Page 1

HALF

31/05/16

ROUND

EVAPORATORS

PRODUCT DATA &

INSTALLATION

T30-T-PDI-17

1047129

Questions about this product?

Email: evaps@t-rp.com

?

Call: 1-844-893-3222 x520

HIGH TEMPERA TURE APPLICATIONS

(35° F AND HIGHER)

AIR DEFROST

ELECTRICAL POWER:

115/1/60, 208-230/1/60

?

• Compatable with Low GWP Refrigerants

• Direct backwall location and minimum height provides

maximum usable storage space.

• Textured heavy gauge aluminum cabinet - lightweight,

doesn’t show scratches.

• Rigid, slotted channel hangers simplify installation.

• Hinged drain pan for ease of cleaning and service.

INCLUDES RATINGS FOR

NOMENCLATURE

T 375 W - M

TRENTON

HALF ROUND EVAPORATOR

BTUH CAPACITY

@ 1 °F TD (60Hz)

e.g. 450 = 4500 @ 10 °F TD

ELECTRICAL DESIGNATION

A = 115/1/60 W = 208-230/1/60

MOTOR

M = SINGLE SPEED EC MOTOR

• Full collar aluminum plate ns on expanded seamless

copper tubes ensure optimum heat transfer efciency.

• Fan motors are inherently protected

• Standard EC motors

CONTENTS PAGE

Nomenclature..........................................

Capacity Data...........................................

Electrical Data..........................................

Typical Field Wiring.................................

Dimensional & Physical Data.................

Thermostatic Expansion Valve..............

Installation Instructions..........................

Service Parts ..........................................

Service Log..............................................

Warranty...................................................

Project Information.................................

“As Built” Service Parts.........................

