energyEGG Assembly Instructions v6.0

Version : v6.0

th

Date : 4

May 2012

TreeGreen Limited

Digital Enterprise Centre,

CBLZ Building,

190 Cathedral St

Glasgow,

G4 OND

Stuart Henderson

07941 222 437

stuart@treegreen.net

Equipment Required

Phillips head screwdriver

Components

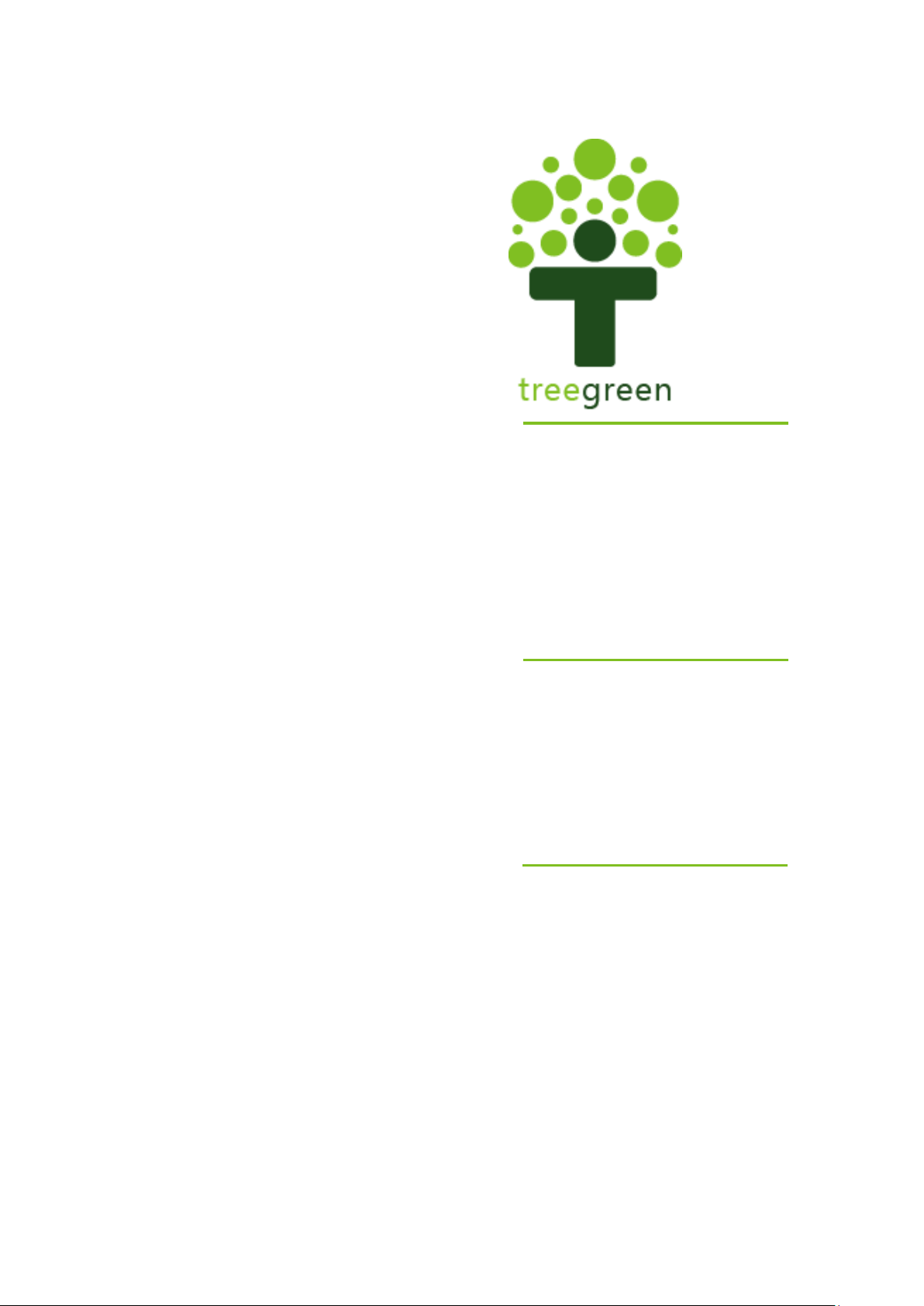

1 x EG-001 : Main Base

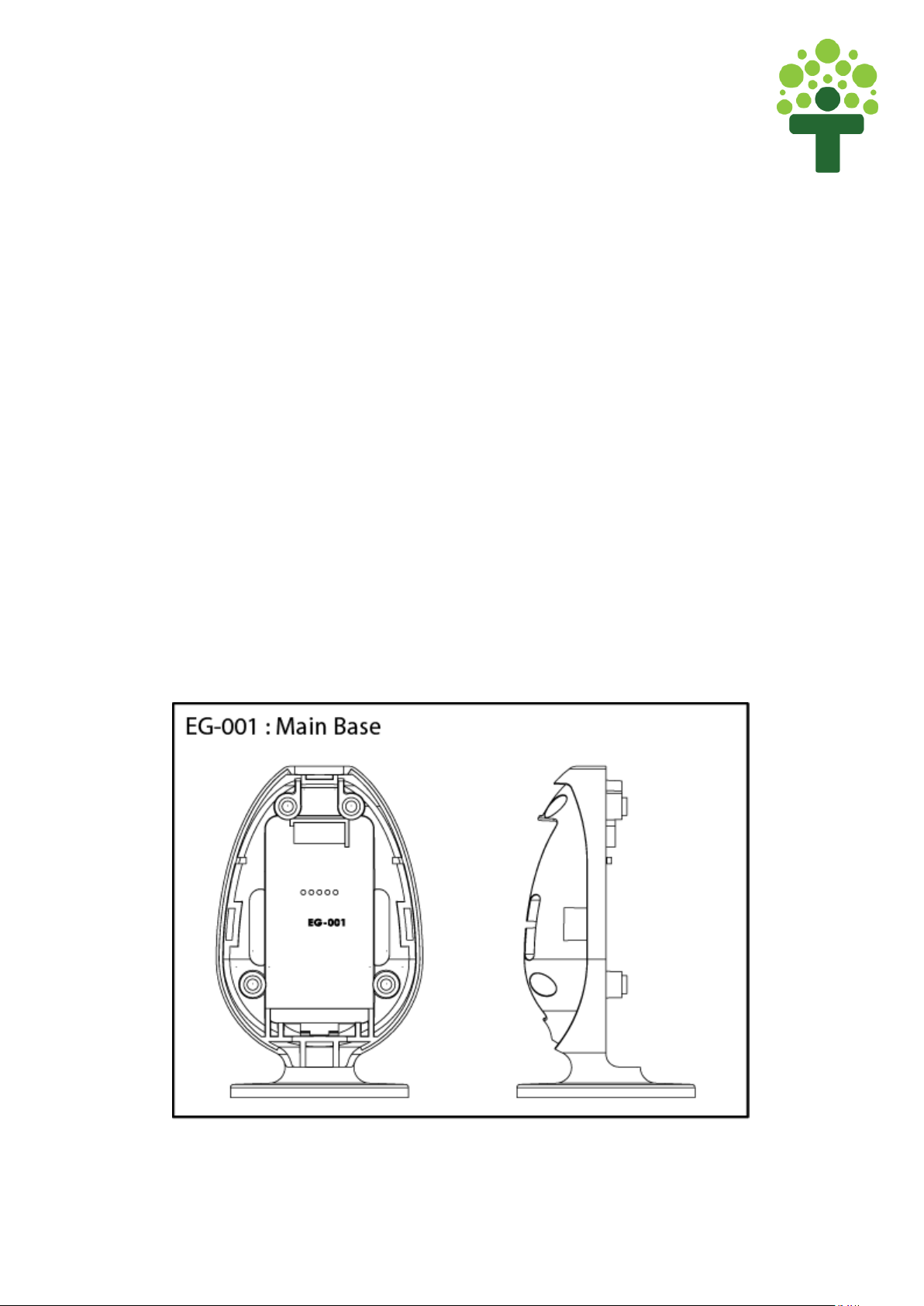

1 x EG-002 : Front Case

1 x EG-004 : Rear Case

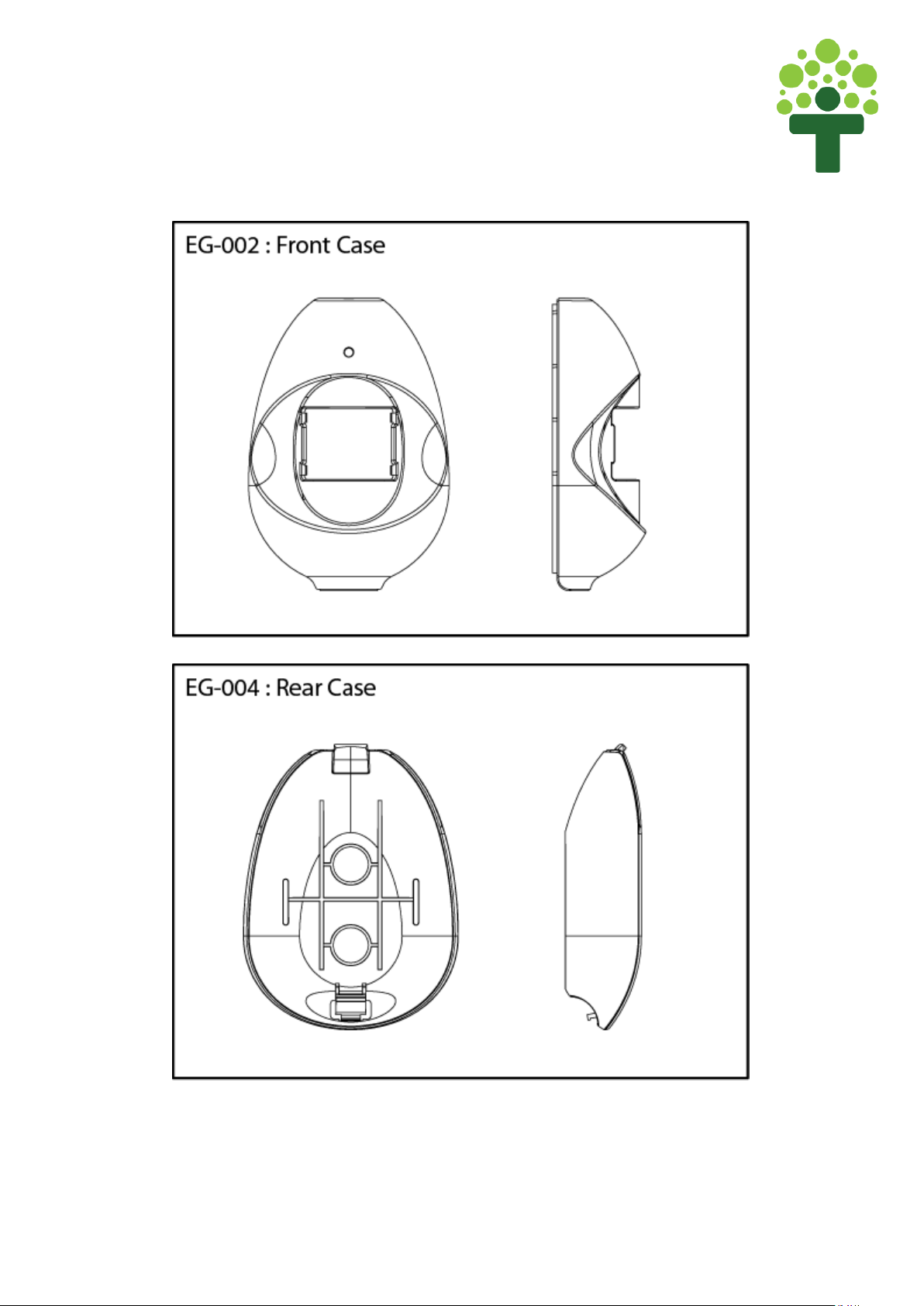

1 x EG-005 : Button

1 x EG-006 : Dial

1 x Lens

1 x PCB (Printed Circuit Board)

4 x Screws

1 x Compliance Label

energyEGG Assembly Instructions

1

energyEGG Assembly Instructions

2

energyEGG Assembly Instructions

3

energyEGG Assembly Instructions

4

energyEGG Assembly Instructions

5

Before beginning assembly please note:

