Page 1

PRODUCT DATA &

05/08/15

INSTALLATION

One to Fourteen Fan Motors

TCL-LINE

AIR COOLED

CONDENSERS

R407A

R22

R407C

R410A

R404A

R134a

R507

Electrical Power:

208-230/3/60, 460/3/60, 575/3/60

Bulletin T50-TCL-PDI-4

1089597

?

Questions about this product?

Email: acc-fc@t-rp.com

Call: 1-844-893-3222 x526

Page

CONTENTS

Nomenclature............................................. 2

Features & Options.................................... 2

Standard Motors

850 RPM Motors:

Capacity Data......................................... 3 - 4

Electrical Data........................................ 5

General Specications........................... 6 - 7

1140 RPM Motors:

Capacity Data......................................... 8 - 9

Electrical Data........................................ 10

General Specications........................... 11 - 12

550 RPM Motors:

Capacity Data......................................... 13 - 14

Electrical Data........................................ 15

General Specications........................... 16 - 17

Wiring Diagrams......................................... 18 - 20

Comparative Sound Data................................. 21

?

INCLUDES RATINGS FOR

EC Motors Page

About EC Motors................................ 22

Power Consumption Comparison....... 22

Capacity Data...................................... 23 - 24

Electrical Data..................................... 25

General Specications........................ 26 - 27

EC Motor Application.......................... 28

Wiring Diagrams................................. 29 -30

Dimensional Data (All Models)............ 31 - 34

Condenser Theory ............................... 35

Glossary of Terms............................... 35 - 36

Condenser Selection........................... 36 - 40

Low Ambient Operation....................... 42 - 47

Installation........................................... 48 - 51

Service Parts...................................... 52

Warranty.............................................. 55

Project Information.............................. 55

“As Built” Service Parts List................. BACK

Page 2

Brand Name:

05/08/15

T50-TCL-PDI-4

- 2 -

T = Trenton

Product name

CL = Large Sized Condenser

Nominal Tons (R404A, 25°F TD, 60Hz)

Voltage

T3 = 208-230/3/60

T4 = 460/3/60

T5 = 575/3/60

T7 = 200-220/3/50

T9 = 380-400/3/50

Design version

STANDARD FEATURES INCLUDE

NOMENCLATURE

T CL 230 - T3 A - A 2 7 V - XXXX

Optional Sufx

Does Not Affect Design

Application

V = Vertical Air Discharge

H = Horizontal Air Discharge

Fans Deep

Fans Wide

1 = Inline; 2 = Double Wide

Motor

A = 850 RPM, 1 HP Motor

B = 550 RPM, 1/2 HP Motor

C = 1140 RPM, 2 HP Motor

E = EC Motor - Packaged Assembly

M = EC Motor - Motor Only

(Conventional Shafted Style Motor)

• Compatable with Low GWP Refrigerants

• Internally Enhanced Tube

• Narrow width condenser design to suit shipment in

containers.

• THERMOSPANTM coil design feature eliminates tube

failure on tube sheets.

• Enhanced Copper Tube, (3/8 O.D. on 1-6 Fan, 1/2 O.D.

on 8-14 Fan) Aluminum Fin Condenser Coils

• Standard 850 RPM quiet low speed fan motors

with male electrical plug, moisture slinger, and rainshield

for complete weather protection.

• Swept wing fan for quiet operation and optimal efciency

• Rugged heavy-gauge galvanized steel rail

motor mounts / support.

OPTIONAL FEATURES

• Multiple refrigeration circuits

• Fan Cycling – Ambient thermostat / fan row

with contactors

• All fan sections individually bafed with full

height partitions, and clean-out panels.

• Complete selection of electrical fan cycling and

speed control options.

• Heavy-gauge galvanized steel cabinet

construction assembled with zinc plated huck

bolts supported on heavy-duty legs.

• 2-Fan wide units have two equal circuits

• Terminal block

• Single entering electrical service

• Control circuit voltage – 230 V

• Control circuit transformer where applicable

• Variable Speed EC Motors which provide optimum

efciency and sound levels (see pg. 22-34 for details)

• Adjustable ooded head pressure control

• Fan Cycling – Pressure control / fan row

with contactors

• Variable speed motor with controller

for header fan motors

• Individual fan motor fusing

• Individual ambient thermostat or pressure control

• Non-fused disconnect

• Horizontal air discharge conguration

• Extended leg kits (36” or 48”) with cross bracing for

extra rigidity

• Optional 550 ultra low and 1140 RPM high

speed motors available.

