowing direct connection to AC mains with the

energy saving and control benets of a DC motor. Ideally

the motors on the uid cooler should all be EC and simultaneously slow down /speed up together. This provides

for maximum energy savings. However some applications

may exist where just the last fan or pair of fans (ones

closest to header) is solely EC motors. (The remaining

conventional type motors are then cycled off by fan cycling

temperature controls).

Important Warnings:

!

(Please read before handling motors)

1. When connecting the unit to the power supply,

dangerous voltages occur. Due to motor

capacitor discharge time, do not open the motor

within 5 minutes after disconnection of all phases.

2. With a Control voltage fed in or a set speed value

being saved, the motor will restart automatically

after a power failure.

3. Dangerous external voltages can be present at the

motor terminals even when the unit is turned off.

4. The Electronics housing can get hot.

5. The cycling on and off of EC motors should be

controlled by the DC control voltage (i.e. 0V DC

will turn motor off). Excessive cycling of the motor

by line voltage contactors may cause stress on

the motors and reduce the motor life.

Speed adjustment Characteristics

The EC motor varies its speed linearly based on a 1-10V

input signal. At 10 VDC, the motor runs at full speed. At 0

to approx. 1 VDC, the motor turns off. A chart of the speed

control curve is shown below. The motor can be controlled

at any speed below its nominal RPM.

Full RPM

RPM

1

Control voltage [V dc]

Control Signal

The input control signal can be supplied by an external

control signal or from a factory installed proportional temperature control. Units with factory installed proportional

temperature controls require no installation wiring and are

adjusted with initial factory settings. These may require

further adjustments to suit local eld conditions.

External Control Signal (Supplied by others)

Contact control manufacturer for setup of external controller to provide a 0-10 VDC control signal. Wire the control

signal to terminal board in unit control box. Refer to the

uid cooler EC wiring diagram for typical external signal

control wiring.

10

Page 12

TFM

T60-TFL-PDI

- 12 -

01/16/11

EC MOTOR APPLICATION (cont’d)

EC MOTORS

60Hz

A350P Proportional Temperature Control (Factory Installed)

Units equipped with factory installed A350 controls use a

proportional plus integral temperature controller to vary

and maintain the motor speed at the desired uid outlet

temperatures. The controller has two main user adjustable

features:

• Temperature Set point

• Throttling range

Leave the minimum Output setting at 0% and Jumpers

should be set for Direct Acting (do not re-adjust)

Module

User Adjust

Setpoint

Potentiometer

User Adjust

Throttli ng Range

Pote ntiom eter

0%

Min i m um

Output

Potentiomet er

LED Indicator

(Percent of Output)

THROT

RANGE

OUTPU

Conn ector

MIN

T

3 4

2

1

N

O

Integration DIP Switch

Direct

Acting

Throttling range

The throttling range potentiometer controls how far the

system uid temperature deviates from the control set

point to generate a 100% output signal from the control

and is adjustable from 2oF to 30oF range. The throttling

range determines how quickly the motor will reach full

speed when detecting a change in uid temperature. For

example, if the set point is 90oF and the throttling range

is 10oF when the system temperature drops below 90oF,

the fans will be off. When the system temperature reaches

100oF (90 + 10) the fans will be at maximum full speed.

To make the fans ramp more slowly the throttling range

should be increased. To maximize sound reduction and

energy efciency and to provide for the most stable control, it is recommended this setting be left at 10oF.

Reverse acting or direct acting mode of operation

The reverse acting/direct acting jumper is used to ensure the controller responds correctly to the desired uid

temperature. In Direct Acting (DA) mode, the motor speed

increases as the temperature rises above desired set

point. For proper uid cooler operation, this jumper MUST

be in Direct Acting (DA) mode. Failure to ensure J1 jumper

is in direct acting mode will cause the system to trip on

high uid temperatures.

Operation Mo de

Jumper Posi tions

Fluid Temperature Set point

The uid temperature set point potentiometer is adjustable

from -30oF to 130oF.

