Page 1

Traulsen Refrigeration

SERVICE MANUAL

Instructions For The Troubleshooting And

Repair Of Traulsen SmartChill

Record And Label Printers

RBC50, RBC100, RBC200, RBC200RT,

RBC400 & RBC400RT Blast Chiller Models

®

Control

This manual is prepared for the use of trained Authorized Traulsen Service Agents and should not be used by

those not properly qualied. This manual is not intended to be all encompassing, but is written to supplement

the formal training, on-the-job experience and other product knowledge acquired by Authorized Traulsen

Service Agents. Before proceeding with any work, you should read, in its entirety, the repair procedure you

wish to perform to determine if you have the necessary tools, instruments and skills required to perform the

procedure. Only a trained Authorized Traulsen Service Agent should perform procedures for which you do

not have the necessary tools, instruments and skills. Reproduction or other use of this manual without the

express written consent of Traulsen, is prohibited.

FORM NUMBER TR35911 REV. 9/09 P/N 370-60307-00

Page 2

TABLE OF CONTENTS

I. GENERAL INFORMATION

a-Introduction 1

b-Operation 1

c-Cleaning 1

d-Applicable Models 1

e-Tool Requirements 1

f-Enable-Disable Label Printer 1

II. BASIC SERVICE PROCEDURES & ADJUSTMENTS

a-Check Record Printer Media 2

b-Check Label Printer Media 2

c-Loading The Printer Media 2

d-Running A Test Print 2

III. PRINTER COMPONENT DIAGRAM 2

I. GENERAL INFORMATION

I. a–INTRODUCTION:

A Traulsen Blast Chiller will come standard with one printer, the

record printer. All SmartChill® controls have the option to enable

or disable the use of a second printer, the label printer.

When facing the front of the unit the record printer is located in

the left printer housing and the label printer is in the right printer

housing.

Both printers, record and label, have the same part number

950-60355-00 and are interchangeable with the exception of

any RBC50 models manufactured prior to 2008, with 90 degree

printer boards in which case the part number is 950-60408-00.

I. b–OPERATION:

SmartChill® printers are thermal printers, meaning no ink is required. Upon receipt of a signal from the SmartChill® control,

the printers will print specied data. The record printer ONLY

uses 2 ¼” thermal paper and the label printer ONLY uses 2 ¼”

Traulsen thermal label stock part number 400-60004-00.

The record printer will print power on diagnostics information,

single batch data, and twelve hour data logs.

IV. ADVANCE SERVICE PROCEDURES & ADJUSTMENTS

a-Cutting Wheel Operation 3

b-Check Printer Power-Basic 3

c-Check Printer Power-Advanced 3

d-Check Printer Data Harness 3

e-Interchange Instructions 3

V. FLOW CHART - SERVICE PROCEDURES

& ADJUSTMENTS 4

VI. SMARTCHILL® BOARD DIAGRAM 5

VII. TROUBLESHOOTING 6

I. d–APPLICABLE MODELS:

This manual applies to the following Traulsen models:

RBC50 Undercounter Blast Chill Model

RBC100 Reach-In Blast Chill Model

RBC200 Roll-In Blast Chill Model

RBC200RT Roll-Thru Blast Chill Model

RBC400 Roll-In Blast Chill Model

RBC400RT Roll-Thru Blast Chill Model

NOTE: This manual refers to the above models built

after June 2003, equipped with the SmartChill® control.

For information regarding models built prior to that date

please contact the factory at 800-825-8220.

I. e–TOOL REQUIREMENTS:

• Basic hand tools

• AC/DC VOM

I. f–ENABLE-DISABLE LABEL PRINTER:

The FACTORY SETTINGS MODE allows service personnel to return various control settings to their factory

preset parameters.

The label printer will print single batch product labels, that may

be applied on food containers.

I. c–CLEANING:

Dirt and debris can build up on the feed roller and cutting wheel

cartridge and impede normal operation. Clean only with electric

contact cleaner using a lint free cloth.

