Page 1

Traulsen & Co., Inc.

Quality Refrigeration

OWNER’S MANUALOWNER’S MANUAL

OWNER’S MANUAL

OWNER’S MANUALOWNER’S MANUAL

Instructions for the installation

and maintenance of most Traulsen models as well as

instructions to operate the following special models:

Even-Thaws

Proofers

Proofer/Retarders

Blast Freezers

Fish Files

This Traulsen unit is built to our highest quality standards. We build our refrigerators, freezers and heated

cabinets this way as a matter of pride. This philosophy has made Traulsen the leader in commercial refrigeration since 1938. We thank you for your choice and confidence in Traulsen equipment and we know you

will receive many years of utility from this equipment.

All Traulsen units are placed on a permanent record file with the service department. In the event of any

future questions you may have, please refer to the model and serial number found on the name tag affixed

to the unit. Should you need service, however, call us on our toll free number, 800-825-8220 between 7:30

am and 4:30 pm CST, Monday thru Friday. It is our pleasure to help and assist you in every possible way.

INSTALLER

COMPLETE THE FOLLOWING INFORMATION PRIOR TO UNIT INSTALLATION

INITIAL START DATE: SERIAL NO.

MODEL TYPE:

COMPANY/INDIVIDUAL NAME:

INSTALLER:

SAP DOC REV. 7/01 P/N 375-60185-00

Page 2

TABLE OF CONTENTS

I. THE SERIAL TAG Page 1

II. RECEIPT INSPECTION Page 2

III. INSTALLATION

a-Location Page 2

b-Packaging Page 2

c-Installing Legs or Casters Page 2

d-Shelf Pins Page 2

e-Roll-In Model Installation Page 3

f-Installing The Condensate Evaporator Page 3

g-Remote Installation Page 3

h-Cord & Plug Page 3

i-Power Supply Page 4

j-Wiring Diagram Page 4

k-Compressor Hold Down Provisions Page 4

l-Clearance Page 4

IV. CARE & MAINTENANCE

a-Cleaning The Condenser Page 4

b-Hinge Replacement Page 4-5

c-Replacing The Gaskets Page 5

d-Cleaning The Exterior Page 5

e-Cleaning The Interior Page 5

V. MISC. OPERATIONS

a-Adjusting The Shelves Page 5

VI. OTHER

a-Service Information Page 5

b-Spare Parts Page 5

c-Warranty Registration Page 5

VII. PROOFER & PROOFER/RETARDER MODELS

a-Installation Page 6

b-Proofer Operating Instructions Page 6

c-Operating The Dial Humidistat Page 6-7

d-Retarder Operation Page 7-8

e- Care of Water Tank & Heating Elements Page 8

f-Interior Arrangements Page 8

VIII. EVEN-THAW MODELS

a-Application Overview Page 9

b-Product Loading Guidelines Page 9

c-Starting An Even-Thaw Cycle Page 9

d-Conclusion Of Even-Thaw Cycle Page 9

e-Interior Arrangements Page 9

f-Frequently Asked Questions Page 9-10

IX. FISH FILE MODELS

a-Fish File Application Page 10

b-Special Installation Note Page 10

c-Drawer Pans Page 10

d-Product Loading Page 10

e-Cleaning Page 10

X. BLAST FREEZER MODELS

a-Blast Freezer Application Page 11

b-Special Installation Note Page 11

c-Interior Arrangements Page 11

d-Blast Freezing vs. Blast Chilling Page 11

e-Normal Operation Page 11

f-Defrost Page 11

g-Blast Chill Operation Page 11

h-Proper Packaging Page 11

XI. TROUBLE SHOOTING GUIDE Page 12

XII. WARRANTY INFORMATION Page 13

XIII. INDEX Page 14

FORT WORTH, TX.

SERIAL MODEL

VOLTS Hz PH

TOTAL CURRENT AMPS

MINIMUM CIRCUIT AMPS

MAXIMUM OVERCURRENT PROTECTION AMPS

LIGHTS WATTS

HEATERS AMPS

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

370-60294-00 REV (A)

-1-

I. THE SERIAL TAG

The serial tag is a permanently affixed sticker on

which is recorded vital electrical and refrigeration data

about your Traulsen product, as well as the model

and serial number. This tag is located in the upper

right interior compartment on all reach-in/pass-thru

and roll-in/roll-thru refrigerator, freezer and dual-temp

models. For hot food and proofer models, this tag is

located on the top of the unit behind the louvers to

protect it from the heat.

READING THE SERIAL TAG

• Serial = The permanent ID# of your Traulsen

• Model = The model # of your Traulsen

• Volts = Voltage

• Hz = Cycle

• PH = Phase

• Total Current = Maximum amp draw

• Minimum Circuit = Minimum circuit ampacity

• Lights = Light wattage

• Heaters = Heater amperage (Hot Food units only)

• Refrigerant = Refrigerant type used

• Design Pressure = High & low side operating

pressures and refrigerant charge

• Agency Labels = Designates agency listings

Page 3

II. RECEIPT INSPECTION

III. INSTALLATION (continued)

All Traulsen products are factory tested for performance and are free from defects when shipped. The

utmost care has been taken in crating this product to

protect against damage in transit. All interior fittings

have been carefully secured and the legs or casters

are boxed and strapped inside to prevent damage.

Door keys will be attached to the handle with a nylon

strip. The handle is protected by an easily removable

nylon netting.

You should carefully inspect your Traulsen unit for

damage during delivery. If damage is detected, you

should save all the crating materials and make note

on the carrier’s Bill Of Lading describing this. A freight

claim should be filed immediately. If damage is subsequently noted during or immediately after installation, contact the respective carrier and file a freight

claim. Under no condition may a damaged unit be returned to Traulsen & Co. without first obtaining written permission (return authorization).

III. INSTALLATION

III. a - LOCATION:

Select a proper location for your Traulsen unit, away

from extreme heat or cold. Allow enough clearance

between the unit and the side wall in order to make

use of the door stay open feature at 120° (self-closing

feature operates up to 90°). The door(s) must be able

to open a minimum of 90° in order to make use of the

maximum clear door width available.

III. b - PACKAGING:

All Traulsen units are shipped from the factory bolted

to a sturdy wooden pallet and packaged in a durable

cardboard container. The carton is attached to the

wooden skid with the use of large staples. These

should first be removed to avoid scratching the unit

when lifting off the crate.

Most exterior stainless steel surfaces have a protective vinyl covering to prevent scratching during manufacturing, shipping and installation. After the unit is

installed in place of service, remove and discard the

covering from all surfaces.