Note: Very low set points may cause the fan motors to run

full speed continually even if the uid cooler is properly

sized. The fans will turn off if the uid temperature falls

below the desired set point.

Minimum Output

The minimum output potentiometer controls the minimum

signal sent to the motor and is factory set at 0%. It is adjustable between 0 and 60% of the output range. If this is

adjusted to 50%, the motors will not start running until 5V

is applied to the motor. The motor will start running at 50%

of full speed. To maximize sound reduction and energy

savings and to provide the most stable control, it is recommended this setting be left at 0%.

Integration constant

The integration constant switch provides ability to change

controller from a proportional only control to a proportional plus integral control. To provide the most responsive

system and to maintain a stable uid temperature, it is

recommended the integration setting be left on “fast” with

the Mode switch set to OFF (Proportional AND Integral

activated)

FAST (on)

3 4

2

1

O

N

MEDIUM (off)

SLOW (off)

OFF (set for PROPORTIONAL /

INTEGRAL MODE)

Page 13

HEADER SIZES

T60-TFL-PDI

- 13 -

01/16/11

TFM 60Hz

GPM (fps)

0 - 10 (0.0 - 3.9) 1 1/8 (29) PLAIN or MPT

11 - 20 (2.8 - 5.1) 1 3/8 (35) PLAIN or MPT

21 - 30 (3.8 - 5.4) 1 5/8 (41) PLAIN or MPT

31 - 50 (3.2 - 5.2) 2 1/8 (54) PLAIN, MPT or FLANGED

51 - 80 (3.4 - 5.4) 2 5/8 (67) PLAIN or MPT

81 - 150 (3.8 - 7.1) 3 1/8 (79) PLAIN, MPT or FLANGED

SIZE

In. (mm)

2

(50.8)

3

(76.2)

HEADER SIZE O.D.

inches (mm)

OPTIONAL FACTORY SUPPLIED FLANGES

FITTING

Flanged

Flanged

FLANGE

DIA.

In. (mm)

6

(152.4)

7 1/2

(190.5)6 (152.4)

CONNECTIONS

AVAILABLE

BOLT

CIRCLE

In. (mm)

4 3/4

(120.7)

HOLES -

In. (mm)

QTY @

4 @

3/4 (19)

4 @

3/4 (19)

OPTIONAL FLANGED CONNECTIONS

BOLT HOLE LOCATION

(150 lbs. working shock pressure)

6” & 7 1/2”

Dia. Flanges

Page 14

DIMENSIONAL DATA

T60-TFL-PDI

- 14 -

01/16/11

TFM 60Hz

Page 15

DIMENSIONAL DATA

T60-TFL-PDI

- 15 -

01/16/11

TFM 60Hz

LEG FOOTPRINT

Page 16

INSTALLATION

T60-TFL-PDI

- 16 -

01/16/11

TFM 60Hz

! !

WARNING

ADEQUATE PRECAUTIONS MUST BE TAKEN, AFTER FIELD LEAK TESTING TO INSURE REMOVAL OF

WATER IN TUBES. IT IS RECOMMENDED THAT AN INHIBITED GYLCOL SOLUTION BE USED TO FLUSH

THE COMPLETE COIL. FAILURE TO TAKE PRECAUTIONS CAN RESULT IN FROZEN TUBES SHOULD THE

UNIT BE SUBJECTED TO LOW AMBIENT CONDITIONS BEFORE PLACED IN OPERATION.

INSPECTION

A thorough inspection of the equipment, including all

component parts and accessories, should be made

immediately upon delivery. Any damage caused in

transit, or missing parts, should be reported to the

carrier at once. The consignee is responsible for

making any claim for losses or damage. Electrical

characteristics should also be checked at this time to

ensure that they are correct.

LOCATION

Before handling and placing the unit into position a

review of the most suitable location must be made.

This uid cooler is designed for outdoor installation.

A number of factors must be taken into consideration

when selecting a location. Most important is the

provision for a supply of ambient air to the uid cooler,

and removal of heated air from the uid cooler area.

Higher uid temperatures, decreased performance, and

the possibility of equipment failure may result from

inadequate air supply.

