Page 1

6100/E/6150/E Treadmill Repair Guide

SPORTS ART INDUSTRIAL CO., LTD.

Page 2

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Series Treadmill Repair Guide

Chapter 1. Treadmill Configuration and Wiring Diagrams

Chapter 2. Operation

Chapter 3. Error Message Definitions

Chapter 4. Measuring and Testing

0-0-1

Page 3

6100/E/6150/E

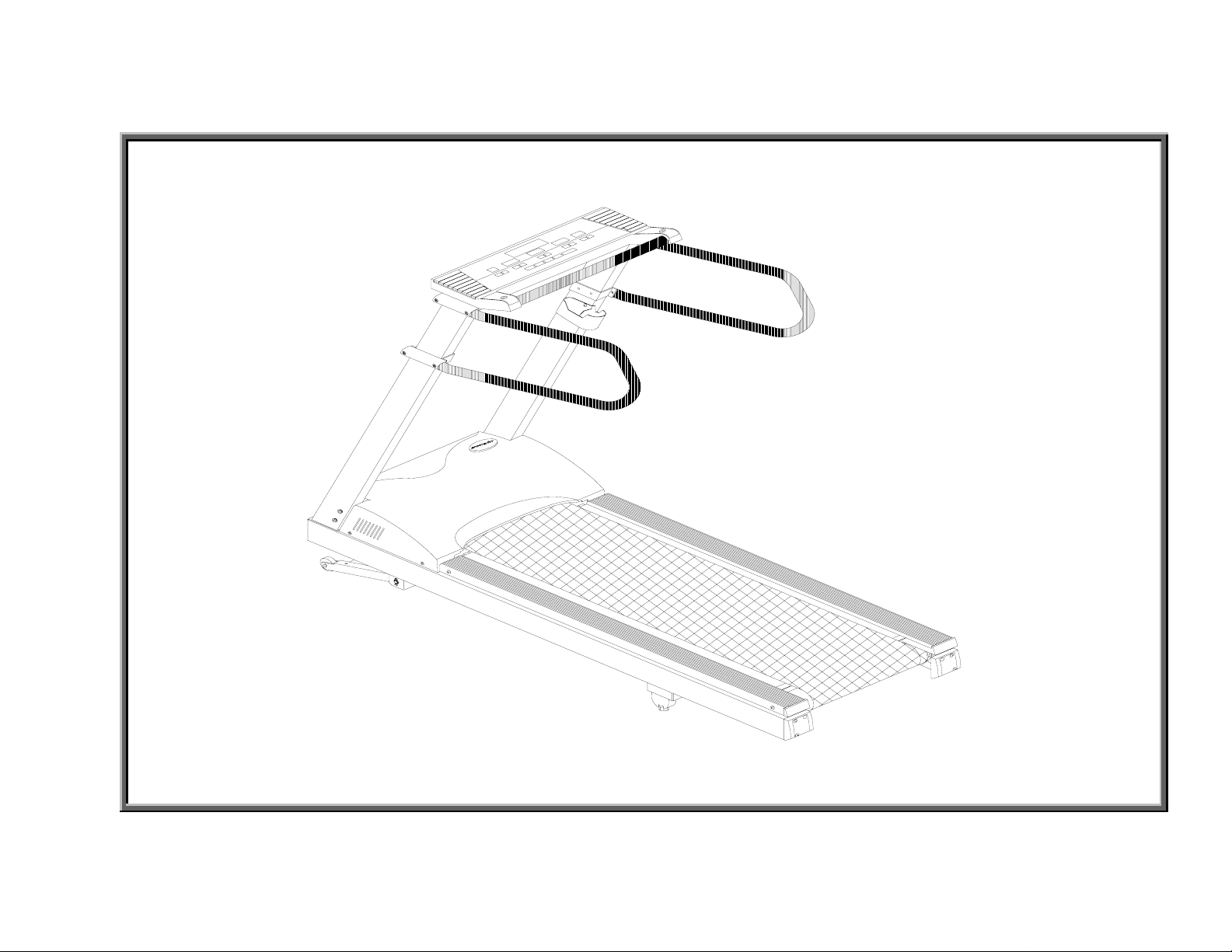

1. Treadmill Configuration and Wiring Diagram

SPOR TS AR T INDUSTRIAL CO., L T D.

Page 4

SPORTS ART INDUSTRIAL CO., LTD.

6150E/6100E Treadmill

1-1-1

Page 5

SPORTS ART INDUSTRIAL CO., LTD.

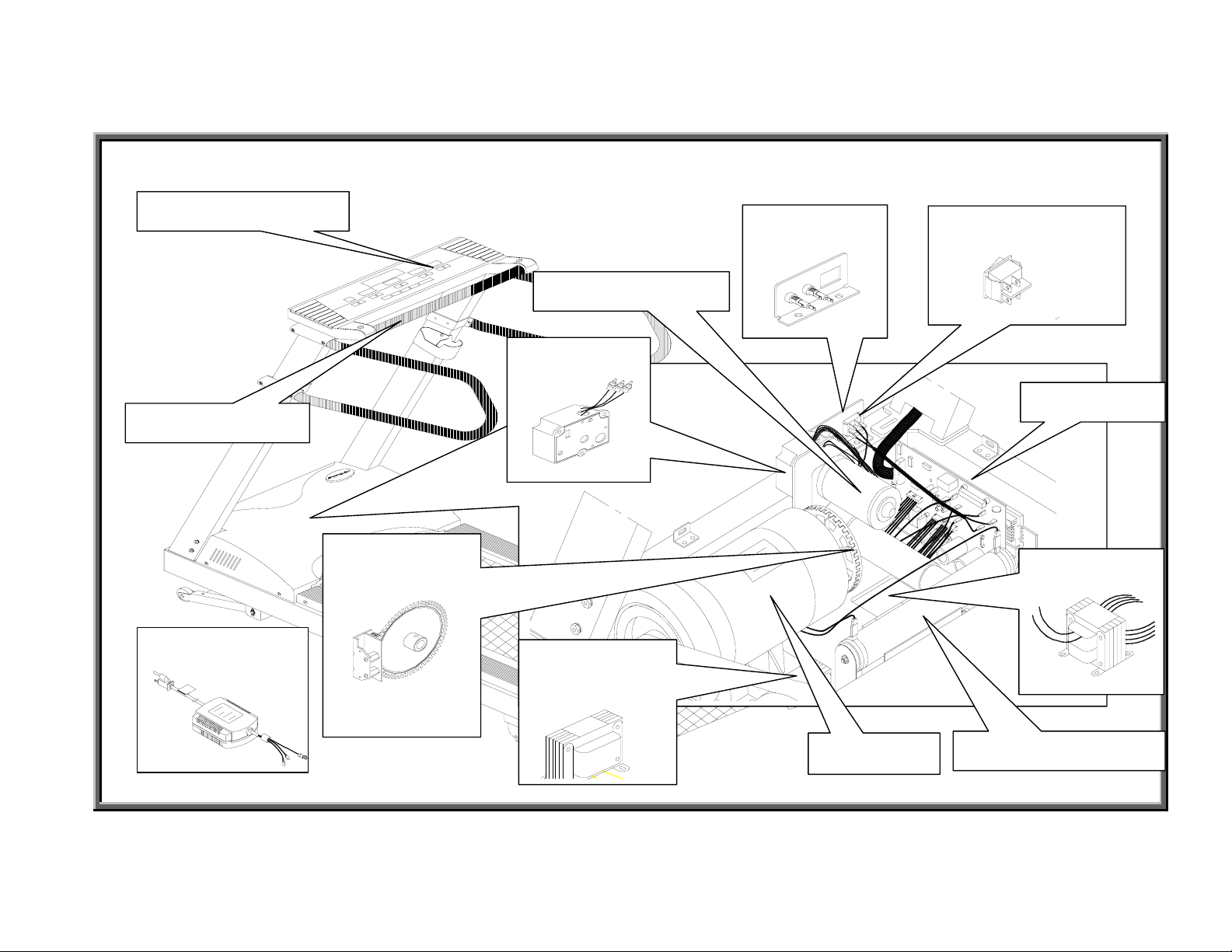

6150E/6100E Treadmill Electronic Component Placement Diagram

Display Window

HTR Handlebar

Power Filter

Optic Sensor

+Tachometer

Fuse Socket

On/off Switch

Incline Motor Set

Incline VR

Drive Board

Transformer

Inductor

(220V)

1-2-1

Motor

Resistance Resistor

Page 6

SPORTS ART INDUSTRIAL CO., LTD.

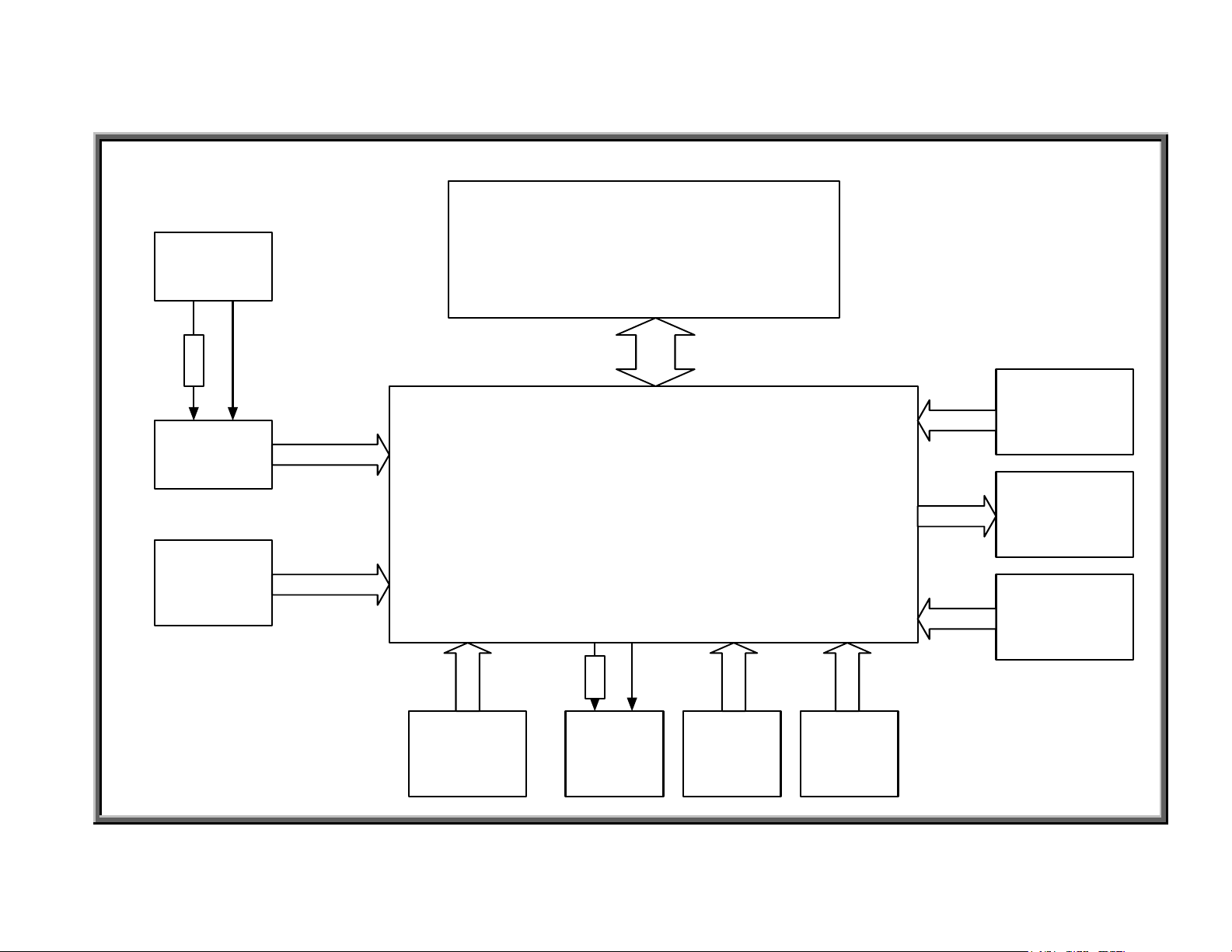

6150/E/6100/E Treadmill Configuration

Power Cord

(Filter)

FUSE

On/Off

Switch

Transformer

2-PIN

10-PIN

Display

Cable

16- PIN

3-PIN

Drive Board

2-PIN

FUSE

3-PIN

2-PIN

2-PIN

2-PIN

Optic Sensor

Motor

Large

Resistor

(FUSE)

Inductor

(220V)

Incline

Motor

1-3-1

Incline

VR Set

Incline

LIMIT

Switch

Page 7

SPORTS ART INDUSTRIAL CO., LTD.

6150/E/6100/E Display Board Wiring Connection Diagram

6150 Display Board Backside

CNT3

TO Drive

Board

STOP

Board

POLAR RECEIVER

16-PIN

STOP

1

HTR HANDLEBAR HTR HANDLEBAR

CNT1

CN3

HTR BOARD

CN1

K1K2

6150 Soft Keys

CN2

POLAR Receiver

STOP2

STOP

Board

1-4-1

Page 8

SPORTS ART INDUSTRIAL CO., LTD.

d

6150/E/6100/E Drive Board Wiring Connection Diagram

Optic

Sensor

Display

Board

Motor

Large

Capacitor

Power Cor

and Filter

FUSE

4

i

n

p

Power

Switch

1

6

P

I

N

Inductor

(

7 pin

Incline Set

(Motor

,VR,

LIMIT Switch)

7 pin

Transformer

220V)

1-5-1

Page 9

SPORTS ART INDUSTRIAL CO., LTD.