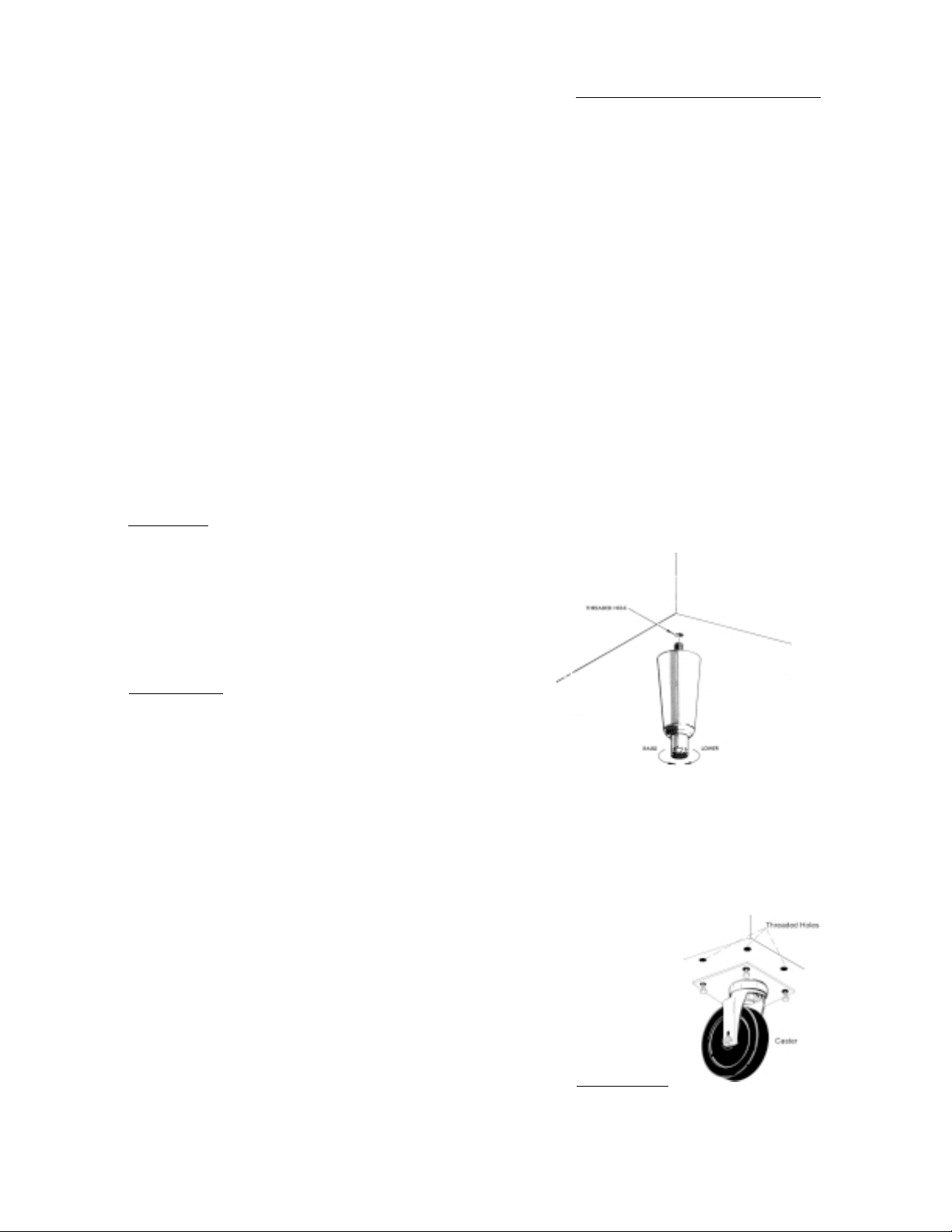

III. c - INSTALLING LEGS OR CASTERS:

6” high stainless steel legs are supplied standard for

all Traulsen reach-in and pass-thru units. Casters in

lieu of legs are available as an optional accessory for

the same models. These are shipped from the factory

packed inside a cardboard box which is strapped to

one of the shelves. Remove the nylon strap and open

the box, it should contain either four (4) legs or four

(4) casters and sixteen (16) bolts.

WARNING: THE CABINET MUST BE BLOCKED AND

STABLE BEFORE INSTALLING LEGS OR CASTERS.

To install the legs or casters, first raise and block the

reach-in a minimum of 7” from the floor. For installing legs, thread the legs into the threaded holes on

the bottom of the cabinet (see figure 1). Be certain

that all legs are tightly secured (legs and casters

should be tightened to 300 inch/pounds, max). When

the unit is set in its final position, it is important for

proper operation that the unit be level. The legs are

adjustable for this purpose, turn the bottom of the leg

counter-clockwise to raise it, clockwise to lower it.

Level the unit from front to back as well as side to side

in this manner, using a level placed in the bottom of

the cabinet.

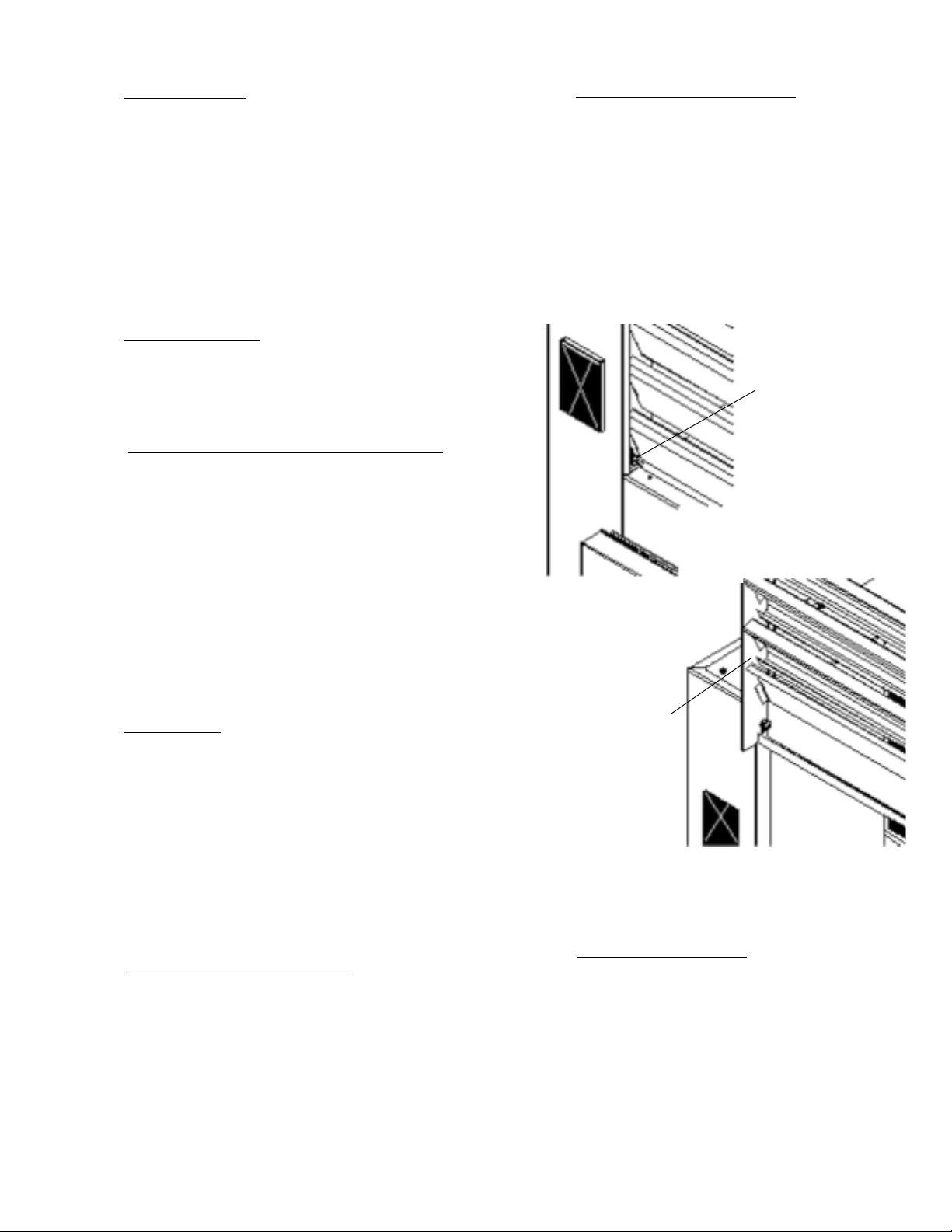

Fig. 1

Please note that Traulsen units are not designed to be

moved while on legs. If the unit requires moving, a

pallet jack or forklift should be used to prevent damage. For installing casters, the casters are “plate”

type, and require the use of four (4) bolts each to secure them firmly to the cabinet bottom at each corner

(see figure 2). The caster bolts are tightened using a

1/2” socket wrench.

