Page 1

READ ALL INSTRUCTIONS BEFORE INSTALLATION

PLANNING YOUR INSTALLATION

Avoid exposure to weather. Product carton is not waterproof. Carton exposed to rain or snow may result in

accummulated water penetrating the back laminates of the shower pan and soak the glassed in

reinforcement supports causing bulges in the gelcoat surface.

1.

Most handling damage is the result of impact blows to the back of the fiberglass units.

2.

Never drag this fiberglass product on any surface. Always carry the pan or use a two wheel dolly.

Due to the size and weight of the product, installation is easier if it is a two person operation.

3.

Never drop the fiberglass shower pan from any height, not even an inch or stress cracks are likely to occur.

4.

Placing objects inside the unit can cause scratches or nicks to the finished surface.

Do not use the shower pan as a trash receptical! Always place a drop cloth or cardboard on the floor

when working inside the shower.

5.

Never clean fiberglass gelcoat surface with metal tools of any kind, including razor blades.

6.

TOOLS NEEDED:

NailsHammer

Drill With Phillips Screw Bit

1/2” Notched Trowel

Spatula

Auger Mixing Tool For Drill

Caulking Gun

4 Foot Level

2 Foot Level

50+ 1 1/4” Wood Screws

Solid Wood Flooring Adhesive

(2-One Gallon Buckets Per Shower)

(For Mixing Bedding Compound And Water Test Around Drain)

2-Gallons Of Water

1-Tube 100% Clear Silicone Caulking

3 - 8 Foot 2 x 4’s

1 - 8 Inch Long 2 x 4

1 - 24 Inch Long 2 x 4

2 - Large Wiping Cloths

Self-Caulking Shower Drain Fitting

MATERIALS NEEDED:

1/8” Drill Bit

1/4” Carbide Tipped Drill Bit

Center Punch

1

BARRIER FREE SHOWER PAN

INSTALLATION INSTRUCTIONS

856-488-9535 www.TrendingAccessibility.com

Page 2

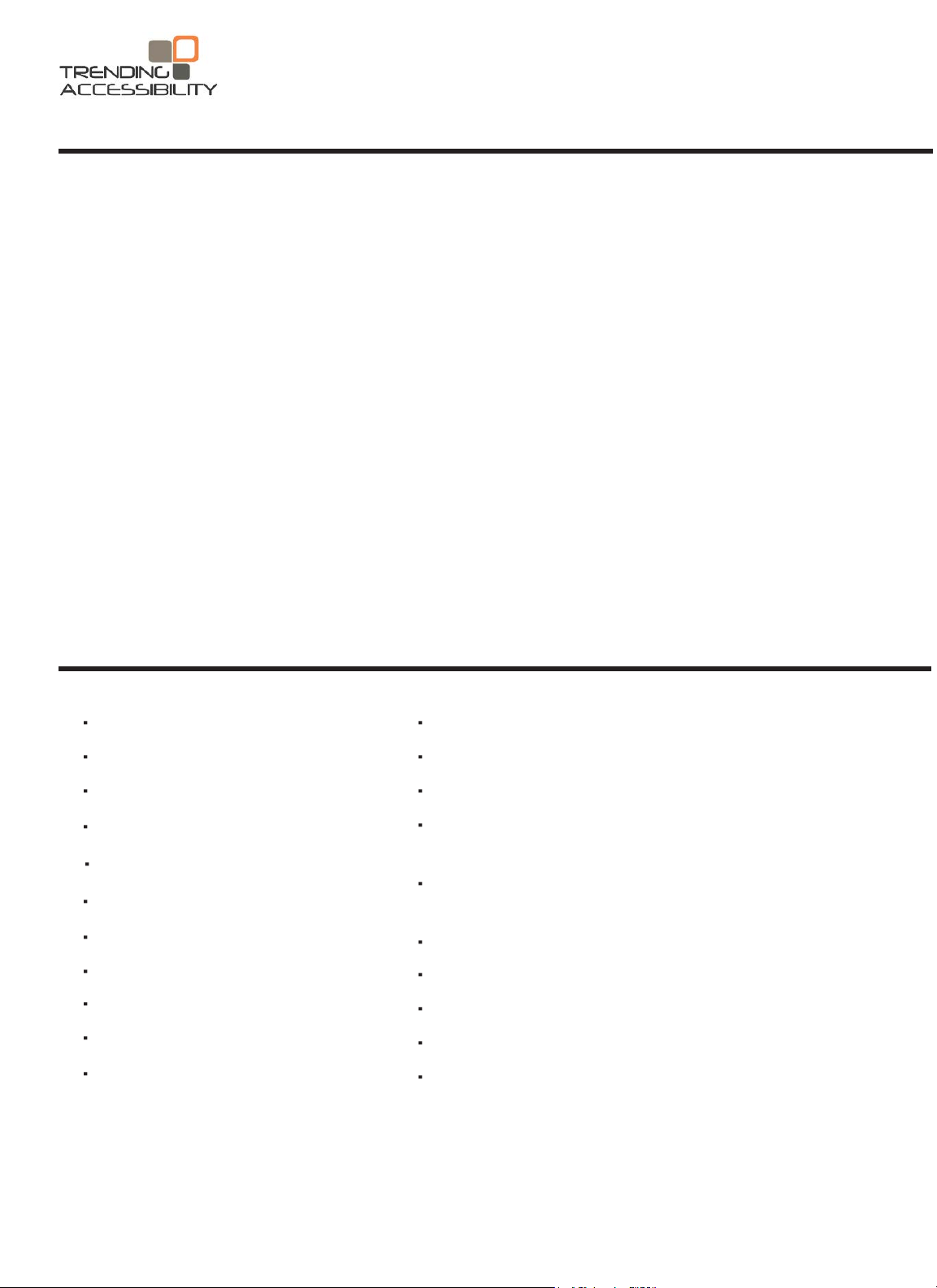

PLANNING YOUR INSTALLATION

6.

In the installation location, the drain opening in the floor should have a 6” core for the drain pipe, and a

10” x 10” x 1/2” deep recess in the sub floor. (The drain core must be blocked when filled with Thin-Set).

The 10” x 10” x 1/2” deep recess is required to to assure proper drainage.

(See “Detail Of Drain Core Area” on Page 3, FRAMING DIAGRAMS).

5.

Plan for the location of the shower water control valve. Plan for routing the water supply lines to the

control valve installation location.

4.

If bolt on accessories such as grab bars or a seat may be installed, plan to provide solid mounting

supports for these items. Wood secured between the framing studs will be required to provide a

mounting surface to install grab bars and a seat.

Develop a plan for structure and finished wall materials to construct the shower wall enclosure before

beginning the installation of the shower pan.

The 2 wall Framing Diagram is for the 6060 double entry shower pan only.

BRIEF OVERVIEW. The actual installation will begin on the next page.

2

Review the Framing Diagrams in Figure 1. Modify existing framing if required. For new construction, build

framing structure in accordance with product dimensions and notes shown in the Framing Diagrams.

1.

3.

The shower pan will be installed, leveled, and fastened to the framing. It is essential the framing pocket be

square and plumb for the shower pan to install properly. The floor also must have no voids or out of level

conditions. If these are present, they must be corrected before installation.

Floor leveling compound can be purchased at Lowes or The Home Depot.

2.

Note: Unit will not install properly if framing pocket is not square and of proper size.

The dimensions shown in the FRAMING DIAGRAM is 1/4” larger than the size of the shower.

This product is manufactured to tight specifications. The 1/4” over sizing is for maneuvering and

installation ease. If 1/4” over is not reasonable, sizing closer to the product actual dimensions is

allowable.

When trial fitting the shower, use a level to confirm the pan is level and plumb. If any gaps are

present between the shower and framing, use furring strips to fill the gaps. A quality installation of

the shower pan is necessary to assure fabrication of enclosure walls will result in a square and

plumb finished shower. (Note: wall enclosure is provided by others).

8.

Locate accessories if any were ordered. They will be packaged in the pan box. Remove those and store

them in a safe location for easy retrieval.