• Optional n materials

• Optional coil coating

• Voltages available for 60Hz or 50Hz

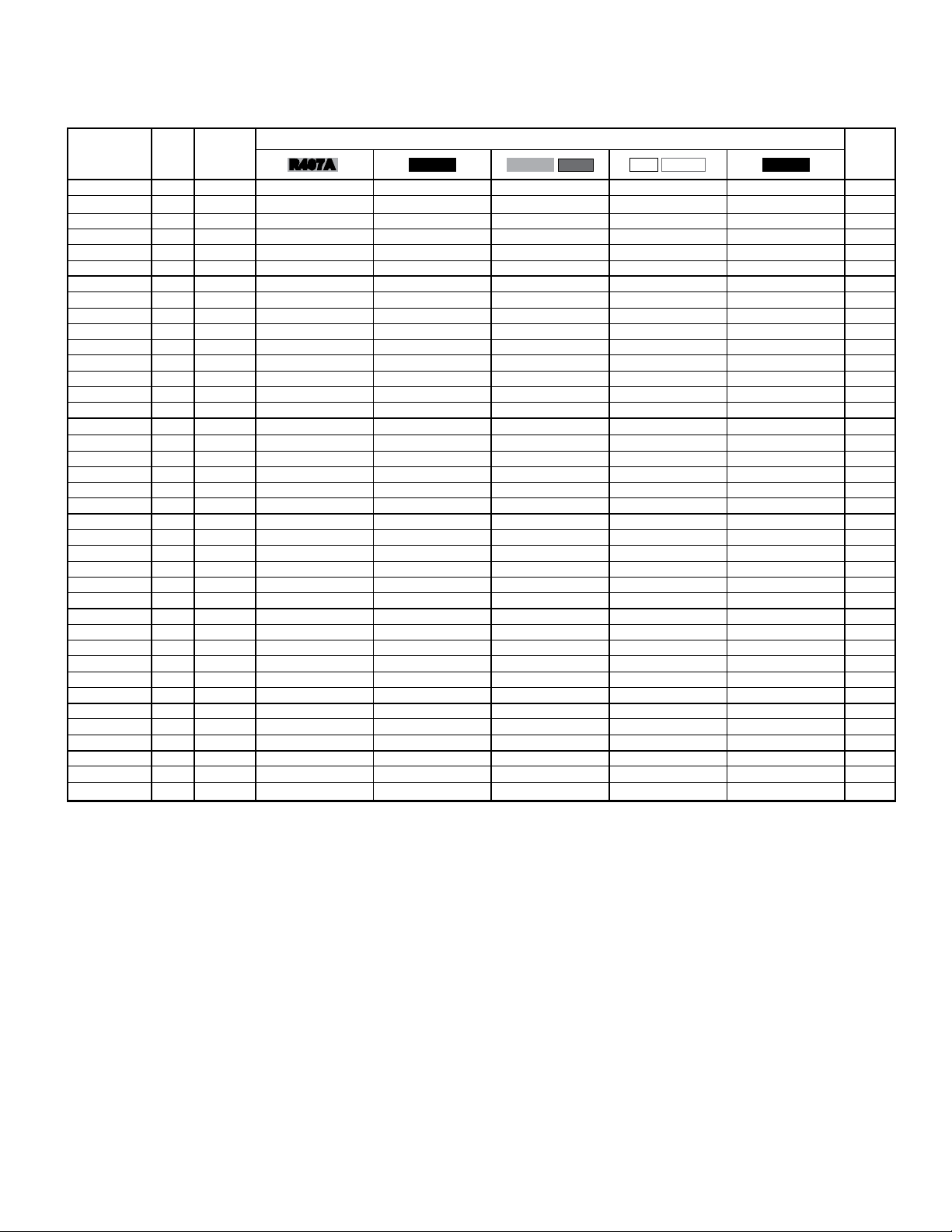

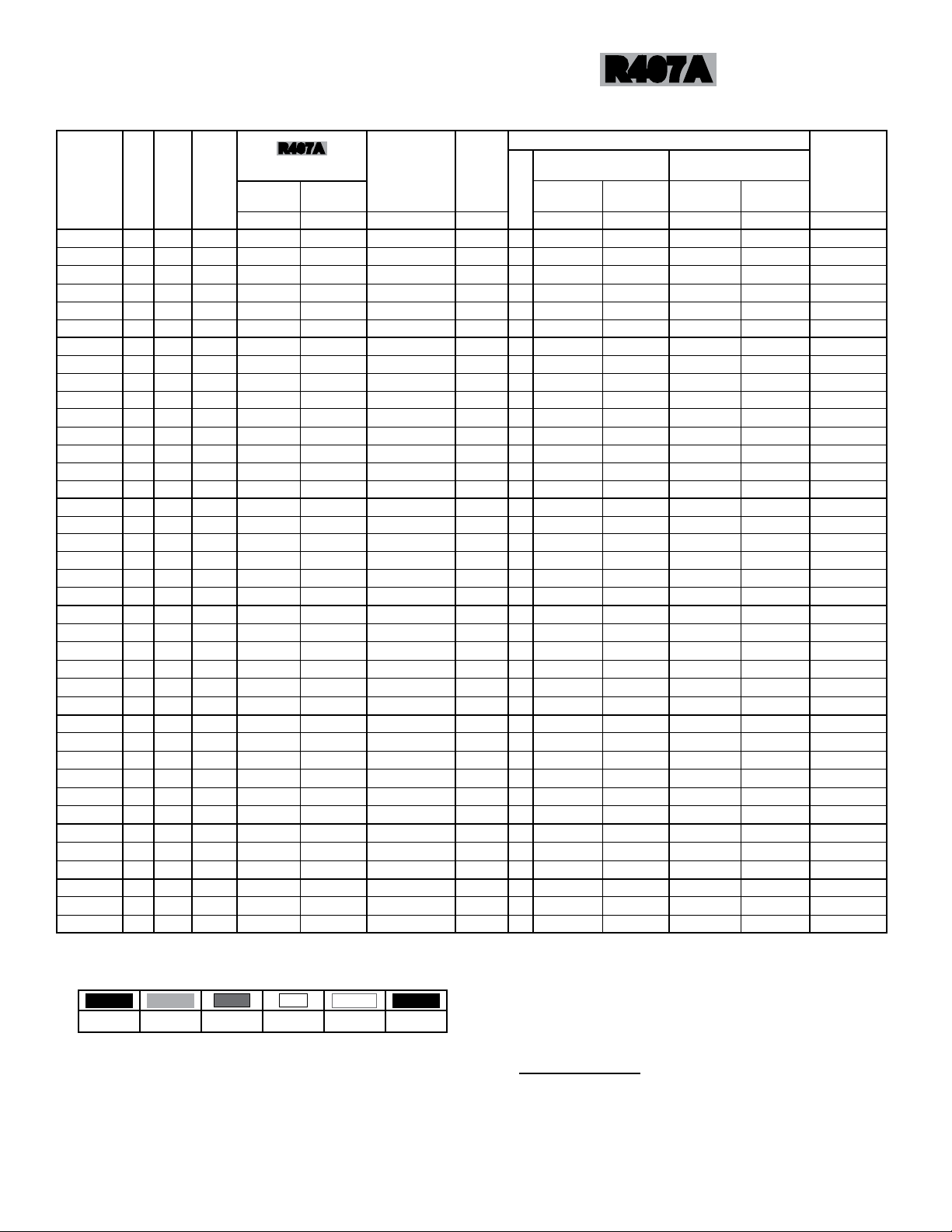

Page 3

TCL

05/08/15

T50-TCL-PDI-4

- 3 -

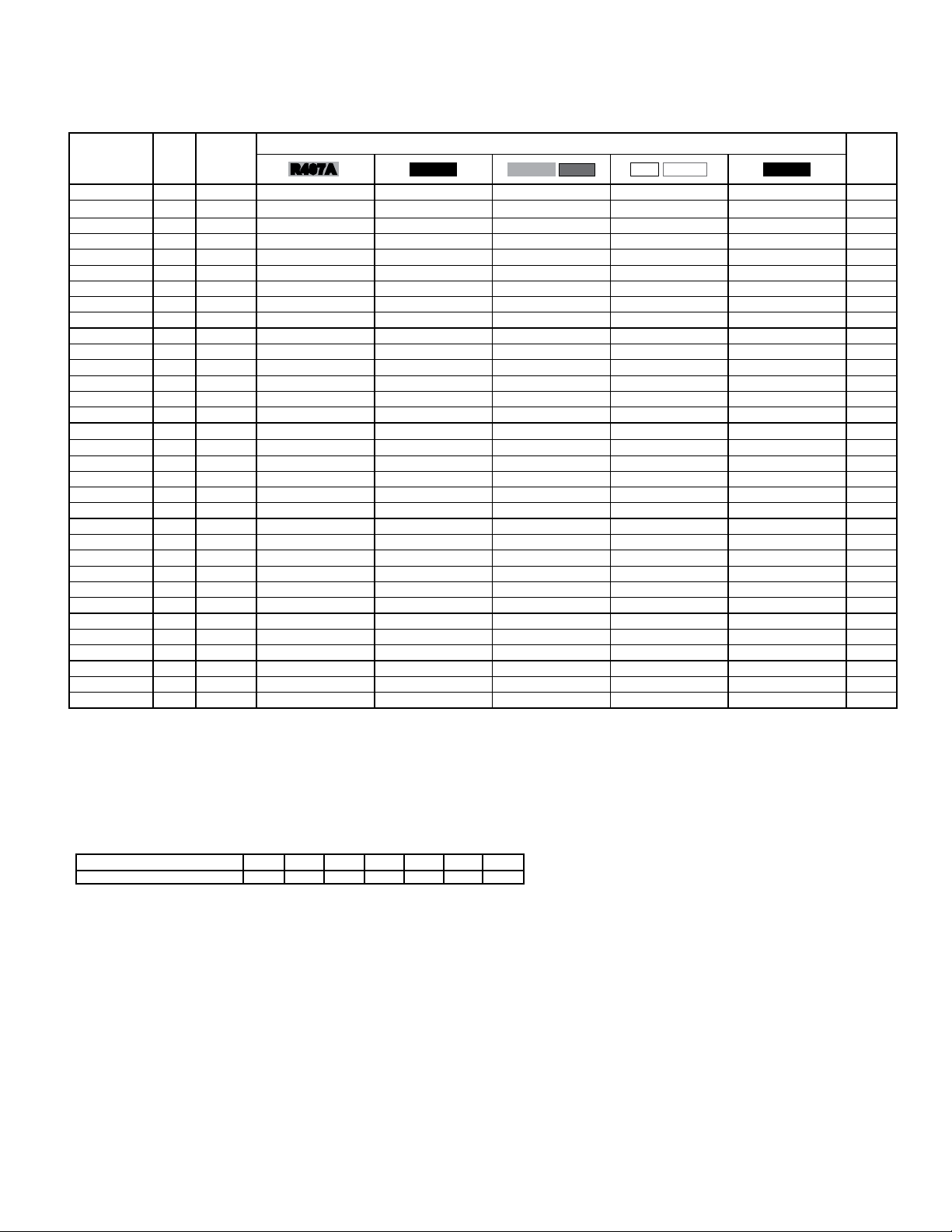

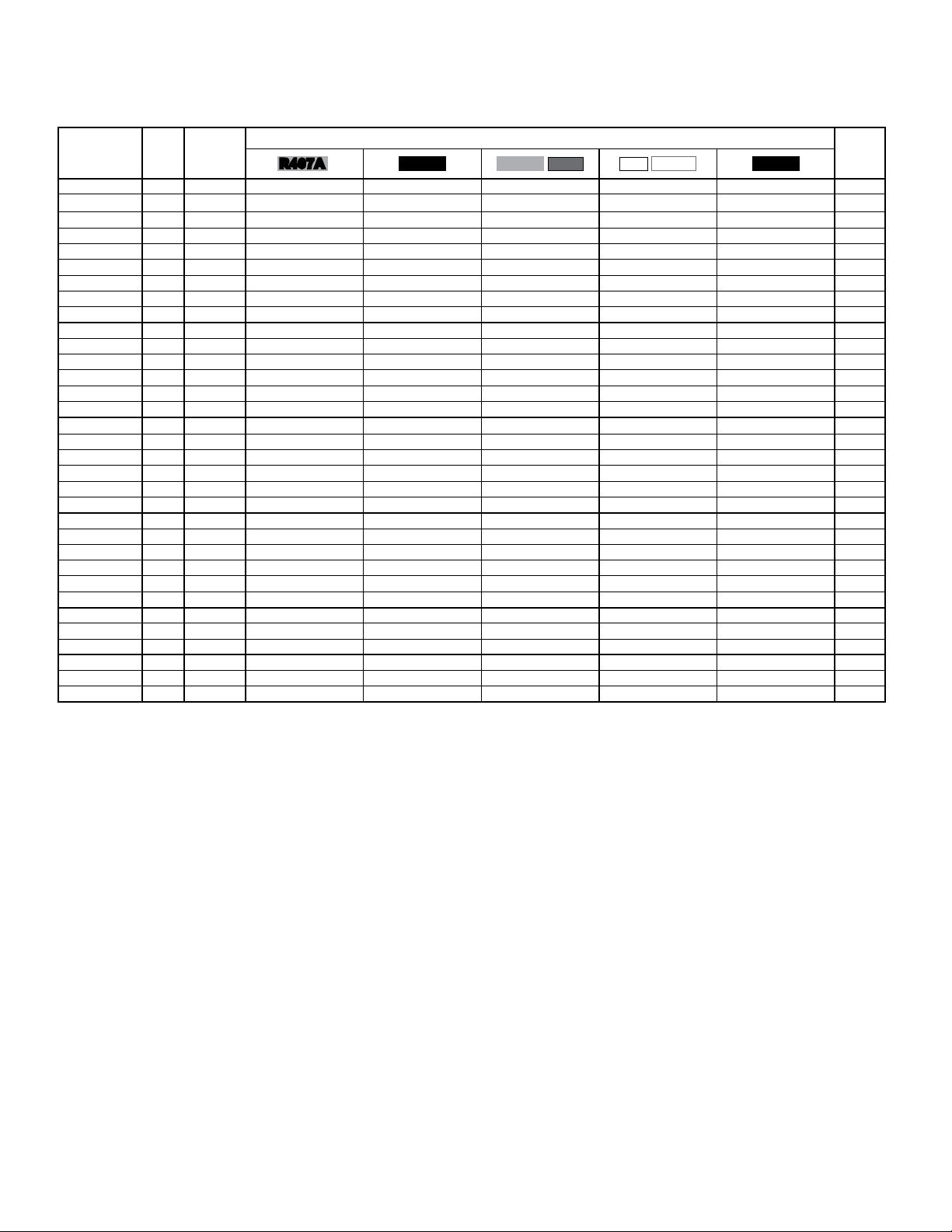

CAPACITY DATA -

SINGLE ROW MODELS

850 RPM

60Hz

MODEL

NO.

TCL 012 8 1 x 1 5.40 (1.58) 5.58 (1.63) 5.87 (1.72) 5.99 (1.75) 5.69 (1.67) 7

TCL 013 10 1 x 1 5.90 (1.73) 6.09 (1.79) 6.41 (1.88) 6.54 (1.92) 6.22 (1.82) 7

TCL 014 12 1 x 1 6.27 (1.84) 6.48 (1.90) 6.82 (2.00) 6.96 (2.04) 6.62 (1.94) 7

TCL 015 8 1 x 1 6.36 (1.87) 6.56 (1.93) 6.91 (2.03) 7.05 (2.07) 6.70 (1.97) 8

TCL 016 10 1 x 1 6.86 (2.01) 7.09 (2.08) 7.46 (2.19) 7.61 (2.23) 7.24 (2.12) 8

TCL 017 12 1 x 1 7.15 (2.10) 7.38 (2.17) 7.77 (2.28) 7.93 (2.33) 7.54 (2.21) 8

TCL 019 8 1 x 2 8.29 (2.43) 8.56 (2.51) 9.01 (2.64) 9.19 (2.69) 8.74 (2.56) 9

TCL 021 10 1 x 2 9.30 (2.72) 9.60 (2.81) 10.11 (2.96) 10.31 (3.02) 9.81 (2.87) 9

TCL 023 12 1 x 2 10.11 (2.96) 10.44 (3.06) 10.99 (3.22) 11.21 (3.28) 10.66 (3.12) 9

TCL 024 8 1 x 2 10.79 (3.16) 11.14 (3.27) 11.73 (3.44) 11.96 (3.51) 11.38 (3.34) 14

TCL 027 10 1 x 2 11.79 (3.46) 12.18 (3.57) 12.82 (3.76) 13.08 (3.84) 12.44 (3.65) 14

TCL 028 12 1 x 2 12.55 (3.68) 12.96 (3.80) 13.64 (4.00) 13.91 (4.08) 13.23 (3.88) 14

TCL 029 8 1 x 2 12.53 (3.67) 12.94 (3.79) 13.62 (3.99) 13.89 (4.07) 13.21 (3.87) 18

TCL 031 10 1 x 2 13.52 (3.97) 13.97 (4.09) 14.7 (4.31) 14.99 (4.40) 14.26 (4.18) 18

TCL 032 12 1 x 2 14.09 (4.13) 14.54 (4.27) 15.31 (4.49) 15.62 (4.58) 14.85 (4.36) 18

TCL 037 8 1 x 3 16.19 (4.75) 16.72 (4.90) 17.6 (5.16) 17.95 (5.26) 17.07 (5.01) 21

TCL 040 10 1 x 3 17.69 (5.19) 18.27 (5.36) 19.23 (5.64) 19.61 (5.75) 18.65 (5.47) 21

TCL 042 12 1 x 3 18.82 (5.52) 19.44 (5.70) 20.46 (6.00) 20.87 (6.12) 19.85 (5.82) 21

TCL 043 8 1 x 3 19.14 (5.61) 19.76 (5.80) 20.8 (6.10) 21.22 (6.22) 20.18 (5.92) 28

TCL 047 10 1 x 3 20.64 (6.05) 21.32 (6.25) 22.44 (6.58) 22.89 (6.71) 21.77 (6.38) 28

TCL 049 12 1 x 3 21.51 (6.30) 22.21 (6.51) 23.38 (6.85) 23.85 (6.99) 22.68 (6.64) 28

TCL 051 8 1 x 4 22.59 (6.61) 23.32 (6.83) 24.55 (7.19) 25.04 (7.33) 23.81 (6.97) 21

TCL 056 10 1 x 4 24.68 (7.23) 25.49 (7.47) 26.83 (7.86) 27.37 (8.02) 26.03 (7.62) 21

TCL 059 12 1 x 4 26.26 (7.70) 27.11 (7.95) 28.54 (8.37) 29.11 (8.54) 27.68 (8.12) 21

TCL 060 8 1 x 4 26.36 (7.73) 27.22 (7.98) 28.65 (8.40) 29.22 (8.57) 27.79 (8.15) 28

TCL 064 10 1 x 4 28.44 (8.34) 29.36 (8.61) 30.91 (9.06) 31.53 (9.24) 29.98 (8.79) 28

TCL 067 12 1 x 4 29.61 (8.68) 30.58 (8.97) 32.19 (9.44) 32.83 (9.63) 31.22 (9.16) 28

TCL 063 8 1 x 5 27.78 (8.14) 28.69 (8.41) 30.2 (8.85) 30.80 (9.03) 29.29 (8.58) 21

TCL 069 10 1 x 5 30.37 (8.91) 31.36 (9.20) 33.01 (9.68) 33.67 (9.87) 32.02 (9.39) 21

TCL 073 12 1 x 5 32.31 (9.47) 33.36 (9.78) 35.12 (10.29) 35.82 (10.50) 34.07 (9.98) 21

TCL 075 8 1 x 5 33.14 (9.72) 34.22 (10.03) 36.02 (10.56) 36.74 (10.77) 34.94 (10.24) 28

TCL 081

TCL 084 12 1 x 5 37.23 (10.91) 38.45 (11.27) 40.47 (11.86) 41.28 (12.10) 39.26 (11.50) 28

TCL 089 8 1 x 6 39.37 (11.54) 40.65 (11.91) 42.79 (12.54) 43.65 (12.79) 41.51 (12.16) 28

TCL 096 10 1 x 6 42.47 (12.45) 43.85 (12.85) 46.16 (13.53) 47.08 (13.80) 44.78 (13.12) 28

TCL 100 12 1 x 6 44.23 (12.96) 45.68 (13.39) 48.08 (14.09) 49.04 (14.37) 46.64 (13.67) 28

TCL 102 8 1 x 7 45.25 (13.26) 46.72 (13.69) 49.18 (14.41) 50.16 (14.70) 47.70 (13.98) 56

TCL 111 10 1 x 7 48.80 (14.31) 50.39 (14.77) 53.04 (15.55) 54.10 (15.86) 51.45 (15.08) 56

TCL 115 12 1 x 7 50.83 (14.89) 52.49 (15.38) 55.25 (16.19) 56.36 (16.51) 53.59 (15.70) 56

FPI

FAN

CONFIG.

10 1 x 5 35.74 (10.48) 36.91 (10.82) 38.85 (11.39) 39.63 (11.62) 37.68 (11.05) 28

R407A

TOTAL HEAT OF REJECTION - MBH (KW) PER 1 °F (0.56 °C) TD MAX.

R407C R404A

R507

R22

R410A

R134a

NO. OF

FEEDS

NOTES:

- Above capacity data based on 0oF subcooling and at sea level.

- For High Altitude applications apply the following correction factors: 0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

- Capacities at other TD within a range of 10 to 30 °F (-12.2 to -1°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

- For 50 HZ capacity multiply by 0.92.

- Capacities for R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated condensing

temperatures at the inlet and outlet of the condenser. For dew point ratings, consult factory.