To remove the wooden pallet, first if at all possible, we

suggest that the cabinet remain bolted to the pallet

during all transportation to the point of final installation. The bolts can then be removed with a 3/4” socket

wrench. Avoid laying the unit on its front, side or

back for removal of the pallet.

NOTE: Traulsen does not recommend laying the unit

down on its front, side or back. However, if you must

please be certain to allow the unit to remain in an upright position afterwards for 24 hours before plugging

it in so that the compressor oils and refrigerant may

settle.

Fig. 2

III. d - SHELF PINS:

The unit is supplied with shelves and shelf pins installed. Check all shelf pins to assure they are tightened down as they may have come loose during shipping. Rotate the pins clockwise until they are secured

against the side of the cabinet.

-2-

Page 4

III. INSTALLATION (continued)

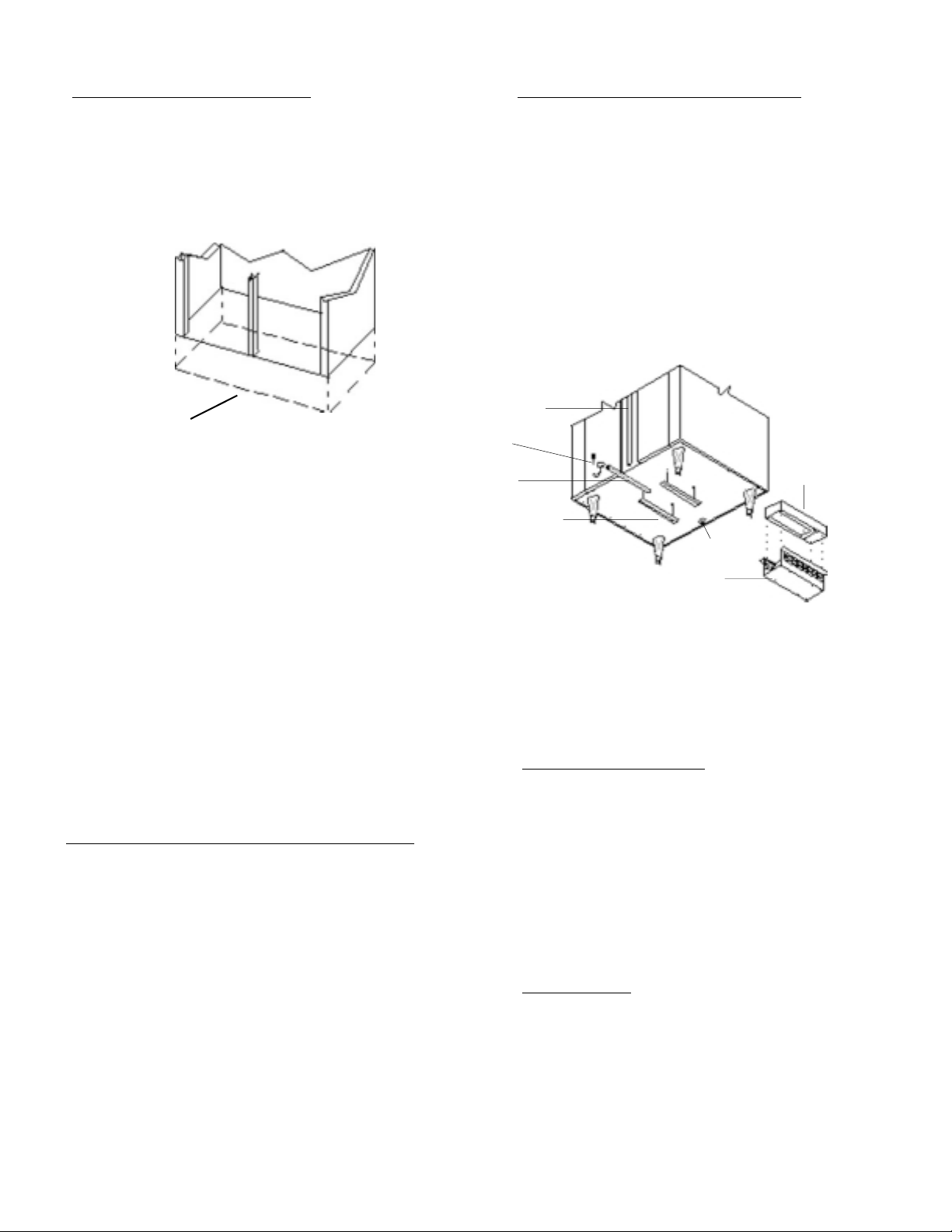

III. e - ROLL-IN MODEL INSTALLATION:

Roll-In cabinets set on the floor require the floor area

to be flat and level. In addition, after the cabinet is set

in place, sealant should be used around the perimeter

of the base to comply with National Sanitation Foundation requirements (see figure 3). After sealing the

unit, the enclosed ramp should then be installed.

SEALING BASE OF ROLL-IN MODELS

A SEALANT MUST BE USED

AROUND THE PERIMETER OF THE

BASE OF CABINET AS SHOWN TO

FULLY COMPLY WITH SANITARY REQUIREMENTS.

A RECOMMENDED SEALANT IS

DOW CORNING SILASTIC RTV #732

Fig. 3

A stainless steel threshold ramp(s) is included to facilitate rolling in racks. It is shipped wrapped in brown

paper and secured to the rack guides inside the cabinet. To secure it in place, remove the two thumb

screws in the breaker strip near the bottom door opening. Next, loosen the thumb screws located along the

floor at the threshold. Place the ramp(s) on top of the

loosened thumb screws and secure tabs on each end

to breaker strips with thumb screws previously removed. After installing the ramp(s), it too should be

sealed to the floor.

Bumper strips are secured to the back of Roll-In models with thumb screws. Loosen these and make them

finger-tight to conform with the requirements of the

National Sanitation Foundation (NSF).

III. f - INSTALLING THE CONDENSATE EVAPORATOR:

A condensate evaporator is normally supplied on all

self-contained models (remote models require provision of either a floor drain or an optional condensate

evaporator). On those models with the evaporator coil

compartment located on the top of the unit, the condensate evaporator is also secured to the top of the

cabinet. Check that the condensate pan is under the

drain tube.

Some models, such as one-section dual-temperature

reach-in refrigerator/freezers, are supplied with a bottom-mounted electric condensate evaporator. This is

shipped in a cardboard carton secured to the cabinet

interior, and must be installed prior to use.

After the cabinet has been uncrated and the legs/casters attached, you must install the bottom-mounted

electric condensate evaporator. Locate the four (4)

III. f - INSTALLING THE CONDENSATE EVAP (cont’d):

holes on the exterior bottom towards the rear of the

cabinet. Then, using the four (4) screws provided, attach the mounting rails to the cabinet bottom (the end

flange is to be up and be facing towards the cabinet

rear). Next, place the heater into the heater bracket

(note the enclosed springs are only to be used when

the heater is placed on the floor). Slide heater and

bracket into the mounting rails. Plug the supplied cord

into both the heater on one end, and the electrical

outlet provided on the cabinet exterior bottom towards

the front (see figure 4). Screw the “U-Trap” on to the

drain line located on the rear of the cabinet and then

screw the drain extension into the “U-Trap.”

