Page 1

TE100-DM/DS Series

Dual-Speed Hub

User’s Guide

Rev. 01 (May, 1998)

6012-0165001

Printed In Taiwan

RECYCLABLE

Page 2

Wichtige Sicherheitshinweise

1. Bitte lesen Sie sich diese Hinweise sorgf? tig durch.

2. Heben Sie diese Anleitung f? den sp? ern Gebrauch auf.

3. Vor jedem Reinigen ist das Ger? vom Stromnetz zu trennen. Vervenden Sie keine Fl? sigoder Aerosolreiniger. Am besten dient ein angefeuchtetes Tuch zur Reinigung.

4. Um eine Besch? igung des Ger? es zu vermeiden sollten Sie nur Zubeh? teile verwenden,

die vom Hersteller zugelassen sind.

5. Das Ger? is vor Feuchtigkeit zu sch? zen.

6. Bei der Aufstellung des Ger? es ist auf sichern Stand zu achten. Ein Kippen oder Fallen k?

nte Verletzungen hervorrufen. Verwenden Sie nur sichere Standorte und beachten Sie die

Aufstellhinweise des Herstellers.

7. Die Bel? tungs? fnungen dienen zur Luftzirkulation die das Ger? vor ? erhitzung sch? zt.

Sorgen Sie daf? , daß diese ? fnungen nicht abgedeckt werden.

8. Beachten Sie beim Anschluß an das Stromnetz die Anschlu? erte.

9. Die Netzanschlu? teckdose muß aus Gr? den der elektrischen Sicherheit einen

Schutzleiterkontakt haben.

10. Verlegen Sie die Netzanschlu? eitung so, daß niemand dar? er fallen kann. Es sollete auch

nichts auf der Leitung abgestellt werden.

11. Alle Hinweise und Warnungen die sich am Ger? en befinden sind zu beachten.

12. Wird das Ger? ? er einen l? geren Zeitraum nicht benutzt, sollten Sie es vom Stromnetz

trennen. Somit wird im Falle einer ? erspannung eine Besch? igung vermieden.

13. Durch die L? tungs? fnungen d? fen niemals Gegenst ? de oder Fl? sigkeiten in das Ger?

gelangen. Dies k? nte einen Brand bzw. Elektrischen Schlag ausl? en.

14. ? fnen Sie niemals das Ger? . Das Ger? darf aus Gr? den der elektrischen Sicherheit nur

von authorisiertem Servicepersonal ge? fnet werden.

15. Wenn folgende Situationen auftreten ist das Ger? vom Stromnetz zu trennen und von einer

qualifizierten Servicestelle zu ? erpr? en:

a– Netzkabel oder Netzstecker sint besch? igt.

b– Fl? sigkeit ist in das Ger? eingedrungen.

c– Das Ger? war Feuchtigkeit ausgesetzt.

d– Wenn das Ger? nicht der Bedienungsanleitung ensprechend funktioniert oder Sie mit

Hilfe dieser Anleitung keine Verbesserung erzielen.

e– Das Ger? ist gefallen und/oder das Geh? se ist besch? igt.

f– Wenn das Ger? deutliche Anzeichen eines Defektes aufweist.

ii

Page 3

16. Bei Reparaturen d? fen nur Orginalersatzteile bzw. den Orginalteilen entsprechende Teile

verwendet werden. Der Einsatz von ungeeigneten Ersatzteilen kann eine weitere Besch?

igung hervorrufen.

17. Wenden Sie sich mit allen Fragen die Service und Repartur betreffen an Ihren

Servicepartner. Somit stellen Sie die Betriebssicherheit des Ger? es sicher.

iii

Page 4

Trademarks

Contents subject to change without prior notice.

All trademarks belong to their respective proprietors.

Copyright Statement

No part of this publication may be reproduced in any form or by any

means or used to make any derivative such as translation, transformation, or adaptation without permission from the manufacturer, as

stipulated by the United States Copyright Act of 1976.

FCC Warning

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance

with this user’s guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

CE Mark Warning

This is a Class A product. In a domestic environment, this product

may cause radio interference in which case the user may be required

to take adequate measures.

VCCI A Warning

iv

Page 5

v

Page 6

TABLE OF C ONTENTS

ABOUT THIS GUIDE.................................................................xi

Models Covered........................................................................xi

Conventions .............................................................................xi

Overview of the User's Guide ..................................................xii

CHAPTER 1 : INTRODUCTION.....................................................1

Product Description..................................................................1

Product Features......................................................................2

Dual-Speed Ethernet Hub..........................................................4

Technology Overview ................................................................4

100BASE-TX Technology Overview............................................5

100Mbps Fast Ethernet Introduction.........................................................5

Cables and Connectors...................................................................................6

Topology.............................................................................................................6

Network Diameter...........................................................................................7

Hub Types.........................................................................................................7

CHAPTER 2 : UNPACKING AND SETUP......................................9

Unpacking ................................................................................9

Identifying External Components ............................................ 10

Front Panel.....................................................................................................10

Rear Panel.......................................................................................................12

Installing the Hub ...................................................................13

About This Guide vi

Page 7

Installation.....................................................................................................13

Rack Mounting...............................................................................................14

Replacing the Power Supply .................................................... 15

CHAPTER 3 : UNDERSTANDING INDICATORS ..........................17

Hub State Indicators............................................................... 18

Module Indicators (SLOT1 & 2) .............................................. 19

Port State Indicators .............................................................. 20

SNMP Indicator ..................................................................... 21

Port Speed Indicators ............................................................. 21

Console Port Indicator (CON).................................................. 22

CHAPTER 4 : MAKING CONNECTIONS.....................................23

Hub Cascad ing/Building a Stack ............................................23

Connectivity Rules.................................................................. 25

The Diagnostic Port................................................................ 26

Diagnostic Port Connection.........................................................................26

Hub to End-Station Connection............................................... 27

Hub-to-Hub Uplink ................................................................. 29

Optional Module Connections ..................................................31

Module Installation......................................................................................31

Switch Module................................................................................................32

Fiber Optic Module.......................................................................................33

Fast Ethernet Module..................................................................................34

CHAPTER 5 : MASTER HUB SETUP AND MANAGEMENT.........37

Navigation and Conventions ................................................... 38

In-Band Setup Instructions..................................................... 39

vii

Page 8

Dual-Speed Stackable Hubs User’s Guide

Backup Master Function ......................................................... 40

Segmenting Hubs.................................................................... 41

Logging in to the Hub Console ................................................ 43

Logging In ........................................................................................................43

Changing Your Password.............................................................................45

Setting Up the Master Hub ..................................................... 47

TCP/IP Settings .............................................................................................47

Out-of-Band Management and Console Settings ..................................49

Software Update on Boot.............................................................................50

SNMP Information........................................................................................52

SNMP Traps...................................................................................................53

SNMP Security (Community Names)......................................................55

Adding and Deleting Users .........................................................................56

Primary/Backup Master..............................................................................58

Hub Stack Management.......................................................... 59

Controlling Hubs in the Hub Stack...........................................................59

Controlling Individual Ports.......................................................................62

Monitoring the Hub Stack....................................................... 64

Displaying Port and Group Statistics.......................................................64

Displaying Segment Statistics...................................................................68

Node Trackin g................................................................................................70

Per-Port Intrusion Security.........................................................................71

Bridge Information........................................................................................71

Resetting the Hub................................................................... 72

System Reset..................................................................................................73

Factory Reset..................................................................................................74

APPENDIX A : CABLES AND CONNECTORS ............................75

100BASE-TX Ethernet Cable and Connectors........................... 75

Crossover Cables .....................................................................76

Diagnostic Port Specifications................................................. 77

RS-232 (DB9) Pin Specification.................................................................77

viii

Page 9

APPENDIX B : BOOT CONFIGURATION FILE...........................79

APPENDIX C : SPECIFICATIONS ..............................................83

General................................................................................... 83

Hub-to-Hub Cascading............................................................ 84

LED Indicators....................................................................... 84

Environmental and Physical ................................................... 84

APPENDIX D : GLOSSARY .......................................................87

INDEX.........................................................................................96

ix

Page 10

Page 11

0 A BOUT THIS GUIDE

This guide discusses how to install and use the TE100-DM/DS series

dual-speed, managed/unmanaged, stackable Ethernet/ Fast Ethernet

Hubs.

Models Covered

Unmanaged Models: TE100-DS16, TE100-DS16X, TE100-DS24,

TE100-DS24X.

Managed Models: TE100-DM16, TE100-DM16X, TE100-DM24,

TE100-DM24X.

All “X” models include a switch module in Slot 1 of the rear panel.

All “M” models are intelligent (that is, “managed”) hubs capable of

managing an entire hub stack.

The model numbers also indicate how many ports a particular hub

has, thus: DM16/DS16 hubs have 16 ports and DM24/ DS24 hubs

have 24 ports.

Conventions

References in this manual to the TE100-DS16, TE100-DS16X,

TE100-DS24, TE100-DS24X; TE100-DM16, TE100-DM16X, TE100DM24, and TE100-DM24X hubs are frequently written simply as

“hub” or “hubs” where the text applies to all models. Model numbers

About This Guide xi

Page 12

Dual-Speed Stackable Hubs User’s Guide

xii

are normally used only to differentiate between them where necessary.

At points in this document, master models are differentiated by referring to, “TE100-DM/DS series master hubs.”

Unless differentiated by model number or other specific reference, all

information applies to all models.

Overview of the User’s Guide

? ?Chapter 1, Introduction. Provides information on Fast

Ethernet networks, and introduces the features of the TE100DM/DS series hubs.

? ?Chapter 2, Unpacking and Setup. Helps you get started in

setting up the hub.

? ?Chapter 3, Understanding Indicators. Describes all LED in-

dicators on the hub’s front panel. Understanding these

indicators is essential to effectively using the hub.

? ?Chapter 4, Making Connections. Provides information on

connecting to the hub’s twisted-pair and console ports, stacking hubs, and linking with other 100BASE-TX hubs.