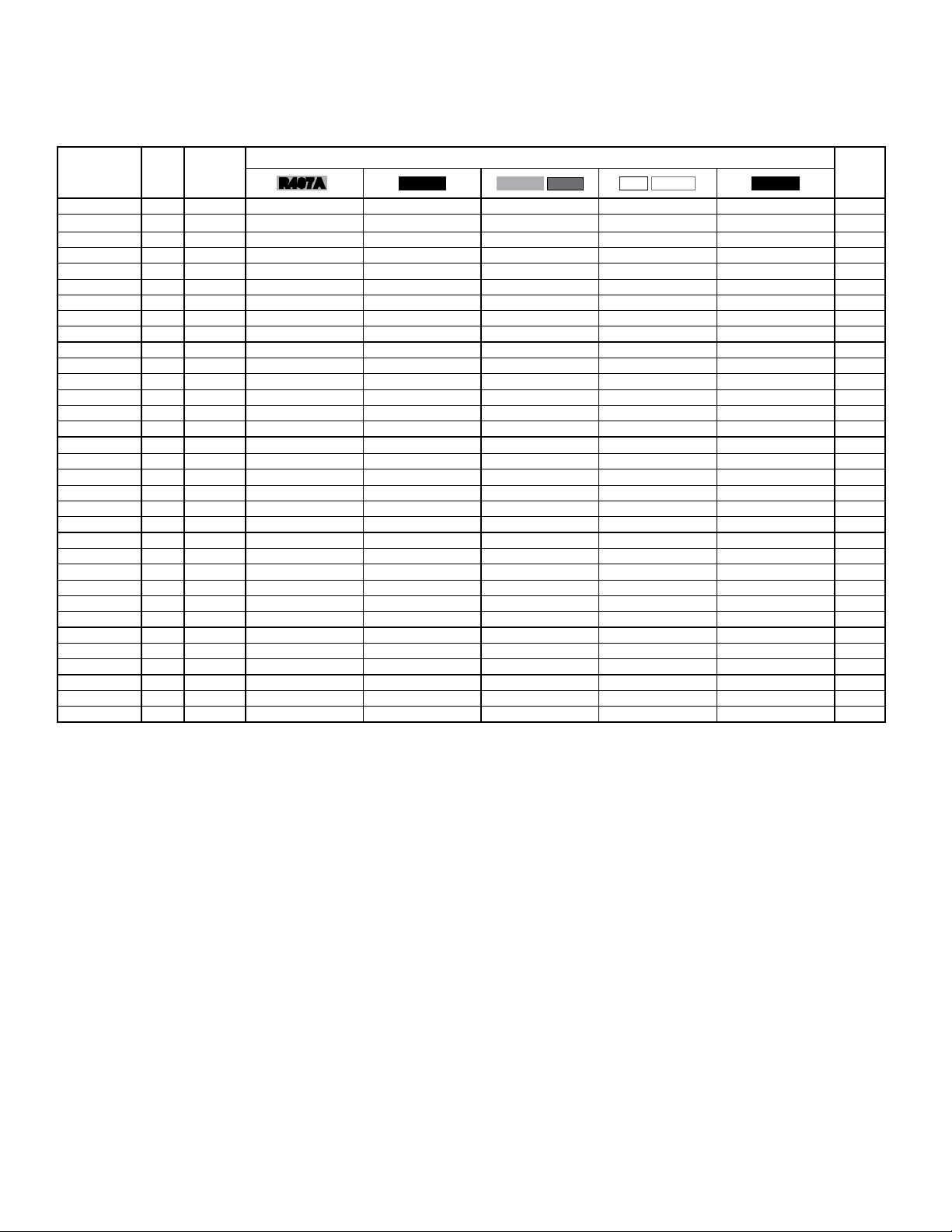

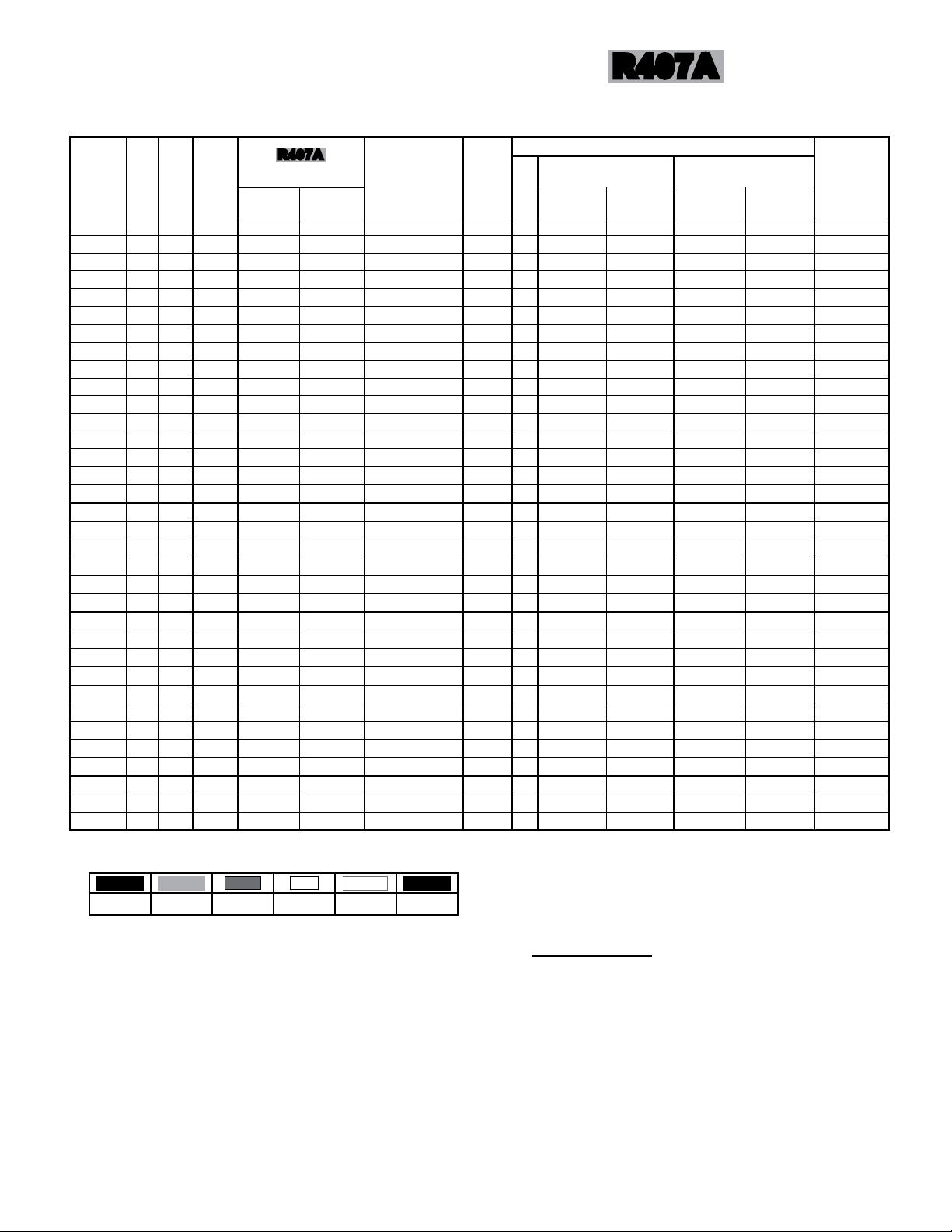

Page 4

TCL

05/08/15

T50-TCL-PDI-4

- 4 -

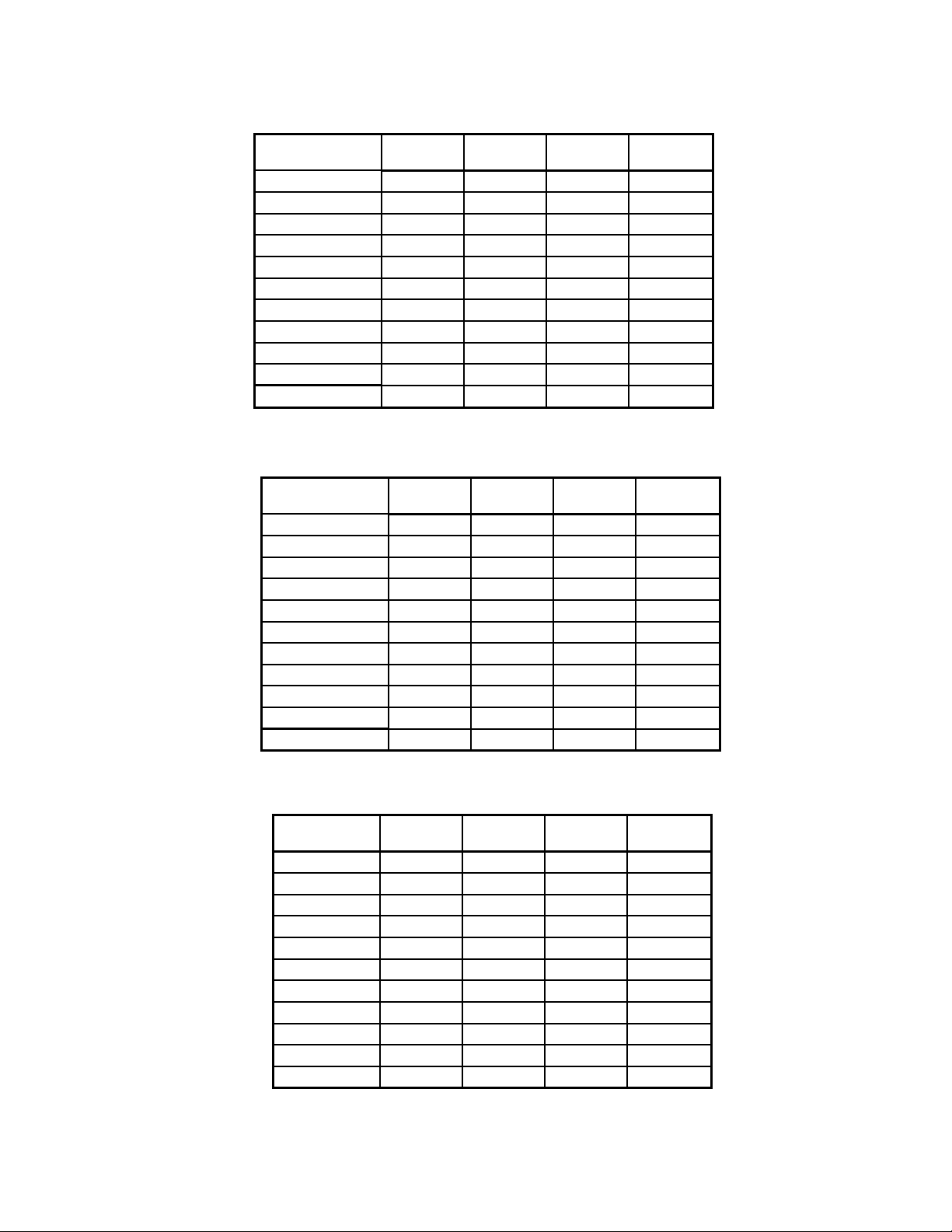

CAPACITY DATA -

DOUBLE ROW MODELS

850 RPM

60Hz

MODEL

NO.

TCL 038 8 2 x 2 16.58 (4.86) 17.12 (5.02) 18.02 (5.28) 18.38 (5.39) 17.48 (5.12) 18

TCL 041 10 2 x 2 18.60 (5.45) 19.21 (5.63) 20.22 (5.93) 20.62 (6.04) 19.61 (5.75) 18

TCL 046 12 2 x 2 20.21 (5.92) 20.87 (6.12) 21.97 (6.44) 22.41 (6.57) 21.31 (6.25) 18

TCL 048 8 2 x 2 21.58 (6.33) 22.29 (6.53) 23.46 (6.88) 23.93 (7.01) 22.76 (6.67) 28

TCL 054 10 2 x 2 23.59 (6.91) 24.36 (7.14) 25.64 (7.52) 26.15 (7.67) 24.87 (7.29) 28

TCL 057 12 2 x 2 25.10 (7.36) 25.92 (7.60) 27.28 (8.00) 27.83 (8.15) 26.46 (7.76) 28

TCL 058 8 2 x 2 25.41 (7.45) 26.24 (7.69) 27.62 (8.09) 28.17 (8.26) 26.79 (7.85) 37

TCL 062 10 2 x 2 27.41 (8.03) 28.30 (8.29) 29.79 (8.73) 30.39 (8.91) 28.90 (8.47) 37

TCL 065 12 2 x 2 28.55 (8.37) 29.48 (8.64) 31.03 (9.09) 31.65 (9.28) 30.10 (8.82) 37

TCL 072 8 2 x 3 32.37 (9.49) 33.43 (9.79) 35.19 (10.31) 35.89 (10.52) 34.13 (10.00) 42

TCL 080 10 2 x 3 35.39 (10.37) 36.55 (10.71) 38.47 (11.27) 39.24 (11.50) 37.32 (10.93) 42

TCL 085 12 2 x 3 37.65 (11.03) 38.87 (11.39) 40.92 (11.99) 41.74 (12.23) 39.69 (11.63) 42

TCL 087 8 2 x 3 38.28 (11.21) 39.53 (11.58) 41.61 (12.19) 42.44 (12.43) 40.36 (11.82) 56

TCL 094 10 2 x 3 41.29 (12.10) 42.64 (12.49) 44.88 (13.15) 45.78 (13.41) 43.53 (12.76) 56

TCL 097 12 2 x 3 43.01 (12.60) 44.41 (13.02) 46.75 (13.70) 47.69 (13.97) 45.35 (13.29) 56

TCL 103 8 2 x 4 45.16 (13.24) 46.64 (13.67) 49.09 (14.39) 50.07 (14.68) 47.62 (13.96) 42

TCL 112 10 2 x 4 49.37 (14.47) 50.98 (14.94) 53.66 (15.73) 54.73 (16.04) 52.05 (15.26) 42

TCL 119 12 2 x 4 52.51 (15.39) 54.23 (15.89) 57.08 (16.73) 58.22 (17.06) 55.37 (16.23) 42

TCL 120 8 2 x 4 52.72 (15.45) 54.44 (15.95) 57.3 (16.79) 58.45 (17.13) 55.58 (16.29) 56

TCL 129 10 2 x 4 56.87 (16.67) 58.72 (17.21) 61.81 (18.12) 63.05 (18.48) 59.96 (17.58) 56

TCL 134 12 2 x 4 59.24 (17.36) 61.17 (17.93) 64.39 (18.87) 65.68 (19.25) 62.46 (18.30) 56

TCL 126 8 2 x 5 55.57 (16.28) 57.38 (16.82) 60.4 (17.70) 61.61 (18.05) 58.59 (17.17) 42

TCL 138 10 2 x 5 60.74 (17.80) 62.72 (18.38) 66.02 (19.35) 67.34 (19.74) 64.04 (18.77) 42

TCL 146 12 2 x 5 64.62 (18.93) 66.73 (19.55) 70.24 (20.58) 71.64 (20.99) 68.13 (19.96) 42

TCL 150 8 2 x 5 66.28 (19.42) 68.44 (20.05) 72.04 (21.11) 73.48 (21.53) 69.88 (20.48) 56

TCL 162 10 2 x 5 71.49 (20.95) 73.82 (21.63) 77.71 (22.77) 79.26 (23.23) 75.38 (22.09) 56

TCL 168 12 2 x 5 74.46 (21.82) 76.89 (22.53) 80.94 (23.72) 82.56 (24.19) 78.51 (23.01) 56

TCL 178 8 2 x 6 78.73 (23.07) 81.30 (23.83) 85.58 (25.08) 87.29 (25.58) 83.01 (24.33) 56

TCL 192 10 2 x 6 84.93 (24.89) 87.69 (25.70) 92.31 (27.05) 94.16 (27.59) 89.54 (26.24) 56

TCL 200 12 2 x 6 88.47 (25.93) 91.35 (26.77) 96.16 (28.18) 98.08 (28.74) 93.28 (27.33) 56

TCL 205 8 2 x 7 90.48 (26.51) 93.43 (27.38) 98.35 (28.82) 100.32 (29.40) 95.40 (27.96) 112

221 10 2 x 7 97.61 (28.60) 100.80 (29.54) 106.1 (31.09) 108.22 (31.71) 102.92 (30.16) 112

TCL

TCL 230 12 2 x 7 101.66 (29.80) 104.98 (30.77) 110.5 (32.39) 112.71 (33.04) 107.19 (31.42) 112

FPI

FAN

CONFIG.

R407A

TOTAL HEAT OF REJECTION - MBH (KW) PER 1 °F (0.56 °C) TD MAX.

R407C R404A

R507

R22

R410A

R134a

NO. OF

FEEDS

NOTES:

- Above capacity data based on 0oF subcooling and at sea level.

- For High Altitude applications apply the following correction factors: 0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

- Capacities at other TD within a range of 10 to 30 °F (-12.2 to -1°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

- For 50 HZ capacity multiply by 0.92.

- Capacities for R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated condensing

temperatures at the inlet and outlet of the condenser. For dew point ratings, consult factory.