Other considerations include:

1. Customer requests

2. Loading capacity of the roof or oor.

3. Distance to suitable electrical supply.

4. Accessibility for maintenance.

5. Local building codes.

6. Adjacent buildings relative to noise levels.

WALLS OR OBSTRUCTIONS

All sides of the unit must be a minimum of 4 feet

(1.25 m) away from any wall or obstruction.

Overhead obstructions are not permitted. If enclosed

by three walls, the uid cooler must be installed as

indicated for units in a pit.

4 ft

(1.25 m)

min

UNITS IN PITS

The top of the uid cooler must be level with, or

above the top of the pit. In addition, a minimum of 8

feet (2.5 m) is required between the unit and the pit

walls.

MULTIPLE UNITS

A minimum of 8 feet (2.5 m) is required between

multiple units placed side by side. If placed end to end,

the minimum distance between units is 4 feet (1.25 m).

8 ft

(2.5 m)

min

LOUVERS/FENCES

Louvers/fences must have a minimum of 80% free area

and 4 feet (1.25 m) minimum clearance between the

unit and louvers/fence. Height of louver/fence must not

exceed top of unit.

8 ft

(2.5 m)

min

8 ft

(2.5 m)

min

4 ft

(1.25 m)

min

4 ft

(1.25 m)

min

Page 17

INSTALLATION (cont’d)

T60-TFL-PDI

- 17 -

01/16/11

TFM 60Hz

LIFTING INSTRUCTIONS

Air cooled uid coolers are large, heavy mechanical

equipment and must be handled as such. A fully

qualied and properly equipped crew with necessary

rigging should be engaged to set the uid cooler into

position. Lifting holes have been provided at the corners

or along sides for attaching lifting slings. Spreader bars

must be used when lifting so that lifting forces are

applied vertically. See Fig. 2. Under no circumstances

should the coil headers or return bends be used in

lifting or moving the uid cooler.

FIG. 2

FIG. 1

LEG INSTALLATION INSTRUCTIONS

Ensure the unit is placed in a level position (to ensure

proper drainage of uid). The legs should be securely

anchored to the building structure, sleeper or concrete

pad. The weight of the uid cooler alone is not enough

to hold in place during a strong wind, the legs must be

anchored.

1) Assemble centre leg as shown.

Remove two bolts from bottom ange of unit side panels

that match the hole pattern on the top anges of both legs.

Attach center legs using hardware provided at center

divider panel location.

Replace bolts that were removed from from side panels

to secure leg assembly to bottom anges of unit side panels.

2) Assemble four corner legs to bottom anges

on unit side panels and end panels using hardware

provided, at matching mounting hole patterns.

All legs are the same.

Page 18

TFM

T60-TFL-PDI

- 18 -

01/16/11

INSTALLATION (cont’d)

60Hz

ELECTRICAL WIRING

All wiring and connections to the air cooled uid cooler must

be made in accordance with the National Electrical Code

and all local codes and regulations. Any wiring diagrams

shown are basic and do not necessarily include electrical components which must be eld supplied. (see pages

7,8,10 for typical wiring diagrams).

Refer to the Electrical Specications table on pages 5, 9 for

voltage availability and entering service requirements.

SYSTEM START-UP CHECKS

1. Check the electrical characteristics of all components

to be sure they agree with the power supply.

2. Check tightness of all fans and motor mounts.

3. Check tightness of all electrical connections.

4. Upon start-up, check fans for correct rotation. Air is

drawn through the condenser coil. To change rotation

on 3 phase units reverse any two (2) fan motor leads.

5. All system piping must be thoroughly leak checked

before a refrigerant charge is introduced.

HYDRONIC SYSTEM COMPONENTS

MAINTENANCE

A semi annual inspection should be carried out by a

qualied refrigeration service mechanic. The main power

supply must be disconnected.

1. Check electrical components. Tighten any loose

connections.

2. Check control capillary tubes and lines for signs of

wear due to excessive vibration or rubbing on metal

parts. Secure if necessary.

