Page 1

Quality Refrigeration

OWNER’S MANUAL

Instructions for the installation, operation

and maintenance of all Traulsen:

R & A Series Reach-In & Roll-In Refrigerators*

R & A Series Pass-Thru & Roll-Thru Refrigerators*

R & A Series Reach-In & Roll-In Freezers*

R & A Series Reach-In Refrigerator/Freezers*

R & A Series Reach-In & Roll-In Hot Food Cabinets*

R & A Series Pass-Thru & Roll-Thru Hot Food Cabinets*

* Please Note: This manual is intended for use with the above referenced equipment manufactured

after January 01, 2013. To obtain a copy of the correct Owner’s Manual to support the same

products manufactured prior to this date, please contact Traulsen Service at (800) 825-8220.

This Traulsen unit is built to our highest quality standards. We build our refrigerators, freezers and heated cabinets this way as a matter of pride. This philosophy has made Traulsen the leader in commercial

refrigeration since 1938. We thank you for your choice and condence in Traulsen equipment and we know

you will receive many years of utility from this equipment.

All Traulsen units are placed on a permanent record le with the service department. In the event of any future

questions you may have, please refer to the model and serial number found on the name tag afxed to the unit.

Should you need service, however, call us on our toll free number, 800-825-8220 between 7:30 am and 4:30 pm

CST, Monday-Friday. It is our pleasure to help and assist you in every possible way.

INSTALLER

COMPLETE THE FOLLOWING INFORMATION PRIOR TO UNIT INSTALLATION

INITIAL START DATE: SERIAL NO.

MODEL TYPE:

COMPANY/INDIVIDUAL NAME:

INSTALLER:

FORM NUMBER TR35743 (REV. 09-03-15) P/N 375-60176-00

Page 2

TABLE OF CONTENTS

I. THE SERIAL TAG Page 1

II. RECEIPT INSPECTION Page 2

III. INSTALLATION

a-Location Page 2

b-Packaging Page 2

c-Installing Legs or Casters Page 2

d-Shelf Pins Page 3

e-Roll-In Model Installation Page 3

f-Attaching Double Depth Units Together Page 3

g-Installing The Condensate Evaporator Page 3

h-Remote Installation Page 4

i-Cord & Plug Page 4

j-Power Supply Page 4

k-Wiring Diagram Page 4

l-Clearance Page 4

IV. OPERATION

a-Refrigerators Page 5

b-Freezers Page 5

c-Hot Food Cabinets Page 5

V. CARE & MAINTENANCE

a-Cleaning The Condenser Page 5

b-Hinge Replacement Page 6

c-Replacing The Gaskets Page 6

d-Cleaning The Exterior Page 6

e-Cleaning The Interior Page 6

f-Adjusting The Shelves Page 6

g-Replacing The Light Bulb Page 7

VI. OTHER

a-Service Information Page 7

b-Spare Parts Page 7

c-Warranty Registration Page 7

VII. INTELA-TRAUL

a-Control Features Page 8

b-Alarm Explanations Page 9

c-Control Panel Page 10

d-Notes To The User Page 10

e-Enter The Customer Access Code Page 10

f-Customer Service Parameters Page 11

g-Adjusting Thermostat Set Point Page 11

h-Adjusting Thermostat Set Point Low Page 12

i-Changing The Temperature Scale Page 12

j-Setting The 24-Hour Clock Page 13

k-Setting The Date Page 14

l-Setting Daylight Savings Time Page 14

m-Starting A Manual Defrost Page 15

n-Setting Defrost Lockouts Page 16

o-Adjusting The Room Temperature Offset Page 17

p-Setting The Audible Alarm Style Page 17

q-Viewing Sensor Temperatures Page 18

r-Door Open Icon Page 18

s-Hot Food Units - Adjusting The Thermostat Page 18

t-Hot Food Units - Turning The Unit OFF & ON Page 19

u-Hot Food Units - Temperature Adjustment Page 19

VIII. TROUBLE SHOOTING GUIDE Page 20

XI. SPARE PARTS LIST Page 21

XII. STAINLESS STEEL OVERVIEW Page 22

XIII. CARE OF STAINLESS STEEL Page 23

XIV. CORROSION REMEDIES Page 23

XV. WARRANTY INFORMATION Page 24

®

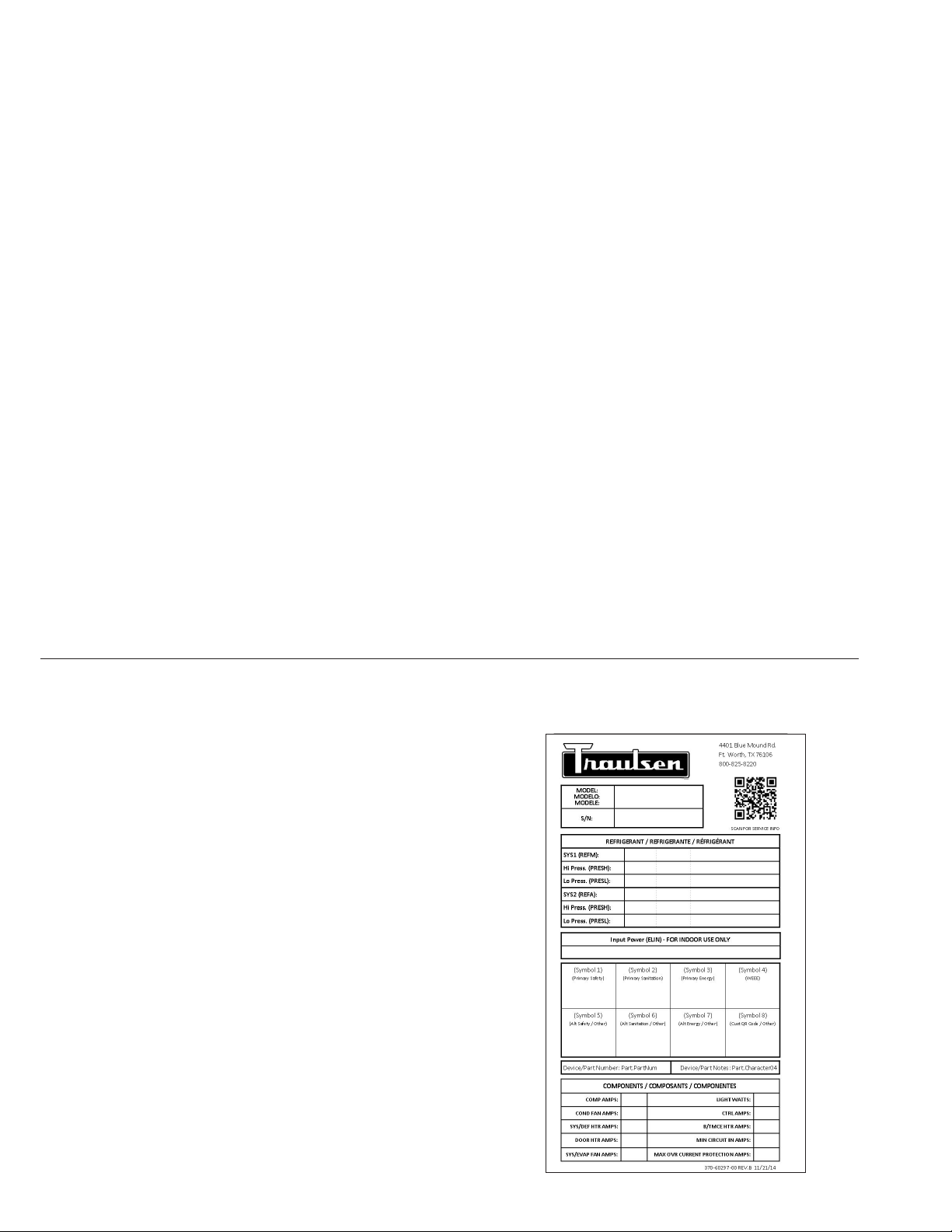

I. THE SERIAL TAG

The serial tag is a permanently afxed sticker on which is recorded vital electrical and refrigeration data about your Traulsen

product, as well as the model and serial number. This tag is

located in the upper right interior compartment on all reach-in/

pass-thru and roll-in/roll-thru refrigerator, freezer and dual-temp

models. For hot food models, this tag is located on the top of

the unit behind the louvers to protect it from the heat.

-1-

Page 3

II. RECEIPT INSPECTION

III. INSTALLATION (continued)

All Traulsen products are factory tested for performance

and are free from defects when shipped. The utmost

care has been taken in crating this product to protect

against damage in transit. All interior ttings have been

carefully secured and the legs or casters are boxed and

strapped inside to prevent damage. Door keys will be

attached to the handle with a nylon strip. The handle is

protected by an easily removable nylon netting.

You should carefully inspect your Traulsen unit for

damage during delivery. If damage is detected, you

should save all the crating materials and make note on

the carrier’s Bill Of Lading describing this. A freight claim

should be led immediately. If damage is subsequently

noted during or immediately after installation, contact the

respective carrier and le a freight claim within 10 days.

Under no condition may a damaged unit be returned to

Traulsen. without rst obtaining written permission (return

authorization).

III. INSTALLATION

III. a - LOCATION:

Select a proper location for your Traulsen unit, away

from extreme heat or cold. Allow enough clearance between the unit and the side wall in order to make use of

the door stay open feature at 120° (self-closing feature

operates up to 90°). The door(s) must be able to open

a minimum of 90° in order to make use of the maximum

clear door width available.

III. b - PACKAGING:

All Traulsen units are shipped from the factory bolted

to a sturdy wooden pallet and packaged in a durable

cardboard container. The carton is attached to the

wooden skid with the use of large staples. These should

rst be removed to avoid scratching the unit when

lifting off the crate.

Most exterior stainless steel surfaces have a protective vinyl covering to prevent scratching during

manufacturing, shipping and installation. After the unit

is installed in place of service, remove and discard the

covering from all surfaces.

To remove the wooden pallet, rst if at all possible, we

suggest that the cabinet remain bolted to the pallet

during all transportation to the point of nal installation. The bolts can then be removed with a 3/4” socket

wrench. Avoid laying the unit on its front, side or back

for removal of the pallet.

NOTE: DO NOT LAY THE UNIT ON ITS SIDE DURING

TRANSPORTATION OR INSTALLATION.