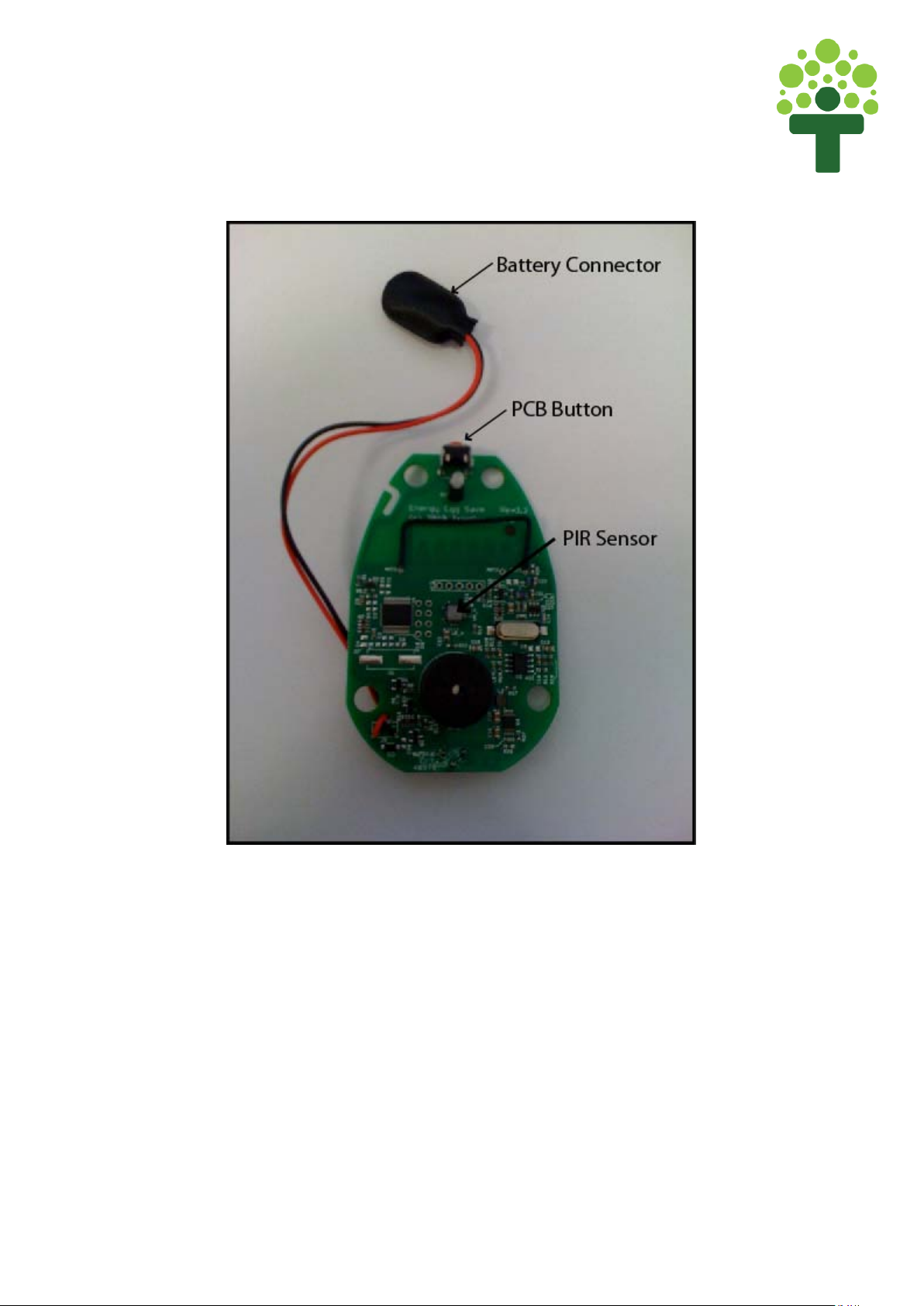

- Be careful when handling the PCB(Printed Circuit Board) as touching the

Sensor can seriously impair functionality.

- Be careful when handling the Lens as it is sensitive and easily scratched –

this can significantly diminish the functionality of the lens.

Step 1 : Insert Button (EG-005)

Insert Button (EG-005) into the slot at the top of the Main Base (EG-001) as

shown in Figure 1a. The Button should slide into the ledge as shown in Figure

1b.