? ?Chapter 5, Master Hub Setup and Management. Provides

information on using the management agent built into master

models in the DH series.

? ?Appendix A, Cables and Connectors. Provides specifications

on the cables and connectors used with the hubs.

? ?Appendix B, Boot Configuration File. Describes the TE100-

DM/DS series master hub boot configuration file.

About This Guide

Page 13

xiii

? ?Appendix C, Specifications. Lists the hubs’ specifications.

? ?Appendix D, Glossary. Provides the meaning for some net-

working terms used in this manual.

About This Guide

Page 14

Page 15

1

1 INTRODUCTION

This chapter introduces the TE100-DM/DS series dual-speed stackable hubs, as well as giving some background information about the

technology the hubs use.

Product Description

The TE100-DM/DS series dual-speed stackable Ethernet/Fast

Ethernet hubs are designed to allow easy migration and integration

between 10Mbps Ethernet and 100Mbps Fast Ethernet, while providing manageability and flexibility in cable connections.

The TE100-DM/DS hubs can operate with either IEEE 802.3

10BASE-T connections (twisted-pair Ethernet operating at 10 meg abits per second), or IEEE 802.3u 100BASE-TX connections (twistedpair Fast Ethernet operating at 100 megabits per second). All of the

twisted-pair ports support NWay auto-negotiation, allowing the hub

to automatically detect the speed of a network connection. This

means you can connect all of your Ethernet and Fast Ethernet hosts

to a TE100-DM/DS series hub stack, without any rewiring required

when a host is upgraded from 10Mbps to 100Mbps.

The TE100-DM/DS series hubs, available in 16-port and 24-port

models, can be stacked with up to five hubs in a stack. A stack of

five 24-port hubs gives a total of 120 Ethernet or Fast Ethernet ports.

Introduction 1

Page 16

Dual-Speed Stackable Hubs User’s Guide

A TE100-DM/DS series hub stack operates as a Class II Fast

Ethernet repeater, allowing it to be linked to another Class II Fast

Ethernet stack in the same collision domain.

In the basic configuration, the 10Mbps and 100Mbps segments are

separate and do not intercommunicate. An optional switch module

(included with the TE100-DS16X, TE100-DS24X, TE100-DM16X, and

TE100-DM24X) can be installed in any hub in the stack, making it

possible to transparently bridge between the 10Mbps and 100Mbps

segments. In a managed hub stack, more than one switch module

can be used to provide redundancy if the two modules are both in the

primary master hub segment.

Other add-in modules are also available, providing switched

100BASE-TX, or switched 100BASE-FX connections. TE100-DM/DS

series hubs each have two slots for accepting slide-in modules.

Product Features

The list below highlights the features and specifications of the

TE100-DM/DS series hubs.

? ?Compatible with the IEEE 802.3 10BASE-T Ethernet and

802.3u 100BASE-TX Fast Ethernet industry standards for interoperability with other Ethernet/Fast Ethernet network

devices.

? ?Ethernet connections support Category 3 or better twisted-pair

cables.

? ?Fast Ethernet connections support both shielded twisted pair

and Category 5 unshielded twisted-pair cables.

? ?Fast Ethernet connections support a maximum distance of 100

meters from end-station to hub, and a total network diameter

of 205 meters.

Introduction 2

Page 17

? ?Sixteen (TE100-DS16, TE100-DS16X, TE100-DM16, TE100-

DM16X) or twenty-four (TE100-DS24, TE100-DS24X, TE100DM24, TE100-DM24X) NWay RJ-45 ports for connecting stations to the network.

? ?Full hub stack and network management provided via a

SNMP management agent (TE100-DM16, TE100-DM16X,

TE100-DM24, TE100-DM24X).

? ?An optional slide-in switch module allows bridging between

10Mbps and 100Mbps segments. Only one switch module is

needed per stack, but managed hub stacks can make use of

additional switch modules for redu ndancy.

? ?LED indicators for power, collisions, link, network activity,

partitioning status, disable, operating speed (10 or 100Mbps)

and network utilization .

? ?Digital hub ID number front panel display.

? ?Auto-partition protection.

? ?Data collision detection and handling.

? ?Preamble regeneration, signal re-timing.

? ?Two proprietary daisy-chain ports for cascading up to five hubs

to form one logical hub; management provided via a master

hub.

? ?Standby backup master capability when two master model

hubs are present within a single stack.

? ?Uplink port allows easy linking of two Fast Ethernet hub

stacks to further expand your network.

? ?Standard-size (19”, 1.25U height), rack mountable

? ?Built-in, removable power supply, replaceable without opening

the hub. Power supply is easily removed and replaced. Auto-

Introduction 3

Page 18

Dual-Speed Stackable Hubs User’s Guide

4

matic voltage selection (100V to 240V, 50 or 60Hz) without

fuses to change or a voltage switch to set.

? ?Optional slide-in modules: Switch, 100BASE-TX, and

100BASE-FX (see Chapter 4 : Making Connections).

Dual-Speed Ethernet Hub

Technology Overview

Dual-speed Ethernet hubs have been developed to make it simpler to

plan networks containing both 10Mbps Ethernet and 100Mbps Fast

Ethernet technologies, especially when network hosts are being

gradually migrated to new Fast Ethernet connections.

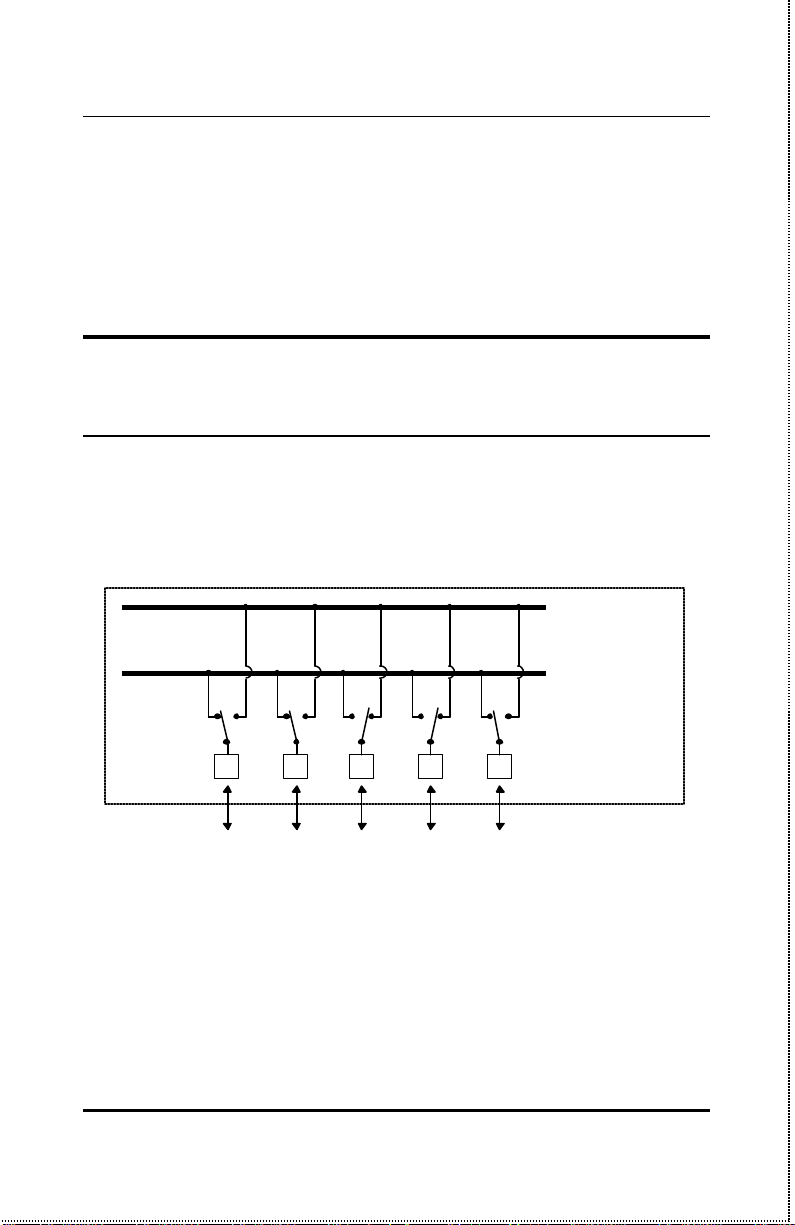

10Mbps Repeater

100Mbps Repeater

NWay Detection

RJ-45 Ports

100Mbps

Ethernet

Station

100Mbps

Ethernet

Station

10Mbps

Ethernet

Station

10Mbps

Ethernet

Station

100Mbps

Ethernet

Station

A dual-speed hub is actually two repeaters in one enclosure. The

10Mbps repeater receives Ethernet transmissions from any of its

ports, and retransmits them to all other ports operating at 10Mbps.

Similarly, the 100Mbps repeater retransmits Fast Ethernet transmissions from ports operating at 100Mbps to all other ports operating

at the same speed.

