Trelleborg C-56 User Manual

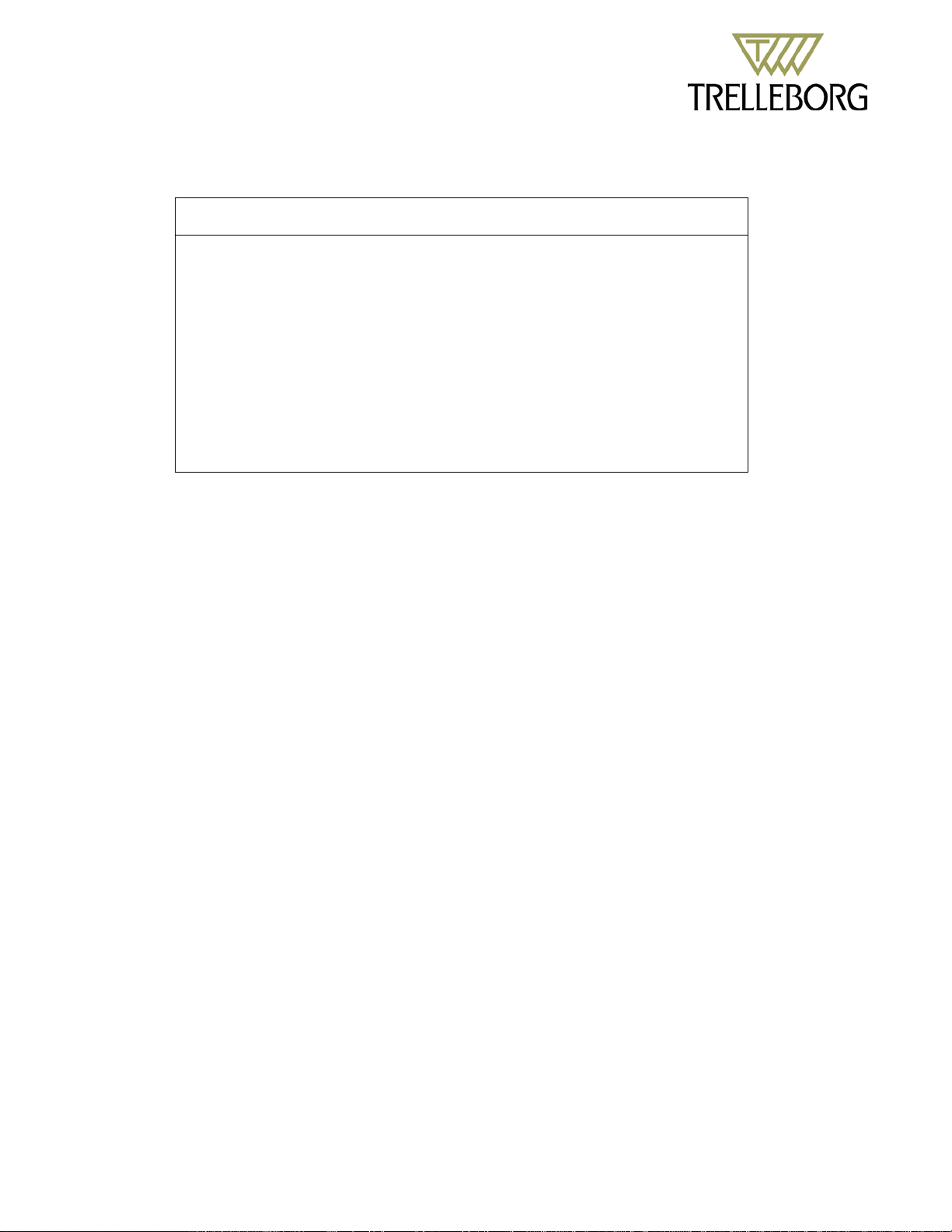

Coils

Width

Cross

Pieces

L.F. Per

Pallet Size

& Length

Section

Per Ctn.

Per Ctn.

# of Ctns./lbs.

Bidco C-56 Sealant

Data Sheet & Installation Instructions

Bidco C-56 Joint Sealant is custom engineered to meet

the most exacting standards of the precast concrete

industry. C-56 remains flexible and forms a permanent

bond to a wide variety of substrates including concrete,

metals and plastics.

Adhesion and cohesion at the time of installation are

excellent and actually improve after the joint has been

formed and placed into service. This sealant is designed

not to shrink, oxidize or harden and has excellent

resistance to temperature extremes, acid and alkaline

environments.

C-56 Joint Sealant is designed to fully comply with current

ASTM Standards and Specifications as required by

Federal, State, and Local agencies for use by the precast

concrete industry and contractors.

Product Features:

• Available in strip or coil form

• Crush-proof packaging

• Non-stick, non-tear plastic backing

Primary Applications:

• Concrete Pipe

• Septic Tanks

• Wet Wells

• Box Culverts

• Utility Vaults

• Burial Vaults

• Sanitary & Storm Sewer Manholes

• Concrete Wall Panel Systems

Bidco C-56 Meets or Exceeds:

• Federal Specifications SS-S-210 A “Sealing

Compound, Preformed Plastic for Pipe Joints”,

Type 1, Rope Form

• ASTM Designation C-990

.5” x 21.0’ oval 10 210 45 ctns./24 lbs.

.75” x 14.5’ .66 x .66 10 145 45 ctns./36 lbs.

1.0” x 14.5’ .88 x .88 8 116 45 ctns./50 lbs.

1.25” x 14.5’ .875 x 1.375 5 72.5 45 ctns./49 lbs.

1.5” x 10.0’ 1.125 x 1.50 5 50 45 ctns./47 lbs.

2.0” x 10.0’ 1.50 x 2.0625 4 40 45 ctns./68 lbs.

Technical Specifications

CHEMICAL COMPOSITION

SPECIFICATION

REQUIREMENT

NPC BIDCO C-56

PHYSICAL PROPERTIES

Content of Hydrocarbon — % by weight ASTM D4 50 min. Meets or Exceeds

Inert Mineral Filler — % by weight AASHTO T III 30 min. Meets or Exceeds

Volitile Matter — % by weight ASTM D-6 2.0 max. Meets or Exceeds

Specific Gravity ASTM D-71 1.15 - 1.40 Meets or Exceeds

Ductility ASTM D-113 5.0 min. Meets or Exceeds

Softening Point ASTM D-36 320° min. M eets or Exceeds

Penetration @ 77° F ASTM D-217 50 - 210 Meets or Exceeds

Surface Preparation:

Joint surfaces should be clean and dry. Due to the high

adhesive quality of Bidco C-56 Sealant, priming of the

joint surface is usually not required. In case of wet or

unusually demanding applications, it is recommended

that an adhesive primer be applied to the joint surface

and allowed to dry before application of the Sealant.

Trelleborg Pipe Seals Park Hills

108 Industrial Dr. Bonne Terre, MO 63628,/P.O. Box 337, Park Hills, MO 63601 U.S.A.

Tel: 573-431-1619 800-442-0141 Fax: 573-431-1035 www.trelleborg.com/npc

5/14

Installation Instructions:

The size (cross-section) of C-56 required for a specific

joint is determined by the annular space resulting in a

fully sealed joint. The joint must be coupled with

sufficient compression to form a proper watertight seal.

C-56 bonds instantly to joint surfaces and to itself. Always

butt ends of preformed sealant together. Never overlap!

Leave protective plastic backing on sealant during

application and remove when joint is ready for coupling.

Loading...

Loading...