Drain

Line

U-Trap

Drain

Extension

10-32 x 3/8 Screw (4)

Mounting Rails

BMCE

Receptacle

Heater

Bracket

Fig. 4

A remote model is normally supplied configured for

condensate to be run to a floor drain unless purchased

with a condensate evaporator. The installer is responsible for making the required extension to the floor

drain in accordance with good practice and local regulations.

III. g - REMOTE INSTALLATION:

Remote models are supplied without compressors,

solenoid valves, etc. The correct voltage, amp listing

and refrigerant are listed on the unit’s serial tag. It is

the responsibility of the installer to specify and supply the correct size compressor(s) based upon this

information and on-site requirements. Refrigerant line

installation must be done in accordance with good

practice and local regulations. See section “III. g” for

information concerning condensate removal for remote models.

III. h - CORD & PLUG:

Most self-contained models are supplied with a cord

& plug attached. It is shipped coiled at the top of the

cabinet, secured by a nylon strip. For your safety and

protection, all units supplied with a cord and plug include a special three-prong grounding plug on the service cord. Select only a dedicated electrical outlet with

grounding plug for power source. NOTE: Do not under any circumstances, cut or remove the round

grounding prong from the plug, or use an extension

cord.

-3-

Electric

Heater

Page 5

III. INSTALLATION (continued) V. CARE & MAINTENANCE (cont’d)

III. i - POWER SUPPLY:

The supply voltage should be checked prior to connection to be certain that proper voltage for the cabinet wiring is available (refer to the serial tag to determine correct unit voltage). Make connections in accordance with local electrical codes. Use qualified

electricians.

Use of a separate, dedicated circuit is required. Size

wiring to handle indicated load and provide necessary overcurrent protector in circuit (see amperage

requirements on the unit’s serial tag).

III. j - WIRING DIAGRAM:

Refer to the wiring diagram for any service work performed on the unit. Should you require one, please

contact Traulsen Service at (800) 825-8220, and provide the model and serial number of the unit involved.

III. k - COMPRESSOR HOLD DOWN PROVISIONS:

To protect the compressor during transit, some selfcontained Traulsen models have compressors tightened down at the factory. The hold down bolts used

to tighten these must be loosened before operation

to allow the vibration eliminators to funtion properly.

Failure to loosen the hold down bolts could result in

refrigerant line leakage, vibration and noise. Check

the top to be sure all factory installed blocking (if used)

is also removed. Likewise, check the compressor enclosure of bottom mounted units (RFD/AFD models)

to be sure all packing is removed and that compressors secured to the base of condensing unit are free

to operate on their vibration eliminators.

IV. a - CLEANING THE CONDENSER (cont’d):

two screws located on both sides at the bottom of the

louver assembly (see figure 6). Once the screws are

removed, the panel can be pivoted upwards allowing

full access to the front facing condenser (see figure

7). Vacuum or brush any dirt, lint or dust from the

finned condenser coil, the compressor and other cooling system parts. If significant dirt is clogging the condenser fins, use compressed air to blow this clear.

Lower louver assembly and replace the screws to hold

it in place.

Fig. 6

Remove

Screws

III. l - CLEARANCE:

In order to assure optimum performance, the condensing unit of your Traulsen unit MUST have an adequate

supply of air for cooling purposes. Therefore, the

operating location must either have a minimum of 12”

clearance overhead of the condensing unit or allow

for unrestricted air flow at the back of the unit. Clearance of at least 12” above is required in order to perform certain maintenance tasks.

IV. CARE & MAINTENANCE

IV. a - CLEANING THE CONDENSER:

The most important thing you can do to insure a long,

reliable service life for your Traulsen is to regularly

clean the condenser coil.

The condensing unit requires regularly scheduled

cleaning to keep the finned condenser clean of lint

and dust accummulation. Keeping the condenser

clean allows the cabinet to operate more efficiently

and use less energy. To clean the condenser, first

disconnect electrical power to the cabinet and lift up

the front louver as sembly. To lift this, remove the

Lift-Up Louver

Fig. 7

Assembly

WARNING: DISCONNECT ELECTRICAL POWER

SUPPLY BEFORE CLEANING ANY PARTS OF THE

UNIT.

IV. b -

HINGE REPLACEMENT:

Both the door and hinge can be easily removed from

the cabinet. To remove the door, remove the plug at

the bottom of the top hinge. Inside the hinge there is

a small screw which secures the door in place. Remove this with a flat head screwdriver and the door

can then be lifted off the hinge. To remove the door

portion of the hinge from the door, lift off the hinge

cover and then remove the three Phillips head screws

which secure the hinge in place on the door. To remove the cabinet portion of the hinge, remove the three

Phillips head screws which hold it in place. On solid

-4-

Page 6

IV. CARE & MAINTENANCE (cont’d)

V. MISC. OPERATIONS

IV. b - HINGE REPLACEMENT:

door units, the top hinge(s) contains a microswitch

for controlling the interior lighting.

To reassemble the hinge reverse the previous procedure.

IV. c - REPLACING THE GASKETS:

To remove the gasket to be replaced, grasp it firmly

by one corner and pull it out. Before attempting to

install a new gasket, both the unit and the gasket itself must be at room temperature. Insert the four corners first by using a rubber mallet (or hammer with a

block of wood). After the corners are properly inserted,

work your way towards the center from both ends by

gently hitting with a mallet until the gasket is completely seated in place (see figure 8 for proper gasket

placement).

Inside Door Panel

○○○

Gasket Assembly

○○○

Fig. 8

Vertical Gasket

Retainer

○○○

NOTE: The gasket may appear too large, but if it is

installed as indicated above it will slip into place.

V. a - ADJUSTING THE SHELVES:

For shelves mounted on pins, first select the desired

location and remove the white plastic covers in the

interior back and sides by rotating them counter-clockwise. Remove the shelf pins by rotating them counterclockwise. Install the pins in the desired location by

rotating clockwise. Make sure the pin is securely tightened down. Do not over tighten. Slide the shelf into

its new position, and replace the white plastic covers

into the holes vacated by the shelf pins.

VI. OTHER

VI. a - SERVICE INFORMATION:

Before calling for service, please check the following:

Is the electrical cord plugged in?

Is the fuse OK or circuit breaker on?

Is the power switch “ON”?

If after checking the above items and the unit is still

not operating properly, please contact an authorized

Traulsen service agent. A complete list of authorized

service agents was provided along with your Traulsen

unit. If you cannot locate this, you may also obtain the

name of a service agent from the Tech Service page of

our website: www.traulsen.com.

IV. d -

CLEANING THE EXTERIOR:

Exterior stainless steel should be cleaned with warm

water, mild soap and a soft cloth. Apply with a dampened cloth and wipe in the direction of the metal grain.

Avoid the use of strong detergents and gritty, abrasive cleaners as they may tend to mar and scratch the

surface. Do NOT use cleansers containing chlorine,

this may promote corrosion of the stainless steel.

Care should also be taken to avoid splashing the unit

with water, containing chlorinated cleansers, when

mopping the floor around the unit.

For stubborn odor spills, use baking soda and water

(mixed to a 1 TBSP baking soda to 1 pint water ratio).

IV. e - CLEANING THE INTERIOR:

For cleaning both stainless steel and anodized aluminum interiors, the use of baking soda as described in

section “IV. d” is recommended. Use on breaker strips

as well as door gaskets. All interior fittings are removable without tools to facilitate cleaning.

