Page 1

Quality Refrigeration

OWNER’S MANUAL

Instructions for the proper installation, operation, care

and maintenance of all Traulsen VPS* Pizza Prep Tables

*U.S. Patent No. 6,089,036

Standard 12” Front to Back Rail Models

VPS48S, VPS54S, VPS66S, VPS72S, VPS90S & VPS114S

Jumbo 20” Front to Back Rail Models Models

VPS54J, VPS66J, VPS72J, VPS90J & VPS120J

This Traulsen unit is built to our highest quality standards. We build our refrigerators, freezers, and heated

cabinets this way as a matter of pride. This philosophy has made Traulsen the leader in commercial

refrigeration since 1938. We thank you for your choice and confidence in Traulsen equipment and we know

you will receive many years of utility from this equipment.

All Traulsen units are placed on a permanent record file with the service department. In the event of any

future questions you may have, please refer to the model and serial number found on the name tag affixed

to the unit. Should you need service, however, call us on our toll free number, 800-825-8220 between 7:30

a.m. and 4:30 p.m. CST, Monday thru Friday. It is our pleasure to help and assist you in every possible way.

INSTALLER

COMPLETE THE FOLLOWING INFORMATION PRIOR TO UNIT INSTALLATION

INITIAL START DATE: SERIAL NO.

MODEL TYPE:

COMPANY/INDIVIDUAL NAME:

INSTALLER:

FORM NUMBER TR35747 REVISED 7/05 P/N 375-60178-00

Page 2

TABLE OF CONTENTS

I. The Serial Tag Page 1

II. Receipt Inspection Page 2

III. Installation

a-Location & Clearance Page 2

b-Power Supply Page 2

c-Packaging Page 2-3

d-Installing Supports Page 3

e-Installing The Optional Ticket Rail Page 3

f-Optional LCD Thermometer Page 3

g-Installing The Shelves Page 3

h-Installing Optional Overshelves Page 3

IV. First Time Start-Up

a-Power Switch Page 4

b-Cord & Plug Page 4

c-Defrost Timer & Temperature Control Page 4

V. Daily Operation

a-Pans Page 4

b-Setting Up The Rail Page 4

c-Loading The Unit Base Page 4

d-Closing Down The Rail At Night Page 4

VI. Routine Cleaning

a-Cleaning The Rail Area Page 5

b-Cleaning The Cabinet Page 5

c-Shelves & Shelf Pins Page 5

d-Sliding Shelf Cover Page 5

VII. Service & Maintenance Information

a-Cleaning The Condenser Page 6

b-Light Bulb Replacement Page 6

c-Gasket Replacement Page 6

d-Door & Hinge Removal Page 6

e-Front Work Surface Removal Page 7

f-Defrost Timer Page 7

g-Temperature Control Page 7-8

h-Service Information Page 8

i-Wiring Diagram Page 8

VIII. Trouble Shooting Guide Page 9

IX. Operational Guidelines Page 9

X. Pan Capacities

a-The VPS System Page 10

b-Pans Page 10

c-Interior Arrangements Page 10

XI. Spare/Replacement Parts List

a-Standard Rail VPS Models Page 11

b-Jumbo Rail VPS Models Page 11

XII. Adapter Bar Chart Page 12

XIII. Warranty Information Page 13

XIV. Index Page 14

FORT WORTH, TX.

SERIAL MODEL

VOLTS Hz PH

TOTAL CURRENT AMPS

MINIMUM CIRCUIT AMPS

MAXIMUM OVERCURRENT PROTECTION AMPS

LIGHTS WATTS

HEATERS AMPS

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

370-60294-00 REV (A)

I. THE SERIAL TAG

The serial tag is located on the left interior wall

of thecompressor compartment. It contains

vital electrical andrefrigeration data as well as

the model and serial numberof your Traulsen

product.

READING THE SERIAL TAG

• Serial = The permanent ID# of your Traulsen product

• Model = The model # of your Traulsen product

• Volts = Voltage required to operate

• Hz = Frequency in Hertz 60 (U.S.) or 50

• PH = Phase 1

• Total Current = Maximum amp draw

• Minimum Circuit = Minimum circuit ampacity

• Maximum Overcurrent Protection = Maximum

recommended breaker or fuse

• Lights = Light wattage

• Heaters = Amperage of heater(s)

• Refrigerant = Refrigerant type & amount used

• Design Pressure = High & low side design pressures

• Agency Labels = Designate agency listing(s)

(most export units)

-1-

Page 3

II. RECEIPT INSPECTION

II. RECEIPT INSPECTION

III. INSTALLATION (cont’d)

All Traulsen products are factory tested for performance

and are free from defects when shipped. The utmost

care has been taken in crating this product to protect

against damage in transit. Casters or legs are boxed

inside to prevent damage.

Upon delivery carefully inspect your Traulsen unit for

shipping damage. If any is detected, note it on the

carrier’s Bill Of Lading and save all the crating

materials. File a freight claim immediately. If concealed

damage is discovered at installation, contact the

carrier and file a freight claim then. Under no

circumstances may any damaged unit(s) be returned

to Traulsen without proper prior authorization.

III. INSTALLATION

NOTE: If the unit is installed or stored near any

incomplete concrete or tile work see the note at the end

of section VI.b

III. a – LOCATION & CLEARANCE:

Select a location for your Traulsen VPS unit away from

extreme heat or cold. These units are designed to

operate in an environment of 86°F (30°C) or less.

Locate the unit so that air drafts (such as heat, A/C or

ventilation) do not blow on or over the rail area.