Introduction

Page 19

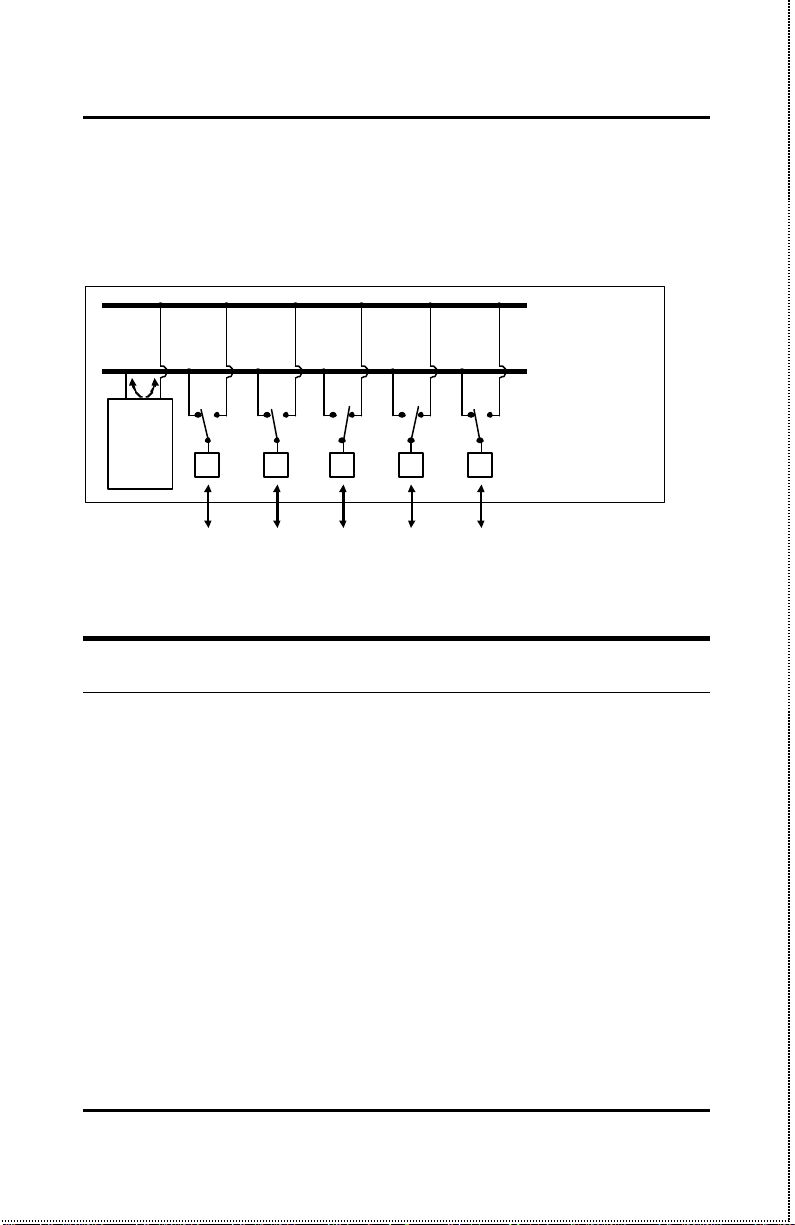

If there is a switch module, or a TE100-DS16X, TE100-DM16X,

TE100-DS24X or TE100-DM24X hub presents in the stack, then the

switch module serves as a bridge between the two indepen dent segments.

10Mbps Repeater

100Mbps Repeater

NWay Detection

TE100-DSM

Switch

Module

RJ-45 Ports

100Mbps

Ethernet

Station

100Mbps

Ethernet

Station

10Mbps

Ethernet

Station

10Mbps

Ethernet

Station

100Mbps

Ethernet

Station

100BASE-TX Technology Overview

100Mbps Fast Ethernet Introduction

Computers today have become increasingly powerful, with the capability to accommodate very sophisticated applications such as

multimedia applications, video-conferencing, and CAD/CAM. To utilize these technologically advanced applications more efficiently, there

is also a growing demand for faster networks that can handle heavy

network traffic.

Recognizing this need for greater bandwidth and lower latency, a

variety of technologies such as FDDI, ATM, and Fast Ethernet

(100Mbps) have been adopted by many vendors. Fast Ethernet tec hnology stands out as the most inexpensive and smoothest migration

Introduction 5

Page 20

Dual-Speed Stackable Hubs User’s Guide

path for existing 10Mbps Ethernet users in part because it doesn’t

require a protocol translation when sharing data with 10Mbps

Ethernet.

Fast Ethernet is a relatively new standard specified by the IEEE

802.3 LAN committee. It is an extension of the 10Mbps Ethernet

standard with the ability to transmit and receive data at 100Mbps,

while maintaining the CSMA/CD Ethernet protocol. Since Fast

Ethernet is compatible with all 10Mbps Ethernet environments, it

provides a straightforward upgrade without wasting the company’s

existing investment in hardware, software, and trained personnel.

Cables and Connectors

Category 5 unshielded twisted-pair (UTP) cables and shielded

twisted-pair (STP) cables are both supported. Category 5 UTP cable

uses the same RJ-45 connector used with 10BASE-T, wired in the

same configuration.

Topology

A Fast Ethernet workgroup is configured in a star topology and is

built around a maximum of two repeaters. Each workgroup forms a

separate LAN (also known as a segment or collision domain), and

these workgroups can be easily interconnected through switches,

bridges, or routers to form one LAN large enough to encompass a

high-rise building or campus environment. Recent innovations in

LAN hub technology such as stackable hubs, coupled with the decreasing cost of switches, bridges, and routers, allow the design of

low-cost, efficient Fast Ethernet workgroups and enterprise LANs.

The following factors strongly influence the architecture of Fast

Ethernet networks:

Introduction 6

Page 21

?? The EIA/TIA 568 Wiring Standard imposes a 100 meter limit

on horizontal runs of twisted-pair cables; that is, connections

from the wiring closet to the end-station.

?? Fast Ethernet’s increased operational speed reduces the

maximum distance between all elemen ts of the LAN (see below).

?? The EIA/TIA 568 Wiring Standard does not support the use of

coaxial cables for horizontal wiring.

Network Diameter

Network diameter, which is the distance between two end-stations in

the same collision domain, is the primary difference between traditional Ethernet and Fast Ethernet. Due to the increased speed in

Fast Ethernet and adherence to the EIA/TIA 568 wiring rules, the

network diameter of a Fast Ethernet collision domain is limited to

205 meters; in contrast, the maximum 10BASE-T Ethernet collision

domain diameter can be up to 500 meters.

Hub Types

Unlike 10BASE-T hubs which are all functionally identical, Fast

Ethernet hubs are divided into two distinct types: Class I and Class

II. A Class I hub repeats all incoming signals on one port to the

other ports by first translating them to digital signals and then retranslating them back to line signals. These translations are

necessary when connecting various network media to the same collision domain, such as when combining two wire-pair 100BASE-TX

media with four wire-pair 100BASE-T4 media. Only one Class I hub

can exist within the same collision domain, thus this type of hub

cannot be directly inter-linked. A Class II repeater, on the other

hand, immediately repeats all incoming line signals on one port to

the other ports; no translations are performed. This type of hub connects identical media within the same collision domain; for example,

Introduction 7

Page 22

Dual-Speed Stackable Hubs User’s Guide

TX to TX. At most, two Class II hubs can exist within the same collision domain.

As mentioned earlier, stackable Class II hubs can be used to increase

the number of available nodes in a collision domain. An entire hub

stack counts as a single repeater. TE100-DM/DS series hubs are

Class II devices.

Introduction 8

Page 23

2

2 U NPACKING AND

S ETUP

This chapter provides information on the unpacking and initial installation of your hub stack.

Unpacking

Open the shipping carton of your hub and carefully unpack the contents. The carton should contain the following items:

? ?One dual-speed stackable hub

? ?One AC power cord, suitable for your area’s electrical power

connections

? ?One daisy-chain cable

? ?Four rubber feet to be used for shock cushioning

? ?Six screws and two mounting brackets

? ?Management module diskette (master models only)

? ?This User’s Guide

Unpacking and Setup 9

Page 24

Dual-Speed Stackable Hubs User’s Guide

Inspect the hub and all accompanying items. If any item is damaged

or missing, report the problem to your dealer.

Identifying External Components

This section identifies all the major external components of the hub.

Both the front and the rear panels are shown, followed by a description of each panel feature. The indicator panel is described in detail

in the next chapter.

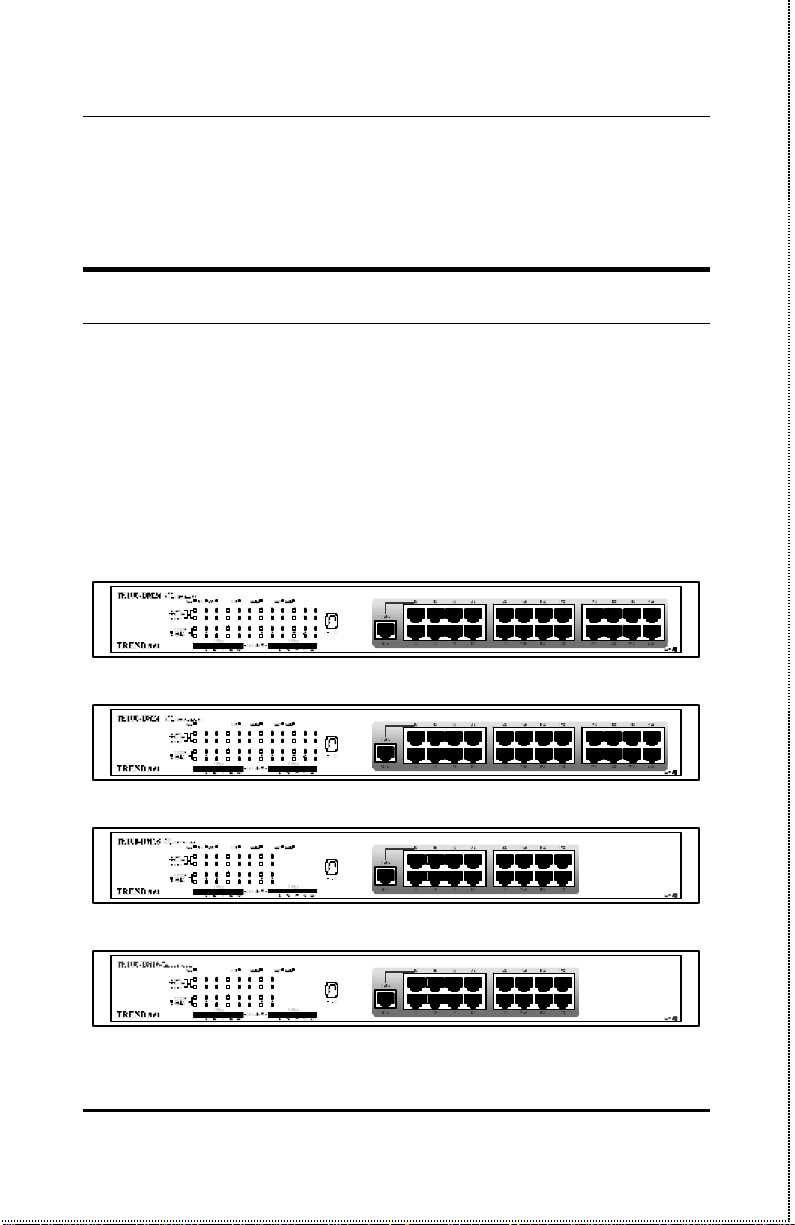

Front Panel

TE100-DM24 / TE100-DM24X Front Panel

TE100-DS24 / TE100-DS24X Front Panel

TE100-DM16 / TE100-DM16X Front Panel

TE100-DS16 / TE100-DS16X Front Panel

Unpacking and Setup 10

Page 25

? ?LED Indicator Panel

Refer to the next chapter, Understanding Indicators, for detailed

information about each of the hub’s LED indicators.