If service is not satisfactory, please contact our inhouse service department at:

Traulsen & Co., Inc.

4401 Blue Mound Road

Fort Worth, TX 76106

(800) 825-8220

Traulsen & Co., Inc. reserves the right to change specifications or discontinue models without notice.

VI. b - SPARE PARTS:

Spare or replacement parts may be obtained through

a parts supplier or one of our authorized service agents.

A complete list of authorized service agents accompanies this manual and is also posted on our company’s

official website @ www.traulsen.com.

VI. c - WARRANTY REGISTRATION:

For your convenience, the warranties on your new

Traulsen unit may be registered with us by one of two

methods. Completing the enclosed warranty card

(shipped with the unit), or by filling out the on-line

warranty registration form located on the Technical Service page of our website (www.traulsen.com).

-5-

Page 7

VII. SPECIALTY PRODUCTS - PROOFER/PROOFER RETARDER MODELS

VII. a - INSTALLATION:

MECHANICAL CONNECTION: For plumbing, connect

water supply to inlet strainer as marked on top of cabinet. This connection should be made with a 3/8” male

NPT connector. Water supply pressure should 50 to

80 PSI for best operation.

The drain connector located at the top rear of the cabinet should be made with a 1/2” NPT drain line which

should be connected to either a floor drain or sink

connection. A back flow prevention device (vacuum

breaker) must be used in the water supply line to this

unit.

CAUTION: Any restriction in the drain line could cause

overflow conditions. It is imperative that the 1/2” NPT

fitting be used and the drain line not be reduced in

diameter. If plastic is used, care must be taken to avoid

collapsing the tubing.

ELECTRICAL CONNECTIONS: The Traulsen Proofer

model requires two separate electrical connections.

The first connection is to operate the heater and humidifier. This connection will either be 208/60/1 or 230/

60/1.

Please note electrical information for each cabinet at

given voltage.

PRI132H

Voltage 208/60/1 230/60/1

Amps 21.5 24.0

Watts 4400 5500

PRI232H

Voltage 208/60/1 230/60/1

Amps 30.0 33.5

Watts 6100 7700

PRI332H/PRR232HUT

Voltage 208/60/1 230/60/1

Amps 30.0 33.5

Watts 6100 7700

The second connection is a standard 115/60/1 to operate the control circuits. When connecting a 115 volt

power supply to the cabinet, be sure to connect neutral to white cabinet wire and “live” wire to cabinet

black wire. Reversal of polarity will cause inconsistent operation. Electrical information on this connection is the same for each proofer cabinet.

PRI PRR

Voltage 115/60/1 115/60/1

Amps 3.0 13.5

Watts 500 2100

VII. b - PROOFER OPERATING INSTRUCTIONS:

The Traulsen proofer is designed to automatically flush

out the water tank once every 24 hours. The operator

should select a flush time when the unit is not proofing.

This unit displays the time of day and temperature of

the unit simultaneously. When the proofer is activated

both the time of day and the flush time must be adjusted.

SETTING THE CLOCK:

A-TIME OF DAY - When the unit is initially activated

the time of day is shown as 12 p.m. Use a pointed

object and insert into the fast or slow openings to advance the time of day. NOTE: P.M. is indicated by a

LED dot in the upper left corner of the time display.

B-FLUSH TIMER - Insert a pointed object into the flush

opening to display the flush time. While the flush time

is being displayed the fast or slow openings should

be used to advance to the desired flush time.

Once the time clock has been set the unit is ready for

operation:

1) Adjust the temperature control to the desired

temperature

2) Adjust the humidity control to the desired

humidity.

To activate the unit turn ON the lower switch and then

the control switch. Let the unit reach the temperature

selected.

HEATER THERMOSTAT: When adjusting the heater

thermostat, keep in mind that the heater element does

not cool instantly. There is an override in temperature

of approximately 9 to 12 degrees. This may vary, depending on location, and the thermostat may have to

be adjusted. Once the unit is warmed up to the desired temperature, you will notice that the temperature will stabilize and not vary significantly.

VII. c - OPERATING THE DIAL HUMIDISTAT

The Traulsen humidifier is controlled by a dial humidistat (R.H.). Adjust dial selector for proper level of

humidity. The humidity setting should be 2 to 3 percent below desired setting. The humidifier, in addition to creating humidity in the cabinet, will also create heat. Activate the power switch to the control

heater element. The level of desired humidity should

be based upon product being proofed. If however, you

are utilizing one level of humidity for all products, it is

not necessary to readjust the humidistat each time the

cabinet is turned on.

-6-

Page 8

VII. SPECIALTY PRODUCTS - PROOFER/PROOFER RETARDER MODELS (cont’d)

VII. c - OPERATING THE DIAL HUMIDISTAT (cont’d):

When the desired temperature and humidity settings

are achieved, the white mode indicating lights will go

OFF and you are now ready to proof your product. The

mode lights indicate the various stages of operation

during the proofing process.

AMBER - “LOWER LEVEL” Will be illuminated during

normal operation. Will only turn off when heater water level is below minimum safety level or at start-up.

WHITE - “THERMOSTAT” Will be illuminated when

cabinet is not at set temperature. When cabinet

achieves set temperature, the light will turn off.

RED - “TROUBLE” Will illuminate whenever the water

level is below minimum safe level. It will also be on at

start-up for approximately 30 seconds. When the red

light illuminates, power to the heaters is turned off.

This light is also lit during the flush period until the

units water level returns to normal.

GREEN - “WATER LEVEL” Will be illuminated when

the water pan is full. This light will turn off when the

solenoid valve opens to replenish the water pan.

WHITE - “HUMIDISTAT” Will be illuminated when cabinet is not at set humidity. When the cabinet reaches

the set point this light will turn off.

VII. d - RETARDER OPERATION:

Additional control features for use with model

PRR232HUT only.

RETARD MODE: When in retard mode, the refrigeration system will maintain the cabinet temperature be-

tween 35° to 40° F. This temperature can be adjusted

through use of the temperature control, located inside

the unit mounted on the front of the evaporator coil

housing. To lower the cabinet temperature, turn the

control knob clockwise. To raise the temperature, turn

the knob counter-clockwise.

TIME DELAY: The Traulsen proofer/retarder cabinet is

supplied equipped with a time delay. When the unit is

in automatic operation, this time delay shuts the unit

down for up to one hour when switching from RETARD

to PROOF mode. This allows the cabinet to gradually

rise in temperature before the air and water heaters

come on.

For the best performance, it is recommended that this

time delay be used. However, a time delay override

allows the user to bypass the relay, and the unit will

go from RETARD directly into PROOF. This is accomplished by placing the delay bypass switch in the “ON”

position.

VII. d AUTOMATIC MODE/24 HOUR TIMER - The Traulsen

proofer retarder cabinet is designed to allow both automatic and manual operation. With the function

switch in the “AUTO” position, a 24-hour timer automatically switches between PROOF and RETARD

modes at preset times daily.

To set these switching times, carefully pull the front

protective cover (clear plastic) from the timer, which

is located on the front panel. These should be one

green “ON” pin and one red “OFF” pin on the timer

dial, as well as two spares for each in the top right

hand corner. Simply pull the red “OFF” pin from the

outside ring of the dial and place it in the position corresponding to the time that the cabinet should switch

out of RETARD. NOTE: White portion of the dial corresponds to daytime hours; black portion corresponds

to nighttime hours.

