Page 1

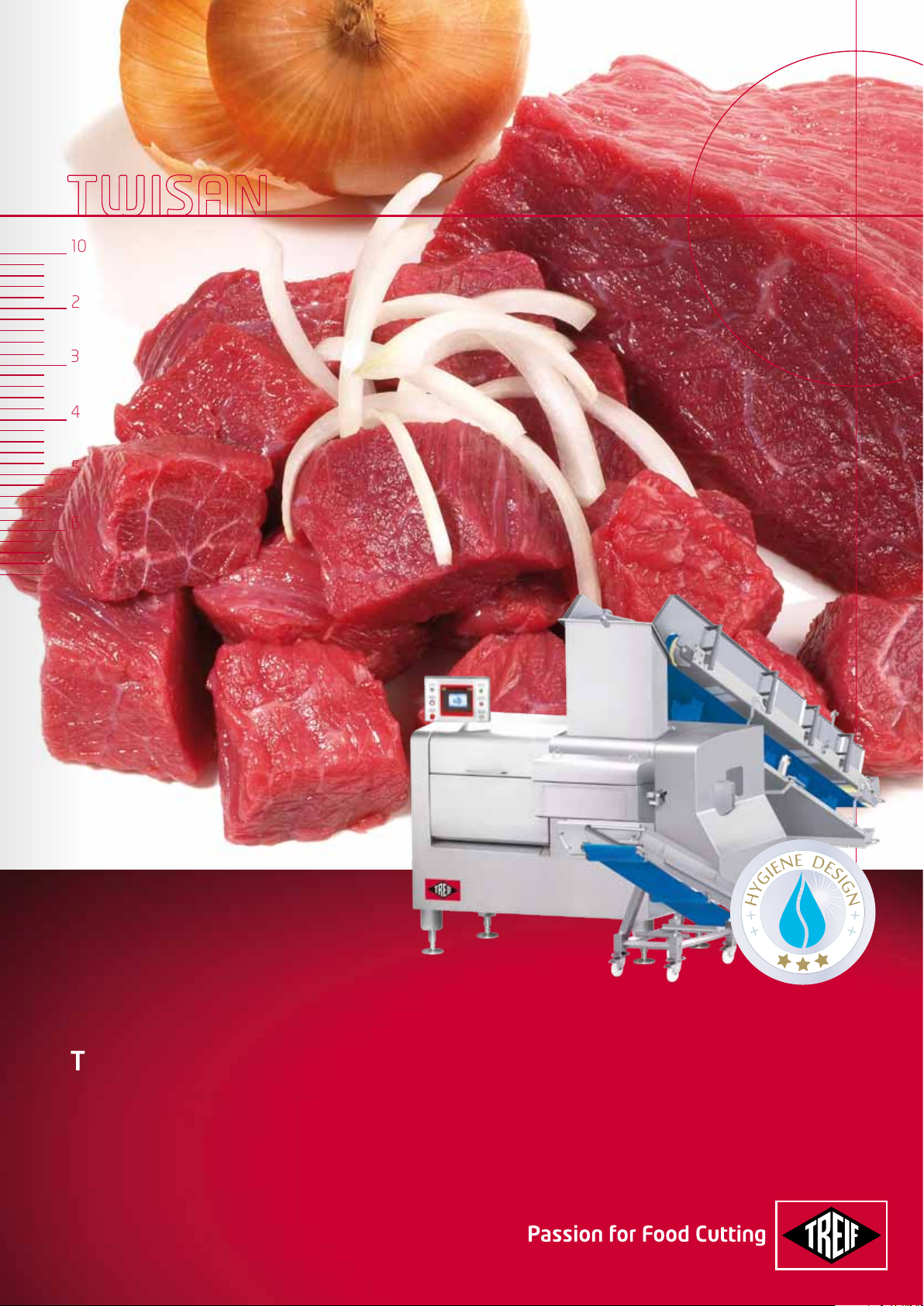

TWISAN

100 mm

200 mm

300 mm

400 mm

500 mm

600 mm

Whether frozen or fresh meat — dicing has never been that hygienic before:

TWISAN

Page 2

Whether frozen or fresh meat — dicing

has never been that hygienic before

The industrial dicer TWISAN, with the appropriate equipment, consistently delivers optimal dicing results, both with frozen meat

blocks and bulk material and also with fresh meat. The machine guarantees your process reliability, regardless whether fresh meat

or extremely temperated products are handled. TWISAN also sets new standards in terms of hygiene. Its hygienic design is well

thought out to the last detail.