Cover

2

2

2

3

4

5

6

6

7

7

Back

Page 2

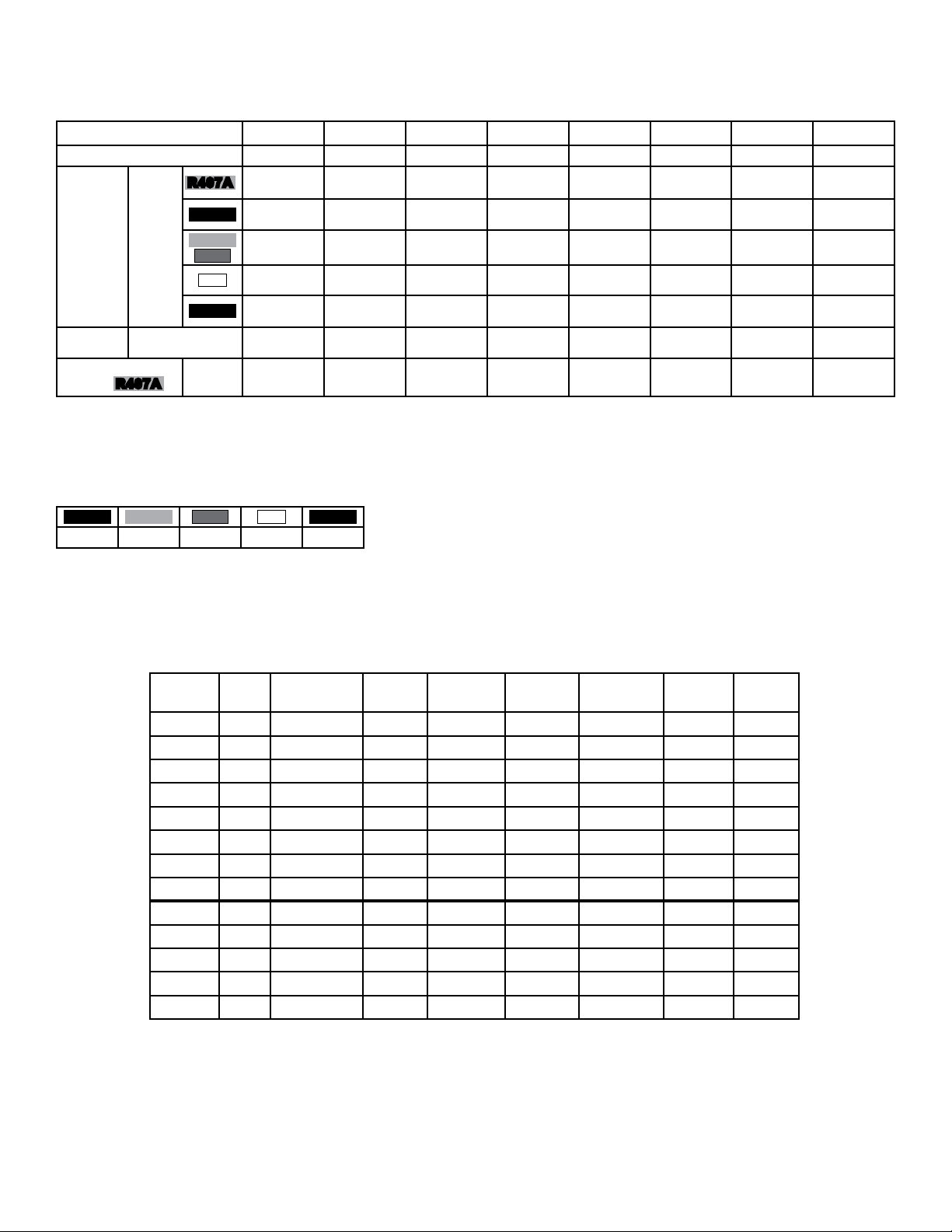

CAPACITY DATA - ALL MODELS

31/05/16

T30-T-PDI-17

- 2 -

T 60Hz

Model T375 T485 T595 T775 T905 T1025 T1305 T2050

Number of Fans 1 1 1 1 1 1 1 2

R407A

Capacity

BTUH

(WATTS)

Air Flow CFM (L/s)

Refrigerant **

Charge

Capacities rated using 10°F (5.6°C) TD & 100°F (38°C) liquid temperature.

Capacities at other TD within a range of 8 to 15 °F (4.4 to 8.3°C) are directly proportional to TD, or use formula: Capacity = Rated capacity ÷ 10 x TD.

For capacities at TD outside of range 8 to 15 °F (4.4 to 8.3°C), or liquid temperature lower than 75°F (24°), consult factory .

Capacities for R407A and R407C are based on mean temperature. Mean temperature is the average temperature between the saturated suction

temperature and the temperature feeding the evaporator. For dew point ratings, consult factory.

** REFRIGERANT CHARGE CONVERSION FACTORS

R407C

0.99 0.92 0.93 1.02 1.03

Evap

Temp.

25°F

(-4°C)

R407A

R404A

R407C

R404A

R507

R22

R134a

Lbs

(Kg)

R507

3540 4640 5750 7510 8460 9700 12200 19400

(1038) (1359) (1684) (2199) (2478) (2840) (3563) (5680)

3360 4392 5445 7110 8010 9180 11600 18400

(984) (1287) (1596) (2084) (2347) (2690) (3376) (5381)

3730 4880 6050 7900 8900 10200 12800 20400

(1093) (1430) (1773) (2315) (2608) (2989) (3751) (5979)

3540 4640 5750 7510 8500 9700 12200 19400

(1038) (1359) (1684) (2199) (2478) (2840) (3563) (5680)

3357 4392 5445 7110 8010 9180 11520 18360

(984) (1287) (1596) (2084) (2347) (2690) (3376) (5381)

770 770 1280 1300 1380 2025 2000 4050

(363) (363) (604) (614) (614) (956) (944) (1911)

1.4

(0.6)

R22

R134a

1.9

(0.9)

2.3

(1.0)

3.3

(1.5)

3.6

(1.6)

4.1

(1.9)

5.3

(2.4)

8.3

(3.7)

ELECTRICAL DATA

SINGLE SPEED EC MOTOR(S)

MODEL QTY.