Check the outside of the package for visible shipping damage. If damage is noted, contact your supplier

before proceeding with the installation.

7.

856-488-9535 www.TrendingAccessibility.com

Page 3

Framing pocket must be sized according to the information provided in the Framing Diagram.

Framing must be extremely square and plumb in order to accomplish a successful installation.

2.

It is extremely important that the floor area intended for the installation be flat and level. Any areas over

1/8” out-of-level will prevent the installation from being successful. If an area out more than 1/8” is found,

float the floor area with a floor leveling compound. This material must be placed and cured (dry) before

proceeding with the shower installation.

4.

1.

Prepare the installation area by sweeping the area completely clean.

3.

If wall board and finished materials for the wall enclosure have been determined, Install hot and cold water

supply lines with the control valve. Mount to the framing.

INSTALLATION INSTRUCTIONS

3

FRAMING DIAGRAMS

Note: Unit will not install properly if framing pocket is not

square and of proper size. The dimensions shown in the

FRAMING DIAGRAMS are 1/4” larger than the size of the

shower pan. This product is manufactured to tight

specifications. The 1/4” over sizing is for manuvering and

installation ease. If 1/4” over is not reasonable, sizing closer

to the product actual dimensions is allowable.

Page 4

6.

Carefully measure the framing pocket to assure it is of

proper size for the unit to be installed. Refer to

dimensional information in the FRAMING DIAGRAMS on

Page 3, Figure 1.