Figure 1a - Insert Button in Main Base

energyEGG Assembly Instructions

6

Figure 1b - Slide Button into Ledge

The Button should sit flush in the Main Base when inserted correctly. When

inserted correclt, there should be no gap between the Button and Main Base

(See Figure 1c).

Figure 1c - There should be no gap between Button and Main Base

energyEGG Assembly Instructions

7

The Button should also be flush and parallel with the top of the Main Base

(See Figure 1d).

Figure 1d – Button should fit into the Main Base and not be angled

energyEGG Assembly Instructions

8

Step 2 : Prepare PCB

The first step of inserting the PCB is to tie a knot in the battery fly wire, around

5cm from the base of the PCB (see figure 2a)

Figure 2a - Tie knot in the battery fly lead

energyEGG Assembly Instructions

9

Ensure that the Pot on the PCB is in the right position (see Figure 2b). The pot

should be slightly angled forward away from the PCB. Figure 2c highlights the

correct and incorrect alignment for the Pot.

Figure 2b - Pot Alignment

Figure 2c – Correct and Incorrect Pot Alignment

energyEGG Assembly Instructions

10

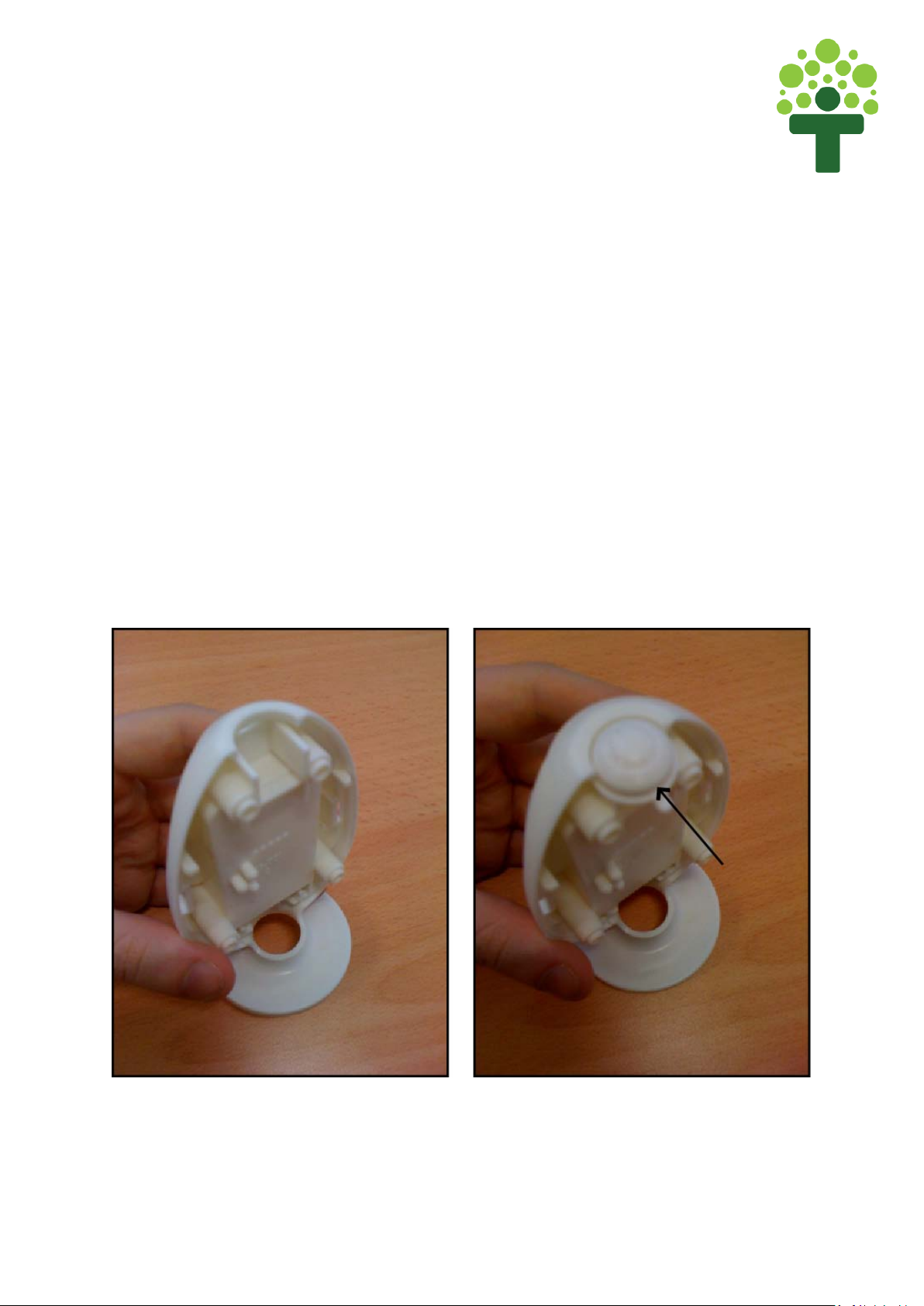

Step 3 : Insert PCB

Figure 3a shows a step by step guide to inserting the PCB into the Main Base.

First thread the battery connector through the gap at the top of the Main Base

as show in

. Next, place the PCB down onto the Main Base ( ), aligning

the four screw holes on the PCB with the screw bosses on the Main Base (

).

Figure 3a - Insert PCB onto Main Base

energyEGG Assembly Instructions

11

The PCB should now sit flush and tight against the Main Base as shown in

Figure 3b. Please ensure that the PCB is tight against the Main Base at each of

the four screw bosses.

Figure 3b - PCB should be flush with Main Base and aligned with Button

The Button (EG-005) aligns with the red button on the PCB and should ‘click’

when depressed. Figure 3b shows the correct and incorrect alignment of the

Button EG-005 to the PCB button.

energyEGG Assembly Instructions

12

Step 4 : Insert Dial

Before inserting the Dial in the Main Base, please ensure that the blue pot is

pointing towards the ‘5’ setting on the Main Base (see Figure 4a).

energyEGG Assembly Instructions

13

Now Place the Dial (EG-006) into the bottom of the Main Base (EG-001). The

Dial (EG-006) should point to the 5 Minute setting on the Main Base (See

Figure 4b).

Figure 4b - Dial pointing towards the '5' minute setting

When inserted correctly, the Dial should sit tight and flush to the Main Base.