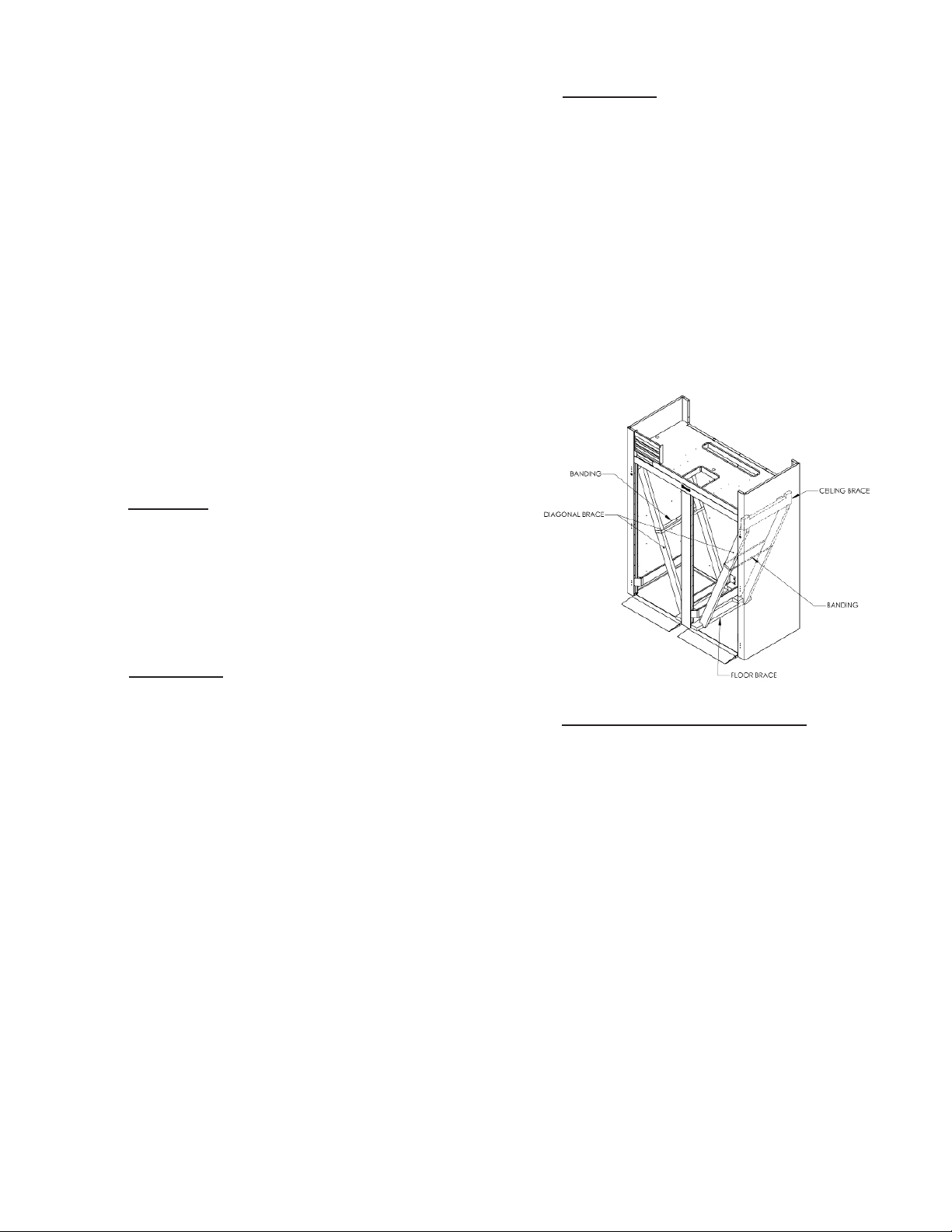

Roll-Thru models also include special interior wood

bracing, intended to protect the cabinet during shipment.

This bracing should under no circumstances be removed

prior to the unit being installed in its nal location.

WARNING: Read and review these instructions, in their

entirety, BEFORE attempting to disassemble and remove

the interior bracing.

III. b - PACKAGING (cont’d):

If either of the diagonal or upper ceiling braces are

dropped, they could cause personal injury or damage

to the equipment.

To disassemble the bracing, first open the doors

and carefully remove the banding that holds the two

diagonal braces together.

WARNING: The diagonal braces will now be loose and

can fall out of position and possibly permit the ceiling

corner brace to fall.

Carefull remove one diagonal brace while supporting

the ceiling corner brace, so that it does not fall (see

gure 1). Next, remove the ceiling brace, the remaining

diagonal brace, and lastly the oor brace - then discard.

Repeat as necessary for each section of the unit.

