Table of Contents

Treker

4220ST & 4420ST Light Utility Vehicles

24700

700-504M

Operator’s Manual

Read the Operator’s manual entirely. When

you see this symbol, the subsequent

!

instructions and warnings are serious - follow

without exception. Your life and the lives of

others depend on it!

© Copyright 2007 Printed

Cover photo may show optional equipment not supplied

with standard unit.

8/05/08

Table of Contents

Section 1: Introduction . . . . . . . . . . . . . . . . . . 1

Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . .1

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Models Covered . . . . . . . . . . . . . . . . . . . . . . . . 1

Getting Acquainted with your Treker . . . . . . . . .1

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 2

Serial Number Plate . . . . . . . . . . . . . . . . . . . . . . . .2

Section 2: Important Safety Information . . . . 3

Look For The Safety Alert Symbol . . . . . . . . . . . . .3

Be Aware of Signal Words . . . . . . . . . . . . . . . . . . .3

Safe Operating Procedures . . . . . . . . . . . . . . . . . . 5

Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . .5

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . 5

Transporting Safety . . . . . . . . . . . . . . . . . . . . . . 6

Towing Safety . . . . . . . . . . . . . . . . . . . . . . . . . .7

Safe Load Capacities . . . . . . . . . . . . . . . . . . . .7

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 3: Pre-Delivery and Check List . . . . 13

Pre-Delivery Certificate . . . . . . . . . . . . . . . . . . . . 13

Vehicle Information . . . . . . . . . . . . . . . . . . . . . 13

Dealer Service and Inspection List . . . . . . . . . 13

Dealer Test Ride List . . . . . . . . . . . . . . . . . . . .14

Dealer Delivery To Customer List . . . . . . . . . . 14

Customer Acceptance List . . . . . . . . . . . . . . . 14

Section 4: Operating Instructions . . . . . . . . 15

Operator Responsibilities . . . . . . . . . . . . . . . . . . . 15

Pre-Start Check List . . . . . . . . . . . . . . . . . . . .15

General Operation . . . . . . . . . . . . . . . . . . . . . . . . 15

Indicating Lights and Gauges . . . . . . . . . . . . . . .16

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Choke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Floor Pedals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Shift Selector and Park Brake . . . . . . . . . . . . . . . 17

Fuel Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Seat Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cup Holders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Glove Box Enclosure . . . . . . . . . . . . . . . . . . . . . . 19

Cargo Box / Flat Bed Set-Up . . . . . . . . . . . . . . . . 19

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Engine Performance . . . . . . . . . . . . . . . . . . . . . . 20

Fuel Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Incomplete Combustion . . . . . . . . . . . . . . . . . . 20

Cold Weather Operation . . . . . . . . . . . . . . . . . 20

Traveling Tips From the Trail Masters . . . . . . . . . . 21

Section 5: Options and Accessories . . . . . . . 23

Treker Options . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Front Bumper . . . . . . . . . . . . . . . . . . . . . . . . . .23

Heavy Duty Brush Guard . . . . . . . . . . . . . . . . .23

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Treker Accessories . . . . . . . . . . . . . . . . . . . . . . . .24

Section 6: Maintenance . . . . . . . . . . . . . . . . . 25

General Maintenance . . . . . . . . . . . . . . . . . . . . . .25

Securing Vehicle for Maintenance . . . . . . . . . . . .25

Torque Values . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Tire Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .25

Jacking the Vehicle . . . . . . . . . . . . . . . . . . . . . . . .26

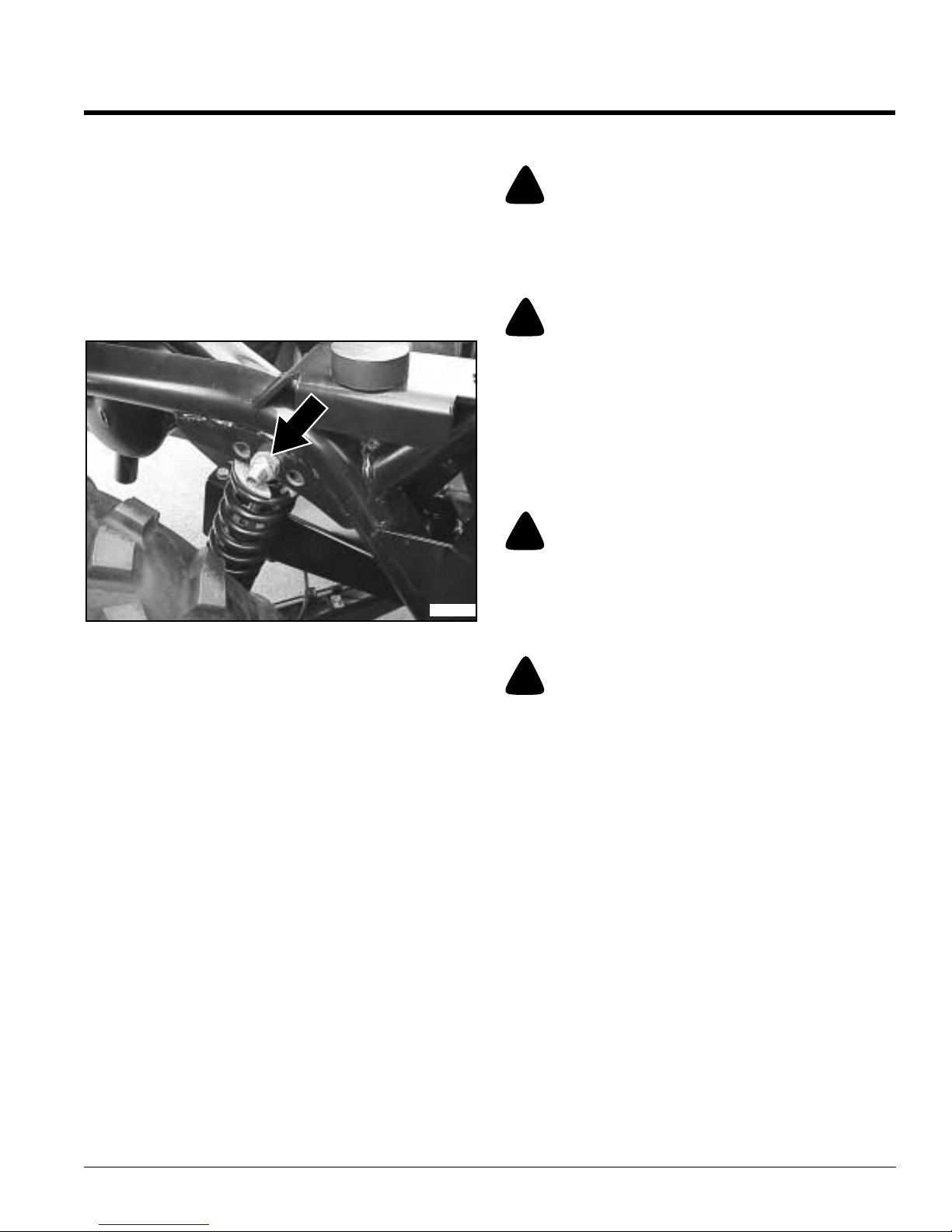

Shock Absorber Adjustment . . . . . . . . . . . . . . . . .26

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . .27

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Adding Water to the Battery . . . . . . . . . . . . . . . . .28

Charging the Battery . . . . . . . . . . . . . . . . . . . . . .28

Jump Starting the Battery . . . . . . . . . . . . . . . . . .28

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . .30

General Information . . . . . . . . . . . . . . . . . . . . .30

High Altitude Carburetor Kit . . . . . . . . . . . . . . .30

Drive Belt Replacement . . . . . . . . . . . . . . . . . . . .31

Driven Pulley Maintenance . . . . . . . . . . . . . . . . . .31

Engine Air Filter Maintenance . . . . . . . . . . . . . . .32

Engine Air Filter Handling . . . . . . . . . . . . . . . . . .32

CVT Snorkel Filter Maintenance . . . . . . . . . . . . .33

Exhaust System . . . . . . . . . . . . . . . . . . . . . . . . . .34

Spark Arrester . . . . . . . . . . . . . . . . . . . . . . . . .34

Park Brake Adjustment . . . . . . . . . . . . . . . . . . . . .35

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . .36

Section 7: Lubrication . . . . . . . . . . . . . . . . . .37

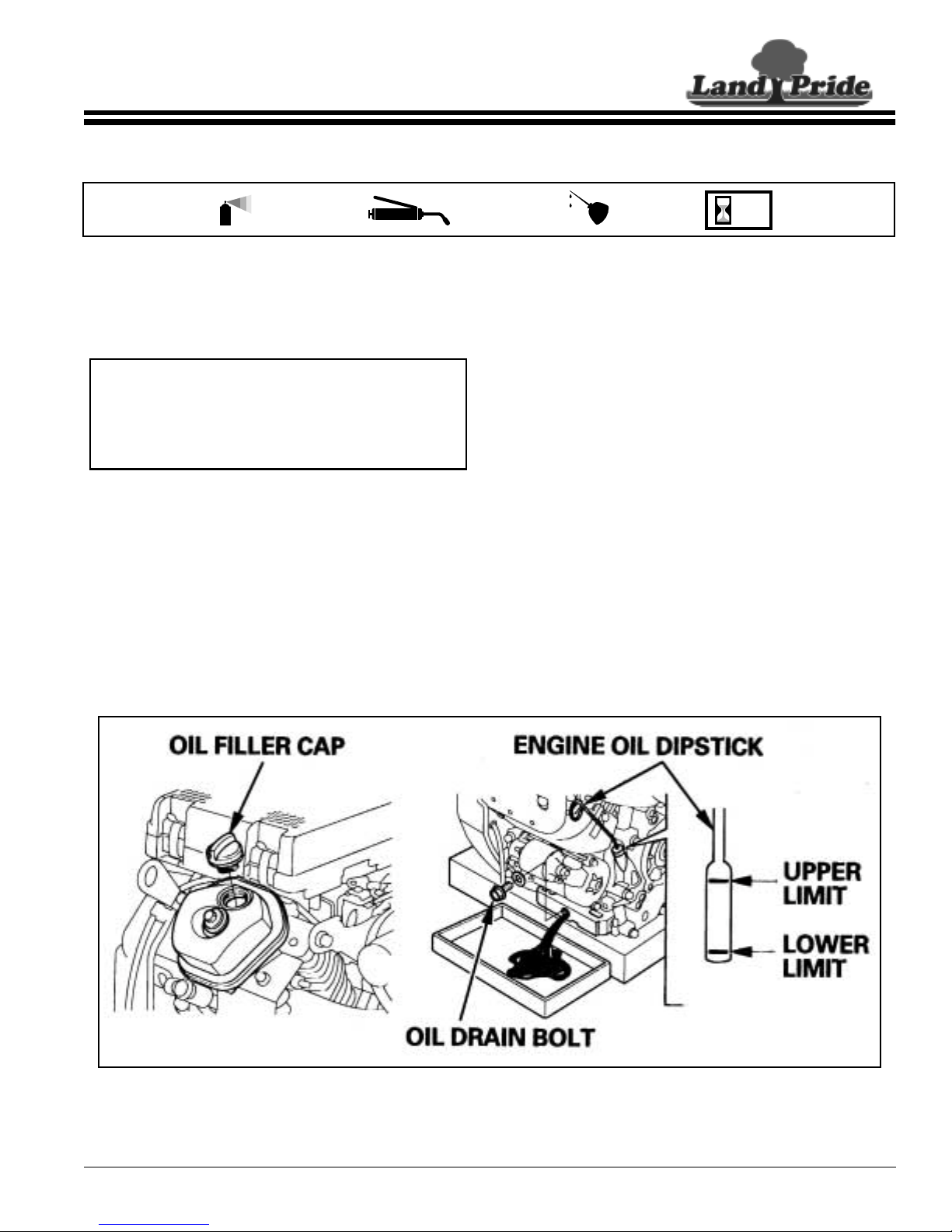

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Case Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Rear Trans-axle Case . . . . . . . . . . . . . . . . . . .39