The condensing unit of your Traulsen VPS unit MUST

have adequate air circulation. Therefore, do not store

anything within of 31” of the condensing unit louvers

(located on the unit front). Allow enough clearance

between the unit and the side wall so that the doors

may open a minimum of 90°. Standard rail models

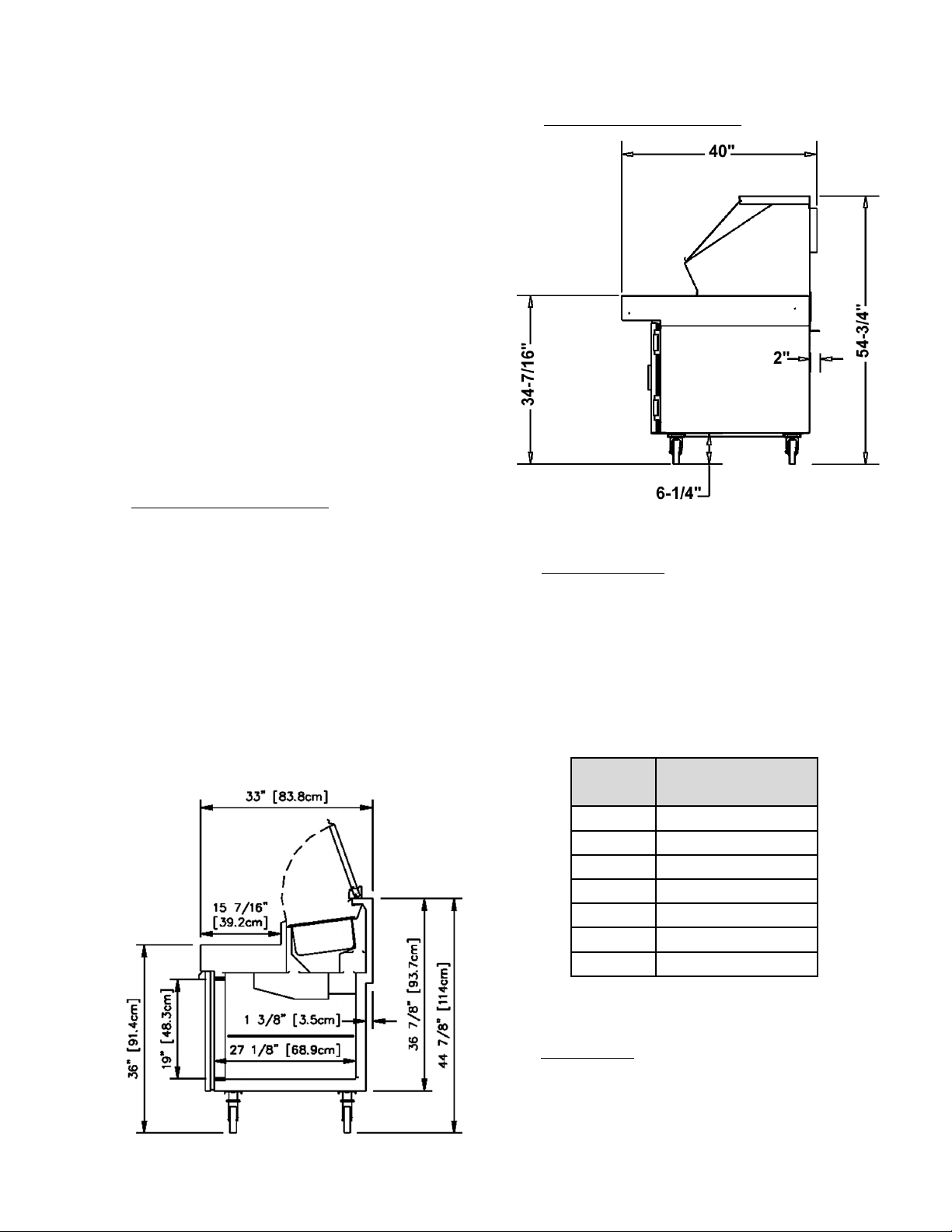

require at least 61-3/8” vertical clearance (16-1/2” above

the unit) to allow the rail cover to open completely (see

figures 1 & 2).

III. a – LOCATION & CLEARANCE (cont’d):

Fig. 2 Section View - Jumbo Rail Models

III. b - POWER SUPPLY:

WARNING

Electrical Shock Hazard

Do not remove ground prong

Do not use an adapter or extension cord

Plug only into a 3-prong

grounding receptacle

This unit requires a dedicated circuit and 3-prong

grounding receptacle.

Model NEMA Receptacle

Number Required

VPS48 5-15R

VPS54 5-15R

VPS66 5-15R

VPS72 5-15R

VPS90 5-20R

VPS114 5-20R

VPS120 5-20R

Fig. 1 Section View - Standard Rail Models

Verify the supply voltage prior to installation. Do not

plug the unit in before reading this entire manual.

III. c - PACKAGING:

Traulsen VPS units are shipped from the factory on a

wooden pallet and protected by a crate. Remove the

crate but leave the unit secured to the pallet until it

reaches its final location. Remove (4) lag screws that

secure the unit to the pallet. Lift and support the unit

-2-

Page 4

III. INSTALLATION (cont’d)

III. c - PACKAGING (cont’d):

then slide the pallet out from under it. DO NOT LAY

THE UNIT ON ITS BACK, FRONT OR SIDE.

NOTE: The front work surface of all Jumbo Rail

models can be removed if necessary to facilitate

transport through narrow doorways. See section VII.e

for details.