? ?Twisted-Pair Ports

Use any of these ports to connect stations to the hub. The ports

are MDI-X Nway ports, which means you can use ordinary

straight-through twisted-pair cable to connect the hub to PCs,

workstations, or servers through these ports, and the speed of the

connection will be detected automatically. If you need to connect

to another device with MDI-X ports such as another hub or an

Ethernet switch, you should use a crossover cable, or connect using the Uplink port (described below). For more information

about crossover connection, see the Crossover Cables section on

page 76.

? ?Uplink Port

The Up-link port is an MDI port, which means you can connect

the hub (or hub stack) to another device with MDI-X ports using

an ordinary straight-through cable, making a crossover cable unnecessary.

Port 1 and the Up-link port are the same logical port, except

their pin-outs are different. Do not use both Port 1 and the

Up-link port at the same time.

Unpacking and Setup 11

Page 26

Dual-Speed Stackable Hubs User’s Guide

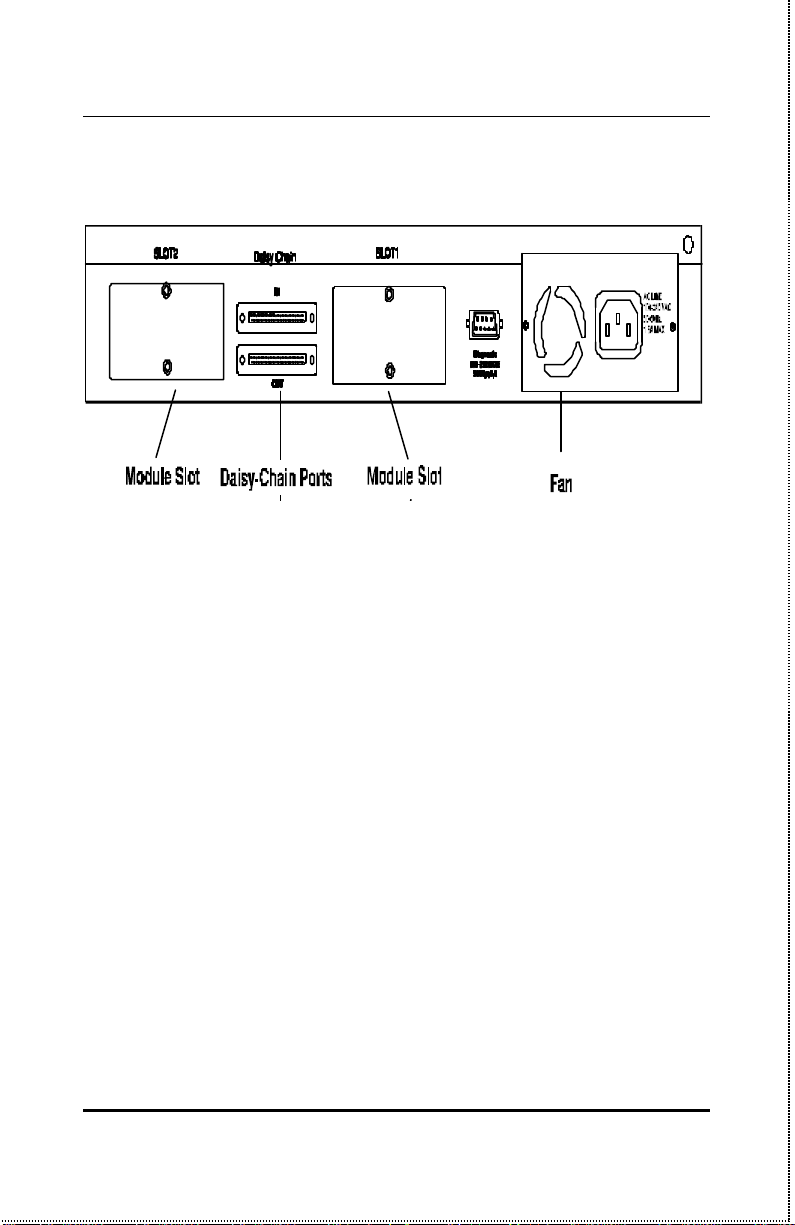

Rear Panel

(Note that the figure shows the rear panel for “Master” model.)

? ?Module Slots

Used to install module options for various kinds of additional con-

nections, as well as the switching 10Mbps/100Mbps bridge

module. (In the TE100-DS16X, TE100-DM16X, TE100-DS24X

and TE100-DM24X, module slot 1 is already occupied by the

“switch module” which is standard on these models.)

? ?Daisy-Chain IN Port

When cascading a set of stackable dual-speed hubs, this port

should be connected to the Daisy-Chain OUT port of the prev ious

hub in the stack (usually placed immediately above it). A cascade

of five hubs can be created in this way. The first and last hubs in

the stack use only one of the daisy-chain ports, while the others

use both.

? ?Daisy-Chain OUT Port

Works in conjunction with the Daisy-Chain IN Port (see above).

Connect this port to the Daisy-Chain IN Port of the next hub in

Unpacking and Setup 12

Page 27

the stack (usually placed immediately below it), using the enclosed daisy-chain cable.

? ?Diagnostic (Console) Port -- Master Models Only

This 9-pin serial connector is used for connecting a console to the

TE100-DM/DS series master hubs for out-of-band management of

this particular hub or the entire stack.

? ?Fan

Provides air circulation and heat dissipation. Be sure to leave

adequate space at the rear of the unit for proper ventilation.

? ?AC Power Connector

For the power cord.

Installing the Hub

Installation

The site where you install the hub stack may greatly affect its performance. When installing, consider the following pointers:

? ?Install the hub stack in a fairly cool and dry place. See Ap-

pendix D, Specifications, for the acceptable temperature and

humidity operating ranges.

? ?Install the hub stack in a site free from strong electromagnetic

field generators (such as motors), vibration, dust, and direct

exposure to sunlight.

Unpacking and Setup 13

Page 28

Dual-Speed Stackable Hubs User’s Guide

14

? ?Leave at least 10cm of space at the front and rear of the hub

for ventilation. For more information see, “Environmental and

Physical” on page 84.

? ?Install the hub on a sturdy, level surface that can support its

weight, or in an EIA standard-size equipment rack. For information on rack installation, see the next section, Rack

Mounting.

When installing the hub stack on a level surface, attach the rubber

feet to the bottom of each device. The rubber feet cushion the hub

and protect the hub case from scratching.

