Page 1

Title

Wing4TRAX modem hardware OEM user manual

Reference

DSE-WING4TRAX OEM-User Manual v1.4.docx

Author

Pascal DARAGON

Stream

TRAX-Net

Security

Level 1 – Restricted

Version/Revision

1.4

Edition Date

20/07/2016

Status

Final

Version/Revision

Details

Date

Editor

1.0

Initial version

28/04/2016

P. DARAGON

1.1

Minor corrections & add typical design

06/05/2016

P. DARAGON

1.2

Change VDD range & add conformity information

22/06/2016

P. DARAGON

1.3

Conformity declarations upgrades & add LBT + AFA

05/07/2016

P. DARAGON

1.4

Add integration guidelines & product testing

20/07/2016

P. DARAGON

DSE

Revision History

Page 2

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

2 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

INDEX

1 Introduction .............................................................................................................................................................................................. 4

1.1 References .................................................................................................................................................................................................................. 4

1.2 Terms and abbreviations ..................................................................................................................................................................................... 4

1.3 General presentation ............................................................................................................................................................................................. 5

1.4 TRAX-Net at a glance ............................................................................................................................................................................................ 6

1.5 Main features ........................................................................................................................................................................................................... 8

1.6 Pinout definition ..................................................................................................................................................................................................... 9

2 Functional interfaces ........................................................................................................................................................................... 10

2.1 Typical design ....................................................................................................................................................................................................... 10

2.2 Host CPU ................................................................................................................................................................................................................. 10

2.3 Antenna ................................................................................................................................................................................................................... 11

2.4 GPIOs ........................................................................................................................................................................................................................ 11

2.5 ADC ............................................................................................................................................................................................................................ 12

2.6 SPI .............................................................................................................................................................................................................................. 12

2.6 I2C ............................................................................................................................................................................................................................. 12

2.7 EXT_IRQ ................................................................................................................................................................................................................... 12

3 Hardware Interfaces ............................................................................................................................................................................ 13

3.1 Absolute Maximum Ratings ............................................................................................................................................................................. 13

3.2 DC characteristics ............................................................................................................................................................................................... 13

3.3 RF characteristics ................................................................................................................................................................................................ 14

3.4 Mechanical characteristics .............................................................................................................................................................................. 16

3.5 Footprint characteristics .................................................................................................................................................................................. 17

4 Declarations of conformity ............................................................................................................................................................... 18

4.1 R&TTE conformity for 433 MHz and 863 MHz bands ........................................................................................................................... 18

4.2 FCC conformity for 915 MHz band ............................................................................................................................................................... 18

4.3 CSA conformity for 915 MHz band ............................................................................................................................................................... 19

5 Integration Guidelines ........................................................................................................................................................................ 20

5.1 Design Checklist ................................................................................................................................................................................................... 20

5.1.1 Schematics ....................................................................................................................................................................................................... 20

5.1.2 Layout ................................................................................................................................................................................................................. 20

5.1.3 Antenna ............................................................................................................................................................................................................. 21

5.2 Layout Recommendations ................................................................................................................................................................................ 21

5.2.1 Guidelines per pin function ...................................................................................................................................................................... 21

5.2.2 RF antenna connection ............................................................................................................................................................................... 21

5.3 Antenna Characteristics ................................................................................................................................................................................... 27

5.3.1 Antenna termination ................................................................................................................................................................................... 28

5.3.2 Antenna radiation ......................................................................................................................................................................................... 29

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 3

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

3 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

6 Product Testing ..................................................................................................................................................................................... 30

6.1 TRAXENS manufacturing tests ...................................................................................................................................................................... 30

6.2 Tests policy for OEM manufacturer .............................................................................................................................................................. 31

6.2.1 “GO/no GO” tests ........................................................................................................................................................................................... 31

6.2.2 Functional RF tests ....................................................................................................................................................................................... 31

7 Disclaimers ............................................................................................................................................................................................. 33

7.1 Document Status .................................................................................................................................................................................................. 33

7.2 ESD ............................................................................................................................................................................................................................ 33

7.3 Warranty ................................................................................................................................................................................................................ 33

7.4 Disposal of waste by users in private households within the European Union ............................................................... 33

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 4

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

4 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

ID

Name

Author

Date

Version

R1

UART COMMUNICATION PROTOCOL WING4TRAX-HOST

N. GUZZO

16/06/2016

1.59

R2

DSE - W4T - HOSTCOM Test commands

P. DARAGON

05/07/2016

1.5

1 INTRODUCTION

This manual is intended solely to TRAXENS internal use, as part of the integration of Wing4TRAX module

into its asset tracking devices TRAX-Box and their derivatives, or to system integrators duly certified by

TRAXENS

All rights to this manual are the exclusive property of TRAXENS. All rights reserved. Copying this manual

without written permission from the owner via printing, copying, recording or by any other means, translating this manual in full or partially is prohibited.

1.1 REFERENCES

1.2 TERMS AND ABBREVIATIONS

AES Advanced Encryption Standard

AFA Adaptive Frequency Agility

AGFS Automatic Geographic-based Frequency Selection

CTS Clear To Send

FHSS Frequency Hopping Spread Spectrum

GMSK Gaussian Minimum Frequency Shift Keying

GPS Global Positioning System

GSM Global System for Mobile communications

ISM Industrial – Scientific – Medical

LBT Listen Before Talk

MAC Media Access Control (radio layer)

MCC Mobile Country Code

NET NETwork (radio layer)

NPM Network Phy Mode (message)

P2P Peer To Peer

PHY PHYsical (radio layer)

PIFA Planar Inverted-F Antenna

RTS Request To Send

UART Universal Asynchronous Receiver Transmitter

VSWR Voltage Standing Wave Ratio

WAN Wide Area Network

WOR Wake On Radio

WSN Wireless Sensor Network

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 5

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

5 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

1.3 GENERAL PRESENTATION

Wing4TRAX is a universal sub-GHz radio module with the native capability to support the 3 unlicensed ISM

bands available worldwide: 433 MHz, 868 MHz and 915 MHz

It has been designed to be connected to a host controller thru an UART interface, like a standard radio

modem. It embeds the robust and efficient TRAX-Net protocol stack, with P2P communication and/or

mesh routing capabilities, between single or several nodes registered into a TRAX-Net cluster

Selection of the working band depends on the country where the Wing4TRAX module is operated and is

performed thanks to a specific command issued by the host controller, using proprietary AGFS algorithm.

TRAXENS provides a fully portable ANSI-C library to be executed on the host controller, to select the proper

band as a function of geolocation information, gathered from multiple sources: GPS position, GSM MCC or

NPM messages broadcasted by other TRAX-Net nodes.

In any case, frequency hopping channels and RF output power are settled to be in conformity with local

regulations; if geolocation information is not available, Wing4TRAX module remains silent and enters by

default in sniffer mode, listening for a NPM message.

Note: AGFS algorithm controls the Wing4TRAX firmware execution and guarantees the non-infringement of

local radio regulations in force where the module is operated by a host controller; therefore, integrity and

conformity of AGFS algorithm implementation into the host controller is verified during the TRAXENS certification process of its own products, as for those developed by integrators

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 6

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

6 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

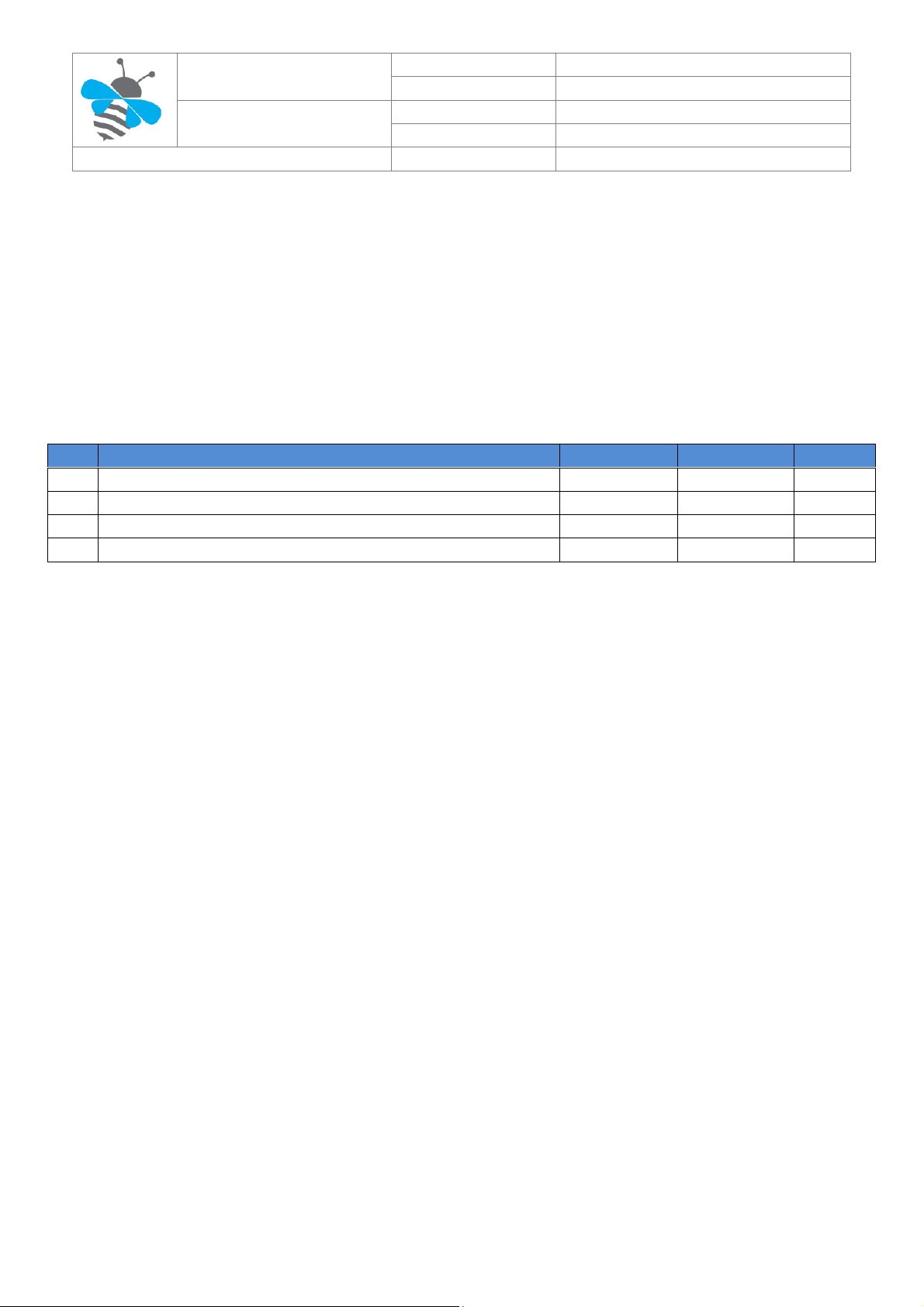

1.4 TRAX-NET AT A GLANCE

TRAX-Net is a cluster-based WSN protocol in which some nodes are in charge to aggregate the data

collected from other nodes and deliver it to the sink. The sink is either a TRAX-Gate gateway connected to a

