Page 1

ACCESSIBLE BATHTUB REPLACEMENT SHOWER

STORAGE AND HANDLING OF FOUR PIECE SHOWER UNITS

Most handling damage is the result of impact blows to the back side of the fiberglass units.

1.

These sectional units are typically unpacked and unbolted so the separate parts may be moved to the installation

2.

area. Please use caution when unbolting the sections. Carry the parts with minimal flexing to avoid stress cracks.

(Measure and mark supply valve and shower head locations before unbolting).

Placing objects inside the unit can cause scratches or nicks to the finished surface.

3.

Do not use the shower as a trash receptacle! Always place a drop cloth or cardboard

inside the shower.

Storing units outside right-side up can cause sunlight to discolor the gelcoat finish. Also, unit becomes unstable

4.

and is easily knocked over by wind or bumping.

The back of a fiberglass unit is not waterproof. Unit must be stored so water will drain off and not accumulate

5.

in one spot. Water can permeate the back laminates and soak the glassed in wood or cardboard supports causing

bulges in the gelcoat surface.

Never drag a fiberglass unit on any surface. Always transport the unit by hand using (2) people or two wheel dolly.

6.

Never let a fiberglass unit drop from any height, not even an inch or stress cracks are likely to occur.

7.

on the floor when working

Never clean fiberglass gelcoat surface with metal tools of any kind, including razor blades.

8.

VERY IMPORTANT FOR LOW THRESHOLD SHOWER:

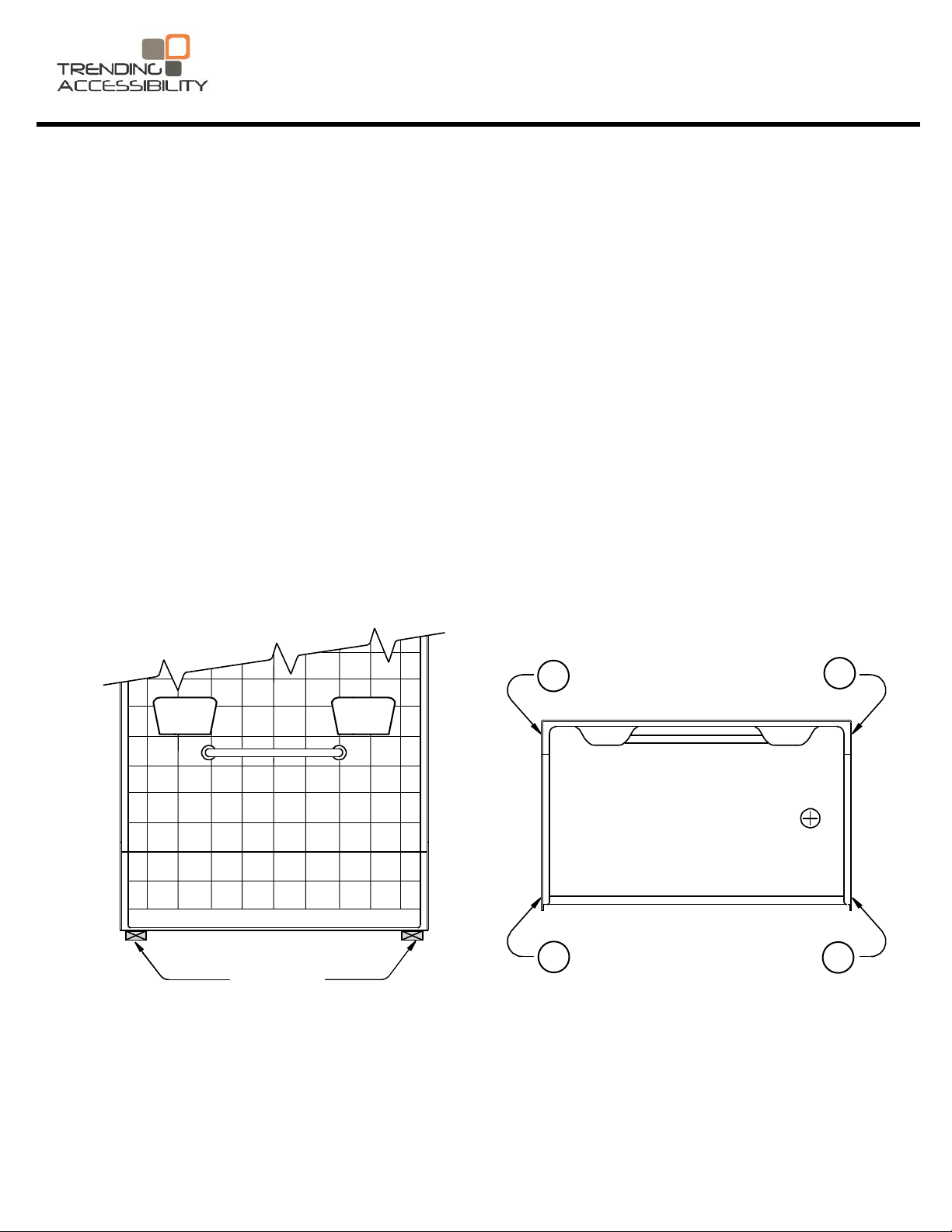

FRONT VIEW

Proper

Block

Placement

2

1

TOP VIEW

4

3

The low threshold shower model: 6030BF1.0 must be stored with special care. During storage, this unit should

never sit as it was received. It should be stored with a 2” x 4”

point

s numbered above in the top view

the floors. By placing the unit on blocks, the molded drain will not rest on the floor. This

to be maintained without the weight of the shower unit pushing the drain upward. The blocks should only be placed at

the outside corner edges of the unit and should not be placed under the middle of the threshold. This procedure should

only be used during storage and not for installation. Certain units may ship with a template under them to prevent the

drain from resting on the floor. This template should remain attached during storage and removed just before installation.

. Unit

s having altered threshold height

block of some other type of material at each of the (4)

s do not have wooden bottoms to reinforce

allow

will

1

856-488-9535 www.TrendingAccessibility.com

the draft of the floor

Page 2

PLANNING YOUR INSTALLATION

Carefully remove the old bathtub at the installation site. The replacement showers are 82” tall so wall board should

1.

be removed on all three walls to at least this height.

The shower unit must be disassembled for installation. All joints must be caulked as they are installed. When

2.

moving the parts, take care to avoid striking the edges of the wall sections to prevent chips or cracks.

Study Framing Diagrams on Page 3 of this manual. Adjust drain and water supply locations if required.

3.

Cutout in floor for drain requires a minimum size of 10” x 10”.

Modify framing if required. There should be a framing member behind each flange. Make sure your framing

4.

is plumb and square.

Planning is necessary for Thin-Set mortar to be placed in the drain core area for all installations. Proper blocking

5.

is required to prevent the Thin-Set from flowing to the floor below.

For installation of showers without Easy Base, wet Thin-Set mortar must be placed under the shower bottom to provide

structural support, and to maintain factory slope to the drain. See Figure 2.

Showers configured with the factory installed Easy Base TM self leveling, reinforced bottom will be installed using

panel adhesive. However, wet mud will be used in the drain core area on these units. See Figure 3.

For ALL installations, apply a heavy bead of polyurethane panel adhesive under the shower threshold.

INSTALLATION INSTRUCTIONS

Before you disassemble the shower unit, transfer the locations for the supply valve and shower head on the unit.

1.

Mark these locations on the back (reinforced surface) of the unit. After double checking the locations, drill 1/4”

pilot holes.

Always place cardboard or a drop cloth in the shower base to protect the finished surface. Working from the finished

2.

side of the unit, using the proper size hole saw, cut holes for supply lines and shower head.

Remove the connection bolts and disassemble the unit. If present, remove shower rod. Carefully carry the parts

3.

to the installation area. Do not flex the parts when moving to avoid scratches and stress cracks.

The shower parts may be caulked, reassembled and installed in one piece if there is sufficient room. Typically,

4.

the parts are installed piece by piece starting with the base.

be used for permanent connection. The installer must apply 100% silicone caulking to all connection surfaces for

final installation. If installing piece by piece, or as one piece, support under the unit must be provided as described

below. The support is necessary to assure factory slope to the drain is maintained.