3. Check tightness of all fans and motor mounts.

Remove any deposits which could effect fan balance.

Note: Fan motors are permanently lubricated and

require only visual inspection.

4. Clean the uid cooler coil using a soft brush or by

ushing with cool water or coil cleansers available

through NRP (National Refrigeration Products Inc.)

5. Update service log information (back page of service

manual)

PIPING CONSIDERATIONS

1. All piping must comply with local city and plumbing

codes.

2. Correct choice of pipe material, diameter, velocity and

friction loss (pressure drop) can result in glycol systems

running at peak efciency and performance and hence

least cost.

3. Studies have indicated that iron pipes are most

susceptible to corrosion, followed by galvanized steel,

lead, copper and copper alloys (i.e brass). PVC is

generally no-corrosive.

4. Good glycol system design therefore requires that

Galvanized Pipe NOT be used and a glycol manufac turer provide the appropriate Corrosion Inhibitor.

5. Parallel, Direct and Reverse Return piping (see

illustration on page 23) networks are the most common

used as they allow the same temperature uid to be

available to all loads and heat rejection devices (Fluid

Coolers). Actual piping should be determined by a

qualied hydronic system designer, based on site and

design requirements.

6. Isolation Valves should be provided for easy removal of

hydronic system components, for repair, maintenance or

replacement.

7. All piping should be leak tested after installation.

8. A pressure reducing valve should not be used in a glycol

hydronic system.

PUMPING SYSTEM

Pumps

1. Mechanical seal type pumps must be used for glycol

systems.

2. Pumps are selected based on Total System Flow and

Total Friction Loss (Highest Pressure Drop) through:

a. The Fluid Cooler

b. The Load (Chiller, CRAC Unit, etc)

c. Supply/Return Glycol Piping, Valves & Fittings

The Sum of the above is the “Total Head” or Pressure

Drop of the system, typically measured in ft-H2O.

3. This is a closed loop system. A counterhead acts on the

pump suction so no allowance is required for vertical lift

as in an open loop (i.e Open Cooling Tower) system.

4. Many hydronic system designers are specifying and

many end-users are purchasing “Pump Packages”.

These Pump Packages come ready for nal pipe and

electrical connection, allowing the installer to focus on

overall pipe connections.

5. Pumps in Parallel are recommended for standby

operation where pump failure may interfere with a

critIcal application ( i.e Data Center Cooling - N + 1

Design).

Page 19

HYDRONIC SYSTEM COMPONENTS

Manual Isolation Valves

Chiller Condenser

Common

Options

Common

Options

Common Options:

Closed Loop System

• Valves, Sensors & Gauges

T60-TFL-PDI

- 19 -

01/16/11

(cont’d)

TFM 60Hz

PUMPING SYSTEM (cont’d)

Expansion Tanks

As ambient temperature changes so does uid density.

System pressure is maintained within an acceptable range

with an Expansion Tank. The expansion tank allows for

the expansion and contraction of the glycol due to the

temperature change in the closed loop system. Expansion

tanks are typically sized based on a percentage of the total

system volume.

Air Separators

Air Separators are designed to remove entrained air allowing the pumps, valves and heat transfer mediums to

operate and transfer energy more efciently.

Other Common Hydronic System Options

Depending on the complexity of the hydronic system other

system components and devices may be specied such as

• Flow, Pressure Gauges and /or Switches

• Isolation and other Valves

• Strainers

Selecting Glycol

Inhibited Propylene or Ethylene Glycol Solutions ranging

from 30 to 50 % are the most commonly used. 30 % is

the minimum amount for inhibitors to be effective. For

freeze protection amounts, see the following guide. (Consult Glycol supplier for most accurate data)

%

By Volume

30 5 (-15) 9 (-17.7)

40 -10 (-23.3) 5 (-15)

50 -32 (-35.5) -29 (-33.8)

Ethylene Glycol Propylene Glycol

Freeze Point °F (°C)

Typical Hydronic System Heat Rejection Closed Loop

c/w Fluid Coolers

Fluid Cooler(s)

Piped in Parallel

Reverse Return

(shown for illustrative purposes only)

Field Installed - By Others

Other components are needed in the closed

loop system to make it functional.