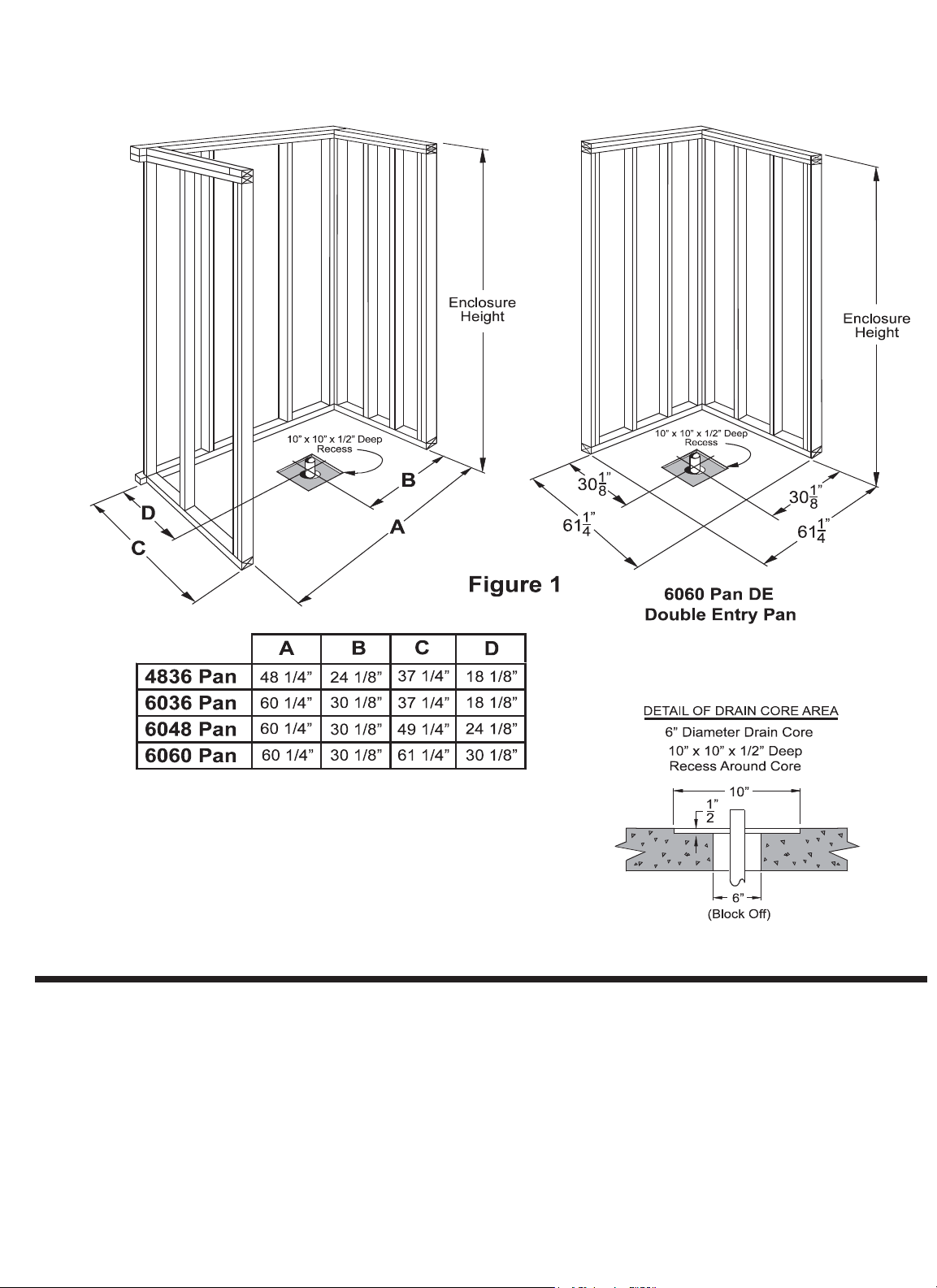

5.

A special note: During handling and transport,

the product may be slightly bent. It is very important

that the threshold of the pan does not have any bow or

bend.This product is engineered with materials that allow

for the threshold to be pressed back to the normal and

straight form it is intended.