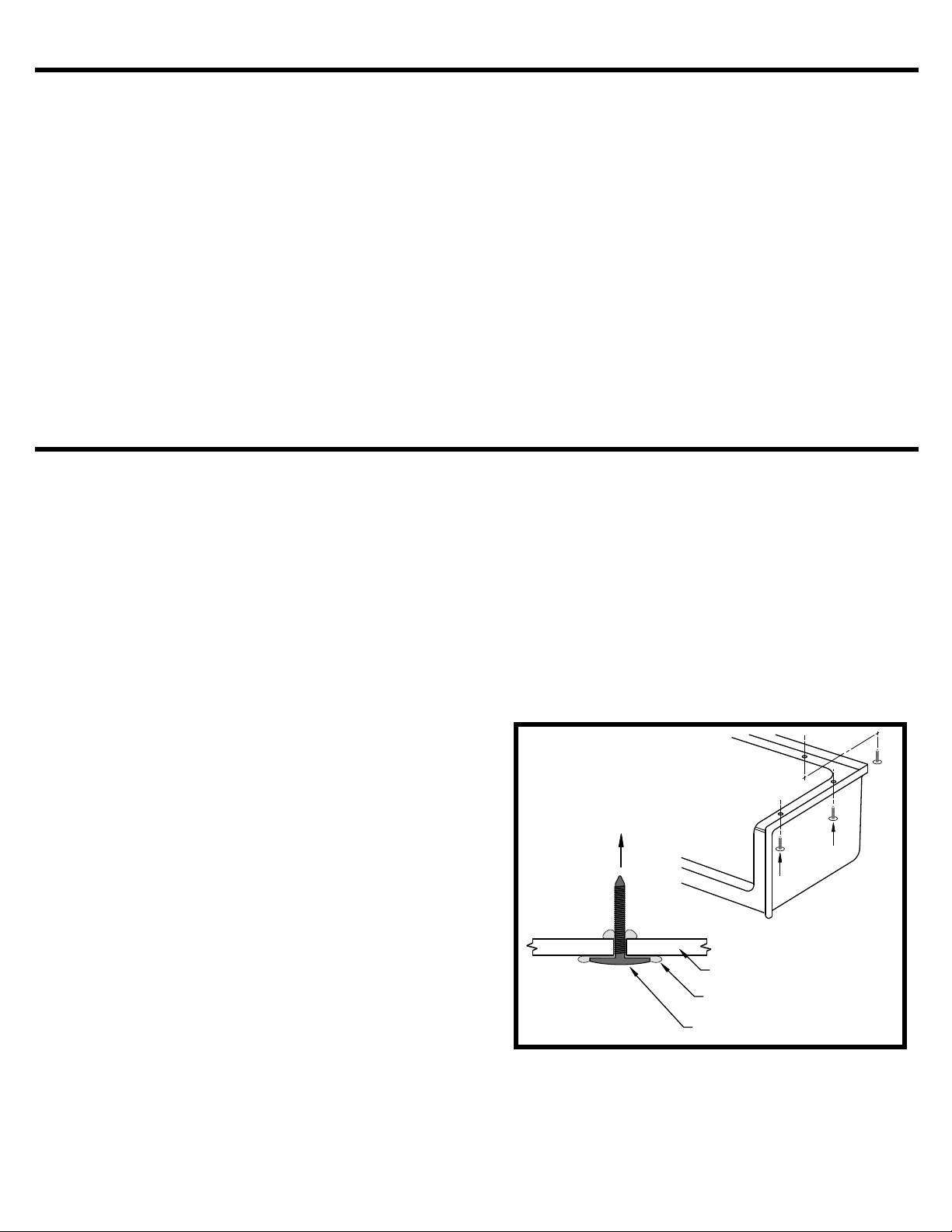

When installing piece by piece, use the plastic fasteners

5.

in place of the nuts and bolts. The fasteners will act as

guides that will index the parts together for installation

where access to the back side in unavailable.

Apply a liberal amount of 100% silicone caulk to each

6.

fastener before inserting them through the holes.