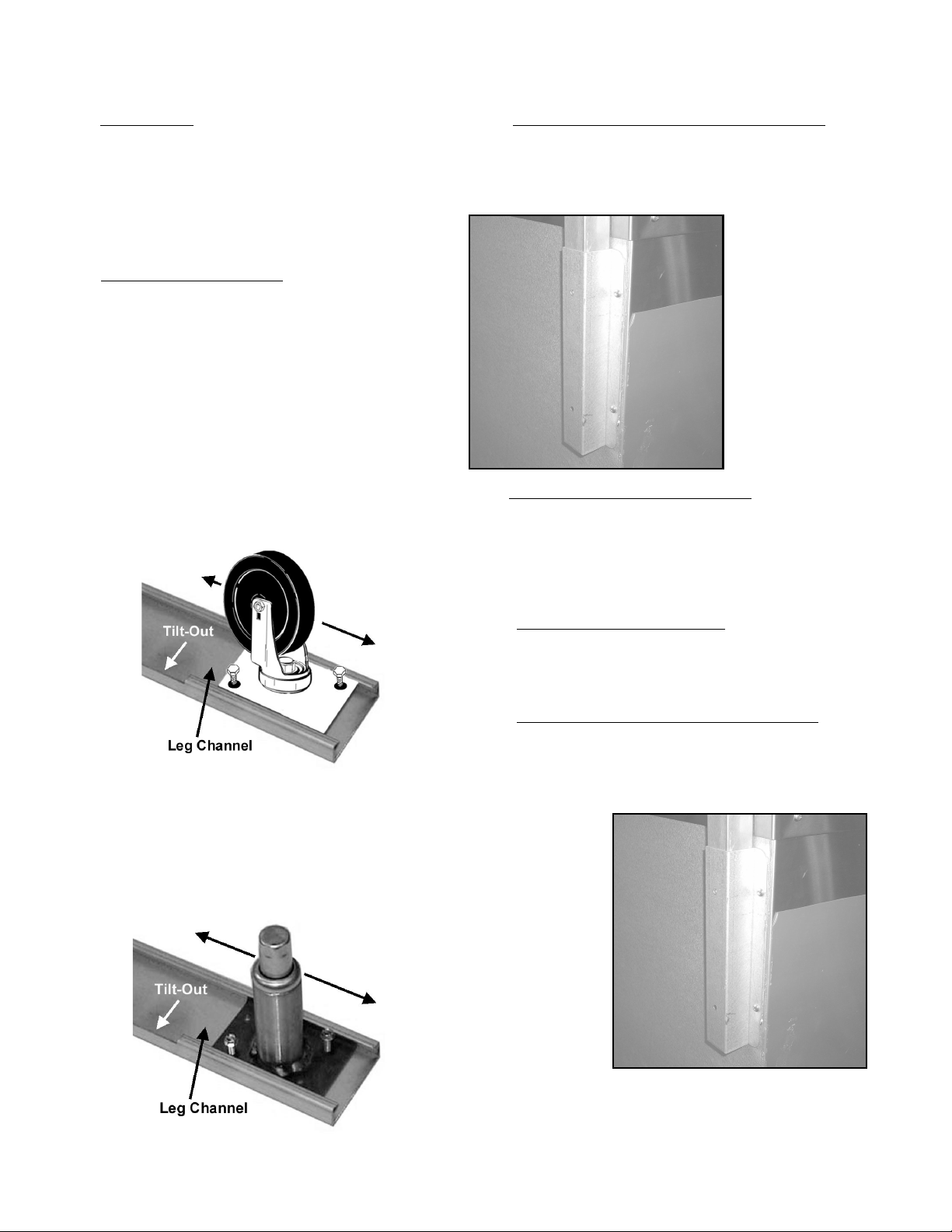

III. d - INSTALLING SUPPORTS:

Casters are supplied standard with all VPS models.

These are shipped from the factory packed inside a

cardboard box, contained within the unit.

WARNING: THE CABINET MUST BE SUPPORTED ON

BLOCKS AND STABLE BEFORE INSTALLING CASTERS

OR LEGS.

Raise and block the unit a minimum of 9” from the floor.

Slide the casters into the two channels under the front

and back of the cabinet. Casters can be positioned

anywhere along the unit’s entire length to avoid floor

obstructions such as drains and outlet boxes. Secure

all casters in place by tightening the two bolts located

at the base of each caster assembly (see figure 3).

III. e - INSTALLING THE OPTIONAL TICKET RAIL:

Supplied standard with jumbo rail models only. Use of

the ticket rail is optional and not required. Insert the

vertical legs of the ticket rail into the two receptacles

located on the rear of the cabinet (see figure 5).

Fig. 5

Ticket Rail Bracket

III. f - OPTIONAL LCD THERMOMETER:

Activate the optional LCD thermometer (if necessary)

by removing the paper insulator from the battery

contacts. One AA size battery is included. Open or

remove the louvered door to access the back of the

thermometer.

Fig. 3

NOTE: Casters or legs must be installed towards the

four corners of the unit as well as under the

compressor compartment for proper support.

Optional legs are installed in the same manner as

casters (see figure 4).

Fig. 4

Optional Legs

III. g – INSTALLING THE SHELVES:

Shelves are shipped in the bottom of the unit. Remove

the packaging from the shelves and place them on the

pins provided.

III. h – INSTALLING OPTIONAL OVERSHELVES:

Optional overshelves are installed in the same manner

as with the ticket rail. Insert the vertical legs of the

overshelf into the two receptacles located on the rear

of the cabinet (see figure 6).

Fig. 6

Overshelf Bracket

Use a pallet jack or forklift to prevent damage when

moving a unit on legs.

-3-

Page 5

IV. FIRST TIME START-UP V. DAILY OPERATION

If this equipment has been stored or shipped in an

ambient colder than room temperature, YOU MUST

ALLOW THE COMPRESSOR TO WARM UP TO ROOM

TEMPERATURE PRIOR TO CONNECTING TO THE

POWER SUPPLY. This could take several hours.