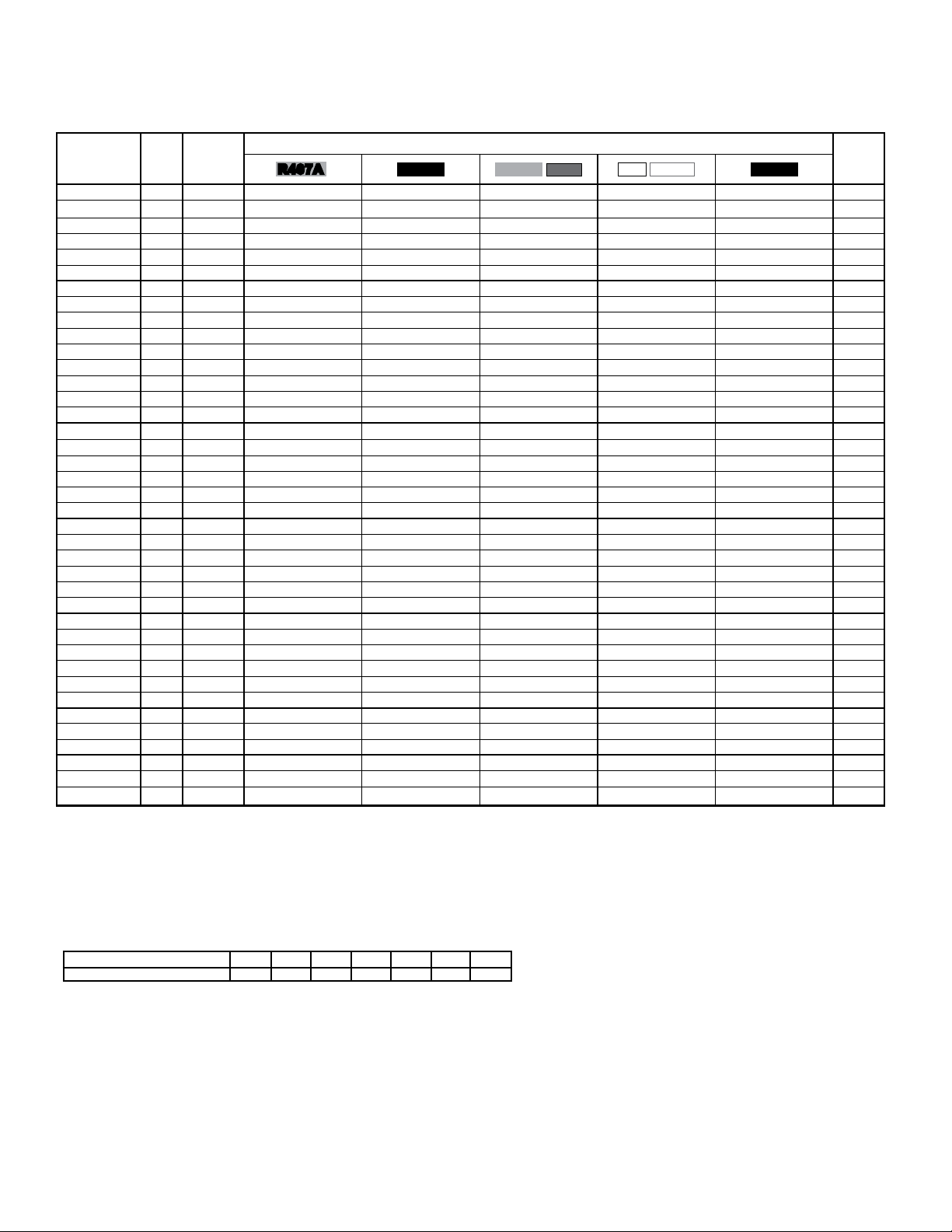

Page 5

TCL

05/08/15

T50-TCL-PDI-4

- 5 -

ELECTRICAL DATA

208-230/3/60

NO. OF FAN

MOTORS

1 4.9 6.1 15 900

2 9.8 11 15 1800

3 14.7 15.9 20 2700

4 19.6 20.8 25 3600

5 24.5 31 35 4500

6 29.4 36 40 5400

7 34.3 41 45 6300

8 39.2 46 50 7200

10 49.0 61 70 9000

12 58.8 71 80 10800

14 68.6 81 90 12600

NO. OF FAN

MOTORS

1 2.2 2.8 15 900

2 4.4 5 15 1800

3 6.6 7.2 15 2700

4 8.8 9.4 15 3600

5 11 11.6 15 4500

6 13.2 16 20 5400

7 15.4 16 20 6300

8 17.6 21 25 7200

10 22 26 30 9000

12 26.4 31 35 10800

14 30.8 36 40 12600

TOTAL FLA MCA MOP WATTS

460/3/60

TOTAL FLA MCA MOP WATTS

850 RPM

60Hz

575/3/60

NO. OF FAN

MOTORS

1 2.1 2.6 15.0 1040

2 4.2 4.7 15.0 2080

3 6.3 6.8 15.0 3120

4 8.4 8.9 15.0 4160

5 10.5 11.0 15.0 5200

6 12.6 16.0 20.0 6240

7 14.7 16.0 20.0 7280

8 16.8 21.0 25.0 8320

10 21.0 26.0 30.0 10400

12 25.2 31.0 35.0 12480

14 29.4 36.0 40.0 14560

M.C.A. = Minimum Circuit Ampacity M.O.P. = Maximum Overcurrent Protection

TOTAL FLA MCA MOP WATTS

Page 6

TCL

05/08/15

T50-TCL-PDI-4

- 6 -

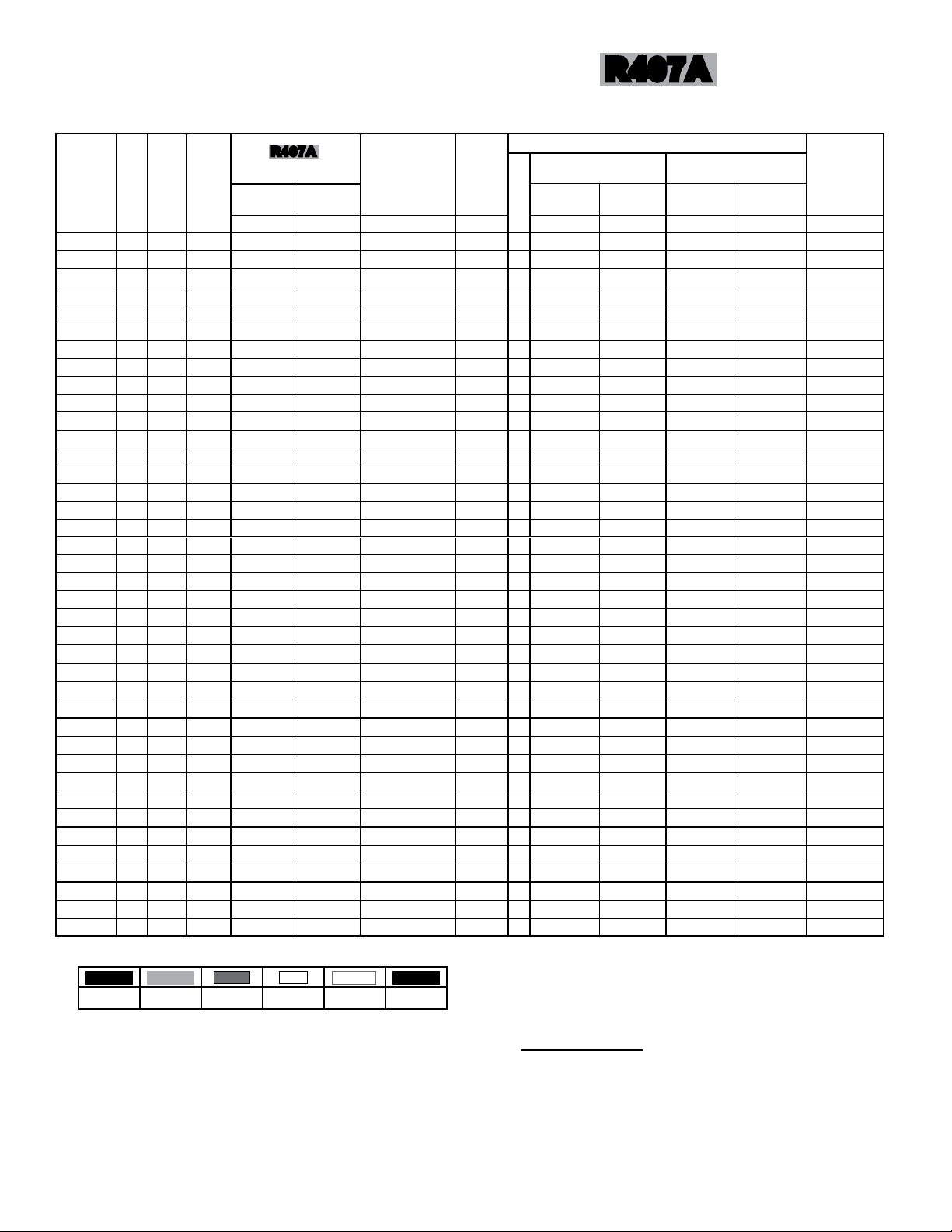

GENERAL SPECIFICATIONS -

SINGLE ROW MODELS

R407A

850 RPM

60Hz

MODEL

NO.

FPI

MAX.

NO. OF

FEEDS

FAN CONFIG.

TCL 012 8 1 x 1 7

TCL 013 10 1 x 1 7

TCL 014 12 1 x 1 7

TCL 015 8 1 x 1 8

TCL 016 10 1 x 1 8

TCL 017 12 1 x 1 8

TCL 019 8 1 x 2 9

TCL 021 10 1 x 2 9

TCL 023 12 1 x 2 9

TCL 024 8 1 x 2 14

TCL 027 10 1 x 2 14

TCL 028 12 1 x 2 14

TCL 029 8 1 x 2 18

TCL 031 10 1 x 2 18

TCL 032 12 1 x 2 18

TCL 037 8 1 x 3 21

TCL 040 10 1 x 3 21

TCL 042 12 1 x 3 21

TCL 043 8 1 x 3 28

TCL 047 10 1 x 3 28

TCL 049 12 1 x 3 28

TCL 051 8 1 x 4 21

TCL 056 10 1 x 4 21

TCL 059 12 1 x 4 21

TCL 060 8 1 x 4 28

TCL 064 10 1 x 4 28

TCL 067 12 1 x 4 28

TCL 063 8 1 x 5 21

TCL 069 10 1 x 5 21

TCL 073 12 1 x 5 21

TCL 075 8 1 x 5 28

TCL 081 10 1 x 5 28

TCL 084 12 1 x 5 28

TCL 089 8 1 x 6 28

TCL 096 10 1 x 6 28

TCL 100 12 1 x 6 28

TCL 102 8 1 x 7 56

TCL 111 10 1 x 7 56

TCL 115 12 1 x 7 56

R407A

REFRIG. CHARGE

(2)

90% FULL

NORMAL

LBS (kg) LBS (kg) CFM (m

6 (2.5) 25 (12) 9000

6 (2.5) 25 (12) 8700

6 (2.5) 25 (12) 8400

7 (3.1) 32 (14) 8500

7 (3.1) 32 (14) 8200

7 (3.1) 32 (14) 7900

8 (3.6) 36 (17) 19100

8 (3.6) 36 (17) 18400

8 (3.6) 36 (17) 17800

11 (5.1) 50 (23) 18000

11 (5.1) 50 (23) 17400

11 (5.1) 50 (23) 16800

13 (6.1) 63 (29) 17000

13 (6.1) 63 (29) 16400

13 (6.1) 63 (29) 15900

15 (6.8) 73 (33) 27000

15 (6.8) 73 (33) 26100

15 (6.8) 73 (33) 25200

21 (9.4) 96 (43) 25500

21 (9.4) 96 (43) 24600

21 (9.4) 96 (43) 23800

32 (14) 162 (74) 34900

32 (14) 162 (74) 33800

32 (14) 162 (74) 32600

41 (19) 210 (96) 33000

41 (19) 210 (96) 31900

41 (19) 210 (96) 30800

42 (19) 206 (94) 43700

42 (19) 206 (94) 42200

42 (19) 206 (94) 40800

53 (24) 266 (121) 41200

53 (24) 266 (121) 39800

53 (24) 266 (121) 38500

61 (28) 314 (143) 49400

61 (28) 314 (143) 47800

61 (28) 314 (143) 46200

69 (31) 362 (165) 57700

69 (31) 362 (165) 55800

69 (31) 362 (165) 53900

(1)

(3)

AIR

FLOW

RATES

(15290)

(14780)

(14270)

(14440)

(13930)

(13420)

(32450)

(31260)

(30240)

(30580)

(29560)

(28540)

(28880)

(27860)

(27010)

(45870)

(44340)

(42810)

(43320)

(41800)

(40440)

(59300)

(57430)

(55390)

(56070)

(54200)

(52330)

(74250)

(71700)

(69320)

(70000)

(67620)

(65410)

(83930)

(81210)

(78490)

(98030)

(94800)

(91580)

SOUND

LEVEL

(5)

3

/h) dBA IN.

QUANTITY

53 1

53 1

53 1

53 1

53 1

53 1

55 1

55 1

55 1

55 1

55 1

55 1

55 1

55 1

55 1

56 1

56 1

56 1

56 1

56 1

56 1

57 1

57 1

57 1

57 1

57 1

57 1

58 1

58 1

58 1

58 1

58 1

58 1

59 1

59 1

59 1

59 1

59 1

59 1

PIPING CONNECTIONS

16°F to 30°F

DESIGN TD

10°F to 15°F

DESIGN TD

INLET OUTLET INLET OUTLET

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

(mm)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(79)

(79)

(79)

(79)

(79)

(79)

IN.

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

(mm)

(29)

(29)

(29)

(29)

(29)

(29)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

IN.

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

(mm)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

IN.

7/8

7/8

7/8

7/8

7/8

7/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

(mm)

(22)

(22)

(22)

(22)

(22)

(22)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

APPROX.

SHIPPING

WEIGHT

LBS (kg)

(161)

355

(164)

360

(168)

370

(173)

380

(177)

390

(182)

400

(302)

665

(305)

670

(309)

680

(323)

710

(327)

720

(336)

740

(350)

770

(355)

780

(364)

800

(477)

1050

(489)

1075

(500)

1100

(523)

1150

(534)

1175

(545)

1200

(648)

1425

(659)

1450

(670)

1475

(693)

1525

(705)

1550

(727)

1600

(784)

1725

(818)

1800

(841)

1850

(875)

1925

(886)

1950

(909)

2000

(1034)

2275

(1045)

2300

(1068)

2350

(1216)

2675

(1227)

2700

(1250)

2750

(1) Refrigerant charge conversion factors:

(2) Normal charge is the refrigerant charge for warm ambient or summer operation.

(3) 90% full is the liquid refrigerant weight at 90% of internal volume and is for reference only.

(4) For 50 Hz fan data use 60 Hz CFM (m3/h) X 0.83

(5) Sound pressure level at 30 ft. (10 m) See page 21 for more data

R407C R404A

R507

R22

R410A

1.0 0.91 0.91 1.05 0.92 1.06

R134a

Page 7

TCL

05/08/15

T50-TCL-PDI-4

- 7 -

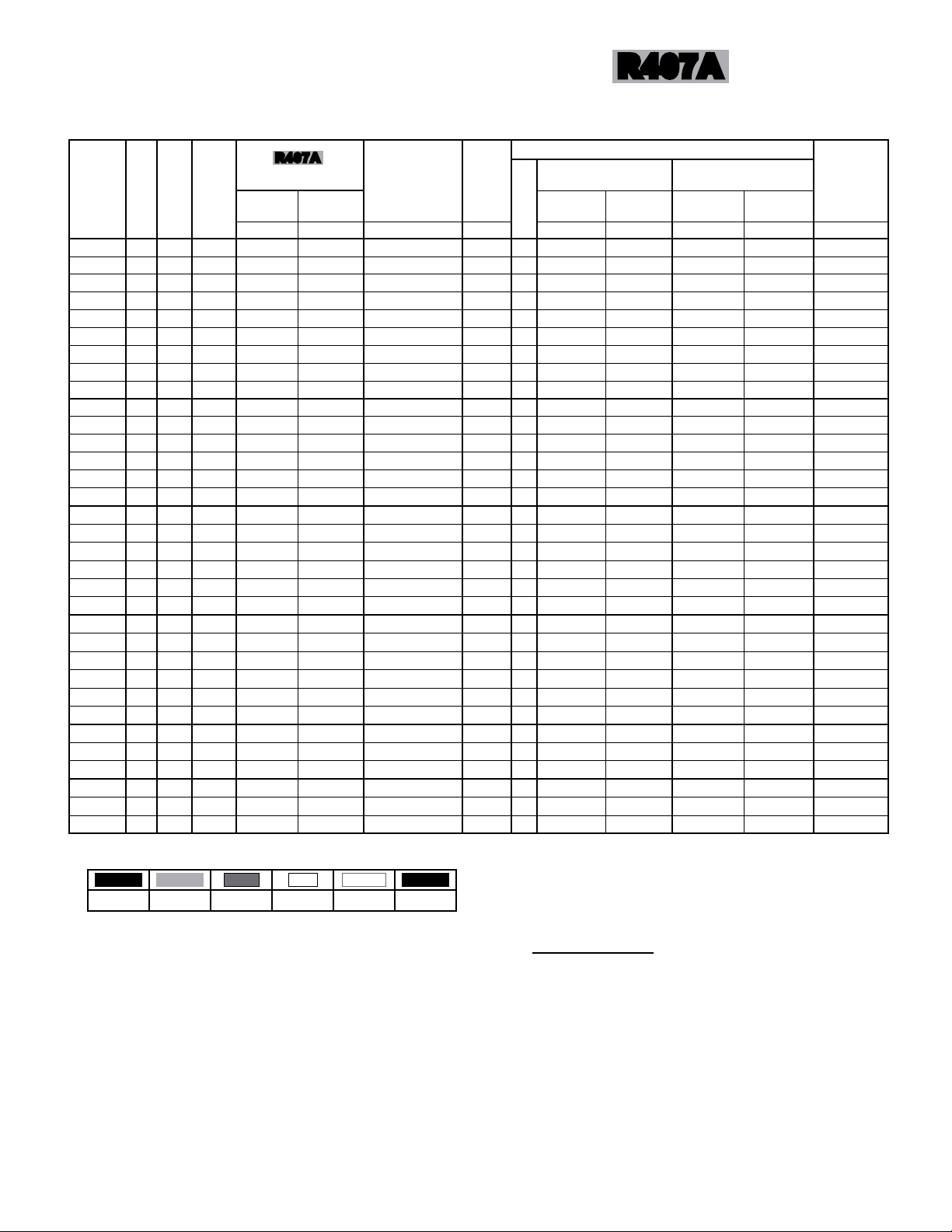

GENERAL SPECIFICATIONS -

DOUBLE ROW MODELS

R407A

850 RPM

60Hz

MODEL

NO.

FPI

MAX.

NO. OF

FEEDS

FAN CONFIG.