Center Transfer Case . . . . . . . . . . . . . . . . . . .40

Front Differential Case . . . . . . . . . . . . . . . . . . .40

Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Section 8: Seasonal Storage . . . . . . . . . . . . . 42

Section 9: Body Repair . . . . . . . . . . . . . . . . . 43

Section 10: Specifications and Capacities . . 45

Section 11: Features and Benefits . . . . . . . . 46

Section 12: Troubleshooting . . . . . . . . . . . . . 47

Section 13: Appendix . . . . . . . . . . . . . . . . . . . 51

Torque Values Chart . . . . . . . . . . . . . . . . . . . . . .51

Tire Inflation Chart . . . . . . . . . . . . . . . . . . . . . . . .51

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Land Pride Limited Warranty . . . . . . . . . . . . . . . .53

© Copyright 2007 All rights Reserved

LandPrideprovidesthispublication “as is” withoutwarrantyofanykind,either expressed or implied.While every precaution hasbeen taken in thepreparationof this manual,

Land Pride assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Land

Pride reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect

the product in the future. The illustrations in this manual are not intended for safe and proper assembly or disassembly of equipment. The illustrations are intended for

ordering parts only.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Weather Pro G is a registered trademark of Spartech Plastic

Land Pride is a registered trademark.

Printed in the United States of America.

4220ST & 4420ST Light Utility Vehicles 700-504M

8/05/08

Section 1: Introduction

Section 1: Introduction

Table of Contents

Land Pr ide welcomes you to its growing familyof new

product owners. Treker series trucks are light utility

vehicles that have been designed with care and built by

skilled workers using quality materials. Proper set-up,

maintenance and safe operating practices will help you

get years of satisfactory use from this vehicle.

Safety First

Land Pr ide is fully aware of the need for safe operating

procedures around all of our equipment. Wehope you

will make a sincere effort to put safety above all other

priorities. The Trekers are designed and built for work,

recreation and enjoyment; however, improper and

irresponsible operation could result in serious injury or

death. Since this is an off-road vehicle, operators will

seldom see road safety and warning signs they are

accustomed to seeing on highways and public streets.

This places additional responsibility on the driver to

operatethisvehiclewell withinsafeoperationallimits and

capabilities of the unit.

Thismanualhas beenprepared toinstr uct youin the safe

and responsible operation of your Treker. Please read

and abide by all safety alert information about this

vehicle.If you do not understand anypart of this manual,

contact your local dealer for additional information and

clarification. As the operator of this piece of equipment,

you are in complete control. Only you can prevent an

accident from happening!

Using This Manual

Prior to any vehicle operation it is absolutely essential

•

that you read and comprehend each section in this

manualto develop an understanding of your vehicle and

safetypractices. After reviewing this manual,store itin a

dry and easily accessible place for future reference.

• TheOperator’s Section is designed to help familiarize

you with safety, assembly, operation, adjustments,

troubleshooting and maintenance. Read this manual

and follow recommendations to help ensure safe and

efficient operation.

• Theinformation contained within this manual was

current at the time of printing. Some parts may change

slightly to assure you of the best performance.

• Toordera new Operator’s orParts Manual contact your

authorized dealer. Manuals can also be downloaded,

free-of-charge from our website at www.landpride.com

orprinted fromthe LandPride Service& Support Center

by your dealer.

Terminology

Right-hand and left-hand as used in this manual are

determined by facing the direction the vehicle will travel

while in use unless otherwise stated.

Definitions

The following terms are used throughout this manual.

IMPORTANT: A special pointof inf ormation related to

its preceding topic. Land Pride’s intention is that this

information should be read and noted before

continuing.

NOTE:A special point of informationthat the operator

must be aware of before continuing.

Application

Models Covered

4220ST 4x2 and 4420ST 4x4

Getting Acquainted with your Treker

TheTreker line of light utility vehiclesisdesigned byLand

Pride exclusivelyfor off-road use. They are not designed

for, nor arethey properly equippedto be safely operated

orlicensed foruseon publicstreetsand highways.These

vehicles are designed to carry two tothree peopleand a

limited amount of gear or cargo comfortably and safely

over rough or difficult off road terrain.

The wide stance ST series is designed to carry three

passengerson the bench seat and 900 lbs. of cargo in its

15.9cu-ft. capacitydumping cargoboxfor a total payload

capacity of 1,300 lbs.The wide stance, longwheelbase,

and high payload make the ST series Trekers a strong

and stable workhorse for ranches, farms, and

construction sites.

The 4220ST series (4x2) is equipped with two wheel

traction drive and the 4420ST series (4x4) is equipped

with four wheel traction dr ive. Both series have an

automotive steering wheel with easy handling rack-andpinion steer ing, four wheeled independent suspension,

McPherson Str uts, large diameter hi-flotation tires, and

high center-frame ground clearances that add up to

excellent stability and smooth ride over tough terrain.

The 4420ST series feature our Command Track four

wheel dr ive system with over-running clutches on the

front differential for unexcelled traction, easy handling

and minimal disturbance to the turf. These models also

feature Auto-Lock rear differentialswith over-running

clutches and sealed torque converters for absolute

maximumtractioncapability inwet or slippery conditions.

Seat belts for two passengers are standard. An

additional seat belt may be added for the center third

person.

8/05/08

4220ST & 4420ST Light Utility Vehicles 700-504M

1

Section 1: Introduction

Table of Contents

Driving a Treker is as easy as driving a pickup with an

automatic transmission. A simple forward and reverse

shifter provides direction control. A neutral start feature

and keyed 12-volt electronic ignition make for safe and

easy starting. We have even provided a manual choke

controlwith spring-loadedreturnforquickercold weather

starting. The infinitely variabletorque converter drive

system means there is no clutching; you just shift into

either forward or reverseand step on the throttle pedal to

go at speeds up to 25 mph. All Trekers are powered by

highly reliableand proven 20 hp.Honda engines that are

EPA certified and meet Califor nia Air Resources Board

(CARB) certification standards.

Braking is accomplished by simply depressing thebrake

pedal located on the floorboard. This activates the rear

hydraulic drum brakesand front mounted disc brakes.

The par k brake is incorporated into the dash-mounted

shifter so when you put the vehicle in park you

simultaneously set the park brake. All modelscome with

a very strong 4-post accessory bar that provides extra

protection against low hanging limbs and brush as well

as providing a mounting systemfor accessories suchas

windshields, canopy tops, and weather enclosures.The

4-post accessory bar also provides a mounting base for

accessories such as cargo racks, gun and bow racks,

back screens, tree stands, and camping or fishing gear

and tool holders. Astandard rearreceiver enables quick

installation of a hitchto pull smalltrailers full ofsupplies,

tools, gear, or game.

Owner Assistance

The safety video should be viewedby the owner and the

Warranty Registration card should be filled out by the

dealer at the time of purchase. The owner should also

receive a copy of the safety video upon purchasing the

vehicle as well as have participated in a shor t drivers

training course with the dealer. This information is

necessary to provide you with quality customer service.

The parts on your Treker Light Utility Vehicle have been

specially designed and should only be replaced with

genuine Land Pride parts.

If customer service or repair parts are required contact a

Land Pride vehicle dealer. They have trainedpersonnel,

genuine repair parts and equipment specially designed

to repair Land Pride products.

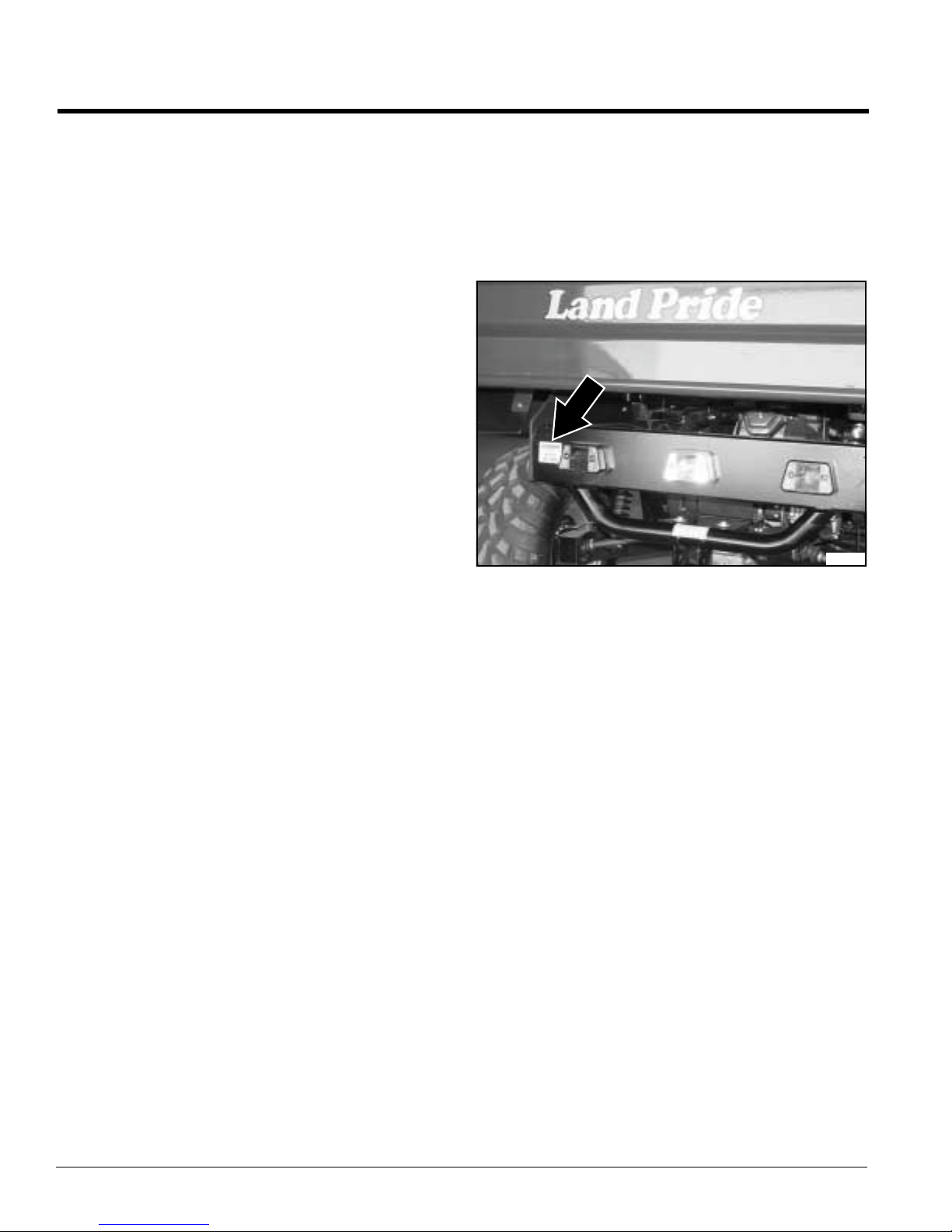

Serial Number Plate

Refer to Figure 1:

Always use serial and model number when ordering

parts from your Land Pride dealer. The serial-number

plate is located on the driver’sside just left of the rear tail

light as shown in figure 1 below.