-1-

Page 3

I. GENERAL INFORMATION (cont’d)

I. f–ENABLE-DISABLE LABEL PRINTER (cont’d):

To enter from the keypad, press “MORE” from the “MAIN

MENU”. Press “SETUP”, and change the “PASSWORD

(PIN)” to “85”. Press and hold the upper left, upper right

and lower right keys simultaneously. Then release all

keys. Display will read as follows:

Press “NEXT”, this will bring you to the Label Printer

option screen:

II. BASIC SERVICE PROCEDURES

& ADJUSTMENTS (cont’d)

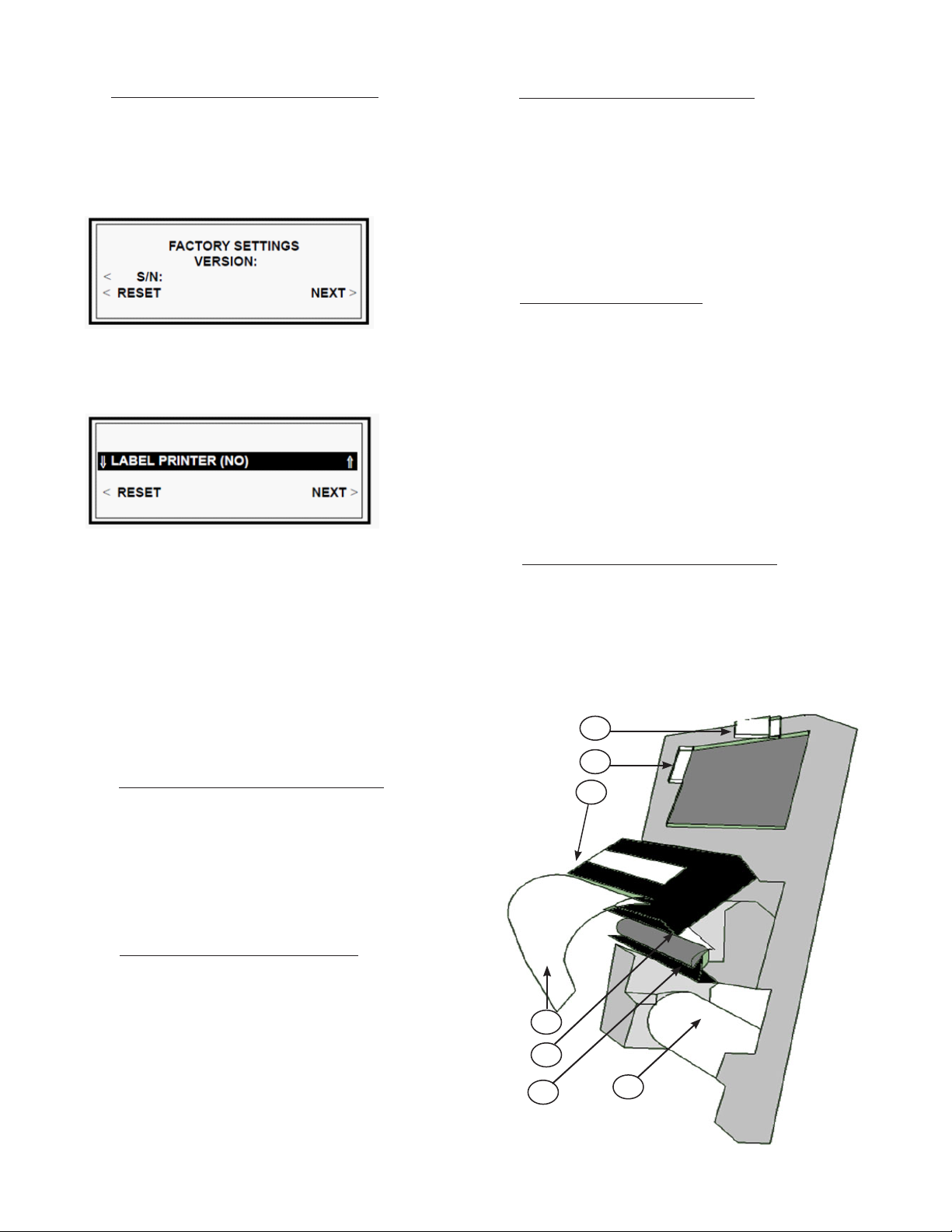

II. c–LOADING THE PRINTER MEDIA:

• Place printer media on spindle (see gure 1; reference 7).

• Fold the end of the printer media to a centered point allows

smoother transition when feeding (see gure 1; reference 4).