Common Option Examples Above :

• Expansion Tank

• Air Separator

Pump Package

Base Unit Includes:

• (1) Pump

• (1) Standby Pump

• Mounting Frame

• Control Panel

• (2) Low Pressure Switches

Process – By Others

Typically a :

• CRAC Unit Condenser

• Engine

•

These items can be

supplied, mounted and

piped to allow the

installer to focus on the

overall pipe connections.

or Cooing Coil

Page 20

PUMP PACKAGE

FLUID COOLER PARAMETERS

Altitude Above Sea Level

Entering Fluid

Total Heat of Rejection

Fluid Type

Electrical ____ V / _____ Phase / _____ Hz

Leaving Fluid

Note: Of EFT, LFT, Fluid Flow and THR - 3 of the

Design Ambient Air

Temperature

Tamb = ____ °F

PUMP PACKAGE PARAMETERS

Total System

Fluid Flow

Fluid Type

%

Total System

Drop

Altitude Above Sea Level

Pressure Drop

Exchanger

T60-TFL-PDI

- 20 -

01/16/11

TFM 60Hz

SELECTION PARAMETERS

To select a Fluid Cooler the following must be known:

Temperature

EFT = ____ °F

(THR) Required

________________ Btu/Hr

( Fluid Cooler Capacity)

Fluid Flow Rate

________ gpm

Ethylene Glycol ______ % or Propylene Glycol ______ %

4 Parameters must be known to make a selection

ASL = _______ ft

(Only if 2,000 ft and above )

At The Fluid Cooler

Temperature

LFT = ____ °F

To select a Pump Package the following must be known:

Head

________ ft-H2O

= +

Rate

________ gpm

Electrical ____ V / _____ Phase / _____ Hz

Ethylene Glycol ______

or

Propylene Glycol ______ %

Volume

________ Gal

= +

Highest

Fluid Cooler

Pressure

____ ft-H2O

Internal

Volume of

Fluid Cooler

_____ Gal

Highest Evaporator

Unit Heat Exchanger

(i.e Cond. As per

below in Chiller)

____ ft H

Glycol/Water

Cooled

E

V

A

P

Internal Volume of

Evaporator Unit Heat

______ Gal

ASL = _______ ft

(Only If 1,000 ft and above)

Pressure Drop of

Supply & Return

+

Glycol Piping +

All Valves &

Fittings

O

2

C

O

N

D

+

_____ ft-H

Internal Volume of

Supply & Return

Glycol Piping + All

Valves & Fittings

_____ Gal

O

2

Page 21

GENERIC SERVICE PARTS

T60-TFL-PDI

- 21 -

01/16/11

TFM

DESCRIPTION Part No

FAN MOTOR - 208-230-460/1/60 1087070

FAN MOTOR - 575/1/60 1087071

FAN MOTOR - 208-230/3/60 1088054

FAN MOTOR - 460/3/60 1088053

FAN MOTOR - 575/3/60 1087073

MOTOR MOUNT 1086090

FAN BLADE - 26”, 30° 1087188

FAN GUARD 1086091

RAIN SHIELD 1085266

LEGS

24” 1086150

36” 1086151

48” 1086152

ANGLE BRACE (36” & 48” LEGS) * 1086153

CROSS BRACE ** 1086154

* 1 Per Leg On Single Fan Wide

** 2 Per Unit On 1, 2 & 3 Fan Models, 3 Per Unit On 1 X 4 Fan Models (Not Req’d On Double Wide)

60Hz

NOTE: Refer to unit service parts label for optional components not listed on this page.