21121

Serial Number Plate

Figure 1

Record your vehicle model number(4220ST or 4420ST)

and ser ial number here for quick reference:

Model Number:__________________________

Serial Number: ___________________________

YourLandPride dealer wantsyou to be satisfied withyour

new vehicle. If you do not understand any part of this

manual or are not satisfied with the service received,

please take the following actions.

1. Discuss the matter with your dealership service

manager.Make surethey are aware of any problems

so they can assist you.

2. If you are still unsatisfied, seek out the owner or

general manager of the dealership.

3. For further assistance write to:

Product Support

Land Pride Service Department

1525 East North Street

P.O. Box 5060

Salina, Ks. 67402-5060

4220ST & 4420ST Light Utility Vehicles 700-504M

2

E-mail address

lpservicedept@landpride.com

8/05/08

Table of Contents

Section 2: Important Safety Information

Section 2: Important Safety Information

IMPORTANT: Read and understand all pages in this manual thoroughly before operating your vehicle.

These are common practices that may or may not be applicable to the products described in

this manual.

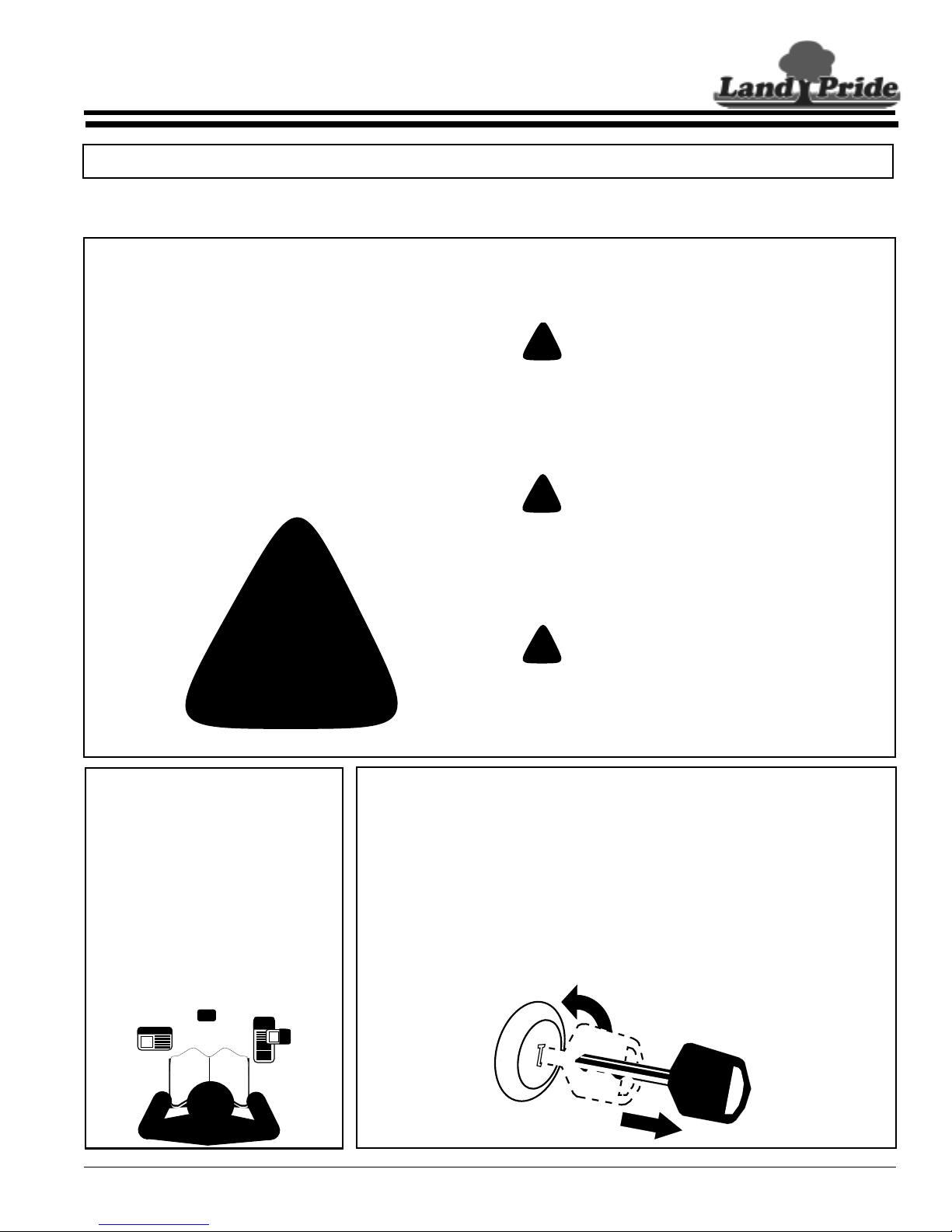

Look For The Safety Alert

Symbol

TheSAFETY ALERTSYMBOL indicates there is

a potential hazard to personal safety involved

andextrasafetyprecaution must be taken.When

you see this symbol, be alert and carefully read

the message that follows it. In addition to design

and configuration of equipment, hazard control

and accident prevention are dependent upon the

awareness, concern, prudence and proper

training of personnel involved in the operation,

transport, maintenance and storage of

equipment.

!

Be Aware of Signal Words

A signal words designate a degree or level of

hazard ser iousness. The signal words are:

!

DANGER

DANGERindicates an imminently hazardoussituation

which, if not avoided, will result in serious or death

injury.This signal word is limited to the most extreme

situations, typically for vehicle components that, for

functional purposes, cannot be guarded.

!

WARNING

WARNINGindicates a potentially hazardoussituation

which, if not avoided, could result in death or serious

injury, and includes hazards that are exposed when

guards are removed. It may also be used to alert

against unsafe practices.

!

CAUTION

CAUTIONindicates a potentially hazardous situation

which, if not avoided, may resultin minor or moderate

injury. It may also be used to alert against unsafe

practices.

For Your Protection

▲ Thoroughly read and understand

the instructions given in this

manual before operation. Refer to

the “Safety Label” section, read all

instructions noted on the decals.

▲ Do not allow anyone to operate

this equipment who has not fully

read and comprehended this

manual and who has not been

properly trained in the safe

operation of the equipment.

8/05/08

Before Operating

▲ This Treker Light Utility Vehicle is

not to be driven on public roads.

▲ Do not operate this vehicle under

the influence of alcohol or drugs.

▲ Always inspect the vehicle before

operating it. See "Pre-Start Check

List" on page 15.

OFF

4220ST & 4420ST Light Utility Vehicles 700-504M

▲ Do not operate this machine

unless all safety shields are in

place and all badly worn, broken or

missing parts have been properly

replaced.

▲ Wear appropriate protective gear

and clothing such as safety

helmet, goggles, gloves, coveralls,

etc., when conditions warrant.

▲ No driver under age of 16.

3

Table of Contents

Section 2: Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Practice Safe

Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment.Refer to this manual for

additional information.

▲ Work in a clean, dry area.

▲ Place the vehicle in neutral, set

parking brake, turn off engine and

remove key before performing

maintenance. Chock wheels if you

must perform maintenance on a

slope.

▲ Make sure all moving parts have

stopped and all system pressure is

relieved.

▲ Allow the engine to cool completely.

▲ Disconnect battery ground cable (-)

before servicing or adjusting

electrical systems or before

welding.

OFF

▲ Inspect all parts. Make sure parts

are in good condition and installed

properly.

▲ Remove build-up of grease, oil or

debris.

▲ Remove all tools and unused parts

from the Treker before operation.

Prepare for

Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire

extinguisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

Wear Pr otective

Equipment

▲ Wear protective clothing and

equipment.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose-fitting clothing.

▲ Because prolonged exposure to

loud noise can cause hearing

impairment or hearing loss, it is

best to wear suitable hearing

protection such as earmuffs or

earplugs.

▲ Because operating equipment

safely requires your full attention,

avoid wearing radio headphones

while operating machinery.

▲ It is the discretion of the operator

and passenger to wear Seat Belts

when available.

Tire Safety

Tire changing can be dangerous

andshould be performedbytrained

personnel using correct tools and

equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough for you to stand to one

side–not in front of or over tire

assembly. Use a safety cage if

available.

▲ When removing and installing

wheels, use wheel-handling

equipment adequate for weight

involved.

911

4220ST & 4420ST Light Utility Vehicles 700-504M

4

8/05/08

Table of Contents

Section 2: Important Safety Information

Safe Operating Procedures

The safe operation of any machiner y is a bigconcern to

allconsumers. YourTreker has been designedwith many

built-in safety features. However, noone should operate

this vehicle beforecarefully reading this Operator’s

Manual. Also read all instructions noted on the safety

decals.

Personal Safety

▲ Be familiar with all functions of this vehicle.

▲ Do not allow anyone to operate this vehicle who has not

fully read and comprehended this manual and who has

not been properly trained in the safe operation of this

vehicle.

▲ Do not operate vehicle while drinking or under the

influence of alcohol or drugs.

▲ Do not allow anyone under 16 years of age to operate

this vehicle even under adult supervision.

▲ Do not run engine indoors except when starting engine

and transporting attachment in or out of a building.

Carbon monoxide gas is colorless, odorless and deadly.

▲ Operator must always use both hands on the steering

wheel.

▲ Keep all bystanders away from this vehicle during

operation. Keep children out of the operating area and

under the watchful eye of another responsible adult.

▲ Riders may, without knowing it, place their foot on the

accelerator pedal while bracing themselves against a

rough ride. This makes it impossible to slow down the

vehicle until the passenger removes his foot from the

pedal. Inform passenger to keep his foot off the

accelerator and always slow down before the ride gets

rough.

▲ Operator and passenger are responsible for deciding if

their situation warrants using seat belts if so equipped.

▲ No riders are allowed except in factory designed and

supplied seating and no more than one person in a

bucketseat and three people in a bench seat. Do not use

cargo bed for carrying people. Maximum vehicle

occupancy including driver is one person per seat

position.

▲ Operate vehicle from driver’s seat only.

▲ Do not leave vehicle unattended with engine running.