Fig. 1

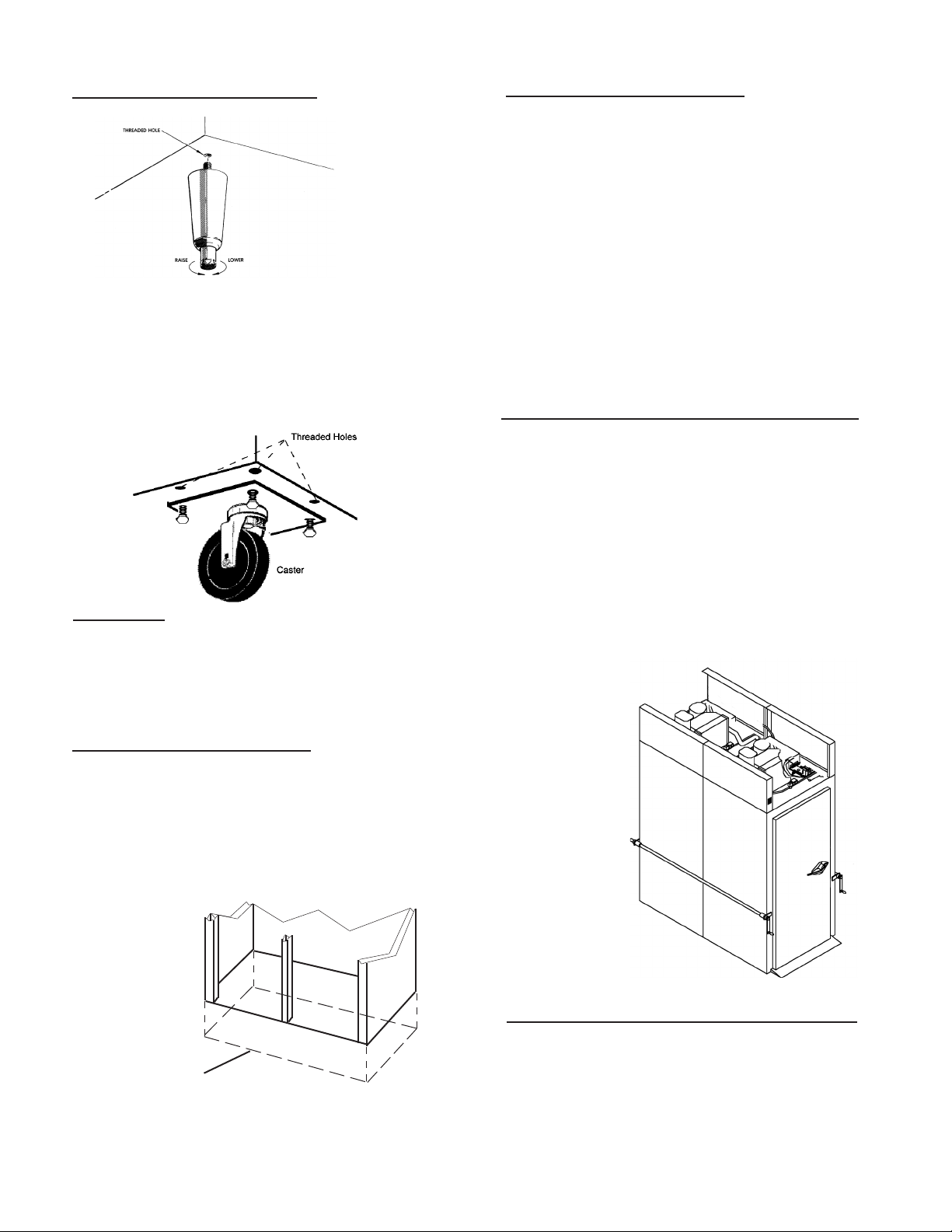

III. c - INSTALLING LEGS OR CASTERS:

6” high stainless steel legs are supplied standard for

all Traulsen reach-in and pass-thru units. Casters in

lieu of legs are available as an optional accessory for

the same models. These are shipped from the factory

packed inside a cardboard box which is strapped to

one of the shelves. Remove the nylon strap and open

the box, it should contain either four (4) legs or four (4)

casters and sixteen (16) bolts.

WARNING: THE CABINET MUST BE BLOCKED AND

STABLE BEFORE INSTALLING LEGS OR CASTERS.

To install the legs or casters, first raise and block

the reach-in a minimum of 7” from the floor. For

installing legs, thread the legs into the threaded holes

on the bottom of the cabinet (see gure 2). Be certain

that all legs are tightly secured (legs and casters should

be tightened to 300 inch/pounds, max). When the unit

is set in its nal position, it is important for proper operation that the unit be level. The legs are adjustable

for this purpose, turn the bottom of the leg counter-

clockwise to raise it, clockwise to lower it. Level the

unit from front to back as well as side to side in this

manner, using a level placed in the bottom of the

cabinet.

-2-

Page 4

III. INSTALLATION (continued)

III. c - INSTALLING LEGS OR CASTERS (cont’d):

Fig. 2

Please note that Traulsen units are not designed to be

moved while on legs. If the unit requires moving, a

pallet jack or forklift should be used to prevent damage.

For installing casters, the casters are “plate” type, and

require the use of four (4) bolts each to secure them

rmly to the cabinet bottom at each corner (see gure

3). The caster bolts are tightened using a 1/2” socket

wrench.

Fig. 3

III. d - SHELF PINS:

The unit is supplied with shelves and shelf pins installed.

Check all shelf pins to assure they are tightened down

as they may have come loose during shipping. Rotate

the pins clockwise until they are secured against the

side of the cabinet.

III. e - ROLL-IN MODEL INSTALLATION:

Roll-In cabinets set on the oor require the oor area to

be at and level. In addition, after the cabinet is set in

place, sealant should be used around the perimeter of

the base to comply with National Sanitation Foundation

requirements (see gure 4). After sealing the unit, the

enclosed ramp should then be installed.

