Page 1

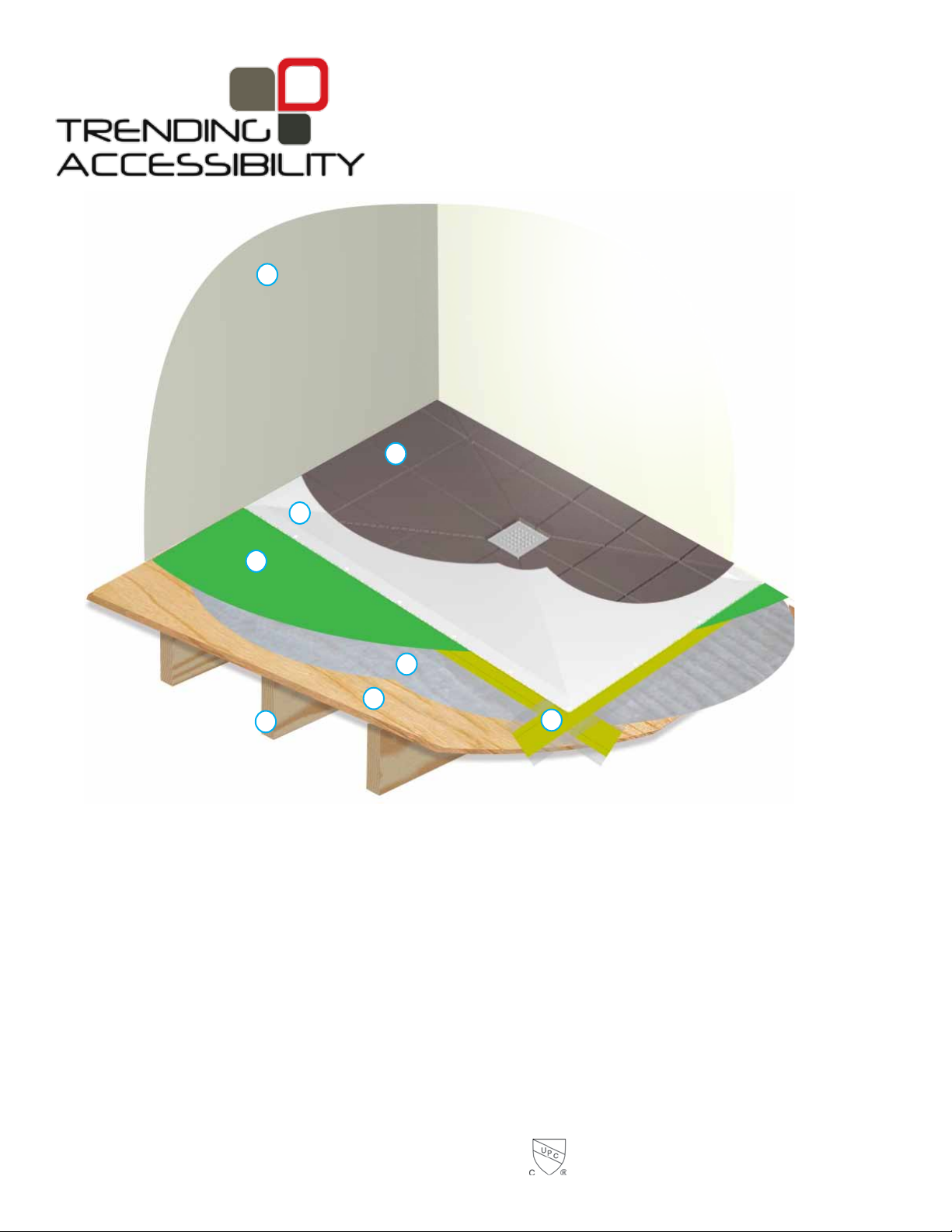

a) Wall

b) Tile

c) Shower Pan

a

b

c

d

d) Liquid waterproofing

e) Crack Isolation Tape

f) Cement Board

g) Subfloor

h) Joists

h

fusion shower pan

surface mounted

www.TrendingAccessibility.com

815 Hylton Road - Suite # 4

Pennsauken, New Jersey 08110

Phone: 856-488-9535 - Fax: 856-488-9576

f

g

e

on suboor

installation guide

2013/3/01Trending Accessibility

Page 2

b)

f)

Installation Guide

for fusion shower pan surface mounted on suboors

Required Components (included)

a) Fusion Standard Shower Pan

b) Tile Drain

c) LiquidWaterproong

d) One Roll Rubberized Crack Isolation Tape

c)

e) 2 - Inside corners of Rubberized Crack Isolation Tape

f) Gasket Membrane

15 - 2 1/2” screws

4 - 3/4” screws

2

e)

d)

a)