WAN thru Ethernet, WiFi or GSM, or another TRAX-Net node with GSM connection capabilities

When a TRAX-Gate is present, it forms a super cluster and all TRAX-Net nodes in its communication range

join it, as illustrated below:

When no Gateway is present in the nearby, an election scheme selects some TRAX-Net nodes to be in

charge of collecting the data generated by the neighbors and transmit it to the TRAXENS data center passing through the GSM connection, as illustrated below:

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 7

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

7 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Parameter

Value

Max number of members in a cluster

250

Max number of members in a super-cluster

Undefined

Max number of affiliates per member

16

Max hop-distance

8+1 hops

Max data in a packet

2500 Bytes

TRAX-Net protocol stack is divided into 3 main layers:

1. PHY, responsible for controlling the output power, channel frequency, modulation/demodulation,

symbol encoding/decoding and bit framing

2. MAC, responsible for controlling frame preamble, synchronization, packet format, node addressing

thanks to unique TRAX-Net ID, integrity checking and communication retries

3. NET, responsible for controlling cluster election policy, node status (HEAD, MEMBER, AFFILIATE,

LOOSE) and message routing thru the cluster

Each layer can be individually started by host controller, respecting a strict order: PHY layer first, followed

by MAC layer, then NET layer. Activation of PHY and MAC layers is direct thru specific commands; activation

of NET layer is conditioned to a prior mutual authentication between the host and Wing4TRAX module,

based on a shared secret AES key. This security has been put in place to avoid malicious generation of fake

TRAX-Net clusters, with intention to dump data of registered nodes and thus create a denial of service

Main features of TRAX-Net are listed in table below:

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 8

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

8 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Technical specifications

Details

Module dimensions

35 x 17.5 x 2.9 mm

Operating temperature

-40°C to +85°C

Operating voltage (VDD)

1.8V to 3.6V (3.0V typical)

RF chip (8 bits µC + RF front end)

AX8052F143

PA voltage (VDD_ANA)

Regulated from VDD to 1.8V (1)

Tx consumption @433.92 MHz

51 mA typ. @+13dBm

Tx consumption @866.5 MHz

49 mA typ. @+13dBm

Tx consumption @921.5 MHz

47 mA typ. @+13dBm

Rx consumption

11 mA

WOR consumption

13.9 µA

Programmable TX power

From -10dBm to +13dBm

ETSI 433 MHz band channel mapping

17 channels of 100KHz

ETSI 868 MHz band channel mapping

68 channels of 100KHz

FCC 915 MHz band channel mapping

68 channels of 100KHz

ARIB 920 MHz band channel mapping

32 channels of 100KHz

Sensitivity @433.92 MHz

Down to -109dBm @BER 10-3

Sensitivity @866.5 MHz

Down to -113dBm @BER 10-3

Sensitivity @921.5 MHz

Down to -110dBm @BER 10-3

Operating range (open space)

Up to 1km with external antenna

Medium access method

ETSI compliant LBT + AFA

RF communication

Unicast, broadcast, mesh routing

RF data rate (raw bit / payload byte)

20Kbps / ~1.1Kbyte per second

Host communication

UART 19200, n, 8, 1

Digital inputs / outputs

Up to 12 (5V tolerant)

Analog inputs (10 bits ADC)

2 channels (0..1V) @20ksample/s

Smart kernel (PHY layer + bootloader)

MAC + NET layers upgradable thru UART

1.5 MAIN FEATURES

Wing4TRAX’s main features are listed in table below:

(1) Power amplifier (PA) runs from the regulated VDD_ANA supply and not directly from the battery voltage VDD. This has

the advantage that the current and output power do not vary much over supply voltage and temperature

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 9

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

9 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

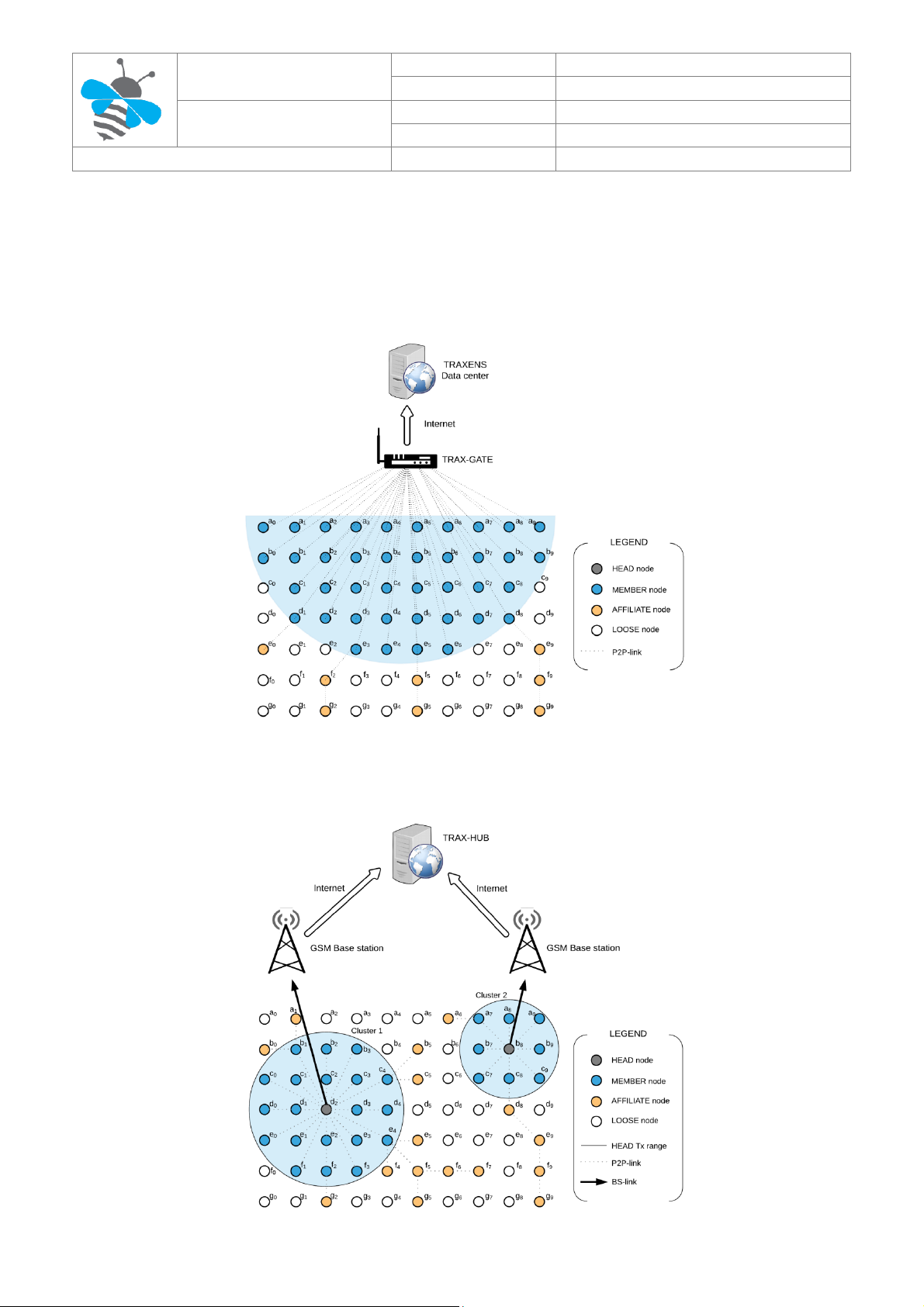

Pin

Type

RST value

Description

1 - VDD

Power supply

X

Source voltage between 2.3V & 3.6V – also pin 6

2 - PA2

Analog input

X

Channel 2 – 10bits ADC – [0..1V] range

3 - GND

Ground

X

Also pins 4, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 18, 19, 20, 21, 22, 23, 24

5 - PA5

Analog input

X

Channel 5 – 10bits ADC – [0..1V] range

17 - ANT

Antenna RX-TX

X

Connect to a 50 antenna thru a 150pF coupling capacitor

25 - SYSCLK

Digital output

Hi-Z

Optional I2C clock line (SCL) or general purpose clock output

26 - PC4

Digital IO

Hi-Z

Optional I2C data line (SDA) or EXT_IRQ input (EXTIRQ_EVENT)

27 - PC3

Digital IO

Hi-Z

Optional SPI MISO input or GPIO (PINC_3 in & PORTC_3 out bits)