III. e - ROLL-IN MODEL INSTALLATION (cont’d):

A stainless steel threshold ramp(s) is included to facilitate roll in racks. It is shipped wrapped in brown

paper and secured to the rack guides inside the

cabinet. To secure it in place, remove the two thumb

screws in the breaker strip near the bottom door

opening. Next, loosen the thumb screws located along

the oor at the threshold. Place the ramp(s) on top of

the loosened thumb screws and secure tabs on each

end to breaker strips with thumb screws previously

removed. After installing the ramp(s), it too should be

sealed to the oor.

Bumper strips are secured to the back of Roll-In models with thumb screws. Loosen these and make them

nger tight to conform with the requirements of the

National Sanitation Foundation (NSF).

III. f - ATTACHING DOUBLE DEPTH UNITS TOGETHER:

Double depth roll-in/roll-thru units are shipped as two

separate components which must be attached together

at the jobsite. To accomplish this, rst, place the front

and rear cabinets in close proximity to each other being

careful to align the drain from the front of the rear unit

to the drain of the front unit. It will be necessary to level

both units together at this time.

Next, using two pipe clamps, pull the units together (see

gure 5). Install the covers over the gap formed between

the units From inside the cabinets, using the screws

provided, install the breaker strips using the strip as a

template.

Fig. 5 - Using two pipe

clamps, pull the two

units together and using

the screws provided.

Align the breaker strips

as a template for the

screw pattern inside and

outside the cabinet.

SEALING BASE OF ROLL-IN MODELS

A SEALANT MUST BE USED

AROUND THE PERIMETER OF THE

BASE OF CABINET AS SHOWN TO

FULLY COMPLY WITH SANITARY

REQUIREMENTS.

A RECOMMENDED SEALANT IS

DOW CORNING SILASTIC RTV

Fig. 4

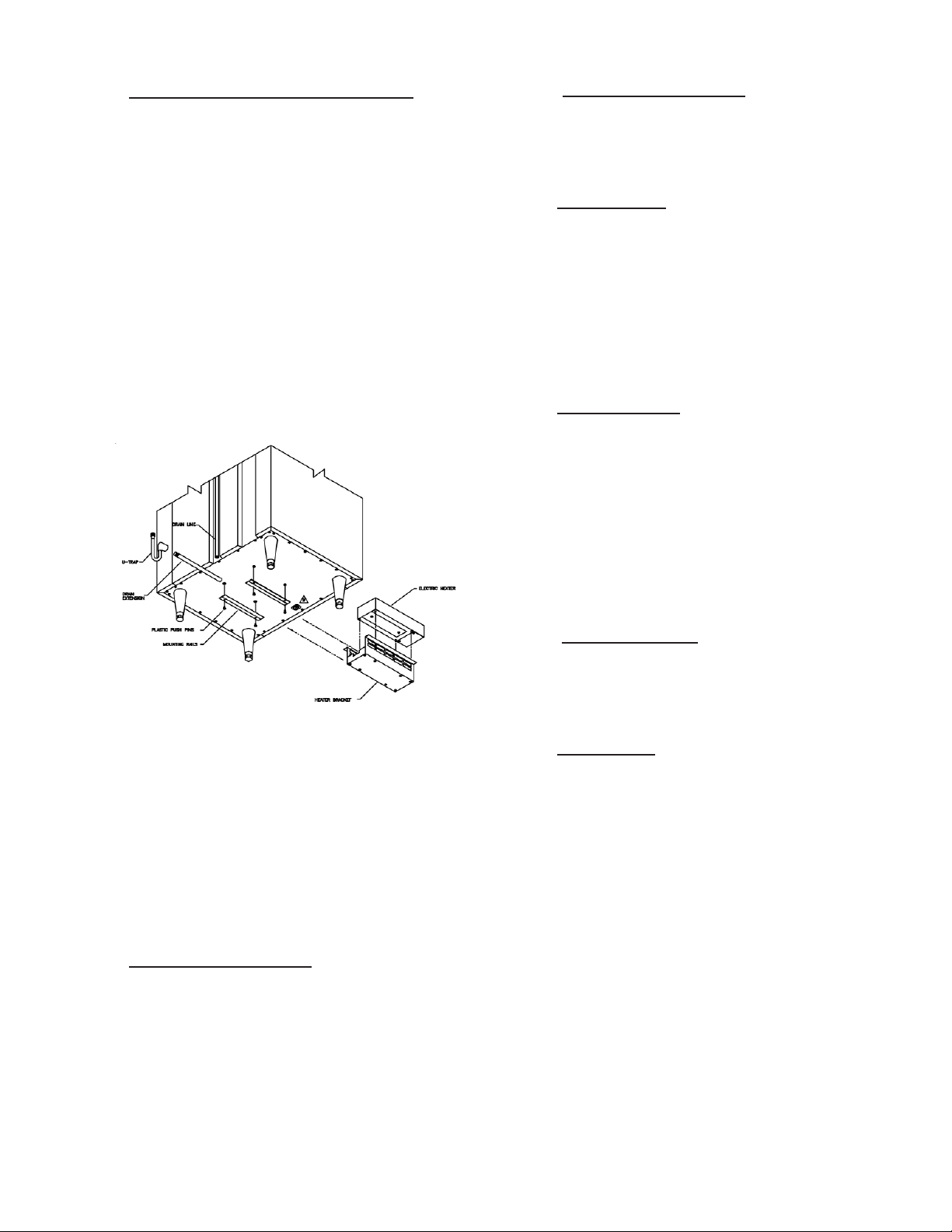

III. g - INSTALLING THE CONDENSATE EVAPORATOR:

A condensate evaporator is normally supplied on all

self-contained models (remote models require provision of either a oor drain or an optional condensate

evaporator). On those models supplied with a

top-mounted evaporator coil compartment, the

condensate evaporator is also secured to the top of the

cabinet. Check that the condensate pan is properly

located underneath the drain tube.

