Page 1

Important: Retain this instructions

INSTALLATION

Installation Instructions

PIL3

Pressure Sensor (Liquid)

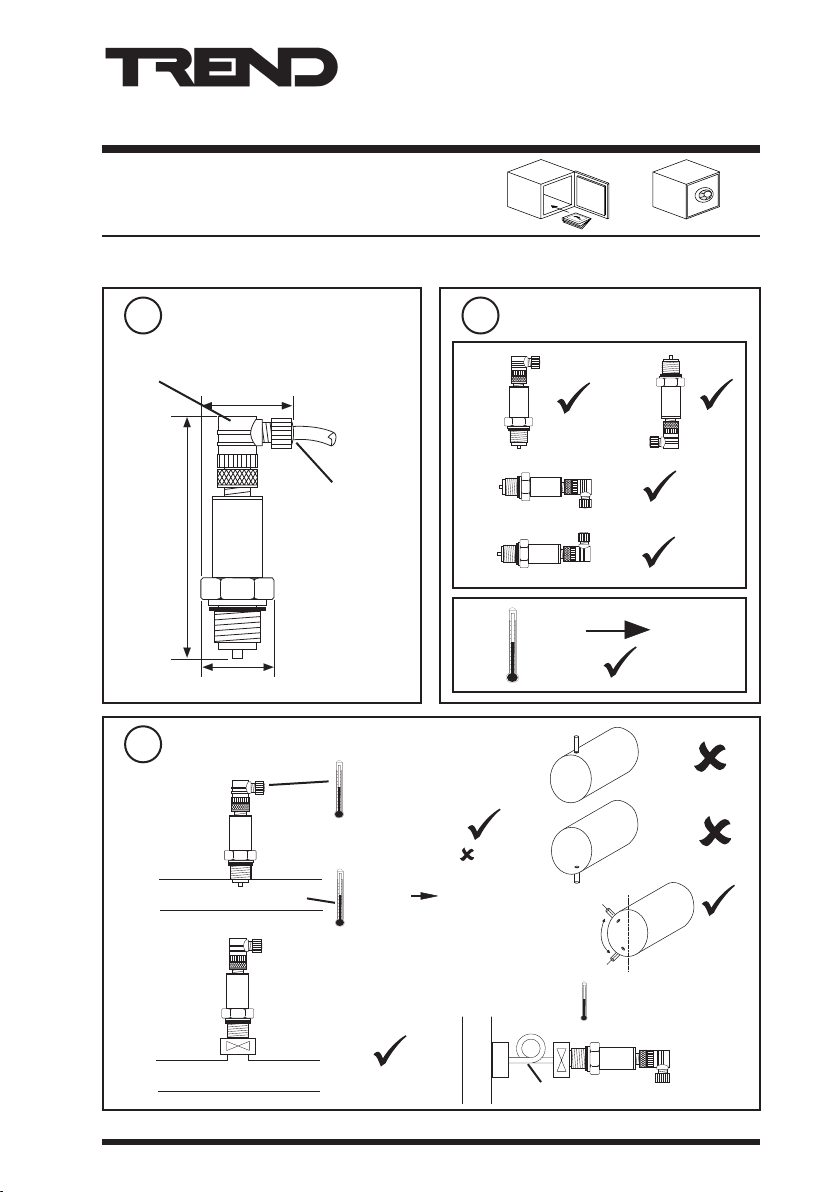

Dimensions

1

access for

connector screws

40 mm (1.57”)

110 mm (4.3”)

27 mm (1.06”)

Fixing requirements

3

a

b

isolating valve

cable

access

85 °C maximum

(185 °F)

P < 2.5 x range

[P > 2.5 x range

-25 °C

(-13 °F)

2

a

b

]

+125 °C

(+257 °F)

Requirements

-15 °C

(+5 °F)

c

70%

30%

d

if > +85 °C

(185 °F)

+85 °C

(185 °F)

100%

0%

ACC/SP

PIL3 Pressure Sensor (Liquid) Installation Instructions TG200127 Issue 4, 18/02/2009 1

