Page 1

TWISTER

70%

70%

30%

100%

Dicing, cutting strips, grating – with TWISTER

In one hour the dicer achieves a max. output of up to 3,500

kg (theoretical maximum value), even during constant operation.

It can handle highest stresses, even with respect to the

loading. TWISTER can be optionally fitted with a convenient

and reliable lift for E-boxes. For the operator that means: At last,

no more straining bending and heavy, strenuous lifting.

Competitor

The AVS (automatic pre-compression

system) facilitates an optimal dimensi-

Goulash cubes are of course part of the

cutting repertoire of the TWISTER.

onal accuracy of the cubes and strips

right from the beginning.

70%

70%

70%

70%

70%

30%

100%

As a result of the DHS (Dynamic

Hydraulic System), the cut products

stay fresh longer (the machine gene-

rates less heat, so there is less of a

chance for bacteria to form).

The separating slide operates in a

curving motion. This enables user-

friendly, one-hand operation.

Cooked products can also be cut with

ease.

TWISTER is very versatile. The diffe-

rent cutting parameters can be saved

(up to 50 cutting programs).

Excellent cutting results thanks to the

patented gentle cut gridset (optional).

This ensures the best possible cutting

geometry for excellent cutting results.

The dicer can process up to 3.5 t in

one hour (theoretical maximum va-

lue). The blade revolution speed can

be individually set.