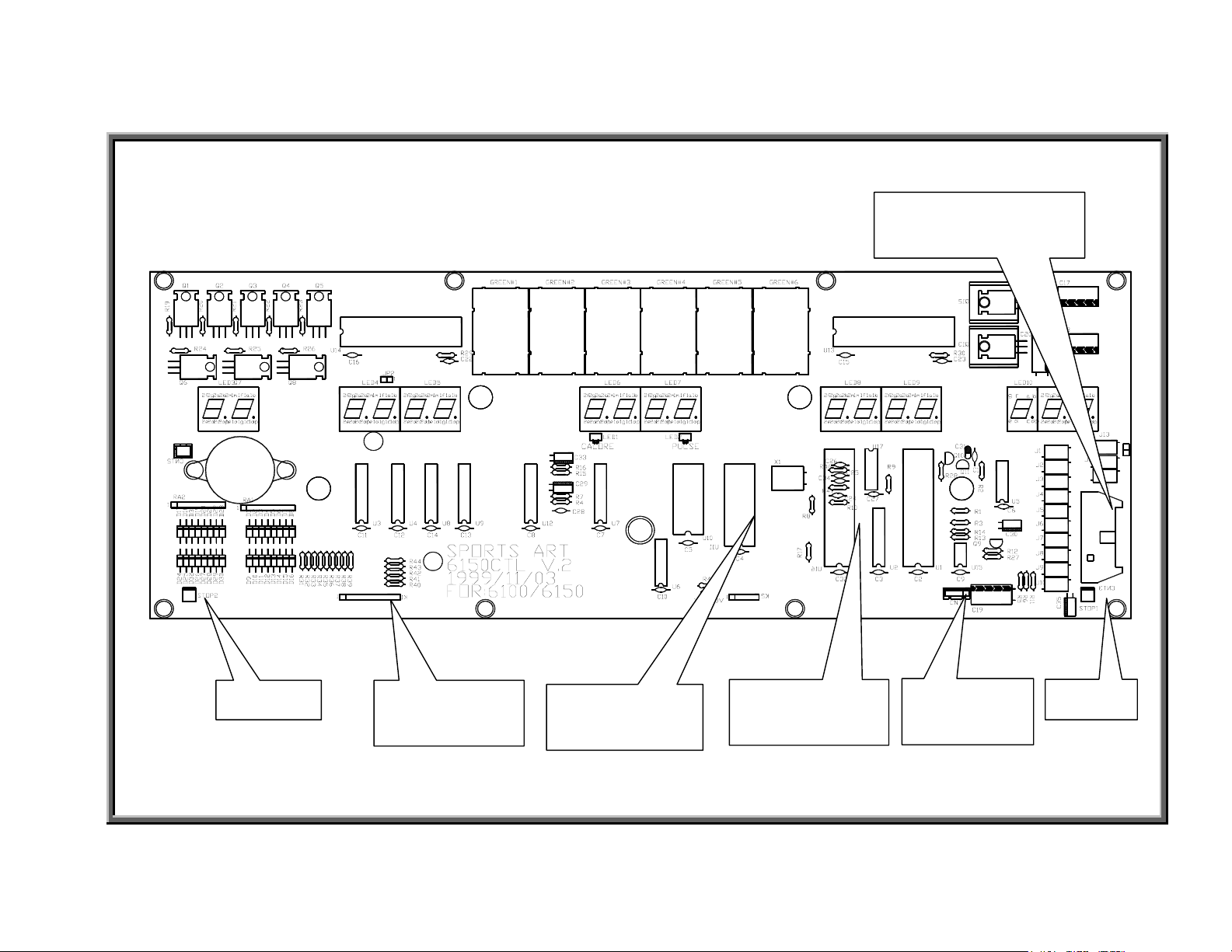

6150/E/6100/E Display Board Component Placement Diagram

CNT3 16-PIN

Cable Connector

STOP2

K1, K2

Soft Keys

U11

Main Program

1-6-1

U16

Motor Program

CNT1

Heart Rate

STOP1

Page 10

SPORTS ART INDUSTRIAL CO., LTD.

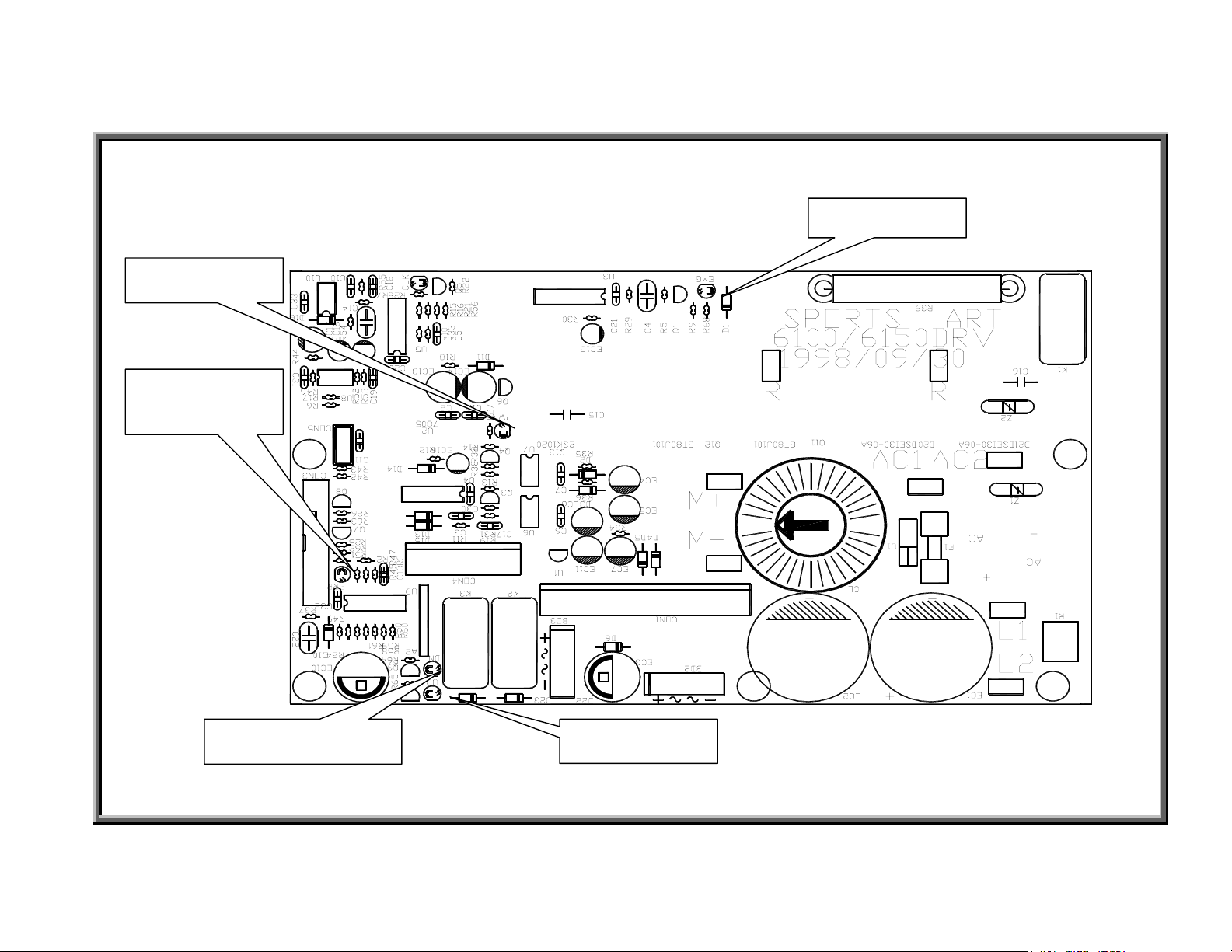

6150/E/6100/E Drive Board Component Placement Diagram

POWER LED

Incline ERR

LED

EMG LED

Incline UP LED Incline DN LED

1-7-1

Page 11

SPORTS ART INDUSTRIAL CO., LTD.

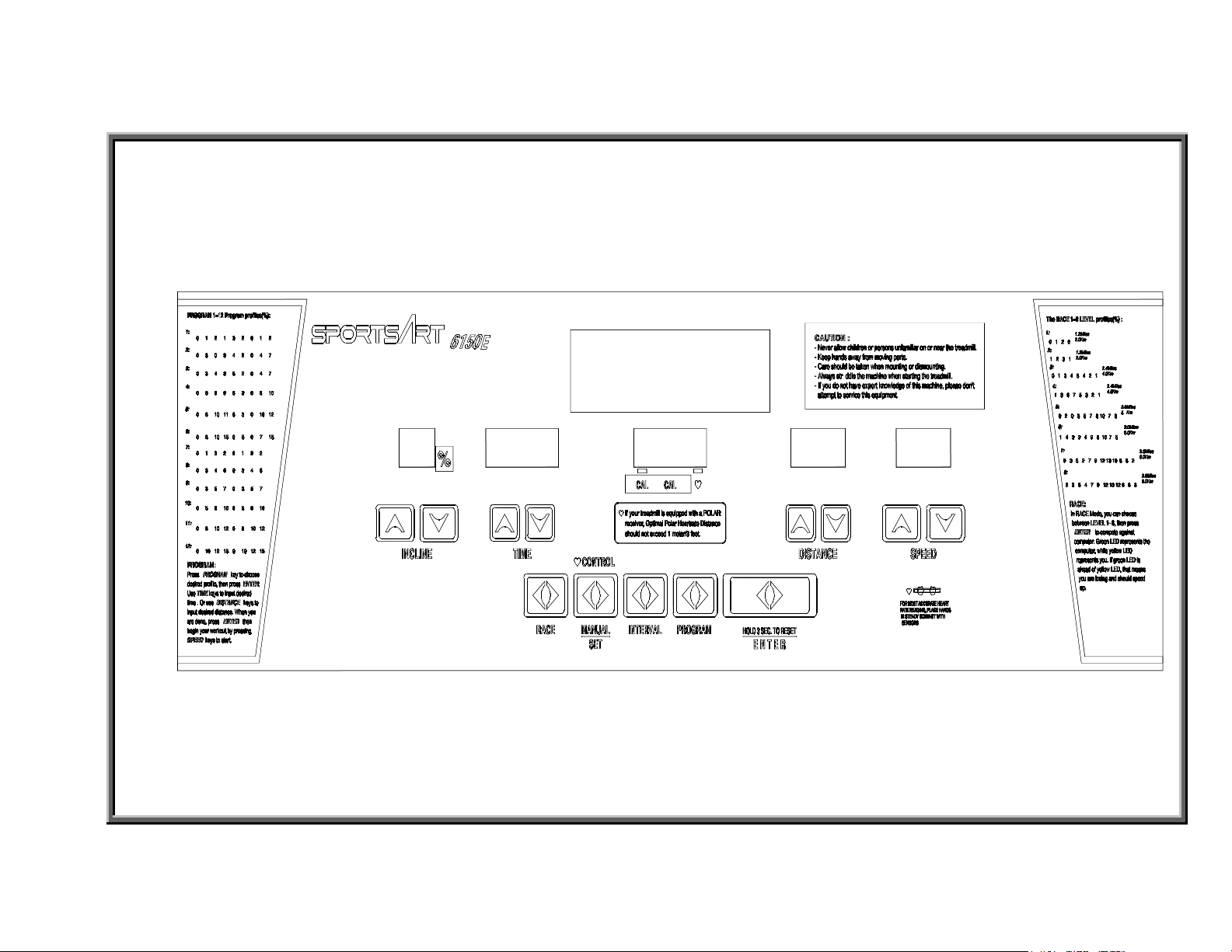

6150/E Display Panel

1-8-1

Page 12

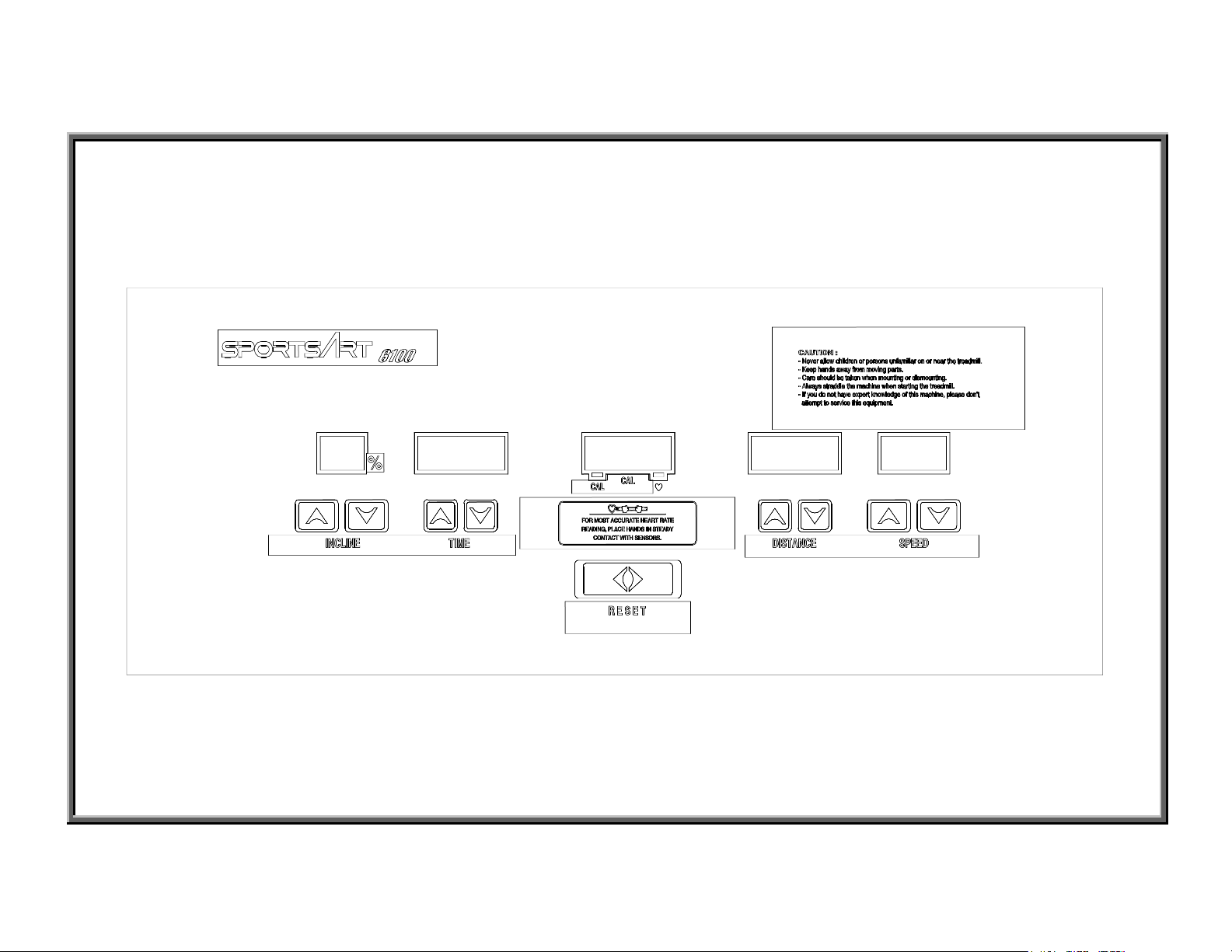

SPORTS ART INDUSTRIAL CO., LTD.

6100/E Display Panel

1-9-1

Page 13

6100/E/6150/E

2. Operation

SPORTS ART INDUSTRIAL CO., LTD.

Page 14

6100/E/6150/E

2. Operation

SPORTS ART INDUSTRIAL CO., LTD.

Page 15

SPORTS ART INDUSTRIAL CO., LTD.