-3-

Page 5

III. INSTALLATION (continued)

III. g - INSTALLING THE CONDENSATE EVAP (cont’d):

NOTE: Some models, such as single section dualtemperature refrigerator/freezers, are supplied with a

bottom-mounted condensate evaporator. This is

shipped in a cardboard carton secured to the cabinet

interior, and must be PROPERLY installed prior to

use (see instructions supplied with the condensate

evaporator).

1) After the cabinet has been uncrated and the legs/

casters attached, you must install the bottom-mounted

condensate evaporator. 2) Locate the four (4) holes on

the exterior bottom towards the rear of the cabinet. 3) Using the provided 10-32 screws, attach the mounting rails

to the bottom, (the folded ange is to be turned up and be

towards the drain line. 4) Slide condensate pan into the

mounting rails. 5) Screw the “U-Trap” on to the drain line

located on the rear of the cabinet. 6) Screw the

drain extension into the “U-Trap.”

III. h - REMOTE INSTALLATION (cont’d):

Refrigerant line installation must be done in accordance

with good practice and local regulations. See section

“III. g” for information concerning condensate removal

for remote models.

III. i - CORD & PLUG:

Most self-contained models are supplied with a cord

& plug attached. It is shipped coiled at the top of the

cabinet, secured by a nylon strip. For your safety

and protection, all units supplied with a cord and plug

include a special three-prong grounding plug on the ser-

vice cord. Select only a dedicated electrical outlet with

grounding plug for power source. NOTE: Do not under

any circumstances, cut or remove the round grounding

prong from the plug, or use an extension cord.

III. j - POWER SUPPLY:

The supply voltage should be checked prior to

connection to be certain that proper voltage for the

cabinet wiring is available (refer to the serial tag to

determine correct unit voltage). Make connections in

accordance with local electrical codes. Use qualied

electricians.

Use of a separate, dedicated circuit is required. Size

wiring to handle indicated load and provide necessary overcurrent protector in circuit (see amperage

requirements on the unit’s serial tag).

Fig. 6

NOTE: The use of the “U-TRAP” supplied is required.

Failure to use this component may allow cold air to

migrate down the drain line, resulting in condensation

on the rear of the cabinet.

A remote model is normally supplied congured for

condensate to be run to a floor drain unless pur-

chased with a condensate evaporator. The installer is

responsible for making the required extension to the

oor drain in accordance with good practice and local

regulations.

III. h - REMOTE INSTALLATION:

Remote models are supplied without compressors,

solenoid valves, etc. The correct voltage, amp listing

and refrigerant are listed on the units serial tag. It is the

responsibility of the installer to specify and supply the

correct size compressor(s) based upon this information

and on-site requirements.

III. k - WIRING DIAGRAM:

Refer to the wiring diagram for any service work

performed on the unit. Should you require one, please

contact Traulsen Service at (800) 825-8220, and provide

the model and serial number of the unit involved.

III. l - CLEARANCE:

In order to assure optimum performance, the

condensing unit of your Traulsen unit MUST have an

adequate supply of air for cooling purposes. Therefore,

the operating location must either have a minimum

of 12” clearance overhead of the condensing unit or

allow for unrestricted air ow at the back of the unit.

Clearance of at least 12” above is required in order to

perform certain maintenance tasks.