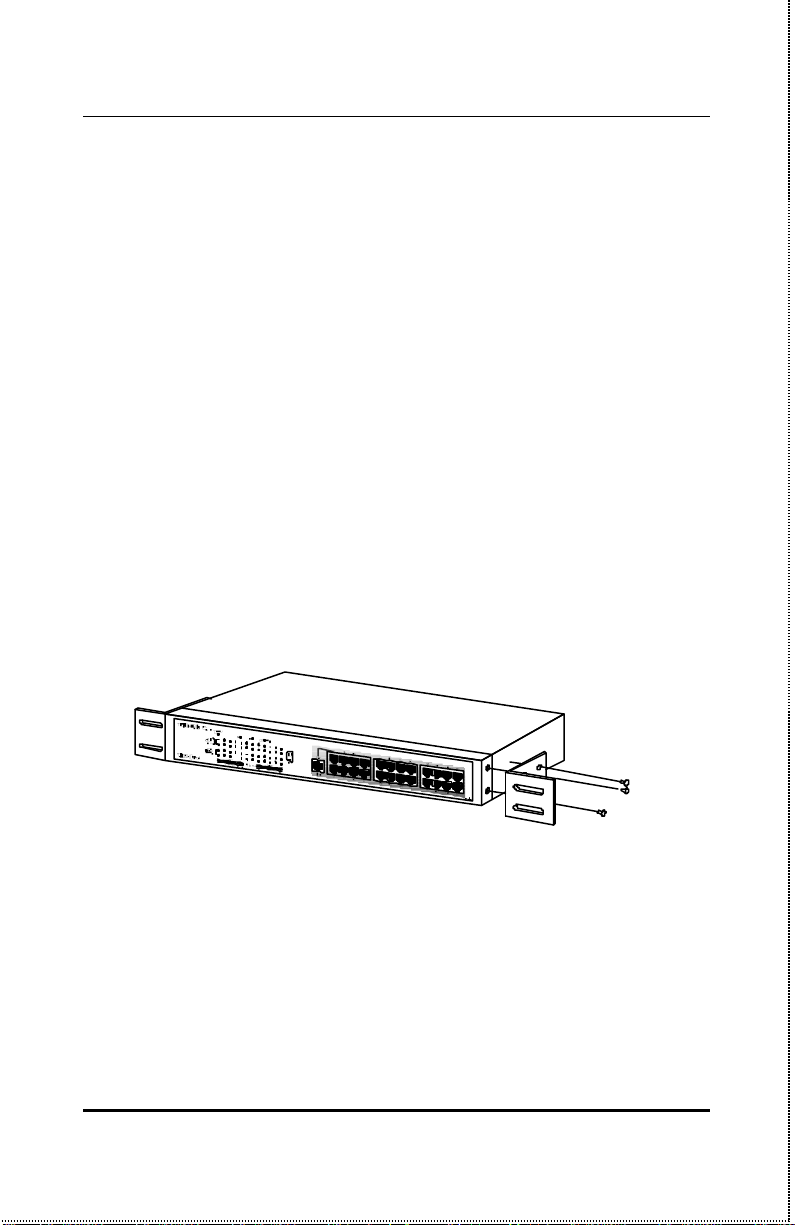

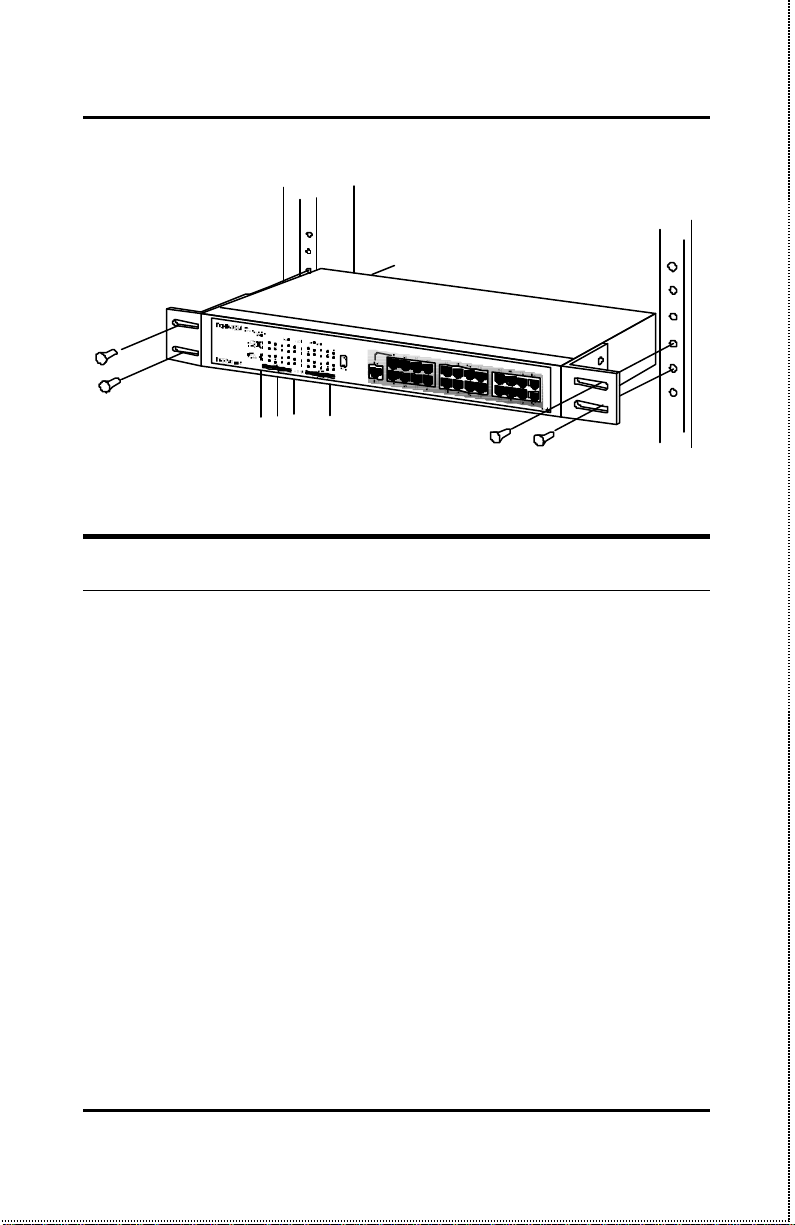

Rack Mounting

The hub can be mounted in an EIA standard-size, 19-inch rack,

which can be placed in a wiring closet with other equipment. Attach

the mounting brackets at the hub’s front panel (one on each side),

and secure them with the pr ovided screws.

Then, use screws provided with the equipment rack to mount each

hub in the rack.

Unpacking and Setup

Page 29

Replacing the Power Supply

The hub comes with a removable power supply for easy replacement.

In the unlikely event that the power supply fails or is damaged, follow the steps below to replace it:

1. Disconnect the power cord from the AC outlet.

2. Disconnect the power cord from its connector on the rear of the

hub.

3. Using a Phillips screwdriver, remove the screws securing the

power supply to release the unit.

4. Remove the power supply by sliding it out the rear of the chas-

sis. Do not plug in the power supply when it is outside the

chassis! Doing so could cause personal injury or damage to the

power supply.

Unpacking and Setup 15

Page 30

Dual-Speed Stackable Hubs User’s Guide

5. Slide the replacement power supply into the chassis, engaging

the connector carefully.

6. Attach the power cord to the connector of the power supply and

connect the other end of the power cord to the AC supply

source.

Unpacking and Setup 16

Page 31

3

3 U NDERSTANDING

INDICATORS

Before connecting network devices to the hub, take a few minutes to

look over this section and familiarize yourself with the front panel

LED indicators of your dual-speed hub, depicted below.

TE100-DM24 / TE100-DM24X Indicator Panel

TE100-DM16 / TE100-DM16X Indicator Panel

TE100-DS24 / TE100-DS24X Indicator Panel

Understanding Indicators 17

Page 32

Dual-Speed Stackable Hubs User’s Guide

TE100-DS16 / TE100-DS16X Indicator Panel

Hub State Indicators

? ?Power Indicator

This indicator lights green when the hub is receiving power ; oth-

erwise, it is off.

? ?Collision Indicators (COL10 and COL100)

These indicators indicate data collisions on the respective 10Mbps

Ethernet or 100Mbps Fast Ethernet segments of the hub. (If several hubs are stacked or linked together, all of them should detect

and indicate the same collision, since collisions span the entire

network segment.) Whenever a collision is detected, the respective COL indicator will briefly blink amber.

Understanding Indicators 18

Page 33

? ?Segment Utilization % (10Mbps and 100Mbps)

The utilization bar graphs provide a quick reference on the cur-

rent traffic load relative to the total available 10Mbps or 100Mbps

network bandwidth. The graphs display a measure of the percentage of bandwidth in use on the respective network segment.

All data packets are counted, whether valid or not.

? ?Hub ID Indicator

The Hub ID readout shows the ID (group) number of the hub

within the hub stack. The first time a hub is powered on within

a hub stack, the master hub in the stack assigns that hub an

available ID number which is then added to each hub’s factory serial number (encoded on an EEPROM memory chip). The hub ID

is then permanently assigned.

In an unmanaged stack (all slave models), all IDs will read “0”

and no permanent ID assignment is made. In a stack with a

master (intelligent) model, the master hub will detect the other

hubs in the stack and automatically assign ID numbers which

are then permanently saved by each hub.

Module Indicators (SLOT1 & 2)

The two module indicators, SLOT1 and SLOT2, indicate a good link

to a module installed in the respective slot. For the switch module

the indicator will come on when the module is installed. For other

modules, the slot link indicator should light whenev er the module is

installed and there is a valid link.

Understanding Indicators 19

Page 34

Dual-Speed Stackable Hubs User’s Guide

Port State Indicators

There is one port state indicator for each of the twisted-pair ports on

the hub. Each port? LED status indicator reports the port? link

and activity status, and shows whether or not the port has been partitioned.

The following describes each indicator and the meaning of each condition:

? ?Link (green)

The indicator of a port lights green when the port is connected to

a powered Ethernet or Fast Ethernet station. If the station to

which the hub is connected is powered off, or if there is a problem

with the link, the LED will remain off.

? ?Receive (blinking green)

When information is received on a port, its indicator will blink off

briefly. Upon reception, the data will be transmitted to all other

connected ports.

? ?Auto-partition (blinking amber)

The indicator of a port blinks amber when the port is automati-

cally partitioned due to an abnormal network condition.

The hub will temporarily partition a port when too many line er-

rors or too many collisions are detected on the port. While the

segment is automatically partitioned, the port will be isolated

from the rest of the network segment. When the problem is corrected or a valid data packet is received through the port, the port

is automatically reconnected.

? ?Disabled (steady amber)

Understanding Indicators 20

Page 35

The indicator of a port is orange when the port has been manually

disabled. No packet transmission or reception can occur on the

port.

If there is a TE100-DM16, TE100-DM16X, TE100-DM24, or

TE100-DM24X master hub in the stack, then ports can be manually disabled and enabled via the on -board console interface or via

an SNMP -based network management pr ogram. You can choose

to partition a port even when there is nothing wrong with it, for

example, to prevent a certain device from accessing the network.

SNMP Indicator

(Master models only.)

This indicator comes on when the SNMP agent of a TE100-DM/DS

series master hub is active. In a stack with both a Primary and a

Backup Master, the SNMP LED of the Primary master will be lit

and will flash to indicate SNMP activity. The SNMP LED of the

Backup Master will remain off at all times.

Port Speed Indicators

There is also a port speed indicator for each of the twisted-pair ports

on the hub. The port? speed indicator should light green when a

100BASE-TX device is connected to the port, it will remain dark if

the port is unconnected or if a 10BASE-T device is connected.

Understanding Indicators 21

Page 36

Dual-Speed Stackable Hubs User’s Guide

Console Port Indicator (CON)

(Master models only.)

This indicator lights continuously under the following two conditions:

1. A good connection has been established with a console (for example, a PC or other computer). The diagnostic port of a

TE100-DM/DS series master hub must be connected to the

console's RS-232 serial port using a normal serial cable.

OR

2. The console computer is on -line and connected to the on-board

console program either through terminal emulation or a

TELNET session.

Refer to Chapter 4, Making Connections, for directions on establishing a connection with the diagnostic port, and Chapter 5, Master

Hub Setup and Management, for information about how to use the

console interface.

Understanding Indicators 22

Page 37

4

4 MAKING C ONNECTIONS

This chapter discusses how to make connections to the hub’s?

twisted-pair ports and console port, cascading hubs to create a stack,

and linking with other hubs (or hub stacks).