IV. a - POWER SWITCH:

The power switch is located at main electrical box

behind the louver panel and is shipped from the

factory in the OFF position.

IV. b - CORD & PLUG:

All self-contained VPS models are supplied with a cord

& NEMA three-prong grounding plug attached. It is

shipped coiled at the bottom of the compressor

compartment, secured by a nylon strip. Plug the power

cord into the proper NEMA receptacle then turn the

power switch ON.

IV. c - DEFROST TIMER & TEMPERATURE CONTROL:

After the unit is plugged in and turned on, set the

defrost timer by turning the small knob (near the outer

edge of the large dial) clockwise until the correct time

of day on the large dial lines up with the TIME pointer.

Defrost times are set from the factory at 10am, 2pm,

8pm, 2am and 6am. Refer to section “VII. f” for more

info (see figure 7).

V. a - PANS:

Standard rail VPS models are designed to operate with

full, half or third size pans without the use of adapter

bars. Other fractional size pans can be used with

optional adapter bars available from Traulsen. (see

section “X. b” for more info).

Jumbo rail VPS models are designed to operate with

full size pans without the use of adapter bars. Other

fractional size pans can be used with optional adapter

bars available from Traulsen. (see section “X. b” for

more info).

Use only stainless steel or aluminum food pans no more

than 4” deep in order to maintain product temperatures

within the current NSF Standard 7 guidelines

SETTING UP THE RAIL:

V. b Install pans in all pan spaces in the rail. Rest each pan

evenly on the front and back support ledges. Do not

use uneven or bent pans, as these will allow

circulating cold air to escape.

Allow the unit to reach operating temperature before

loading any food product. Load only refrigerated

product @ 36

o

F or below.

All pan spaces should be filled, even if some pans are

empty (even during nighttime storage).

When not in constant use, the VPS rail covers should

be kept closed over the pans.

Fig. 7

Defrost Time Clock

NOTE: The defrost time clock will have to be reset to

the current time if the unit loses power or the Power

switch is turned off for any significant amount of time.

Temperature is controlled electronically and needs no

adjustment in normal use. Reprogramming is not

necessary even if the power is interrupted.

V. c - LOADING THE UNIT BASE:

When loading product into the base take care that the

evaporator fans, located at the top of the compartment,

are not obstructed. Secure all paper and plastic wrap

to prevent it being drawn into the fans. Keep the doors

closed except when loading or removing product.

V. d - CLOSING DOWN THE RAIL AT NIGHT:

Food product may be stored in the rail overnight if

needed. Cover the entire rail with plastic wrap prior to

closing the rail covers over the pans.

-4-

Page 6

VI. ROUTINE CLEANING

Use only cleaning products designed for use on stainless steel in conjunction with the proper tools to retain the

like-new appearance of your Traulsen refrigeration product. Occasional use of a commercial stainless steel

polish, such as “Sheila Shine,” will help protect the stainless steel surface. Follow the directions on the spray

can for proper use.

VI. a - CLEANING THE RAIL AREA:

Remove all food pans and rail inserts for cleaning

separately. Wipe out the rail area being careful not to

wipe debris into any of the raised openings in the rail

bottom. These are air discharge and air returns for the

VPS system, and must be kept clean, clear and open

for proper operation.

VI. b - CLEANING THE CABINET:

Remove the cutting board and crumb cans for cleaning

separately.

Clean all stainless steel surfaces frequently and

thoroughly with mild soap and plenty of water, followed

by a clean water rinse. Wipe dry with a clean soft cloth.

Keeping the unit clean and dry will minimize the risk of

rust and corrosion. Remove food spills before they dry

and harden. The salt and acid in many foods will

promote corrosion of the stainless steel if it is left in

place too long.

Use a nylon brush or scouring pad only if necessary,

scrubbing in the same direction as the grain of the steel.

Don’t use bleach or harsh abrasives, as both will

promote corrosion. You can use a 1% ammonia

solution or a mixture of baking soda and water for

stubborn residue. Always follow any cleaning with a

clean water rinse then wipe dry with a clean cloth.

VI. b stainless steel so badly that it is difficult or impossible

to restore to its original appearance.

VI. c - SHELVES & SHELF PINS:

The interior shelves are mounted on shelf pins and are

easily removable for cleaning. Lift the shelf off the shelf

pins, tilting up slightly on one side to allow it to slide

through the door opening.

The shelf pins can be unscrewed by hand if

necessary. Reinstall the pins in their correct

locations, then hand tighten securely. Do not over

tighten.

VI. d All jumbo rail VPS models are supplied standard with a

sliding rail cover. To remove this for cleaning, hold the

cover slightly above horizontal, making sure the lower

edge of the “hook” at the rear of the cover clears the

retaining rod, then pull sharply. To reinstall the cover,

place the rear of the cover on top of the retaining rod (it

will wedge between the rod and the top of the unit),

and then bump it into place.

CLEANING THE CABINET (cont’d):

SLIDING RAIL COVER:

Clean all interior surfaces, including the door gaskets

and the gray vinyl breaker strips around the door

openings in the same way. All interior fittings are

removable without tools to facilitate cleaning.

Never use mild steel scrapers, tools or steel wool on

the stainless steel cabinet. In addition to scratching

the surface, they will leave microscopic residue that

will cause rust. Even the cleaning or drying cloth, if

previously used on mild steel (other than stainless) can

leave a residue that promotes rust. Always use a

cloth.

Clean the cabinet exterior thoroughly after every time

the floor is mopped to minimize damage from harsh

floor-cleaning chemicals.

