Page 1

CASAN 200

100 mm

200 mm

300 mm

400 mm

500 mm

600 mm

Your compact professional all-rounder for industrial dicing:

CASAN 200

Page 2

100 mm

200 mm

300 mm

400 mm

500 mm

600 mm

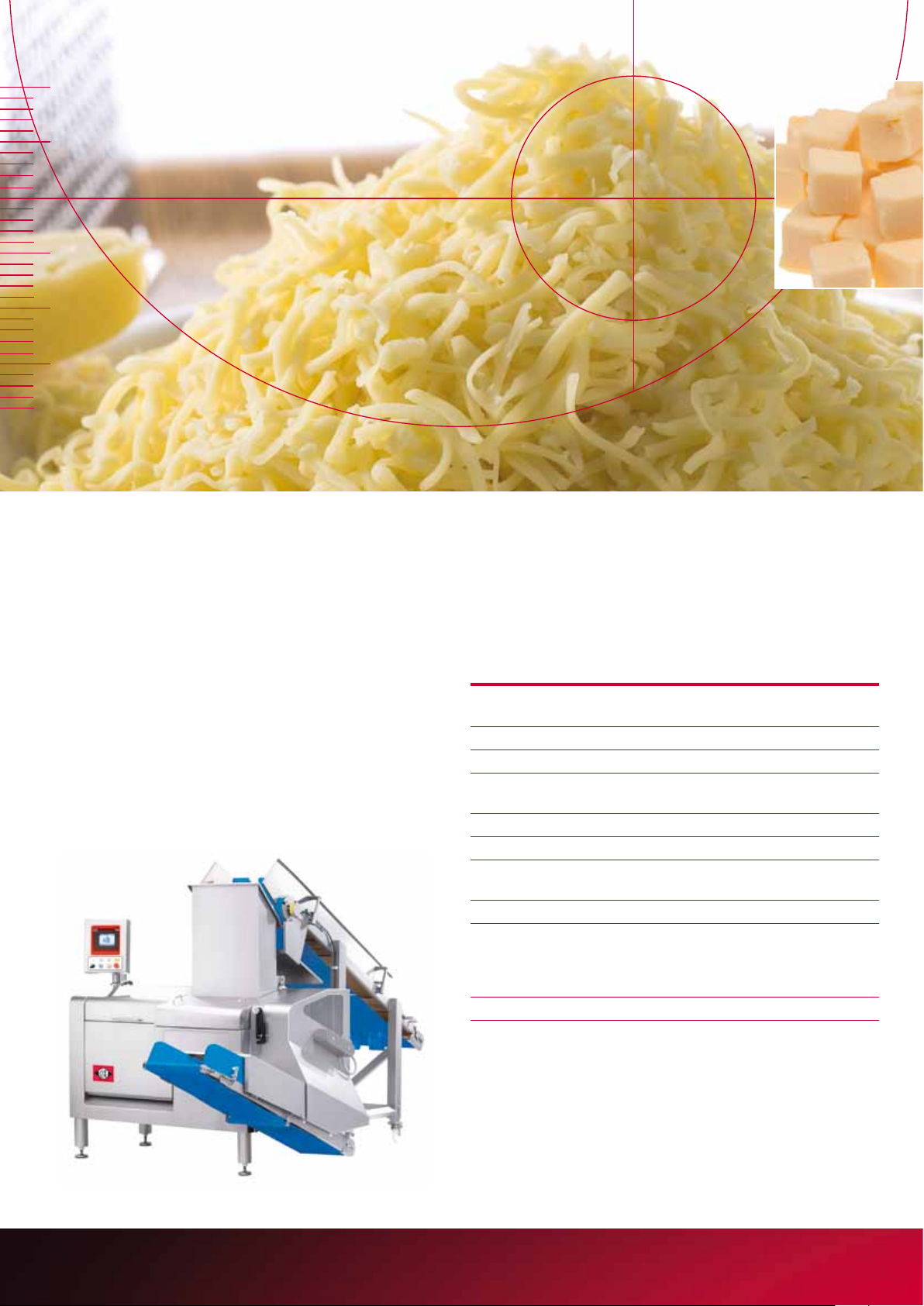

Your compact professional all-rounder for industrial dicing:

CASAN 200

Cutting results that set standards. A convincingly high output.

As a specialist for industrial cheese dicing, the CASAN 200 is

extremely tough and thus offers security in production.

The machine is loaded fully automatically. Two Euroblocks

can be fed in lying on top of one another. The opening of the

cutting chamber is generously dimensioned with 240 mm /

1

9

/2

“. There are numerous possibilities for the feeding and

discharge of your products.