▲ Do not dismount a moving vehicle as serious injury or

death could occur.

▲ Wear snug-fitting clothing to avoid entanglement with

moving parts.

▲ Keep hands, feet, long hair, clothing and jewelry away

from moving parts and obvious pinch points to avoid

getting caught.

▲ Keep hands, arms, feet and all bodily appendages safely

inside the confines of the vehicle. Alwaysbe aware of and

avoid tree limbs and brush that have a potential of hitting

and/or poking individuals riding the vehicle. Serious body

harm could result.

▲ Some conditions may warrant extra safety gear to be

worn such as safety helmets and/or goggles.

▲ Do not touch engine, engine exhaust pipe and/or muffler

while they are hot.

▲ Avoid pinch point hazards. Cargo bed and seat platform

hinge creating pinch points.

▲ Battery fumes are explosive. A spark will ignite battery

fumes. Wear a face shield when charging or jumping a

battery. Follow all battery safety rules outlined in this

manual.

▲ Avoid battery acid spills. Do not get battery acid on eyes,

face, or other body parts. Flush eyes and other body

parts immediately with water for at least 15 minutes if

battery acid has gotten on them.

▲ When refueling use a UL approved nonmetallic container

that has no screen or filter. Set container on the ground

beforefueling to eliminate static discharge and do not use

Methanol fuel.

▲ Do not smoke or use electrical devices including cell

phones while refueling.

▲ Support this vehicle securely before working beneath.

Chock wheels to prevent vehicle from rolling.

Mechanical Safety

▲ Do not operate a vehicle with damaged or worn parts.

Repair all damages and worn parts before putting vehicle

back in to service.

▲ Never attempt to make any adjustments while engine is

running or hot. Keep clear of all rotating parts.

▲ Make sure engine surface, cooling fins and fan screen

are clean of all debris including dirt, trash and oil.

▲ Always operate vehicle with drive belt enclosure installed.

Do not leave pulleys and belts exposed.

▲ Never modify any parts on the vehicle without

authorization. Unauthorized modifications will void

warranty to all parts directly and indirectly affected by the

modification.

▲ Do not use cargo tail gate as a seat.

▲ Do not use cargo bed as a working platform.

▲ The power lift is designed todump cargo only.Do not use

it to lift other objects.

▲ Never attempt “wheelies”, jumps, or other stunts. Never

drive recklessly. Always operate your vehicle at a safe

speed that will allow you to maintain control.

▲ Do not use vehicle as an anchor device.

8/05/08

4220ST & 4420ST Light Utility Vehicles 700-504M

5

Table of Contents

Section 2: Important Safety Information

▲ Do not mount a receiver hitch type carrier platform to the

vehicle.

▲ Front bumper, brush guards and cargo box are not

designed as pusher bars. Do not attempt to push other

vehicles or implements or damage may result.

▲ Always maintain proper tire inflation. See "Tire

Maintenance" on page 25.

▲ Always disconnect negative battery terminal before

making adjustments to vehicle electrical system or

welding on this vehicle.

▲ Always check wheel lug nut torque valuestwo hours after

initial operation and two hours after each tire repair or

replacement. Routinely check lug nut torque every 100

hours of operation. See "Wheel Lug Nuts" on page 25.

▲ Do not shift trans-axle unless this vehicle is fully stopped

and engine is at idle or damage may occur.

▲ Keep safety decals clean of dirt and grime.

▲ Replace all missing, illegible, or damaged safety decals.

See list of safety decals in this manual.

Transporting Safety

!

WARNING

Most accidents with off road vehicles occur when traveling up,

down, or across the face of a slope. Refer to operation

instructions and safety video for proper operation procedures.

▲ Use extreme caution when driving through dry grass,

brush and other fire hazard materials. Never stop or park

over combustible materials. Keep grass and brush from

collecting on and around engine and muffler parts.

▲ Be aware of cargo shifting when stopping or moving.

Make sure all cargo is properly secured and tied down.

Injury could result from loose cargo.

▲ Avoid sudden stops, starts and turns.

▲ Always make sure vehicle pathway is clear of all objects

when backing up. Know location of persons around

vehicle and especially location of small children. Take

extra precautions when rear view is hindered by cargo.

▲ Do not attach an implement, trailer or other device to the

hitch that will produce negative tongue weight.

▲ Reduce speed and payload on hilly, rough, wet, slick or

unstable ground.

▲ Reduce speed when loaded with cargo. Heavycargo load

takes longer to stop.

▲ Always make turns at a speed that willmaintain control of

vehicle. Never make turns at full speed. Reduce speed

when turning empty and reduce speed even more when

turning loaded. The heavier the cargo load, the slower the

turn should be.

▲ The 4-post accessory bar is not a certified ROPS (Roll

Over Protection System). Always avoid roll-overs.

▲ Do not load 4-post accessory bar with heavy equipment.

Rollover could result from such loading.

▲ Always park on level ground, stop engine, set park brake

(see "Shift Selector and Park Brake" on page 17) and

remove ignition key before leaving vehicle. Chock tires if

condition warrants.

▲ Use extreme caution when cresting hills, approaching

blind corners, shrubs, trees or other obstructions that

might limit visibility. Proceed slowly until youare sure trail

conditions immediately ahead are safe. Use extra care

when approaching obstructions that might hide children.

▲ Be especially observant of operating area and terrain.

Watch for holes, rocks, or other hidden hazards. Do not

operate vehicle near the edge of drop-offs or banks.

▲ Keep front wheels straight when cresting hills or going

over bumps.

▲ Do not stop, start suddenly or over accelerate on hills.

Loss of control and rollover could result.

▲ Use extreme caution when descending hills, running on

loose slippery surfaces, or when towing at maximum

capacity. Towing, braking and tractive capabilities are

greatly diminished.

▲ Avoid changing direction or making sharp steering

corrections on slopes or rollover may occur.

▲ If this vehicle begins to tip when crossing a slope, turn

front wheels downhill to regain stability and control.

▲ Do not operate vehicle on slopes over 15

▲ When crossing a slope on soft terrain, turn front wheels

slightly uphill and maintain a constant speed to maintain a

straight line of travel.

▲ When descending hills or slopes apply steady pressure to

the foot brake to avoid potential of freewheeling or

runaway.

▲ Never allow vehicle to coast or free wheel in neutral or

loss of control may result.

▲ If your vehicle loses power and stops on a hill,

immediately engage foot brake and backslowly down the

hill maintaining a straight downhill line of travel. Do not

attempt to turn vehicle sideways on the hill or a rollover

could result.

▲ Never operate vehicle without good visibility and lighting.

When traveling at night always use your headlights and

reduce speed according to visibility, trail and terrain

conditions.

▲ Do not operate this vehicle on highways, public roads, or

where it may be a hazard to faster moving traffic.

▲ Exercise extreme caution when operating on or crossing

a gravel drive, walks, or roads. stay alert for hidden

hazards or traffic.

o

.

4220ST & 4420ST Light Utility Vehicles 700-504M

6

8/05/08

Table of Contents

Section 2: Important Safety Information

▲ Avoid water crossings when possible and never cross a

body of water where depth is unknown. Loss of power will

occur if drive belt becomes submerged or wet.

Unnecessary crossing of streams and waterways erodes

shore line and damages water-born habitat. If you must

cross, do it at a point where banks are not steep and

proceed at a slow and steady speed. Do not travel in

water that ishigher than the bottom wheel lug nuts. Water

higher than the bottom wheel lug nut can damage the

brake system and get the drive belt wet stalling the

vehicle. However, intermittent stream crossings where

depth of water briefly comes into contact with bottom of

floorboards is acceptable. See "Going Out on the Trail"

Note 7 on page 21.

▲ Never use vehicle for racing and never modify engine to

exceed 25 MPH vehicle speed.

Towing Safety

▲ Follow all towing instructions in this manual when towing

the Treker behind another vehicle. Do not tow the vehicle

faster than 25 MPH. See "Towing" on page 20.

▲ Beware, tow ropes, cables and chains can break when

pulling another vehicle or object causing serious injury or

death to anyone in line with the whipping action created

when they break. Never jerk when pulling, always ease

into a pull gently. Always stay clear of tow line. Never be

in line with tow line.

Safe Load Capacities

Refer to Vehicle Specifications onpage 45:

▲ Do not exceed total payload capacity of this vehicle.

▲ Do not pull a trailer or implement exceeding maximum

towing capacity and/or maximum tongue weight.

Loss of control may result.

▲ Do not exceed front cargo rack carrying capacity.

▲ Do not exceed rear cargo box payload capacity.

8/05/08

4220ST & 4420ST Light Utility Vehicles 700-504M

7

Table of Contents

Section 2: Important Safety Information

Safety Decals

Your Treker comes equipped with all safety labels in place.

They were designed to help you safely operate your implement.

Read and follow their directions.

1. Keep all safety decals clean and legible.

2. Replace all damaged or missing decals. Order new safety

decals through your Land Pride dealer.

3. Some new equipment installed during repair requires safety

labels to be affixed to the replaced component as specified

24690

by Land Pride. When ordering new parts or components,

also request corresponding safety decals.

4. Refer to this section for proper label placement. Install new

decals as follows

a. Clean area on which decal is to be placed.

b. Spray soapy water on the surface where decal is to be

placed.

c. Peel backing from decal. Press firmly on surface,

being careful not to cause air bubbles under decal.

d. Squeeze out air bubbles with edge of a credit card.