energyEGG Assembly Instructions

14

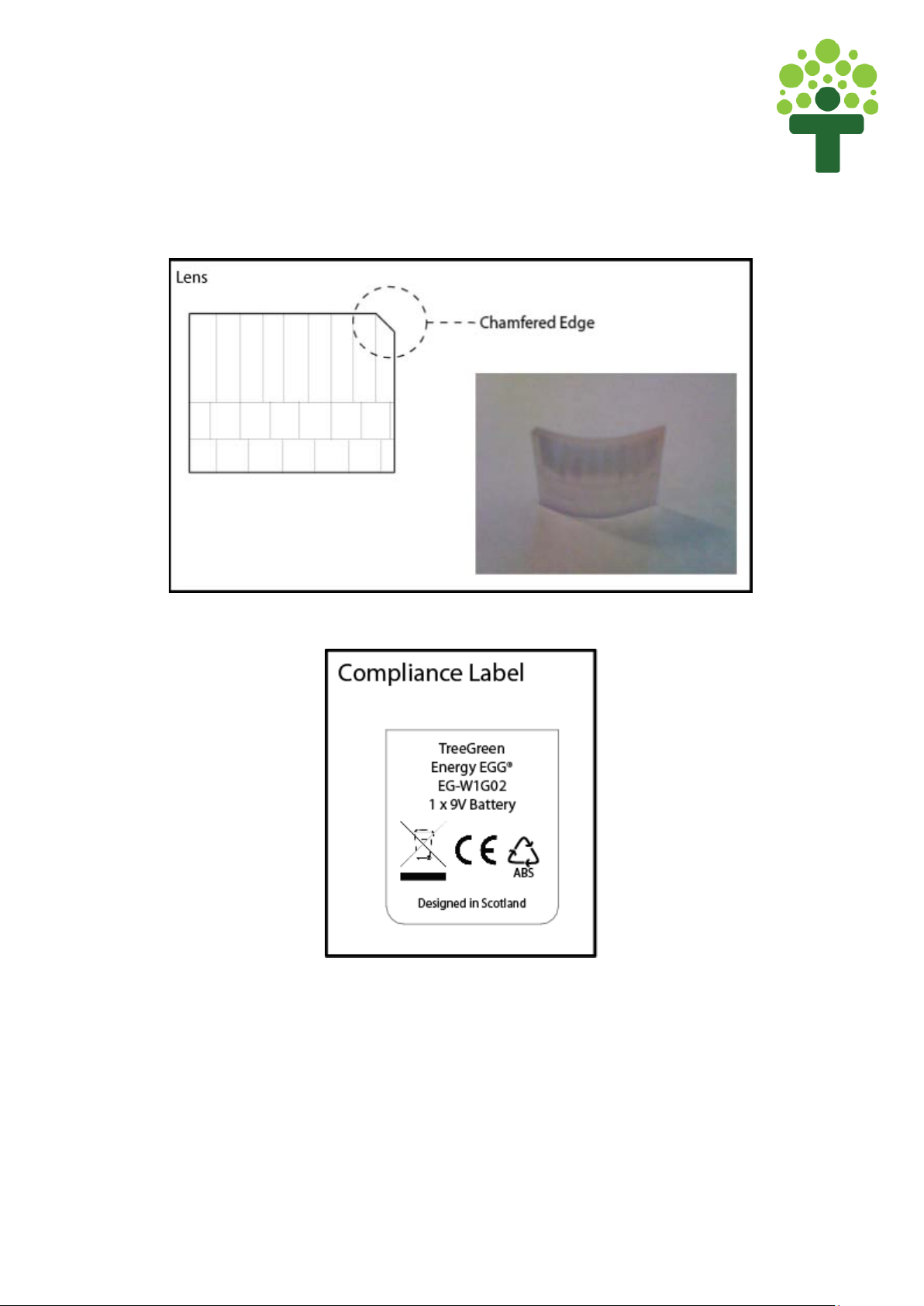

Step 5 : Attach Lens to Front Case

Attach the Lens to the Front Case (EG-002), with the smooth, glossy surface

facing out. To do so, align the Lens so that chamfered corner is at the top right

hand edge of the enclosure and clip into place (Figure 5a).

Figure 5a - Ensure the chamfered edge of the Lens is at the top right corner

energyEGG Assembly Instructions

15

The Lens should ‘click’ into place at each of the four areas highlighted in

Figure 5b.

Figure 5b - Lens should 'click' into place.

With the Lens correctly attached to the Front Case, apply a small amount of

adhesive to hold the lens firmly in place.

energyEGG Assembly Instructions

16

Step 5 : Attached Front Case to Main Base

Now take the assembled Front Case(EG-002) and the assembled Main

Base(EG-001) and piece together (see Figure 5a). The Front Case (EG-002)

should fit flush with the Main Base (EG-001) and no components should be

loose. If assembled correctly:

- The Button (EG-005) should click when pressed and then return to its

original position.

- The Dial (Eg-006) should be able to rotate freely and click at each

setting.

- No components should be loose or rattle.

Figure 5a - Attach Front Case to Main Base

energyEGG Assembly Instructions

17

Step 6 : Insert Screws

Whilst holding the assembled EGG together, fasten 4 screws into the back of

the Main Base (EG-001) as shown in Figure 6a.

energyEGG Assembly Instructions

Figure 6a - Screw Locations

18

Now place the Compliance label in the recessed area on the Energy EGG as

shown in Figure 6b. The Compliance label should not obstruct the 5 pinholes.

The energyEGG is not shipped with the battery pre-installed, and as such, the

Compliance Label must be visible to the user.

energyEGG Assembly Instructions

19

Step 7 : Attach Rear Case

energyEGG Assembly Instructions

20

Now attach the Rear Case (EG-004) to the assembled unit. Firstly, insert the

upper clip of the Rear Case into the assembled unit, and then the rest of the

case should clip into place (see Figure 7a).

energyEGG Assembly Instructions

21

Now set the timer dial to the ’10 minute’ setting as shown in Figure 7c

The Energy EGG should now be fully assembled. There are a number of checks you

can perform in order to determine whether the Energy EGG is correctly assembled,

these include:

Testing the Button - the button should be flush with the rest of the EGG and will

click when pressed. It should not be jammed.

Testing the Dial - the dial should turn freely in the base, making a ‘click’ at each

setting.

Check the split lines - the gaps where components meet each other

should be minimal and uniform.

energyEGG Assembly Instructions

22

Loading...

Loading...