-4-

Page 6

IV. OPERATION

IV. a - REFRIGERATORS:

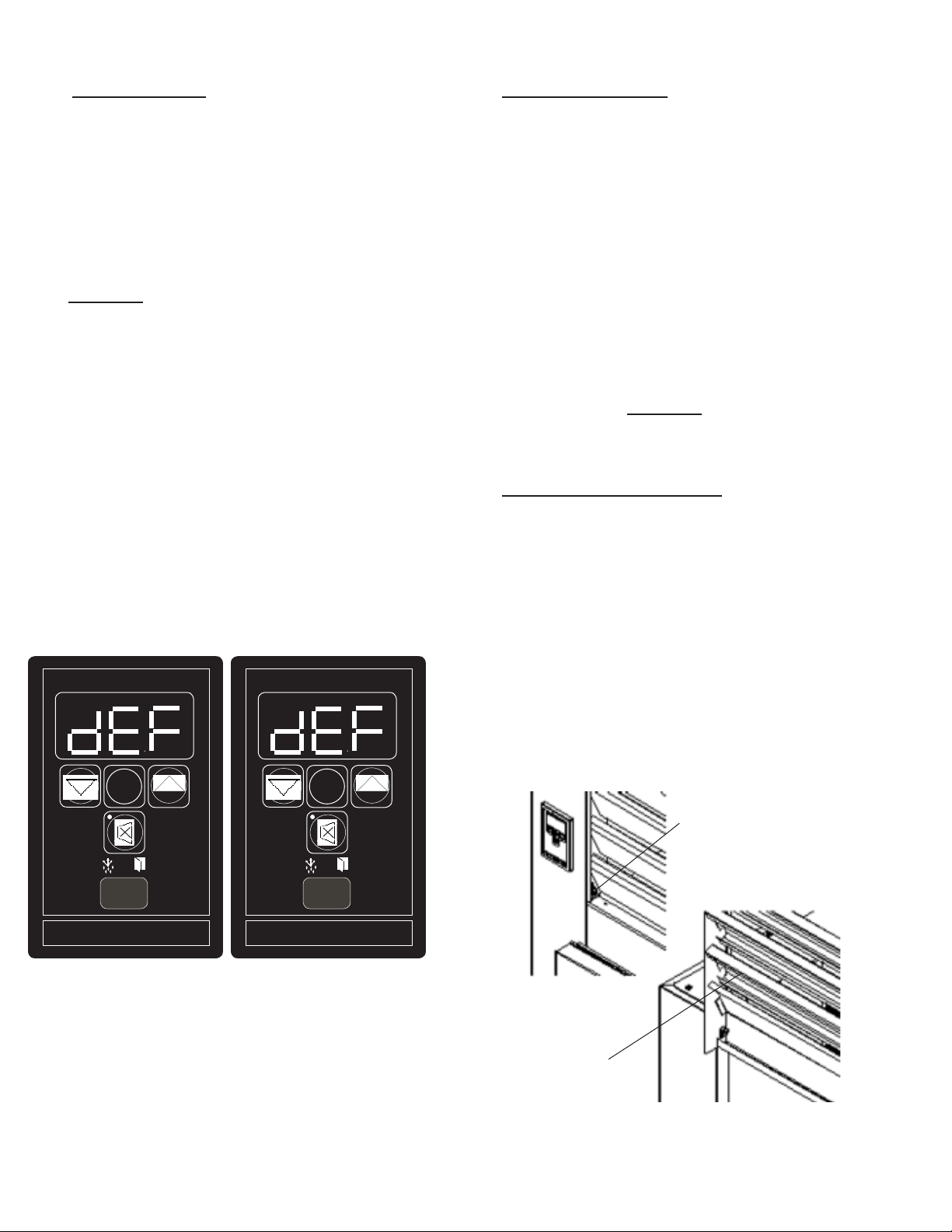

Both refrigerators and freezers do not require manual

defrosting. During normal operation, a refrigerator con-

tinuosly circulates above freezing cabinet air through

the coil. A compressor “OFF” cycle occurs

every hour

to melt any frost which may accumulate on the coil during the

compressor “ON” cycle. The control will read “dEF” when this

occurs and the evaporator fans will continue to operate. With

standard holding refrigerators, high relative humidity is also

maintained to prevent dehydration of stored product.

IV. b - FREEZERS:

During normal operation, a freezer continuously circulates

below freezing cabinet air through the coil. The coil requires a

IV. c- HOT FOOD CABINETS:

Hot food cabinet operation is governed by the

INTELA-TRAUL control, which controls the ON/OFF

operation of the strip heaters. The control can bet set to

maintain any operational temperature between 140 - 180°

F (in 5°F increments).

Hot food cabinets are delivered from the factory with

the control set to the “OFF” position. Follow the

instructions in section “VII. t” to get started.

NOTE: A vent is included at the top of all hot food

cabinets. The vent opening is factory set and secured

for best position. Be certain to make sure this vent is

kept free of any obstruction.

periodic defrosting for proper operation. This is accomplished

by an automatic, time activated, temperature/time terminated,

defrost program. The controller is preset at the factory for six

equally spaced defrost cycles within each 24-hour period.

At the start of a freezer defrost cycle, both the compressor

and evaporator fans are OFF. The INTELA-TRAUL® control

will read “dEF” (see gure 7). The electric heater (attached

to the coil) is energized. When a temperature device afxed

to the coil senses 70°F (models with electric defrost), the coil

is fully defrosted and the compressor operation is resumed,

defrost heaters are automatically turned off. The coil fans are

delayed from starting at the termination of a defrost cycle. Fan

operation is automatically resumed, or they can also be started

by a time or temp delay (whichever comes rst). In case of

temp delay, it uses the same coil sensor and starts at 32°F.

The total refrigeration system operation is then resumed.