T 375 1 115/1/60 1/20 1550 26 0.5 0.63 15

T 485 1 115/1/60 1/20 1550 26 0.5 0.63 15

T 595 1 115/1/60 1/20 1550 26 0.5 0.63 15

T 775 1 115/1/60 1/12 1070 84 1.5 1.88 15

T 905 1 115/1/60 1/12 1070 84 1.5 1.88 15

T 1025 1 115/1/60 1/12 1070 84 1.5 1.88 15

T 1305 1 115/1/60 1/12 1070 84 1.5 1.88 15

T 2050 2 115/1/60 1/12 1070 168 3.0 3.38 15

T 775 1 208-230/1/60 1/10 1070 86 1 1.25 15

T 905 1 208-230/1/60 1/10 1070 86 1 1.25 15

T 1025 1 208-230/1/60 1/10 1070 86 1 1.25 15

T 1305 1 208-230/1/60 1/10 1070 86 1 1.25 15

T 2050 2 208-230/1/60 1/10 1070 172 2 2.25 15

POWER

SUPPLY

HP RPM

WATTS

TOTAL

MOTOR FLA

MCA MOP

Page 3

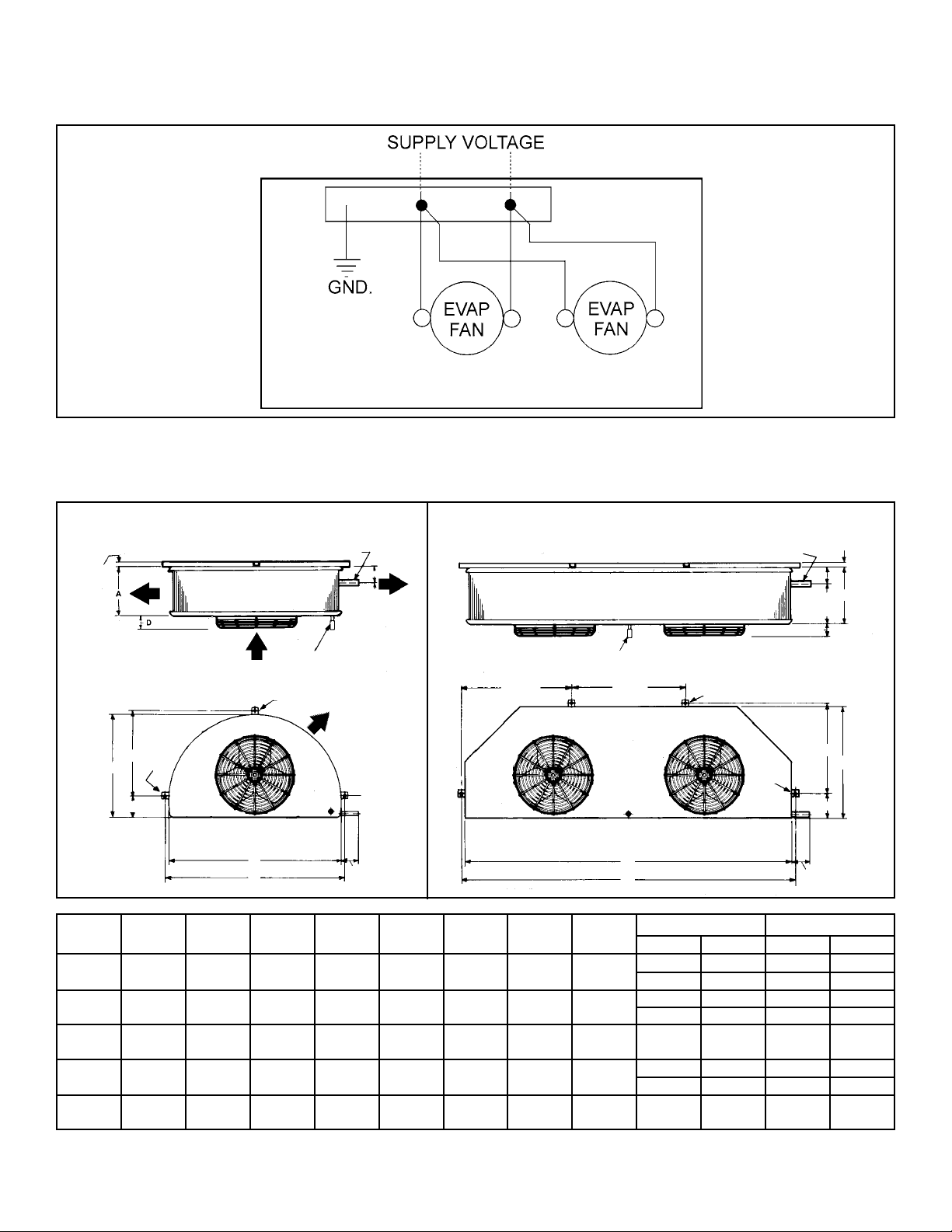

TYPICAL FIELD WIRING

31/05/16

T30-T-PDI-17

- 3 -

T 60Hz

2nd FAN MOTOR

ON T2050 MODEL

DIMENSIONAL AND PHYSICAL DATA

MODELS T375 to R1305 (Single Fan) MODEL T2050 (Double Fan)

FLOW

3 3/4”

(96mm)

AIR

FLOW

(APPROX.