If the time delay is not bypassed, the cabinet will go

into a waiting period and then switch into PROOF

mode. Therefore, the “OFF” pin should be set at least

one hour and thirty minutes before the cabinet is ready

to proof. Of course, this will vary with conditions and

the user should find the best time for application.

The “ON” pin should be placed at the time when the

unit should switch out of PROOF. When the pressure

in the refrigeration system is in the operating range,

the system will start and soon come down to standard retarding temperatures ( 37

necessary for this function of operating conditions

(proof temperature, room temperature, etc.) and will

vary.

Once both pins have been properly placed, set the

correct time of day. This is accomplished by turning

the center knob clockwise until the correct hour is indicated at the white marker in the left-hand corner. Now

adjust for correct minutes, which are indicated by the

pointer in the interior cut out on the dial. The timer

runs independent of the control circuits, and should

only need adjustment in the event of a power failure.

1. Set the 24-hour timer for the correct time of day

2. Set pins for desired switching times on 24-hour time

3. Choose time delay bypass; “ON” or “OFF”

4. Set mode switch for “AUTO”

5. Set desired proof temperature and humidity

6. Place control switch in the “ON” position

The unit will now run automatically.

RETARDER OPERATION (cont’d):

° to 42° F). The time

TO SET THE UNIT FOR AUTOMATIC OPERATION:

-7-

Page 9

VII. SPECIALTY PRODUCTS - PROOFER/PROOFER RETARDER MODELS (cont’d)

VII. d - RETARDER OPERATION (cont’d):

MANUAL OPERATION - The Traulsen proofer retarder

can also be used in either PROOF or RETARD mode,

regardless of what the 24-hour timer is set for. By

switching manually to PROOF or RETARD, the cabinet can be run as needed without disturbing the preset schedule you have the 24-hour timer set for.

Amber

“Lower Level”

Light

The Proofer Control

White

“Thermostat

Indicator”

Light

Red

“Trouble”

Light

Green

“Water Level”

Light

White

“Humidistat

Indicator”

Light

VII. e - CARE OF WATER TANK & HEATING ELEMENTS:

The automatic flush system on the Traulsen proof cabinet will help minimize the amount of cleaning necessary to maintain an accurate and consistent operation

of this cabinet. Because water conditions vary from

location to location, we recommend that the tank cover

be removed and the interior of the water tank, along

with the heating elements, be cleaned with a soft nylon bristled brush. We recommend cleaning twice a

year or as conditions dictate. Replace tank cover before placing proof cabinet back into operation. If your

area has extremely hard water, a local water treatment

expert should be consulted. It is important to note

that after treatment the water should not be deionized.

A simple zeolite conditioner is usually the best system. Use of an in-line cartridge will reduce the frequency of cleaning the heating coil, but remember to

frequently replace the cartridge.

VII. f -

INTERIOR ARRANGEMENTS:

Traulsen proofer and proofer retarder models are designed to accommodate roll-in bakery racks. See below for size and capacities.

Model PRI132H can accommodate one (1) roll-in rack

with a maximum size, with wheels inboard of frame, of

27” wide by 29” deep by 72” high.

Model PRI232H can accommodate two (2) standard 18”

x 26” pan racks or two (2) 23” x 23” donut screen racks.

Model PRI332H can accommodate three (3) standard

18” x 26” pan racks or two (2) 23” x 23” donut screen

racks.

Blower

ON/OFF

Switch

Blower

Power

Switch

Delay

Bypass

Switch

Mode

Switches

OFF

TEMP

“Flush

Indicator”

Light

Traulsen

Thermostat

FLUSH

102.5 F 11:30

TEMPERATURE PM TIME

LOWER LEVEL TROUBLE

BLOWER

ON OFF

CONTROL

The Proofer/Retarder Control

White

“Thermostat

Indicator”

Light

DELAY

BYPASS

CONTROL

ON OFF

Amber

“Lower Level”

Light

OFF

Thermostat

Red

“Trouble”

Light

Traulsen

FLUSH

102.5 F 11:30

TEMPERATURE PM TIME

HOUR

FLUSH MINUTE

Flush Time

&

Time of Day

Adjustment

Ports

“Water Level”

HOUR

FLUSH MINUTE

Flush Time

&

Time of Day

Adjustment

Ports

WATER

LEVEL

Green

Light

Humidistat

Control

Humidistat

Control

HUMIDISTAT

White

“Humidistat

Indicator”

Light

HUMIDISTAT

Model PRR232HUT can accommodate two (2) standard

18” x 26” pan racks or two (2) 23” x 23” donut screen

racks.

-8-

Page 10

VIII. SPECIALTY PRODUCTS - EVEN-THAW MODELS

VIII. a - APPLICATION OVERVIEW:

The Even-Thaw is designed to thaw product at safe

temperatures. By keeping the cabinet temperature

from rising above 40o F, the Even-Thaw inputs small

amounts of heat while moving large volumes of air

around the product. This design allows the product

to thaw at temperatures that minimize bacteria growth.

When in Even-Thaw mode, the refrigeration system is

disabled and a second control adds enough heat to

keep the cabinet at the upper limit of normal refrigerator temperatures. The rate at which the frozen product absorbs heat gradually slows as it warms. During

the Even-Thaw process, the unit will continue to operate in this mode (refrigeration OFF, blower and heater

ON) until the product being thawed can no longer absorb the heat as fast as it is being put into the cabinet.

When this happens, the air temperature will slowly rise

to 40o F at which time the heater will turn OFF and the

refrigeration system will begin to cycle. As the refrigeration system begins to cycle the product continues

to thaw. Based on the product being thawed and the

way it is loaded, the end-user will have to determine

how much time it takes to thaw each particular product.

VIII. b - PRODUCT LOADING GUIDELINES:

THE EVEN-THAW IS DESIGNED TO BE LOADED TO

CAPACITY FOR EACH EVEN-THAW CYCLE. When the

unit is cycling at refrigerator temperatures (approximately 36o to 39o f), load the cabinet with frozen product to be thawed. If possible, remove all packaging

and place the product directly on aluminum sheet pans

for optimum heat transfer. While it is possible to EvenThaw product that is wrapped, it will be slower than if

it were unwrapped. At the very least the packaging

should be opened to allow air to circulate. Also, it is

not recommended to thaw product that is stored or

packaged in cardboard boxes. Product should be

placed on the pans in a single layer; each pan should

be filled with as much product as can arranged without the pieces touching each other. The cabinet should

be loaded with as many pans as it will hold and still

allow air circulation on all sides of the pan.

VIII. c - STARTING AN EVEN-THAW CYCLE:

With the cabinet filled with frozen product and the

doors closed, the compressor will run until the air temperature falls to its lower set point. The blower will

continue to run, circulating air across the frozen product, which will lower the air temperature further. At

approximately 32 o f, the unit will automatically switch

to the Even-Thaw mode, disabling the compressor and

enabling the heater. If the doors are not left open too

long during the loading stage, this automatic switching to Even-Thaw mode normally takes 5 - 10 minutes.

An amber light on the upper left hand face of the cabinet indicates Even-Thaw mode. Even-Thaw mode can

also be initiated manually by the start button located

between the green (refrigeration) and amber (EvenThaw) indicator lights.

VIII. d - CONCLUSION OF EVEN-THAW CYCLE:

The Even-Thaw cycle will end automatically (return to

refrigeration mode), when the air circulating in the

cabinet reaches 40 o f. A green light on the upper left

hand face of the cabinet indicates refrigeration mode.

At this point the unit can be used as a holding cabinet

at refrigerator temperatures with no operator action

required. If the unit is needed for thawing additional

frozen product, all previously thawed product should

be moved to another unit.