28 - PC2

Digital IO

Hi-Z

Optional SPI MOSI output or GPIO (PINC_2 in & PORTC_2 out bits)

29 - PC1

Digital IO

Hi-Z

Optional SPI SCK output or GPIO (PINC_1 in & PORTC_1 out bits)

30 - PC0

Digital IO

Hi-Z

Optional SPI SS output or GPIO (PINC_0 in & PORTC_0 out bits)

31 - PB0

Digital input

Hi-Z

Optional UART CTS or general purpose (HOSTCTS_EVENT on PINB_0)

32 - PB1

Digital output

0 / 1

Optional UART RTS or general purpose (PORTB_1 out bit)

33 - PB2

Digital output

0

General purpose (PORTB_2 out bit)

34 - PB3

Digital input

Hi-Z

General purpose (GPINPUT_EVENT on PINB_3) & DEEPSLEEP wakeup

35 - PB4

Digital output

1

UART TXD for host interface

36 - PB5

Digital input

Hi-Z

UART RXD for host interface

37 - PB6

Digital output

0

General purpose (PORTB_6 out bit)

38 - PB7

Digital output

0

General purpose (PORTB_7 out bit)

39 – DBG_EN

Digital input

Pull-down

DEBUG only - Leave this pin unconnected

40 – RESET_N

Digital input

Pull-up

Internal 65K pull-up – if not used, leave this pin unconnected

1.6 PINOUT DEFINITION

Figure 1: top view pins numbering & naming

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 10

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

10 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

2 FUNCTIONAL INTERFACES

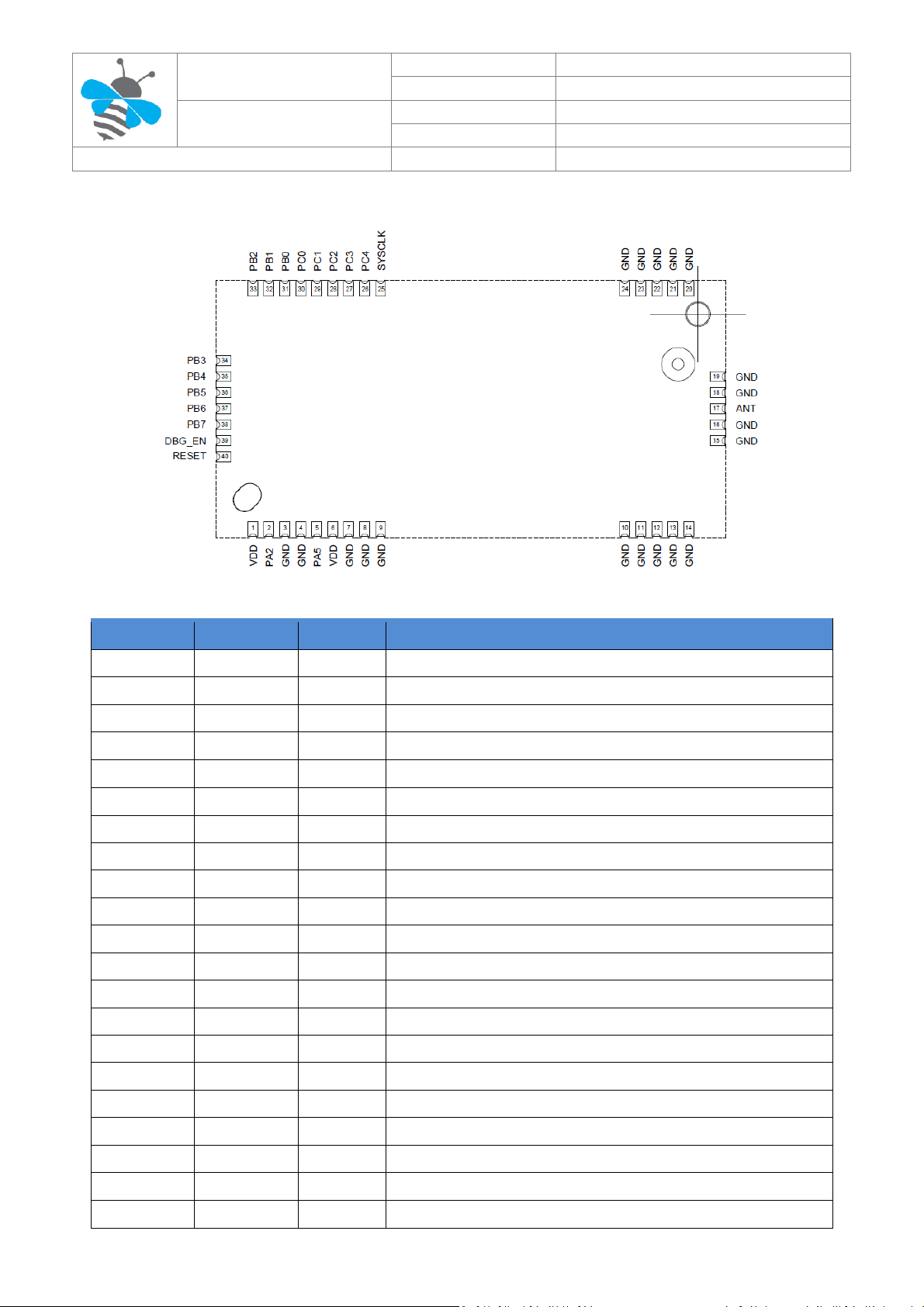

2.1 TYPICAL DESIGN

2.2 HOST CPU

Communication between the host controller and Wing4TRAX module is based on a standard UART working

in half-duplex mode, as illustrated below:

Default factory UART setup is 19200 bauds, no parity, 8 data bits and 1 stop bit

By default, hardware flow control thru RTS/CTS handshaking signals is deactivated and RTS signal is set to 0

after reset; in this case, PB0 pin can be used as a general purpose input and PB1 as output

RTS/CTS handling can be activated thanks to a specific command issued by the host and RTS signal is set to

1 after reset; in this case PB0 and PB1 pins are reserved and driven by Wing4TRAX kernel

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 11

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

11 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

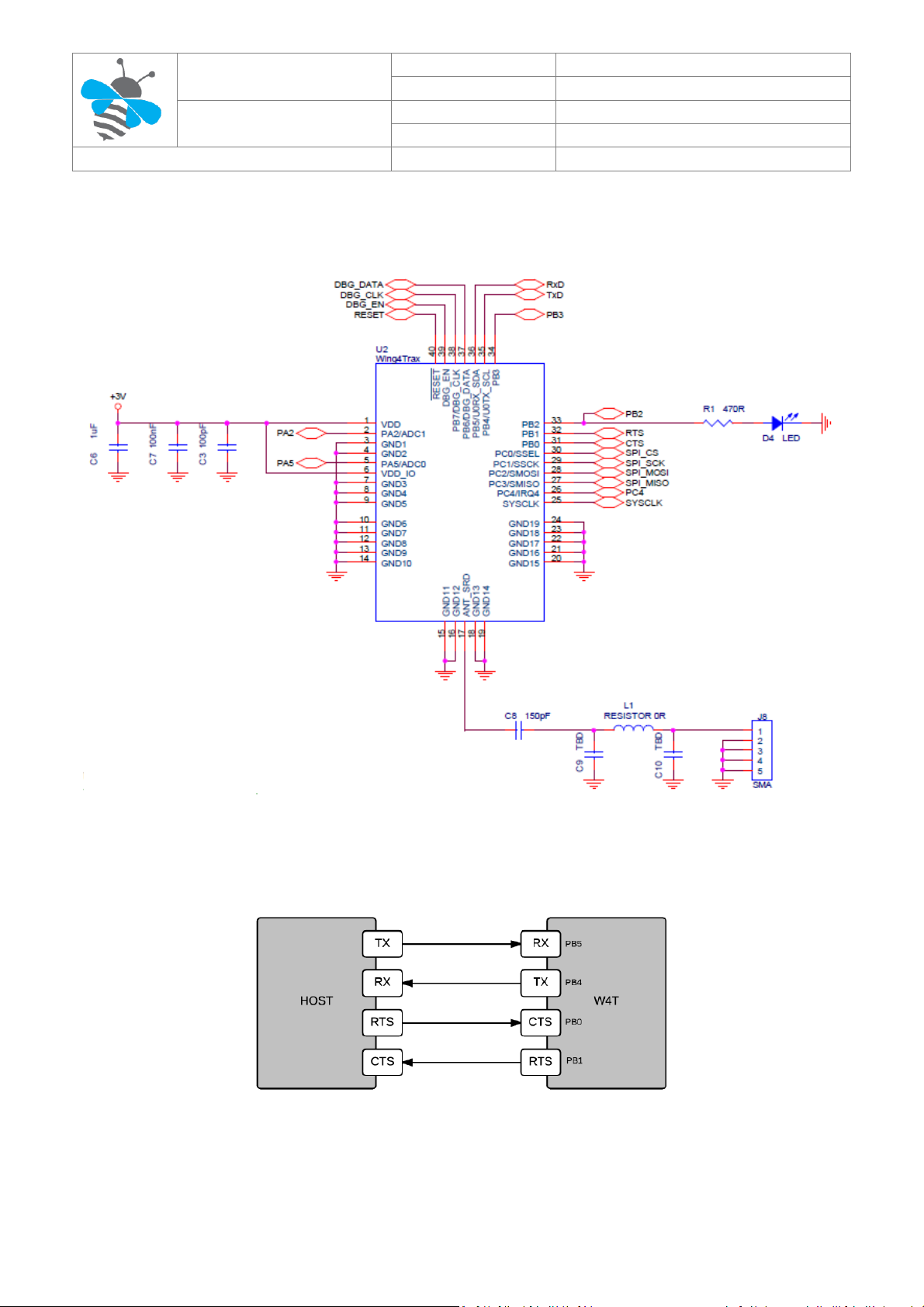

Name

SPI

I2C

IN

OUT

PC0

SS

-

PC1

SCK

-

PC2

MOSI

-

PC3

MISO

-

PC4

-

SDA

EXT_IRQ

SYSCLK

-

SCL

-

Frame format in both directions is as follows:

Communication protocol details can be found in specification [R1]

2.3 ANTENNA

ANT pin must be connected to a single pole antenna via a ceramic capacitor to avoid DC coupling with GND

A capacitor value between 100pF and 220pF (150pF typical) is commonly used

An additional inductance can be mounted between ANT pin and the capacitor to improve impedance

matching with the chosen antenna, as well as two foot capacitors to build a filter if extra filtering is

required. Feel free to contact us if you need more information about antenna design

2.4 GPIOS

Wing4TRAX offers a large panel of GPIOs on both ports B and C

Port B mapping is statically defined by the kernel, with 2 inputs and 4 outputs (UART RXD & TXD not

counted), meaning that direction of signal cannot be changed by the user; level change on PB0 and PB3

can be sensed by the kernel which generates events intercepted by user application. PB3, when tied low, is

also the sole pin by which the Wing4TRAX can exit the minimum consumption mode (DEEPSLEEP)

Port C & SYSCLK mapping can be dynamically defined by user application, with the possibility to interface

multiple slave devices, thru SPI bus and/or I2C bus, or thru discrete lines; the following table lists possible

alternate functions for port C & SYSCLK user pins:

SYSCLK is a special function pin, giving the opportunity to output permanent states 0 or 1 (0Hz clock), a

software programmable clock (e.g. 100KHz for I2C bus) or a hardware XTAL clock @32.768KHz with a

precision of +/-20ppm at @+25°C

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 12

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

12 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

2.5 ADC

Wing4TRAX features 2 external channels of analog-to-digital conversion on Port A pins PA2 and PA5

Conversion full scale is achieved with 1V voltage, and in any case, voltage applied on these pins shall not

exceed power supply voltage applied on VDD (pins 1 and 6)

In addition, Wing4TRAX provides 2 internal channels for application supervision:

An embedded temperature sensor with a precision of +/-2°C, over the full temperature range

Voltage applied on VDD pin calculated using the following formula:

VDD_Value = (ADC_Value x 0.0390625) – 4.5

Even if all conversions are performed with 10 bits resolution, the 2 LSBs are shifted out and results are

transferred to the application in 8 bits format (signed for temperature and unsigned for others)

2.6 SPI

SPI interface is only available in the configuration where the Wing4TRAX is the bus master

Slave Select (SS) signal is fully controlled by application, because active/inactive voltage to be applied to the

Chip Select (CS) pin varies with slave device manufacturer; if more than one SPI device must be interfaced,

free Port B outputs can be used too, as well as PC4 and SYSCLK, but with I2C interface exclusion

SPI clock can reach up to 5MHz and Wing4TRAX implements by default a clock setup without inversion (0V

when inactive) and MOSI/MISO data lines latch on clock rising edge; other setup is available on demand, as

illustrated below:

2.6 I2C

I2C interface is only available in the configuration where the Wing4TRAX is the bus master

Optionally, SCL and SDA lines can be internally pulled up with 65K, but most of the time this value is too

weak for normal bus operation under VDD voltage and external resistors are required

I2C clock signal SCL can reach up to 200KHz

2.7 EXT_IRQ

If not used by I2C interface, PC4 pin is available as an external interrupt source

EXT_IRQ function is sensitive to rising or falling edges of signal applied to pin PC4, and each change can be

intercepted by the Wing4TRAX kernel and notified to the application thanks to EXTIRQ_EVENT

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 13

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

13 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Symbol

Description

Conditions

Min.

Max.

Unit

VDD

Supply voltage

-0.5

+5.5

V

IDD

Supply current

- 200

mA

P

WRT

Total power consumption

- 800

mW

P

WRA

Maximum input power on ANT pin

Wing4TRAX in RX mode

-

10

dBm

IDC

DC current into any pin except ANT

-10

+10

mA

I

OUT

Output current

- 40

mA

VDC

Input voltage any pin except ANT

-0.5

+5.5

V

T

AMB

Operating temperature

-40

+85

°C

T

STG

Storage temperature

-65

+150

°C

V

ESD

Electrostatic handling

-2

+2

kV

Symbol

Description

Conditions

Min.

Typ.

Max.

Unit

Supplies

T

AMB

Operational ambient temperature

-40

25

+85

°C

VDD

Power supply and I/O voltage

1.8

3.0

3.6

V

V

BOT

Brown-out threshold

- 1.3 - V

I

DSLEEP

Deep Sleep current

- 100

-

nA

I

SLEEP

Sleep current

8.25Kb RAM retained

-

2.2 - µA

I

STANDBY

Standby current

- 85 - µA

I

RUN

Microcontroller running current

- 3 - mA

I

RFRX

RF receiver consumption

- 9.5 - mA

I

RFTX

RF transmitter consumption

- 45 - mA

I

RFOSC

RF XTAL oscillator consumption

48MHz

-

500

-

µA

I

TMOSC

Time XTAL oscillator consumption

32.768KHz

-

700

-

nA

I

ADC

ADC current

312.5 ksample/s

-

1.1 - mA

I

WOR

Typical Wake-On-Radio duty cycle

360ms, 20Kbps

-

13.9

-

µA

Digital inputs

VT+

Schmitt trigger low to high threshold

VDD = 3.0V

-

1.4 - V

VT-

Schmitt trigger high to low threshold

-

1.13 - V

VIL

Input voltage low

- - 0.8

V

VIH

Input voltage high

2.0 - -

V

V

IPA

Input voltage range port A

-0.5

-

VDD

V

V

IPBC

Input voltage range ports B and C

-0.5 - 5.5

V

IL

Input leakage current

-10 - +10

µA

R

IPU

Programmable internal pull-up resistor

- 65 - k

3 HARDWARE INTERFACES

3.1 ABSOLUTE MAXIMUM RATINGS

Stresses above those listed values below may cause permanent damage to the device

Exposure to absolute maximum rating conditions for extended periods may affect device reliability

3.2 DC CHARACTERISTICS

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 14

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

14 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Digital outputs

I

OHPBC

Output current high ports B and C

VOH = 2.4V

8 - -

mA

I

OLPBC

Output current low ports B and C

VOL = 0.4V

8 - -

mA

I

OHSYSCLK

Output current high SYSCLK pin

VOH = 2.4V

4 - -

mA

I

OLSYSCLK

Output current low SYSCLK pin

VOL = 0.4V

4 - -

mA

IOZ

Tri-states output leakage current

-10 - +10

µA

Analog inputs

F

ADCSR

ADC sampling rate

30 500

kHz

F

ADCSRT

ADC sampling rate temperature sensor

10

15.6

30

kHz

B

ADCRES

ADC resolution

- 10 - Bits

C

IPA

Input capacitance on PA2 and PA5 pins

- -

2.5

pF

B

ADCERR

ADC non linearity error

-1 - +1

LSB

B

ADCOFF

ADC offset

- 3 - LSB

V

ADCFS

ADC full swing input

0 - 1 V

Temperature sensor

T

RNG

Temperature range

-40 - +85

°C

T

RES

Temperature resolution

- 0.1607

-

°C/LSB

T

ERR

Temperature error

-2 - +2

°C

Symbol

Description

Conditions

Min.

Typ.

Max.

Unit

Generic

P

TXRNG

Programmable transmitter power

50 measurement

-10 - +13

dBm

P

TXTEMP

Transmitter power drift versus T°

-40°C to +85°C

-0.5

-

+0.5

dB

P

TXVDD

Transmitter power drift versus VDD

1.8V to 3.6V

-0.5

-

+0.5

dB

F

IPRECS

Frequency absolute precision

@25°C

-10

-

+10

ppm

F

DTEMP

Frequency drift versus temperature

-40°C to +85°C

-15

-

+15

ppm

F

AGING

Frequency aging

1 year

-1 - +1

ppm

SBR

Signal bit rate

- 20 - Kbps

F

SKMI

Modulation index (GMSK)

- 0.5 - -

F

SKGBT

Gaussian pulse shaping

- 0.5 - -

F

CHSPACE

Channel spacing

AGFS dependent

100

-

250

KHz

F

CHNUM

Number of channels

12 - 68

-

433 MHz band

F

R433

Frequency range

433.05

-

434.79

MHz

P

TX433_2

Harmonic 2 TX power

See note 1

-

-37 - dBm

P

TX433_3

Harmonic 3 TX power

-

-34 - dBm

S

RX433_1

RX sensitivity @433.12 MHz

BER = 10-3

-

-108

-

dBm

S

RX433_2

RX sensitivity @433.92 MHz

-

-108

-

dBm

S

RX433_3

RX sensitivity @434.72 MHz

-

-109

-

dBm

B

RX433_1

RX blocking @433.92 MHz

Offset = +/-2 MHz

-

71 - dB

B

RX433_2

Offset = +/-10 MHz

-

86 - dB

3.3 RF CHARACTERISTICS

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 15

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

15 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

868 MHz band

F

R868

Frequency range

863

-

870

MHz

P

TX868_2

Harmonic 2 TX power

See note 2

-

-50 - dBm

P

TX868_3

Harmonic 3 TX power

-

-58 - dBm

S

RX868_1

RX sensitivity @863.05 MHz

BER = 10-3

-

-111.5

-

dBm

S

RX868_2

RX sensitivity @866.50 MHz

-

-113

-

dBm

S

RX868_3

RX sensitivity @869.95 MHz

-

-112.5

-

dBm

B

RX868_1

RX blocking @866.5 MHz

Offset = +/-2 MHz

-

71 - dB

B

RX868_2

Offset = +/- 10 MHz

-

85 - dB

915 MHz band

F

R915

Frequency range

902

-

928

MHz

P

TX915_2

Harmonic 2 TX power

See note 3

-

38

-

dBµV/m

P

TX915_3

Harmonic 3 TX power

-

45

-

dBµV/m

S

RX915_1

Sensitivity @915.05 MHz

BER = 10-3

-

-112

-

dBm

S

RX915_2

Sensitivity @918.275 MHz

BER = 10-3

-

-111

-

dBm

S

RX915_3

Sensitivity @921.50 MHz

BER = 10-3

-

-110

-

dBm

S

RX915_4

Sensitivity @924.725 MHz

BER = 10-3

-

-109

-

dBm

S

RX915_5

Sensitivity @9271.95 MHz

BER = 10-3

-

-108

-

dBm

B

RX915_1

RX blocking @921.5 MHz

Offset = +/-2 MHz

-

70 - dB

B

RX915_2

Offset = +/- 10 MHz

-

84 - dB

Miscellaneous

P

RXWKP

RX wake-up period

- 360 - ms

D

TXPRMB

TX preamble duration

- -

390

ms

R

PAYLOAD

Effective payload rate (throughput)