Page 22

PARAMETERS FOR SELECTION OF A FLUID COOLER

T60-TFL-PDI

- 22 -

01/16/11

Fluid Type: □ Water □ Ethylene Glycol / Water

□ Propylene Glycol / Water

Elevation: ___________ Feet Above Sea Level

Fluid Concentration: ___________%Water ___________%Glycol

Air Inlet (ambient temp.) __________ ºF

Three of the four following parameters must be specied:

1. Required Capacity __________ Btu/h 2. Fluid Inlet Temperature __________ ºF

3. Fluid Flow Rate __________ GPM 4. Fluid Outlet Temperature __________ ºF

Other Items To Specify:

1. Voltage (S2 = 208-230/1/60 S4 = 460/1/60 S5 = 575/1/60

T3 = 208-230/3/60 T4 = 460/3/60 T5 = 575/3/60) ______Specify S2,S4, S5,T3,T4 or T5

2. Please Specify (Check Box) Options Required:

Control Voltage 240V (Standard) Variable Speed EC Motor

Control Voltage 120V Extended leg kits 36”

Control Voltage 24V Extended leg kits 48”

Fan Cycling Ambient Thermostat Gold Coat Fin

Fan Cycling Aquastat Thermostat Copper Fin

Fan Cycling Control by Others Heresite Coating

Non-fused disconnect 50 Hz

Horizontal air discharge conguration

Customer Info:

Name: ______________________ Telephone Number: _____________________

Fax: ______________________ Email: ______________________

Fax or email completed sheet to your sales representative.

Page 23

Finished Goods Warranty

T60-TFL-PDI

- 23 -

01/16/11

The terms and conditions as described below in the General Warranty Policy cover all products

manufactured by National Refrigeration.

GENERAL WARRANTY POLICY

Subject to the terms and conditions hereof, the Company warrants all Products, including Service Parts,

manufactured by the Company to be free of defects in material or workmanship, under normal use and

application for a period of one (1) year from the original date of installation, or eighteen (18) months from

the date of shipment from the Company, whichever occurs rst. Any replacement part(s) so supplied will

be warranted for the balance of the product’s original warranty. The part(s) to be replaced must be made

available in exchange for the replacement part(s) and reasonable proof of the original installation date of

the product must be presented in order to establish the effective date of the warranty, failing which, the effective date will be based upon the date of manufacture plus thirty (30) days. Any labour, material, refrigerant, transportation, freight or other charges incurred in connection with the performance of this warranty

will be the responsibility of the owner at the current rates and prices then in effect. This warranty may be

transferred to a subsequent owner of the product.

THIS WARRANTY DOES NOT COVER

(a) Damages caused by accident, abuse, negligence, misuse, riot, re, ood, or Acts of God (b) damages

caused by operating the product in a corrosive atmosphere (c) damages caused by any unauthorized

alteration or repair of the system affecting the product’s reliability or performance (d) damages caused

by improper matching or application of the product or the product’s components (e) damages caused by

failing to provide routine and proper maintenance or service to the product (f) expenses incurred for the

erecting, disconnecting, or dismantling the product (g) parts used in connection with normal maintenance,

such as lters or belts (h) products no longer at the site of the original installation (i) products installed or

operated other than in accordance with the printed instructions, with the local installation or building codes

and with good trade practices (j) products lost or stolen.

No one is authorized to change this WARRANTY or to create for or on behalf of the Company any

other obligation or liability in connection with the Product(s). There is no other representation, warranty

or condition in any respect, expressed or implied, made by or binding upon the Company other than the

above or as provided by provincial or state law and which cannot be limited or excluded by such law, nor

will we be liable in any way for incidental, consequential, or special damages however caused.

The provisions of this additional written warranty are in addition to and not a modication of or subtraction

from the statutory warranties and other rights and remedies provided by Federal, Provincial or State laws.

PROJECT INFORMATION

System

Model Number Date of Start-Up

Serial Number Service Contractor

Refrigerant Phone

Electrical Supply Fax

Page 24

“AS BUILT” SERVICE PARTS LIST

01/16/11

Service Parts List

Label

To Be Attached

HERE

NATIONAL REFRIGERATION & AIR CONDITIONING CANADA CORP.

159 Roy Blvd. Brantford Ontario, Canada N3R 7K1

PHONE: (519) 751-0444 800-463-9517 FAX (519) 753-1140

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

Loading...

Loading...