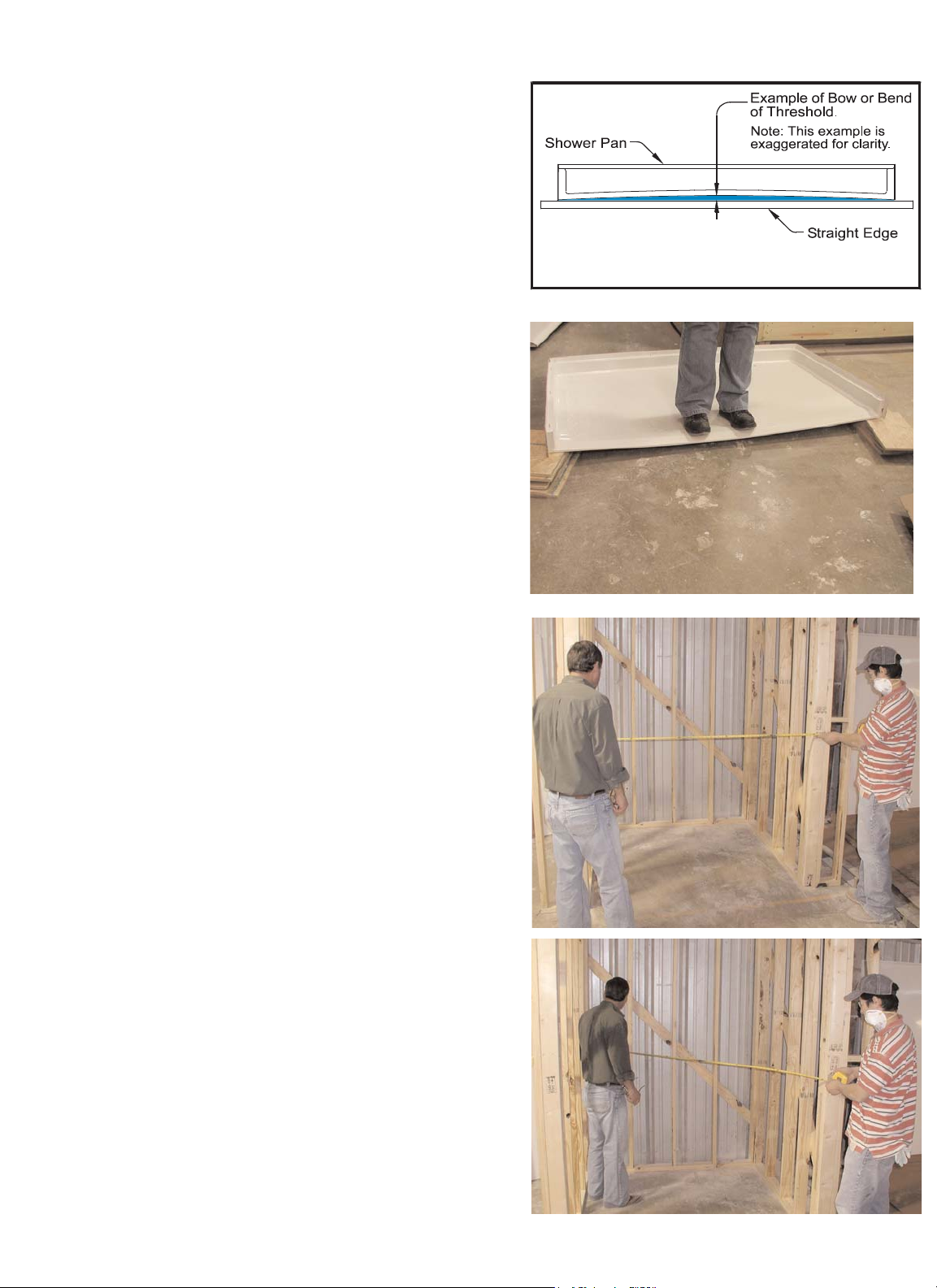

7.

Check the framing pocket for square. Check to assure

the vertical studs are plumb. Check for square by

holding a measuring tape from the back left corner to the

right front corner, as shown in Figure 4. Repeat for the other

side. If both dimensions are the same, the framing is

square. Adjust if necessary.

These steps are necessary to assure a good installation of

the walls (provided by others) to be installed later.

When the shower pan is removed from the packaging, use

a straight edge to check the straightness of the threshold.

Place a straight edge on the under side of the threshold

across the front to check the straightness. (See Figure 2A)

In the event it is not straight to 1/16”, pressure can be

applied to the top side of the material. This can be

accomplished by placing blocks under the two extreme

corners of approximately, 3” high.

Always place a soft rag on the finished surface where it

contacts the wood blocks, and under your feet to avoid

damaging the finish.

Gently step on this area and allow your body weight (Up

to 250 pounds), to flex the material back straight.

Confirm straightness, repeat if necessary until

+/- 1/16” is accomplished. (See Figure 2B)

4

Figure 3

Figure 4

Figure 2B

Figure 2A

856-488-9535 www.TrendingAccessibility.com

Page 5

9.

Once the shower pan is put into place and

fit is confirmed, draw a pencil line on the sub floor

indicating the front point of the threshold of the pan.

(See Figure 8).

The back corners of the shower pan should be in contact

with the framing, as seen in Figure 7.

Shim these areas if required.

Place a piece of cardboard in the floor of the shower to

protect the floor during the additional steps of installation.

There is a cut out for this on the pan box.

5

After the pan is set, fill any gaps between the mounting

flange and the framing with wood shims or furring strips to

achieve solid contact. The flange must be in contact with

the studs along all sides.

Figure 7

Figure 8

Figure 5

Figure 6

8.

The next step is to dry fit the shower pan to check the

fit to the studs and to the drain location.

Note in Figure 5 the two installers have placed the shower

pan on the floor, and are pushing it into the installed

position. One of the installers is using a short piece of

2 x 4 wood to hold the front of the shower pan off the floor.

This will assist in moving the pan into the installed position

while preventing chipping the front edge if it were to slide

along the sub floor.

856-488-9535 www.TrendingAccessibility.com

Page 6

12.

The next step is to permanently install the

shower pan. A helpful tip to make this easier is to

rotate the pan upward and lean against the back framing

studs of the pocket. This will remove the pan from the

work zone without removing it from the stud pocket. Do

not secure the pan to the studs at this point because you

may need to reach around the pan as you install the

drain fitting detailed in the next step. Make sure pan is

angled enough so it will not fall.