15 FEET

THROW)

4” (102mm)

MAX

AIR

EXTERNAL EQUALIZER CONNECTION

1/4” (5mm) O.D. (INSIDE CASING)

5/8” (16mm) O.D. DRAIN

WITH PLASTIC SLEEVE

24 7/8”

(632mm)

1” (25mm)

AIR

FLOW

SUCTION

EXTERNAL EQUALIZER

CONNECTION

1/4” (5MM) O.D. (INSIDE CASING)

AIR

FLOW

7/16” (11mm) DIA. HOLE

E

C

G

5/8” (16mm) O.D. DRAIN

WITH PLASTIC SLEEVE

B

F

MODEL A B C D E F G

T375

T485

T595

T775

T905

T1025

T1305

T2050

in

mm

in

mm

in

mm

in

mm

in

mm

8 1/8

(206.4)

11 1/8

(282.6)

11 1/8

(282.6)

12 5/8

(320.7)

33 1/4

(844.6)

39 1/4

(997.0)

42 1/4

(1073.1)

42 1/4

(1073.1)

12 5/8

(320.7)74(1879.6)

20 3/4

(527.0)2(50.8)

23 3/4

(603.3)

25 1/4

(641.4)

25 1/4

(641.4)

25 1/4

(641.4)

2 1/4

(57.2)

2 1/2

(63.5)

2 1/2

(63.5)

2 1/2

(63.5)

16 3/4

(425.5)

19 3/8

(492.1)

20 3/8

(417.5)

20 3/8

(417.5)

20 3/8

(417.5)

34 3/4

(882.7)

40 3/4

(1035.0)

43 3/4

(1111.3)

43 3/4

(1111.3)

75 1/2

(1917.5)

4 3/4

(120.7)

5 1/8

(130.2)

5 5/8

(142.9)

5 5/8

(142.9)

5 5/8

(142.9)

NOTE: 5/8” (15.9 mm) O.D. Drain connection on all models.

1/2” (12.7 mm) Sweat TX Valve connection on all models.

SUCTION

25 3/4

(654mm)

B

F

7/16” (11mm) DIA. HOLE

Suct. Conn. O.D. Shipping Weight

in mm Lbs. Kg.

5/8 15.9 72 32.7

5/8 15.9 76 34.5

5/8 15.9 98 44.5

7/8 22.2 104 47.2

7/8 22.2 108 49

7/8 22.2 114 51.2

7/8 22.2 124 56.2

1 1/8 28.6 187 84.8

1” (25mm)

A

3 3/4”

(96mm)

D

E

C

4” (102mm) MAX.