Per second

1.1

KByte

Note 1: EN 300 220-2 measurement conditions §7.8.2.1, at 867.84 MHz for harmonic 2 and 1.30176 GHz for

harmonic 3 (433.92 MHz carrier power set at +13dBm)

Note 2: EN 300 220-2 measurement conditions §7.8.2.1, at 1.733 GHz for harmonic 2 and 2.5995 GHz for

harmonic 3 (866.5 MHz carrier power set at +13dBm)

Note 3: FCC part 15.247 test method (15.109, 15.209, 15.215b, 15.247), at 1.843 GHz for harmonic 2 and

2.764 GHz for harmonic 3 (921.5 MHz carrier measured with 114 dBµV/m at 3m)

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 16

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

16 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

3.4 MECHANICAL CHARACTERISTICS

Mechanical tolerances:

PCB dimensions on X & Y axis: +/- 0.2 mm

PCB + shield thickness: +/- 0.4 mm

Pad position and size: +/- 0.05 mm

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Figure 2: mechanical dimensions

Page 17

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

17 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

3.5 FOOTPRINT CHARACTERISTICS

Layout precautions: module bottom layer in contact with host PCB must be considered as a

KEEP OUT area; except for host pads, avoid copper plan, tracks and via on the host PCB layer in

contact with the module

Note: KiCAD or ALTIUM Designer footprints are available on request

Figure 3: footprint dimensions

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 18

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

18 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

4 DECLARATIONS OF CONFORMITY

The gain of the system antenna(s) used with Wing4TRAX (i.e. the combined transmission line,

connector, cable losses and radiating element gain) must not exceed 6dBi (in 433 MHz, 868 MHz

and 915 MHz bands) for mobile and fixed or mobile operating configurations.

4.1 R&TTE CONFORMITY FOR 433 MHZ AND 863 MHZ BANDS

Name: Wing4TRAX

Reference: W4T-V1.0-REV.F

This device complies with EN 300 220-1 v2.4.1 and EN 300 220-2 v2.4.1

According to the R&TTE Directive (1999/5/CE)

4.2 FCC CONFORMITY FOR 915 MHZ BAND

This RF module (Model: WING4TRAX – FCC ID: 2AHZ6WING4TRAX) is limited to OEM installation only, in

mobile or fixed applications; separate approval is required for all other operating configurations, including

portable configuration with respect to Part 2.1093

It can only be used in devices certified by TRAXENS under the following conditions:

The antenna(s) must be installed such that a minimum separation distance of 20cm is maintained

between the antenna and user’s/nearby person’s body at all times

The device must not be co-located with any other antenna or transmitter

OEM integrators shall not provide installation and/or removal instructions to end-users.

End-user’s operating manual delivered with finished products shall include the following information:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired

operation

Finished products integrating this RF module (Model: WING4TRAX) shall bear the following label:

This device contains RF module (FCC ID: 2AHZ6WING4TRAX)

Prior to any distribution or installation, all products integrating the Wing4TRAX module shall be certified by

TRAXENS; changes or modifications applied afterwards and not expressly approved by TRAXENS SAS could

void the user's authority to operate the equipment.

Note: the grantee is not responsible for any changes or modifications not expressly approved by the party

responsible for compliance. Such modifications could void the user’s authority to operate the equipment

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 19

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

19 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

4.3 CSA CONFORMITY FOR 915 MHZ BAND

Canada, Industry Canada (IC) Notices

This device complies with Industry Canada license-exempt RSS-210 standard(s). Operation is subject to the

following two conditions:

This device may not cause interference, and

This device must accept any interference, including interference that may cause undesired

operation of the device

Radio Frequency (RF) Exposure Information

The radiated output power of the Wing4TRAX Module is below the Industry Canada (IC) radio frequency

exposure limits. The Wing4TRAX Module should be used in such a manner such that the potential for human contact during normal operation is minimized.

This device has been evaluated and shown compliant with the IC RF Exposure limits under mobile exposure

conditions (antennas are greater than 20cm from a person's body).

IMPORTANT: Manufacturers of portable applications incorporating the Wing4TRAX module are required to

have their final product certified and apply for their own FCC Grant and Industry Canada Certificate related

to the specific portable device. This is mandatory to meet the SAR requirements for portable devices.

Changes or modifications not expressly approved by the party responsible for compliance could void the

user's authority to operate the equipment.

Canada, avis d'Industrie Canada (IC)

Cet appareil numérique de classe B est conforme aux normes canadiennes RSS-210. Son fonctionnement

est soumis aux deux conditions suivantes:

cet appareil ne doit pas causer d'interférence

cet appareil doit accepter toute interférence, notamment les interférences qui peuvent affecter son

fonctionnement

Informations concernant l'exposition aux fréquences radio (RF)

La puissance de sortie émise par l’appareil sans fil Wing4TRAX Module est inférieure à la limite d'exposition

aux fréquences radio d'Industrie Canada (IC). Utilisez l’appareil sans fil Wing4TRAX Module de façon à minimiser les contacts humains lors du fonctionnement normal.

Ce périphérique a été évalué et démontré conforme aux limites d'exposition aux fréquences radio (RF) d'IC

lorsqu'il est installé dans des produits hôtes particuliers qui fonctionnent dans des conditions d'exposition à

des appareils mobiles (les antennes se situent à plus de 20 centimètres du corps d'une personne).

IMPORTANT: les fabricants d'applications portables contenant le module Wing4TRAX doivent faire certifier

leur produit final et déposer directement leur candidature pour une certification FCC ainsi que pour un

certificat Industrie Canada délivré par l'organisme chargé de ce type d'appareil portable. Ceci est obligatoire afin d'être en accord avec les exigences SAR pour les appareils portables.

Tout changement ou modification non expressément approuvé par la partie responsable de la certification

peut annuler le droit d'utiliser l'équipement

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 20

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

20 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

5 INTEGRATION GUIDELINES

5.1 DESIGN CHECKLIST

5.1.1 SCHEMATICS

The following are the most important points for a simple schematic check:

DC supply must provide a nominal voltage at VDD pins above the minimum operating range limit.

DC supply must be capable of providing up to 75 mA current, providing a voltage at VDD pins above

the minimum operating range limit and with a maximum 150 mV voltage drop from the nominal

value.

VDD supply should be clean, with very low ripple/noise: provide the suggested series ferrite bead

and bypass capacitors, in particular if the application device integrates an internal antenna.

VDD voltage must ramp from 0.1V maximum and then rise with a slope of at least 0.1V/ms to the

normal operating voltage.

Check that voltage level of any connected pin does not exceed the specific operating range.

Provide appropriate access to UART RxD and TxD lines for debugging (resp. PB5 and PB4).

Capacitance and series resistance must be limited on each line of the SPI interface, if the interface

is used.

Add a proper pull-up resistor to a proper supply on each I2C interface line, if the interface is used.

Capacitance and series resistance must be limited on each line of the I2C interface.

Connect all the pins referred as GND to the ground.

Provide proper precautions for ESD immunity as required on the application board.

Any external signal connected to the UART interface, SPI interface, I2C interface and GPIOs must be

tri-stated when the module is in power-down mode, when the external reset is forced low and during the module power-on sequence (at least for 100 ms after the start-up event), to avoid latch-up

of circuits and let a proper boot of the module.

All unused pins can be left floating on the application board, except the PB3 pin if the module has

to be put in DEEP_SLEEP mode

5.1.2 LAYOUT

The following are the most important points for a simple layout check:

Check 50 Ω nominal characteristic impedance of the RF transmission line connected to the ANT pad

(main RF input/output).

Follow the recommendations of the antenna producer for correct antenna installation and deploy-

ment (PCB layout and matching circuitry).

Ensure no coupling occurs with other noisy or sensitive signals (primarily SPI and/or I2C interfaces).

VDD line should be as wide and as short as possible (i.e. width of 0.25mm min.)

Provide the suggested series ferrite bead and bypass capacitors close to the VDD pins implement-

ing the recommended layout and placement, especially if the application device integrates an internal antenna.

Route VDD supply line away from sensitive analog signals.

Ensure proper grounding.

Consider “No-routing” areas for the Module footprint (see section § 3.5).

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 21

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

21 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Rank

Function

Pin(s)

Attention to pay

Remark

1st

RF antenna

ANT

VERY HIGH

Design for 50 Ω characteristic impedance

2nd

Main DC supply

VDD

HIGH

VDD line should be wide and short.

Route away from sensitive analog signals

3rd

Ground

GND

HIGH

Provide proper grounding

4th

Analog pins

PA2, PA5

HIGH

If ADC0 and/or ADC1 lines are used

Avoid coupling with noisy signals

5th

High-speed

digital pins

PC1..PC3

HIGH

If SCK, MOSI and MISO lines are used

Avoid coupling with sensitive signals

6th

Digital pins &

supplies

PB0..PB7,

PC0, PC4,

SYSCLK,

DBG_EN,

RESET_N

Medium

Follow common practice rules for digital pin

routing

Optimize placement for minimum length of RF line and closer path from DC source for VDD.

