Page 1

TWISTER basic

70%

70%

30%

100%

High-end cubes at a low price:

TWISTER basic

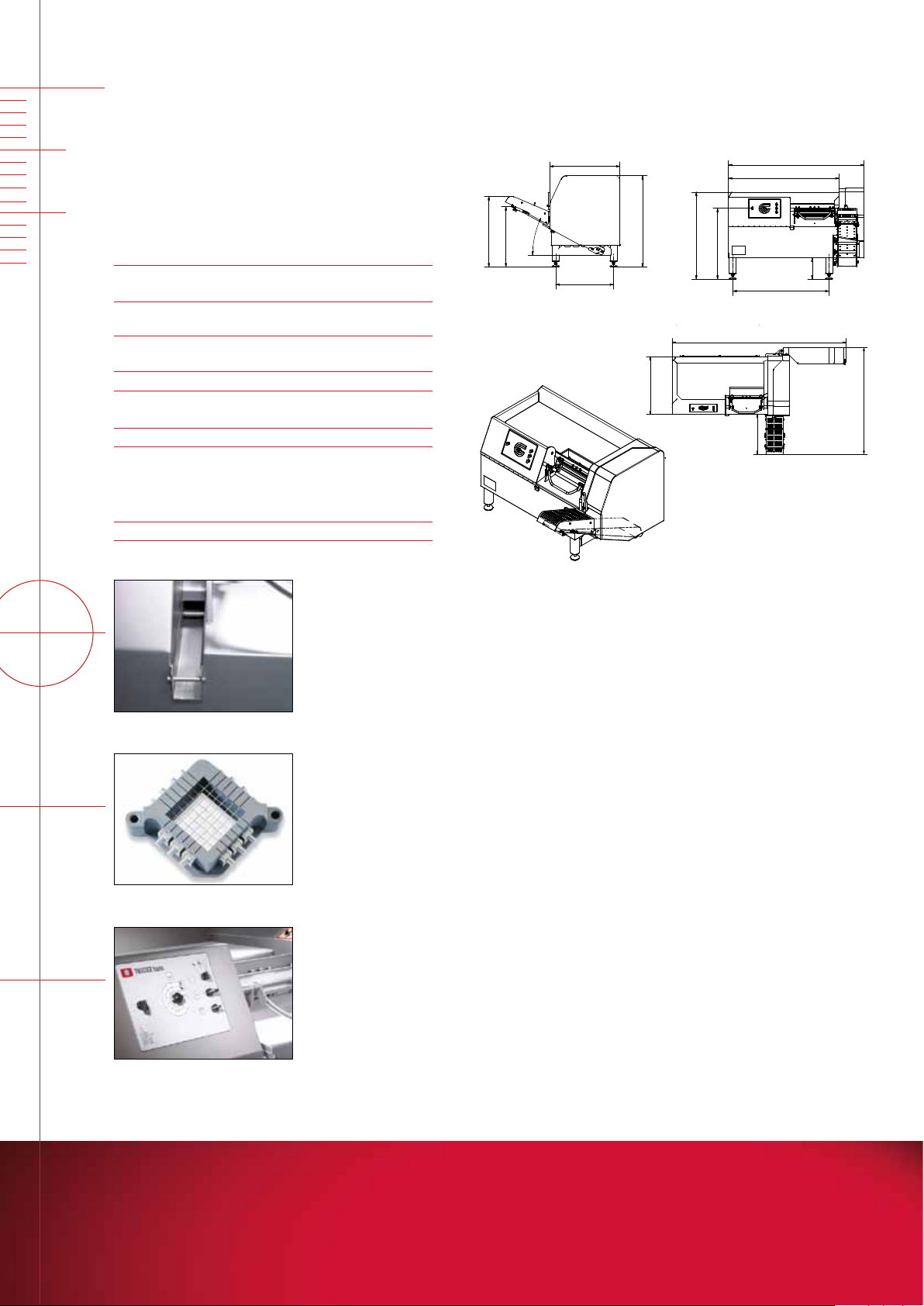

The cube and strip cutting machine TWISTER basic is ideal for

all who are looking for a cost-effective solution for perfect cutting quality in the mid-range performance class.

In one hour the machine achieves an output of up to 2,000 kg

(theoretical maximum value), even during constant operation.

The cutting chamber has a generous size of 550 x 120 x 120

mm (L x W x H), ensuring a high fill volume.

Competitor

The robust technology of the gridset

is the basis for the cutting power of

TWISTER basic.