Hub Cascading/Building a Stack

You can stack up to five hubs using the daisy-chain ports to form one

logical hub. In this configuration, the interconnected hubs constitute

a single logical unit, providing a maximum of 120 twisted-pair ports.

Use the provided daisy-chain cable to connect the Daisy-Chain OUT

port on the rear panel of one hub to the Daisy-Chain IN port on the

hub below it, as shown in the figure below. Repeat this pr ocedure for

each hub to be included in the stack.

Each time a new hub is added to the stack, all hub IDs will temporarily revert to 0, indicating a system reset. After the reset, the hub

IDs should return to their previous values.

Making Connections 23

Page 38

Dual-Speed Stackable Hubs User’s Guide

24

Hubs should not be added to the stack or removed from the stack

while the power is on at any hub in the stack.

Note: Always turns off power to the entire

stack before adding or removing hubs.

Making Connections

Page 39

Connectivity Rules

Ethernet (10Mbps) networks have the following connectivity rules:

? The maximum length of a twisted-pair cable segment is 100

meters. Cabling should be Category 3 or better (Category 5 for

100Base-TX connections).

? Between any two end-stations in a collision domain, there may

be up to five cable segments and four intermediate repeaters

(hubs, hub stacks, or other repeaters).

? If there is a path between any two end-stations containing five

segments and four repeaters, then at least two of the cable

segments must be point-to-point link segments (e.g., 10BASET or 10BASE-FL), while the remaining segments may be populated (mixing) segments (e.g., 10BASE-2 or 10BASE-5).

Fast Ethernet (100Mbps) networks have the following connectivity

rules:

? The maximum length of a twisted-pair segment (that is, the

distance between a port in the hub to a single-address network

device such as a PC, server, or Ethernet switch) is 100 meters.

Cabling and other wiring should be certified as Category 5

UTP or shielded twisted-pair (STP).

? The maximum diameter in a collision domain is about 205

meters using two Class II hubs (or hub stacks).

? Between any two end-stations in a collision domain, there may

be up to three cable segments and two Class II hubs or hub

stacks.

Making Connections 25

Page 40

Dual-Speed Stackable Hubs User’s Guide

The Diagnostic Port

The diagnostic port on the rear panel of the master hub is used to

establish a connection with a device to allow out-of-band management of the TE100-DM/DS series hubs stacked with it. The console

device connected to the diagnostic port can be a terminal (or a computer running terminal-emulating software) or a PC running

TCP/IP TELNET .

Diagnostic Port Connection

The diagnostic port is an RS-232 DCE interface. To establish a

physical line connection with an RS-232 serial port (DTE) on a PC

acting as a console, all you need is a straight serial cable, as shown

in below. Note that a DCE-to-DTE connection requires a straight

serial cable, not a null-modem cable.

You can use the diagnostic port on a TE100-DM/DS series master

hub to connect a VT100-compatible terminal or a computer running

an ordinary terminal emulation program (such as the Terminal Program included with the Windows operating system). In all cases,

your terminal parameters will need to be set to:

? VT-100/ANSI compatible,

? Arrow keys enabled,

? 9600 baud,

? 8 data bits,

? No parity,

? 1 stop bit.

Making Connections 26

Page 41

You can also access the same functions over a TELNET link. Once

you have set an IP address for your hub (see the beginning of this

chapter), you can use a TELNET program (in a VT -100 compatible

terminal mode) to access and control the hub. All of the screens are

for the most part identical, whether accessed from the diagnostic port

or from TELNET.

A console device can manage a TE100-DM/DS series master hub

operating in a stack master or stand-alone master role. Use the

on-board console program for out-of-band management or a SNMP

management software for in-band or out-of-band management.

A console device can only manage a TE100-DM/DS series hub if it

is cascaded to a TE100-DM/DS series master hub. Use either the

on-board console program or an SNMP-based network management program to manage the stack.

Hub to End-Station Connection

After installing the hub properly, it can support up to sixteen

(TE100-DS16, TE100-DS16X, TE100-DM16, TE100-DM16X) or

Making Connections 27

Page 42

Dual-Speed Stackable Hubs User’s Guide

twenty-four (TE100-DS24, TE100-DS24X, TE100-DM24, TE100DM24X) end-station connections. Fast Ethernet connections require

either a Category 5 UTP cable or a STP cable. These cables can be

up to 100 meters long.

Each Ethernet connection requires a Category 3 or better UTP cable.

It is recommended that you use Category 5 cabling for all connections. This makes it easier to upgrade all stations to 100Mbps.

You can connect any combination of PCs, servers, and other singleaddress network devices to the twisted-pair ports using straightthrough twisted-pair cables. These cables should not be crossed over.

The following figure illustrates the pin assignments for a straightthrough cable:

When connecting a PC or a server, the system being connected

should have an Ethernet or Fast Ethernet network interface card

with a twisted-pair port. The following figure shows a typical connection between the hub and end-stations:

Making Connections 28

Page 43

Hub-to-Hub Uplink

You can link two hubs or hub stacks to each other using any of the

twisted-pair ports or the Up-link port. Linking hubs using ordinary

twisted-pair ports requires crossover twisted-pair cables; linking using one ordinary twisted-pair port and the Up-link port requires an

ordinary straight-through twisted-pair cable. The Up-link port is

shared with Port 1, and you should not use both Port 1 and the Uplink port at the same time.

When connecting two hubs or hub stacks in this fashion, the maximum distance between any two end-stations in a collision domain is

205 meters. If each link between the hub and an end-station is 100

meters, then the hub-to-hub connection is limited to 5 meters. However, if the longest hub-to-end-station connection is less than 100

meters, then the hub-to-hub connection can be up to 100 meters as

long as 205-meter total network diameter rule is followed.

The following table describes different methods of linking hubs (or

hub stacks):

Making Connections 29

Page 44

Dual-Speed Stackable Hubs User’s Guide

HUB PORT

USED

Normal Switch or

Uplink Straight-Through (||)

Server (or PC) Straight-Through (||)

Uplink Switch or

Uplink Crossover (X)

Server (or PC) Crossover (X)

A crossover cable is a straight-through twisted-pair cable in which

the wires have been crossed. The figure below shows the pin assignments for an Ethernet or Fast Ethernet crossover cable:

DEVICE PORT

TYPE

Non-

Hub

Hub

Uplink

NonUplink

CABLE TO USE

Crossover (X)

Straight-Through (||)

NOTE: The first twisted-pair port (Port 1) is logically

shared with the Up-link port. If you connect

a hub to the Up-link port, then do not use

Port 1.

Making Connections 30

Page 45

Optional Module Connections

There are three optional modules that may be added to any of the

TE100-DM/DS series hubs. Each hub can accommodate two modules. Each of the modules offers a different additional network

interface that allows for greater flexibility in how these hubs may be

used in a network.

The sections that follow provide a brief overview of the module and

basic instructions on any settings and indicators.

Module Installation

The installation procedure for each module is the same. Additional

information about each module is provided below.

To install any of the modules:

1. Locate one of the module slots in the hub’s rear panel. (Note

that the TE100-DSM Switch Module can only be installed in Slot

1 – the center slot.)

2. Using a screwdriver, undo the two screws and remove the dust

cover on the module slot.

3. Holding the module component-side up and connector-side in,

gently slide the module along the guides and seat it in the internal connector.

4. Using a screwdriver, replace the two screws and tighten until

snug.

Making Connections 31

Page 46

Dual-Speed Stackable Hubs User’s Guide

We recommend that you retain the dust cover in case you need to

remove the module for an extended period sometime in the future.

Switch Module

The switch module is used to allow interconnection between the

10Mbps and 100Mbps segments in the hub or hub stack. Each hub

stack should have one switch module (such as the one included in the

TE100-DS16X, TE100-DM16X, TE100-DS24X or TE100-DM24X) to

allow 10Mbps and 100Mbps stations to intercommunicate. Note that

the switch module can only be installed in Slot 1 – the center slot.

Also the presence of switch modules and their operational status can

be viewed on the ”Network Monitoring – Bridge Information” screen.

NOTE: In a stack containing a TE100-DM16,

TE100-DM24, TE100-DM16X, or TE100DM24X intelligent master hub, more than

one switch module may be used to provide

increased reliability through redundancy.

The Spanning Tree Protocol implemented in

the management agent can control the

switch modules to provide link redundancy

and prevent network loops but only when

Making Connections 32

Page 47

multiple modules are installed in hubs on the

primary master segment.

Fiber Optic Module

The Fiber Optic module provides a standard Fast Ethernet

100BASE-FX fiber optic connector. A fiber optic connection of this

kind is particularly useful for creating a link between two TE100DM/DS series hub stacks, placing them in separate collision domains. A link of this sort eliminates the need for an external switch

to divide stacks into separate domains. Dividing the stacks into

separate collision domains overcomes the Fast Ethernet two-repeater

limitation, and effectively doubles overall bandwidth.

The Fiber Optic module includes the following LED indicators:

?? Power/Tx? this LED is lit when the hub is on and blinks when

the module is transmitting packets.

?? Link/Rx? this LED is lit when the fiber optic ports are properly

connected to a powered-on device and blinks when the module is

receiving packets.

?? Collision? this LED blinks when there are packet collisions on

the fiber optic link.

Making Connections 33

Page 48

Dual-Speed Stackable Hubs User’s Guide

34

?? FDX? this LED is lit when the fiber optic port is set for Full

Duplex transmit and receive. When the LED is off, the fiber optic port is in Half Duplex mode.

The duplex mode DIP switch allows you to set the fiber optic lines to

Full Duplex mode operation. Only the right-hand switch (number 2)

is active. Use it to set the duplex mode.

Fast Ethernet Module

The Fast Ethernet module provides one additional twisted-pair Fast

Ethernet connection. A twisted-pair connection of this kind is particularly useful for creating a link between two TE100-DM/DS series

hub stacks, placing them in separate collision domains. A link of this

sort eliminates the need for an external switch to divide stacks into

separate domains. Dividing the stacks into separate collision domains overcomes the Fast Ethernet two-repeater limitation, and

effectively doubles overall bandwidth.