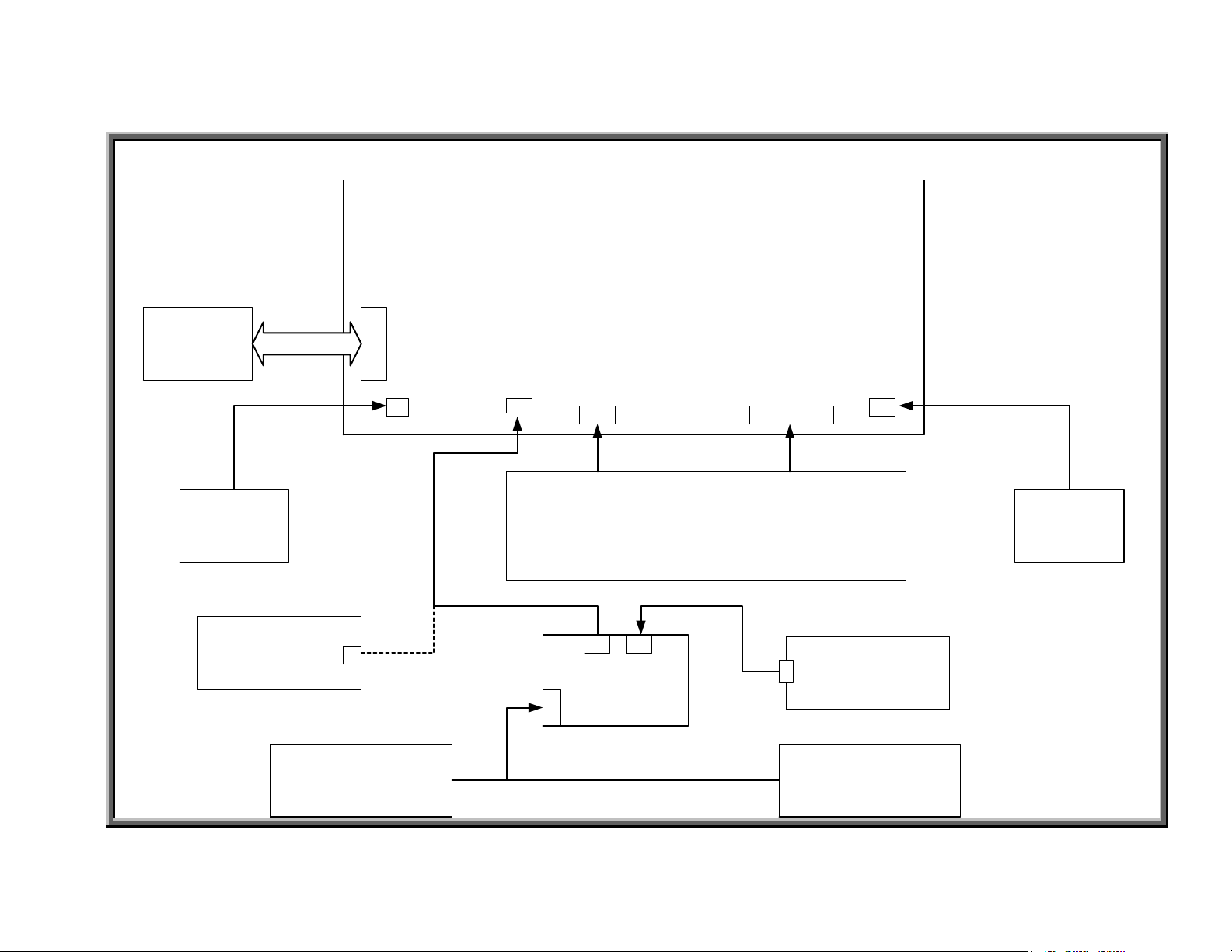

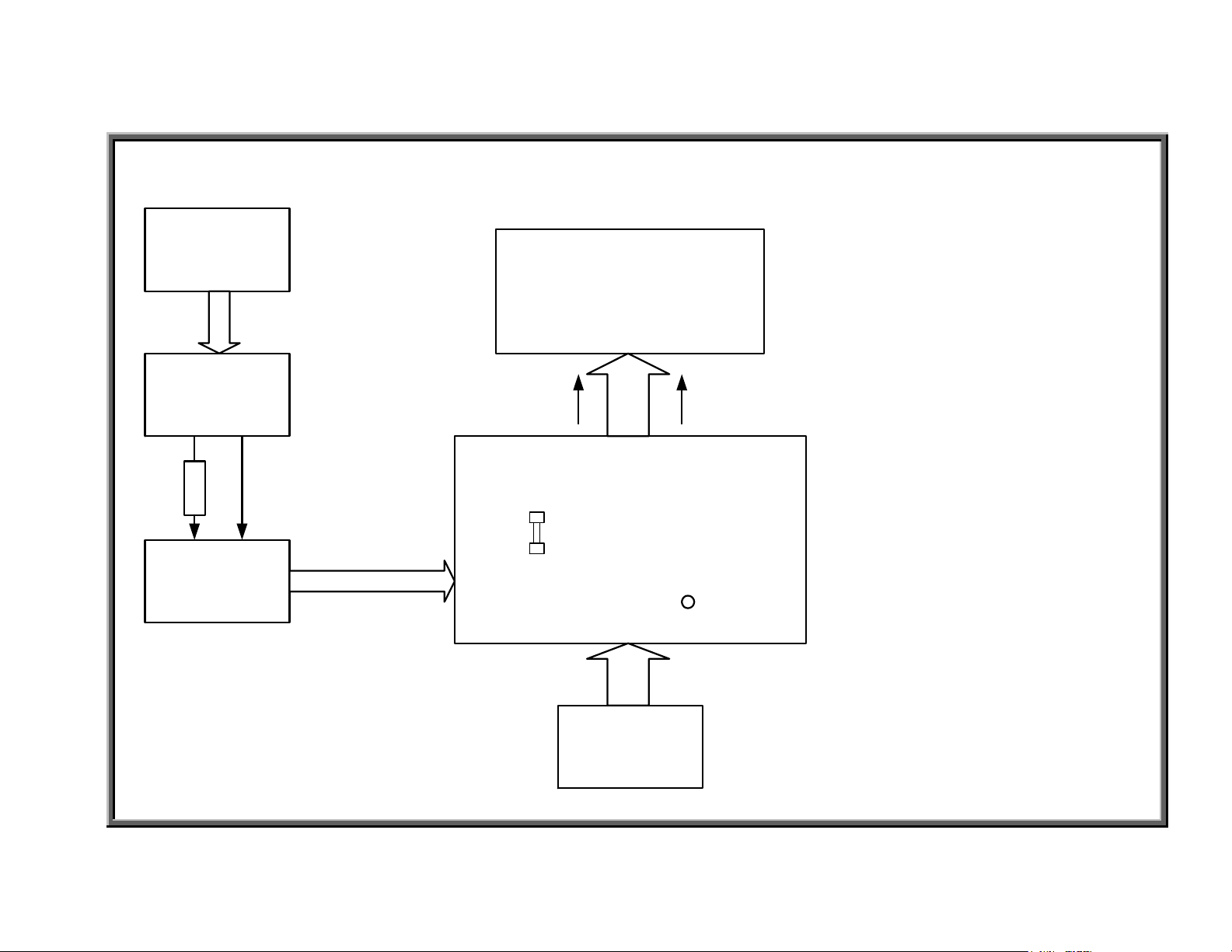

6150/E/6100/E Voltage Flow Chart

1. Configuration

POWER CORD

DISPLAY BOARD

FILTER

(CE)

FUSE

F1

DRIVE BOARD

ON/OFF

SWITCH

AC1,AC2

VBB 12VVCC 5V

POWER

VAC

TRANSFORMER

2-1-1

Page 16

2. How the Unit Operates

Order Name Operation

1 Power Cord 1. Brings power in from the power supply.

2 Filter 1. Filters power, preventing interference (220V CE products only).

3 Fuse 1. Prevents damage to components from high current.

4 Power Switch 1. Turn power on “1”; power switch lights; power comes from the

5 Drive Board 1. Drive board has sent AC power through the fuse F1 to the

SPORTS ART INDUSTRIAL CO., LTD.

filter into the unit.

2. Turn power off “0”; power switch doesn’t light; power doesn’t

come from the filter into the unit.

transformer connector.

2. After the transformer power enters the drive board, the power is

stabilized as VCC, VBB, which supplies drive and display board

power.

3. VCC and VBB power go through the 16-PIN cable to the display

board.

6 Transformer 1. Takes power voltage from high volt AC1, AC2 to low voltage,

supplying power to components.

7 Display Board 1. VCC and VBB power are supplied to the display board CPU to

activate the unit.

2. The display windows light up once it has power.

2-1-2

Page 17

3. Operational Procedure

Step Operation

SPORTS ART INDUSTRIAL CO., LTD.

1

2

3

4

5

Plug unit into power supply.

Turn on power, flipping switch to ”1”; power light lights.

Drive board POWER LED lights.

Display board screen shows ”MAN’L”.

Turn off power switch, flipping switch to ”0”; power light doesn’t light; display

doesn’t light.

2-1-3

Page 18

SPORTS ART INDUSTRIAL CO., LTD.