Required Tools (not included)

• Drill

• Jigsaw

• Level

• Square

• Caulk Gun

• Hammer

• Utility Knife or Scissors

• Tape Measure

• Paint Rollers

• Paint Brush

• Belt or Orbital Sander / Sandpaper

• Latex or Acrylic Caulk

• Splash Goggles

• Chemically resistant or impermeable

gloves

www.trendingaccessibility.com info@trendingaccessibility.com

Page 3

Installation Guide

for fusion shower pan surface mounted on suboors

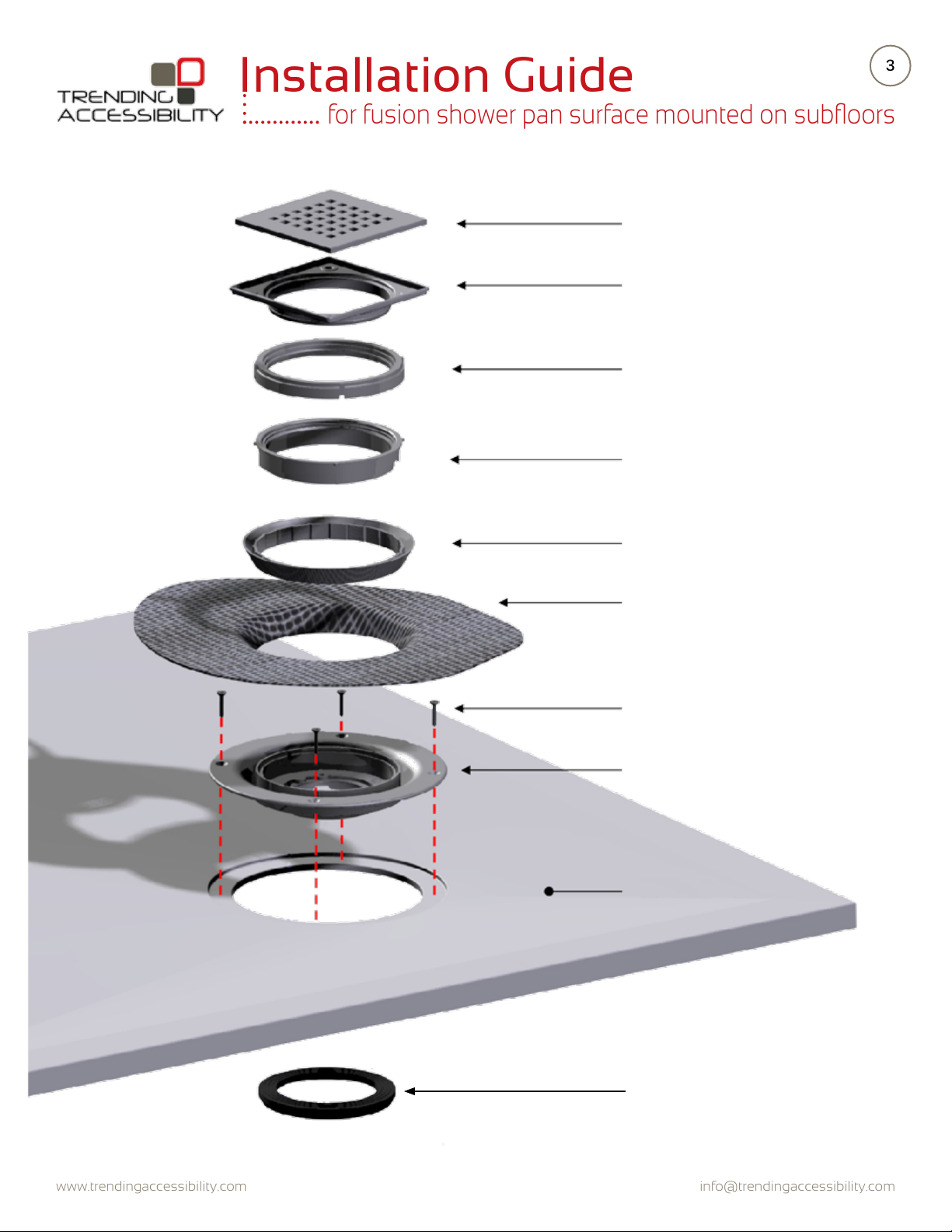

Stainless Steel Grate

Stainless Steel Grate Frame

Height Extension Ring (5/8” - 1”) -

This must be fixed in place using solvent cement.

Height Adjustment Ring (1/4” - 5/8”

rotate counter-clockwise to increase height - This must be

fixed in place using solvent cement.