TCL 038 8 2 x 2 18

TCL 041 10 2 x 2 18

TCL 046 12 2 x 2 18

TCL 048 8 2 x 2 28

TCL 054 10 2 x 2 28

TCL 057 12 2 x 2 28

TCL 058 8 2 x 2 37

TCL 062 10 2 x 2 37

TCL 065 12 2 x 2 37

TCL 072 8 2 x 3 42

TCL 080 10 2 x 3 42

TCL 085 12 2 x 3 42

TCL 087 8 2 x 3 56

TCL 094 10 2 x 3 56

TCL 097 12 2 x 3 56

TCL 103 8 2 x 4 42

TCL 112 10 2 x 4 42

TCL 119 12 2 x 4 42

TCL 120 8 2 x 4 56

TCL 129 10 2 x 4 56

TCL 134 12 2 x 4 56

TCL 126 8 2 x 5 42

TCL 138 10 2 x 5 42

TCL 146 12 2 x 5 42

TCL 150 8 2 x 5 56

TCL 162 10 2 x 5 56

TCL 168 12 2 x 5 56

TCL 178 8 2 x 6 56

TCL 192 10 2 x 6 56

TCL 200 12 2 x 6 56

TCL 205 8 2 x 7 112

TCL 221 10 2 x 7 112

TCL 230 12 2 x 7 112

R407A

REFRIG. CHARGE

(2)

90% FULL

NORMAL

LBS (kg) LBS (kg) CFM (m

15 (7.7) 72 (33) 36000

15 (7.7) 72 (33) 34800

15 (7.7) 72 (33) 35600

22 (9.9) 100 (45) 33900

22 (9.9) 100 (45) 32800

22 (9.9) 100 (45) 33600

26 (12) 125 (57) 33900

26 (12) 125 (57) 32800

26 (12) 125 (57) 31700

30 (13) 146 (66) 54000

30 (13) 146 (66) 52200

30 (13) 146 (66) 50400

42 (19) 190 (87) 50900

42 (19) 190 (87) 49300

42 (19) 190 (87) 47600

64 (29) 323 (147) 69900

64 (29) 323 (147) 67600

64 (29) 323 (147) 65300

80 (36) 419 (190) 65900

80 (36) 419 (190) 63800

80 (36) 419 (190) 61600

84 (39) 411 (187) 87300

84 (39) 411 (187) 84500

84 (39) 411 (187) 81600

105 (47) 531 (242) 82400

105 (47) 531 (242) 79700

105 (47) 531 (242) 77000

121 (55) 628 (285) 98900

121 (55) 628 (285) 95600

121 (55) 628 (285) 92400

138 (63) 724 (329) 115300

138 (63) 724 (329) 111600

138 (63) 724 (329) 107800

(1)

(3)

AIR

FLOW

RATES

(61160)

(59130)

(60480)

(57600)

(55730)

(57090)

(57600)

(55730)

(53860)

(91750)

(88690)

(85630)

(86480)

(83760)

(80870)

(118760)

(114850)

(110940)

(111960)

(108400)

(104660)

(148320)

(143570)

(138640)

(140000)

(135410)

(130820)

(168030)

(162420)

(156990)

(195890)

(189610)

(183150)

SOUND

LEVEL

(5)

3

/h) dBA IN.

57 2

57 2

57 2

57 2

57 2

57 2

57 2

57 2

57 2

59 2

59 2

59 2

59 2

59 2

59 2

60 2

60 2

60 2

60 2

60 2

60 2

61 2

61 2

61 2

61 2

61 2

61 2

62 2

62 2

62 2

62 2

62 2

62 2

QUANTITY

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

PIPING CONNECTIONS

16°F to 30°F

DESIGN TD

10°F to 15°F

DESIGN TD

INLET OUTLET INLET OUTLET

(mm)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(79)

(79)

(79)

(79)

(79)

(79)

IN.

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

(mm)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

IN.

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

(mm)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

IN.

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

(mm)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

APPROX.

SHIPPING

WEIGHT

LBS (kg)

(568)

1250

(580)

1275

(591)

1300

(602)

1325

(614)

1350

(636)

1400

(659)

1450

(670)

1475

(693)

1525

(920)

2025

(932)

2050

(955)

2100

(989)

2175

(1011)

2225

(1034)

2275

(1216)

2675

(1239)

2725

(1273)

2800

(1318)

2900

(1341)

2950

(1375)

3025

(1534)

3375

(1557)

3425

(1591)

3500

(1659)

3650

(1682)

3700

(1716)

3775

(1977)

4350

(2000)

4400

(2045)

4500

(2295)

5050

(2318)

5100

(2364)

5200

(1) Refrigerant charge conversion factors:

(2) Normal charge is the refrigerant charge for warm ambient or summer operation.

(3) 90% full is the liquid refrigerant weight at 90% of internal volume and is for reference only.

(4) For 50 Hz fan data use 60 Hz CFM (m3/h) X 0.83

(5) Sound pressure level at 30 ft. (10 m) See page 21 for more data

R407C R404A

R507

R22

R410A

1.0 0.91 0.91 1.05 0.92 1.06

R134a

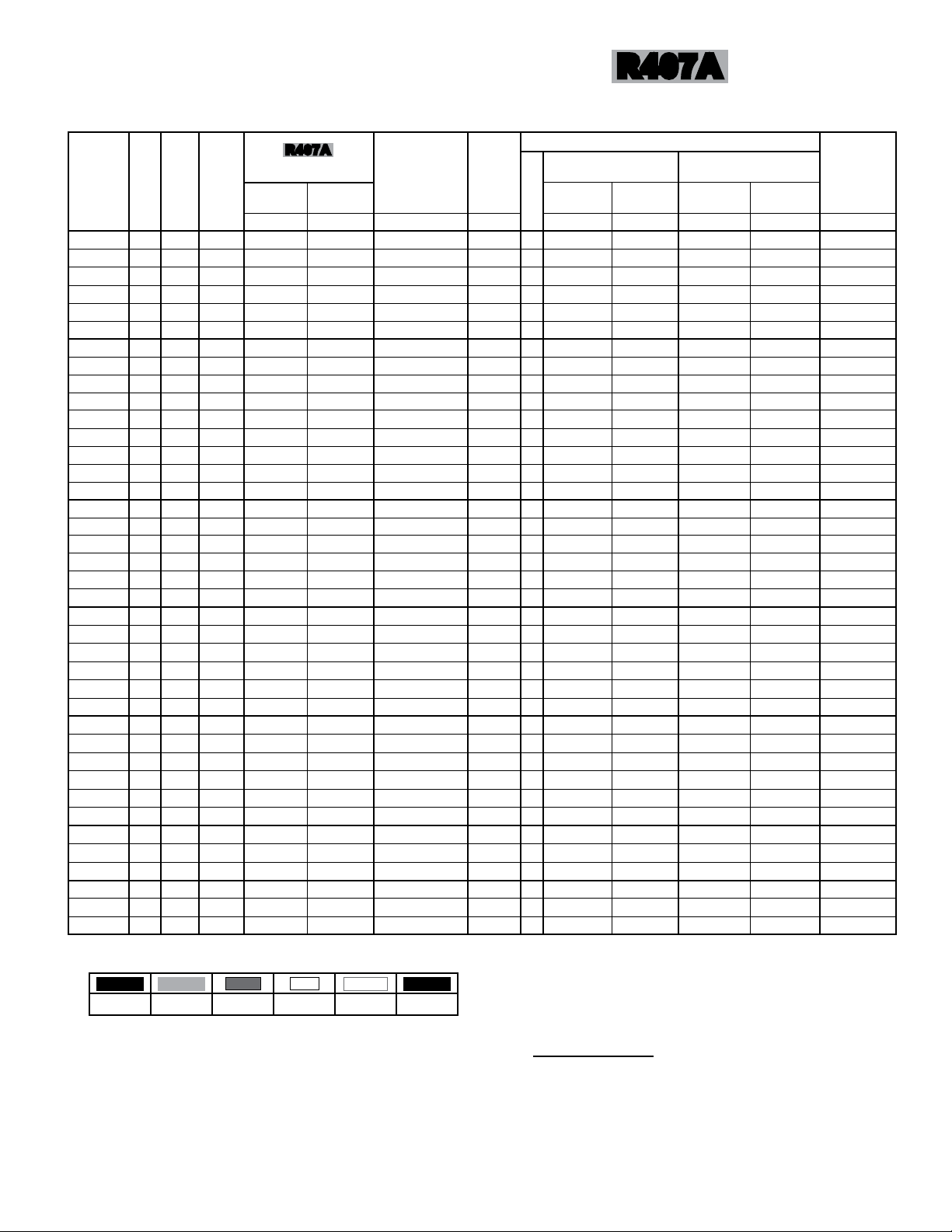

Page 8

TCL

05/08/15

T50-TCL-PDI-4

- 8 -

CAPACITY DATA -

SINGLE ROW MODELS

1140 RPM

60Hz

MODEL

NO.

TCL 014 8 1 x 1 6.03 (1.76) 6.22 (1.82) 6.55 (1.92) 6.68 (1.96) 6.35 (1.86) 7

TCL 015 10 1 x 1 6.58 (1.93) 6.79 (1.99) 7.15 (2.10) 7.29 (2.14) 6.94 (2.03) 7

TCL 016 12 1 x 1 7.00 (2.05) 7.23 (2.12) 7.61 (2.23) 7.76 (2.27) 7.38 (2.16) 7

TCL 017 8 1 x 1 7.29 (2.14) 7.52 (2.21) 7.92 (2.32) 8.08 (2.37) 7.68 (2.25) 8

TCL 018 10 1 x 1 7.87 (2.30) 8.12 (2.38) 8.55 (2.51) 8.72 (2.56) 8.29 (2.43) 8

TCL 019 12 1 x 1 8.19 (2.40) 8.46 (2.48) 8.9 (2.61) 9.08 (2.66) 8.63 (2.53) 8

TCL 021 8 1 x 2 9.15 (2.68) 9.45 (2.77) 9.95 (2.92) 10.15 (2.98) 9.65 (2.83) 9

TCL 023 10 1 x 2 10.28 (3.01) 10.61 (3.11) 11.17 (3.27) 11.39 (3.34) 10.83 (3.17) 9

TCL 025 12 1 x 2 11.17 (3.27) 11.53 (3.38) 12.14 (3.56) 12.38 (3.63) 11.78 (3.45) 9

TCL 027 8 1 x 2 12.04 (3.53) 12.44 (3.64) 13.09 (3.84) 13.35 (3.91) 12.70 (3.72) 14

TCL 030 10 1 x 2 13.17 (3.86) 13.59 (3.98) 14.31 (4.19) 14.60 (4.28) 13.88 (4.07) 14

TCL 032 12 1 x 2 14.00 (4.10) 14.46 (4.24) 15.22 (4.46) 15.52 (4.55) 14.76 (4.33) 14

TCL 033 8 1 x 2 14.38 (4.21) 14.85 (4.35) 15.63 (4.58) 15.94 (4.67) 15.16 (4.44) 18

TCL 035 10 1 x 2 15.50 (4.54) 16.01 (4.69) 16.85 (4.94) 17.19 (5.04) 16.34 (4.79) 18

TCL 037 12 1 x 2 16.16 (4.73) 16.68 (4.89) 17.56 (5.15) 17.91 (5.25) 17.03 (4.99) 18

TCL 041 8 1 x 3 18.07 (5.29) 18.66 (5.47) 19.64 (5.76) 20.03 (5.87) 19.05 (5.58) 21

TCL 045 10 1 x 3 19.74 (5.79) 20.39 (5.98) 21.46 (6.29) 21.89 (6.42) 20.82 (6.10) 21

TCL 048 12 1 x 3 21.00 (6.16) 21.69 (6.36) 22.83 (6.69) 23.29 (6.82) 22.15 (6.49) 21

TCL 050 8 1 x 3 21.95 (6.43) 22.67 (6.64) 23.86 (6.99) 24.34 (7.13) 23.14 (6.78) 28

TCL 054 10 1 x 3 23.68 (6.94) 24.45 (7.17) 25.74 (7.54) 26.25 (7.69) 24.97 (7.32) 28

TCL 056 12 1 x 3 24.67 (7.23) 25.47 (7.46) 26.81 (7.86) 27.35 (8.01) 26.01 (7.62) 28

TCL 059 8 1 x 4 25.94 (7.60) 26.79 (7.85) 28.2 (8.26) 28.76 (8.43) 27.35 (8.02) 21

TCL 064 10 1 x 4 28.35 (8.31) 29.28 (8.58) 30.82 (9.03) 31.44 (9.21) 29.90 (8.76) 21

TCL 068 12 1 x 4 30.17 (8.84) 31.15 (9.13) 32.79 (9.61) 33.45 (9.80) 31.81 (9.32) 21

TCL 070 8 1 x 4 30.88 (9.05) 31.88 (9.34) 33.56 (9.84) 34.23 (10.03) 32.55 (9.54) 28

TCL 075 10 1 x 4 33.30 (9.76) 34.39 (10.08) 36.2 (10.61) 36.92 (10.82) 35.11 (10.29) 28

TCL 079 12 1 x 4 34.69 (10.17) 35.82 (10.50) 37.71 (11.05) 38.46 (11.27) 36.58 (10.72) 28

TCL 072 8 1 x 5 31.80 (9.32) 32.83 (9.62) 34.56 (10.13) 35.25 (10.33) 33.52 (9.83) 21

TCL 078 10 1 x 5 34.75 (10.18) 35.88 (10.52) 37.77 (11.07) 38.53 (11.29) 36.64 (10.74) 21

TCL 084 12 1 x 5 36.97 (10.84) 38.17 (11.19) 40.18 (1

TCL 088 8 1 x 5 38.82 (11.38) 40.09 (11.75) 42.2 (12.37) 43.04 (12.62) 40.93 (12.00) 28

TCL 095 10 1 x 5 41.88 (12.27) 43.24 (12.67) 45.52 (13.34) 46.43 (13.61) 44.15 (12.94) 28

TCL 099 12 1 x 5 43.62 (12.79) 45.04 (13.21) 47.41 (13.90) 48.36 (14.18) 45.99 (13.48) 28

TCL 102 8 1 x 6 45.90 (13.45) 47.40 (13.89) 49.89 (14.62) 50.89 (14.91) 48.39 (14.18) 28

TCL 110 10 1 x 6 49.51 (14.51) 51.12 (14.98) 53.81 (15.77) 54.89 (16.09) 52.20 (15.30) 28

TCL 115 12 1 x 6 51.58 (15.12) 53.26 (15.61) 56.06 (16.43) 57.18 (16.76) 54.38 (15.94) 28

TCL 120 8 1 x 7 52.92 (15.51) 54.64 (16.02) 57.52 (16.86) 58.67 (17.20) 55.79 (16.35) 56

TCL 130 10 1 x 7 57.08 (16.73) 58.94 (17.27) 62.04 (18.18) 63.28 (18.54) 60.18 (17.63) 56

TCL 135 12 1 x 7 59.45 (17.42) 61.39 (17.99) 64.62 (18.94) 65.91 (19.32) 62.68 (18.37) 56

FPI

FAN

CONFIG.

R407A

TOTAL HEAT OF REJECTION - MBH (KW) PER 1 °F (0.56 °C) TD MAX.

R407C R404A

R507

1.78) 40.98 (12.02) 38.97 (11.43) 21

R22

R410A

R134a

NO. OF

FEEDS

NOTES:

- Above capacity data based on 0oF subcooling and at sea level.

- For High Altitude applications apply the following correction factors: 0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

- Capacities at other TD within a range of 10 to 30 °F (-12.2 to -1°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

- For 50 HZ capacity multiply by 0.92.

- Capacities for R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated condensing

temperatures at the inlet and outlet of the condenser. For dew point ratings, consult factory.

- Capacity correction factors if fan speed control is used on lead fan only:

Multiply Above Capacity by: 0.750 0.875 0.916 0.937 0.950 0.958 0.964

Fans Long 1 2 3 4 5 6 7

Page 9

TCL

05/08/15

T50-TCL-PDI-4

- 9 -

CAPACITY DATA -

DOUBLE ROW MODELS

1140 RPM

60Hz

MODEL

NO.