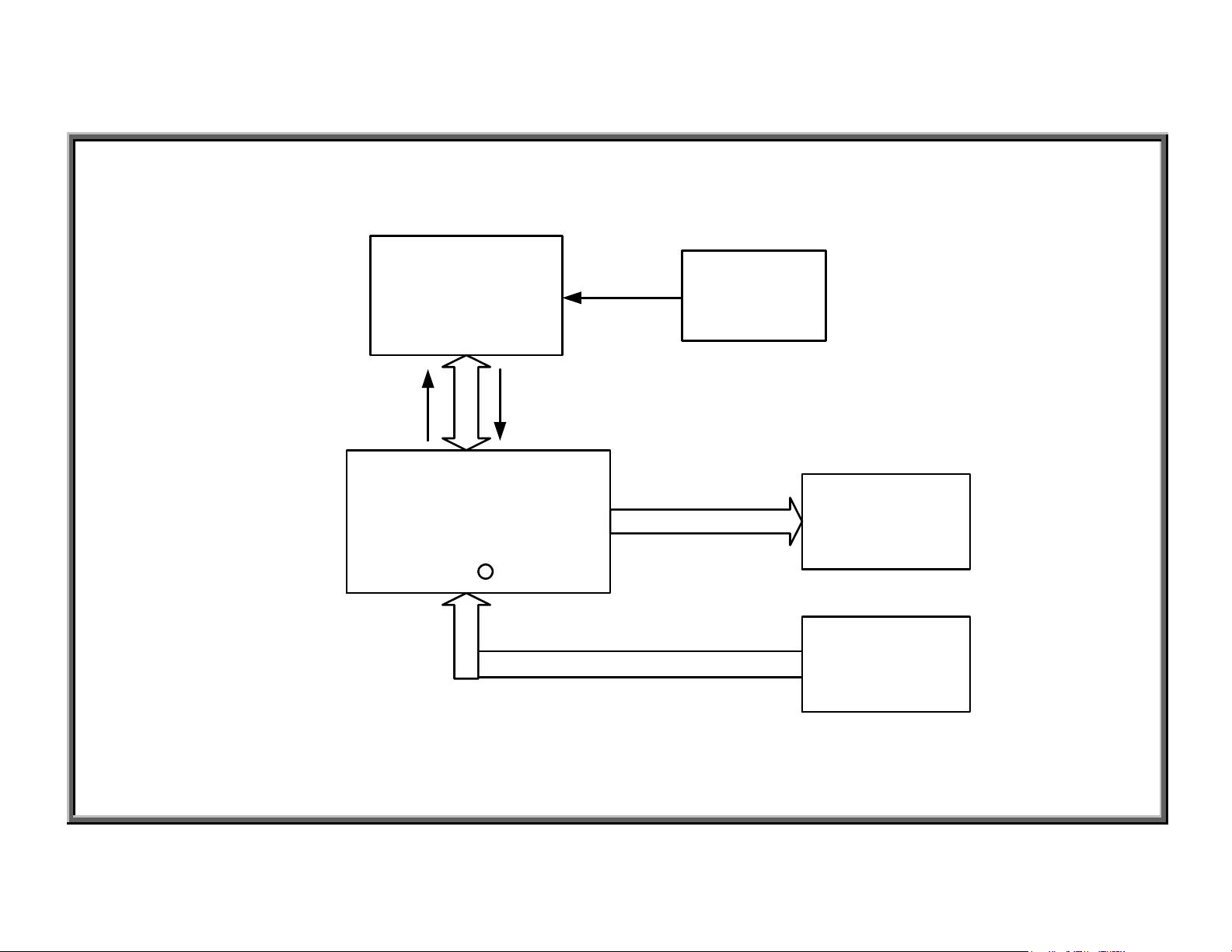

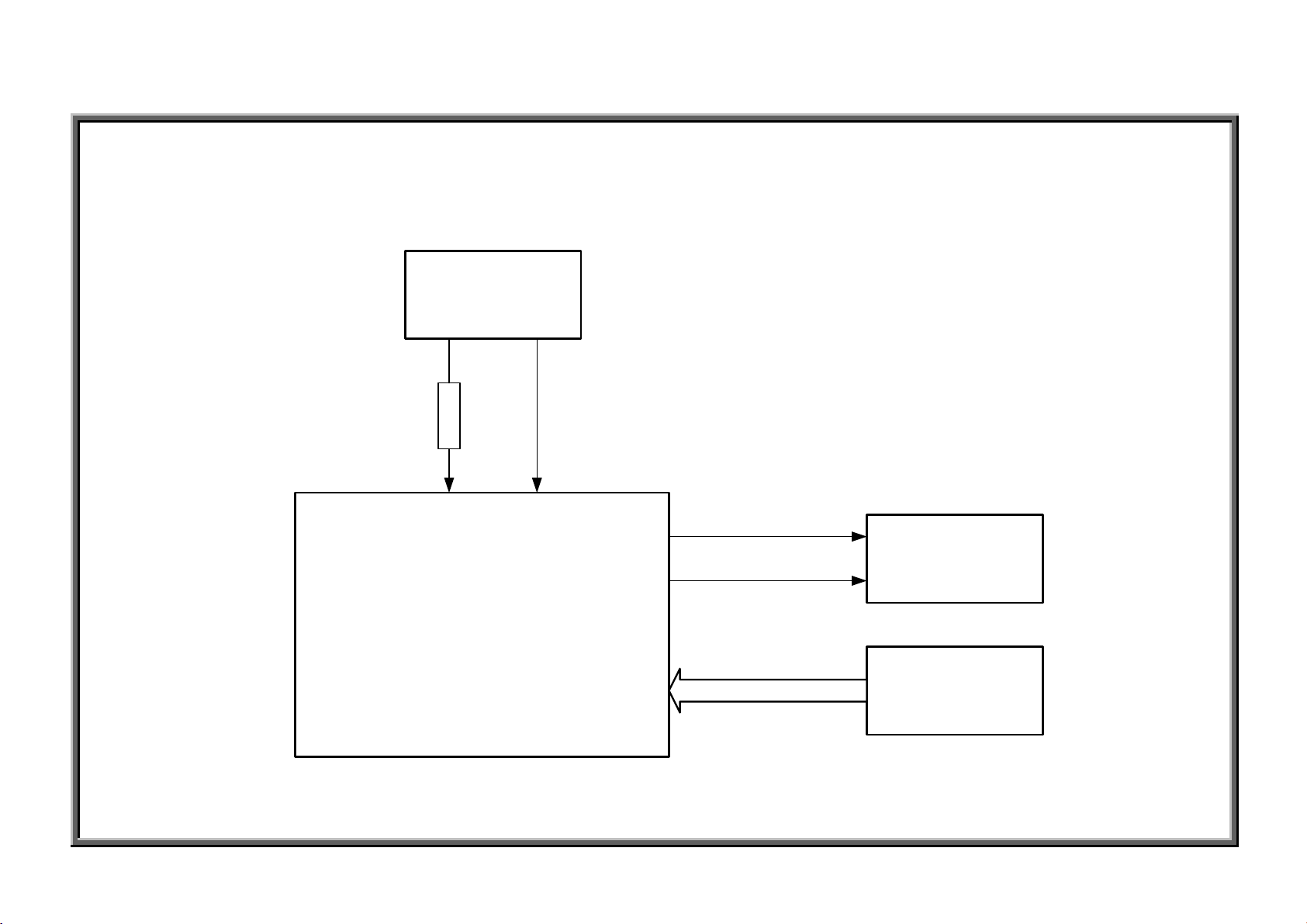

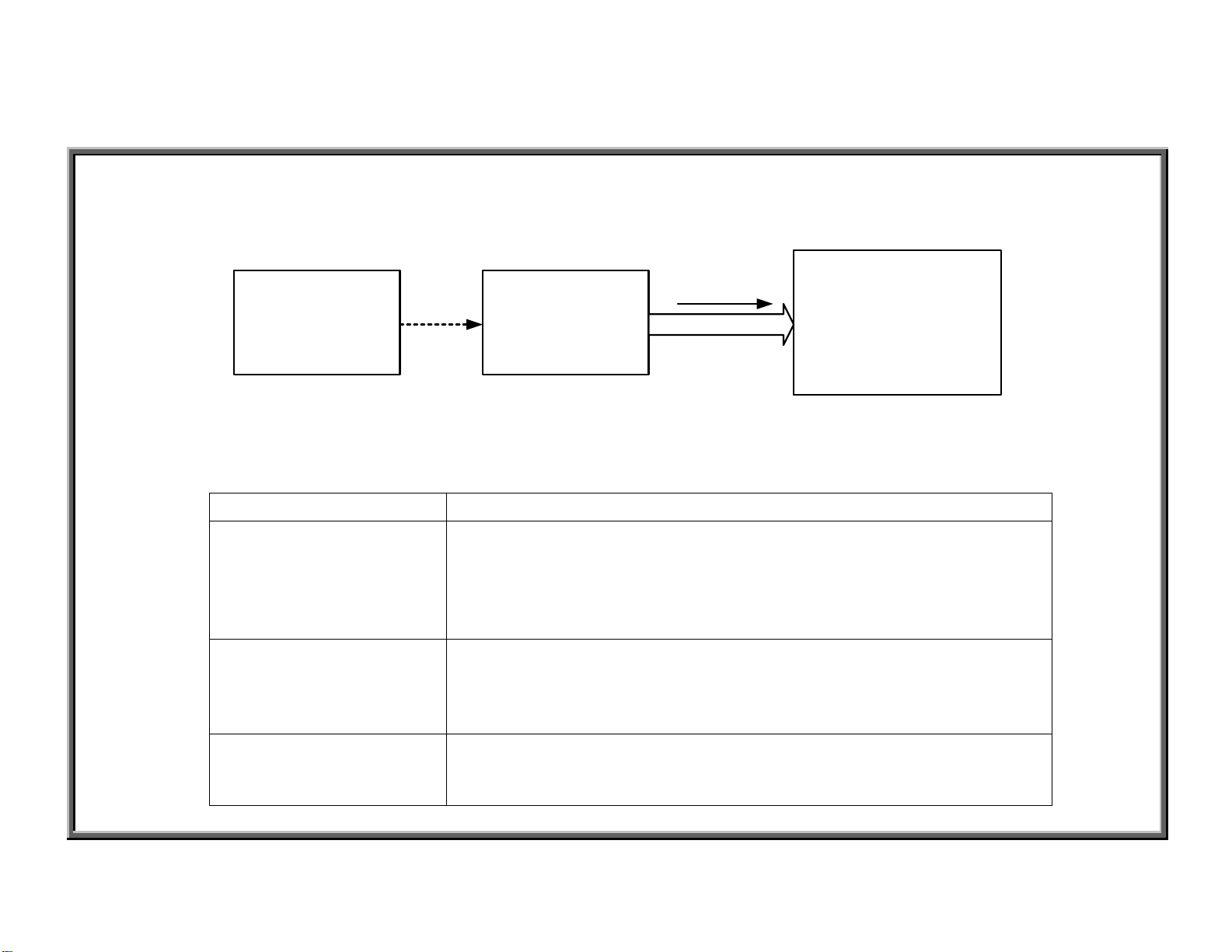

6150/E/6100/E Motor Operation Flow Chart

1. Configuration

Key Signal

Display Board

Soft Keys

Optic Sensor

Signal

Motor Speed

16 PIN

Drive Board Motor

Signal

Motor

Voltage

2 pin

CLK

Optic Sensor Signal

4pin

Optic Sensor

2-2-1

Page 19

SPOR TS AR T INDUSTRIAL CO., LTD.

2. Operational Steps

Order Component Operation

1 Soft Keys 1.User inputs the desired speed.

2. Display board SPEED window shows SPEED key setting value.

2 Display Board 1. Display board CPU sends the motor speed signal to the drive board to

control motor speed.

2. The signal travels from the display board to the drive board through the

16-PIN cable.

3 Drive Board 1. Drive board translates the display board motor speed signal into the PWM

speed signal for the display board.

2. The PWM signal emits the drive board motor voltage to control motor

speed.

4 Motor 1.The motor rotates according to the drive board voltage.

2. After the motor operates, the rollers turn, moving the walking belt.

5 Tach Wheel; Optic Sensor 1. Motor operation moves the tachometer wheel.

2. The optic sensor detect the tachometer signal.

3. The signal travels the 4-PIN cable to the drive board.

6 Drive Board 1. The drive board translates the optic sensor signal from wave to rectified

form.

2. The drive board CLK indicator flashes or remains lit.

3. The optic sensor signal travels the 16-PIN cable to the display board.

7 Display Board 1. If the display board senses the optic sensor signal, it keeps emitting the

motor signal, allowing the motor to operate.

2-2-2

Page 20

3. Operational Procedure

Step Operation

SPORTS ART INDUSTRIAL CO., LTD.

1

Press SPEED<▲> or SPEED<▼> key

2 Display board SPEED window setting speed value appears.

3 Motor starts operating; the tachometer wheel moves, and the treadmill belt rotates.

4 Drive board CLK indicator lights.

5 The display doesn’t show any error message; the motor continues to operate.

2-2-3

Page 21

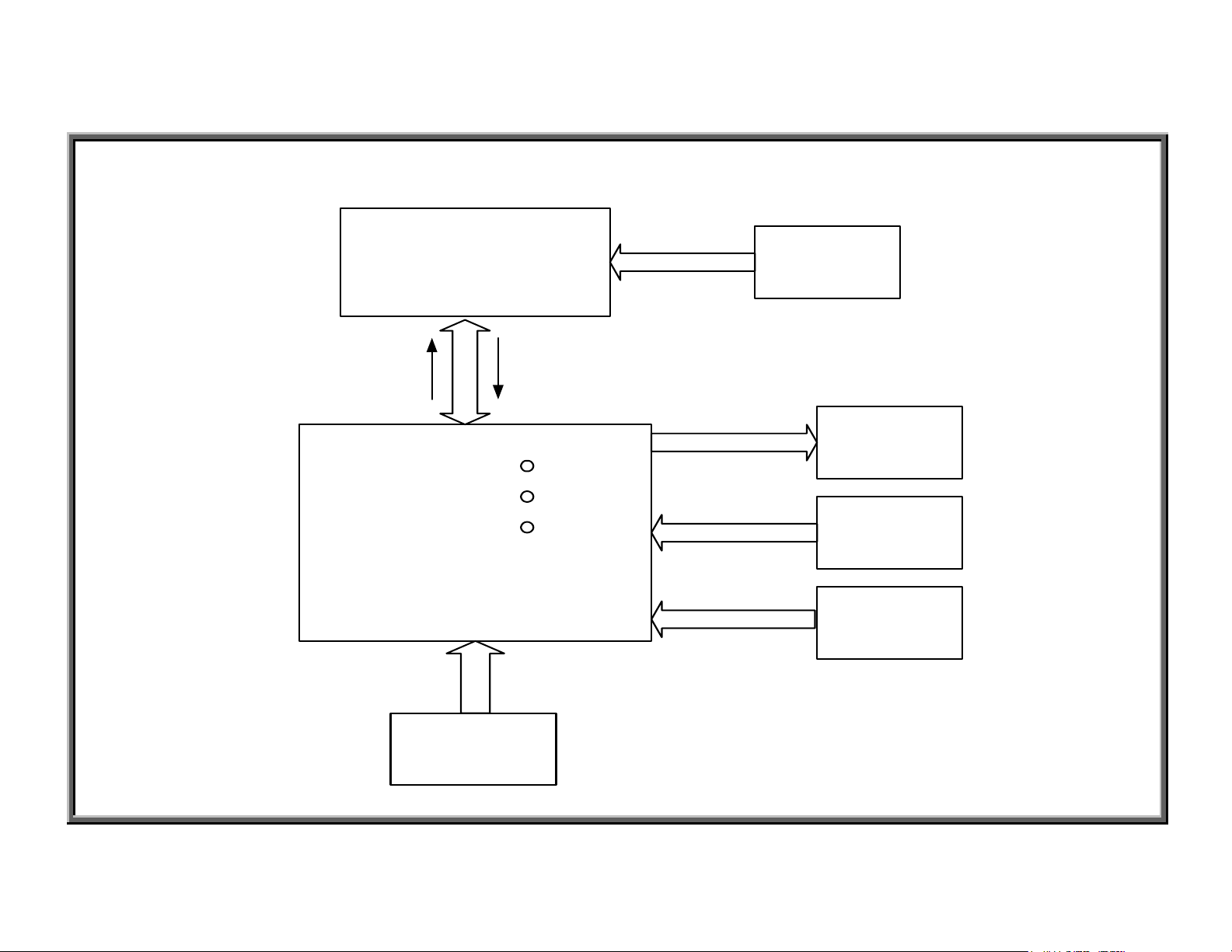

SPORTS ART INDUSTRIAL CO., LTD.

6150/E/6100/E Incline Operation Flow Chart

1. Configuration

INC UP,DN

Display Board

Soft Key

Incline VR

Voltage; LIMIT

Signal

16 PIN

Drive Board

Transformer

Incline Up/Down

Signal

UP

DOWN

ERR

Transformer

Voltage

Incline

Motor

Voltage

Incline LIMIT

Signal

Incline VR

Voltage

Incline

Motor

Incline

LIMIT Switch

Incline VR

Set

2-3-1

Page 22

1. Operation

4

Order Part Operation

1 Soft Keys 1.User inputs incline height through the keys.

2 Display Board 1.The display board CPU sends the incline height setting signal to the drive board to

3 Transformer 1.The transformer provides the incline motor with power to operate.

4 Drive Board 1.The drive board incline circuit operates according to the incline signal from the display

5 Incline VR Set 1. The incline gears turn, turning the VR, which increases or decreases the incline value.

6 LIMIT 1. When the incline motor leaves the incline VR value range, the incline VR gear hits the

7 Drive Board 1.The incline LIMIT signal enters the drive board for processing. If the LIMIT switch

8 Display Board 1.The display board senses the VR value and constantly emits the incline signal.

SPORTS ART INDUSTRIAL CO., LTD.

command incline action.

2.The signal travels from the display board through the16-PIN cable to the drive board.

board.

2.By changing the polarity of the voltage, the drive board makes the DC incline motor turn

up or down.

3.The drive board UP indicator lights to indicate up incline action.

.The drive board DN indicator lights to indicate down incline action.

2. Incline height is determined according to the incline VR value voltage.

LIMIT switch.

2. A broken LIMIT switch circuit means that the incline set has exceeded its range.

circuit is short (normal), then ERR indicator doesn’t light. If the LIMIT switch circuit is

broken (not normal), the ERR indicator lights.

2.If the ERR indicator lights, incline action immediately stops.

3.The incline VR wire VR value enters the drive board.

4.The incline LIMIT signal and VR value travels the 16-PIN cable to the display board.

2. The signal is emitted until the incline VR value and the setting value are the same. Once

these are the same, the signal stops, and the incline action stops.

2-3-2

Page 23

3. Operational Steps

Step Operation

SPORTS ART INDUSTRIAL CO., LTD.

1

2 Display board INCL window shows incline value setting.

3 Drive board UP or DOWN indicator lights; ERR indicator doesn’t light.

4 Incline action begins.

5 Once the incline position is reached, action stops.

Press the INCL<▲> or INCL<▼> key.

2-3-3

Page 24

SPORTS ART INDUSTRIAL CO., LTD.

6150/E/6100/E Motor/Resistor Operation Flow Chart

1. Configuration

Big Resistor

FUSE

Motor Voltage

Drive Board

Motor

CLK

Optic Sensor

2-4-1

Page 25

2. Operation

Order Name Operation

1 Motor 1. When the treadmill motor is operating, if the belt is pulled, the motor will speed up.

2 Optic Sensor 1. When the motor speeds up, the optic sensor signal speeds up.

3 Drive Board 1. When the drive board receives the optic sensor signal, if the signal and the setting differ,

4 Motor 1. When the resistor operates, the motor amp draw creates resistance.

3. Operational Procedure

Steps Operation

1 Pulling the belt increases belt speed.

2 Resistance is created, and the treadmill belt speed is held steady.

SPORTS ART INDUSTRIAL CO., LTD.

2. The optic sensor signal travels the 4-PIN cable to the drive board.

the drive board creates a resistance signal and the drive resistance (large resistor)

operates.

2. If the user pulls the belt, the treadmill belt speed doesn’t increase; resistance is felt.

2-4-2

Page 26

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Display Key Function Flow Chart

1. Configuration

Key Signal

2. Operation

Soft Keys

Name Operation

Soft Keys 1.Press the display soft keys.

2.The keys send their signal to the display board.

Display Board

1.The key signal is read by the CPU.

2. The CPU implements the key signal action.

Display Board

2-5-1

Page 27

3. Operational Steps

w

Key Operation

INCL<▲> key Continuously press INCL<▲> key; the INCL window value increases to 15.

INCL<▼> key Continuously press INCL<▼> key; the INCL window value decreases to 0.

TIME<▲> key Continuously press TIME<▲> key; the TIME window value increases to 99.00.

TIME<▼> key Continuously press TIME<▼> key; the TIME window value decreases to 0000.

DIST<▲> key Continuously press DIST<▲> key; the LOAD window value increases to 999.0.

DIST<▼> key Continuously press DIST<▼> key; the LOAD window value decreases to 0000.

SPORTS ART INDUSTRIAL CO., LTD.

SPEED<▲> key

Continuously press SPEED<▲> key; the SPEED window value increases to 20.0KPH

(16.0MPH).

Continuously press SPEED<▼> key; the SPEED window value decreases to 0.2KPH

SPEED<▼> key

(0.1MPH).

<RACE> key

<MANUAL/SET> key

<INTERVAL> key Continuously press <INTV> key; the main display window switches between

<PROGRAM> key

<RESET> key

Continuously press <RACE> key; the main display window shows “LEVEL

1”-“LEVEL 8”.