Page 4

THERMOSTATIC EXPANSION VALVE

31/05/16

T30-T-PDI-17

- 4 -

T 60Hz

SELECTION CHART

FOR +35°F ROOMS AND UP

DEFROST

MODEL

T375

T485

T595

T775

T905

T1025

T1305

T2050

AIR

TD

R407A

°F

10 SBFVE-AAA-C SBFSE-AA-C SBFJE-AA-C

12 SBFVE-AAA-C SBFSE-AA-C SBFJE-AA-C

15 SBFVE-AA-C SBFSE-AA-C SBFJE-AA-C

10 SBFVE-AA-C SBFSE-AA-C SBFJE-AA-C

12 SBFVE-AA-C SBFSE-AA-C SBFJE-AA-C

15 SBFVE-AA-C SBFSE-A-C SBFJE-A-C

10 SBFVE-AA-C SBFSE-AA-C SBFJE-AA-C

12 SBFVE-AA-C SBFSE-A-C SBFJE-A-C

15 SBFVE-AA-C SBFSE-A-C SBFJE-A-C

10 SBFVE-AA-C SBFSE-A-C SBFJE-A-C

12 SBFVE-AA-C SBFSE-A-C SBFJE-A-C

15 SBFVE-A-C SBFSE-A-C SBFJE-A-C

10 SBFVE-AA-C SBFSE-A-C SBFJE-A-C

12 SBFVE-A-C SBFSE-A-C SBFJE-A-C

15 SBFVE-A-C SBFSE-A-C SBFJE-A-C

10 SBFVE-AA-C SBFSE-A-C SBFJE-A-C

12 SBFVE-A-C SBFSE-A-C SBFJE-A-C

15 SBFVE-A-C SBFSE-B-C SBFJE-B-C

10 SBFVE-A-C SBFSE-A-C SBFJE-A-C

12 SBFVE-A-C SBFSE-B-C SBFJE-B-C

15 SBFVE-A-C SBFSE-B-C SBFJE-B-C

10 SBFVE-A-C SBFSE-B-C SBFJE-B-C

12 SBFVE-B-C SBFSE-B-C SBFJE-B-C

15

SBFVE-B-C SBFSE-C-C SBFJE-C-C

SPORLAN VALVE MODEL

R407C

R22

R404A

R507

R134a

Selections based on 100° Liquid

Page 5

INSTALLATION INSTRUCTIONS

31/05/16

T30-T-PDI-17

- 5 -

T 60Hz

APPLICATION

High Temp Evaporators are designed for use with a wide

variety of popular refrigerants. At room temperatures above

34

°F and evaporating temps no lower than 27°F the air owing

through the coil will accomplish the defrost. Temperatures of

34

°F and below (to -40°F) require positive defrosting. (either

Electric or Hot Gas). The coil must not be exposed to any

abnormal atmospheric or acidic environments. This may result

in corrosion to the cabinet and possible coil failure (leaks).

(Consult manufacturer for optional baked on phenolic protective coatings).

INSTALLATION

The installation and start-up of evaporators should only be

performed by qualied refrigeration mechanics.

This equipment should be installed in accordance with all applicable codes, ordinances and local by-laws.

INSPECTION

Inspect all equipment before unpacking for visible signs of

damage or loss. Check shipping list against material received

to ensure shipment is complete.

IMPORTANT: Remember, you, the consignee, must make any

claim necessary against the transportation company.

Shipping damage or missing parts, when discovered at the

outset, will prevent later unnecessary and costly delays.

If damage or loss during transport is evident, make claim

to carrier, as this will be their responsibility, not the

manufacturer’s.

Should carton be damaged, but damage to equipment is not

obvious, a claim should be led for “concealed damage” with

the carrier.

IMPORTANT: The electrical characteristics of the unit should

be checked at this time to make sure they correspond to those

ordered and to electrical power available at the job site.

Save all shipping papers, tags and instruction sheets for reference by installer and owner.

LOCATION

The unit location in the room should be selected to ensure

uniform air distribution throughout the entire space to be refrigerated. Make sure that the air is not blown directly out through

the opened door and that the product does not obstruct the

free circulation of air.

NOTE: These units drawn air through the fan and discharge air from the coil side.

When installing the unit adjacent to a wall sucient

clearance (2” (50mm) minimum) must be provided to allow the

hinged drain pan to be lowered for servicing the unit. Channel

type hangers are provided. Rear hangers are slotted to facilitate installation. See dimensional data.

MOUNTING

Mounting brackets with 7/16” dia holes are provided for ush

mounting to the ceiling. For details refer to dimensional data on

page 3.

Ensure that the ceiling is level since the drain pan has

been sloped for drainage during the defrost cycle.

DRAIN LINE

The drain line should be run from the drain connection, sloping

at least 4” per foot. A trap outside the room will prevent warm

air from entering through the tubing.

Connection should be made to proper drainage facilities that

comply with local regulations.

Ensure that the drain pan has sucient slope for proper

drainage (prevention of ice build up/blockage in pan).

PIPING

Refrigerant line sizes are important and may not be the same

size as the coil connections. (depends on the length of run) If

in doubt, consult “Recommended refrigerant line sizes” charts.

(Engineering Manuals or other recognized sources of

information).

WIRING

Wire system in accordance with governing standards and local

codes. See data and wiring diagram on pages 2-3, for wiring

arrangement. Electrical wiring is to be sized in accordance with

minimum ampacity rating.