VIII. e Traulsen reach-in even-thaw models are supplied standard with tray slides to facilitate thawing.

Roll-in even-thaw models are designed to accommodate two (2) 27” wide by 29” deep by 66” high roll-in

racks (measurements with wheels inboard of frame).

VIII. f Q. How much product can I load at one time?

A. As much as the cabinet will hold with individual

pieces flat on the sheet without touching each other,

and with space for air circulation between sheets. This

could be a hundred pounds or more per section.

Q. How long will it take to thaw?

A. It can vary greatly depending on the type of product being thawed, packaging (if any), and size of the

individual pieces. Small “flat” pieces (chicken breasts,

fish fillets etc.) will thaw the fastest, while large “round”

items (whole fowl, hams or roasts) will be the slowest.

In any event the EvenThaw process is much faster than

thawing in a standard refrigerator, and much safer than

thawing at room temperature because the product

never exceeds 40 o f.

Q. Will the EvenThaw work with a small batch?

A. Not very well. Heat will be introduced into the cabinet faster than a small batch of frozen food can absorb it, causing the EvenThaw cycle to end prematurely, and return to refrigeration mode. The product

will continue to thaw while in refrigeration mode, but

at a slower rate.

Q. Why is some product not completely thawed when

the EvenThaw cycle ends?

A. A partial load, large pieces or packaged product can

cause the cycle to end prematurely.

Q. Why does nothing happen when I push the

EvenThaw cycle start button?

A. The unit is too warm. The internal air temperature

must be in the normal refrigeration range to initiate

the EvenThaw cycle.

-9-

INTERIOR ARRANGEMENTS:

FREQUENTLY ASKED QUESTIONS:

Page 11

VIII. SPECIALTY PRODUCTS - EVEN-THAW MODELS (cont’d)

VIII. f - FREQUENTLY ASKED QUESTIONS (cont’d):

Q. What happens if we lose electrical power during

the EvenThaw process?

A. The unit will return to operation in refrigeration mode

when power is restored.

Q. What about bagged or boxed product?

A. It will thaw more slowly than individual pieces because the packaging acts as an insulator, hindering

heat transfer to the frozen product. The EvenThaw

cycle will probably end prematurely, returning to refrigeration mode before the product is completely

thawed. It will continue to thaw, but at a slower rate.

Q. What will happen if I open the door while the unit is

in EvenThaw mode?

A. The influx of warm air will cause the EvenThaw cycle

to end, returning the unit to refrigeration mode. As

soon as the air is back down to refrigerator temperature, the EvenThaw can be restarted using the push

button located between the indicator lights. DO NOT

OPEN DOORS DURING EVEN-THAW CYCLE.

IX. SPECIALTY PRODUCTS - FISH FILE MODELS

IX. a - FISH FILE APPLICATION:

Traulsen fish file models are specifically designed for

the storage of fresh fish or poultry in a moist refrigerated environment, packed in crushed ice, thereby preventing dehydration and bacteria growth. For best results, product should be layered between ice starting

and ending with a layer of ice. The normal operating

temperature should be approximately 36° F, just right

to prevent the ice from melting away too quickly. For

temperature monitoring a digital thermometer is included (dial thermometer on model RFC232WSC).

IX. b - SPECIAL INSTALLATION NOTE:

Installation should be performed as typical with any

other model, see “Section III.” However, a fish file requires provision of a floor drain for removing water

resulting from the melted ice. The drain line should

be located at the bottom of the cabinet. Connect this

drain line to the floor drain using a 3/4” FPT connector

(furnished) or equivalent depending on location. Close

proximity of a hose reel or hose connection is helpful

to wash out the unit.

IX. d -

PRODUCT LOADING:

Product should be layered in ice, starting and ending

with a layer of ice. The ice cools the product, keeping

its surface moist and cleansing it as it slowly melts.

Fish and poultry should be held in separate units to

avoid transferring odors.

Product should be removed for off hours storage.

IX. e - CLEANING:

This unit should be cleaned on a daily basis. The entire interior should be sprayed with water. Both drawer

pans and inserts should be thoroughly cleaned and

sanitized each day.

The weep hole in the bottom of the drawer liner should

be checked to make sure it remians clear, to drain excess moisture. Product should not be set in water.

Both drawer pans and inserts should be thoroughly

cleaned and sanitized each day.

CAUTION: An electric condensate evaporator cannot

be used to dispose of water from melted ice.

IX. c - DRAWER PANS:

Each fish file drawer is supplied with one (1) 16” wide

by 18-7/8” long by 6-1/2” deep plastic pan, each pan

contains a plastic perforated insert. When the ice

melts, the resulting water drains through the perforated insert at the bottom of the pan into the drain port

of the pan.

-10-

Page 12

X. SPECIALTY PRODUCTS - BLAST FREEZER MODELS

X. a - BLAST FREEZER APPLICATION:

The roll-in blast freezer models were specifically designed for batch processing, where quick freezing is

required to help prolong product shelf life.

Temperature

Display

The Blast Freezer Control

Traulsen

X. b - SPECIAL INSTALLATION NOTE:

Installation should be performed as typical with any

other model, see “Section III.” However, a blast freezer

also requires provision of a floor drain for removing

condensate. A floor mounted electric condensate

evaporator is available from Traulsen as an optional

accessory.

Additionally, these models do not include a cord and

plug. Actual wiring to the power supply should be provided by a qualified electrician.

X. c - INTERIOR ARRANGEMENTS:

Traulsen blast freezers are designed to accommodate

27” wide by 29” deep by 66” high roll-in racks (measurements with wheels inboard of frame). One section model accommodates one (1) roll-in rack. Two

section model accommodates two (2) roll-in racks.

X. d - BLAST FREEZING vs. BLAST CHILLING:

The Traulsen blast freezer models were designed to

quickly freeze up to 200 lbs. of refrigerated product

(maximum start temperature of 40° F) per batch. How-

ever, it was not designed to refrigerate hot, cooked

product (140° F) down to either a chilled or frozen state.

CAUTION: Room temperature or warmer product

placed in the blast freezer can ice the coil and result in

reduced performance and/or unit failure.

To cool foods at that temperature, a blast chiller is required. It was designed to chill its respective capacity

of product from 140° F down to 40° F in approximately

90 minutes. If freezing is then required, only then can

a blast freezer be utilized.

X. e - NORMAL OPERATION:

The blast freezer operates as a conventional freezer,

maintaining temperatures of 0° to -5° F, when not in

BLAST FREEZE MODE (i.e. with the blast freeze timer

in the “OFF” position).

X. f - DEFROST:

The cabinet has been shipped from the factory with

three (3) timeclock defrost settings (12 midnight, 8 a.m.

and 4 p.m.). For proper operation of the defrost system it is imperative that the timeclock be set to the

correct time of day when the electrician makes the

original installation. Similarly, if a power failure should

occur, the timeclock must be reset after resumption

of normal operation.

DIGITRAUL

DEFOGGER

ON OFF

ON OFF

Defogger

Switch

BLAST FREEZE OPERATION:

X. g -

Timer

To operate in BLAST FREEZE MODE, the blast freeze

timer must be turned to the appropriate time period

desired. In this mode, two (2) additional fans will operate in order to promote rapid freezing of the product

and a secondary control assumes command of the

condensing units so as to maintain cabinet air temperatures of -20

° F.