NOTE

Muriatic or Hydrochloric acid is sometimes used to

clean concrete or tile work and can severely damage

the unit, even if it doesn’t make direct contact! Fumes

from an open container in the same room can discolor

clean

-5-

Page 7

VII. SERVICE & MAINTENANCE INFORMATION

VII. a - CLEANING THE CONDENSER:

Clean the condenser at least monthly (more often if

necessary) to insure long service life. Keeping the

condenser free of lint and dust will allow the

refrigeration system to operate at peak efficiency and

minimize the risk of premature failure.

To clean the condenser, open or remove the front

louver assembly then turn the Power switch OFF. If the

louvered door is not hinged, lift the door out of the lower

cradle and then slide it down and out of the top bracket.

Vacuum and brush any dirt, lint or dust from the finned

condenser coil, taking care not to bend the thin

aluminum fins.

VII. b - LIGHT BULB REPLACEMENT (if equipped):

Turn the power switch OFF, remove the light cover and

unscrew the light bulb. Replace with a bulb of identical

type (115V 40-Watt T-6 1/2 Intermediate Base Clear

Refrigerator Lamp) and reinstall the light cover.

VII. c - GASKET REPLACEMENT :

Allow the new gasket to warm up to room temperature

before unfolding it. Soak the gasket in warm water if

necessary to speed up the warming process. Open (or

remove) the door and carefully pull the old gasket out

of the retainer. Clean the gasket retainer groove and

the area under the gasket. Start in one corner and push

the tongue of the new gasket into the groove for about

3 inches in each direction. Repeat with the other three

corners. The new gasket may appear too large at this

point. Using a rubber mallet, tap on the face of the

gasket to work the remainder of the tongue into the

retainer, starting at the corners and working toward the

middle (see figure 8)

VII. d - DOOR & HINGE REMOVAL:

Remove the hinge cover from both hinges. On the lower

hinge insert a 3/32” pin punch into one of the holes in

the spring retainer. Rotate the retainer clockwise

slightly and remove the locking pin. Allow the punch

to come to rest against the hinge body where the

locking pin was. Insert another 3/32” punch into one

of the holes in the spring retainer and rotate clockwise

slightly so the first punch can be removed. Repeat until

there is no tension on the spring. Grip the upper spring

retainer with Vise-Grips and push it straight down, then

out of the hinge. Be careful not to lose the flat washer

above the upper spring retainer, or the shoulder

bushing below the lower spring retainer. The screws

that secure the hinge to the cabinet and the hinge to

the door are all now accessible (see figure 9).

Fig. 9

Door Hinge

Reinstall in reverse order, first hinges to the door, then

door & hinge assembly to the cabinet. Install the spring

assist parts in the lower door hinge in order from the

bottom up: shoulder bushing, lower spring retainer

(with holes), spring, upper spring retainer and flat

washer. Grip the upper spring retainer with Vise-Grips

and push it straight down, then in and over the pin in

the hinge assembly. Use the two 3/32” punches and

the holes in the lower spring retainer to rotate the spring

clockwise approximately half a turn before inserting the

locking pin. The door should open past 900 and close

completely from any position.

Fig. 8

Gasket Installation

-6-

Page 8

VII. SERVICE & MAINTENANCE INFORMATION (cont’d)

VII. e - FRONT WORK SURFACE REMOVAL :

To facilitate transport through narrow doorways all

Jumbo Rail VPS models are supplied standard with a

removable front work surface (see figure 10).

WARNING: Excess weight hazard. Use two or more

people and to remove and reinstall. Failure to do so

can result in damage to the unit and/or injury.

1) Remove the side cover (held in place by two screws)

from each side.

2) Remove the screw from each side.

3) Remove the screws under the work surface, above

the louver and hinged doors.

4) Support the work surface securely then remove the

screws from the vertical lip at the rear of the work

surface.

5) Lift the work surface up and away from the cabinet.

Reinstall in reverse order and seal the perimeter with

silicone.

VII. f - DEFROST TIMER:

In normal operation the defrost timer only needs to be

set on startup and after each power loss. Rotate the

small knob (near the outer edge of the large dial)

clockwise until the correct time of day on the large dial

is opposite the TIME pointer. Pins that initiate each

defrost cycle are set at the factory at 2am, 6am, 10am,

2pm and 8pm. If your operation requires different

defrost times simply relocate one or more of the pins

(around the outer edge of the large dial) to the

appropriate time. Leave four hours minimum time

between pins. A minimum of five (5) defrost cycles are

required per day. Defrost is terminated by a nonadjustable temperature-activated switch located in the

evaporator housing. The bronze pointer on the inner

dial controls the time-activated backup termination and

should not be changed from the factory setting of 30

minutes.

Remove the stainless

steel side brackets

from each side.

Fig. 10

Removing the

Work Surface

Lift work surface up

and away from unit

when all screws are

removed.

Fig. 11

Defrost Timer

VII. g - TEMPERATURE CONTROL:

The electronic temperature control is set at the factory

and needs no adjustment in normal use.

Reprogramming is not necessary even if the power is

interrupted. If the control has to be replaced, verify

that the settings match the original factory settings. See

below for factory settings.

The control is equipped with a lockout switch to

prevent unauthorized tampering. VPS units are shipped

from the factory with this switch in the LOCK position,

with the keypad disabled.

To check or change the settings:

Turn the power switch OFF then loosen the 4 screws

that hold the control cover in place. The lockout switch

is located on the inside cover about two inches above

the bottom (see figure 12). To enable the keypad, slide

the switch to the right (UNLOCK) position. Replace the

control cover and turn the power switch ON. Always

disable the keypad by moving the switch to left (LOCK)

position after checking the settings.

-7-

Page 9

VII. SERVICE & MAINTENANCE INFORMATION (cont’d)

VII. g - TEMPERATURE CONTROL (cont’d):

With the switch in the UNLOCK position, the settings

can be checked (or changed) in four simple steps

using the LCD display and the three keys on the

control face.