3

Gasket Clamp (use solvent cement

on inner face to achieve seal)

Gasket Membrane

3/4” Screws

Drain Adapter Flange

Fusion Pan

Sealing Washers

www.trendingaccessibility.com info@trendingaccessibility.com

Page 4

Installation Guide

for fusion shower pan surface mounted on suboors

Step 1 > > > > > > > >

For optimal performance, it is imperative there

is a level surface prior to installation of new

Fusion Shower Pan. Check existing floor to make

sure it is level. If it is not, please correct prior

to installation. Place the Fusion pan in desired

location and check to make sure it is level.

Step 2 > > > > > > > >

4

subfloor

The Standard Fusion

Pan is trimmable

up to 2” around the

perimeter.

Once the pan is in the desired location, holding the

pan steady, trace the inner circle of the pan. You

have now marked the location of the drain on your

subfloor.

Step 3 > > > > > > > >

Using your mark as a guide, cut a hole that is

10” in diameter. Make sure to adjust the depth of

your saw to the thickness of the subfloor to avoid

cutting through the joists. It is best to use a jigsaw

to accurately cut your circle. Note: If possible,

please check or mark location of existing plumbing

and electrical to avoid damaging them.

Step 4 > > > > > > > >

Set the pan into place. Note location of the drain

and make your connections to the waste line.

Install drain in accordance with current plumbing

and building codes.

www.trendingaccessibility.com info@trendingaccessibility.com

Page 5

Installation Guide

for fusion shower pan surface mounted on suboors

Step 5 > > > > > > > >

For your dry run, position the Fusion pan into place

and check to make sure the pan is level. If you

notice any rocking or flexing in the pan, you may

need to shim or shave areas.

Step 6 > > > > > > > >

5

IMPORTANT: You must sand the top of the pan

lightly with a palm or belt sander to roughen up the

surface for proper adhesion of waterproofing.

Step 7 > > > > > > > >

To prep for permanent installation, remove the Fusion

pan from the surface. Apply a generous amount of

construction adhesive to the subfloor.

Step 8 > > > > > > > >

Carefully set the Fusion pan into place. Drill and

countersink holes in the Fusion pan. Using the 2 ½”

screws provided, attach the pan. Do not aggressively

screw and over tighten, as you may force the pan out

of level.

www.trendingaccessibility.com info@trendingaccessibility.com

Page 6

Installation Guide

for fusion shower pan surface mounted on suboors

6

Step 9 > > > > > > > >

On top of existing subfloor and walls install cement

backerboard in preparation for tiling. Make sure

that the top of the backerboard is roughly 1/8”

higher than the Fusion pan. Start with a bed of

thinset using a 1/4” notched trowel. Next, attach

the first layer of

board screws 8” on center. Then, making sure to

stagger the joints, attach the second

backerboard with 1 5/8” cement board screws 8” on

center. Finally, finish the joints with alkali-resistant

mesh tape.

1/2” backerboard with 1 1/4” cement

layer of

1/2”

Step 10> > > > > > > >

Check that the Fusion Pan is level on all four sides.

Fill in any gaps around the perimeter of the pan over

1/8” with latex or acrylic caulk.

Do not use 100% silicone.

thinset

1/2” backerboard

1/2” backerboard

subfloor

Step 11 > > > > > > > >

You now want to attach the Drain adapter flange

to the Fusion Pan. First apply a bead of caulk to

the underside of the drain adapter flange. Lightly

push the flange into place, and screw it down

using the four ¾” screws provided. Remove any

excess caulk that squeezes out.

Step 12 > > > > > > > >

Make your final connections to the drain. First

apply a bead of caulk to the underside of the

strainer body. Pass the strainer through the drain

adapter flange, and tighten. Make sure connection

is snug but do not over tighten.

Gasket Clamp

Adapter Drain Flange

membrane clamp

height adjustment ring

Remove the tile height adjustment ring and membrane clamp and

place to one side; these will be required later in the installation.

www.trendingaccessibility.com info@trendingaccessibility.com

Page 7

Installation Guide

for fusion shower pan surface mounted on suboors

Step 13 > > > > > > > >

You will now begin waterproofing the wet room.

BEST PRACTICE: To achieve the best results, we

recommend waterproofing the whole room.

Minimum requirements, shown in these

instructions, show you that you only have to

waterproof the shower zone, which is 6 ½ feet high

and about 2 feet outside of the showering area.

Step 14 > > > > > > > >

Begin taping the wetroom floor at the interior corners

of the Fusion Pan using the corner pieces of the

crack isolation tape provided. Using a paint brush or

trowel, slather liquid waterproofing into corner, press

piece into place, then apply liquid waterproofing on

top. Make sure to smooth out any creases. Repeat for

additional corners.