13.

Install the drain fitting on the shower pan.

Apply a bead of 100% silicone caulking around

the recessed molded drain area on the finished side of

the pan. Remove the nut and all gaskets from the drain

body. Slip the threaded shank of the drain body through

the hole. Follow the instructions provided with the drain

fitting to install the gaskets in the proper location. When

all gaskets and Locknut are in place on the bottom side

of the shower, tighten the nut to secure the shower drain

assembly. From the top side of the drain assembly,

remove the rubber caulking gasket that will fit around

the drain pipe until the installation is complete. This will

allow the drain pipe to slip with the floor slope unit it is

properly braced.

A diagram of a typical drain assembly is shown on

Page 10 of this manual.

6

Figure 11

10.

Confirm the pan is level by using a long level on

top of the threshold, and along the sides and back.

Note the level is used on the finished horizontal surfaces

along the back and both sides. (See Figures 9A and 9B).

11.

Drill holes through the mounting flanges into each

framing stud. These holes should be drilled using a

1/8” drill bit. (See Figure 10).

Note: Plan on using flat or pan head screws to secure the

shower pan. A minimal screw head exposure will allow for

easier installation of wall board and finished wall materials.

(Wall materials furnished and installed by others).

Wipe away any excess caulking that may have squeezed

out on the inside of the pan.

If the pan is not level, shim the appropriate areas

to achieve level. Do not shim more than 1/8”. If

shimming over 1/8” is required, remove the pan

and correct the sub-floor area by

“floating” a floor leveling compound.

Figure 10

Figure 9B

Figure 9A

856-488-9535 www.TrendingAccessibility.com

Page 7

Non shrink thin-set mortar can be purchased at Lowes or

The Home Depot. Please follow the mixing directions on the

bag.

In this step, apply the adhesive to the flat floor area and fill

the boxed area around the drain pipe with the Thin-Set

mortar.

After the adhesive is troweled over the sub floor, use a

spatula to wipe the adhesive over the entire area where the

pan will sit.

The exception will be the drain box area. This area will be

filled with thin-set non shrink mortar. Do not fill this area

above the floor line and do not spill any of this thin-set

material onto the contact adhesive.

(See Figure 13B.)

7

14.

A solid wood floor adhesive will be used to “glue” the

bottom side of the shower pan to the sub floor.

The following steps will detail the appropriate steps to

accomplish this.

15.

Clean the sub-floor thoroughly, wiping away all lose debris.

Wipe up any moisture. Never use adhesive on a dirty or

damp surface.

16.

Now secure the pan in the upright position to the back framing.

Use a piece of scrap 2 x 4 lumber to temporarily secure it. See

the example in Figure 12.

Figure 12

To secure the shower pan to the floor a solid wood

floor adhesive must be applied to the entire sub floor

area where the shower pan will rest.

Using a 1/2” notched trowel, apply adhesive evenly over the

pan contact area. Bring the adhesive up to the threshold

pencil mark and also make sure the adhesive will be in

contact with the back side of the pan. The long edge of the

trowel may be needed to get the adhesive to the far back of

the contact area where the pan is resting against the framing

studs in a vertical position.

(Pan not shown in Figures 13 A and B).

Figure 13A

Figure 13B

856-488-9535 www.TrendingAccessibility.com

Page 8

17.

After the adhesive and thin-set materials are in place, rotate

the pan back into place for installation.

(Hint) In order to reach the pan without stepping on the adhesive,

place a short piece of wood over the drain area. Use this to step

on to remove the 2 x 4 that is holding the pan against the back

framing. (See Figure 14).

18.

19.

Before moving on to installing the shower wall

enclosure, level the pan as shown in Figure 15. The

shower pan has minimal slope to the drain, and must be

very level to drain properly. Use a long level along all

finished edges. If there is an out of level condition, remove

screws and adjust the shower pan. When satisfied with the fit,

re-install the mounting screws.