LOCK UNLOCK

LOCKOUT: LOCK UNLOCK

R

○○○

DISPLAY CODES

FFAHRENHEIT

C CELCIUS

H1 HEAT SATGE 1

C1 COOL STAGE 1

EP PROBE FAILURE/

OUT OF RANGE

EE EEPROM ERROR

E1 IMPROPER SET

E2 MEMORY ERROR

Fig. 12

NOTE: The control will automatically end programming

if no keys are pressed for a period of thirty seconds.

The last settings will be saved to the control at that

point.

STEP 1- Press the SET key once to access the

Fahrenheit/Celsius mode. The display will show the

current status, either F for Fahrenheit or C for Celsius.

The up & down arrow keys will toggle between F and

C. Factory setting is F.

VII. g - TEMPERATURE CONTROL (cont’d):

STEP 4- Press the SET key again to access the

cooling/heating mode. The LCD will display the

current mode. Pressing the up and down arrow keys

will toggle between C1 and H1. Factory setting is C1.

Press the SET key once more to end programming.

VII. h - SERVICE INFORMATION:

Before calling for service, please check the following:

Is the electrical cord plugged in?

Is the fuse OK or circuit breaker on?

Is the power switch ON?

If after checking the above items the unit is still not

operating properly, please contact an authorized

Traulsen service agent. A complete list of authorized

service agents was provided along with your Traulsen

unit. You may also obtain the name of a service agent

from the Technical Service section of our company

website: www.traulsen.com.

If service is not satisfactory, please contact our

in-house service department at:

Traulsen

4401 Blue Mound Road

Fort Worth, TX 76106

(800) 825-8220

Traulsen reserves the right to change specifications

or discontinue models without notice.

Fig. 13

Temperature

Control

STEP 2- Press the SET key again to access the setpoint.

The LCD will display the current setpoint and blink S1.

Pressing the up and down arrow keys will change the

setpoint. The compressor will shut off when the

cabinet cools to this temperature. Factory setting is

35.

STEP 3- Press the SET key again to access the

differential. The LCD will display the current

differential and blink DIF1. Pressing the up and down

arrow keys will change the differential. The

compressor will come on when the cabinet

temperature rises above the setpoint (step 2) by the

amount of the differential. Factory setting is 3.

VII. i - WIRING DIAGRAM:

A wiring diagram is supplied along with the unit and is

also available by request from the Traulsen Service

Department by calling (800) 825-8220. To expedite

service, please have the model and serial number of

the unit involved available to you whenever calling with

any service related questions.

-8-

Page 10

VIII. TROUBLE SHOOTING GUIDE

OPERATIONAL SYMPTOM POTENTIAL CAUSE/REMEDY

1.Unit fails to start. a. Unit unplugged, breaker tripped or fuse blown.

b. Switch in OFF position.

2. Interior compartment is too warm. a. Door(s) open.

b. Warm product recently loaded.

c. Door gaskets damaged or worn.

d. Pan(s) missing.

3. Condensation on the exterior surface. a. Condensation on the exterior surface of the

unit is perfectly normal during periods of

high humidity.

b. Door(s) misaligned or gaskets faulty.

4. Product temperature in rail too warm. a. Product held in plastic pans.

b. Room ambient temperature exceeds 86°F.

Operate in room ambient below this temperature.

c. Air drafts disrupting air-flow over product pans.

d. Food debris blocking air discharge and/or return

vents.

e. Product loaded in pans above 36°F.

f. Rail inserts missing.

g. Base doors left open.

h. Pan(s) missing.

IX. OPERATIONAL GUIDELINES

Follow these simple guidelines for proper VPS operation:

• Keep the condenser clean. Don’t obstruct the airflow.

• Reset the defrost timer to the proper time of day upon startup after any power loss or

shutdown.

• Rail inserts must be in place (under pans) before loading any pans.

• Use only 4” deep stainless steel or aluminum pans.

• All pan spaces should be filled any time the unit is running, even if some pans are empty.

• Keep the room temperature at 86°F (30°C) or less.

• Do not allow air drafts (such as heat, A/C or ventilation) to blow on or over the rail area.

This will disrupt the air blanket over the product area, resulting in poor holding

temperatures.

• Rail covers should be closed over the rail as much as possible.

• Product should be loaded into the rail at a maximum temperature of 36°F. The VPS unit

was not designed to chill warm product, but to hold refrigerated product at a safe

temperature.

• Keep the area around the evaporator fans clear.

• When cleaning the rail area, do not wipe debris into the raised openings in the rail

bottom. These are air discharge and air returns for the VPS system, and must be kept

clean, clear and open.

-9-

Page 11

X. PAN CAPACITIES

X. a - THE VPS SYSTEM:

The Venturi Plenum System (VPS) pizza prep tables are

designed to keep all foods fresh, at an even

temperature, without freezing. The VPS system

accomplishes this task by surrounding product with cold

air top to bottom and on all sides without drying the

ingredients. This extends shelf life, eliminating the need

to stir products or rotate pans. It has the added benefit

of eliminating cleanup associated with the frost and

condensation found in “wrapped rail” (cold wall type)

designs. The Standard 12” and Jumbo 20” front-to-back

raised rail places pans in full view, where they are easy

to use and can be completely filled, reducing labor.

X. b - PANS:

The standard rail (12” front to back) VPS models are all

designed to accommodate either full size (12” x 20”),

half or third size pans without the use of adapter bars

(pans supplied by others). See below for individual model

pan capacities.