TCL 042 8 2 x 2 18.32 (5.37) 18.91 (5.54) 19.91 (5.83) 20.31 (5.95) 19.31 (5.66) 18

TCL 047 10 2 x 2 20.54 (6.02) 21.21 (6.22) 22.33 (6.55) 22.78 (6.68) 21.66 (6.35) 18

TCL 051 12 2 x 2 22.34 (6.55) 23.07 (6.76) 24.28 (7.12) 24.77 (7.26) 23.55 (6.90) 18

TCL 055 8 2 x 2 24.09 (7.06) 24.87 (7.29) 26.18 (7.67) 26.70 (7.83) 25.39 (7.44) 28

TCL 060 10 2 x 2 26.33 (7.72) 27.19 (7.97) 28.62 (8.39) 29.19 (8.55) 27.76 (8.14) 28

TCL 063 12 2 x 2 28.00 (8.21) 28.92 (8.48) 30.44 (8.92) 31.05 (9.10) 29.53 (8.65) 28

TCL 066 8 2 x 2 29.14 (8.54) 30.09 (8.82) 31.67 (9.28) 32.30 (9.47) 30.72 (9.00) 37

TCL 071 10 2 x 2 31.44 (9.21) 32.46 (9.51) 34.17 (10.01) 34.85 (10.21) 33.14 (9.71) 37

TCL 074 12 2 x 2 32.74 (9.60) 33.81 (9.91) 35.59 (10.43) 36.30 (10.64) 34.52 (10.12) 37

TCL 082 8 2 x 3 36.13 (10.59) 37.31 (10.93) 39.27 (11.51) 40.06 (11.74) 38.09 (11.16) 42

TCL 090 10 2 x 3 39.49 (11.57) 40.77 (11.95) 42.92 (12.58) 43.78 (12.83) 41.63 (12.20) 42

TCL 096 12 2 x 3 42.01 (12.31) 43.38 (12.71) 45.66 (13.38) 46.57 (13.65) 44.29 (12.98) 42

TCL 100 8 2 x 3 43.90 (12.87) 45.33 (13.29) 47.72 (13.99) 48.67 (14.27) 46.29 (13.57) 56

TCL 107 10 2 x 3 47.35 (13.88) 48.90 (14.34) 51.47 (15.09) 52.50 (15.39) 49.93 (14.64) 56

TCL 112 12 2 x 3 49.33 (14.45) 50.94 (14.92) 53.62 (15.71) 54.69 (16.02) 52.01 (15.24) 56

TCL 118 8 2 x 4 51.88 (15.21) 53.57 (15.70) 56.39 (16.53) 57.52 (16.86) 54.70 (16.03) 42

TCL 128 10 2 x 4 56.71 (16.62) 58.56 (17.16) 61.64 (18.06) 62.87 (18.42) 59.79 (17.52) 42

TCL 137 12 2 x 4 60.32 (17.68) 62.29 (18.26) 65.57 (19.22) 66.88 (19.60) 63.60 (18.64) 42

TCL 140 8 2 x 4 61.75 (18.10) 63.76 (18.69) 67.12 (19.67) 68.46 (20.06) 65.11 (19.08) 56

TCL 151 10 2 x 4 66.61 (19.52) 68.78 (20.16) 72.4 (21.22) 73.85 (21.64) 70.23 (20.58) 56

TCL 157 12 2 x 4 69.38 (20.33) 71.64 (21.00) 75.41 (22.10) 76.92 (22.54) 73.15 (21.44) 56

TCL 144 8 2 x 5 63.58 (18.64) 65.65 (19.25) 69.11 (20.26) 70.49 (20.67) 67.04 (19.65) 42

TCL 158 10 2 x 5 69.50 (20.37) 71.76 (21.03) 75.54 (22.14) 77.05 (22.58) 73.27 (21.48) 42

TCL 167 12 2 x 5 73.94 (21.67) 76.35 (22.37) 80.37 (23.55) 81.98 (24.02) 77.96 (22.84) 42

TCL 176 8 2 x 5 77.64 (22.75) 80.17 (23.49) 84.39 (24.73) 86.08 (25.22) 81.86 (23.99) 56

TCL 190 10 2 x 5 83.75 (24.55) 86.48 (25.35) 91.03 (26.68) 92.85 (27.21) 88.30 (25.88) 56

TCL 198 12 2 x 5 87.23 (25.57) 90.08 (26.40) 94.82 (27.79) 96.72 (28.35) 91.98 (26.96) 56

TCL 208 8 2 x 6 91.80 (26.90) 94.79 (27.78) 99.78 (29.24) 101.78 (29.82) 96.79 (28.36) 56

TCL 224 10 2 x 6 98.99 (29.02) 102.22 (29.96) 107.6 (31.54) 109.75 (32.17) 104.37 (30.59) 56

TCL 234 12 2 x 6 103.13 (30.23) 106.50 (31.22) 112.1 (32.86) 114.34 (33.52) 108.74 (31.87) 56

TCL 240

TCL 260 10 2 x 7 114.17 (33.45) 117.90 (34.54) 124.1 (36.36) 126.58 (37.09) 120.38 (35.27) 112

TCL 270 12 2 x 7 118.86 (34.85) 122.74 (35.99) 129.2 (37.88) 131.78 (38.64) 125.32 (36.74) 112

FPI

FAN

CONFIG.

8 2 x 7 105.80 (31.01) 109.25 (32.02) 115 (33.71) 117.30 (34.38) 111.55 (32.70) 112

R407A

TOTAL HEAT OF REJECTION - MBH (KW) PER 1 °F (0.56 °C) TD MAX.

R407C R404A

R507

R22

R410A

R134a

NO. OF

FEEDS

NOTES:

- Above capacity data based on 0oF subcooling and at sea level.

- For High Altitude applications apply the following correction factors: 0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

- Capacities at other TD within a range of 10 to 30 °F (-12.2 to -1°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

- For 50 HZ capacity multiply by 0.92.

- Capacities for R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated condensing

temperatures at the inlet and outlet of the condenser. For dew point ratings, consult factory.

- Capacity correction factors if fan speed control is used on lead fan only:

Fans Long 1 2 3 4 5 6 7

Multiply Above Capacity by: 0.750 0.875 0.916 0.937 0.950 0.958 0.964

Page 10

TCL

05/08/15

T50-TCL-PDI-4

- 10 -

ELECTRICAL DATA

208-230/3/60

NO. OF FAN MOTORS TOTAL FLA MCA MOP WATTS

VARIABLE SPEED MOTOR WITH

CONTROLLER ON HEADER FAN *

1 6.6 8.3 15 1860

2 13.2 16.0 20 3720

3 19.8 21.5 25 5580

4 26.4 31.0 35 7440

5 33.0 41.0 45 9300

6 39.6 46.0 50 1116 0

7 46.2 51.0 60 13020

8 52.8 61.0 70 14880

10 66.0 81.0 90 18600

12 79.2 91.0 100 22320

14 92.4 111.0 125 26040

NO. OF FAN MOTORS TOTAL FLA MCA MOP WATTS

VARIABLE SPEED MOTOR WITH

CONTROLLER ON HEADER FAN *

1 3.1 3.9 15 1860

2 6.2 7.0 15 3720

3 9.3 10.1 15 5580

4 12.4 16.0 20 7440

5 15.5 16.0 20 9300

6 18.6 21.0 25 11160

7 21.7 26.0 30 13020

8 24.8 31.0 35 14880

10 31.0 36.0 40 18600

12 37.2 46.0 50 22320

14 43.4 51.0 60 26040

5.0 6.3 15 590

460/3/60

2.5 3.1 15 590

1140 RPM

60Hz

575/3/60

NO. OF FAN MOTORS TOTAL FLA MCA MOP WATTS

VARIABLE SPEED MOTOR WITH

CONTROLLER ON HEADER FAN *

1 2.5 3.1 15 1860

2 5.0 5.6 15 3720

3 7.5 8.1 15 5580

4 10.0 10.6 15 7440

5 12.5 16.0 20 9300

6 15.0 16.0 20 11160

7 17.5 21.0 25 13020

8 20.0 21.0 25 14880

10 25.0 31.0 35 18600

12 30.0 36.0 40 22320

14 35.0 41.0 50 26040

* Single Phase Motor Used

M.C.A. = Minimum Circuit Ampacity M.O.P. = Maximum Overcurrent Protection

2.0 2.5 15 590

Page 11

TCL

05/08/15

T50-TCL-PDI-4

- 11 -

GENERAL SPECIFICATIONS -

SINGLE ROW MODELS

R407A

1140 RPM

60Hz

MODEL

NO.

FPI

MAX.

NO. OF

FEEDS

FAN CONFIG.

TCL 014 8 1 x 1 7

TCL 015 10 1 x 1 7

TCL 016 12 1 x 1 7

TCL 017 8 1 x 1 8

TCL 018 10 1 x 1 8

TCL 019 12 1 x 1 8

TCL 021 8 1 x 2 9

TCL 023 10 1 x 2 9

TCL 025 12 1 x 2 9

TCL 027 8 1 x 2 14

TCL 030 10 1 x 2 14

TCL 032 12 1 x 2 14

TCL 033 8 1 x 2 18

TCL 035 10 1 x 2 18

TCL 037 12 1 x 2 18

TCL 041 8 1 x 3 21

TCL 045 10 1 x 3 21

TCL 048 12 1 x 3 21

TCL 050 8 1 x 3 28

TCL 054 10 1 x 3 28

TCL 056 12 1 x 3 28

TCL 059 8 1 x 4 21

TCL 064 10 1 x 4 21

TCL 068 12 1 x 4 21

TCL 070 8 1 x 4 28

TCL 075 10 1 x 4 28

TCL 079 12 1 x 4 28

TCL 072 8 1 x 5 21

TCL 078 10 1 x 5 21

TCL 084 12 1 x 5 21

TCL 088 8 1 x 5 28

TCL 095 10 1 x 5 28

TCL 099 12 1 x 5 28

TCL 102 8 1 x 6 28

TCL 110 10 1 x 6 28

TCL 115 12 1 x 6 28

TCL 120 8 1 x 7 56

TCL 130 10 1 x 7 56

TCL 135 12 1 x 7 56

R407A

REFRIG. CHARGE

(2)

90% FULL

NORMAL

LBS (kg) LBS (kg) CFM (m

6 (2.5) 25 (12) 11700

6 (2.5) 25 (12) 11300

6 (2.5) 25 (12) 10900

7 (3.1) 32 (14) 11000

7 (3.1) 32 (14) 10700

7 (3.1) 32 (14) 10300

8 (3.6) 36 (17) 24800

8 (3.6) 36 (17) 24000

8 (3.6) 36 (17) 23100

11 (5.1) 50 (23) 23400

11 (5.1) 50 (23) 22600

11 (5.1) 50 (23) 21800

13 (6.1) 63 (29) 22000

13 (6.1) 63 (29) 21300

13 (6.1) 63 (29) 20600

15 (6.8) 73 (33) 35000

15 (6.8) 73 (33) 33900

15 (6.8) 73 (33) 32800

21 (9.4) 96 (43) 33100

21 (9.4) 96 (43) 32000

21 (9.4) 96 (43) 30900

32 (14) 162 (74) 45400

32 (14) 162 (74) 43900

32 (14) 162 (74) 42400

41 (19) 210 (96) 42800

41 (19) 210 (96) 41400

41 (19) 210 (96) 40000

42 (19) 206 (94) 56700

42 (19) 206 (94) 54900

42 (19) 206 (94) 53000

53 (24) 266 (121) 53500

53 (24) 266 (121) 51800

53 (24) 266 (121) 50000

61 (28) 314 (143) 64200

61 (28) 314 (143) 62100

61 (28) 314 (143) 60000

69 (31) 362 (165) 74900

69 (31) 362 (165) 72500

69 (31) 362 (165) 70000

(1)

(3)

AIR

FLOW

RATES

(19880)

(19200)

(18520)

(18690)

(18180)

(17500)

(42140)

(40780)

(39250)

(39760)

(38400)

(37040)

(37380)

(36190)

(35000)

(59470)

(57600)

(55730)

(56240)

(54370)

(52500)

(77130)

(74590)

(72040)

(72720)

(70340)

(67960)

(96330)

(93280)

(90050)

(90900)

(88010)

(84950)

(109080)

(105510)

(101940)

(127260)

(123180)

(118930)

SOUND

LEVEL

(5)

3

/h) dBA IN.

61 1

61 1

61 1

61 1

61 1

61 1

63 1

63 1

63 1

63 1

63 1

63 1

63 1

63 1

63 1

64 1

64 1

64 1

64 1

64 1

64 1

65 1

65 1

65 1

65 1

65 1

65 1

66 1

66 1

66 1

66 1

66 1

66 1

67 1

67 1

67 1

67 1

67 1

67 1

QUANTITY

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

PIPING CONNECTIONS

16°F to 30°F

DESIGN TD

10°F to 15°F

DESIGN TD

INLET OUTLET INLET OUTLET

(mm)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

IN.

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

(mm)

(29)

(29)

(29)

(29)

(29)

(29)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

IN.

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

(mm)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(79)

(79)

(79)

(79)

(79)

(79)

IN.

7/8

7/8

7/8

7/8

7/8

7/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

(mm)

(22)

(22)

(22)

(22)

(22)

(22)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

APPROX.

SHIPPING

WEIGHT

LBS (kg)

(161)

355

(164)

360

(168)

370

(173)

380

(177)

390

(182)

400

(302)

665

(305)

670

(309)

680

(323)

710

(327)

720

(336)

740

(350)

770

(355)

780

(364)

800

(477)

1050

(489)

1075

(500)

1100

(523)

1150

(534)

1175

(545)

1200

(648)

1425

(659)

1450

(670)

1475

(693)

1525

(705)

1550

(727)

1600

(784)

1725

(818)

1800

(841)

1850

(875)

1925

(886)

1950

(909)

2000

(1034)

2275

(1045)

2300

(1068)

2350

(1216)

2675

(1227)

2700

(1250)

2750

(1) Refrigerant charge conversion factors:

(2) Normal charge is the refrigerant charge for warm ambient or summer operation.

(3) 90% full is the liquid refrigerant weight at 90% of internal volume and is for reference only.

(4) For 50 Hz fan data use 60 Hz CFM (m3/h) X 0.83

(5) Sound pressure level at 30 ft. (10 m) See page 21 for more data

R407C

R404A

R507

R22

R410A

1.0 0.91 0.91 1.05 0.92 1.06

R134a

Page 12

TCL

05/08/15

T50-TCL-PDI-4

- 12 -

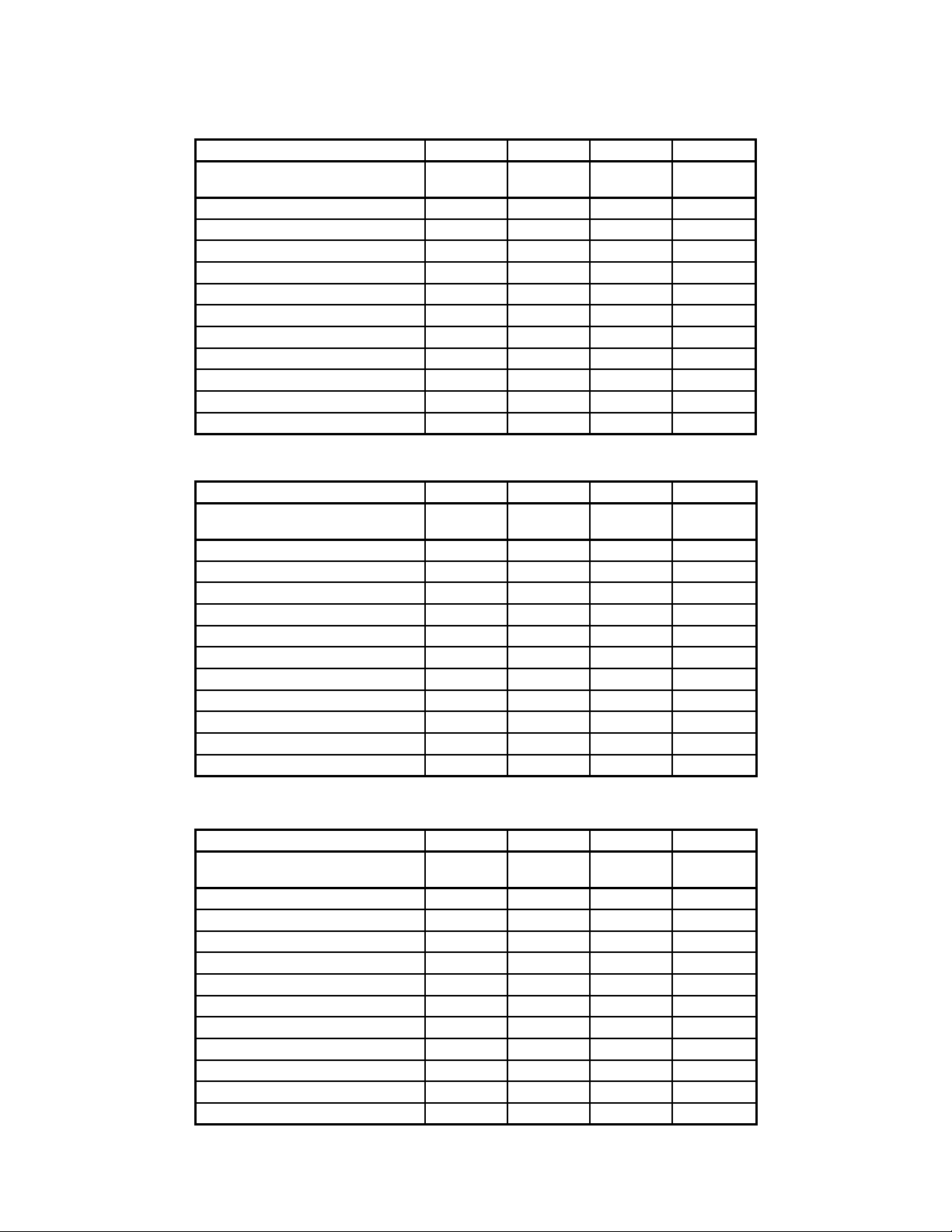

GENERAL SPECIFICATIONS -

DOUBLE ROW MODELS

R407A

1140 RPM

60Hz

MODEL

NO.