See Figure 1.

If installing in one piece, the metal nuts and bolts must

Insert the plastic fasteners through the holes from

below so they point to the ceiling.

Insert plastic fasteners through the holes in the vertical

7.

mounting surfaces on each side of the back wall. These

must be inserted from the back so they point toward

the front of the shower. Again, apply 100% silicone caulk

to the fasteners before inserting them through the holes.

NOTE: The caulking must be allowed to cure before

assembly of the unit.

Figure 1

Fiberglass Shower

Silicone Bead

Plastic Fastener

Carefully position the shower base so it sits on the front mounting flanges. Install the drain fitting in accordance

8.

with instructions provided with the fitting. Do not allow the base to sit on the drain fitting.

Study Framing Diagrams Figures 2 and 3 and note the important installation requirements.

9.

Unless the shower is caulked and parts fastened together with nuts, washers and bolts as a one piece unit, the

shower base is installed separately from the wall sections. Before applying any Thin-Set or Adhesive, trial fit the

shower

Make any adjustements at this time.

base to confirm the alcove is of proper size and the drain is located properly.

2

856-488-9535 www.TrendingAccessibility.com

Page 3

FRAMING DIAGRAM FOR BATHTUB REPLACEMENT SHOWER

Example of Mortar Thin Set Pattern

Laticrete thin set

mortar troweled

under shower.

Include drain core

Blocking

between studs

to secure the

mounting flange

Box out for

sub floor

plumbing.

10” x 10” core

size required

Note that thin set

mortar must be

applied to the drain

core area

3M polyurethane adhesive

heavy bead applied under

the shower threshold

(Without Easy Base)

Figure 2

10.

11.

12.

13.

14.

Before beginning final installation, it is ESSENTIAL that the sub floor in the installation area be completely clean.

It must be free of all dirt, trash, oil, grease, water and other contaminants that may

Thoughly clean the area before proceeding with the shower installation.

Note that for ALL installations, Thin-Set mortar is used in the Drain Core area. Fill the drain core only 2/3rds full

of Thin-Set. Do not overfill as this will prevent proper floor draft and may push

not to drain properly. Make sure you block off the drain core to prevent the Thin-set from escaping to the floor

below.

Note that for ALL installations, 3M Polyurethane Adhesive (or equivelent) is use to adhere the shower threshold

to the sub-floor.

the drain area up causing the unit

affect adhesion.

Installation of Units Without Easy Base

When installing showers without the factory Easy Base, wet Thin-Set mortar must be appled to the sub-floor to

provide support of the shower base. The Thin-Set should be applied

in place. This Thin-Set should be thick enough to assure it will contact the bottom of the shower, but be plyable

enough so it may be dispalced as the shower is leveled.

Apply a thick bead of 3M Polyurethane Adhesive (or equivelent) along the sub-floor where the shower threshold

will be located as illustrated in Figure 2.

After blocking the drain core, apply the appropriate amount of Thin-Set in the drain core area. Then appy the

Thin-Set mortar to the installation area, as shown

(or equivelent) at the front where the shower threshold will be located.

Carefully lift the shower base into the framing alcove. Guide the shower drain pipe with a hammer handle or

equivelent. The entire bottom of the shower must be in contact with the Thin-Set mortar. The front threshold must

seat into the heavy bead on 3M adhesive.

in Figure 2. Apply a wide bead of 3M polyurethane adhesive

immediately before the shower base is set

Installation of Units With Factory Easy Base

15.15.

16.

After blocking the drain core, apply the apropriate amount of Thin-Set in the drain core area. Then appy the

adhesive to the installation area as shown in Figure 3. Use a notched trowel to spread the adhesive. Apply a wide

bead of

Carefully lift the shower base into the framing alcove. Guide the shower drain pipe with a hammer handle or

equivelent. The entire bottom of the Easy Base including the threshold must be in full contact with the Construction

Adhesive.

3M polyurethane adhesive (or equivelent) at the front where the shower threshold will be located.

3

Page 4

17.

Check level in two directions: Front to back and side to side. Use a carpenters level placed on top of the

threshold and along the top surface of each side wall.