70%

70%

70%

70%

70%

30%

100%

As a result of the DHS (Dynamic Hy-

draulic System), the cut products stay

fresh longer (the machine generates

less heat, so there is less of a chance

for bacteria to form).

Extremely easy to insert, so that no

time is lost for cleaning and refitting:

“click&go“ gridset.

Goulash cubes – a typical product for

the TWISTER basic.

Cutting meat into strips is also part of

the “line of action“ of the machine.

With an hourly output of up to 2.0 t

(theoretical maximum value), the ma-

chine is ideally suited for manual arti-

san and mid-range applications.

The separating slide operates in a

curving motion. This enables user-

friendly, one-hand operation.

The slice length can be selected with-

in a range of 0.5 mm to 34 mm.

www.treif.com

Page 2

High standards

1

2

3

1902

3

0

0

1350

1

2

2

1

9

9

7

1552

1

2

3

4

5

6

1902

3

0

0

1350

1

2

2

1

9

9

7

1552

1

2

3

1902

1

2

3

4

5

Material

Rohteil

Id.-Nr.

Id.-Nr.

Ers. durch:

/ /

MASSBLATT -4240

Allgemeintoleranzen

Nicht tolerierte Gewinde

Oberflächenzeichen

Werkstückkanten

Längenmaßtoleranzen

DIN ISO 2768-m und -k

DIN ISO 262 und

DIN ISO 965 -1 und -2

DIN EN ISO 1302

DIN ISO 13715

DIN ISO 2768

Ers. für:

Ursprung:

-0412

2827

1

7

3

1

1902

3

0

0

1350

811

1

2

2

1

25°

982

9

9

7

1552

6

4

4

1

2

8

0

9

3

3

TWISTER basic is a solid machine that impresses

with its easy equipment and nevertheless convinces

with high standards.

Technical data:

Max. output t/h

(Theoretical maximum value)

Max. cut-off length (mm/inch) 0.5–34;

Max. cut-off blade speed/min.

(fixed blade speed)

Housing dimensions (mm/inch)

Length / Width / Height

(mm/inch)

Connecting load (kW) 4.0

Gridsets (mm/inch) 4/5/6/8/10/12/13/15/17/

Weight (kg/lb) approx. 670; 1,477

Product specific accessories on request

2.0; 4,410 lbs

1

/5“–1 2/5“

180

1,902 / 1,731 / 1,280;

4

/5“ / 68“ / 50 2/5“

74

20/24/30/40/60;

1

/5“; 3/10“; 2/5“; 1/2“; 3/5“;

7

/10“; 5/4“; 1“; 1 1/5“; 1 3/5“

Cleaning channel for a

better flow of liquids,

e.g. meat juice, rinsing

water.

1

9

8

9

4

25°

8

All measurements in mm.

982

811

0

8

2

1

1

2

2

7

1

9

9

3

3

9

2827

4

4

6

1552

1350

0

0

3

Your benefits at a glance:

• Basic model from the TWISTER family

• Flexibility and strong performance thanks to choice bet-

ween continuous and intermittent cutting

1

3

7

1

• Optimum product compression as a result of the automatic pre-compression system (AVS)

For dicing cheese a spe-

cial cheese grid is used.

• Ergonomic, one-hand operating system for the closing of

the product loading chamber; chamber size: 550 x 120 x

7

/10“ x 4 7/10“ x 4 7/10“ (length x width x height)

120 mm / 21

• Reliable protection against the hydraulic oil of the feed

cylinder entering the cutting chamber; patented hygiene

cylinder (optional) makes product contamination with

hydraulic oil (only foodstuff hydraulic oil is employed at

Simple operation.

HEADQUARTERS:

TREIF Maschinenbau GmbH

Toni-Reifenhäuser-Str. 1

D-57641 Oberlahr

Phone +49 2685 944 0

Fax +49 2685 1025

E-Mail: info@treif.com

Further LOCATIONS:

TREIF U.K. Ltd.

Genesis House, Poole Hall Road

Poole Hall Industrial Estate

Ellesmere Port, GB-Cheshire CH66 1ST

Phone: +44 (0) 151 3506100

Fax: +44 (0) 151 3506101

E-Mail: treifuk@treif.com

TREIF USA Inc.

50 Waterview Drive, Suite 130

Shelton, CT 06484

Phone: +1 203 929 9930

Fax: +1 203 929 9949

E-Mail: treifusa@treif.com

TREIF) technically impossible

• Particularly cost-effective solution for perfect cutting

quality in the mid-range performance class

Belgium

China

France Italy Russia

www.treif.com

Subject to modifications for technical progress. 0.25 08/2015 DieDruckerei

Loading...

Loading...