Model No. Third Full

VPS48S 6 2

VPS54S 7 2-1/3

VPS66S 9 3

VPS72S 10 3-1/3

VPS90S 12 4

VPS114S 16 5-1/3

The jumbo rail (20” front to back) VPS models are all

designed to accommodate full size (12” x 20”) pans

without the use of adapter bars (pans supplied by

others). See below for individual model pan capacities.

Model No. Third Full

VPS54J 12 4

VPS66J 12 4-1/2

VPS72J 16 5-1/3

VPS90J 18 6-1/2

VPS120J 7-1/3

Raised Ingredient Rail Details

X. c - INTERIOR ARRANGEMENTS:

One (1) powder-coated shelf is mounted behind each

door. Optional angle type tray slides may be ordered in

place of shelves on all units EXCEPT 48” or 54” long

models.

-10-

Page 12

XI. SPARE/REPLACEMENT PARTS LISTING

XI. a - SPARE/REPLACEMENT PARTS LIST FOR ALL STANDARD RAIL VPS PIZZA PREP TABLE MODELS:

Part Description VPS48S VPS54S VPS66S VPS72S VPS90S VPS114S

Door Gasket 341-60070-00 341-60070-00 341-60050-00 341-60050-00 341-60050-00 341-60050-00

Door - Hinged Left 200-60150-00 200-60150-00 200-60144-00 200-60144-00 200-60144-00 200-60144-00

Door - Hinged Right 200-60151-00 200-60151-00 200-60145-00 200-60145-00 200-60145-00 200-60145-00

Temperature Control 403-130-103-100 403-130-103-100 403-130-103-100 403-130-103-100 403-130-103-100 403-130-103-200

Condensing Unit 414-130-104-500 414-130-104-500 414-130-104-600 414-130-104-600 414-130-104-600 414-130-104-200

Metering Device 403-130-103-000 403-130-103-000 403-130-103-000 403-130-103-000 403-130-103-000 403-130-103-000

Evaporator Assembly 325-60091-00 325-60091-00 325-60090-00 325-60090-00 325-60091-00 (2) 325-60091-00 (2)

Evaporator Fan Motor 403-130-051-800 403-130-051-800 403-130-051-800 403-130-051-800 403-130-051-800 403-130-051-800

Evaporator Fan Blade 403-130-051-700 403-130-051-700 403-130-051-700 403-130-051-700 403-130-051-700 403-130-051-700

Evaporator Fan Guard SER-60432-00 SER-60432-00 SER-60432-00 SER-60432-00 SER-60432-00 SER-60432-00

Defrost Heaters 403-130-057-100 403-130-057-100 403-130-090-700 403-130-090-700 403-130-057-100 403-130-090-700

Vertical Pan Support 7000070 7000070 7000070 7000070 7000070 7000070

Short Horiz. Pan Supp. 7000071 7000071 7000071 7000071 7000071 7000071

Long Horiz. Pan Supp. 7000204 7000204 7000204 7000204 7000204 7000204

Nylon Cutting Board 340-60142-00 340-60106-00 340-60144-00 340-60141-00 340-60145-00 340-60146-00

Std. Interior Shelf 410-130-104-900 410-130-104-900 410-130-104-800 410-130-104-800 410-130-104-800 410-130-104-800

Shelf Mounting Pin 344-24759-01 344-24759-01 344-24759-01 344-24759-01 344-24759-01 344-24759-01

Rail Cover (lid) 8700071 8700141 8700158 8700103 8700177 8700009

Air Deflector 8700038 700-60120-00 8700129 700-60132-00 700-60129-00 700-60131-00

Air Diffuser 8700202 8700153 8700252 8700121 8700213 8700050

Door Hinges 409-130-056-200 409-130-056-200 409-130-056-200 409-130-056-200 409-130-056-200 409-130-056-200

Door Hinge Spring Kit 409-130-056-300 409-130-056-300 409-130-056-300 409-130-056-300 409-130-056-300 409-130-056-300

8” Casters - w/Brake 101510 101510 101510 101510 101510 101510

8” Casters - w/o Brake 101509 101509 101509 101509 101509 101509

XI. b - SPARE/REPLACEMENT PARTS LIST FOR ALL JUMBO RAIL VPS PIZZA PREP TABLE MODELS:

Part Description VPS66J VPS90J VPS90J VPS120J

Door Gasket 341-60050-00 341-60050-00 341-60050-00 341-60050-00

Door 200-60287-00 200-60287-00 200-60287-00 200-60287-00

Temperature Control 403-130-113-700 403-130-113-700 403-130-113-700 403-130-113-700

Metering Device 403-130-103-000 403-130-103-000 403-130-103-000 403-130-103-000

6” Casters - w/Brake 500-60350-00 500-60350-00 500-60350-00 500-60350-00

6” Casters - w/o Brake 500-60349-00 500-60349-00 500-60349-00 500-60349-00

Door Hinges 409-130-056-200 409-130-056-200 409-130-056-200 409-130-056-200

Hinge Spring Kit 409-130-056-300 409-130-056-300 409-130-056-300 409-130-056-300

Condenser 414-130-104-600 414-130-104-600 414-130-104-600 321-60140-00

Evaporator Fan Motor 404-130-051-800 404-130-051-800 404-130-051-800 404-130-051-800

Evaporator Fan Blade 404-130-051-700 404-130-051-700 404-130-051-700 404-130-051-700

Evaporator Fan Guard SER-60432-00 SER-60432-00 SER-60432-00 SER-60432-00

Std. Interior Shelf 410-130-104-800 410-130-104-800 410-130-104-800 410-006-039-043