Keep routing short and minimize parasitic capacitance on the SPI lines to preserve signal integrity.

5.1.3 ANTENNA

Antenna should have a 50 Ω impedance, VSWR less than 3:1 (recommended 2:1) on operating

bands in deployment geographical area.

Follow the recommendations of the antenna producer for correct antenna installation and deploy-

ment (PCB layout and matching circuitry).

Follow the additional guidelines for products marked with the FCC logo (United States only) report-

ed in section §5.2

The antenna connected to the ANT pad should be DC isolated with a ceramic COG/NPO capacitor of

150pF.

5.2 LAYOUT RECOMMENDATIONS

5.2.1 GUIDELINES PER PIN FUNCTION

The following design guidelines must be met for optimal integration of Wing4TRAX module on the final

application board

5.2.2 RF ANTENNA CONNECTION

The ANT pin provided by Wing4TRAX module is very critical in layout design.

Proper transition between ANT pad and the application board must be provided, implementing the following design-in guidelines for the layout of the application PCB close to the ANT pad:

On a multi-layer board, the whole layer stack below the RF connection should be free of digital lines

Increase GND keep-out (i.e. clearance) for ANT pad to at least 175 μm up to adjacent pads metal

definition, as described in Figure 4

Add GND keep-out (i.e. clearance) on buried metal layers below ANT pad and below any other pad

of component present on the RF line, if top-layer to buried layer dielectric thickness is below 200

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 22

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

22 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

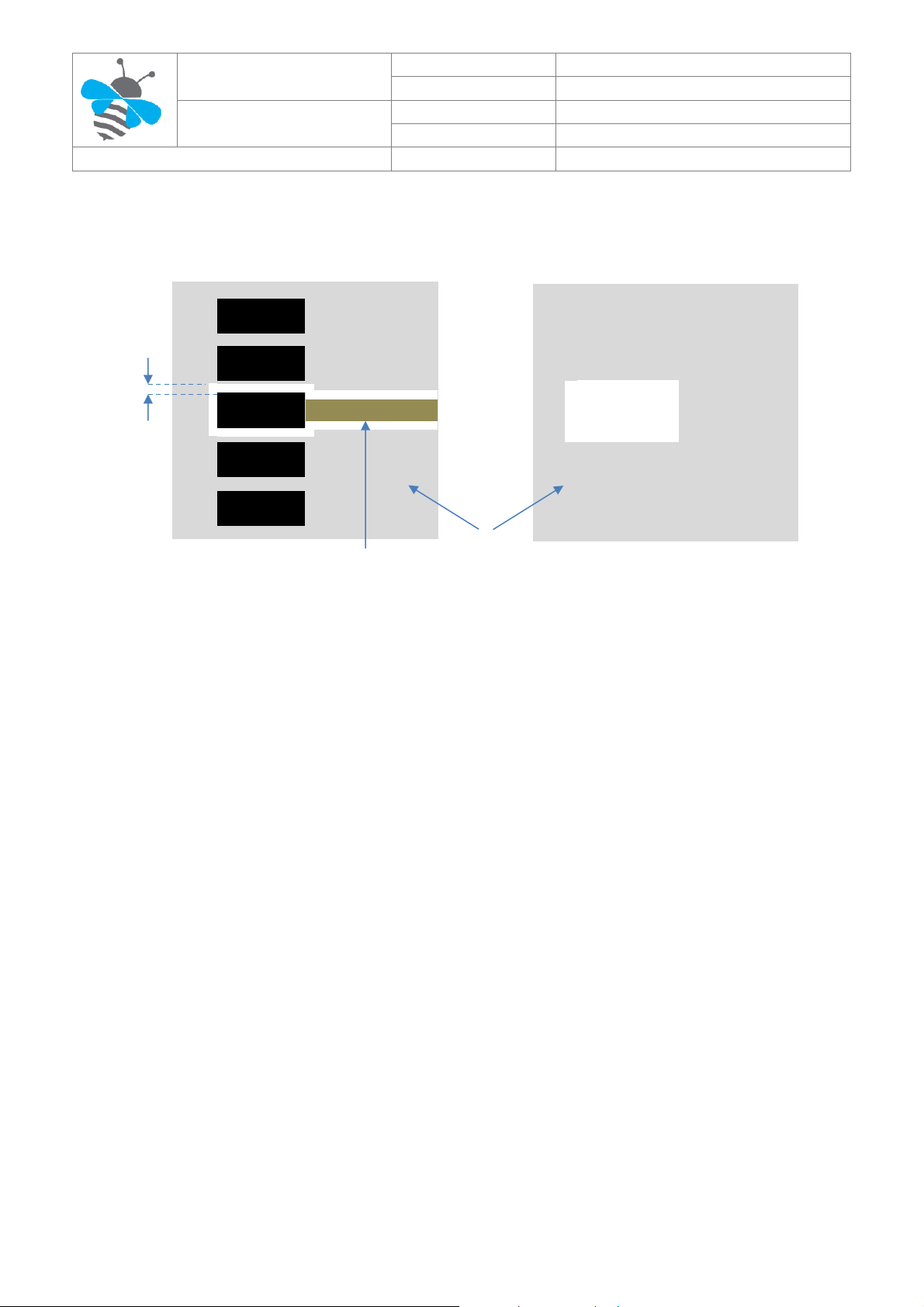

Top Layer

Ground

Buried metal Layer

175µm min.

Microstrip line 50 Ohm

μm, to reduce parasitic capacitance to ground (see Figure 4 for the description of the GND keep-out

area below ANT pad)

Figure 4: GND keep-out area on top layer around and on buried layer below ANT pad

The transmission line from the ANT pad up to antenna connector or up to the internal antenna pad must

be designed so that the characteristic impedance is as close as possible to 50 Ω.

The transmission line up to antenna connector or pad may be a microstrip (consists of a conducting

strip separated from a ground plane by a dielectric material) or a strip line (consists of a flat strip of

metal which is sandwiched between two parallel ground planes within a dielectric material). In any

case must be designed to achieve 50 Ω characteristic impedance

Microstrip lines are usually easier to implement and the reduced number of layer transitions up to

antenna connector simplifies the design and diminishes reflection losses. However, the electromagnetic field extends to the free air interface above the stripline and may interact with other circuitry

Buried striplines exhibit better shielding to external and internally generated interferences. They

are therefore preferred for sensitive application. In case a stripline is implemented, carefully check

that the via pad-stack does not couple with other signals on the crossed and adjacent layers

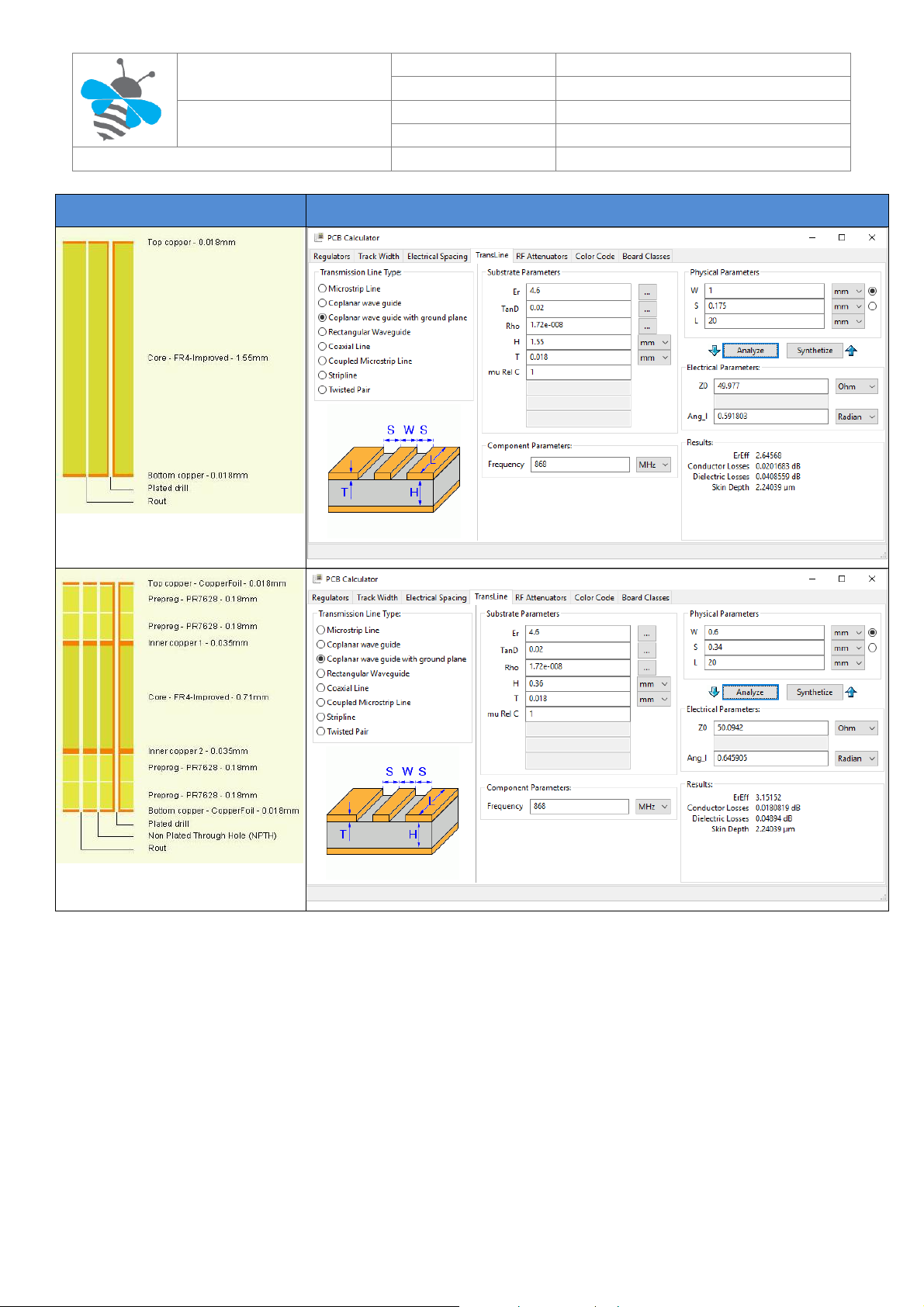

Figures 5 below provide two examples of proper 50 Ω coplanar waveguide designs. The first transmission

line can be implemented in case of 2-layer PCB stack-up herein described, the second transmission line can

be implemented in case of 4-layer PCB stack-up herein described:

With a 2-layer PCB stack using FR-4 material (

layers, 18µm of copper thickness for the top layer, a 50 Ω microstrip line can be achieved with a line

of 1.0mm width and a clearance of 0.175mm from GND

With a 4-layer PCB stack using FR-4 material (

layers, 18µm of copper thickness for the top layer, a 50 Ω microstrip line can be achieved with a line

of 0.6mm width and a clearance of 0.34mm from GND

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

= 4.6) of 1.55mm height between top and bottom

r

= 4.6) of 0.36mm height between top and first inner

r

Page 23

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

23 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Board buildup

Coplanar waveguide transmission line parameters

Figure 5: 50 Ω coplanar waveguide transmission line calculation with different PCB buildup

If the two examples do not match the application PCB layup, the 50 Ω characteristic impedance calculation

can be made using the HFSS commercial finite element method solver for electromagnetic structures from

ANSYS Corporation, or using freeware tools like AppCAD from Agilent or TXLine from Applied Wave Research, taking care of the approximation formulas used by the tools for the impedance computation.

To achieve a 50 Ω characteristic impedance, the width of the transmission line must be chosen depending

on:

the thickness of the transmission line itself (e.g. 18 μm in the example of Figure 5)

the thickness of the dielectric material between the top layer (where the transmission line is rout-

ed) and the inner closer layer implementing the ground plane (e.g. 360 μm or 1550 μm in Figure 5)

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 24

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

24 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

the dielectric constant of the dielectric material (e.g. dielectric constant of the FR-4 dielectric mate-

rial in Figure 5 given at r = 4.6)

the gap from the transmission line to the adjacent ground plane on the same layer of the transmis-

sion line (e.g. 175 μm or 340 μm in Figure 5)

Additionally to the impedance matching at 50 Ω, the following guidelines are recommended for the RF line

design:

Minimize the transmission line length; the insertion loss should be minimized as much as possible,

in the order of a few tenths of a dB

The transmission line should not have abrupt change to thickness and spacing to GND, but must be

uniform and routed as smoothly as possible

The transmission line must be routed in a section of the PCB where minimal interference from

noise sources can be expected

Route RF transmission line far from other sensitive circuits as it is a source of electromagnetic inter-

ference

Avoid coupling with VDD routing and analog lines

Ensure solid metal connection of the adjacent metal layer on the PCB stack-up to main ground layer

Add GND via around transmission line (e.g. repetitive pattern of via spaced by 2.54mm)

Ensure no other signals are routed parallel to transmission line, or that other signals cross on adja-

cent metal layer

If the distance between the transmission line and the adjacent GND area (on the same layer) does

not exceed 5 times the track width of the microstrip, use the “Coplanar Waveguide” model for 50 Ω

characteristic impedance calculation

Do not route microstrip line below discrete component or other mechanics placed on top layer

When terminating transmission line on antenna connector (or antenna pad) it is very important to

strictly follow the connector manufacturer’s recommended layout

GND layer under RF connectors and close to buried via should be cut out in order to remove stray

capacitance and thus keep the RF line 50 Ω. In most cases the large active pad of the integrated antenna or antenna connector needs to have a GND keep-out (i.e. clearance) at least on first inner

layer to reduce parasitic capacitance to ground. Note that the layout recommendation is not always

available from connector manufacturer: e.g. the classical SMA Pin-Through-Hole needs to have

GND cleared on all the layers around the central pin up to annular pads of the four GND posts.

Ensure no coupling occurs with other noisy or sensitive signals

Additional guidelines for products marked with the FCC logo - United States only

Wing4TRAX module can only be used with a host antenna circuit trace layout according to these guidelines; a host system designer must follow the guidelines to keep the original Grant of Wing4TRAX module.

Strict compliance to the layout reference design already approved (described in the following guidelines) is

required to ensure that only approved antenna shall be used in the host system.

If in a host system there is any difference from the trace layout already approved, it requires a Class II

permissive change or a new grant as appropriate as FCC defines.

Compliance of this device in all final host configurations is the responsibility of the Grantee.

The approved reference design for Wing4TRAX modules has a structure of 2 layers described below.

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 25

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

25 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

ANT pin pad

150pF capacitor

Microstrip line

Antenna connector

The top layer provides a microstrip line to connect the ANT pin of the Wing4TRAX module to the antenna

connector. The ANT pin of the Wing4TRAX module must be soldered on the designed pad which is connected to the antenna connector by a microstrip. The characteristics of the microstrip line (coplanar wave

guide) are the following:

Thickness = 0.018 mm

Width = 1.0 mm

Length = 20 mm

Gap (signal to GND) = 0.175 mm

The microstrip line must be designed to achieve 50 Ω characteristic impedance

The dimensions of the microstrip line must be calculated in a host system according to PCB characteristics

provided by PCB manufacturer.

Additional coupling and filtering components between the ANT pin pad and the antenna connector shall be

placed all along the microstrip line, in a way that preserves as much as possible integrity of the line; a special attention must be paid to the placement of components mounted in parallel to the microstrip line in

order to avoid generation of unexpected stubs

Figure 6: Layer 1 (top layer) of TRAXENS approved interface board for Wing4TRAX module

The thickness of the dielectric from Layer 1 (top layer) to Layer 2 (bottom layer) is 1.55 mm.

The Layer 2 (bottom layer) is designed for signals routing, components placement and GND plane.

Layer 2 thickness is 0.018 mm.

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 26

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

26 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Figure 7: Layer 2 (bottom layer) of TRAXENS approved interface board for Wing4TRAX module

The antenna gain must not exceed the levels reported in the section §4 introduction to preserve

the original TRAXENS FCC ID.

The antenna must be installed and operated with a minimum distance of 20 cm from all persons

and must not be co-located or operating in conjunction with any other antenna or transmitter.

Under the requirements of FCC Section 15.212(a)-iv, the module must contain a permanently at-

tached antenna, or contain a unique antenna connector, and be marketed and operated only with

specific antenna(s).

In accordance with FCC Section 15.203, the antenna should use a unique coupling connector to the

approved reference design for Wing4TRAX module, to ensure that the design will not be deployed

with antenna of different characteristic from the approved type.

The use of standard SMA type connector is not permitted, as its standard usage allows easy re-

placement of the attached antenna. However RP-SMA (Reverse-Polarized-SMA) connector type fulfills the minimum requirements to prevent exchangeability of antenna on the reference design.

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 27

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

27 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Item

Recommendations

Impedance

50 Ω nominal characteristic impedance

Frequency Range

Wing4TRAX module supports 3 sub-GHz ISM bands:

1. 433.05.. 434.79MHz

2. 863.. 869 MHz

3. 902.. 928 MHz

Input Power

20mW peak

VSWR

<2:1 recommended, <3:1 acceptable

Return Loss

S11 < -10dB recommended, S11 < -6dB acceptable

5.3 ANTENNA CHARACTERISTICS

Antenna characteristics are essential for good functionality of the module. Antenna radiating performance

has direct impact on the reliability of connections over the Air Interface. A bad termination of the ANT pin

can result in poor performance of the module.

The following parameters should be checked:

Sub-GHz ISM bands antennas are typically available as:

Linear monopole: typical for fixed applications (e.g. TRAX-Net gateway). The antenna extends most-

ly as a linear element with a dimension comparable to /4 of the lowest frequency of the operating

band. Magnetic base may be available. Cable or direct RF connectors are common options. The integration normally requires the fulfillment of some minimum guidelines suggested by antenna

manufacturer

PIFA: typical for mobile applications (e.g. TRAX-Box mounted onto a container). It consists of a

monopole antenna running parallel to a ground plane and grounded at one end. The antenna is fed

from an intermediate point a distance from the grounded end. The design has two advantages over

a simple monopole: the antenna is shorter and more compact, and the impedance matching can be

controlled by the designer without the need for additional matching components. However, the

design is complex and we recommend to rely on TRAXENS expertise in this field before considering

to implement this technology

Patch-like antenna: better suited for integration in compact designs (e.g. USB key). These are most-

ly custom designs where the exact definition of the PCB and product mechanical design is fundamental for tuning of antenna characteristics

For integration observe these recommendations:

Ensure 50 Ω antenna termination, minimize the V.S.W.R. or return loss, as this will optimize the

electrical performance of the module. See section §5.2.2

Select antenna with best radiating performance. See section §5.3.2

If a cable is used to connect the antenna radiating element to application board, select a short ca-

ble with minimum insertion loss. The higher the additional insertion loss due to low quality or long

cable, the lower the connectivity

Follow the recommendations of the antenna manufacturer for correct installation and deployment

Do not include antenna within closed metal case

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 28

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

28 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Do not place the main antenna in close vicinity to end user since the emitted radiation in human

tissue is limited by S.A.R. regulatory requirements

Do not use directivity antenna since the electromagnetic field radiation intensity is limited in some

countries

Take care of interaction between co-located RF systems since the Wing4TRAX transmitted power

may interact or disturb the performance of companion systems

Place antenna far from sensitive analog systems or employ countermeasures to reduce electro-

magnetic compatibility issues that may arise

5.3.1 ANTENNA TERMINATION

The Wing4TRAX module is designed to work on a 50 Ω load. However, real antennas have no perfect 50 Ω

load on all the supported frequency bands. Therefore, to reduce as much as possible performance degradation due to antenna mismatch, the following requirements should be met:

With a network analyzer, connect the antenna through a coaxial cable to the measurement device;

S11 parameter indicates the power which is reflected by the antenna back to the module output.