Continuously press <MAN’L> key; the main display window:

(1) switches between “MAN’L”/”SET” notices (No HRC function units)

(2) switches between “MAN’L”/”SET”/”HRC” (HRC function units)

“INTV1”/”INTV2” notices.

Continuously press <PROG> key; the main display window shows “PRO 1”

-”PRO12” in order.

Continuously press <RESET> key three seconds; the display beeps; the main display

indow shows; the small window deletes to 0.

2-5-2

Page 28

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E POLAR Heart Rate Operation Flow Chart

1. Configuration

2. Operational Procedure

Heart Rate

Transmitter

Part Operation

Heart Rate Transmitter 1. Put on the POLAR transmitter.

POLAR Heart Rate

Receiver

Display Board

POLAR

Heart Rate

Receiver

PULSE

3 PIN CABLE

Display Board

2. The POLAR transmitter senses the wearer ’s heart beat and transmits

the heart rate to the receiver.

3.POLAR heart rate transmitter transmits within a distance of 90

centimeters.

1.POLAR receiver receives the signal from the transmitter through a

wireless transmission.

2. After the heart rate signal is processed, it travels the 3-PIN cable to the

display board.

1.After receiving and processing the heart rate signal, it is sent to the

program which then determines the heart rate value.

2. The display board PULSE window shows the heart rate value.

2-6-1

Page 29

SPORTS ART INDUSTRIAL CO., LTD.

3. Operational Procedure

Step Operation

1 Put on the POLAR transmitter; stand on the treadmill.

2 Within 5 seconds, the PULSE window shows the heart rate value.

2-6-2

Page 30

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Display Board HTR Heart Rate Flow Chart

1. Configuration

Display Board

Heart Rate

Signal

HTR Handlebar

(left)

HTR Board

HTR Handlebar

Signal

HTR Handlebar

Signal

2-7-1

POLAR Receiver

HTR Handlebar

(Right)

POLAR

Transmitter

Page 31

2.HTR Operation

Name Operation

HTR HANDLE BAR 1. Put both hands on the HTR handlebar. The user’s pulse signal travels

HTR Board 1. The HTR board translates the pulse into the heart rate signal.

Display Board

3. POLAR Heart Rate Operation

Name Operation

POLAR Heart Rate

Transmitter

Heart Rate Receiver 1.The receiver receives the heart rate signal.

Display Board

SPORTS ART INDUSTRIAL CO., LTD.

from the HANDLE BAR to the HTR small board.

2. The HTR board indicator lights, showing the heart rate. Please refer to

the HTR explanation.

1.The heart rate signal is read by the program.

2.The display PULSE window shows the pulse value.

1.The heart rate transmitter senses the pulse signal.

2.The transmitter sends the pulse signal to the receiver.

2. The receiver sends the signal through the 3-pin cable to the display

board.

1. The CPU determines the heart rate value.

2. The display PULSE window shows the heart rate value.

2-7-2

Page 32

SPORTS ART INDUSTRIAL CO., LTD.

4. HTR Operation Procedure

Step Operation

1 Hold onto the handlebar

2 HTR small board D4 indicator lights; D5 and D6 indicators continue to flash.

3 The PULSE window shows the HR value within about 10 seconds.

4 Take your hand off the handlebar; within about 5 minutes, the PULSE window

shows the base display with no HR value.

5.POLAR Operation

Step Operation

1 Put POLAR strap in place; Don’t hold onto the HTR handlebar.

2 Stand on the treadmill.

3 The PULSE window signal lights and the heart rate value appears.

2-7-3

Page 33

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150 STOP Switch Flow Chart

1. Configuration

Display Board

Motor Stop

Signal

Drive Board Motor

STOP

Switch

Motor Speed

Signal

Motor

Voltage

2 pin

2-8-1

Page 34

2. Operation

Order Part Name Operation

1 STOP Switch

2 Display Board

3 Drive Board

4 Motor

3. Operation Procedure

Step Operation

SPORTS ART INDUSTRIAL CO., LTD.

1. Hit the STOP pad.

2. STOP switch operates, sending its signal to the display board.

1. The display board sends the STOP signal to the CPU for determination.

2. When the display detects the STOP switch operation, SPEED window

shows “0.0” (flashing); Other windows remain unchanged with memory

preserved.

3. The CPU sends the motor stop signal to the drive board.

1. After receiving the motor stop signal, the drive board stops emitting the

motor drive voltage.

1. Once the motor doesn’t have power from the drive board, it stops

operating.

1

2 1. Press the display left or right STOP switch; the display board SPEED window shows

3 1. Motor stops operating.

1. Press SPEED<▲>; The motor operates.

“0.00” (flashing).

2. Other windows remain unchanged with memory preserved.

2-8-2

Page 35

SPORTS ART INDUSTRIAL CO., LTD.

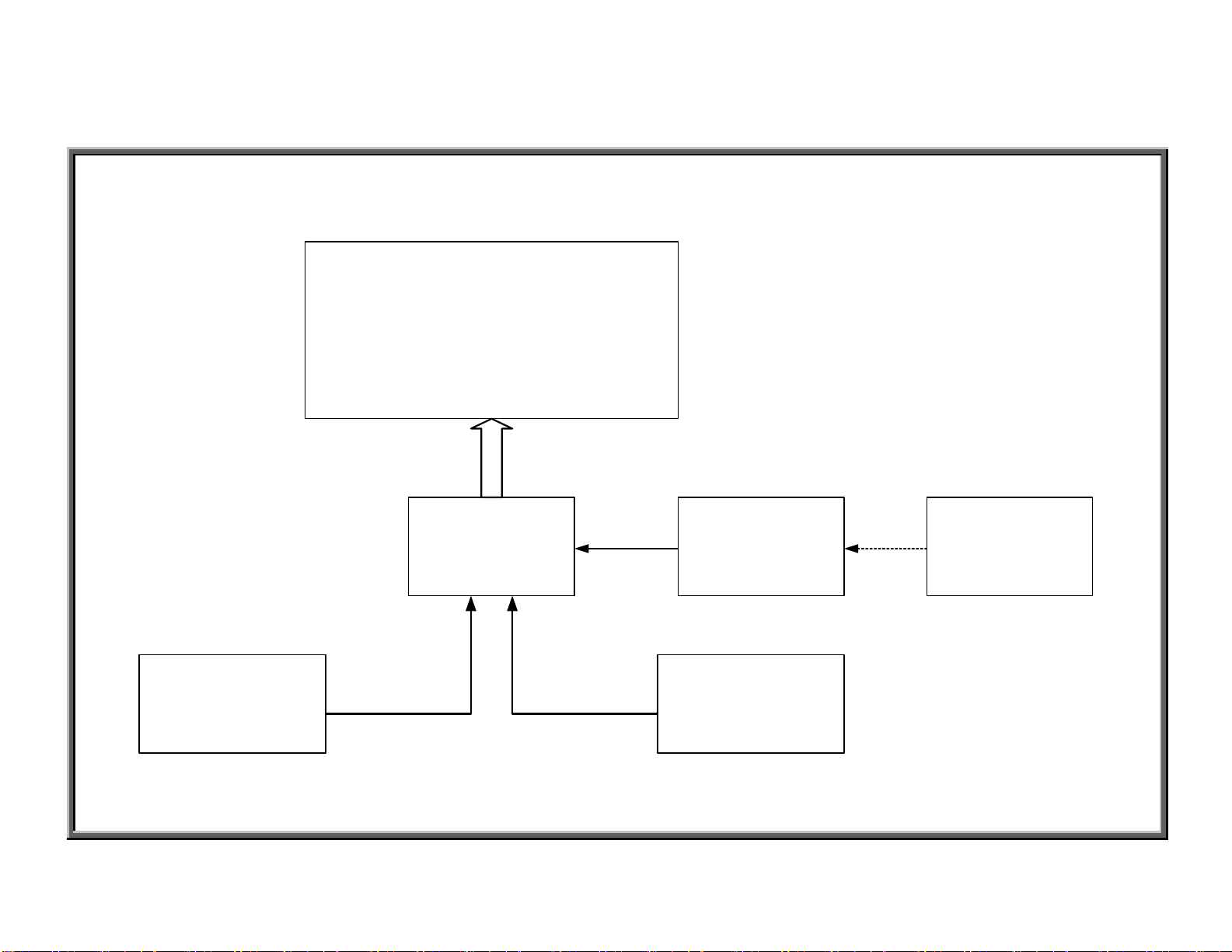

6150/E/6100/E Incline Function Protection Flow Chart

1. Configuration

INC UP,DN

Display Board

Incline VR

Voltage

LIMIT Signal

16 PIN

Drive

Board

Incline Up/Down

Signal

Off After Action

UP

DOWN

ERR

Incline

Motor

Voltage

Incline

LIMITSignal

Incline VR

Voltage

Soft Key

Incline

Motor

Incline

LIMIT

Switch

Incline VR

Set

2-9-1

Page 36

2. Operation

2-1. Incline action activates the incline protection function.

Order Name Operation

SPORTS ART INDUSTRIAL CO., LTD.

1 Soft keys

2 Display board 1. Display board CPU sends the incline up/down signal to the drive board, thus controlling

3 Drive board 1. The drive board incline circuit operates according to the display board incline signal.

4 Incline VR set 1. When the incline gears turn, the VR turns, and the VR value increases or decreases.

5 LIMIT 1. When the incline motor range exceeds the VR value range, the gears in the incline VR set

6 Drive board 1. The incline LIMIT signal enters the drive board for processing; If the LIMIT switch

7 Display board 1. The display board senses the LIMIT signal action, stopping incline signal action.

1. Pressing INCL<▲> or INCL<▼> key causes incline action.

incline action.

2. The signal travels the 16-PIN cable from the control to display board.

2. By changing the output voltage polarity, the drive board makes the DC incline motor turn

clockwise or counterclockwise.

3. When in up incline action, the drive board UP signal lights.

4. When in down incline action, the drive board DOWN indicator lights.

2. The VR uses the VR value voltage to determine incline position.

hit the LIMIT switch.

2. A broken LIMIT switch circuit means that the incline height range has been exceeded.

circuit is short (normal), the ERR light doesn’t light; If the LIMIT switch circuit is broken

(abnormal), the ERR indicator lights.

2. During incline operation, if the ERR indicator lights, incline action immediately stops.

3. The incline VR value enters the drive board through the VR wire.

4. The incline LIMIT signal and VR value travel the 16-PIN cable to the display board.

2. The display board INCL window shows height at the time of LIMIT action.

2-9-2

Page 37

SPORTS ART INDUSTRIAL CO., LTD.

2-2. Drive board

Order Name Operation

1 Incline LIMIT 1. When incline height exceeds the range, the LIMIT switch operates (broken

2 Drive Board 1. The drive board detects LIMIT signal operation, and ERR indicator lights.

3 Display board 1. When the display board senses LIMIT signal operation, the program

ERR indicator lights, incline protection function acts

circuit).

2. The LIMIT signal travels the incline cable to the drive board.

2. The signal travels the 16-pin cable to the display board.

implements incline protection.

2. When incline protection is activated, only one direction will operate when

incline keys are pressed.

3. Once the LIMIT signal is not activated, incline action resumes.

2-9-3

Page 38

SPORTS ART INDUSTRIAL CO., LTD.

1. Operation

3-1. Activating incline protection during incline operation

Step Operation

1

2

3 Drive board ERR indicator lights, incline action immediately stops.

4 Display board INCL window shows actual incline position.

3-2. Activating incline protection after the drive board ERR indicator lights

Step Operation

1 Incline LIMIT signal is broken (LIMIT yellow wire connection removed))

2 Drive board ERR indicator lights.

3

4 The drive board UP or DN indicator lights; Incline operates.

5 Reconnect the LIMIT yellow switch; The drive board ERR indicator doesn’t light.

6

Press INCL<▲> or INCL<▼> key; Incline up or down operates.

Before incline action stops, the incline LIMIT switch signal operates (LIMIT yellow wire

connection removed)

Press display INCL<▲> or INCL<▼> key; Incline window numerical values only change in one

direction.

Press INCL<▲> or INCL<▼> key; The incline window operates normally, with incline values

increasing or decreasing.

2-9-4

Page 39

6100/E/6150/E

3. Error Message Definitions

SPORTS ART INDUSTRIAL CO., LTD.

Page 40

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Error Message Definition:ERR 1

Definition

2. Configuration

(220V only)

: Display board CPU has not received the optic sensor signal.

Display Board

Inductor

Optic Sensor

Signal

Drive Board

Motor Speed

Signal

16 -PIN Cable

Transformer

Voltage

Motor Voltage

2-pin cable

Optic Sensor

Signal

4-pin cable

Tachomete

Motor

& Optic

Sensor

Transformer

3-1-1

Page 41

SPORTS ART INDUSTRIAL CO., LTD.

3. Explanation for ERR1

1. Motor doesn’t operate; ERR1 appears.

1-1. Explanation:

Drive board has not sent power to the motor, so the motor doesn’t operate; the optic

sensor signal hasn’t returned to the display board.

2-1. Configuration

Display

Board

Motor Speed

Cable

16-pin

Signal

Motor Voltage

Inductor

(220V only)

2-pin Cable

Drive Board Motor

Transformer

Voltage

Transformer

4-pin Cable

3-1-2

Page 42

1-3. Operation:

SPORTS ART INDUSTRIAL CO., LTD.

Order

1 Display

2 Inductor (220V) 2. After inducting drive board AC voltage, the inductor sends VH voltage to

3 Transformer 1. Provides the motor drive circuit with all power.

4 16-pin cable Transfers display board signals to the drive board.

5 Drive Board

6 Motor

Component Troubleshooting

1. Press SPEED key; Display SPEED window shows “0.0”

2. The display board CPU sends the motor signal to the drive board, thereby

controlling motor speed.

1. 220V units only

the drive board motor circuit.

After processing the motor speed signal, the drive board provides power to

the motor, making the motor operate.

Operates according to power from the drive board, making the motor turn,

which makes the treadmill belt turn.

1-4. Error Message Simulation

Order Operation

1

2

3 Motor doesn’t rotate.

4 “ERR:1” appears on the display.

Don’t turn on the power. Remove motor M+, M- wire connections.

Turn on power. Press SPEED<▲> or <▼> key; display board shows “0.1”MPH or “0.2” KPH.

1-5. Circumstances of Malfunction

(1) Press SPEED<

▲> or <▼> key; the treadmill belt doesn’t move; “ERR:1” appears on the

display.

3-1-3

Page 43

SPORTS ART INDUSTRIAL CO., LTD.

1-6. Troubleshooting

Order Component Troubleshooting

1 Display Board

2 16-pin cable 1. Test the cable by replacing it and seeing if that helps.

3 Inductor 1. Reconnect inductor wiring.

4 Transformer

5 Drive Board

6 Motor

1. Press firmly on the display board program IC.

2. Inspect the 16-pin cable connections.

1. Inspect the transformer wiring connections.

2. Test transformer voltage.

1. Inspect the drive board wire connections.

2. Place multi-meter probes on the drive board M+,M- ends; press the SPEED

key; there should be some voltage.

3. If there is no voltage, the drive board is bad or the display board signal,

which travels the 16-pin cable, is in question.