FPI

MAX.

NO. OF

FEEDS

FAN CONFIG.

TCL 042 8 2 x 2 18

TCL 047 10 2 x 2 18

TCL 051 12 2 x 2 18

TCL 055 8 2 x 2 28

TCL 060 10 2 x 2 28

TCL 063 12 2 x 2 28

TCL 066 8 2 x 2 37

TCL 071 10 2 x 2 37

TCL 074 12 2 x 2 37

TCL 082 8 2 x 3 42

TCL 090 10 2 x 3 42

TCL 096 12 2 x 3 42

TCL 100 8 2 x 3 56

TCL 107 10 2 x 3 56

TCL 112 12 2 x 3 56

TCL 118 8 2 x 4 42

TCL 128 10 2 x 4 42

TCL 137 12 2 x 4 42

TCL 140 8 2 x 4 56

TCL 151 10 2 x 4 56

TCL 157 12 2 x 4 56

TCL 144 8 2 x 5 42

TCL 158 10 2 x 5 42

TCL 167 12 2 x 5 42

TCL 176 8 2 x 5 56

TCL 190 10 2 x 5 56

TCL 198 12 2 x 5 56

TCL 208 8 2 x 6 56

TCL 224 10 2 x 6 56

TCL 234 12 2 x 6 56

TCL 240 8 2 x 7 112

TCL 260 10 2 x 7 112

TCL 270 12 2 x 7 112

R407A

REFRIG. CHARGE

(2)

90% FULL

NORMAL

LBS (kg) LBS (kg) CFM (m

15 (7.3) 72 (33) 49500

15 (7.3) 72 (33) 47900

15 (7.3) 72 (33) 46300

22 (10) 100 (45) 46700

22 (10) 100 (45) 45200

22 (10) 100 (45) 43700

26 (12) 125 (57) 44100

26 (12) 125 (57) 42600

26 (12) 125 (57) 41200

30 (13) 146 (66) 70100

30 (13) 146 (66) 67800

30 (13) 146 (66) 65500

42 (19) 190 (87) 66100

42 (19) 190 (87) 64000

42 (19) 190 (87) 61800

64 (29) 323 (147) 90700

64 (29) 323 (147) 87800

64 (29) 323 (147) 84800

80 (36) 419 (190) 85600

80 (36) 419 (190) 82800

80 (36) 419 (190) 80000

84 (39) 411 (187) 113400

84 (39) 411 (187) 109700

84 (39) 411 (187) 106000

105 (47) 531 (242) 107000

105 (47) 531 (242) 103500

105 (47) 531 (242) 100000

121 (55) 628 (285) 128400

121 (55) 628 (285) 124200

121 (55) 628 (285) 120000

138 (63) 724 (329) 149800

138 (63) 724 (329) 144900

138 (63) 724 (329) 140000

(1)

(3)

AIR

FLOW

RATES

(84100)

(81380)

(78660)

(79340)

(76790)

(74250)

(74930)

(72380)

(70000)

(119100)

(115190)

(111280)

(112300)

(108740)

(105000)

(154100)

(149170)

(144080)

(145430)

(140680)

(135920)

(192670)

(186380)

(180090)

(181790)

(175850)

(169900)

(218150)

(211020)

(203880)

(254510)

(246190)

(237860)

SOUND

LEVEL

(5)

3

/h) dBA IN.

QUANTITY

65 2

65 2

65 2

65 2

65 2

65 2

65 2

65 2

65 2

67 2

67 2

67 2

67 2

67 2

67 2

68 2

68 2

68 2

68 2

68 2

68 2

69 2

69 2

69 2

69 2

69 2

69 2

70 2

70 2

70 2

70 2

70 2

70 2

PIPING CONNECTIONS

16°F to 30°F

DESIGN TD

10°F to 15°F

DESIGN TD

INLET OUTLET INLET OUTLET

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

(mm)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

(79)

IN.

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

(mm)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

IN.

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

(mm)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(79)

(79)

(79)

(79)

(79)

(79)

IN.

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

(mm)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

APPROX.

SHIPPING

WEIGHT

LBS (kg)

(568)

1250

(580)

1275

(591)

1300

(602)

1325

(614)

1350

(636)

1400

(659)

1450

(670)

1475

(693)

1525

(920)

2025

(932)

2050

(955)

2100

(989)

2175

(1011)

2225

(1034)

2275

(1216)

2675

(1239)

2725

(1273)

2800

(1318)

2900

(1341)

2950

(1375)

3025

(1534)

3375

(1557)

3425

(1591)

3500

(1659)

3650

(1682)

3700

(1716)

3775

(1977)

4350

(2000)

4400

(2045)

4500

(2295)

5050

(2318)

5100

(2364)

5200

(1) Refrigerant charge conversion factors:

(2) Normal charge is the refrigerant charge for warm ambient or summer operation.

(3) 90% full is the liquid refrigerant weight at 90% of internal volume and is for reference only.

(4) For 50 Hz fan data use 60 Hz CFM (m3/h) X 0.83

(5) Sound pressure level at 30 ft. (10 m) See page 21 for more data

R407C R404A

R507

R22

R410A

1.0 0.91 0.91 1.05 0.92 1.06

R134a

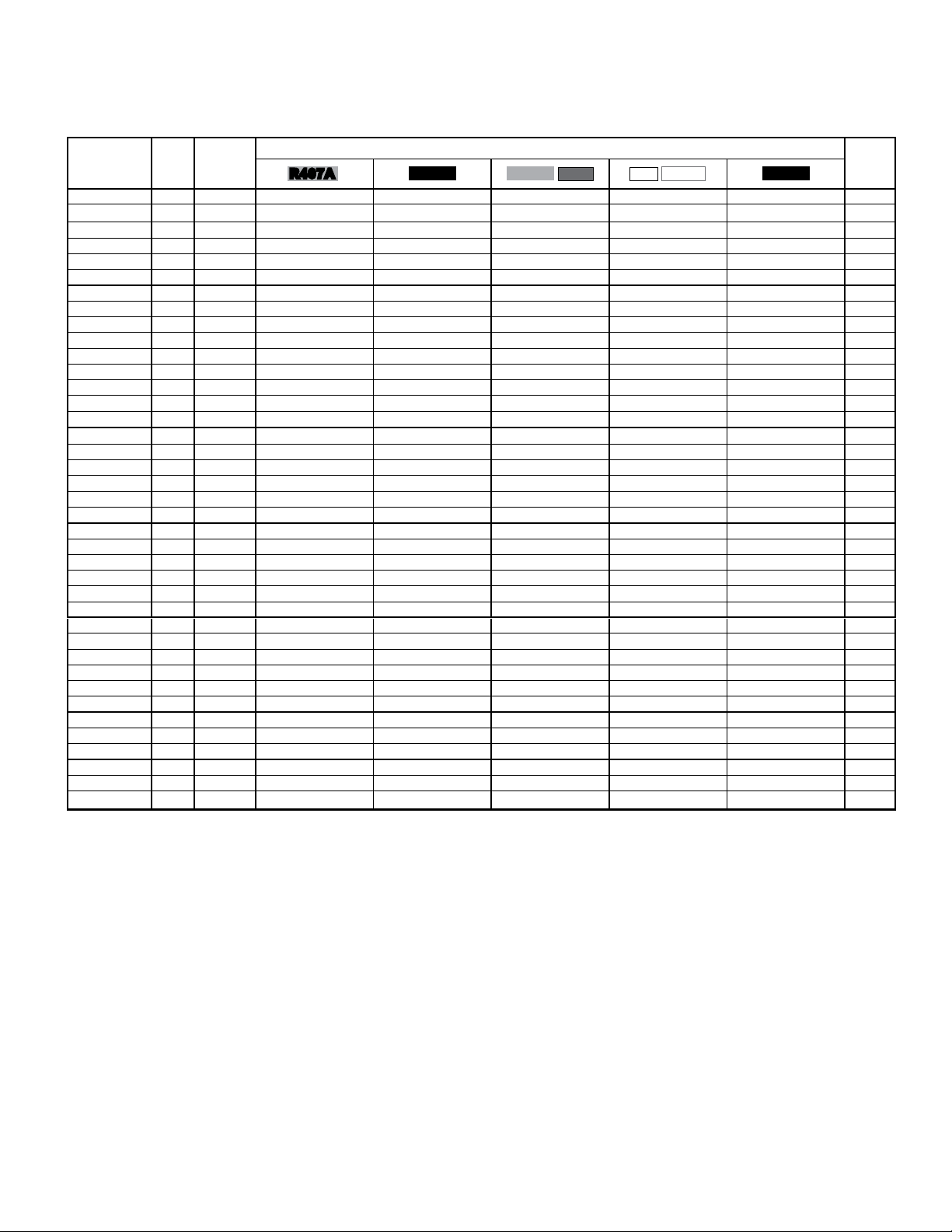

Page 13

TCL

05/08/15

T50-TCL-PDI-4

- 13 -

CAPACITY DATA -

SINGLE ROW MODELS

550 RPM

60Hz

MODEL

NO.

TCL 007 8 1 x 1 4.12 (1.21) 4.26 (1.25) 4.48 (1.31) 4.57 (1.34) 4.35 (1.27) 7

TCL 008 10 1 x 1 4.51 (1.32) 4.66 (1.36) 4.9 (1.44) 5.00 (1.46) 4.75 (1.39) 7

TCL 009 12 1 x 1 4.79 (1.40) 4.95 (1.45) 5.21 (1.53) 5.31 (1.56) 5.05 (1.48) 7

TCL 010 8 1 x 1 4.78 (1.40) 4.94 (1.45) 5.2 (1.52) 5.30 (1.55) 5.04 (1.48) 8

TCL 011 10 1 x 1 5.16 (1.51) 5.33 (1.56) 5.61 (1.64) 5.72 (1.68) 5.44 (1.59) 8

TCL 012 12 1 x 1 5.37 (1.58) 5.55 (1.63) 5.84 (1.71) 5.96 (1.75) 5.66 (1.66) 8

TCL 014 8 1 x 2 6.38 (1.87) 6.59 (1.93) 6.94 (2.03) 7.08 (2.07) 6.73 (1.97) 9

TCL 016 10 1 x 2 7.16 (2.10) 7.39 (2.17) 7.78 (2.28) 7.94 (2.33) 7.55 (2.21) 9

TCL 018 12 1 x 2 7.78 (2.28) 8.04 (2.36) 8.46 (2.48) 8.63 (2.53) 8.21 (2.40) 9

TCL 019 8 1 x 2 8.24 (2.42) 8.51 (2.49) 8.96 (2.63) 9.14 (2.68) 8.69 (2.55) 14

TCL 020 10 1 x 2 9.01 (2.64) 9.30 (2.73) 9.79 (2.87) 9.99 (2.93) 9.50 (2.78) 14

TCL 022 12 1 x 2 9.59 (2.81) 9.90 (2.90) 10.42 (3.05) 10.63 (3.11) 10.11 (2.96) 14

TCL 021 8 1 x 2 9.44 (2.77) 9.75 (2.86) 10.26 (3.01) 10.47 (3.07) 9.95 (2.92) 18

TCL 023 10 1 x 2 10.18 (2.98) 10.52 (3.08) 11.07 (3.24) 11.29 (3.31) 10.74 (3.15) 18

TCL 024 12 1 x 2 10.61 (3.11) 10.95 (3.21) 11.53 (3.38) 11.76 (3.45) 11.18 (3.28) 18

TCL 028 8 1 x 3 12.36 (3.62) 12.77 (3.74) 13.44 (3.94) 13.71 (4.02) 13.04 (3.82) 21

TCL 031 10 1 x 3 13.51 (3.96) 13.96 (4.09) 14.69 (4.30) 14.98 (4.39) 14.25 (4.17) 21

TCL 032 12 1 x 3 14.37 (4.21) 14.84 (4.35) 15.62 (4.58) 15.93 (4.67) 15.15 (4.44) 21

TCL 033 8 1 x 3 14.42 (4.23) 14.89 (4.36) 15.67 (4.59) 15.98 (4.68) 15.20 (4.46) 28

TCL 035 10 1 x 3 15.56 (4.56) 16.06 (4.71) 16.91 (4.96) 17.25 (5.05) 16.40 (4.81) 28

TCL 037 12 1 x 3 16.20 (4.75) 16.73 (4.90) 17.61 (5.16) 17.96 (5.26) 17.08 (5.01) 28

TCL 038 8 1 x 4 16.75 (4.91) 17.30 (5.07) 18.21 (5.34) 18.57 (5.44) 17.66 (5.17) 21

TCL 041 10 1 x 4 18.31 (5.37) 18.91 (5.54) 19.9 (5.83) 20.30 (5.95) 19.30 (5.66) 21

TCL 045 12 1 x 4 19.48 (5.71) 20.11 (5.89) 21.17 (6.20) 21.59 (6.33) 20.53 (6.02) 21

TCL 042 8 1 x 4 19.08 (5.59) 19.70 (5.77) 20.74 (6.08) 21.15 (6.20) 20.12 (5.90) 28

TCL 046 10 1 x 4 20.58 (6.03) 21.25 (6.23) 22.37 (6.56) 22.82 (6.69) 21.70 (6.36) 28

TCL 048 12 1 x 4 21.44 (6.28) 22.14 (6.49) 23.3 (6.83) 23.77 (6.97) 22.60 (6.62) 28

TCL 047 8 1 x 5 20.78 (6.09) 21.46 (6.29) 22.59 (6.62) 23.04 (6.75) 21.91 (6.42) 21

TCL 051 10 1 x 5 22.72 (6.66) 23.47 (6.88) 24.7 (7.24) 25.19 (7.38) 23.96 (7.02) 21

TCL 055 12 1 x 5 24.17 (7.08) 24.96 (7.32) 26.27 (7.70) 26.80 (7.85) 25.48 (7.47) 21

TCL 054 8 1 x 5 23.93 (7.01) 24.71 (7.24) 26.01 (7.62) 26.53 (7.78) 25.23 (7.39) 28

TCL 058

TCL 061 12 1 x 5 26.89 (7.88) 27.77 (8.14) 29.23 (8.57) 29.81 (8.74) 28.35 (8.31) 28

TCL 064 8 1 x 6 28.06 (8.22) 28.98 (8.49) 30.5 (8.94) 31.11 (9.12) 29.59 (8.67) 28

TCL 069 10 1 x 6 30.27 (8.87) 31.26 (9.16) 32.9 (9.64) 33.56 (9.84) 31.91 (9.35) 28

TCL 071 12 1 x 6 31.53 (9.25) 32.56 (9.55) 34.27 (10.05) 34.96 (10.25) 33.24 (9.75) 28

TCL 074 8 1 x 7 32.83 (9.62) 33.91 (9.94) 35.69 (10.46) 36.40 (10.67) 34.62 (10.15) 56

TCL 080 10 1 x 7 35.41 (10.38) 36.57 (10.72) 38.49 (11.28) 39.26 (11.51) 37.34 (10.94) 56

TCL 084 12 1 x 7 36.89 (10.81) 38.10 (11.16) 40.1 (11.75) 40.90 (11.99) 38.90 (11.40) 56

FPI

FAN

CONFIG.