www.treif.com

Page 2

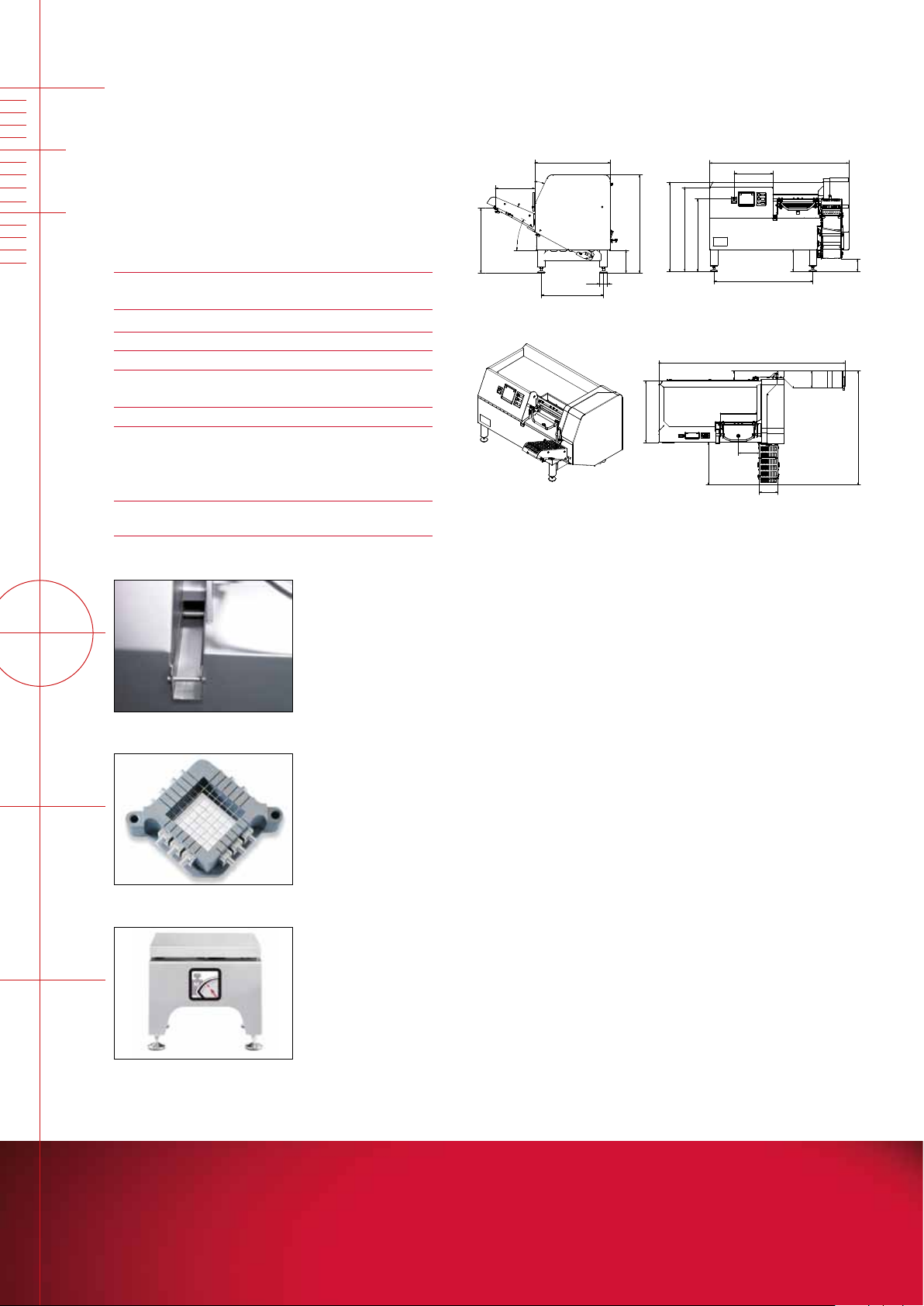

Gentle cut

1

2

3

4

3

0

0

1350

9

9

4

1902

530

1

7

2

1

2

3

4

5

1

2

3

4

5

6

7

3

0

0

1350

9

9

4

1

1

5

0

1

2

2

1

1902

530

1

7

2

1

2

3

4

5

6

7

8

3

0

0

1350

9

9

4

1

1

5

0

1

2

2

1

811

1

2

8

2

1902

530

513

2

5

°

985

3

0

0

1

7

2

25°

100

1

2

3

4

5

6

7

Material

Rohteil

Id.-Nr.

Id.-Nr.

Ers. durch:

/ /

MASSBLATT -4120

Allgemeintoleranzen

Nicht tolerierte Gewinde

Oberflächenzeichen

Werkstückkanten

Längenmaßtoleranzen

DIN ISO 2768-m und -k

DIN ISO 262 und

DIN ISO 965 -1 und -2

DIN EN ISO 1302

DIN ISO 13715

DIN ISO 2768

Ers. für:

Ursprung:

-0412

282

1

7

3

1

2828

6

4

4

9

3

3

1

3

5

2

6

0

3

0

0

1350

9

9

4

1

1

5

0

1

2

2

1

811

1

2

8

2

1902

530

513

2

5

°

985

3

0

0

1

7

2

316

25°

100

With the help of the gentle cut gridset (optional),

delicate products such as cooked meat, poultry or

boiled sausage are cut gently, thus achieving excellent cutting results.

Technical data:

Max. output t/h (Theoretical

maximum value)

Max. cut-off length (mm/inch) 1–50;

Max. cut-off blade speed/min. 300/ 400

Housing dimensions (mm/inch)

Length / Width / Height with lift

& outlet conveyor (mm/inch)

Connecting load (kW) 4.5 (TWISTER G: 6.0)

Gridsets (mm/inch)

Weight with lift & outlet conveyor

(kg/lb)

Product specific accessoires on request

3.5; 7,716 lbs

1

“–2“

/

25

(TWISTER G)

1,902 / 1,800 / 1,282;

4

74

/5“ / 71“ / 50 1/2“

4/5/6/8/10/12/15/17/20/

1

“

/

24/30/40/60/120

3

2

1

“

“

;

“

; 1“; 1

“

/

/

;

;

5

2

1

“

/

; 1

5

/

10

4

/

5

3

/

3

7

“;

5

“; 4 7/10“

/

5

;

5

“;

/

10

approx. 670; 1,477

Cleaning channel for a

better flow of liquids,

e.g. meat juice, rinsing

water.

985

2

5

°

513

2

8

1

2

2

0

1

2

5

1

1

1

4

25°

8

4

8

0

0

3

100

811

3

3

9

9

9

4

4

6

1902

530

0

0

3

1350

2828

5

3

1

316

282

2

7

1

0

6

2

1

3

7

1

All measurements in mm.

Your benefits at a glance:

• Semi-automatic loading

• Flexibility and top performance thanks to continuous and

intermittent cutting options and the ability to individually

set the blade speed

• Optimum product compression as a result of the automa-

For dicing cheese a spe-

cial cheese grid is used.

tic pre-compression system (AVS)

• Ergonomic, one-hand operating system for closing the

loading chamber; chamber size: 550 x 120 x 120 mm /

21

7

/

10“

x 4

7

/

10

“ x 4

7

/

“ (length x width x height)

10

• Patented gentle cut gridset for delicate products (optional)

TWISTER can also be fit-

ted with a scale.

• Reliable protection against the hydraulic oil of the feed

cylinder entering the cutting chamber; hygiene cylinder

(optional) makes product contamination with hydraulic

TREIF USA Inc.

50 Waterview Drive, Suite 130

Shelton, CT 06484

Phone: +1 203 929 9930

Fax: +1 203 929 9949

E-Mail: treifusa@treif.com

HEADQUARTERS:

TREIF Maschinenbau GmbH

Toni-Reifenhäuser-Str. 1

D-57641 Oberlahr

Phone +49 2685 944 0

Fax +49 2685 1025

E-Mail: info@treif.com

Further LOCATIONS:

TREIF U.K. Ltd.

Genesis House, Poole Hall Road

Poole Hall Industrial Estate

Ellesmere Port, GB-Cheshire CH66 1ST

Phone: +44 (0) 151 3506100

Fax: +44 (0) 151 3506101

E-Mail: treifuk@treif.com

oil (only foodstuff hydraulic oil is employed at TREIF)

technically impossible

Belgium

China

France Italy Russia

www.treif.com

Subject to modifications for technical progress. 0.25 09/2015 DieDruckerei

Loading...

Loading...