1. If the drive board motor voltage is OK and the motor doesn’t operate, the

motor is bad.

2. Inspect the motor M+, M- terminals for a broken circuit.

3. Inspect the motor wire connections.

4. Inspect the motor brushes.

3-1-4

Page 44

SPORTS ART INDUSTRIAL CO., LTD.

3. Reason for ERR1

2. Motor operates; ERR1 appears

2-1. Explanation:

The motor operates; the optic sensor signal didn’t reach the display board CPU; ERR 1 appears.

2-1. Configuration

Optic Sensor

Signal

Drive Board

Display

16 pin

Optic Sensor

Signal

4 pin

Motor

Optic Wheel

Optic Sensor

3-1-5

Page 45

SPORTS ART INDUSTRIAL CO., LTD.

2-3. Operation

Order Component Troubleshooting

1 Motor 1. The motor operates after the SPEED key is pressed.

2

3 4-pin Cable 1. The optic sensor signal travels the 4-pin cable to the display board.

4 Drive Board

5 16-pin Cable The optic sensor signal travels the 16-pin cable to the display board.

6 Display Board

Tachometer &

Optic Sensor

2-4. Error Message Simulation

Order Operation

1 Don’t turn on power. Remove optic sensor wire connections.

1. Motor operation rotates the tachometer.

2. The optic sensor senses the tachometer rotation speed.

1. After processing the optic sensor signal, the drive board CLK indicator

lights.

2. The drive board sends the optic sensor signal to the display board.

1. The CPU reads the optic sensor signal and emits the motor speed signal.

2. If the CPU doesn’t read the optic sensor sign al, t he ERR1 message appear s

and the motor speed signal isn’t sent to the drive board.

Turn on power. Press SPEED<▲> or <▼> key. The display board shows “0.1” MPH or “0.2”

2

KPH.

3 Motor speed surges.

4 Drive board CLK indicator doesn’t light.

5 Display board immediately shows “ERR:1.” Motor stops operating.

3-1-6

Page 46

SPORTS ART INDUSTRIAL CO., LTD.

2-5. Circumstance of Malfunction

(1) Press SPEED <

(2) Press SPEED <

▲> or <▼> key; motor speed surges; display shows “ERR:1”.

▲> or <▼> key; motor operates; display shows “ERR1:1”.

2-6. Troubleshooting

Order Component Troubleshooting

1 Motor 1. After pressing the SPEED key, inspect whether the motor rotates.

1. Inspect whether the optic wheel is fastened securely and placed in the

center of the optic sensor.

2

3

4 Drive Board

5 16-pin Cable 1. Test by replacing the 16-pin cable with one known to work properly.

6 Display Board

Optic Wheel &

Optic Sensor

Optic Sensor

Cable (4PIN)

2. Inspect whether the optic wheel teeth are broken or bent.

3. Inspect whether the optic sensor has been hit or damaged.

4. Inspect the optic sensor output: When rotating, the drive board CLK

indicator flashes or remains lit.

1. Test the optic sensor wire for continuity.

2. Test by replacing the optic sensor 4-pin cable.

1. Check the CLK light: When the motor rotates, the CLK indicator flashes or

remains lit.

2. Inspect the 16-pin cable and optic sensor cable connections.

1. Inspect the 16-pin cable connection.

2. Press firmly on the motor program IC.

3-1-7

Page 47

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Error Message Definition: ERR 3

1. Definition: The optic sensor speed signal and the speed setting differ too much,

so ERR3 appears.

2. Configuration

Large Resistor

Display Board

Optic Sensor Signal

FUSE

16 PIN

Drive Board

Motor Speed Signal

Motor Voltage

Motor

Optic Sensor

Signal

Optic Sensor

3-2-1

Page 48

3. Reason for ERR3

1. Receiving an ERR3 message when the incline is high

1-1. Explanation

2-1. Configuration

SPORTS ART INDUSTRIAL CO., LTD.

(1) When the incline is at or above 7%, the walk board slope is steep, and the walk belt

builds up momentum. Walk belt speed increases. The optic sensor detects the speed increase.

(2) Detecting the faster optic sensor speed, the drive board produces resistance, making

the belt speed return to normal.

(3) If the drive board resistance doesn’t take effect, the treadmill belt speeds up, and the

display shows ERR3.

Display Board

Large

Capacitor

Optic Sensor Signal

FUSE

Drive Board

Motor Speed Signal

16 PIN

Motor Voltage

Motor

Optic Sensor

Signal

Optic Sensor

3-2-2

Page 49

1-3. Operation

Order Part Troubleshooting

1 Display 1. Display CPU emits the motor signal to the drive board, thus controlling motor speed.

2 16-pin Cable 1. Display signal travels the 16-pin cable to the drive board.

3 Drive Board

4 Resistor

5 Motor

6 Optic Sensor

7 Drive Board 1. The drive board processes the optic sensor signal and its CLK indicator lights.

8 16-pin Cable

9 Display Board

SPORTS ART INDUSTRIAL CO., LTD.

1. After processing the motor signal, the drive board emits voltage to the motor, making

the motor rotate.

2. If the motor speed quickens because of momentum (the optic sensor signal speeds up),

the resistance circuit operates, making the motor speed slow down.

1. The drive board resistance circuit operates through the resistor to produce motor

resistance.

1. The motor operates according to the drive board voltage emission, causing treadmill belt

rotation.

2. Drive board resistance circuit operation makes the walk belt speed slow down.

1. The optic sensor sends its signal, detected from the tachometer wheel movement, to the

drive board.

1. The drive board sends the optic sensor signal to the display board through the 16-pin

cable.

1. The CPU reads the optic sensor signal.

2. If the optic sensor signal and the actual speed differ too much, ERR3 appears.

1-4. Error Message Simulation

Order Operation

1 Don’t turn on the power. Remove the large resistor wires on the drive board.

2

Turn on the power. Press INCLINE<▲> key to 15%; the incline operates to the 15% position.

3 Press the SPEED key; the motor starts operating.

4 Run on the walk belt.

5 The display board immediately shows ERR3.

3-2-3

Page 50

SPORTS ART INDUSTRIAL CO., LTD.

1-5. Circumstance of the Error

(1) Press SPEED<

▲> key; after the motor operates, run on the walk belt; speed

increases; “ERR3” appears.

1-6. Troubleshooting

Order Part Troubleshooting

1. Inspect the large capacitor fuse. 220V units: 5A; 110V units: 10A.

1 Large Resistor

2 Drive Board 1. Replace the drive board.

2. Inspect the drive board R, R connections.

3. Test whether the large resistor circuit is broken. 220V units: 5 Ohms; 110V

units: 1.5 Ohms.

3-2-4

Page 51

SPORTS ART INDUSTRIAL CO., LTD.

3. Reason for ERR3

2. After the motor operates, ERR3 immediately appears.

2-1.

(1) After the order operates, the optic sensor signal goes to the display board; the CPU

reads the motor signal.

(2) If the optic sensor signal and the SPEED window signal differ too much, ERR3 appears.

2-1. Configuration

Display Board

Optic Sensor

Signal

Drive Board

Motor Speed

16 pin

Signal

CLK燈

Motor Voltage

2PIN

Optic Sensor Signal

n

i

p

4

3-2-5

Motor

Tach Wheel,

Optic Sensor

Page 52

2-3. Operation

Order Part Troubleshooting

1 Display Board 1. The motor speed signal is sent to the drive board.

2 Drive Board

3 Motor 1. The motor operates according to the drive board motor voltage.

4 Optic Sensor

5 Optic Sensor Cable 1. The optic sensor signal travels the optic sensor cable to the drive board.

6 Drive Board

7 16-pin Cable 1. The optic sensor signal travels the 16-pin cable to the display board.

6 Display Board

SPORTS ART INDUSTRIAL CO., LTD.

1. The drive board supplies voltage for the motor.

2. After the optic sensor signal arrives at the drive board, the drive board adjusts power

output.

1. Once the tachometer wheel rotates, the optic sensor transmits its signal to the drive

board.

1. After processing the drive board signal, the drive board CLK indicator lights.

2. The drive board adjusts voltage output to the motor according to the optic sensor signal.

1. The CPU reads the optic sensor signal and emits a motor speed signal.

2. If the CPU optic sensor signal and SPEED window speed setting differ too much, ERR3

appears.

2-4. Error Message Simulation

Order Operation

1

Turn on power; Press SPEED<▲> key; Display shows “0.1” MPH or “0.2” KPH.

2 The treadmill belt speeds up.

3 Drive board CLK indicator flashes or remains lit.

4 The display board immediately shows “ERR3”; motor stops operating.

3-2-6

Page 53

SPORTS ART INDUSTRIAL CO., LTD.

2-5. Circumstance of Error

(1) Press SPEED<

▲> key; Don’t stand on the treadmill; Display immediately shows

“ERR3”.

(2) Press SPEED<

▲> key; The treadmill belt moves; Display immediately shows “ERR3”.

2-6. Troubleshooting

Order Part Troubleshooting

1. Press firmly on the motor program.

1 Display Board

2

3 Motor 1. Inspect the motor or test it by replacing it with another.

4 Drive Board

Optic Wheel;

Optic Sensor

2. Inspect the 16-pin cable connection.

3. Replace the motor program IC with a new motor program IC.

1. Inspect whether the optic wheel fastened tightly and rotates in the middle

of the optic sensor.

2. Inspect whether the optic wheel teeth are missing.

3. Replace optic sensor.

1. Inspect the 16-pin cable connections; Inspect the optic sensor cable

connections.

2. Test the drive board by replacing it.

3-2-7

Page 54

SPORTS ART INDUSTRIAL CO., LTD.

3. Reason for ERR 3

3. While the motor is in operation, ERR 3 appears occasionally.

3-1. Explanation:

(1) After the motor moves, the optic sensor sends its signal to the display board, and the

CPU reads the signal.

(2) If the optic sensor signal and SPEED window signal differ too much, ERR3 appears.

(3) If the CPU receives environmental interference and cannot read the optic sensor

signal, ERR3 appears.

3-2. Configuration

Display Board

Large

Capacitor

Optic Sensor Signal

FUSE

3-2-8

16 PIN

Drive Board

Motor Speed Signal

Motor Voltage

Motor

Optic Sensor

Signal

Optic Sensor

Page 55

SPORTS ART INDUSTRIAL CO., LTD.

3-3. Operation

Order Part Troubleshooting

1 Display Board 1. The motor speed signal is sent to the drive board.

1. The drive board supplies voltage for the motor.

2 Drive Board

3 Motor 1. The motor operates according to the drive board motor voltage.

4 Optic Sensor 1. Once the optic wheel rotates, the optic sensor transmits its signal to the drive board.

5 Optic Sensor Cable 1. The optic sensor signal travels the optic sensor cable to the drive board.

6 Drive Board

7 16-pin Cable 1. The optic sensor signal travels the 16-pin cable to the display board.

6 Display Board

3-4. Error Message Simulation

Order Operation

1

Turn on the power; Press SPEED<▲> or<▼> key; Display shows “0.1” MPH or “0.2” KPH.

2 Walk on the walk belt; Pull the belt speed faster than the setting speed.

3 Drive board CLK indicator flashes or remains lit.

4 Display board immediately shows “ERR3”; Motor stops operating.

2. After the optic sensor signal arrives at the drive board, the drive board adjusts power

output.

1. After processing the drive board signal, the drive board CLK indicator lights.

2. The drive board adjusts voltage output to the motor according to the optic sensor signal.

1. The CPU reads the optic sensor signal and emits a motor speed signal.

2. If the CPU optic sensor signal and SPEED window speed setting differ too much, ERR3

appears.

3-2-9

Page 56

SPORTS ART INDUSTRIAL CO., LTD.

3-5. Circumstance of Malfunction

(1) Press SPEED <

▲> key. Motor operates for some time. Then ERR3 appears on the display.

3-6. Troubleshooting

Order Part Troubleshooting

1. Reinsert motor IC.

1 Display Board

2

Optic Wheel

Optic Sensor

2. Inspect the 16-pin cable and its connections.

3. Replace motor program with one of a newer version.

1. Inspect whether the optic wheel is screwed in securely and rotating in the

middle of the optic sensor.

2. Test the optic sensor by replacing it with another and checking whether the

problem is resolved.

3-2-10

Page 57

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Error Message:ERR 6

1. Definition

In the midst of incline action, the display board CPU didn’t read the VR value, so ERR6 appears.

2. Configuration

Transformer

Transformer

Voltage

Incline VR

and Limit

Signal

Display Board

16 PIN

Drive

Board

Incline UP, DN

Incline Up/Down

Signal

UP

DOWN

ERR

FUSE

Incline Motor

Voltage

Incline Limit Signal

Incline VR Signal

Keys

Incline

Motor

Incline

LIMIT Switch

Incline VR

3-3-1

Page 58

3. Reason for ERR6

1. Press incline up/down key; incline doesn’t operate; ERR6 appears.

1-1. (1) Press incline up or down keys; Drive board UP or DN indicator lights; Incline up/down

SPORTS ART INDUSTRIAL CO., LTD.

operates; The incline VR value changes.

(2) The display board CPU reads the incline VR value. If there’s no voltage variation,

the incline motor isn’t operating; ERR6 appears.

2-1. Configuration

Transformer

Transformer

Voltage

Display Board

Incline VR

and Limit

Signal

16 PIN

Drive

Board

Incline UP, DN

Incline Up/Down

Signal

UP

DOWN

ERR

FUSE

Incline Motor

Voltage

Incline Limit Signal

Incline VR Signal

Keys

Incline

Motor

Incline

LIMIT Switch

3-3-2

Incline VR

Page 59

1-3. Operation

Order Part Operation

SPORTS ART INDUSTRIAL CO., LTD.

1 Display Board

2 16-pin Cable 1. The display incline signal travels the 16-pin cable to the drive board.

3 Transformer 1. The transformer provides power to the drive board incline motor circuit.

4

6 Incline Motor

Drive Board

(ERR LED)

1. Press INCL<▲> or INCL<▼> key; Incline window shows incline value.

2. CPU sends the incline up/down signal to the drive board.

1. Press INCL<▲> key; Drive board UP LED lights; Press INCL<▼>key;

the drive board DN LED lights.

2. When the UP LED lights, the drive board drive circuit emits positive

voltage, making for up incline action.

3. When the DN LED lights, the drive board drive circuit emits negative

voltage, making for down incline action.

1. When the drive board UP LED lights, the incline motor operates up.

2. When the drive board DN LED lights, the incline motor operates down.

1-4. Error Message Simulation

Order Operation

1 Don’t turn on power. Remove the incline fuse.

2

3 Drive board UP or DN indicator lights.

4 Incline doesn’t operate.

5 Display board shows ERR6.

Turn on power. Press INCLINE<▲> or INCLINE<▼> key.

1-5. Circumstances of the Malfunction

(1) Press INCLINE<▲> key; Incline motor doesn’t operate; Display immediately shows ERR6.

(2) Press INCLINE<▼> key; Incline motor doesn’t operate; Display immediately shows ERR6.

3-3-3

Page 60

SPORTS ART INDUSTRIAL CO., LTD.