A good antenna should have a S

below -10 dB over the entire frequency band. Due to miniaturiza-

11

tion, mechanical constraints and other design issues, this value may not be achieved; a S11 value of

about -6 dB is therefore acceptable.

Picture below shows an example of this measurement, with a good value of S11 in the 860-930MHz band

and an acceptable value in the 433MHz band (Frequency span = 150MHz, starting at 50MHz)

Figure 8: S11 measurement with a Nagoya NA-915-2 monopole antenna

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 29

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

29 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

Radiation patterns at 430-435-440 MHz

Radiation patterns at 860-900-930 MHz

5.3.2 ANTENNA RADIATION

An indication of the antenna’s radiated power can be approximated by measuring the S21 parameter from a

target antenna to the measurement antenna, using a network analyzer with a wideband antenna.

Measurements should be done at a fixed distance and orientation, and results compared to measurements

performed on a known good antenna.

For good antenna radiation performance, antenna dimensions should be comparable to a quarter of the

wavelength. Different antenna types can be used for the module, many of them (e.g. patch antennas,

monopole) are based on a resonating element that works in combination with a ground plane. The ground

plane, ideally infinite, can be reduced down to a minimum size that must be similar to one quarter of the

wavelength of the minimum frequency that has to be radiated (transmitted/received).

Numerical samples are given below (below calculated size, the antenna efficiency is reduced):

for a frequency = 450MHz wavelength = 66 cm minimum antenna size = 16.5 cm

for a frequency = 900MHz wavelength = 33 cm minimum antenna size = 8.3 cm

Picture below shows 3D radiation patterns for an omnidirectional antenna, designed to work over the 3

ISM bands, with a gain of 2dBi in lower band and 2.5dBi in upper bands:

Figure 9: radiation patterns of PULSE RO3ISMNM omnidirectional & wideband antenna

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Page 30

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

30 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

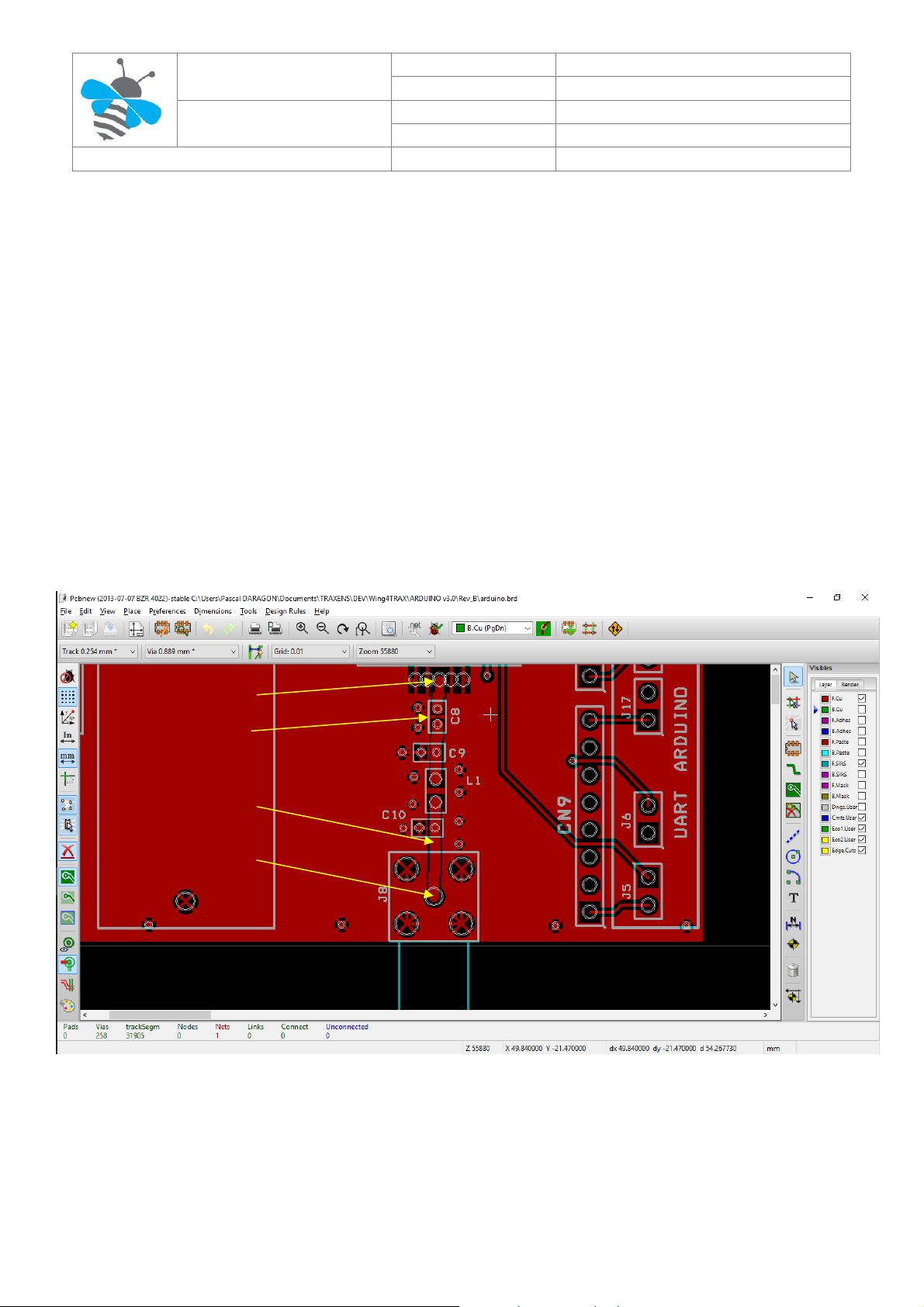

6 PRODUCT TESTING

6.1 TRAXENS MANUFACTURING TESTS

TRAXENS focuses on high quality for its products. All units produced are fully tested. Defective units are

analyzed in detail to improve the production quality.

This is achieved with automatic test equipment, which delivers a detailed test report for each unit. The

following measurements are done:

Digital self-test (firmware download, network UID and version information programming)

Measurement of voltages and currents in different power saving modes

Functional tests (serial interface communication, frame synchronization clock)

Digital tests (GPIOs, digital interfaces)

Analog tests (external ADCs, internal temperature sensor & reference voltage)

Measurement and calibration of RF characteristics in all supported bands (receiver sensitivity vs

BER, RSSI verification, tuning of frequency synthesizer, calibration of transmitter)

Verification of RF characteristics after calibration (power levels and spectrum performance are

checked to be within tolerances when calibration parameters are applied)

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

Figure 10: Wing4TRAX manufacturing test bench

Page 31

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

31 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

controller

Wing4TRAX

ANT

Spectrum Analyser

IN

6.2 TESTS POLICY FOR OEM MANUFACTURER

Because of the testing done by TRAXENS with 100% coverage, an OEM manufacturer does not need to repeat firmware tests or measurements of the module RF performance or tests over analog and digital interfaces in their production test.

An OEM manufacturer should focus on:

Module assembly on the device; it should be verified that:

Soldering and handling process did not damaged the module components

All module pins are well soldered on the host board

There are no short circuits between pins

Component assembly on the device; it should be verified that:

Communication with host controller can be established

The interfaces between module and device are working (for those used)

RF performance tests of the device including antenna are conform to expectations

Dedicated tests can be implemented to check the device. For example, the measurement of module current consumption when set in a specified status can be performed to detect a short circuit when compared

with a “Golden Device” result.

Specific test commands [refer to R2] can be used to perform functional tests (communication with host

controller, reading of network UID, GPIOs, ADCs, etc.) and to perform RF performance tests.

6.2.1 “GO/NO GO” TESTS

A “GO/No GO” test is intended to simply compare the signal quality with a “Golden Device”, in a position

where it can communicate in P2P mode with another “Golden Device”, with a stable and well known level

of signal (refer to CMD_MAC_SHORT_SEND and CMD_MAC_GET_RSSI commands in R1)

This test is suitable to quickly check the communication between host controller and the Wing4TRAX

module, power-good functionality and RF path integrity from the module to the device antenna.

6.2.2 FUNCTIONAL RF TESTS

Overall RF performance test of the device including antenna can be performed with basic instruments such

as a spectrum analyzer (or RF power meter) and a signal generator using test commands [refer to R2].

The test command set gives a simple interface to set the module into TX and RX test modes, ignoring TRAXNet signaling protocol. Each command can set the module:

In transmitting mode, in a specified channel and power level without modulation

In receiving mode, in a specified channel to returns the measured power level

Host

TRAXENS SAS – Les Baronnies – Bâtiment C – 15 Rue Marc Donadille – 13453 Marseille – France

SIRET 750 626 871 00016 ⎜APE 3320C ⎜Bureau : +33 4 91 11 88 16 ⎥ e-mail : info@traxens.com

module

Or

Power Meter

Page 32

TRAX-Net module

Doc Reference

DSE-WING4TRAX OEM-User Manual

Page

32 / 33

DSE

Version/Revision

1.4

Date

20/07/2016

User’s manual

Security

Level 1 – Restricted

controller

Wing4TRAX

ANT

Signal Generator

OUT

Host

module

Figure 11: synoptic of OEM test platform for radiation measurement

This feature allows the measurement of the transmitter and receiver power levels to check component