10 1 x 5 25.82 (7.56) 26.66 (7.81) 28.06 (8.22) 28.62 (8.39) 27.22 (7.98) 28

R407A

TOTAL HEAT OF REJECTION - MBH (KW) PER 1 °F (0.56 °C) TD MAX.

R407C R404A

R507

R22

R410A

R134a

NO. OF

FEEDS

NOTES:

- Above capacity data based on 0oF subcooling and at sea level.

- For High Altitude applications apply the following correction factors: 0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

- Capacities at other TD within a range of 10 to 30 °F (-12.2 to -1°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

- For 50 HZ capacity multiply by 0.92.

- Capacities for R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated condensing

temperatures at the inlet and outlet of the condenser. For dew point ratings, consult factory.

Page 14

TCL

05/08/15

T50-TCL-PDI-4

- 14 -

CAPACITY DATA -

DOUBLE ROW MODELS

550 RPM

60Hz

MODEL

NO.

TCL 029 8 2 x 2 12.76 (3.74) 13.18 (3.86) 13.87 (4.07) 14.15 (4.15) 13.45 (3.94) 18

TCL 034 10 2 x 2 14.32 (4.20) 14.78 (4.33) 15.56 (4.56) 15.87 (4.65) 15.09 (4.42) 18

TCL 036 12 2 x 2 15.57 (4.56) 16.07 (4.71) 16.92 (4.96) 17.26 (5.06) 16.41 (4.81) 18

TCL 039 8 2 x 2 16.48 (4.83) 17.01 (4.99) 17.91 (5.25) 18.27 (5.36) 17.37 (5.09) 28

TCL 040 10 2 x 2 18.01 (5.28) 18.60 (5.45) 19.58 (5.74) 19.97 (5.85) 18.99 (5.57) 28

TCL 043 12 2 x 2 19.16 (5.62) 19.79 (5.80) 20.83 (6.11) 21.25 (6.23) 20.21 (5.92) 28

TCL 044 8 2 x 2 19.14 (5.61) 19.76 (5.79) 20.8 (6.10) 21.22 (6.22) 20.18 (5.91) 37

TCL 049 10 2 x 2 20.64 (6.05) 21.32 (6.25) 22.44 (6.58) 22.89 (6.71) 21.77 (6.38) 37

TCL 050 12 2 x 2 21.51 (6.30) 22.21 (6.51) 23.38 (6.85) 23.85 (6.99) 22.68 (6.65) 37

TCL 056 8 2 x 3 24.72 (7.25) 25.53 (7.48) 26.87 (7.88) 27.41 (8.03) 26.06 (7.64) 42

TCL 060 10 2 x 3 27.02 (7.92) 27.90 (8.18) 29.37 (8.61) 29.96 (8.78) 28.49 (8.35) 42

TCL 065 12 2 x 3 28.75 (8.43) 29.69 (8.70) 31.25 (9.16) 31.88 (9.34) 30.31 (8.88) 42

TCL 066 8 2 x 3 28.84 (8.45) 29.78 (8.73) 31.35 (9.19) 31.98 (9.37) 30.41 (8.91) 56

TCL 070 10 2 x 3 31.11 (9.12) 32.12 (9.41) 33.81 (9.91) 34.49 (10.11) 32.80 (9.61) 56

TCL 073 12 2 x 3 32.40 (9.49) 33.46 (9.80) 35.22 (10.32) 35.92 (10.53) 34.16 (10.01) 56

TCL 076 8 2 x 4 33.50 (9.82) 34.59 (10.14) 36.41 (10.67) 37.14 (10.88) 35.32 (10.35) 42

TCL 083 10 2 x 4 36.62 (10.73) 37.81 (11.08) 39.8 (11.66) 40.60 (11.89) 38.61 (11.31) 42

TCL 088 12 2 x 4 38.95 (11.42) 40.22 (11.79) 42.34 (12.41) 43.19 (12.66) 41.07 (12.04) 42

TCL 086 8 2 x 4 38.16 (11.19) 39.41 (11.55) 41.48 (12.16) 42.31 (12.40) 40.24 (11.80) 56

TCL 093 10 2 x 4 41.16 (12.06) 42.50 (12.45) 44.74 (13.11) 45.63 (13.37) 43.40 (12.72) 56

TCL 097 12 2 x 4 42.88 (12.57) 44.28 (12.98) 46.61 (13.66) 47.54 (13.93) 45.21 (13.25) 56

TCL 094 8 2 x 5 41.57 (12.18) 42.93 (12.58) 45.19 (13.24) 46.09 (13.50) 43.83 (12.84) 42

TCL 103 10 2 x 5 45.44 (13.32) 46.92 (13.76) 49.39 (14.48) 50.38 (14.77) 47.91 (14.05) 42

TCL 110 12 2 x 5 48.34 (14.17) 49.91 (14.63) 52.54 (15.40) 53.59 (15.71) 50.96 (14.94) 42

TCL 108 8 2 x 5 47.86 (14.03) 49.42 (14.49) 52.02 (15.25) 53.06 (15.56) 50.46 (14.79) 56

TCL 117 10 2 x 5 51.62 (15.12) 53.30 (15.62) 56.11 (16.44) 57.23 (16.77) 54.43 (15.95) 56

TCL 122 12 2 x 5 53.77 (15.76) 55.53 (16.27) 58.45 (17.13) 59.62 (17.47) 56.70 (16.62) 56

TCL 127 8 2 x 6 56.13 (16.45) 57.96 (16.99) 61.01 (17.88) 62.23 (18.24) 59.18 (17.34) 56

TCL 137 10 2 x 6 60.55 (17.75) 62.52 (18.33) 65.81 (19.29) 67.13 (19.68) 63.84 (18.71) 56

TCL 143 12 2 x 6 63.07 (18.48) 65.12 (19.09) 68.55 (20.09) 69.92 (20.49) 66.49 (19.49) 56

TCL 149 8 2 x 7 65.66 (19.25) 67.80 (19.87) 71.37 (20.92) 72.80 (21.34) 69.23 (20.29) 112

160 10 2 x 7 70.82 (20.76) 73.13 (21.43) 76.98 (22.56) 78.52 (23.01) 74.67 (21.88) 112

TCL

TCL 167 12 2 x 7 73.77 (21.62) 76.18 (22.33) 80.19 (23.50) 81.79 (23.97) 77.78 (22.80) 112

FPI

FAN

CONFIG.

R407A

TOTAL HEAT OF REJECTION - MBH (KW) PER 1 °F (0.56 °C) TD MAX.

R407C R404A

R507

R22

R410A

R134a

NO. OF

FEEDS

NOTES:

- Above capacity data based on 0oF subcooling and at sea level.

- For High Altitude applications apply the following correction factors: 0.94 for 2000 feet, 0.88 for 4000 feet and 0.81 for 6000 feet.

- Capacities at other TD within a range of 10 to 30 °F (-12.2 to -1°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

- For 50 HZ capacity multiply by 0.92.

- Capacities for R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated condensing

temperatures at the inlet and outlet of the condenser. For dew point ratings, consult factory.

Page 15

TCL

05/08/15

T50-TCL-PDI-4

- 15 -

ELECTRICAL DATA

208-230/3/60

NO. OF FAN

MOTORS

1 2.8 3.5 15 355

2 5.6 6.3 15 710

3 8.4 9.1 15 1065

4 11.2 11.9 15 1420

5 14.0 16.0 20 1775

6 16.8 21.0 25 2130

7 19.6 21.0 25 2485

8 22.4 26.0 30 2840

10 28.0 31.0 35 3550

12 33.6 41.0 45 4260

14 39.2 46.0 50 4970

NO. OF FAN

MOTORS

1 1.3 1.6 15 355

2 2.6 2.9 15 710

3 3.9 4.2 15 1065

4 5.2 5.5 15 1420

5 6.5 6.8 15 1775

6 7.8 8.1 15 2130

7 9.1 9.4 15 2485

8 10.4 10.7 15 2840

10 13.0 16.0 20 3550

12 15.6 16.0 20 4260

14 18.2 21.0 25 4970

TOTAL FLA MCA MOP WATTS

460/3/60

TOTAL FLA MCA MOP WATTS

550 RPM

60Hz

575/3/60

NO. OF FAN

MOTORS

1 1.1 1.4 15 355

2 2.2 2.5 15 710

3 3.3 3.6 15 1065

4 4.4 4.7 15 1420

5 5.5 5.8 15 1775

6 6.6 6.9 15 2130

7 7.7 8.0 15 2485

8 8.8 9.1 15 2840

10 11.0 11.3 15 3550

12 13.2 16.0 20 4260

14 15.4 16.0 20 4970

M.C.A. = Minimum Circuit Ampacity M.O.P. = Maximum Overcurrent Protection

TOTAL FLA MCA MOP WATTS

* Single Phase Motor Used

Page 16

TCL

05/08/15

T50-TCL-PDI-4

- 16 -

GENERAL SPECIFICATIONS -

SINGLE ROW MODELS

R407A

550 RPM

60Hz

MODEL

NO.

FPI

MAX.

NO. OF

FEEDS

FAN CONFIG.

TCL 007 8 1 x 1 7

TCL 008 10 1 x 1 7

TCL 009 12 1 x 1 7

TCL 010 8 1 x 1 8

TCL 011 10 1 x 1 8

TCL 012 12 1 x 1 8

TCL 014 8 1 x 2 9

TCL 016 10 1 x 2 9

TCL 018 12 1 x 2 9

TCL 019 8 1 x 2 14

TCL 020 10 1 x 2 14

TCL 022 12 1 x 2 14

TCL 021 8 1 x 2 18

TCL 023 10 1 x 2 18

TCL 024 12 1 x 2 18

TCL 028 8 1 x 3 21

TCL 031 10 1 x 3 21

TCL 032 12 1 x 3 21

TCL 033 8 1 x 3 28

TCL 035 10 1 x 3 28

TCL 037 12 1 x 3 28

TCL 038 8 1 x 4 21

TCL 041 10 1 x 4 21

TCL 045 12 1 x 4 21

TCL 042 8 1 x 4 28

TCL 046 10 1 x 4 28

TCL 048 12 1 x 4 28

TCL 047 8 1 x 5 21

TCL 051 10 1 x 5 21

TCL 055 12 1 x 5 21

TCL 054 8 1 x 5 28

TCL 058 10 1 x 5 28

TCL 061 12 1 x 5 28

TCL 064 8 1 x 6 28

TCL 069 10 1 x 6 28

TCL 071 12 1 x 6 28

TCL 074 8 1 x 7 56

TCL 080 10 1 x 7 56

TCL 084 12 1 x 7 56

R407A

REFRIG. CHARGE

(2)

90% FULL

NORMAL

LBS (kg) LBS (kg) CFM (m

6 (2.5) 25 (12) 5600

6 (2.5) 25 (12) 5400

6 (2.5) 25 (12) 5200

7 (3.1) 32 (14) 5300

7 (3.1) 32 (14) 5100

7 (3.1) 32 (14) 4900

8 (3.6) 36 (17) 11800

8 (3.6) 36 (17) 11400

8 (3.6) 36 (17) 11100

11 (5.1) 50 (23) 11200

11 (5.1) 50 (23) 10800

11 (5.1) 50 (23) 10400

13 (6.1) 63 (29) 10500

13 (6.1) 63 (29) 10200

13 (6.1) 63 (29) 9800

15 (6.8) 73 (33) 16700

15 (6.8) 73 (33) 16200

15 (6.8) 73 (33) 15600

21 (9.4) 96 (43) 15800

21 (9.4) 96 (43) 15300

21 (9.4) 96 (43) 14800

32 (14) 162 (74) 21700

32 (14) 162 (74) 21000

32 (14) 162 (74) 20300

41 (19) 210 (96) 20400

41 (19) 210 (96) 19800

41 (19) 210 (96) 19100

42 (19) 206 (94) 27100

42 (19) 206 (94) 26200

42 (19) 206 (94) 25300

53 (24) 266 (121) 25600

53 (24) 266 (121) 24700

53 (24) 266 (121) 23900

61 (28) 314 (143) 30700

61 (28) 314 (143) 29700

61 (28) 314 (143) 28700

69 (31) 362 (165) 35800

69 (31) 362 (165) 34600

69 (31) 362 (165) 33400

(1)

(3)

AIR

FLOW

RATES

(9510)

(9170)

(8830)

(9000)

(8660)

(8330)

(20050)

(19370)

(18860)

(19030)

(18350)

(17670)

(17840)

(17330)

(16650)

(28370)

(27520)

(26500)

(26840)

(25990)

(25150)

(36870)

(35680)

(34490)

(34660)

(33640)

(32450)

(46040)

(44510)

(42980)

(43490)

(41970)

(40610)

(52160)

(50460)

(48760)

(60820)

(58790)

(56750)

SOUND

LEVEL

(5)

3

/h) dBA IN.

QUANTITY

44 1

44 1

44 1

44 1

44 1

44 1

46 1

46 1

46 1

46 1

46 1

46 1

46 1

46 1

46 1

47 1

47 1

47 1

47 1

47 1

47 1

48 1

48 1

48 1

48 1

48 1

48 1

49 1

49 1

49 1

49 1

49 1

49 1

50 1

50 1

50 1

50 1

50 1

50 1

PIPING CONNECTIONS

16°F to 30°F

DESIGN TD

10°F to 15°F

DESIGN TD

INLET OUTLET INLET OUTLET

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

3 1/8

(mm)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(79)

(79)

(79)

(79)

(79)

(79)

IN.

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

(mm)

(29)

(29)

(29)

(29)

(29)

(29)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

(67)

IN.

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

2 5/8

(mm)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(54)

(67)

(67)

(67)

(67)

(67)

(67)

IN.

7/8

7/8

7/8

7/8

7/8

7/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 1/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 3/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

1 5/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

2 1/8

(mm)

(22)

(22)

(22)

(22)

(22)

(22)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(29)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(35)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(41)

(54)

(54)

(54)

(54)

(54)

(54)

APPROX.

SHIPPING

WEIGHT

LBS (kg)

(161)

355

(164)

360

(168)

370

(173)

380

(177)

390

(182)

400

(302)

665

(305)

670

(309)

680

(323)

710

(327)

720

(336)

740

(350)

770

(355)

780

(364)

800

(477)

1050

(489)

1075

(500)

1100

(523)

1150

(534)

1175

(545)

1200

(648)

1425

(659)

1450

(670)

1475

(693)

1525

(705)

1550

(727)

1600

(784)

1725

(818)

1800

(841)

1850

(875)

1925

(886)

1950

(909)

2000

(1034)

2275

(1045)

2300

(1068)

2350

(1216)

2675

(1227)

2700

(1250)

2750

(1) Refrigerant charge conversion factors:

(2) Normal charge is the refrigerant charge for warm ambient or summer operation.