Technical data:

Max. output in t/h

(Theoretical maximum value)

Max. cut-off length (mm/inch) 1–50;

Max. blade speed/min. 500

Cutting chamber size W x H

(mm/inch)

Max. infeed length (mm/inch) 550; 21

Housing dimensions (mm/inch)

Length / Width open blade box

door / Height (mm/inch)

Connecting load (kW) 9.0

Gridsets (mm/inch) 5/6/8/10/12/15/17/20/24/

Weight (kg/lb) approx. 1,500; 3,307

Product specific accessories /

Scale for precisely portioned

dicing

3.0;

6,614 lbs

1

/25"–2"

200 x 120; 7

7

/10"

3,894 / 2,850 / 2,183;

3

/10" / 112 1/5" / 86"

153

30/40/60

3

/10"; 2/5"; 1/2"; 3/5"; 7/10"; 1"; 1 1/5";

3

1 1/4“; 1

on request

/

5

9

/10" x 4 7/10"

"

Page 3

Precision, high output, top hygiene in a minimum of space

Load two Euroblocks on top of

one another at the same time.

The easy way to produce mixed

cheese.

The cheese is fed automatically

with just the hydraulic pressure

necessary for a good cutting result with the set parameters. That

is gentle on the product and energy as well as hydraulic oil can be

saved compared with conventional systems.

Sensors control the frequency of

the blade in order to achieve exactly the desired dice or strip size.

The result is a convincingly clear

cutting pattern. The sensor-based

cutting technology is patented by

TREIF.

Quick but so precise – the CASAN

200 guarantees exact cuts even

at high cutting speeds, as here during cutting sticks.

Ideal for pizza production and the

convenience sector: The CASAN

200 with its high-performance

grating mode. This is where it

shows its power.

High output starts with the detail:

After the transport into the hopper,

the blocks are precut to the size of

the cutting chamber by a cut-off

blade. The left-over material is returned to the cutting chamber by

the patented residue channel (at

the lower end of the hopper, see

arrow).

Thanks to the open design, everything is easily accessible, even the

hydraulic feed cylinder (see arrow). The feed cylinder with which the

CASAN 200 is equipped as standard is also called the hygiene cylinder

because it makes product contamination with hydraulic oil (only foodstuff hydraulic oil is employed at TREIF) technically impossible. No oil

can get into the cutting chamber.

Page 4

Intelligent hydraulics — smart sensors

2161

540

1330

1148

1276

Sensors control the frequency of the blade to achieve exactly the set product length. The formation of cheese scraps

is thus reduced to a minimum. The sensors are unbeatable in combination with the automatic feed pressure control

system that ensures the optimum hydraulic pressure during

advancing of the cheese. And a positive side-effect: The

energy savings.

Whether for pizza, salads or convenience foods – there are so many

meals that call for grated cheese. So it‘s good that the CASAN 200 has

a high-performance grating mode.

2183

2008

1180

150

899

421

2161

540

109

777

1148

1276

mechanical latching

Verriegelung

200

638

°

5

2

907

1791

Rasps, cubes, sticks, strips, slices – and all that with a convincing high

output and performance.

The CASAN 200 is fast and precise, even for very small cubes or slices.

Your benefits at a glance:

• High production reliability for orientation to industrial de-

mands: High output / High-performance grating mode / Filling level monitoring at the hopper / Scraper on the discharge belt / Automatic lateral compression device

• Generously dimensioned cutting chamber; processing of

two Euroblocks lying on top of one another / Ideal for the

production of mixed cheese

• Compact design / very space-saving

• Operation possible from both sides of the machine thanks

to the rotatable display and hopper changeover

• Automatic discharge of product left-overs via residue

channel (patented) with left-over material return to the

cutting chamber

1330

All measurements in mm.

• Automatic feed pressure control: Considerable energy

savings compared with conventional systems and more

gentle on the product

• Reliable protection against the hydraulic oil of the feed

cylinder entering the cutting chamber; hygiene cylinder

(as standard) makes product contamination with hydraulic oil (only foodstuff hydraulic oil is employed at TREIF)

technically impossible

• Top cutting pattern thanks to sensor-based cutting tech-

nology (TREIF patent)

• Data transfer via USB stick: e.g. backup and re-use of the

data (such as cutting statistics) for diagnosis by after-sales

service; all parameters in Excel-readable format

Subject to modifications for technical progress. 0.25 07/2014 DieDruckerei

HEADQUARTERS:

TREIF Maschinenbau GmbH

Südstraße 4

D-57641 Oberlahr

Tel. +49 2685 944 0

Fax +49 2685 1025

E-Mail: info@treif.com

Further LOCATIONS:

Belgium

China

France Italy Russia United Kingdom USA

www.treif.com

Loading...

Loading...