(3) Press INCLINE<▲> or <▼> key; The incline sounds strange; ERR6 appears.

(4) Press INCLINE<▲> or <▼> key; The incline fuse breaks, ERR6 appears.

1-6. Troubleshooting

Order Part Troubleshooting

1 Display Board

2 16-pin Cable

3 Transformer 1. Inspect whether the transformer voltage (orange) is AC 27V.

4

5

6 Incline Fuse 1. Inspect whether the fuse is broken; Replace it if broken.

7 Incline Motor

Drive Board

(ERR lights)

Drive Board

(ERR doesn’t

light)

1. Press incline <▲> key; Drive board UP indicator lights.

2. Press incline <▼> key; Drive board DN indicator lights.

3. If not as above, press down on the display CPU or inspect the cable.

1. Inspect the 16-PIN cable connection.

2. Test the cable by replacing it.

1. Inspect whether the ERR indicator is lit.

2. Press incline up or down key to make the incline return to normal position.

3. If ERR6 still appears, adjust the incline VR set to base level.

1. Press INCL<▲ >/<▼> key; Inspect whether the drive board UP/DN

indicator lights.

2. When the drive board UP or DN indicator lights, test the incline motor

terminals for voltage.

1. Inspect whether the incline motor is stuck.

2. Inspect whether the incline motor gear is broken.

3. Test whether the incline motor circuit is broken.

4. Readjust the incline VR.

3-3-4

Page 61

3. Reasons for ERR6

1. Press the Incline Up/Down key; Incline operates, ERR6 appears.

1-1. Explanation:

(1) Press incline up or down key; After incline operates, the incline VR value signal is sent to

the display board.

(2) Display board CPU reads the incline VR value. If the VR value and the setting value differ,

ERR6 appears.

SPORTS ART INDUSTRIAL CO., LTD.

2-1. Configuration

Incline VR

Voltage

LIMIT Signal

Display Board

16 PIN

Drive

Board

INCL UP,DN

Incline Up/Down

Signal

UP

DOWN

ERR

Incline Motor

Voltage

FUSE

Incline LIMIT

Signal

Incline VR

Voltage

Soft Keys

Incline

Motor

Incline

LIMIT Switch

Incline VR

Set

3-3-5

Page 62

SPORTS ART INDUSTRIAL CO., LTD.

1-3. Operation

Order Part Operation

1 Display Board

2 16-pin Cable 1. The display board incline signal travels the 16-pin cable to the drive board.

3

4 Incline Motor

5 Incline LIMIT

6 Incline VR

7 Drive Board 1. The drive board sends the incline VR value to the display board.

8 16-pin Cable 1. The incline VR value travels the 16-pin cable from the drive board to the display board.

9 Display Board

Drive Board

(ERR lights)

1. Press INCL<▲> or INCL<▼> key; The incline window shows the incline value.

2. The CPU sends the incline up/down signal to the drive board.

1. Press INCL<▲> key; Drive board UP indicator lights; Press INCL<▼> key; Driv e board

DN indicator lights.

2. When the UP indicator lights, the drive board drive circuit emits positive voltage,

making the incline operate up.

3. When the DN indicator lights, the drive board drive circuit emits negative voltage,

making the incline operate down.

1. When the drive board UP indicator lights, the incline motor operates up.

2. When the drive board DN indicator lights, the incline motor operates down.

1. When the LIMIT switch operates, the drive board ERR indicator lights; When the

LIMIT switch doesn’t operate, the drive board ERR indicator doesn’t light.

2. When the incline is from 0-15%, the indicator normally doesn’t light. If it does light, the

incline range has been exceeded. Adjust the incline set.

1.Incline up or down action makes the VR value change.

2. At 0% incline, the VR value voltage is 3.55V (green-blue wire).

1. The CPU reads the VR value. At 0% incline, the VR voltage is 3.55V; At 15% incline,

the voltage is 1.20V.

1-4. Error Message Simulation

Order Operation

1 Remove the incline VR set without tightening down the incline set.

2

Turn on the power. Press INCLINE<▲> or INCLINE<▼> key .

3 Drive board UP or DN indicator lights.

4 Incline operates up or down.

5 ERR6 immediately appears.

3-3-6

Page 63

SPORTS ART INDUSTRIAL CO., LTD.

1-5. Circumstance of Malfunction

(1) Press INCLINE<▲> key; Incline motor operates halfway; ERR6 appears.

(2) Press INCLINE<▼> key; Incline motor operates halfway; ERR6 appears.

1-6. Troubleshooting

Order Part Troubleshooting

1 Display Board

2 16-pin Cable 1. Test by replacing the 16-pin cable.

3 Drive Board

4 Incline Motor

5

6 Incline VR Set

7 Incline Fuse 1. Inspect whether the incline fuse has broken. Replace it if necessary.

8 Incline Motor

Incline LIMIT

Switch

1. Press on the main program.

2. Inspect the 16-PIN cable connection.

1. Press display INCL<▲>/<▼> key; Inspect whether the drive board UP/DN indicator

lights.

2. When UP or DN indicators are lit, test whether incline motor terminals have voltage.

3. If ERR indicator lights, adjust the incline set to the base position.

1. Inspect whether the incline motor is stuck.

2. Inspect whether the incline motor internal gears are broken.

3. Inspect whether the incline motor is broken.

1. Inspect whether at 0-15% position the ERR indicator lights.

2. If the ERR indicator lights at the 0-15% position, readjust the incline set to the base

position.

1. Inspect the incline VR wire connection.

2. Inspect whether the incline VR wire voltage at 0% = 3.55V; at 15% =1.20V.

1. Inspect whether the incline motor is stuck.

2. Inspect whether the incline gear is broken.

3. Test whether the motor has a broken circuit.

4. Readjust the incline VR and incline motor.

3-3-7

Page 64

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Error Message:ERR 7

1. Definition: The display board didn’t sense the incline VR value or the value exceeds the normal

range, so “ERR7” appears.

2. Configuration

Incline VR

Value

Display Board

Drive Board

Incline

Motor

Incline

LIMIT Switch

Incline VR

Voltage

Incline VR

Set

3-4-1

Page 65

SPORTS ART INDUSTRIAL CO., LTD.

3. Reason for ERR 7

1. Incline VR Value Exceeds Normal Range, so ERR7 appears.

1-1. Explanation:

(1) The incline operation error makes the VR value exceed the range.

(2) After turning on unit, the display board detects the VR voltage exceeds the range; ERR7 appears.

1-2. Configuration

Display Board

Incline VR

Voltage

Incline

Motor

Drive Board

Incline VR

Voltage

Incline

LIMIT Switch

Incline VR

Set

3-4-2

Page 66

1-3. Operation:

Order Part Operation

1 Incline VR

2 Drive Board 1. The drive board sends the incline VR value to the display board.

3 Display Board

SPORTS ART INDUSTRIAL CO., LTD.

1. Incline operation changes the VR value.

2. The incline VR value travels the incline VR cable to the drive board.

1. After turning on the unit, inspect the incline VR voltage.

2. If the VR voltage exceeds the normal range or is undetected, ERR7 appears.

1-4. Error Message Simulation

Order Operation

1 Turn on power; Remove the drive board up incline wire.

2 Turn on the power.

3 The display board shows “ERR7”.

1-5. Circumstances of the Malfunction

(1) Turn on power; ERR7 hmmediately appears on the display.

1-6. Troubleshooting

Order Part Troubleshooting

1. Test whether VR voltage exceeds the normal range.

1 Incline VR

2 Display Board 1. Replace the display board U12 and ADC0804.

2. If the VR value exceeds the normal range, readjust the incline motor and

VR set to base level.

3-4-3

Page 67

SPORTS ART INDUSTRIAL CO., LTD.

2. VR Signal Circuit is Broken; ERR7 Appears

2-1. Explanation:

(1) Incline VR signal is broken, so the display CPU doesn’t detect the VR signal, so

“ERR 7” appears.

2-2. Configuration

Display Board

Incline VR

Voltage

Incline

Motor

Drive Board

Incline VR

Voltage

Incline

LIMIT Switch

Incline VR

Set

3-4-4

Page 68

2-3. Operation:

Order Part Operation

1 Incline VR

2 Drive Board 1. The drive board sends the incline VR value to the display board.

3 Display Board

SPORTS ART INDUSTRIAL CO., LTD.

1. Incline operation changes the VR voltage value.

2. The incline VR value travels the incline VR cable to the drive board.

1. After turning off the unit, inspect the incline VR voltage.

2. If the VR voltage exceeds the normal range or the value is not detected, ERR7

appears.

2-4. Error Message Simulation

Order Operation

1 Don’t turn on the power. Remove the drive board incline cable.

2 Turn on the power switch.

3 “ERR7” appears on the display.

2-5. Circumstances of Malfunction

(1) Turn on the power. ERR7 immediately appears on the display.

3-4-5

Page 69

SPORTS ART INDUSTRIAL CO., LTD.

2-6. Troubleshooting

Order Part Troubleshooting

1 Incline VR

2 Drive Board 1. Inspect the incline cable and 16-pin cable connections.

3 Cable

4 Display Board

1. Reconnect the incline VR cable.

2. Check whether the incline wire is broken.

1. Inspect the cable connections.

2. Inspect whether the cable is broken or pinched.

3. Test by replacing the cable.

1. Inspect the 16-pin cable connections.

2. Press on the main program IC.

3. Replace U12 ADC0804.

3-4-6

Page 70

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Error Message :ERR 8

1. Definition:

Poor communication between display board CPUs causes ERR 8 to appear.

2. Configuration

Display

U16

Motor Program

Main Program

U2

3-5-1

Page 71

SPORTS ART INDUSTRIAL CO., LTD.

3. Reason for ERR 8

1. Turn on unit; Display board immediately shows ERR 8.

1-1. Explanation:

(1) After turning on the power, display board U2 and U16 read off each other.

(2) If they are unable to read material, ERR 8 appears.

1-2. Configuration

Display

1-3. Operation

Order Part Operation

1 Display Board

U16

Motor Program

1. After turning on the unit, U2 sends its signal to U16; and U16 sends its signal

to U2.

4. If unable to read U16, “ERR 8” appears.

3-5-2

Main Program

U2

Page 72

SPORTS ART INDUSTRIAL CO., LTD.

3. Reason for ERR 8

1. Turn on unit; ERR 8 immediately appears on the display.

1-1. Explanation:

(1) After power is turned on, the display U2 and U16 components read off each other.

(2) If unable to read material, ERR8 appears on the display.

1-2. Configuration

Display

1-3. Operation

Order Part Operation

1 Display Board

U16

Motor Program

1. Turn on the unit. U2 sends its signal to U16; U16 sends information back to

U2.

4. If unable to read U16, ERR8 appears.

3-5-2

Main Program

U2

Page 73

SPORTS ART INDUSTRIAL CO., LTD.

1-4. Error Message Simulation

Order Operation

1 Don’t turn on the power. Don’t put the first pin of U16 into the U16IC.

2 Turn on power.

3 Display shows “ERR8” and emits a beep sound.

1-5. Circumstances of the Malfunction

(1) Turn on the power. The display beeps once and ERR 8 appears.

1-6. Troubleshooting

Order Part Troubleshooting

1. Inspect whether the U16 program IC pins are in place and soldered well.

Re-solder if necessary.

1 Display Board

2. Check whether the U16 program IC pins are in place. Reinsert the IC.

3. Replace the U16 program IC(motor program).

3-5-3

Page 74

SPORTS ART INDUSTRIAL CO., LTD.

2. With the treadmill in operation, ERR8 appears.

2-1. Explanation:

(1) In operation, the display board U2 and U16 ICs read off each other.

(2) If the ICs are unable to read material, ERR8 appears.

(3) Often, if the unit grounding system is poor, there’s too much interference for the CPU to get

a clear signal.

2-2. Configuration

Display Board

2-3. Operation

Order Part Operation

1 Display Board

U16

Motor Program

1. When the motor operates, U2 sends its signal to the U16 motor program.

2. The U16 motor program information is sent to U2.

3. If U2 cannot read material or reads error material from U16, “ERR 8”

appears.

3-5-4

Main Program

U2

Page 75

SPORTS ART INDUSTRIAL CO., LTD.

2-4. Circumstances of Malfunction

(1) Press SPEED key; treadmill motor operates for a while, ERR 8 appears.

2-5. Troubleshooting

Order Part Troubleshooting

1

2 Ground System

Display Board

(Program IC)

1. A program revision 4-20-00 eliminated ERR 8.

2. Replace program with one made after 4-20-00.

1. The power input in the facility must have adequate grounding.

2. Inspect whether the unit is grounded to the facility ground.

3-5-5

Page 76

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Error Message:ERR 9

1. Definition

The treadmill operation distance exceeds its range.

2. Configuration

Display Board

Main CPU Memory

3-6-1

Page 77

SPORTS ART INDUSTRIAL CO., LTD.

3. Reason for ERR 9

1. As soon as the unit is turned on, ERR9 immediately appears.

1-1. Explanation:

(1) CPU stores the treadmill operation distance in the memory.

(2) When the operation distance exceeds the memory capacity, the display shows ERR9.

(3) When ERR 9 appears, clear the mileage from memory.

1-2. Configuration

Display Board

Main CPU Memory

1-3. Operation

Order Part Operation

1 Display Board

1. The CPU calculates the accruing operation DIST value and stores it in

memory.

2. When the operating distance read by the CPU exceeds the memory, the

display shows “ERR9”.

3-6-2

Page 78

SPORTS ART INDUSTRIAL CO., LTD.

A

1-4. Error Message Simulation: No Error Message Simulation

1-5. Circumstances of Malfunction: Turn on power; display board immediately shows “ERR9.”

1-6. Troubleshooting: Run Self-Test to Delete Distance Memory

Run Self-Test to Delete Distance Memory

First, read the instructions below and be ready for action. A pause at the first step will prevent the self-test process from

starting.

1. Turn off the power. Turn on the power. Immediately (while the word “MANU

simultaneously press INCL<▲>+INCL<▼>+<ENTER> keys.

2. The display shows “KM”. Simultaneously press TIME<▲>+TIME<▼>+DIST<▲>+DIST<▼> keys to enter the se lf-test

mode (Figure 1-8).

3. The unit starts a self-test procedure:

(a) The top row of LEDs in the main screen appears, then the second line, then third, etc., until every row of LEDs

has been tested.

(b) Rows of zeroes appear in the LCD displays, then ones, twos, etc., up to nine. An “8” skits across the LCD

windows.

(c) In the main screen, “S3C46 TEST” appears, then “…”, then “OK”.

(d) Next every key is tested. The main screen shows “INCL▲”. Press INCL<▲> key. Then “INCL▼” appears. Press

L” still appears in the LED window)

INCL<▼> key. Press keys as directed through tests on incline, time, distance, speed, race, manual, interval,

and program keys. When the main screen shows “STOP1”, press the left pause/stop pad. When it says

“ENTER”, press the enter key. When it says “STOP2”, press the right pause/stop pad.

(e) The main window shows “Motor Test” then “0.1 MPH” as the motor moves briefly. Then the main window

shows “INCLINE TEST”, then “UP” as the up incline starts operating, then “DOWN” as the down incline starts

operating.

