Page 1

ARGON

70%

70%

30%

100%

ARGON: The highest-performance dicer

of its class

With a cost-effective hourly output of up to 2.0 t (theoretical

maximum value), ARGON is the highest-performance machine

of its class.

The speed can be individually set by the operator (between 50

and 300 revolutions per minute), so that the cutting output can

be precisely aligned with the respective requirements.

Competitor

The AVS (automatic pre-compression

system) facilitates an optimum di-

mensional accuracy of the cubes and

stripes right from the beginning.

70%

70%

70%

70%

70%

30%

100%

As a result of the DHS (Dynamic Hy-

draulic System), the cut products stay

fresh longer (the machine generates

less heat, so there is less of a chance

for bacteria to form).

The drive is synched automatically

after the machine is turned on.

Poultry stripes

Ham cubes

Beef cubes

The separating slide operates in a

curving motion. This enables user-

friendly, one-hand operation.

Speciality meat salad

www.treif.com

Page 2

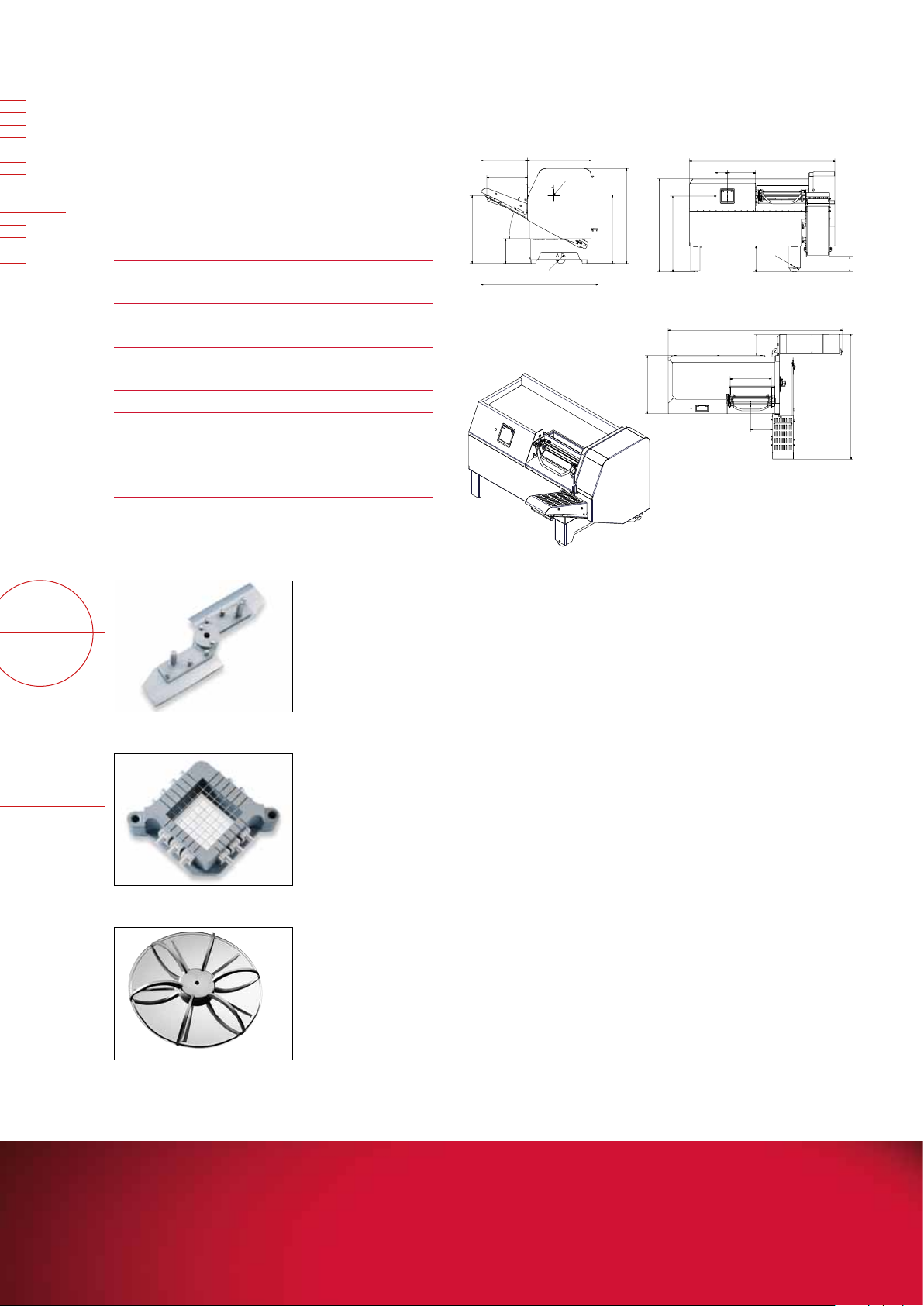

More cutting flexibility

1

2

3

4

337

3

1

0

n

12

5

1

8

6

145

9

0

8

1

1

1

3

1740

1

2

3

4

5

6

7

8

337

3

1

0

n

12

5

1

8

6

145

9

0

8

1

1

1

3

1740

2

8

6

2

6

0

2334

1

2

3

4

1

2

3

4

5

6

7

8

Freimaßtoleranzen

bis 6 ± 0.1

bis 30 ± 0.2

bis 100 ± 0.3

bis 300 ± 0.5

bis 1000 ± 0.8

bis 2000 ± 1.2

Nicht tolerierte Gewinde

nach Toleranzklasse

mittel DIN 13 Bl. 32

Artikelbezeichnung

Material

Rohteil

Abstechlänge

Id.-Nr.

Id.-Nr.

zul. Rauhtiefe

nach DIN ISO 1302

Reihe 2

Typ

Stück

Bearb.

Gepr.

Für diese Zeichnung be-

halten wir uns alle

Rechte vor. Sie darf

ohne unsere Genehmigung

Paßmaße Abmaße

Id.-Nr.

Nr.

Änderung

Änd.-Nr.

Datum

Name

119341

22.02.2005

K-H Müller

410

1

*

MASSBLATT

ARGON

-4100

-

337

3

1

0

n

12

5

8

6

2

1

2

0

0

n

1

2

5

3

1

0

1479,5

513

587 807

Kammer-

mitte

25

°

1

8

6

332

145

9

0

8

1

1

1

3

1740

7

7

4

2

8

6

2

6

0

2334

290

1

6

6

9

,5

550

8

5

6

When equipped with the optional scale, ARGON

stops as soon as the specified weight has been

reached. Deviation from target weight is a maximum

of +/- 0.3 %.

Technical data:

Max. output t/h

2.0; 4,410 lbs

(theoretical maximum value)

Max. cut-off length (mm/inch) 1–50;

1

/25“–2“

Housing dimensions (mm/inch)

Length/Width/Height (mm/inch)

1,740/1,479.5/1,200;

681/2“ / 583/10“ / 471/5“

Connecting load (kW) 2.0

Gridsets (mm/inch)

4/5/6/8/10/12/14/

16/20/24/32/48/96;

1

/5“;3/10“;2/5“;1/2“;3/5“;

4

/5“;1“;13/10“;2“; 34/5“

Weight (kg/lb) approx. 415; 915

Product specific accessories on request

The output capacity can

be increased with the

double blade.

6

5

8

587 807

513

332

°

25

0

1

3

1479,5

5

2

1

n

Kammermitte

0

0

2

1

3

1

2

6

8

1

1

8

0

9

4

7

7

1740

337

145

n

12

0

5

1

3

2334

6

8

2

550

290

0

6

2

All measurements in mm.

Your benefits at a glance:

• High cutting output due to the generous cutting chamber

size of 550 x 96 x 96 mm / 21

7

/10“ x 3 4/5“ x 3 4/5“ (length

x width x height)

6

8

1

,5

9

6

6

1

HEADQUARTERS:

TREIF Maschinenbau GmbH

Südstraße 4

D-57641 Oberlahr

Phone +49 2685 944 0

Fax +49 2685 1025

E-Mail: info@treif.com

Further LOCATIONS:

TREIF U.K. Ltd.

Genesis House, Poole Hall Road

Poole Hall Industrial Estate

Ellesmere Port, GB-Cheshire CH66 1ST

Phone: +44 (0) 151 3506100

Fax: +44 (0) 151 3506101

E-Mail: treifuk@treif.com

For dicing cheese a spe-

cial cheese grid is used.

Accessories such as

for slicing potatoes in

thin stripes or for gra-

ting cheese boost your

flexibility.

TREIF USA Inc.

50 Waterview Drive, Suite 130

Shelton, CT 06484

Phone: +1 203 929 9930

Fax: +1 203 929 9949

E-Mail: treifusa@treif.com

• Flexibility and top performance thanks to continuous and

intermittent cutting options and the ability to individually

set the blade speed

• Optimum product compression as a result of the automatic

pre-compression system (AVS)

• Ergonomic, one-hand operating system for closing the

product loading chamber

• Up to 50 cutting programs

• The DHS system (Dynamic Hydraulic System) reduces the

machine‘s heat load, which saves energy and keeps the

product fresh longer, and is proven to reduce the wear

and tear on the machine as well.

Belgium

China

France Italy Russia

www.treif.com

Subject to modifications for technical progress. 0.25 09/2014 DieDruckerei

Loading...

Loading...