18.

19.

Shower bases installed into Thin-Set may be adjusted for level by gently shifting the base into the mortar unit level

is acheived. Units with factory Easy Base, may have small adjustment by using thin wood shims.

It is essential the shower base be VERY level and pumb in order to acheive a successful shower installation.

Fasten the shower base to the framing through the flanges using 6D galvanized screws on 8 inch centers along

both sides, across the back and at the front of each side vertically.

ADDITIONAL INFORMATION FOR LOW THRESHOLD SHOWER

The low threshold shower is constructed without wood reinforcement built into the bottom. It is critical that

20.

factory shape of the shower floor and threshold be maintained.

Cut a 2 x 4 member of 10” to place directly over

the drain area. Cut a similar member and place

on top of the threshold at the center. Install cloth

or cardboard under these boards to protect the

gelcoat finish.

Install 2 x 4’s on top of each of the blocks that

extend to the ceiling.

The purpose of this bracing is to hold the drain

area and threshold in the proper factory position.

This bracing must be done immediately after Step

15 before the support materials have had a chance

to set up. (See Figure 4).

This should be a tight fit.

Figure 4

Wood 2 x 4’s

to ceiling

A torpedo level should be placed from floor to assure the unit has proper slope for drainage. If unit

21.

doesn’t drain properly, the unit must be pulled back to determine where the problem lies.

If any high spots are found,

to avoid pooling of water.

Perform a test walk in the unit to determine the floor is stable and without flex. The mortar and adhesive should

22.

be given time to firm up before installing the wall

reinforcing materials to shift resulting in depressions in the floor. Under normal conditions, waiting 90 minutes

before installing the wall sections should give enough time for the materials to firm up. Leave the wood bracing

in place 72 hours to achieve full cure.

remove excess mortar to correct the problem. Low spots must also be corrected

sections. Working in the unit too soon could cause the

INSTALLING THE BACK WALL

23.

24.

25.

The silicone around the plastic fasteners should be cured before proceeding to the wall installation.

Use 6 wooden 2 x 2 blocks spaced evenly along the top connection surface of the shower base. These blocks

will hold the wall sections above the mounting surface until you are ready for final installation. Use masking

to temporarily secure the blocks. See Figure 5.

Apply a continuous bead of silicone caulk to the top connection surface. Apply the caulk between the inside

edge and plastic fasteners. (See Figure 6). The holes in the back wall mounting surface will index with the

plastic fasteners to line up the part with the

See Figure 7.

Wood Blocks

Taped in Place

base. The caulking will secure the parts together when it cures.

1/4” Bead of

Silicone Caulk

tape

Back

Wall

Figure 5

Caulking

on

Figure 6 Figure 7

4

Base

Page 5

Place the center wall panel in place resting on the wood blocks. One by one, remove the back blocks and carefully

26.

lower the wall p

approximately 3/8” when it is in the installed position. This is a normal function of the design.Take care to make

sure the plastic fasteners slip through the corresponding holes in the wall panel.

Work the wall panel down so the caulking will spread along the bottom to create a water resistant seal.

27.

Make sure the edge of the panel is even with the edge on the shower base. Wipe away excess caulking. Once

the caulking cures, it will assist in securing the bottom of the wall in place.

Using a carpenters level, make sure the back wall is plumb. Fasten the wall to the framing through the mounting

28.

flange using 6D galvanized screws. At this point, fasten at each corner, and do

There may be need for slight adjustment after the two side walls are installed.

anel down on the connection surface. Note that the wall p

sticks

anel

not tighten the screws completely.

Fasten Back Wall

At Corners.

past the base unit

out

Figure 8

INSTALLING THE SIDE WALLS

To install the side walls, apply a bead of 100%

29.

silicone caulking along the entire connection

surface of the back wall and shower base.

The caulk should be applied between the

plactic fasteners and inside edge of the base.

Carefully lift the wall panel opposite the fittings

30.

and place it on the wood block. Take care to

line up all holes in the side wall with the

corresponding plastic fasteners in the back

wall and shower base. Remove the wood

block and move the wall into the installed

position. As with the back wall, the side walls

will stick out 3/8” past the base unit when the

walls are in the installed position.