(f) The main window shows ENTER RESET. Pre ss the enter/reset key for three seconds. The self-test process

ends. Zeroes appear on the LCD windows. The LED window shows the usual commands.

4. Turn off the unit. Turn on the unit. If the operation was successful, ERR9 will not appear.

3-6-3

Page 79

SPORTS ART INDUSTRIAL CO., LTD.

6150E Display at Self-Test Prompt

Km appears in main window.

CAL and DISTANCE

CAL 及 DISTANCE

windows

Km

3-6-4

Page 80

SPORTS ART INDUSTRIAL CO., LTD.

1-8. 6150E Display Self-Test Function

1. Press INCL<▲>+INCL<▼

>+<ENTER> keys

simultaneously. The first row

of LEDs lights, then the

second, etc.

3-6-5

Page 81

SPORTS ART INDUSTRIAL CO., LTD.

1-9. 6150E Display: Keypad Operation Test

Keypad Operation Test

shown above. After that,

TIME, CAL,

DISTANCE windows

show “0”, indicating

that distance has been

erased.

3-6-6

Page 82

SPORTS ART INDUSTRIAL CO., LTD.

1. Resolving ERR9 in a 6150 Treadmill

1.1 Cause: When the accumulated distance run exceeds 30,000 miles (48,000 kilometers), ERR9

appears, reminding the user to do maintenance work, replacing the treadmill belt, the drive

belt, etc.

1.2 Response: After carrying out routine maintenance, erase the ERR9 message as follows.

2. How to Erase the ERR9 Message in a 6150 Treadmill

2.1 Turn on POWER.

2.2 Enter the distance mode.

After entering the distance mode, the matrix window

After entering the distance mode, CAL and DISTANCE windows show

accumulated distance.

shows miles or kilometers.

Km

▲▼ ▲▼ ▲▼ ▲▼

◄►◄► ◄► ◄► ◄►

Simultaneously press INCLINE up/down key and the ENTER key.

3-6-7

Page 83

SPORTS ART INDUSTRIAL CO., LTD.

2.2 Erase the Distance Display

After entering the erase distance mode, the matrix display shows from high to low and gradually shows the window value.

▲▼ ▲▼ ▲▼ ▲▼

◄►◄► ◄► ◄► ◄►

……………………..

Simultaneously press TIME up/down key and DISTANCE up/down key (altogether 4 keys) to enter erase distance mode.

2.3 While the display window shows values, turn off the unit power, completing the ERR9 erase process.

3-6-8

Page 84

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Error Message:ERR 10

1. Definition

When the display board detects that the motor is speeding upwards uncontrolled, ERR10 appears.

2. Configuration

Display Board

Optic

Sensor

Signal

16 PIN

Drive Board

Motor Speed Signal

Motor

Voltage

2 pin

Optic

Sensor

Signal

4 pin

Motor

Tachomete

Optic

Sensor

3-7-1

Page 85

SPORTS ART INDUSTRIAL CO., LTD.

3. Reason for ERR10

1. Turn power on; the motor immediately speeds uncontrolled; ERR 10 appears.

1-1. Explanation

The drive board IGBT short-circuited; The drive board immediately sends full power to the motor;

So the motor speeds uncontrolled; “ERR10” appears.

1-2. Configuration

Drive Board

Motor Voltage

2

p

n

i

Motor

1-3. Operation

Order Part Operation

1 Drive Board

2 Motor

1. Turn on power; don’t press SPEED key; d rive board doesn’t send voltage to

the motor.

2. If the drive board IGBT short-circuits, the drive board sends full power to the

motor.

1. The drive board doesn’t send voltage to the motor; the motor doesn’t operate.

2. If the drive board sends full power to the motor, the motor speeds full power;

“ERR10” appears on the display.

3-7-2

Page 86

SPORTS ART INDUSTRIAL CO., LTD.

1-4.Circumstance of Malfunction

(1) Turn on the power. Motor immediately speeds uncontrolled. ERR 10 appears.

1-5. Troubleshooting

Order Part Troubleshooting

1 Drive board

1. Remove connections. Test whether the IGBTs have shorted out.

2. If so , replace them.

3-7-3

Page 87

6100/E/6150/E

4. Measuring and Testing

SPORTS ART INDUSTRIAL CO., LTD.

Page 88

SPORTS ART INDUSTRIAL CO., LTD.

6100/E/6150/E Drive Board Switchmode Power Rectifier Testing

1. Switchmode Power Rectifier Testing

1-1. Test Configuration

1-2. Test Procedur e

(1) Put multimeter to the Ohm setting(

(2) If the multimeter shows 0.4-0.6, the component is normal.

(3) If the multimeter shows 0, the component has a short circuit.

). Place probes as shown.

4-1-1

Page 89

1. Bridge Rectifier Testing

2-1. Test Configuration

Meter 1 Meter 2

SPORTS ART INDUSTRIAL CO., LTD.

2-2. Test Procedure

(1) Put multimeter to the Ohm setting(

(2) Place probes as shown in Meter 1 above. Multimeter should show 0.5-0.8.

(3) Don’t move the black probe. Place red probe on the other pin. The multimeter shows 0.5-0.8.

(4) Place probes as shown in Meter 2 above.

(5) If the meter shows 0, the component has a short circuit.

).

4-1-2

Page 90

SPORTS ART INDUSTRIAL CO., LTD.

1. IGBT and MOSFET Testing

3-1. IGBT (Q11,Q12) and MOSFET (Q13,Q14) Testing

3-2. Test Procedure

(1) Put the multimeter to the Ohm setting(

(2) Place probes as shown above.

(3) If the multimeter shows 0, the component has a short circuit and is malfunctioning.

(4) Cut out the IGBT in question and test again.

(5) Test the MOSFET (Q13,Q14) in the same way.

4-1-3

).

Page 91

SPORTS ART INDUSTRIAL CO., LTD.

1. IGBT and MOSFET Testing

4-1. Test IGBT (Q11,Q12) and MOSFET (Q13,Q14)

4-2. Test Procedure

(1) Put the multimeter to the Ohm setting.

(2) Place probes as shown above.

(3) If the meter shows 0, the component has a short circuit and is malfunctioning.

(4) Cut out the component in question and test it again.

4-1-4

Page 92

SPORTS ART INDUSTRIAL CO., LTD.

5. Circumstances of Malfunction

5-1. Turn on power; Power switch doesn’t light up; Fuse is broken.

5-2. After turning on power, the drive board EMG LED lights; Press SPEED key; The motor doesn’t

operate; ERR1 appears.

4-1-5

Page 93

SPORTS ART INDUSTRIAL CO., LTD.

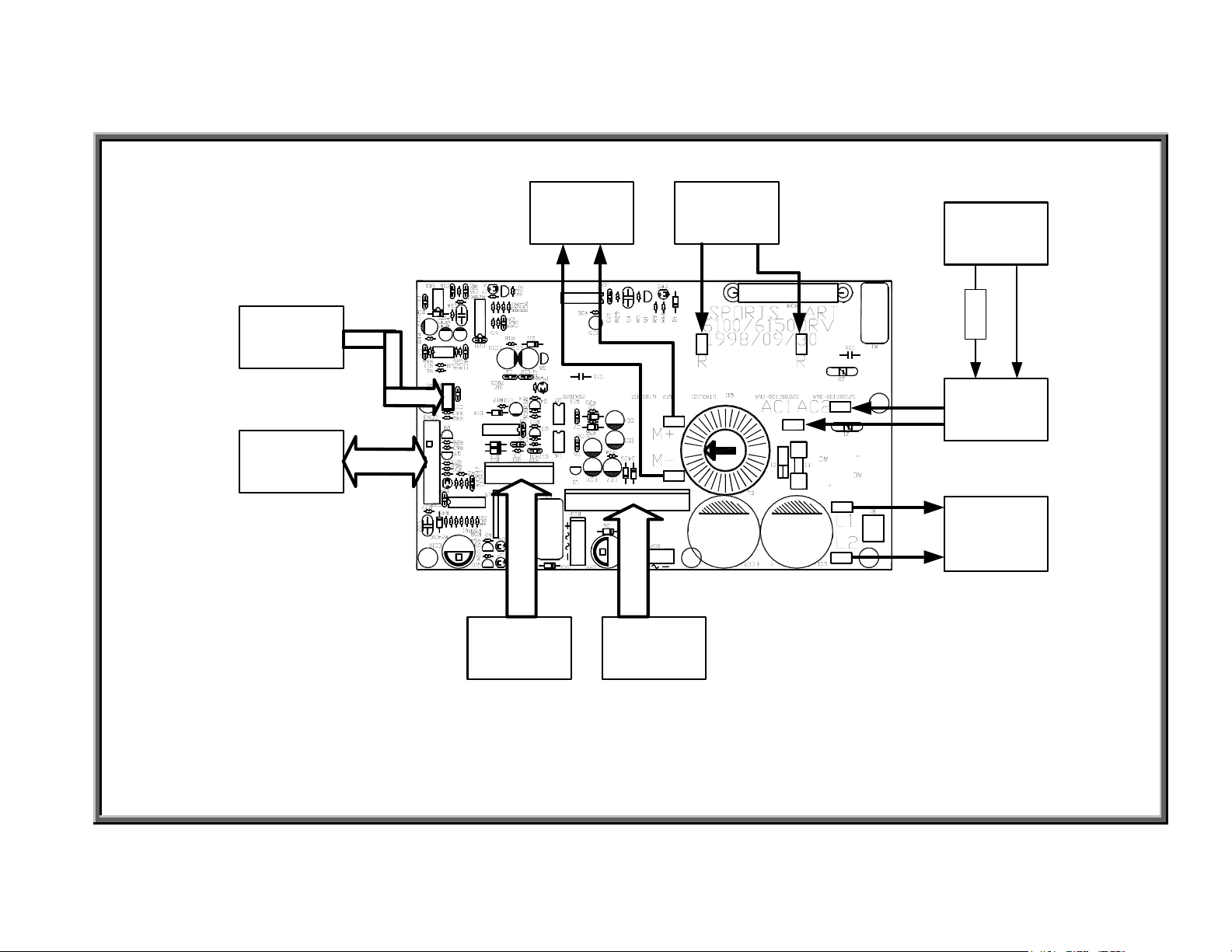

6100/E/6150/E Drive Board Power VCC Test

1. Related Component Positions

POWER

Transformer Connection

AC1AC2

F1

Transformer;

Fuse

4-2-1

Page 94

SPORTS ART INDUSTRIAL CO., LTD.

2. Test Procedure

2-1. Turn on power. Power switch lights. If it doesn’t light, inspect the main fuse.

2-2. If the drive board POWER LED lights, then the board is getting 5VDC on the VCC circuit.

2-3. If the POWER LED is not lit,

(1) Inspect whether power is coming into the board: Put multimeter to the 750 VAC setting.

Place probes on the drive board AC1, AC2 terminals as shown above. The multimeter should show

110V(N. America) or 220V(Europe).

(2) Inspect whether the F1 fuse is broken. Replace the fuse.

(3) Test whether the transformer is putting out voltage.

(4) Remove the 16-PIN cable. If the POWER LED lights, the display board is in question;

inspect the display board.

3. Circumstances of Malfunction

3-1. Turn on power. If the drive board POWER LED doesn’t light, the display board cannot light;

the display will be dark.

4-2-2

Page 95

SPORTS ART INDUSTRIAL CO., LTD.

0

0

6100/E/6150/E Transformer Test Configuration

1. Test Configuration:

YELLOW

ORANGE

10-12V

27-29

WHITE

11-13V

BLACK

11-13V

BLUE-BLUE 22

RED-RED 11

F1

Transformer Fuse

4-3-1

Page 96

SPORTS ART INDUSTRIAL CO., LTD.

2. Test Procedure

2-1. The transformer connects to the CON1 connector on the drive board.

2-2. Put multimeter to the AC 200V setting.

2-3. Turn on power. Place probes as shown in Figure 1.

2-4. Normal voltage: AC 11-13V.

2-5. Test the voltage on the following:

Multimeter

Red Probe Black Probe

BLACK BLACK 11-13V

WHITE WHITE 11-13V

ORANGE ORANGE 27-29V

YELLOW YELLOW 10-12V

3. Circumstances of Malfunction

3-1. Turn on the power. Power switch lights; drive board POWER LED doesn’t light; display doesn’t light.

Voltage Value

3-2. Press SPEED<▲> key; the motor doesn’t operate; the display shows “ERR1.”

3-3. Press INCL<▲> or INCL<▼> key; incline doesn’t operate; ERR6 appears.

4-3-2

Page 97

SPORTS ART INDUSTRIAL CO., LTD.

6100E/6150E Drive Board Incline Motor Voltage Test

1. Test Configuration

RED

BLUE

GREEN

YELLOW

YELLOW

WHITE

GREEN

4-4-1

Page 98

SPORTS ART INDUSTRIAL CO., LTD.

2. Test Procedure

2-1. Put multimeter to the DC 200V setting. Place the red probe into the CON4-WHITE wire PIN;

Place the black probe into the CON4-GREEN wire PIN.

2-2. Turn on power. The display lights up.

2-3. Press INCL<▲> key; Drive board UP LED lights; Multimeter shows +35V or more;

Incline operates up.

2-4. Press INCL<▼> key; Drive board DN LED lights; Multimeter shows -35V or more; Incline operates

down.

2-5. If the multimeter doesn’t get a reading:

(1) Measure the transformer voltage value.

(2) If the transformer has voltage, then the drive board is bad.

3. Circumstance of Malfunction

3-1. Press INCL<▲> or INCL<▼> key; incline doesn’t operate; ERR6 appears on the display.

4-4-2

Page 99

SPORTS ART INDUSTRIAL CO., LTD.

6100E/6150E Drive Board Incline LIMIT Test

1. Test Configuration

BLUE

RED

GREEN

YELLOW

YELLOW

WHITE

GREEN

4-5-1

Page 100

SPORTS ART INDUSTRIAL CO., LTD.

2. Test Procedure

2-1. Put the multimeter to the DC 20V setting. Place probes into the CON4-YELLOW wire PIN.

2-2. Turn on power. The display lights up. Multimeter shows 0.0V.

2-3. Remove the VR set yellow wire. The multimeter shows 5V. Drive board ERR LED lights.

2-4. Re-attach the LIMIT wire. Multimeter shows 0V. Drive board ERR LED lights.

2-5. Press INCL<▲> key until the INCL window shows 15%. Incline operates to 15%. Drive

board ERR LED doesn’t light.

2-6. Press INCL<▼> key until the INCL window shows 0%. Incline operates to 0%. Drive board

ERR LED doesn’t light.

2-7. If operating the incline and the drive board ERR LED lights up:

(1) Calibrate the incline VR set.

(2) Replace the incline VR set.

3. Circumstances of Malfunction

3-1. Drive board ERR LED lights; Incline exceeds 0,15% position or gets stuck.

3-1. Press INCL<▲> or INCL<▼> key. Incline stops midway.

3-2. Press INCL<▲> or INCL<▼> key. Incline display window values change in only one direction.

4-5-2

Loading...

Loading...