7

Materials needed for wet room waterproofing.

Step 15 > > > > > > > >

Using the 5” crack isolation tape provided, cut

strips of tape to length, to cover all seams (Corner

seams, wall/floor seams, pan/floor joint). Put

pieces aside.

If you are creating full wet room, you will need to tape

any seams throughout the entire room.

If you are only waterproofing the shower zone, you

will only need to tape the seams up to 2 feet outside

the shower area.

Step 16 > > > > > > > >

Just like you applied the corner pieces, use your

cut strips of Crack Insulation Tape to cover all the

seams. Again, trowel or paint liquid waterproofing

onto seam, press tape into position and coat

the top to seal. Make sure to fully cover both

sides of the crack isolation tape with the liquid

waterproofing product. To make this process more

manageable, it is best to work in two foot sections.

NOTE:

Illustration just shows tape use.

Please apply liquid waterproofing to the wall and tape before

applying.

2 feet

Extend the tape

2 feet past the

shower pan

www.trendingaccessibility.com info@trendingaccessibility.com

Page 8

Installation Guide

for fusion shower pan surface mounted on suboors

Step 17 > > > > > > > >

Using the 5” crack isolation tape. Overlap all seams

of cement board used on either the floors or walls.

Overlap the seam where the Fusion pan and cement

board meet.

8

Make sure the tape

overlaps the seams

equally.

Step 18 > > > > > > > >

Using the provided precut piece of gasket

membrane, slather area where gasket piece

will adhered to the drain area. Place over drain

adapter flange, making sure to cover all screw

holes, and securely press down into flange. Coat

top of gasket piece with liquid waterproofing.

Important: Remember to remove the clamping

ring prior to placing drain gasket.

Step 19 > > > > > > > >

Now attach the clamping ring. Apply solvent

cement to inside of clamping ring. Press firmly into

position and allow the solvent to set.

NOTE: Do not allow the solvent cement to come

into contact with the membrane

Gasket Clamp

Drain Adapter Flange

Gasket

Membrane

Gasket Clamp

Drain Adapter Flange

Gasket Membrane

Step 20 > > > > > > >

Begin the application of the liquid waterproofing

membrane. Paint a layer of liquid waterproofing

over all taped joints. It is easiest to begin with the

walls first and then proceed to the floor area. For

consistant application, use a paint roller to apply

waterproofing to all surfaces. After first coat is dry,

re-coat.

www.trendingaccessibility.com info@trendingaccessibility.com

Page 9

Installation Guide

for fusion shower pan surface mounted on suboors

Step 21 > > > > > > > >

Apply two coats of liquid waterproofing to achieve

2 mils. (roughly the thickness of a credit card)

Make sure that the “V” section of the gasket clamp

is filled with the liquid waterproofing.

Pro-Tip > > > > > > > >

9

To achive the best results, we recommend

waterproofing the whole room.

1/4” to 5/8” Tile Height

5/8” - 1” Tile Height

Step 22 > > > > > > >

In order to set the correct height of the grate frame,

you may need to use the height extension ring

(see diagram to the right). If the height extension

ring is required, it will need to be fixed to the height

adjustment ring using solvent cement. The grate

frame can now be attached to the height adjustment

or extension ring, depending on tile thickness. This is

done by using firm pressure to clip the components

together; it is a tight fit.

grate frame

“click”

adjusting ring

Step 23 > > > > > > >

The height adjustment ring and floor drain must

now be fixed together using solvent cement.

Because solvent cements sets very rapidly we

strongly recommend the adjustment is done “dry”

first.

To set the permanent height of the grate frame,

place a floor tile beside the frame. Rotate the frame

until the height is about 1/16” higher (this accounts

for adhesive thickness). Now mark the position

of the adjustment ring. This mark shows the

final height position. Remove ring, apply solvent

cement, and re-align components to your marked

position. It is best to hold securely until pieces are

fully bonded.

www.trendingaccessibility.com info@trendingaccessibility.com

grate frame

extention ring

adjusting ring

Page 10

Installation Guide

for fusion shower pan surface mounted on suboors

Step 24 > > > > > > >

You are now ready to tile. If you are using large

format tiles, they must be cut diagonally and laid

to follow the pitch in the Fusion Pan (From the

corners of the grate frame to the corners of the

Fusion Pan). Apply the tile adhesive, and lay the

tiles in a regular pattern.

Step 25 > > > > > > >

10

Once your tiling is complete, grout the floors and

walls. Finalize by adding the drain grate.

Your Fusion Pan installation is now complete.

Enjoy!

www.trendingaccessibility.com info@trendingaccessibility.com

Loading...

Loading...