838-303C

Danger: Battery

4220ST & 4420ST Light Utility Vehicles 700-504M

8

24691

23536

818-543C

Danger: Guard Missing

838-629C

Warning: Pinch Point or Crushing Hazard

8/05/08

Table of Contents

Section 2: Important Safety Information

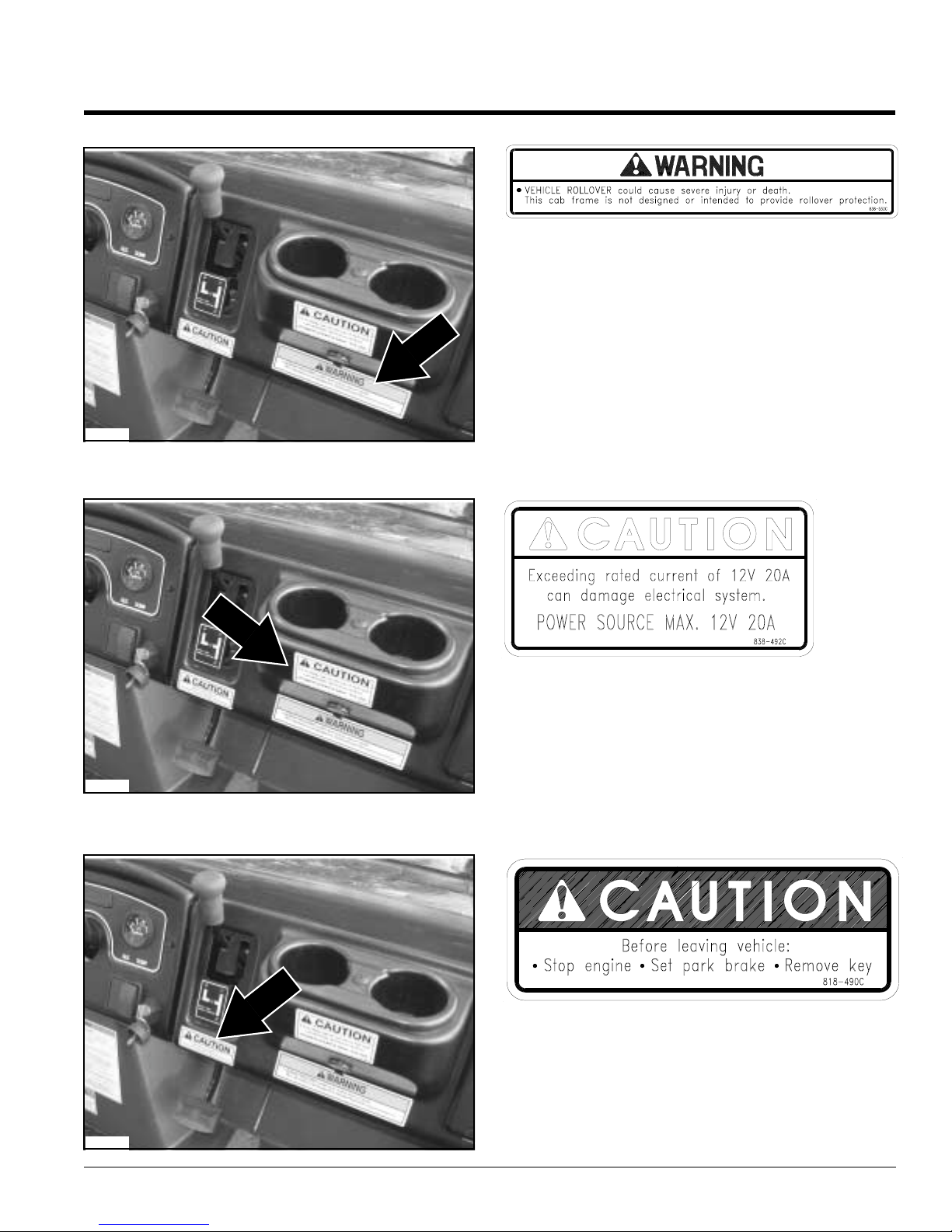

24697

838-532C

Warning: Cab Rollover Protection

24697

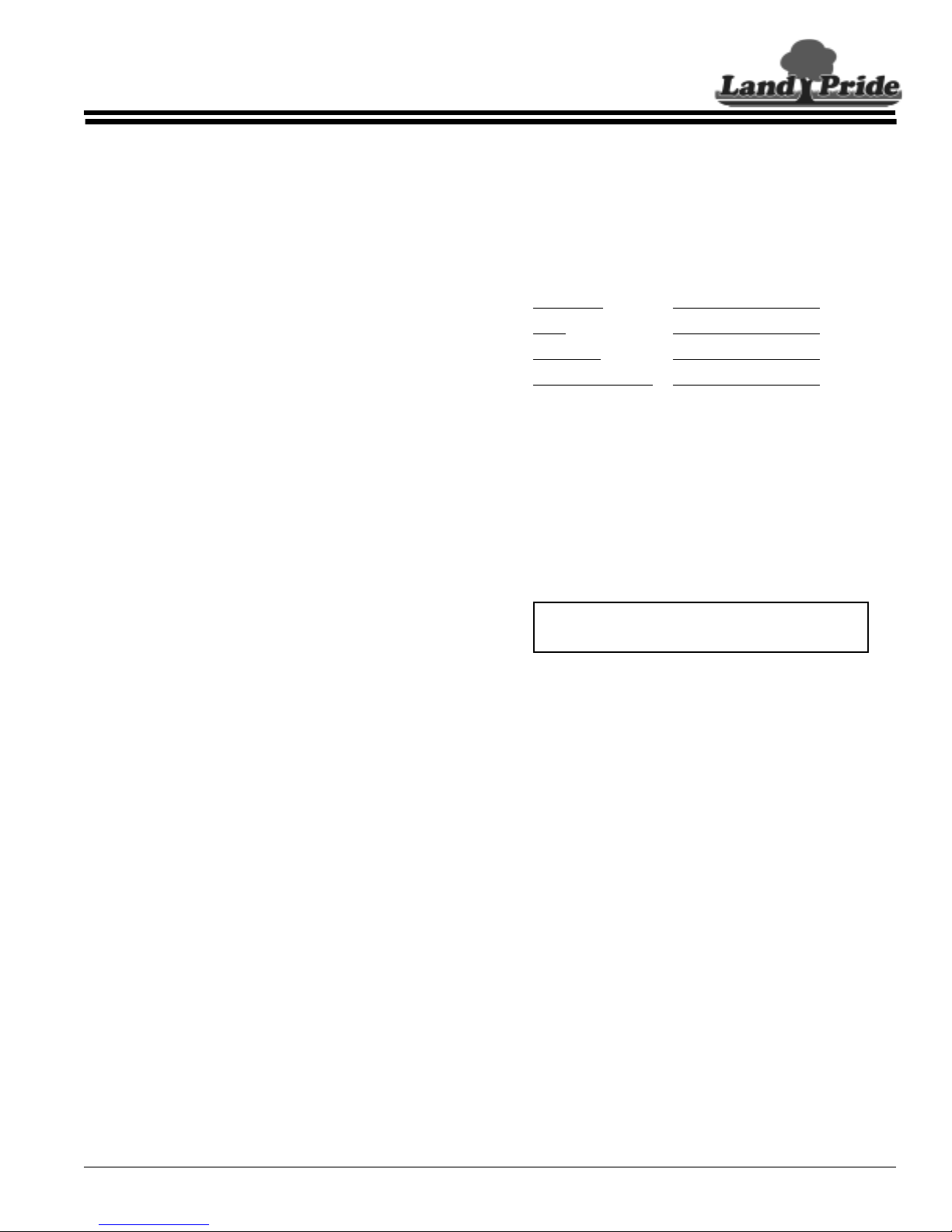

24697

838-492C

Caution: Maximum Power Source

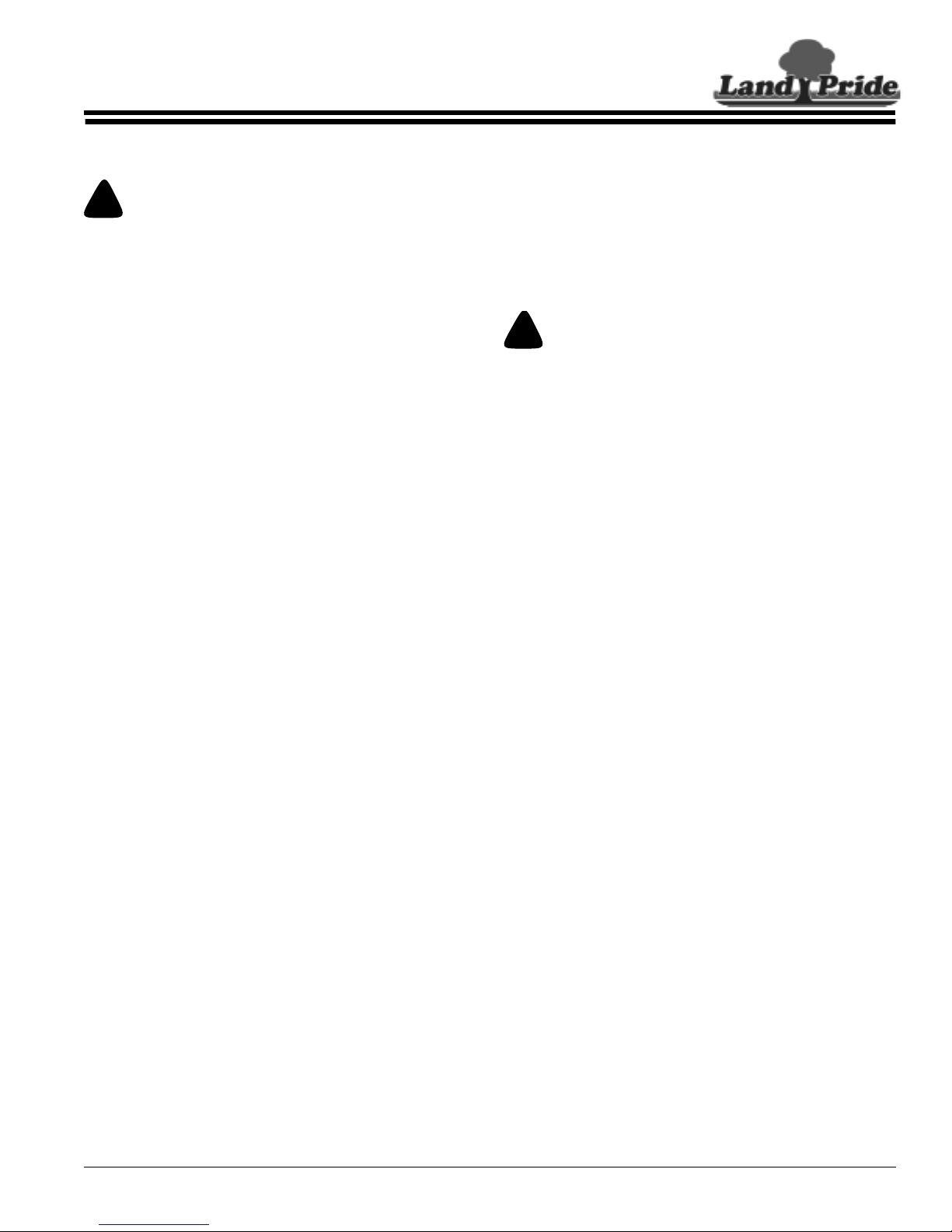

838-490C

Caution: Stop Engine

8/05/08

4220ST & 4420ST Light Utility Vehicles 700-504M

9

Table of Contents

Section 2: Important Safety Information

4220ST & 4420ST Light Utility Vehicles 700-504M

10

838-486C

Warning: General Utility Vehicle

24694

8/05/08

Table of Contents

Section 2: Important Safety Information

838-570C

Vehicle Loading Capacities, 4220ST Series

24694

21147

838-663C

Vehicle Loading Capacities, 4420ST Series

838-579C

Trailer Towing Information

8/05/08

24735

838-508C

Warning: Before Filling Tank with Gasoline

4220ST & 4420ST Light Utility Vehicles 700-504M

11

Table of Contents

Section 2: Important Safety Information

21110

21110

838-491C

Warning: Improper Use

838-489C

Warning: Rollover Hazard

4220ST & 4420ST Light Utility Vehicles 700-504M

12

24695

838-444C

Danger: Muffler hot

8/05/08

Table of Contents

Section 3: Pre-Delivery and Check List

Section 3: Pre-Delivery and Check List

Each vehicle must undergo a Pre-Delivery Inspection by the Dealer. Listed below is an example of the checklist that

is included with the Warranty Registration that is to be submitted to Land Pride upon Retail Sale. The Pre-Delivery

Certificate and Warranty Registration must be submitted to Land Pride in order to activate the vehicle warranty.