• Lift the cutting wheel cartridge (see gure 1; reference 3) and

release the feed roller tension arm (see gure 1; reference 6).

• Feed the printer media over the feed roller (see gure 1; refer

ence 5) and through the cutting wheel cartridge.

NOTE: Thermal coating side must face up.

• Engage feed roller tension arm and cutting wheel cartridge.

II. d–RUNNING A TEST PRINT:

• Start at the “MAIN MENU”

• Press “MORE”

• Press “SET UP”

• Change “PASSWORD (PIN)” to “75”

• Press the top left, top right and the bottom right buttons

simultaneously and release to enter the “SERVICE MENU”

• Press “NEXT”

• Select “PRINTERS”

• Press “RECORD READY” or “LABEL READY” for a test print.

Press the up or down arrow to toggle between “LABEL

PRINTER (NO)” and “LABEL PRINTER (YES)”.

Press “NEXT” until you reach the screen with “EXIT” option. Press “EXIT” then press “YES” to save settings.

II. BASIC SERVICE PROCEDURES

& ADJUSTMENTS:

II. a–CHECK RECORD PRINTER MEDIA:

The record printer must be loaded with 2 ¼” thermal

paper. The thermal side must be facing up.

Verify paper has thermal coating by running a blunt object across the thermal coating. The friction will create

enough heat to leave markings on the thermal coated

side.

II. b–CHECK LABEL PRINTER MEDIA:

The Label printer must be loaded with 2 ¼” Traulsen

label stock, part number 400-60004-00. Labels must

be facing up.

Traulsen label stock can be identied by the ½” or by

¼” black place marker on the top right corner of each

label.

III. PRINTER COMPONENT DIAGRAM

III. a-PRINTER COMPONENT DIAGRAM:

Reference 1=Printer Power Port-Red Harness

Reference 2=Printer Data Port-White Harness

Reference 3=Cutting Wheel Cartridge

Reference 4=Paper Folded To Point For Easy Feed

Reference 5=Feed Roller

Reference 6=Feed Roller Tension Arm

Reference 7=Thermal Paper Or Label Stock

1

2

3

4

5

6

7

-2-

Figure 1

Page 4

IV. ADVANCE SERVICE PROCEDURES & ADJUSTMENTS

IV. a–CUTTING WHEEL OPERATION:

The cutting wheel is located in the cutting wheel cartridge (see

gure1; reference 3; page 2). The cutting wheel moves right to

left to cut paper/labels then resets back to the right.

The cutting wheel must reset all the way back to the right for the

printer to initialize. If the cutting wheel jams the printer will not

initialize and will not print.

If debris is blocking the cutting wheel remove debris and cycle

power. The cutting wheel should reset on its own. If cutting

wheel does not reset, manually reset the cutting wheel by adjusting the plastic Phillips head adjustment screw located on the

left hand side of the cutting wheel cartridge. If the wheel will not

move or is very resistive in movement it is likely it will not reset

properly and the printer must be replaced.

IV. b–CHECK PRINTER POWER-BASIC:

1) The quickest way to verify the printer is receiving power is to

release then re-engage the feed roller tension arm (see gure

1; reference 6; page 2). Any time the feed roller tension arm is

re-engaged the printer should index the printer media approxi-

mately 1/8”. The printer media will also index on system power

up.

2) If the printer media does index when the feed roller tension

arm is engaged and printer still does not print then reference

Section II. a, b, c, & d to check printer media or Section IV. d to

check data cables and SmartChill® control.

IV. c–CHECK PRINTER POWER-ADVANCED (cont’d):

4) If 2 pin connector is secure and has proper voltage

and still does not print, replace printer.

5) If 2 pin connector does not read 8.5VDC check DC

power supply for proper voltage. (Voltages are labeled

on relay board and DC power supply terminals). For

more information on troubleshooting DC power supply

contact Traulsen Service Department at 800-825-8220.

IV. d–CHECK PRINTER DATA HARNESS:

The white harness is the printer data harness. If the

printer indexes when following instructions in Section IV.

b but does not print, check the white data harness (see

gure1; reference 2; page 2) for damage or weak connection.