Selecting the correct length of time required for blast

freezing a particular product must be calculated by

the operator. Freezing times will vary as a result of

many factors, such as:

Product Density

Product Water/Fat Content

Product Temperature

Product Load

Product Packaging & Spacing

All these factors need to be taken into account when

determining the length of a blast freeze batch. We

suggest that the operator begin a chart to record their

own operational experience with frequently used loads

and their respective freezing times.

X. h - PROPER PACKAGING:

Packaging of food product is necessary to prevent

dehydration, inhibit oxidation and allow accelerated

heat transafer. This is due to the combination of high

air velocities and cold temperatures required for blast

freezing.

The particular type of packaging chosen should meet

the following requirements:

• It MUST have the ability to withstand the

temperature range through which it will pass (-20° F

through to 400° F if also used for reheating).

• It MUST be protected against oxidation.

• It MUST have the ability to prevent dehydration.

• It MUST allow for rapid heat trasfer to the food

during freezing and reheating.

-11-

Page 13

XI. TROUBLE SHOOTING GUIDE

FIND YOUR PROBLEM HERE REMEDY

1. Condensing unit fails to start. a. Check if cord & plug has been disconnected.

2. Condensing unit operates for a. Are doors closing properly?

prolonged periods or continuously. b. Dirty condenser or filter. Clean properly.

c. Evaporator coil iced. Needs to defrost.

d. Shortage of refrigerant, call service.

3. Food compartment is too warm. a. Check door(s) and gasket(s) for proper seal

b. Perhaps a large quantity of warm food has

recently been added or the door was kept

open for a long period of time, in both

cases, allow adequate time for the cabinet

to recover its normal operating temperature.

4. Food compartment is too cold. a. Perhaps a large quantity of very cold or frozen

food has recently been added. Allow adequate

time for the cabinet to recover its normal operating

temperature.

5. Condensation on the exterior surface. a. Check door alignment and gaskets for proper seal.

b. Condensation on the exterior surface of the

unit is perfectly normal during periods of

high humidity.

6. Compressor hums but does not start. a. Call for service.

-12-

Page 14

XII. WARRANTY INFORMATION

STANDARD DOMESTIC WARRANTY

TRAULSEN & CO., INC. warrants new equipment to the original purchaser, when installed within the United States against

defective material and workmanship for one (1) year from the date of original installation, not to exceed 15 months from

date of shipment. Under this warranty, TRAULSEN & CO., INC. will repair or replace, at its option, including service and

labor, all parts found to be defective and subject to this warranty. The compressor part is warranted for an additional

four (4) years. During this period TRAULSEN & CO., INC. will supply replacement compressor(s) if deemed defective,

however, all installation, recharging and repair costs will remain the responsibility of the owner.

This warranty does not apply to damage resulting from fire, water, burglary, accident, abuse, misuse, transit, acts of

God, attempted repairs, improper installation by unauthorized persons, and will not apply to food loss.

THERE ARE NO ORAL, STATUTORY OR IMPLIED WARRANTIES APPLICABLE TO TRAULSEN, INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. TRAULSEN SHALL HAVE NO OBLIGATION OR LIABILITY FOR

CONSEQUENTIAL OR SPECIAL DAMAGES, GROWING OUT OF OR WITH RESPECT TO THE EQUIPMENT OR ITS SALE,

OPERATION OR USE, AND TRAULSEN NEITHER ASSUMES NOR AUTHORIZES ANYONE ELSE TO ASSUME FOR IT ANY

OBLIGATION OR LIABILITY IN CONNECTION WITH THE EQUIPMENT OR ITS SALE, OPERATION OR USE OTHER THAN

AS STATED HEREIN.

INTERNATIONAL COMMERCIAL WARRANTY

(for Canadian warranties see domestic US warranty)

TRAULSEN & CO., INC. warrants to the original purchaser the Refrigeration Equipment manufactured and sold by it to be free

from defects in material and workmanship under normal use and service for a period of one (1) year from date of shipment. Under

this warranty, TRAULSEN & CO., INC. will reimburse the purchaser for the replacement of any part of said equipment (excluding

dryers & refrigerant gas) which then proves to be defective. This warranty is void if said equipment or any part thereof has been

subject to misuse, damage in transit, accident, negligence or alteration.

TRAULSEN’S standard warranty does not apply to Export Sales. Rather, for a period of one (1) year from date of original

installation not to exceed Fifteen (15) months from date of shipment from factory, TRAULSEN:

will replace, F.O.B. factory, any defective parts normally subject to warranty.

will not cover the cost of packing, freight or labor such costs being the sole responsibility of the dealer.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EITHER EXPRESSED OR IMPLIED AND CONSTITUTES

TRAULSEN’S FULL OBLIGATION AND LIABILITY. WARRANTIES NOT AVAILABLE ON REMOTE MODELS.

-13-

Page 15

XIII. INDEX

A

Auto Function 7

B

Back Flow Prevention Device 6

Batch 11

Blast Chiller 11

Blast Freeze Mode 11

Blast Freezer 11

Blower ON/OFF Switch 8

Blower Power Switch 8

C

Cleaning 5, 6

Casters 2

Condensate Evaporator 3

Condensate Evaporator, Floor Mounted 11

Cord & Plug 3

Compressor Hold Down Provisions 4

Clearance 4

Clock, Setting The 6

D

Defrost 4

Dehyrdation 11

Dial Humidistat 6, 7

Donut Screen Racks 8

Drain Connector 6

Drain Line 6, 10, 11

Drawer Pans, Fish File 10

E

Even-Thaw 9, 10

M

Mode Lights 7

N

O

OFF Pin 7

ON Pin 7

Oxidation 11

P

Packaging, Product 11

Polarity, Reversal 6

Power Supply 4

Proof Mode 7, 8

Proofer Control 8

Proofer/Retarder Control 8

R

Remote Installation 3

Retard Mode 7

Retarder Operation 7

Retarding Temperatures, Standard 7

Return Authorization 2

Roll-In Models 3

Roll-In Racks 8, 11

S

Sealant 3

Serial Tag 1

Shelf Pins 2, 6

Shelves 2, 6

Strip Heaters 5

F

Fish File 10

Floor Drain 11

Floor mounted Condensate Evaporator 11

Flush Indicator Light 8

Flush Timer 6

Freezing Times 11

G

Gaskets 5

H

Heater 9

Heater Thermostat 6

Heating Elements 8

Hinge 4, 5

Humidifier 6

Humidistat Indicator Light 7

Humidity Control 6

I

Ice, Crushed 10

Inlet Strainer 6

J

K

L

Legs 2

Louver Assembly 5

Lower Level Indicator Light 7

T

Temperature Control, Proofer 6

Thermostat Indicator Light 7

Threshold Ramp 3

Time Delay 7

Timer, 24-Hour 7

Trouble Indicator Light 7

U

U-Trap 3

V

Vacuum Breaker 6

Vinyl, Protective Covering 2

W

Warranty 20

Warranty, Registration 5

Water Level Indicator Light 7

Water Supply, Pressure 6

Water Tank 6, 8

Weep Hole 10

Wiring Diagram 4

X

Y

Z

Zeolite Conditioner 8

-14-

Page 16

HOURS OF OPERATION:

Monday thru Friday 7:30 am - 4:30 pm CST

EXTENDED WARRANTY SERVICE HOURS

Monday thru Friday 4:30 pm - 6:00 pm CST

Traulsen & Co., Inc.

4401 Blue Mound Road Fort Worth, TX 76106

Phone: (800) 825-8220 Fax-Svce: (817) 740-6757

Website: www.traulsen.com

Quality Refrigeration

Loading...

Loading...