SYSTEM CHECK

Before Start-Up:

1. All wiring should be in accordance with local codes.

2. Refrigerant lines should be properly sized.

3. O-cycle defrost systems should include a liquid line

solenoid valve.

4. Thorough evacuation and, dehydration has been

performed.

5. The suction, discharge, and receiver service valves must

be open.

6. The system should include a liquid line drier moisture

indicator and suction lter.

7. Pour enough water into the drain pan to allow a good check

on drainage and seal the trap.

After Start-Up:

1. Check the compressor oil level to ensure the correct oil

charge.

2. Be sure that the expansion valve is properly set to provide

the correct amount of superheat.

3. Heavy moisture loads are usually encountered when

starting the system for the rst time.

4. Check for proper evaporator fan blade rotation.

MAINTENANCE

The unit should be periodically inspected for any dirt or

build-up on the n surface and cleaned if necessary with a soft

whisk or brush.

Page 6

SERVICE PARTS

31/05/16

T30-T-PDI-17

- 6 -

FOR SERVICE PARTS LOOK-UP:

visit: http://www.t-rp.com/serv_parts.htm

email: parts@t-rp.com

call: 1-844-893-3222 x501

SERVICE LOG

DATE COMMENTS

Page 7

FINISHED GOODS WARRANTY

31/05/16

T30-T-PDI-17

- 7 -

The terms and conditions as described below in the General Warranty Policy cover all products

manufactured by National Refrigeration.

GENERAL WARRANTY POLICY

Subject to the terms and conditions hereof, the Company warrants all Products, including Service

Parts, manufactured by the Company to be free of defects in material or workmanship, under normal use and application for a period of one (1) year from the original date of installation, or eighteen

(18) months from the date of shipment from the Company, whichever occurs rst. Any replacement

part(s) so supplied will be warranted for the balance of the product’s original warranty. The part(s) to

be replaced must be made available in exchange for the replacement part(s) and reasonable proof

of the original installation date of the product must be presented in order to establish the eective

date of the warranty, failing which, the eective date will be based upon the date of manufacture plus

thirty (30) days. Any labour, material, refrigerant, transportation, freight or other charges incurred in

connection with the performance of this warranty will be the responsibility of the owner at the cur-

rent rates and prices then in eect. This warranty may be transferred to a subsequent owner of the

product.

THIS WARRANTY DOES NOT COVER

(a) Damages caused by accident, abuse, negligence, misuse, riot, re, ood, or Acts of God (b) damages

caused by operating the product in a corrosive atmosphere (c) damages caused by any unauthorized

alteration or repair of the system aecting the product’s reliability or performance (d) damages caused

by improper matching or application of the product or the product’s components (e) damages caused by

failing to provide routine and proper maintenance or service to the product (f) expenses incurred for the

erecting, disconnecting, or dismantling the product (g) parts used in connection with normal maintenance,

such as lters or belts (h) products no longer at the site of the original installation (i) products installed

or operated other than in accordance with the printed instructions, with the local installation or building

codes and with good trade practices (j) products lost or stolen.

No one is authorized to change this WARRANTY or to create for or on behalf of the Company any

other obligation or liability in connection with the Product(s). There is no other representation, warranty

or condition in any respect, expressed or implied, made by or binding upon the Company other than

the above or as provided by provincial or state law and which cannot be limited or excluded by such

law, nor will we be liable in any way for incidental, consequential, or special damages however caused.

The provisions of this additional written warranty are in addition to and not a modication of or subtraction

from the statutory warranties and other rights and remedies provided by Federal, Provincial or State laws.

PROJECT INFORMATION

System

Model Number Date of Start-Up

Serial Number Service Contractor

Refrigerant Phone

Electrical Supply Fax

Page 8

“AS BUILT” SERVICE PARTS LIST

31/05/16

Service Parts List

Label

To Be Attached

HERE

NATIONAL REFRIGERATION &

AIR CONDITIONING CANADA CORP.

159 Roy Blvd.

Brantford Ontario Canada N3R 7K1

PHONE: (519) 751-0444 800-463-9517

FAX (519) 753-1140 www.t-rp.com

Due to National Refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice.

Loading...

Loading...