Pre-Delivery Certificate

The dealer is required to complete Land Pride’s

“Certificate of Light Utility Vehicle Pre-Deliver y” form

before customer may take possession of vehicle. The

information must be filled in and check list checkedoff or

initialed by individuals performing the checks.

Dealership’sname, signatures of individualsfilling in the

form,seller’ssignature,customer’ssignature andsigning

dates are also required before the form is returned to

Land Pride. Below is a listof the information found in the

form that is required to be completed and checked off.

Vehicle Information

Model No. _________________

Date _________________

Serial No. _________________

Engine Serial No. _________________

Dealer Service and Inspection List

___Fully charge battery. Check battery voltage to verify

that it is fully charged.

___Connect negative battery cable. (Negative battery

cable is disconnected before leaving factory and is to

be disconnected after initial dealer set-up to prevent

battery discharge while setting on the dealer’s lot.)

___Check tire pressure to make sure front and rear tires

havea minimum of 7 psi. See "Tire Inflation Chart" on

page 26.

___Make sure wheellug bolts/nuts are tightened to 90

Newton meters/(65ft. lbs.).

___Check master cylinderto make sure it is filled.

___Checkengine oil levelat thedipstick. Add SAE 10W30

oil if oil is below the full mark on the dipstick. Do not

overfill.

___Check engine for correct RPM. Set to factory

specification if needed. (See page 45)

___Check Tie Rods for tightness.

___Step on footbrake to make sure there is plenty of

pedal and that brakes hold pressureand do not bleed

off. Add brake fluid and bleed brakes if required.

___Make sure seats and seatbelts areproperly fastened

to vehicle frame if so equipped.

___Make sure allsafety decalsare in place.

___Check headlights tomake sure they are working and

are properly mounted.

___Checktail lights and brakelightsto makesure theyare

working and are properly mounted.

___Inspect air cleaner element. Make certain it is clean

and in place.

___Inspect fuel tank to make sure it is properly installed

and that there are no leaks.

NOTE: Vehicles are shipped from thefactory with

about a quart of fuel in the tank

___Checkfuel levelin tank.If needed, add gasoline with a

fuel stabilizer to perform initial starting operations.

See "Fuel System" instructions onpage 29 before

adding fuel.

___Inspect fuel lines to make sure they are properly

installed and that there are no leaks.

___Check steering byexecuting a full lock to lock turn in

each direction.

___Checkpark brake to makesure itwill engage, holdand

release.

___Make sure neutral start feature is working bytrying to

start unit while shifter is located in the forward and

reversepositions.

___Check throttle controlto make sure it moves and

returns freely.

___Check choke control to make sure it moves and

returns freely.

___Check Rear Trans-axleoil level at the oil plug. Add

Land Pride special formulated gear lube noted on

page 39 if oil is low.

___Checkoverallappearanceforcleanliness and forbody

and molding damage.

.

8/05/08

4220ST & 4420ST Light Utility Vehicles 700-504M

13

Table of Contents

Section 3: Pre-Delivery and Check List

Dealer Test Ride List

___Check engine for starting, accelerating, running and

idling smoothly.

___Check steering response.There should be no free-

play.

___Checkforward, neutral and reverseshifting response.

Also check neutral start response.

___Check park brake to make sure itengages, holds and

disengages.

___Make sure rocker switches are all working.

___Make sure throttleis responsive and returns freely.

___Make sure suspensionride is satisfactory and stable.

___Make sure thereare no fuel or petroleum leaks.

___Makesure foot brake has a firm engagement and that

stopping is straight.

___Make sure thereare no bad rattles or vibrations.

Dealer Delivery To Customer List

___Warranty registration form is complete.

___Owner’s Manual has been delivered to and reviewed

by customer.

___EngineManual has been delivered to and reviewedby

customer.

___Warranty Policy limits and requirements have been

explained to customer.

___Customer has reviewed safety video.

___Location and functions of vehicle controls have been

explained.

___Fuel transportation and storage procedures have

been explained.

___Fluid fill and lubrication points have been locatedand

explained to customer.

___Customer has completed the driving course.

___Information on safetydecals have been reviewedwith

customer.

Customer Acceptance List

Customer initials required where accepted as

successfully completed.

___Customer has reviewed and understands Land Pride

warranty policy.

___Customer has inspected the vehicle and it meets

customer’s satisfaction.

___Customerunderstandsthe importance offollowingthe

owner’smanual instructions.

___Customer has completed the Land Pride safety

training course.

4220ST & 4420ST Light Utility Vehicles 700-504M

14

8/05/08

Section 4: Operating Instructions

Section 4: Operating Instructions

Table of Contents

Operator Responsibilities

!

WARNING

It is the operator’s responsibility to have read this manual

thoroughlyand to know how to operate this vehicle safely in all

situations. See "Section 2: Important Safety Information"

starting on page 3.

Pre-Start Check List

• Lubricatevehicle as indicated in "Section 7:

Lubrication" starting on page 37.

• Makesure engine cooling fan screen is clean of all

debris including dirt, trash and oil. Also, make sure

engine surface andcooling fins are clean. See “Engine

Maintenance” on page 30.

• Makesure exhaust system is clean of all dirt, trash and

oil. Check spark arresterevery 100hours tomake sure

it is cleanand in good working condition.See “Exhaust

System” on page 34.

• Checktire pressure as indicated in the "Tire Inflation

Chart" on page 26.

• Makesure wheel lug bolts/nuts are tightened to 65ft. lbs.

• Allnuts, bolts,screws andfasteners shouldbe checked.

Refer to Torque Value Chart in "Section 13:

Appendix" on page 51.

• Turnon headlights to make sure battery has a charge

and electrical lighting circuit is working.

• Checktail lights and brake lights.

• Stepon foot brake to make surethere is plenty of pedal

and that brakes hold pressure and do not bleed off. Add

brake fluid as indicated in "Brake Fluid" on page 41

and bleed brakes if required.

• Checkpark brake to make sure it will engage, hold and

release.

• Checksteering by executing a full lock to lock turn in

each direction.

• Checkto make sure neutral start feature is working by

trying to start unit with the shift selector located in

forward and reverse positions. (Unit should not start.)

• Checkengine oil level at the dipstick. Add oil as

indicated in "Engine Oil" on page 37 if oil is at or below

the add mark on the dipstick. Do not overfill or plug

fouling will occur.

• Checkdifferential oil level atthe differential oil plug. Add

gear lube as indicated in "Case Oil" on page 39.

• Checkfuel level to make sure there is at least 1/8of a

tankof gas prior toperforming initial starting operations.

• Checkair intake filtering system. Clean or replace

filtering system per instructions for “Engine Air Filter

Maintenance” on page 32 and “CVT Snorkel Filter

Maintenance” on page 33.

• Makesure low engine idle speed is set between 1250

and 1350 rpm and that maximum engine static speed

does not exceed 3800 rpm. Modifying or adjusting

carburetor to increase vehicle speed above factory

set specification is a safety violation and could

result in voiding the warranty.

General Operation

!

DANGER

Avoid injury or death from entanglement in the rotating drive

belt. All shields must be in place and secure when operating.

Keep all persons away from rotating driveline.

To start the Treker, following starting procedures

displayed at the gearshift lever and as noted below.

1. Set park brake and shift selector inPark.

2. Pull choke fully out and hold when engine is cold.

3. Turn ignitionkey fully clockwiseand hold until engine

starts.

4. Release ignition key to run position and choke to

normal operatingposition immediately after engine

starts.

5. Turn ignition key counterclockwise to stop engine.

Operating a Trekeris as easy as operating a car with an

automatic transmission. A simple forward and reverse

shifter provides direction control. A neutral start feature

and keyed 12 volt electronic ignition makes for safe and

easy starting. A manual choke control under the seat

assist quick cold weatherstarting. The infinitelyvariable

torque converter drive system means there is no

clutching. Shift into either forward or reverse when the

vehicle is stopped andstep onthe throttle pedal to go at

speedsup to 25mph. Nevershift whilevehicle ismoving.

The unit will only start when shift lever is in neutral or

park and dash mounted indicator light is on.

Braking is accomplished by simply depressing thebrake

pedal located on the floorboard. This activates the rear

hydraulic drum brakesand front hydraulic disc brakes.

The par k brake is incorporated in the shift selector. A

dash mounted park brake indicator light will remain on

until par k brake is disengaged.

8/05/08

4220ST & 4420ST Light Utility Vehicles 700-504M

15

Section 4: Operating Instructions

Table of Contents

Indicating Lights and Gauges

Refer to Figure 4-1:

#1 Hour Meter: Indicates number of hours, to the

nearest 1/10 of an hour, the vehiclehas run.

#2 Park Brake Light:Indicates park brake is on when

illuminated. Do not move vehicle with park brake

light on. See note below.

#3 4-Wheel Drive Light: Indicates 4-wheel drive is

activated when illuminated.

#4 Neutral Light: Indicates shift selector is in neutral

when illuminated.

1 2

3

54

6

lower cargo box. Release switch at any position to

stop cargo box.Release switchimmediately if

Power Bed Lift Cylinder makes a ratchet noise.

IMPORTANT: The Power Bed Lift is protected by an

internal clutch in both directions and will make a loud

“ratchet” noise indicating end of travel has been

reached or Pow er Bed Lift is overloaded. Release

switch immediately when this noise is heard.

#10 Auxiliary SwitchSlot:12volton/off accessory with

switch may be installed at this location.

#11 Light Switch: Turns on head and tail lights. Press

topof switchto turn onlights and bottomof switchto

turn offlights.

#12 4-Wheel Drive Switch: Engages the4-wheel drive

system.Press topof switchtoengage 4-wheeldrive

and bottom of switch to disengage 4-wheel drive.

The 4-wheel drive system should be used only

when required to get through a difficult situation.

NOTE: 4x4 drive should not be engaged at transport

speed or on hard surface roads.

24696

Figure 4-1

#5 Oil Light: Indicates low oil pressure when

illuminated. Stop engine immediately. Checkoil

levelandadd if low. See yourauthorized Land Pride

dealerif oil light stayson and engine isfull of oil. It is

normal for the oil light to come on whenever the

ignition switch is turned on and will stay onuntil

engine is running.

#6 Volt Meter: Indicates battery is charging. Check

battery if volt meter registers a charge thatis lower

thannormal. Seeyour authorizedLandPride dealer

if battery is good and volt meter still registers low

charge.

Switches

Refer to Figure 4-2 and Figure 4-3:

#7 PowerPlugOutlet: Locatedon the dashis a power

plug outlet forconnecting 12 volt accessories such

as a cell phone or light.

#8 Ignition Switch: Starts and stops engine. Vertical

position is off.Turn switch key clockwise to start

engine. See “GeneralOperation” on page 15 for

correct vehicle starting procedures.