Shelf Mounting Pin 344-24759-01 344-24759-01 344-24759-01 344-24759-01

Defrost Heaters 403-130-090-700 403-130-090-700 403-130-057-100 403-130-090-700

Scrap Pan 405-090-054-000 405-090-054-000 405-090-054-000 405-090-054-000

Ticket Rail 284-206 239-205 240-235 700-60161-00

Sauce Pan Platform* 7000405 7000405 7000405 7000405

Cheese Deflector* n/a n/a n/a 700-60180-00

Light Bulb 378-29776-00 378-29776-00 378-29776-00 378-29776-00

NOTE

To identify or obtain replacement parts for other VPS models, or for parts not

listed above, please contact the Traulsen Parts Department at (800) 825-8220

-11-

Page 13

XII. ADAPTER BAR CHART

(not shown to scale)

p/n 6084006

Vertical Support For Standard Rail Models Only

p/n 7000070A

Vertical Support For Jumbo Rail Models Only

p/n 8700226

Horizontal Support For Standard Rail Models Only

p/n 7000071A

Horizontal Support For Jumbo Rail Models Only

p/n 8700008

Horizontal Support For Jumbo Rail Models Only

p/n 7000204

Horizontal Support For Jumbo Rail Models Only

-12-

Page 14

XIII. WARRANTY INFORMATION

STANDARD DOMESTIC WARRANTY

TRAULSEN warrants new equipment to the original purchaser, when installed within the United States

against defective material and workmanship for one (1) year from the date of original installation.

Under this warranty, TRAULSEN will repair or replace, at its option, including service and labor, all

parts found to be defective and subject to this warranty. The compressor part is warranted for an

additional four (4) years. During this period TRAULSEN will supply replacement compressor(s) if deemed

defective, however, all installation, recharging and repair costs will remain the responsibility of the

owner.

This warranty does not apply to damage resulting from fire, water, burglary, accident, abuse, misuse,

transit, acts of God, terrorism, attempted repairs, improper installation by unauthorized persons, and

will not apply to food loss.

THERE ARE NO ORAL, STATUTORY OR IMPLIED WARRANTIES APPLICABLE TO TRAULSEN,

INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

TRAULSEN SHALL HAVE NO OBLIGATION OR LIABILITY FOR CONSEQUENTIAL OR SPECIAL

DAMAGES, GROWING OUT OF OR WITH RESPECT TO THE EQUIPMENT OR ITS SALE, OPERATION OR

USE, AND TRAULSEN NEITHER ASSUMES NOR AUTHORIZES ANYONE ELSE TO ASSUME FOR IT ANY

OBLIGATION OR LIABILITY IN CONNECTION WITH THE EQUIPMENT OR ITS SALE, OPERATION OR

USE OTHER THAN AS STATED HEREIN.

INTERNATIONAL COMMERCIAL WARRANTY

(for Canadian warranties see domestic US warranty)

TRAULSEN warrants to the original purchaser the Refrigeration Equipment manufactured and sold by it to be

free from defects in material and workmanship under normal use and service for a period of one (1) year from

date of shipment. Under this warranty, TRAULSEN will reimburse the purchaser for the replacement of any

part of said equipment (excluding dryers & refrigerant gas) which then proves to be defective. This warranty

does not apply to damage resulting from fire, water, burglary, accident, abuse, misuse, transit, acts of

God, terrorism, attempted repairs, improper installation by unauthorized persons, and will not apply to

food loss.

TRAULSEN’S standard warranty does not apply to Export Sales. Rather, for a period of one (1) year from date

of original installation not to exceed Fifteen (15) months from date of shipment from factory, TRAULSEN:

will replace, F.O.B. factory, any defective parts normally subject to warranty.

will not cover the cost of packing, freight or labor such costs being the sole responsibility of the dealer.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EITHER EXPRESSED OR IMPLIED AND

CONSTITUTES TRAULSEN’S FULL OBLIGATION AND LIABILITY. WARRANTIES NOT AVAILABLE ON

REMOTE MODELS.

-13-

Page 15

XIV. INDEX

A

Adapter Bars 12

B

C

Casters, Installing 3

Cleaning, All 5-6

Clearance 2

Cord & Plug 4

D

Defrost Timer 4, 7

Door, Removal 6

E

F

Freight Damage 2

G

Gasket, Replacement 6

H

Hinge, Removal 6

I

Interior Arrangements 10

J

K

L

Leg Channel Mounting System 3

Legs, Installing 3

Light Bulb, Replacing The 6

Loading, Unit Base 4

Locking Pin, Hinge 6

Lock-Out Switch 7-8

M

N

NEMA Receptacle 2

O

Operating Guidelines 9

Overshelves, Installing The Optional 3

P

Packaging 2

Pans 4

Pan Capacities 10

Parts, Replacement List 11

Power Supply 2

Power Switch 4

R

Return Authorization 2

Rail Cover, Sliding 5

Rail, Closing Down At Night 4

Rail, Setting Up The 4

S

Serial Tag 1

Shelf Pins 5

Shelves, Installing 3, 10

Spring Retainer, Hinge 6

Start-Up, First-Time 4

T

Temperature Control 4, 7-8

Temperature Scale, Changing The 8

Ticket Rail, Installing The Optional 3

Thermometer, Optional LCD 3

Trooubleshooting 9

U

V

Venturi Plenum System, Description 10

W

Warranty 13

Wiring Diagram 8

Work Surface, Removal 7

X

Y

-14-

Z

Page 16

HOURS OF OPERATION:

Monday thru Friday 7:30 a.m. - 4:30 p.m. CST

Traulsen

4401 Blue Mound Road Fort Worth, TX 76106

Phone: (800) 825-8220 Fax-Svce: (817) 740-6757

Website: www.traulsen.com

Quality Refrigeration

© 2005 Traulsen - All Rights Reserved

Loading...

Loading...