Press the wall into the caulking to create a

31.

water resistant seal. Make sure all seams

line up in a satisfactory manner.

Install one galvanized screw in each corner

32.

of the wall panel to hold it in position.

Repeat this steps to install the opposite wall. The exception is to

33.

guide the control valve stems through the panel as it is moved into

place. Press the panel into the

arm fitting is lined up with the hole so the shower head can be

installed.

caulking. Make certain the shower

Apply

Silicone

Caulking to

Connection

Surface

Figure 9

5

Page 6

34.

Insure the seams on all three wall sections line up with the shower base. Make certain the walls are seated in

the caulking. Make cert

the wall section. When satisfied with the fit, tighten the galvanized screws. Inst

vertically and 16” centers horizont

ain the control valve stems and shower arm connections are lines up with the holes in

all additional screws on 8” centers

ally around the top of the wall.

35.

36.

37.

Proceed with all plumbing hook ups. Water test all connections before enclosing behind the unit. Wipe away any

excess silicone caulking along all seams before it cures. Moisten a finger to smooth the caulking for a good finish.

INSTALLING THE SHOWER ROD

If the unit was ordered with the curtain rod, reinstall it from the backside using the hardware provided. Secure

the rod with panel adhesive on the backside to prevent it from turning.

WALL BOARD INSTALLATION

Typically, wallboard is installed to cover all mounting flanges. Wallboard should be held about 1/8” away from

the finished surface of the shower walls. This small gap should be caulked to create a water resistant seal along

the edge of the wallboard. Fasten the wallboard to framing with nails or screws. Finish as typical using corner

bead if required. Remove joint compound before it dries.

CLEANING AND CARE

Wallboard Installation

Do not use abrasive cleaners

Framing

Studs

Do not use abrasive cleaners which may scratch and dull the

surface of the unit. To clean the unit after installation, use warm

and one of the stronger liquid detergents such as: top Job,

water

Liquid Ajax or Mr Clean. Use these liquid detergents for normal

day to day cleaning also.

Plaster can be removed with a nylon or polypropylene scrubber.

Wallboard

Mounting

Flange

Screws

1/8” or less

gap along

finished

Shower

Trending Accessibility (Trending) warrants to the owner of its Tub/Shower units as follows:

LIMITED WARRANTY

Units manufactured of fiberglass reinforced polyester resin, that it will, free of charge, repair or exchange as its option, any Trending unit found to be defective

in materials or workmanship upon inspection by an authorized representitive of Comfort Designs for a period of three (3) years from date of purchase. The exchange

of a unit is limited to supplying a replacement unit of comparable size and

This warranty shall be voided if the unit is moved from its place of initial installation or is not installed in accordance with the instructions supplied by the manufacturer

of the unit. Further, this warranty does not apply if the unit has been subjected to accident, abuse, misuse, damage caused by flood, fire or act of God.

Since local code requirements vary greatly throughout the country, distributers, dealers, installation contractors and users of plumbing products should determine whether

there are any code restrictions on the use of a specific product. Trending makes no representation or warranty regarding and shall not be responsible for any

code compliance.

The owner agrees by use of this unit that the obligations of Trending shall not exceed to contingent or indirect damage or injury to the structure of its contents,

that the obligations of Trending are limited to those set forth herin, and that no other obligations, expressed or implied, are assumed by Trending.

surface.

Apply

Caulking

Do not use metal tools of any kind. Powder detergents such as

Spic & Span may be used with a damp cloth to remove residue

plaster. Minor stains may be removed using ammonia or bleach.

Lighted smoking materials will leave burn marks. This damage

can often be repaired by using automotive polishing compound

followed by an application of automotive body wax.

Extensive damage can be repaired. Such repair work should be

performed by a professional repairman. If local service is not

available or if you need further assistance, contact Comfort

Designs Bathware, Customer service by calling:1-800-801-2820.

style and does not include any costs of removal or installation.

Spec No. CDI4P BFKD-A REV: 8/24/09.

6

856-488-9535 www.TrendingAccessibility.com

Loading...

Loading...