#9 Dump Switch: An electric cylinder raises and

lowersthecargobox.Press topofswitchand holdto

raise cargo box. Press bottom of switch andhold to

24693

10

9

8

Figure 4-2

Figure 4-3

7

12

11

21460

4220ST & 4420ST Light Utility Vehicles 700-504M

16

8/05/08

Section 4: Operating Instructions

Table of Contents

Choke

Refer to Figure 4-4:

#13 Choke Control: Located under the driver’s seat.

Use to choke engine whenstarting. Pull onknob to

start a cold engine. Release knob after engine has

started. Do not choke an engine that is hotfrom

operating, engine flooding may result.

13

22386

Figure 4-4

Floor Pedals

Refer to Figure 4-5:

#14 Brake Pedal: Applying pressure to brake pedal

instead of acceleratorpedal with your foot will slow

downand/or stopvehicle.Riding or resting your foot

on the pedal unnecessarily willwear the brakes out

prematurely.

#15 Accelerator Pedal: Changes engine rpm and

vehicle ground speed. Press down on the

accelerator pedal with your footto increase speed

and let upon the pedal to decreasespeed. Vehicle

should not move when engine is idling. Adjust

engineidle speedif vehiclemoveswhileaccelerator

pedal is not being depressed.

Shift Selector and Park Brake

Refer to Figure 4-6:

#16 Shift Selector & Park Brake Control: Sets and

releases the park brake and changes trans-axle

gears from neutral to forwardor reverse. Always

start engine in park or neutral.

• To place trans-axle in neutral from park position,

move shift selectorup and over to theleft and then

pull straight down to neutral position.

• From neutral, move shift selector over to the right

and up to place trans-axle in forward gear.

• From neutral, move shift selector over to the right

and down to place trans-axle in reverse gear.

• Make a full stop by letting up on accelerator pedal

and applying brakes before returning shift selector

to park or switching from reverse to forward and

forward to reverse.

16

22482

Shift Selector Shown in Park

Figure 4-6

Figure 4-5

8/05/08

14

15

24694

4220ST & 4420ST Light Utility Vehicles 700-504M

17

Table of Contents

Section 4: Operating Instructions

Fuel Gauge

Refer to Figure 4-7:

#17 Fuel Gauge: The fuel gauge, located on the gas

tank, displays approximately how much fuel you

have in the fuel tank. Always park vehicle on level

ground to get an accurate reading. The fuel tank is

empty when the fuel gauge needle points to E and

full when the needle points to F.

17

Release

Button

18

Tongue

19

Retractor

22485

Figure 4-8

22489

Figure 4-7

Seat Belts

!

WARNING

Seat belts should fit snugly and as low around the hips as

possible. Wearing seat belts high around the waist greatly

increases the chances of that person being injured in a

dangerous situation.

!

WARNING

Neveruse a seat belt for morethan one person and never buckle

the seat belt to a buckle designed to receive the other seat belt.

Twoseat belts are factor y supplied with the bench seat. A

third accessory seat belt may be added. See “Treker

Accessories” on page 24. It is the responsibility of the

operator and passenger to decide if their situation

warrants using seat belts. Make sure seats and seat

belts are properly fastened to the frame.

Seat Belt Components

Refer to Figure 4-8:

#18 Seat Belt: Theseat beltis thebelt thatextendsfrom

the retractor when pulled across your lap to be

buckled. It is located on the left side of the driver’s

seat and right side of the passenger’s seat.

#19 Buckle: Both operator and passenger buckles are

located in the middle. It secures the seat belt in

place.

Seat Belt Operation

Pull the seat belt across your hips and insert its tongue

into the buckle until you hear it snap. Release the seat

belt by pressing the release button in the center of the

buckle. Guide the seat belt to its original position as it

retracts to keep it aligned and to preventits tongue from

striking and damaging surfaces on the vehicle.

Cup Holders

Refer to Figure 4-9:

A removable rivet secures the cup holder to the dash.

The cups may be removed from the dash for cleaning.

Cup Holders

22479

Figure 4-9

4220ST & 4420ST Light Utility Vehicles 700-504M

18

8/05/08

Table of Contents

Section 4: Operating Instructions

Glove Box Enclosure

Refer to Figure 4-10:

Unlock glove box by inserting key and rotating clockwise

90 degrees to the position shown. Rotate twist lock

clockwise another 90 degrees to open. Toclose, push

glove box lid shut. To lock while shut, rotate key 90

degrees counterclockwise and remove. Key can be

removed in locked and unlocked positions.

Keyed Twist Lock

(Shown Unlocked)

23534

Figure 4-10

Cargo Box / Flat Bed Set-Up

!

CAUTION

Always load front of cargo box first and back last. Never load

back with more weight than the front.

!

DANGER

Make sure area behind cargo box is clear of personnel before

raising the cargo box. Bodily harm can result from being

pinched between cargo box and another object or from a load

dumping and/or rolling onto a bystander.

Thecargo box isfactory standardwith removabletailgate

and side panels for changing cargo box into a flatbed.

Refer to Figure 4-11:

1. Remove cotter pins (#6) and flat washers (#5) from

tailgate cable pins(#8). (2-places)

2. Remove 1/4”-20 hex screws (#4) and tailgate pivots

(#1) from tailgate. (2-places)

3. Pull gate release lever (#7) back on both sides and

remove gate (#3) from cargo box.

4. Replace flat washers (#5) and cotter pins(#6) in

tailgate cable pins(#8) forstorage.

234698

Figure 4-11

Refer to Figure 4-12:

5. Remove5 5/16”-18 hex flange screws (#10) and right

hand side panel (#9) as shown.

6. Repeat step 5 for left hand side panel.

234699

Figure 4-12

8/05/08

4220ST & 4420ST Light Utility Vehicles 700-504M

19

Section 4: Operating Instructions

Table of Contents

Towing

The Treker iscapable of being towed behind a tractor or

another vehicle as long as certain precautions are

followed:

• Theignition switch must be turned off.

• Thegear selector must be placed in neutral position.

• Thevehicle must be towed with a rigid tow-bar that is

designed to tow the gross weight of the Treker. See

"Section 10: Specifications and Capacities"on page 45

for vehicle gross weight.

• Tow-barmust be securely attached to the Treker at a

location that willnot damage the vehicle orcome loose

from the vehicle.

• Owner/usertakes on all responsibility and liability

resulting from attaching tow-bar to the Treker and to the

vehicle towing the Treker.

• Donot allow anyoneto ride inthe Treker whileit is being

towed.

• Donot tow a trailer or vehicle behind the Treker thatis

being towed.

• Donot towvehicle atspeeds over 25 mph. Thevehicle

is designed to travel up to 25 mph. Higher speeds may

resultindamage tothe Treker, vehicletowing theTreker

and personnel.

• Slowdown when turning to prevent loss of control and

rollovers.

• Obeyall state and local laws for towing vehicles.

Engine Performance

All small gas enginesneed fuel,air, and spar k inexactly

the r ight proportions in order to run properly at peak

performance.Bad orstale fuel, afouled spark plug,a wet

or corroded spark plug wire, agummed up carburetor,a

wet or dirty air filter, a low oil situation, incomplete fuel

combustion,carburetoricing, highoil situation(gas inthe

oil reservoir), and low engine temperature are all causes

of small gas engine problems or diminished

performance.

Fuel Quality

The normal shelf life of gasoline from the time it leaves

the refinery is about 30 days. Unused gas that is stored

too long can oxidize and break down causing formation

of gum and varnish deposits in carburetors, needle

valves,jets and venturis. This stopsor chokes offflow of

proper fuel/air mixture.

Incomplete Combustion

Incomplete combustionis when fuel is not fully bur ned in

the engine combustion chamber. This condition can

occur when an engine is started but is not allowed to run

long enough to reach full operating temperature. Cold

weathercan accelerate this condition. Also, fouledspark

plugs,wet electrical circuits and/or a plugged air filterwill

prevent fuel from being fully burned.

Unburnedfuel pools on topof the piston and seeps down

the cylinder walls into the oil reservoir. Often the oil

dipstick will show an oil over-fill condition as fuel

accumulates in the reservoir.

The oil reservoir filling up with gas can foul the spark

plugs. If left unchecked, oil will become so diluted with

gasoline that it can no longerfunction as alubricant. Itis

extremely impor tant to change oil and oil filter often

wheneverthereis ahigh frequency of gas gettinginto the

oilreser voir.Notchanging oil and oil filteroften canresult

in premature wear on cylinder walls and piston rings.

Also, replace fouled spark plugs, regap weak plugs,

check electrical system for capability of delivering a

strong spar k and clean the air filter when dirty.

Cold Weather Operation

Small gasoline engines must get up to operating

temperature before they will operate properly. Most air

cooled engines draw a large volume of air through their

intakefan. In sub-zero temperatures or freezing weather

it can become almost impossible for an engine to reach

normal operating temperature unless intake air is

restricted or warmer air is fed into the carburetor. Land

Pride offers a cold weather kit that directs air warmed

from the exhaust manifold into the carburetor.

Chokes, throttle cables, and other mechanical linkages

are also subject to freezing and sticking in cold weather.

Products like WD-40 or dry graphite lubricants can be

invaluable in keeping these items working freely.

Whenever possible, park your Treker in a warm, dry

environment to allow time for the linkages to dry out.

Draining the tank or running the engine until the tank is

empty can result in dried out gasketsthat, whendry, will

crack and leak. Also, emptying metal fuel tanks and

storagecontainers can result in corroded containers and

contaminated fuel.

Land Pride highly recommends using a fuel stabilizer or

oxygen inhibitor such as STA-BIL.

4220ST & 4420ST Light Utility Vehicles 700-504M

20

8/05/08

Section 4: Operating Instructions

Table of Contents

Traveling Tips From the Trail Masters

At Land Pride wewant you to get maximumworking and

recreational enjoyment out of your utility vehicle. If your

work project or recreational adventure is going to take

you on anextended ride deep into thewilderness orway

out on the prairie, you’ll need to seriously consider some

of the following tips from experienced pros about safety,

gear, clothing, supplies and driving techniques.

Preparation and Planning

Do a complete equipment check as follows:

1. Make sure you have plenty offuel and oilto make the

trip and then some.

2. Make sure your tires have proper inflation, your lug

bolts are tight and that you have a spare and the tools

to change, repair and inflate a tire.Consider adding a

puncture sealant to your tires as a preventative

measure.

3. Check for any loose or missing parts and definitely

makethose needed repairs before going anywhere.It

is especially important that you check steering,

braking, throttle, electrical and engine components

thoroughly.

Plan Your Route

1. Plan your route, destination and rendezvous points

before starting out.

2. Don’t go it alone if at all possible. Taking someone

elsealongreduces thepotential forlossof lifeormajor

injury from inclement weather, animal attacks, or

accidents. Besides, it’s more fun when you have

someone to share the adventure with.

3. Obtain trail or area maps of your travel routes to and

from your destination. Communicate yourtravelplans

to responsible friends and or proper authorities. Plan

rendezvous points at conspicuous landmarks along

yourroutejust in case yourun into unexpectedtrouble

on the trail.

4. Make sure you take a weather radio and two-way

communication devices such as cell phones or long

range-two way radios. It is also good to have ground

flares, a flare gun, a smoke canister, emergency

strobe light, a reflecting mirror, matches fora signal

fire and a compass.