IV. e–INTERCHANGE INSTRUCTIONS:

Both printers, label and record, are exactly the same

printer and interchangeable. When plugged into PTR

1 ports (see gure 2; reference 1; page 5) on the back

of the SmartChill® board the printer will act as a record

printer. When plugged into PTR 2 ports (see gure 2;

reference 2; page 5) on the back of the SmartChill® board

the printer will act as a label printer.

NOTE: Always inspect all boards and cables for signs of

water damage or corrosion. Corrosion will impede printer

and or control board operation.

3) If the printer media does not index when the feed roller tension arm is engaged reference Section IV. c to further check

printer power.

NOTE: The printer media will not index if the cutting wheel is

jammed.

IV. c–CHECK PRINTER POWER-ADVANCED:

1) The red harness is the power harness for the printer. Ensure

this harness is plugged in securely and shows no signs of dam-

age to both the printer (see gure 1; reference 1; page 2) and

the SmartChill® board (see gure 2; page 5).

2) If the red power cable seems to have a weak connection

tighten the connection and refer back to Section IV. b to check

printer operation.

3) If the red power cable seems to be secure and shows no

signs of damage, check the 2 pin connector, grey and black

wires, on the back of the SmartChill® board (see gure 2; refer-

ence 3; page 5) for 8.5VDC and secure connection.

-3-

Page 5

V. FLOW CHART - SERVICE PROCEDURES & ADJUSTMENTS

No Print

1

Is

Thermal

Paper?

Replace

Printer

Media

NO

YES

3

Does

Printer Have

Power?

Re-feed

Media/Re-

Boot Check

Data Cables

YES

2

Is

Cutting

Wheel

Stuck

Manually

Reset or

Replace

Printer

YES

NO

NO

4

Are Power

Cables

Damaged/

Loose

Replace

/Secure

Damaged

Power

Cables

YES

NO

Replace

Printer

V. FLOW CHART - SERVICE PROCEDURES & ADJUSTMENTS:

Reference 1 (No Print)=Is Printer Media Thermal Paper?

Reference 2 (No Print)=Is Cutting Wheel Stuck?

Reference 3 (No Print)=Does Printer Have Power?

Reference 4 (Replace Printer)=Are Power Cables Damaged or Loose?

Reference 1

Reference 2

Reference 3

Reference 4

-4-

Page 6

VI. SMARTCHILL® BOARD

VI. SMARTCHILL BOARD:

Reference 1=PTR1 Ports - Record Printer

Reference 2=PTR2 Ports - Label Printer

Reference 3=2 Pin Connector - Printer Power

Figure 2

-5-

Page 7

VII. TROUBLESHOOTING

Certain procedures in this section may require electrical and refrigeration system test or measure

ments while power is applied to the cabinet. Exercise extreme caution at all times. If test points

are not easily accessible, disconnect power, attach test equipment and reapply power to test.

Not Printing 1. Check printer media to insure it is the proper type and loaded properly see Sec. II. a, b.

2. Check printer power see Sec. III. b, c, d.

3. Check for water damage or corrosion see Section III. e.

Loading Media 1. Always fold the tip of the media to a point Section III c.

Error Code 1. Check Printer Media.

2. Generic error message indicating a printer has failed to print (printer not specied).

Corrosion 1. Routinely inspect printer boards, cutting wheel cartridges, cables & board for signs of

corrosion.

2 Pin Connector 1. Often after resent service the 2 pin connector (grey and black wires) on the back of the

SmartChill

®

control can become loose or disconnected causing a printer failure.

Verify Printer Power 1. The quickest way to verify a printer has power is to release then re-engage the

tension arm. The printer should index the media about 1/8”.

Printer Fails To Initialize 1. If a printer continues to feed paper with only a few random characters printed every so

often, the printer has failed to initialize. If this happens simply power cycle the control.

Printer Replacement 1. Both printers, record and label, have the same part number 950-60355-00 and are inter

changeable with the exception of any RBC50 models manufactured prior to 2008, with

90

degree printer boards in which case the part number is 950-60408-00.

-6-

Page 8

HOURS OF OPERATION:

Monday thru Friday 7:30 am - 4:30 pm CST

Traulsen

4401 Blue Moud Road Fort Worth, TX 76106

Phone (800) 825-8220 Fax (817) 740-6757

Traulsen Refrigeration

Website: www.traulsen.com

© 2009 Traulsen - All Rights Reserved

Loading...

Loading...