Before the adhesive cures, confirm the floor slope to the

drain has been maintained. To do this, remove the cardboard

protection from the floor and use a 2 foot level at various points

around the drain to the adjacent wall to check for draft. Make

sure there is a downward slope to the drain in all directions

around the drain. Visually inspect the floor to be sure there are

no humps or dips that could cause improper drainage.

See Figure 16A and 16B.

Rotate the pan back to the horizontal position. As you lower the

pan to the sub floor, align the drain pipe with the drain fitting,

and with the pencil mark at the front of the threshold.

NOTE: The working life of the flooring adhesive is roughly

one hour. (Refer to the label on the adhesive for actual

working time). After step 16 is complete, the entire

installation process though step 21 must continue. If for

any reason the installation cannot be completed within the

working time of the adhesive, after step 16, jump ahead to

step 21.

When the pan is seated into the adhesive, place the cardboard

on the shower floor for protection. Thoroughly walk around in

the shower. This will assist in seating the pan into the adhesive.

Attach the pan to the studs by installing the screws through

the holes drilled into the flange. Snug the screws up tight but

not to the point of flange breakage. The screws must be tight

so they will not interfere when the wall board and finshed

walls materials are installed.

Figure 14

Figure 15

8

Figure 16B

Figure 16A

2 Ft. Level

Floor Level To

Drain - No Humps

Wood

856-488-9535 www.TrendingAccessibility.com

Page 9

9

21.

Since there is minimal floor slope to the drain it is critical

factory slope to the drain is maintained so the shower

drains well. To accomplish this, temporary bracing must be

put in place to assure the floor remains in the proper position

as the adhesives cures.

20.

Install the rubber caulking gasket around the drain pipe.

Trim the length of the pipe if necessary. Apply soap to the

caulking gasket to lubricate it. Place the caulking gasket on

the drain pipe and press it down into the drain assembly until

it seats. Snap the strainer plate onto the drain.

Before installing the bracing, place a padded piece of wood

on the top center of the threshold and directly on top of the

drain. Pad the wood with soft cloth or cardboard to prevent

damage to the finish.

The water resistant wall enclosure is provided by others. The installer must develop a plan to ensure the

chosen wall materails work with the fiberglass shower pan. The seam between the shower pan and the

finished wall materials should be caulked when installation is complete. Before beginning construction of

the shower wall enclosure, place a drop cloth or card board on the floor of the shower pan to protect the

gelcoat surface.

Install temporary 2 x 4 stud bracing so they sit on top of

these wood pieces. Attach these studs to the room framing

above the shower, or pad to the ceiling as shown.

(See Figure 17).

Pour water across the floor to confirm good draft to the

drain so the water drains completely with no puddling.

Make certain the drain does not leak.

Note: The manufacturer and supplier of this product is not

responsible for leaking drain conditions. Proper installation

of the drain fitting and pipe is the installers responsibillity.

After 72 hours, remove the bracing.

The shower pan installation is now complete.

Remember to install wood reinforcements to the framing for grab bars and seat, should these bolt on

accessories be installed. A procedure for installing a fold up seat to a ceramic tile wall is described on

Page 10.

Figure 17

856-488-9535 www.TrendingAccessibility.com

Page 10

10

5.- Using a power drill with a 1/4” diameter Carbide bit, drill through the wall tile the three (3)

mounting holes for each flange

.

Recommended tools for installation:

THIS COMPLETES THE INSTALLATION OF THE SEAT

7.- Place the seat against the mounting wall with each hinge aligned to the mounting holes.

Utilizing the six (6) #10 x 2” Stainless Steel screws, place a Phillips screw driver into

your power drill and securely tighten each of the six (6) screws.

1/4” Power Drill

1/8” drill bit when drilling through fiberglass

(Use a 1/4” Carbide drill bit when drilling through ceramic tile)

#2 Phillips Screw Driver and/or Phillips drill insert

1/2” Open end wrench or a small Crescent wrench

Tape measure

Pencil/pen

Center Punch

Silicone Caulk

6.- Apply silicone caulking around and inside each drilled hole before installing the seat.