Plan Your Gear

1. Check the short and longrange weather forecast and

take protective gear and clothing to cover all

contingencies. It doesn’t have to snow for you to fall

victim to hypothermia or exposure. Take or wear

appropriate eyeand head protection,gloves,boots, a

long sleeve shirt, long pants, a jacket,rain gear, dry

socks and a full change of dry clothing.

2. Plan your gear and gear up for the best and worst of

environmental conditions.

3. Packa first aid kit, sunblocker, lip balm, insect

repellent, personal medications, water, tarp or tent,

flash light, survival knife, binoculars, camera, tool kit,

rope, duct tape,tow strap, winch or come-along,

eating utensils, cooking utensils and high energytrail

food.

4. Tie and lash down your gear and supplies securely.

Keepthe bulk of the weight centered and mounted as

low as possible on the vehicle in order to maintain a

lowcenter of gravity forsafe and stableoff-road travel.

Going Out on the Trail

1. When it’s time to hit the trail “take it all in” but do it

safely!

2. Make sure you brief yourpassenger onproper safety

procedures like keeping hands, arms, feet andother

bodily appendages inside the vehicle. Passengers

shouldonly be transported in factorysupplied seating.

3. Operator and passenger areresponsible for deciding

if their situation warrants using Seat Belts.

4. Avoidoperating on excessivelysteep hills and

especially on hills that are steeper than 15 degrees.

Avoidcrossing slopes if possible and don’t make

sharp uphill steering corrections or a rollover could

result. If your vehicle starts to tip overon a slope turn

the front wheels quickly down hill to regain stability

andcontrol. Thebest wayto climbmost hills is to drive

straight up while maintaining a steady groundspeed

and constant engine rpm. The best way to descend

mosthillsis straightdownwhile usingsteady pressure

on the brakes without locking them up. Locking up the

brakes in a steep downhill situation can result in loss

oftraction, steering and control. Whenyou mustcross

a slope on soft terrain, keepthe front wheels turned

slightly uphill and maintain a constant speed and a

straight line of travel.

5. Driving too fast, being inattentive and turning too

sharplyon slipperysurfacescan resultinrolloversand

accidents almost quicker than any other ground

condition. Snow cover, wet trails, loose graveland

frozen ground can all contribute to this dangerous

condition.In theseconditions maintain sharp focuson

the trail ahead. Don’t make sharp turns and avoid the

needforhard brakingif at all possible.Ifyoudo start to

slideturn the frontwheels inthe direction ofthe skidto

regain control.

6. Avoidpaved surfaces. Land Pride vehicles are

designed exclusively for off-road use only. We

understand that occasionally operatorshave to cross

publicroads or right of waysto gain access to workor

recreationsites,but don’tget inthe wayoffastertraffic

and cross quicklyand safely.

7. Land Pride Vehicles with shielded torque converters

are capable of making intermittent stream crossings

where the depth of water briefly comes into contact

with the bottom of floorboards, butyou mustkeep

these considerations in mind; you must know how

8/05/08

4220ST & 4420ST Light Utility Vehicles 700-504M

21

Table of Contents

Section 4: Operating Instructions

deep the water is and the strengthof the current.

Cross where youhave a gradual incline for entry and

exit and the bottom is fairly clean and free of

obstacles. Maintain a slow steady speed disturbing

the stream bed as little as possible. If you submerge

theengine orthe whole vehicle,do not attempt to start

the vehicle but takeit to your nearest Land Pride

dealer immediately.After intermittent stream or

shallowwater crossings, dry out the brake linings and

drivebelt byslightly accelerating the engine rpm while

riding the brakes momentarily until full drive power

and braking are restored. You may lose forward

momentum and powerif water gets into the sealed

torque converter and drive belt through the

enclosure’s vents. Always remove the CVT drain cap

to drain anywater that may have entered the

enclosure. Replace cap once all water is drained.

8. Backing up in an off-road situation might seem a

simplething todo toa novice,buthavingto backdown

a hill is a very dangerous situation.If you are on level

ground always look behind youand back up slowly. If

you find yourself having to back down a hill,apply the

brakes very lightly. Hard braking can cause total loss

of control anda rollover situation. Try to back straight

down the hill without turning. Turning in this situation

can also cause a rollover.

9. Wheneverpossible, park your vehicle on a level

surface,set the park brake by placing shiftselector in

(P) and remove ignition key. Ifyou do have to park on

a hillside makesure you chock the rear wheels on the

downhill side topreventa rollaway. It’s a good idea to

keep your spare key stashed separately.

10. Never operate a vehicle under the influence of drugs

or alcohol. When you’redriving off-road vehicles you

need to keepyour senses keen and capable of quick

reaction, sharp perception and good balance.

11. Working orrecreation inthe deepwildernessor onthe

prairies can be personally rewarding and very

enjoyable to those who truly love and understand

nature and the outdoors. Good judgement, maturity,

proper preparation and planning can turn these

adventuresinto great experiences you’ll talk about for

a lifetime. Share theseadventures with young people

wheneveryou can and show them how to do it

properly. Don’t let anyone under 16 operate this

vehicle. They just aren’t mature and experienced

enough to takeon the serious responsibility of

operating a vehicle in the off-road environment

without the benefit of an experienced adult with them.

Remember, the only one whocan prevent and avoid

an accident is the operator in control and that’s you!

4220ST & 4420ST Light Utility Vehicles 700-504M

22

8/05/08

Section 5: Options and Accessories

Section 5: Options and Accessories

Table of Contents

Treker Options

Front Bumper

Refer to Figure 5-1:

The front bumper is the most economical bumperoption.

It can be unbolted from the Treker to add the optional

brush guard.

Front Bumper

21145

Front Bumper

Figure 5-1

Heavy Duty Brush Guard

Refer to Figure 5-2:

The Heavy Duty Brush Guard withfront hitch receiver is

a great option for accessor ies and front protection. The

hitch receiver on the Heavy Duty Brush Guard is

removable for adding a winch and roller fairlead

accessory. The front cargo accessory rack (not shown)

can be mounted to the Brush Guard.

Tires

Refer to Figure 5-3:

There are two types of tires availablefor your Land Pride

Treker. See Figure 5-3. The AllTerrain Tire isa good tire

to choose when tractionis your firstprior ity.This tireis a

tough tire for going over rough terrain. It can be

purchased mounted on gray rims or black rims.

The Turf Tire,mounted on gray rims, is a good selection

when one wants to preserve the terrain being traveled

over. Golf courses, parks and other maintained areas

make the Turf Tire an excellent choice.

All Terrain Tire

Figure 5-3

Turf Tire

21143

Heavy Duty

Brush Guard

22484

Heavy Duty Brush Guard

Figure 5-2

8/05/08

Hitch Receiver

4220ST & 4420ST Light Utility Vehicles 700-504M

23

Section 5: Options and Accessories

Table of Contents

Treker Accessories

A variety of accessory equipment has been designed to

complement your needs and makeyour Land Pride

Treker a very functional and useful vehicle. See your

nearest Land Pride Dealer for all available accessories.

Accessories available are:

• 2,000lb. Winch

• RollerFairlead

• RearTire Chains

• FrontTire chains

• GrabLight

• VerticalGun Case

• FifthWheel Trailer

• FrontBumper

• FrontBrush Guard

• FrontRack

• Rearhitch

• BackScreen

• BackScreen Head Rest

• HeadRest

• MudFlaps

• 60”Snow Blade

• CanopyTop - Black

• FrontWindshieldas

• HardCab Enclosure with

Hard Doors

• FrontBoot Guards

• RearBoot Guards

• SkidPlate

• 3rdSeat Belt

• ElectricSpin Spreader

• Back-upLight

• Back-upAlarm

Electric Spin Spreader

Refer to Figure 5-1:

The Land Pride Electr ic Spin Spreader is a highly

versatile full component package designed to plant or

spread seeds. It can then be used to spread pr illed or

granulated fertilizer, lime, gypsum, and other soil

conditioning amendments at distances ranging from 4 ft.

to20 ft.The combination spinspreader/planter por tion of

this system can also be used inthe off-season to spread

sand or salt for winter icing or slick snow conditions.

The combination of maximum versatility and narrow to

widespread pattern makes the ElectricSpin Spreaderan

excellent choice for applications in wild game foodplots,

hunting clubs, hunting resorts, ranches, farms, game

preserves, landscaping, hobby farming, smaller

nurseries, and gardens.

4220ST & 4420ST Light Utility Vehicles 700-504M

24

23921

Figure 5-1

The Land Pride Electric Spin Spreader can be attached

to any vehicle equipped with a 2" receiver hitch and

12 volt accessory receptacle. Description and part

number are listed below. See your nearest Land Pride

dealer for additional information.

ELECTRIC SPIN SPREADER . . . . . . . 701-130A

8/05/08

Section 6: Maintenance

Section 6: Maintenance

Table of Contents

General Maintenance

!

WARNING

Read and observe all safety warnings in this manual and in the

engine service manual.

!

WARNING

Except when checking or changing components, always keep

protective shields on for safety as well as for cleanliness.

!

WARNING

Keep engine clean of oil, grease, trash and debris which can

cause engine overheating, fires and belt wear. Clean only after

engine has completely cooled. Wear gloves to protect hands

from cuts, puncture wounds and burns.

!

WARNING

DO NOT have engine running when servicing or making

adjustments to the vehicle. Shut engine off, place transmission

in park and remove ignition switch key for maximum safety.

Some repairs require theassistance of atrained service

mechanic and should not be attempted by unskilled

personnel. Consult your Land Pride dealer when

assistance is needed.

Securing Vehicle for Maintenance

Beforeservicingthe vehiclethefollowingproceduremust

be met to secure the vehicle:

1. Park vehicle on a level surface. Don’t workunder or

around a vehicle parked on an incline.

2. Set shift selector in Park.

3. Turn ignition switch off and remove switch key.

4. Chock front and back side of the wheels not being

raised off the ground when jacking a vehicleor when

ground surface slopes.

5. Always use jack stands to support the vehicle when

working under the vehicle.

6. Always secure cargo box in the up position when

working under the cargo box.

Torque Values

Wheel Lug Nuts

!

DANGER

Repairs or maintenance specifically requiring engine power

should be performed by trained personnel only. Transmission

gearshould be set in neutral with tiresproperlychockedor with

drive tires properly supported off the floor. Enclosed areas

should be properly ventilated to prevent carbon monoxide

poisoning.

!

DANGER

Exercise extreme caution when working with and around the

belt drive. Make certain the engine cannot be accidentally

started. Shut engine off and remove ignition switch key for

maximum safety. Repairs or maintenance requiring engine

power should be performed by trained personnel only.

Regular maintenance is the best prevention for costly

downtime or expensive, premature repair. The following

pages contain suggested maintenance information and

schedules which the operator should follow on a routine

basis.

Remain alert for unusualnoises; they could besignaling

a problem. Visually inspect vehicle for any abnormal

wear or damage. A good time to detect potential

problems is while performing scheduled maintenance