Page 2

2 PIL3 Pressure Sensor (Liquid) Installation Instructions TG200127 Issue 4, 18/02/2009

PIL3 Installation Instructions

INSTALLATION (continued)

Fix sensor

4

G½“(DIN 259)

½“(BSP)

inside thread

Remove terminal cover

6

27 mm

Remove connector

5

a

knurled

ring

Remove cable compression nut

7

b

Feed cable through cover

8

a

b

c

d

Page 3

3

4

1

3

4

1

PIL3 Pressure Sensor (Liquid) Installation Instructions TG200127 Issue 4, 18/02/2009 3

Installation Instructions PIL3

INSTALLATION (continued)

Connect cable to screw terminals

9

IN (+) supply

IQ1xx, IQ2xx

24 V

IN

inside connector

OUT (-) signal

IN (+) supply

analogue input channel

linked for current (I)

OUT (-) signal

Replace terminal cover

10

Replace connector

12

a

IQ3

0 (0 V)

N (in)

+ (+24 V)

13

b

N

Tighten cable

11

compression nut

Congure IQ

I

IQ Conguration

Manual 90-1533

or

knurled

ring

Page 4

PIL3 Installation Instructions

INSTALLATION (continued)

14

Set up IQ sensor type

It is recommended to use SET (software Tool) for the setting of the sensor type module. For

all IQ2 series controllers with rmware version 2.1 or greater, or IQ3 series controllers, the

appropriate SET Unique Sensor Reference from those given below should be used:

PIL3/4: Pressure I 4 bar

PIL3/6: Pressure I 6 bar

PIL3/10: Pressure I 10 bar

PIL3/16: Pressure I 16 bar

PIL3/25: Pressure I 25 bar

Alternatively enter scaling manually as dened in table below:

For all other IQ controllers see the Sensor Scaling Reference Card TB100521A.

tYpe Sensor digI/P Driver Function loGic Loop

scHedule seQnc

Analog digBit Knob sWitch TimeZone Oss

User addRess intcoN calarM reView Plot calEndar

=?

Pressure Sensor

Yx<CR>

TYPE n

:

=?

S = 5 (characterise)

PIL3/4 2 (current) 2 4.1 0 2 4 20 0 4

PIL3/6 2 (current) 2 6.1 0 2 4 20 0 6

PIL3/10 2 (current) 2 10.1 0 2 4 20 0 10

PIL3/16 2 (current) 2 16.1 0 2 4 20 0 16

PIL3/25 2 (current) 3 25.1 0 2 4 20 0 25

Y E U L P I1 I2 O1 O2

Y=, E=, U=, L=, P=, I1=, I2=, O1=, O2=,

X <CR>

15

IQ

P = X

DISPOSAL

WEEE Directive :

At the end of their useful life the packaging and product, should

be disposed of by a suitable recycling centre.

Do not dispose of with normal household waste. Do not burn.

Please send any comments about this or any other Trend technical publication to techpubs@trendcontrols.com

© 2009 Honeywell Technologies Sàrl, ECC Division. All rights reserved. Manufactured for and on behalf of the Environmental and Combustion Controls

Division of Honeywell Technologies Sàrl, Ecublens, Z.A. La Pièce, 16, 1180 Rolle, Switzerland by its Authorized Representative.

Trend Control Systems Limited reserves the right to revise this publication from time to time and make changes to the content hereof without obligation

to notify any person of such revisions or changes.

Trend Control Systems Limited

P.O. Box 34, Horsham, West Sussex, RH12 2YF, UK. Tel:+44 (0)1403 211888 Fax:+44 (0)1403 241608 www.trend-controls.com

Trend Control System USA

6670 185th Avenue NE, Redmond, Washington 98052, USA. Tel:(425) 869-3900 Fax:(425) 869-8445 www.trend-controls.com

4 PIL3 Pressure Sensor (Liquid) Installation Instructions TG200127 Issue 4, 18/02/2009

Loading...

Loading...