Page 1

JAGUAR

JAGUAR: For a professional entrance

into new markets

The JAGUAR slicing and portion cutting machine is characterised by a simple design, high functionality and operational

safety.

The high capacity and wide variety of cutting applications

make it ideal for use in the butcher‘s trade, canteen kitchens,

industrial applications, supermarkets, and mega markets.

Competitor

A look in the blade box shows a thin

blade for a precise cut.

Uniform cross-section thanks to the

DVS (dynamic feeding system).

Most user-friendly operation.

Cutting pork rib chops is “child‘s play“

for the powerful JAGUAR.

Rump steak – one of the many pro-

ducts that can be sliced with the flexi-

ble portion cutting machine.

Pork belly is part of the machine‘s

“standard repertoire“.

www.treif.com

The intelligent gripper recognises

which areas of the food product are

harder than others (i.e. those contai-

ning bones). In this area the gripper

just rests on the product. The other

hooks keep a tight, secure grip on the

meat.

JAGUAR can produce up to 180 cuts/

min. and is available in 700 and 1,100

models. These numbers stand for the

max. insertion length in mm.

Page 2

JAGUAR and its capabilities

It has the capability to slice bone-in products as well as

boneless products. The chilled or frozen products are cut

at temperatures as cold as -4 °C/ 24.8 °F.

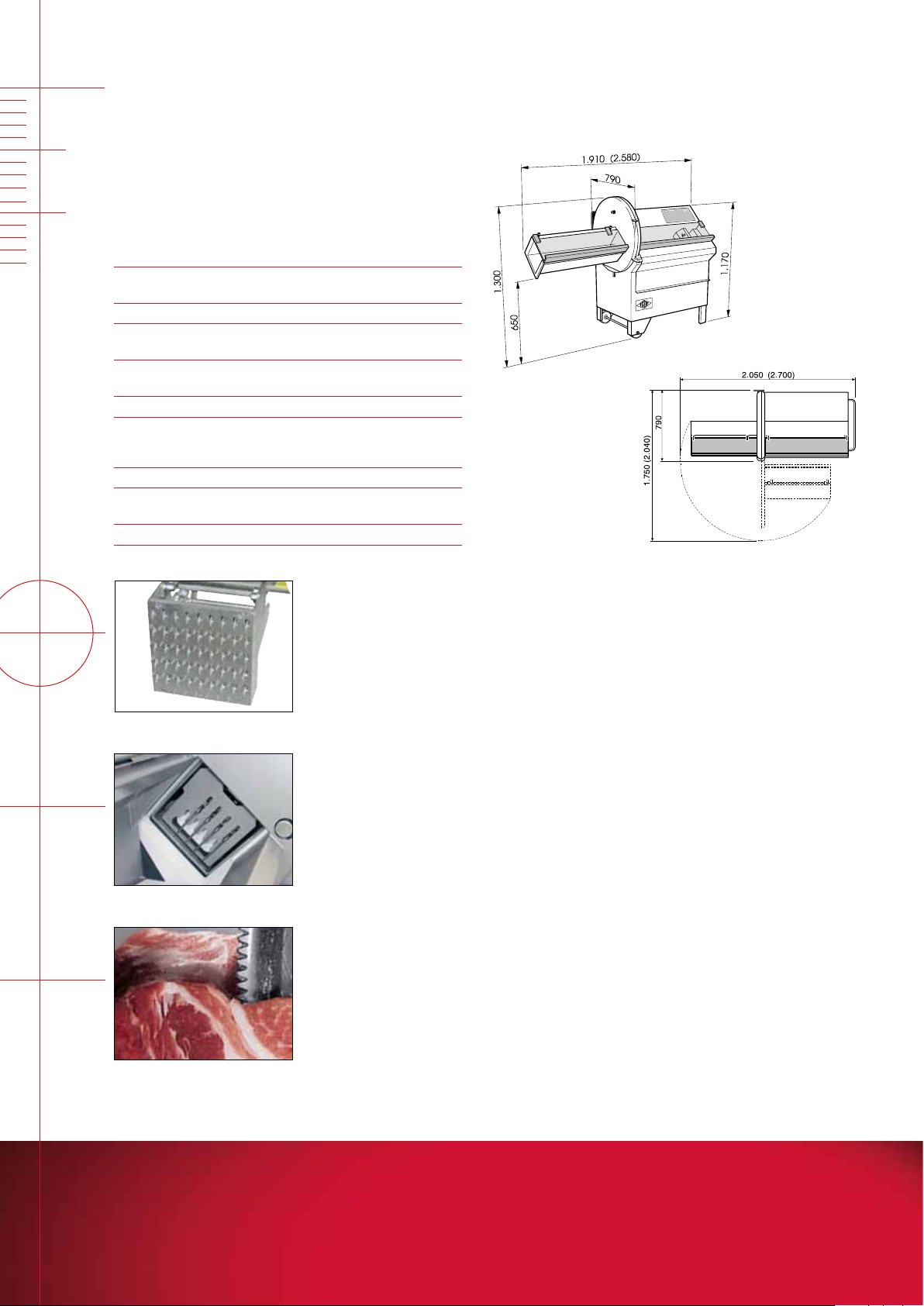

Technical data: JAGUAR 700 JAGUAR 1100

Max. cut-off length

(mm/inch)

Max. cuts per minute 180 180

Cross-section of product

w x h (mm/inch)

Max. infeed length

(mm/inch)

Housing dimensions (mm/inch)

Length/ Width/ Height

(mm/inch)

Connecting load (kW) 2.6 2.6

Products Up to -4°C/

Weight (kg/lb) 204; 450 221; 487

Product specific accessoires on request on request

0.5–30;

1

1

“

“

/

/

–1

50

5

200 x 190;

1

“

/

8“ x 7

2

3

700; 27

1,910 / 790 /

1,300; 75

31

/

1

/

1

1

“

/

10

/51

24.8 °F

“

5

“

5

/

“

/

2

0.5–30;

1

1

“

“

/

/

–1

50

5

200 x 190;

1

“

/

8“ x 7

2

1,100; 43

2,580 / 790 /

1,300; 101

31

3

1

1

“

/

/

10

/51

Up to -4°C/

24.8 °F

3

“

/

10

“

/

5

/

“

2

All measurements in mm.

The multi-toothed grip-

per enables the best

fixation of the boneless

products (optional).

The product feed holder

automatically expels

the residual piece after

slicing.

A sickle blade for various

applications is available

as an option (smooth or

serrated blade).

Your benefits at a glance:

• Entrance into new markets with TREIF‘s smallest, yet

extremely powerful cutting machine

• High-capacity portioning of boneless and bone-in products: up to 180 cuts/minute

• High-performance combined with precise portioning of

products such as cutlets, steaks, schnitzel and many other

products that have been chilled or frozen down to -4 °C/

24.8 °F (even deep-frozen products depending on the

product and applications)

• Fulfilment of the highest hygiene requirements as a result

of labyrinth guidance

• Precision sickle blade

• Intelligent product feed holder

HEADQUARTERS:

TREIF Maschinenbau GmbH

Südstraße 4

D-57641 Oberlahr

Tel. +49 2685 944 0

Fax +49 2685 1025

E-Mail: info@treif.com

For more information about our worldwide Sales and Service offices please look at www.treif.com

Subject to modifications for technical progress. 0.25 09/2013 DieDruckerei

www.treif.com

Loading...

Loading...