Frosty precision work — for cubes, strips and

more

Smart „vartronic“ technology

The smart vartronic technology is important, especially when frozen meat

is diced. The machine is able to adapt

its cutting tools if products are too cold

or too hard – thanks to separate drive

mechanisms for the lower grid, upper

grid and blade.

Frosty precision work

As frozen meat dicer TWISAN is specialized in dicing blocks of frozen meat and

frozen bulk material.

Breaks down any block

The machine can cut blocks of frozen

meat into cubes or strips of up to 75 mm

/ 3¨ in length.

Page 3

PremiumHygiene-Design:

thought out in detail

The hygiene package

Benefit from the unique advantages

of the new Premium-Hygiene-Design.

Here, TWISAN offers a complete package with hygiene features that cannot

be found on any other system.

Collection devices

TWISAN is equipped with multiple collection devices (“Hygiene Plus“ Collection Systems as

option). They allow, for example, drainage of meat juice away from the meat or

feed it back to the final product. This also

shows the sophisticated hygienic design

again.

Precision on 6 sides: Say “yes” to

perfectly formed cubes

PQS

The PQS (Product Quality Separation)

prevents possible product residues

from entering the OK material. The

gridset is shielded by the PQS (also

see photo above) so that residual

material drops behind the wall where it

is collected.

Clear cutting results

The Automatic Prepressing System

(AVS) guarantees clear cutting results.

The sensor (optional) can be used in

addition for even more precise cubes

and strips, especially for premium

demands.

Cubes, strips, discs

With TWISAN products can be cut in

cubes, strips, rasped or, as shown here,

cut in 3-mm (1/10¨) discs.

Various applications

Goulash, strips for gyros, pig’s head and

pork tongue are just a few of the products covered by the standard program of

TWISAN with fresh meat equipment.

Page 4

Where hygiene and ergonomics come together:

TWISAN

Changing the gridset on an industrial dicer can be this

effortless. Ergonomics are the top priority for this new assembly trolley. Changing the gridset is easy and fast and

requires very little effort. Another benefit: it safely stores all

removable parts for cleaning (except for the cut-off blade).

Keep track of things: the special wall bracket is designed for

clean and safe storage of the gridsets which are currently

not in use.

Technical data:

Max. output in t/h

(theoretical maximum value)

Max. cut-off length

4.5;

9,920 lbs

1

/25¨-3¨

1-75;

(mm/inch)

Max. blade speed/min. 400

Cutting chamber size

150 x 150; 5

WxH (mm/inch)

Max. infeed length (mm/inch) 620; 24

Housing dimensions

(mm/inch)

Length with conveyor belt/

with lift-tilt-device (mm/inch)

2,345/ max. 3,600

3

/10¨/ max. 142¨

92

2

/5¨

9

/10¨ x 5 9/10¨

The hygiene cylinder (supplied as standard) makes product

contamination with hydraulic oil a technical impossibility. No oil

can enter the cutting chamber.

Double seals on the gridset shafts and the blade shaft

seal the machine interior even better against the ingress of

foreign bodies and moisture.

Width with conveyor belt/ with

lift-tilt-device (mm/inch)

Height with conveyor belt/

with lift-tilt-device (mm/inch)

Connected load (kW) 15.0

Gridsets (mm/inch) 8/10/12/15/17/19/21/25/

Weight (kg/lb) approx. 1,300; 2,866

Product specific accessories on request

4,660/ max. 3,000

183 1/2¨/ max. 118 1/10¨

2,415/ max. 3,400

95¨/ max. 134¨

30/37,5

3

/10¨; 2/5¨; 1/2¨; 3/5¨; 7/10¨; 3/4¨; 4/5¨;

1¨; 1 1/5¨; 1 1/2¨;

more options on

request

HEADQUARTERS:

TREIF Maschinenbau GmbH

Toni-Reifenhäuser-Str. 1

D-57641 Oberlahr

Phone +49 2685 944 0

Fax +49 2685 1025

E-Mail: info@treif.com

Further LOCATIONS:

TREIF U.K. Ltd.

Genesis House, Poole Hall Road

Poole Hall Industrial Estate

Ellesmere Port, GB-Cheshire CH66 1ST

Phone: +44 (0) 151 3506100

Fax: +44 (0) 151 3506101

E-Mail: treifuk@treif.com

TREIF USA Inc.

50 Waterview Drive, Suite 130

Shelton, CT 06484

Phone: +1 203 929 9930

Fax: +1 203 929 9949

E-Mail: treifusa@treif.com

Belgium

China

Subject to modifications for technical progress. 0.25 05/2016 CM Digitaldruck Photos: www.fotolia.com

France Italy Russia

www.treif.com

Loading...

Loading...