Note: When installing the seat onto a Ceramic Tiled wall, prior to drilling the three (3) mounting holes

for each flange that you previously marked, use a center punch and lightly chip a small hole in the

center of each of the three hole locations. (For drilling holes through tile, you require a 1/4” Carbide

tipped drill bit). Only drill through the tile and base materials.

DO NOT DRILL THROUGH THE BACKING.

Your seat with swing down legs is fully assembled. Remove it from the box and proceed as follows:

These primary instructions are for installing the seat onto a CERAMIC TILED WALL. The tiles wall

must be properly constructed so as to be rigid. In addition, it is MANDATORY that wood

reinforcements be installed to the framing studs behind the wall board and tile to provide a solid

mounting surface when fastening the seat to the wall.

(This style seat has four (4) adjustable height legs)

1.- Choose the height of the seat you want. Barrier Free style showers will typically have fold up

seat installed at 17” to 19” height.

2.- After selecting the height you desire, adjust each of the four legs to that height while

maintaining the seat in a level position. Lock each of the lock nuts.

3.- Place the seat against the wall of the shower where you want the seat to be located.

Seat may be centered on the wall for a Barrier Free installation.

INSTALLATION INSTRUCTIONS FOR SHOWER SEATS

WITH SWING DOWN LEGS

4.- With the seat placed against the mounting wall, position the two hinges to the wall.

Using a pencil, mark the three holes (3) holes in the flange onto the wall for each hinge.

Remove seat from wall.

856-488-9535 www.TrendingAccessibility.com

Page 11

2.- Select the particular size and style of grab bar you want to install. Certain grab bars

have snap in place flange covers, and others have exposed flanges.

1.- As indicated earlier in this manual, wood reinforcements must be solidly installed behind the

tile wall surface to provide a secure mounting surface to attach the grab bars. Grab bars must be

installed at these locations only.

3.- For grab bars with snap in place flange covers, use the handle of a Phillips screw

driver to tap back the covers on the bottom edge of the covers. It will be convenient in

the installation process if the covers are tapped together in the center of the grab bar.

4.- Determine the position you want the to install the bar. Place the bar against the wall.

Using a pencil, mark the location of each mounting hole at both ends of the bar.

5.- Using a power drill with a 1/4” diameter carbide tipped drill bit, drill, each mounting hole.

Note: When installing the grab bars onto a CERAMIC TILED WALL, prior to drilling the mounting

holes for each flange previously marked, use a center punch and lightly chip a small hole in the

center of each hole location. (for drilling through ceramic tile, you require a 1/4” carbide tipped drill

bit. Only drill through the tile and base materials.

DO NOT DRILL THROUGH THE WOOD REINFORCEMENTS

Recommended tools for installation:

THIS COMPLETES THE INSTALLATION OF THE GRAB BAR

7.- Take two (2) of the #10 x 2” Stainless Steel screws. By hand, start one mounting screw

in each end of the bar into the wall.

8.- Use a power drill with a Phillips drill bit to fully install these mounting screws.

9.- Take the remaining #10 x 2” screws and place them into the remaining open holes.

Use care to snug up the screws, but to not over-torque that the screws strip out the

factory installed backer board.

10.- If installing a bar with snap-on covers, move the covers into place at each flange.

Twist the covers clockwise or counter clockwise to tighten the covers onto the flanges.

INSTALLATION INSTRUCTIONS FOR GRAB BARS

6.- Apply silicone caulking around and inside each drilled hole before installing the grab bar.

11

1/4” Power Drill

1/8” drill bit when drilling through fiberglass

(Use a 1/4” Carbide drill bit when drilling through ceramic tile)

#2 Phillips Screw Driver and/or Phillips drill insert

1/2” Open end wrench or a small Crescent wrench

Tape measure

Pencil/pen

Hammer

Center Punch

Silicone Caulk

856-488-9535 www.TrendingAccessibility.com

Page 12

815 Hylton Rd., Ste. #4 I Pennsauken, NJ 08110 I Tel: (856) 488-9535 I Fax: (956) 488-9576

Trending Accessibility

Loading...

Loading...