The Fast Ethernet module uses a MDI-X connector (not a straight

MDI) and, therefore, a crossover cable must be used when connecting

the module to another module (and under most other circumstances).

See Appendix A for pin-out information.

The Fast Ethernet module includes the following LED indicators:

?? Power/Tx? this LED is lit when the hub is on and blinks when

the module is transmitting packets.

?? Link/Rx? this LED is lit when the port is properly connected to

a powered-on device and blinks when the module is receiving

packets.

Making Connections

Page 49

?? Collision? this LED blinks when there are packet collisions on

the module line.

?? FDX ? this LED is lit when the port is set for Full Duplex

transmit and receive. When the LED is off, the port is in Half

Duplex mode.

NOTE: Because the Fast Ethernet module? port is

a NWay UTP port, once the hub is powered

on, it will automatically detect the duplex and

speed modes of any device connected to it.

The DIP switch may then be set to force the

duplex mode into a particular state. After the

DIP switch is set, the module will only operate at 100Mbps in the duplex mode selected.

The duplex mode DIP switch allows you to set the port to Full Duplex mode operation. Only the right-hand switch (number 2) is

active. Use the DIP switch to set the duplex mode.

Making Connections 35

Page 50

Page 51

5

5 MASTER H UB SETUP

AND MANAGEMENT

The TE100-DM16, TE100-DM16X, TE100-DM24, and TE100DM24X master hubs (hereafter and elsewhere referred to as

“SNMP master hubs”) provide an on -board console program that

allows you to set up and control all TE100-DM/DS hubs stacked

with it. This program can be accessed either with an ordinary

terminal (or terminal emulator) or over the network using the

TCP/IP TELNET protocol. You can use this program to perform

many basic network management functions.

The console program also allows you to prepare the hub for management using an SNMP-based network management system.

This chapter describes how to use the console pr ogram to access

the hub, change its settings, and monitor its operation.

Note that if you want to manage the hub in-band you need to follow the instructions in the first section of this chapter (below) to

prepare the hub for in-band management. If you need information about connecting a console device to the diagnostic port for

out-of-band management, see the relevant sections of Chapter 4.

Master Hub Setup and Management 37

Page 52

Dual-Speed Stackable Hubs User’s Guide

Navigation and Co nventions

This section describes how to navigate the master hub management software and the conventions used in that software.

Navigation

The Tab keys move the cursor from field to field. Note that they

are uni-directional (i.e., Shift+Tab is not a functional combination). Up and Down arrow keys allow cursor movement between

some fields.

The Spacebar is a toggle switch for all variables that can be

changed but wherein possible values are preset.

The Delete and Backspace keys remove entered text as in most

software packages.

Pressing Ctrl-r refreshes the current screen.

Screen Conventions

A colon(“:”) precedes fields that cannot be changed.

Toggle changed fields are surrounded by angle brackets <>.

Variables with values that must be keyed-in are surrounded by

square brackets [].

Uppercase letters are reserved for command items such as SAVE

or LOGOFF. Highlighting the item and pressing Enter activates

the command.

Note: Both the navigation and screen conven-

tions information can be obtained under

HELP in the system management software.

Master Hub Setup and Management 38

Page 53

In-Band Setup Instructions

This section describes how to setup the hub for in-band management.

Getting Started

Physically install and cascade the hubs and power on the hub

stack according to the directions in other parts of this manual. At

this point, the hub stack is ready for use as an ordinary

unmanaged repeater.

The master hubs in the series come without IP addresses assigned (IP = 0.0.0.0). Without a valid IP address, the master hub

will show a POST error indication and repeatedly restart itself

once every minute or so. If you want to manage your hub using a

network management system, you will have to assign an IP address to the hub. There are two different ways to configure the

hub with a new address, as described below.

Assigning an IP Address Using BOOTP

If your Fast Ethernet network has a BOOTP (BOOTstrap Protocol) server, you can add the hub’s Ethernet (MAC) address (which

is printed on a sticker on the bottom of the hub, or you can obtain

it using the master hub console interface), IP address, subnet

mask, and boot filename to your BOOTP server’s configuration

tables. The boot filename field of the hub’s BOOTP configuration

should contain the filename of a TE100-DM/DS series master hub

boot configuration file accessible on your local TFTP (Trivial File

Transfer Protocol) server. This file can be empty. For more detailed information about the boot configuration file contents, see

Appendix C : Boot Configuration File of this manual.

Assigning an IP Address Using the Diagnostic Port

To assign an IP address manually,

Master Hub Setup and Management 39

Page 54

Dual-Speed Stackable Hubs User’s Guide

1. Connect a VT -100 compatible terminal or a personal com-

puter running a VT-100 compatible terminal emulation

program to the DB-9 console port at the rear of the master

hub. The cable should be an ordinary RS-232C cable. The

terminal communications parameters should be set to

9600bps, 8 bits, no parity, and 1 stop bit.

2. As the hub begins its boot process, hit Control-C to enter

the PROM System Menu.

3. Choose TCP/IP Parameters Configuration, and enter a

valid IP address, network mask, and (optional) gateway

router IP address. Choose SAVE and press <Enter> to let

the changes take effect, and then choose EXIT.

4. If you will not be using TFTP to download a hub configura-

tion file, choose Software Update and toggle the Software

Update Control to “Disable” using the Space Bar. Again,

choose SAVE and then EXIT.

5. Choose Execute Bootstrap to restart the hub.

You are now ready to use your TE100-DM/DS series hub stack,

and to manage it from a network management station on your

network. See the Stack Management User’s Guide for more information about how to manage the stack using a network

management pr ogram.

Backup Master Function

Within a TE100-DM/DS series hub stack, in addition to a master

hub for management purposes, a standby backup master can also

be installed. If a hub stack has two master units, the first powered-on Master unit or the unit that is higher in the stack will

Master Hub Setup and Management 40

Page 55

manage the stack and be designated as the ”Primary Master.”

Master hubs in the series include a built-in contention algorithm

which determines which hub will manage the stack and which

will operate in standby mode. If, during power -on, the two master

hubs in the stack both attempt to initialize as the Primary Master, this collision will result in an automatic stack reset indicated

by all hub ID numbers changing to 0 temporarily. If the current

Primary Master Hub fails or loses power, the standby master will

take over and manage the hub stack.

Segmenting Hubs

Switching hub technology has made it more common to segment

local area networks into smaller pieces to reduce congestion.

Segmenting makes it easier to balance network loads, since fewer

users are sharing the available bandwidth.

A hub stack makes network management convenient, but too

many stations on a single network segment may give slow response at peak network loads. Therefore, this hub series provides

a way to segment hubs from the stack into their own collision

domains. Segmenting hubs can be accomplished with a simple

management command and does not require any hardware or wiring changes.

Though the hubs continue to be cascaded together and are managed as a single unit, each hub can either be a part of the collision

domain of the rest of the stack, or can be separated into its own

network segment. These separate segments can be bridged by

connecting them through a compatible switching hub.

Master Hub Setup and Management 41

Page 56

Dual-Speed Stackable Hubs User’s Guide

The figure above shows an unsegmented hub stack. All hubs in

the stack are in the same collision domain because they are connected together through the daisy-chain ports.

The figure below shows a stack of hubs that is divided into three

separate collision domains. Hub three and four are isolated from

the main segment (collision domain one) using the hub's segmentation capability, putting them into their own isolated collision

domains two and three respectively. A switch, bridge or router

can be used to connect the three collision domains so that traffic

can pass between them, yet keeping them isolated to reduce congestion on each segment.

For information about segmenting hubs using the network management module for the hub, see the ”Hub Stack Management:

Controlling Hubs in the Hub Stack” section later in this chapter.

Master Hub Setup and Management 42

Page 57

NOTE: Hub Segmentation is controlled by the

master hub. When the master hub completes its initialization, it will restore any

prior segmentation of the hubs. Therefore, if you are using a switch or bridge to

join different segments, be sure to enable

the IEEE 803.1d Spanning Tree Protocol

to prevent temporary network loops

Logging in to the Hub Console

The TE100-DM/DS series master hubs support user-based security that allows you to prevent unauthorized users from accessing

the hub or changing its settings. This means that before you can

access the functions of the hub, you will need to first log into the

hub, providing a password. This section tells how to log onto the

hub, and how to change your password.

Logging In

When you first connect to the hub, it will display the login screen:

Master Hub Setup and Management 43

Page 58

Dual-Speed Stackable Hubs User’s Guide

44

To log in, complete these steps:

1. Type in your user name and press <Enter>.

2. Type in your password and press <Enter>.

3. With the cursor on the OK selection, press <Enter>.

NOTE: When the hub is shipped, the default user

name is TREND, and the default password is also TREND. You will need to use

this user name and password when you

first set up your hub or if you use the Factory Reset NVRAM to Default Value

menu selection. Change this user name

and password to protect the security

of your hub.

There are two levels of user privilege: Super User and General

User. The default user (TREND) has Super User privileges.

Some functions available to Super Users are not available to General Users. The main menu below is the menu for Super Users:

Master Hub Setup and Management

Page 59

Changing Your Password

To change your user password, follow these steps:

1. Choose User Account Change from the main menu.

2. Select Change Password. The following screen will be

displayed:

Master Hub Setup and Management 45

Page 60

Dual-Speed Stackable Hubs User’s Guide

Type in your user name and press <Enter>.

3. Type in your old password and press <Enter>.

4. Type in the new password you have chosen, and press <En-

ter>. Type in the same new password again in the next

blank space to verify what you typed.

5. Choose SAVE to put the new password into effect.

6. Choose EXIT to exit this screen.

This method can also be used by a Super User to change another

user’s password.

Master Hub Setup and Management 46

Page 61

Setting Up the Master Hub

This section describes how to set the hub’s console parameters for

various management options it supports. Note that the hub can

be managed in-band or out-of-band, and either through the builtin console program , or using an SNMP-management program.

TCP/IP Settings

The hub needs to have an IP address assigned to it so that the

network management system or TELNET client can communicate with it over the network. The TCP/IP Parameters

Configuration Menu allows you to change the settings for the two

different interfaces used by the hub: the internal Fast Ethernet

interface used for in-band communication, and the SLIP interface

used through the diagnostic port for out-of-band communication.

Note: if you need to set an IP address so that you can access the

hub console through a network, please see the first section of this

chapter.

Saved changes to any of the fields on this menu take effect the

next time the system is restarted. Fields that can be set include:

? ?Interface. This parameter displays the type of interface the

hub will use for management communications.

? IP Address. This parameter determines the IP address

used by the hub for receiving SNMP and TELNET messages. The address should be of the form xxx.xxx.xxx.xxx,

where each xxx is a number (represented in decimal) between 0 and 255. This address should be a unique address

on the network assigned to you by a network administrator.

The same IP address is shared by both the SLIP and

Ethernet network interfaces.

Master Hub Setup and Management 47

Page 62

Dual-Speed Stackable Hubs User’s Guide

? Subnet Mask. This parameter sets the subnet mask that

determines the level of the subnet that the hub is on. It

should be of the form xxx.xxx.xxx.xxx, where each xxx is a

number (represented in decimal) between 0 and 255. If no

subnetting is being done, the value should be 255.0.0.0 for a

Class A network, 255.255.0.0 for a Class B network, and

255.255.255.0 for a Class C network.

? Default Gateway. This parameter specifies the IP ad-

dress for a gateway or a router where frames with

destinations outside the current subnet should be sent. If

your network is not part of an inter -network, or you do not

want the hub to be accessible outside your local network,

you can leave this field blank.

? Send BOOTP Request upon Power Up. This parame-

ter determines whether or not the hub should send out a

BOOTP request when it is powered up. The BOOTP pr otocol allows IP addresses, network masks, and default

gateways to be assigned from a central BOOTP server; if

this option is set to “Yes”, the hub will first look for a

BOOTP server to provide it with this information before using local settings.

Master Hub Setup and Management 48

Page 63

The default setting for all TCP/IP variables is 0.0.0.0.

Out-of-Band Management and Console

Settings

You can use the Out-of-Band/Console Setting menu to choose

whether to use the hub’s RS-232 serial port for console management or for out-of-band TCP/IP communication using SLIP , and

to set the baud rate used for SLIP communications.

The following fields can be set:

? System Restart Out-of-Band Baud Rate. This pa-

rameter determines the serial port baud rate that will be

used the next time the hub is restarted. It applies only

when the serial port is being used for out-of-band (SLIP)

management; it does not apply when the port is used as a

console port. Available speeds are 1200, 2400, 9600, and

19200 bits per second.

Master Hub Setup and Management 49

Page 64

Dual-Speed Stackable Hubs User’s Guide

? Out-of-Band Dial-Up Phone Number . This information

is stored as a reference for the benefit of the system manager and does not cause the hub to dial out.

? System Restart Serial Port Setting. This parameter

determines whether the serial port should be used for out-ofband (SLIP ) management or for console management, starting from the next time the hub is restarted. It can be set to

either “Console” or “Out-of-Band.”

Software Update on Boot

The hub is capable of obtaining its boot-time configuration information, as well as updated versions of its internal firmware,

using TFTP (the Trivial File Transfer Protocol) and BOOTP (the

BOOT strap Protocol). You can use the Software Update menu to

control this feature.

The fields you can set on this menu are:

Master Hub Setup and Management 50

Page 65

? Software Update. This parameter determines whether or

not the hub will try to look for the configuration file over the

network. If set to Disable, the parameters below become irrelevant.

? Software Update Mode. This variable can be set to ei-

ther Network or Out-of-band. Determines whether the

configuration file should be obtained through the Ethernet

network or through the console port.

? Boot Protocol. This parameter can be set to either TFTP

ONLY or BOOTP & TFTP. Applies only if the S/W Update

control is enabled.

? Boot Server IP Address. This variable is the IP address

of the TFTP server where the configuration file is located.

This entry is used only if the S/W Update Control is en-

abled and your boot protocol is TFTP only ; if you are using

BOOTP&TFTP mode, or if Send BOOTP Request on Power

Up is enabled, the address will be obtained from the

BOOTP server.

? Boot File Name. The pathname of the configuration file

on your TFTP server. Normally, this is the pathname of

the .CFG file on your hard disk. This entry is used only if

your boot protocol is TFTP ONLY; if you are using BOOTP

& TFTP mode, or if Use BOOTP to get IP after start up is

enabled, the pathname will be obtained from the BOOTP

server. For more information about the TE100-DM/DS Series Master Hub configuration file, please see Appendix C,

Boot Configuration File.

Master Hub Setup and Management 51

Page 66

Dual-Speed Stackable Hubs User’s Guide

SNMP Information

The System Configuration Menu screen shows a variety of information about your hub, and allows you to set the System Name,

System Location, and System Contact. These settings can be retrieved from the hub using SNMP requests, allowing them to be

used for network management purposes. Each of these fields is

restricted to 64 characters:

? System Name. This parameter corresponds to the MIB-II

object sysName, and is used to assign a name to the hub for

administrative purposes. The hub’s domain name is often

used, provided a name has been assigned.

? System Location. This parameter corresponds to the

MIB-II object sysLocation, and is used to indicate the physical location of the hub for administrative pu rposes.

? System Contact. This parameter corresponds to the

MIB-II object sysContact, and is used to note the name and

Master Hub Setup and Management 52

Page 67

contact information of the person responsible for administering the hub.

? Display Timeout. An additional setting, the console

time-out, may be used to automatically log out the console

interface after a predetermined period of inactivity. This

feature increases hub security by preventing access to the

hub after the interface has been inadvertently left logged

on. A setting of 0 disables this feature.

SNMP Traps

The hub sends out SNMP traps to network management stations

whenever certain exceptional events occur, such as when the hub

is powered on or when an SNMP request is made using an unknown community name. An SNMP trap sent to another

network management site provides a warning about, for example,

an attempted unauthorized access to the network or hub, or

changes to a network hub’s configuration that may effect other

Master Hub Setup and Management 53

Page 68

Dual-Speed Stackable Hubs User’s Guide

54

parts of the network. Traps are sent only to selected network

management hosts. The hub allows up to four different hosts to

receive traps from the system.

The following trap parameters can be set:

? IP Address. This parameter specifies the IP address of the

network management station which will receive traps from the

hub.

? SNMP Community String. This parameter specifies

the SNMP community name to be included in the trap request.

? Status. This determines whether this trap entry is valid

or invalid. You can delete an entry by changing its status

to Invalid.

Master Hub Setup and Management

Page 69

SNMP Security (Community Names)

SNMP (version 1) implements a rudimentary form of security by

requiring that each request includes a community name. A

community name is an arbitrary string of characters used as a

”Password” to control access to the hub. If the hub receives a request with a community name it does not recognize, it will trigger

an authentication trap, provided this feature has not been disabled.

The TE100-DM/DS series master hubs allow up to four different

community names to be defined, and the access rights for each

community can be separately set to either read only or read/write.

The status for each string can be toggled to either valid or invalid.

The community names public and private are defined by default;

you can change these names in addition to adding others. You

will need to coordinate these names with the community name

settings you use in your network management system.

Master Hub Setup and Management 55

Page 70

Dual-Speed Stackable Hubs User’s Guide

Adding and Deleting Users

Access to the console program, whether using the diagnostic port

or TELNET, is controlled by user names and passwords. Up to

three user names can be defined. One user, named TREND, is

defined by default; this user name can be removed if desired.

However, the console program will not let you delete the currently

logged-in user to prevent you from accidentally deleting all users

with Super User privileges – making it impossible to change important hub settings.

Only users with Super User privileges can add and delete users.

Add a User

To add a new user, perform these steps:

1. Choose User Account Change from the main menu. The

following screen will appear:

Master Hub Setup and Management 56

Page 71

2. Choose Create New User fr om the User Account Change

menu.

3. Enter the new user name, and assign an initial password.

Determine whether the new user should have Super User

or General User privileges.

4. Choose SAVE and press <Enter> to let the user addition

take effect.

5. Choose EXIT to leave the Create New User menu.

Delete a User

To delete a user, follow these steps:

1. Choose User Account Change from the main menu.

2. Choose Change Access/Delete Users from the User Ac-

count Change menu.

Master Hub Setup and Management 57

Page 72

Dual-Speed Stackable Hubs User’s Guide

3. Toggle the Status field of the user you wish to remove to

N/A. (To temporarily restrict a user’s access to the hub

console, you can toggle that user’s Status to Inactive.)

4. Choose SAVE and press <Enter> to let the user deletion

take effect.

5. Choose EXIT to leave the Delete Users menu.

Primary/Backup Master

The Primary/Backup Master Hub screen, accessible from the

Network Monitoring menu, is used to display the stack management status of each master hub in the stack. Fields in this

screen are for information only and cannot be changed. The

group ID, primary/backup status, IP address, and MAC address

for master hubs in the stack are displayed.

Master Hub Setup and Management 58

Page 73

Hub Stack Management

Several important hub parameters useful in the day-to-day management of the hub can be viewed and controlled using the Group

Configuration and Port State menus.

Controlling Hubs in the Hub Stack

The Group Configuration Menu screen, found under the Network

Monitoring menu, displays information about each of the hubs in

the stack.

Note: In this context, “Group” means “Hub.”

Master Hub Setup and Management 59

Page 74

Dual-Speed Stackable Hubs User’s Guide

The items displayed on this screen are:

? Group ID . This field indicates which hub is being dis-

played.

? Group Serial Number. Displays the hub’s factory

assigned serial number.

? Group Position Number. Displays the hub’s stack

position relative to the other hubs (1 is the highest in the

stack, 5 the lowest).

? Group Description. This field gives a description of the

given hub, showing its model number .

? Group Role. Shows what role the hub is currently play-

ing in the hub stack (primary master , standby master, or

slave).

? Group Port Capacity. This field shows the total num

ber of network ports on the hub.

Note: When modules with additional ports are

installed in TE100-DM/DS series hubs,

the Port Capacity number will