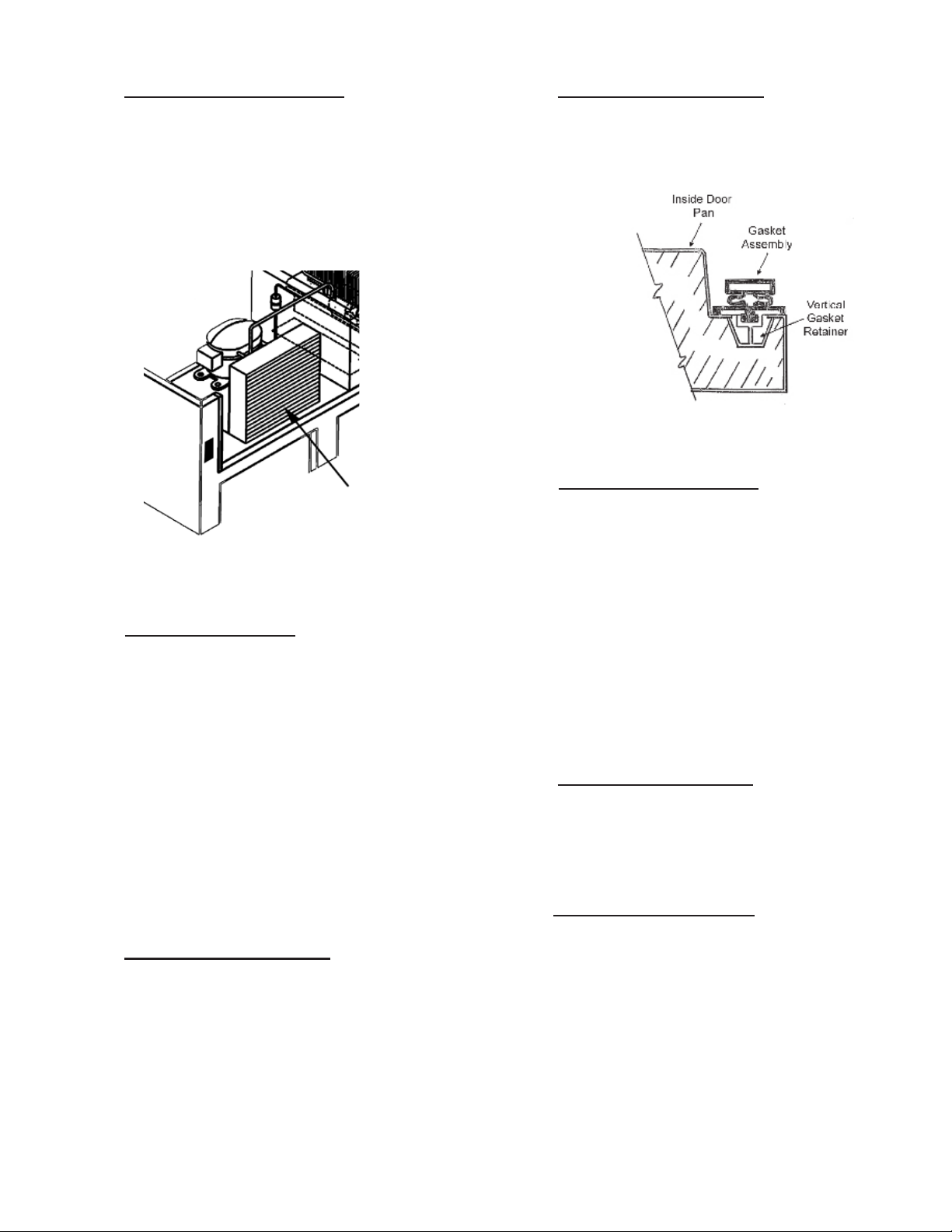

V. a - CLEANING THE CONDENSER:

The most important thing you can do to insure a long,

reliable service life for your Traulsen is to regularly clean

the condenser coil.

The condensing unit requires regularly scheduled

cleaning to keep the nned condenser clean of lint

and dust accummulation. The INTELA-TRAUL control

will notify you through a “CLN-FIL” message when

cleaning is necessary (see page 8). Keeping the

condenser clean allows the cabinet to operate more

INTELA-TRAUL

°F °C

INTELA-TRAUL

°F °C

efciently and use less energy.

To clean the condenser, rst disconnect electrical power

to the cabinet and lift up the front louver assembly. To

lift this, remove the two screws located on both sides at

the bottom of the louver assembly (see gure 8).

SET

SET

V. CARE & MAINTENANCE

WARNING

DISCONNECT ELECTRICAL POWER SUPPLY

BEFORE CLEANING ANY PARTS OF THE UNIT

)

)

)

REFRIGERATOR

FREEZER

Fig. 7

FREEZER

FREEZER

)

)

)

During freezer defrost operation, heat is confined to the

coil enclosure to prevent any signicant rise in temperature

within the food zone. The fan delay controls function upon

termination of a defrost cycle is two-fold. First, to prevent

blowing warm air into the food storage area. Second, to

prevent any condensation on the defrost coil from being blown

into the food storage area.

The INTELA-TRAUL® control is set from the factory to

terminate defrost at 20 minutes in the event of a sensor

failure. This setting should never be tampered with, without

rst consulting the factory.

Fig. 8

Remove

Screws

Fig. 9

Lift-Up Louver

Assembly

-5-

Page 7

V. CARE & MAINTENANCE (cont’d)

V. a - CLEANING THE CONDENSER:

Once the screws are removed, the panel can be pivoted

upwards allowing full access to the front facing

condenser (see gure 9).

Vacuum or brush any dirt, lint or dust from the nned

condenser coil, the compressor and other cooling

system parts (see figure 10). If significant dirt is

clogging the condenser ns, use compressed air to

blow this clear.

Fig. 10

Condenser

Surface

Lower louver assembly and replace the screws to hold

it in place.

V. b - HINGE REPLACEMENT:

Both the door and hinge can be easily removed from

the cabinet. To remove the door, remove the plug at

the bottom of the top hinge. Inside the hinge there is a

small screw which secures the door in place. Remove

this with a at head screwdriver and the door can then

be lifted off the hinge. To remove the door portion of

the hinge from the door, lift off the hinge cover and then

remove the three Phillips head screws which secure

the hinge in place on the door. To remove the cabinet

portion of the hinge, remove the three Phillips head

screws which hold it in place. On solid door units, the

top hinge(s) contains a microswitch for controlling the

interior lighting.

To reassemble the hinge reverse the previous procedure.

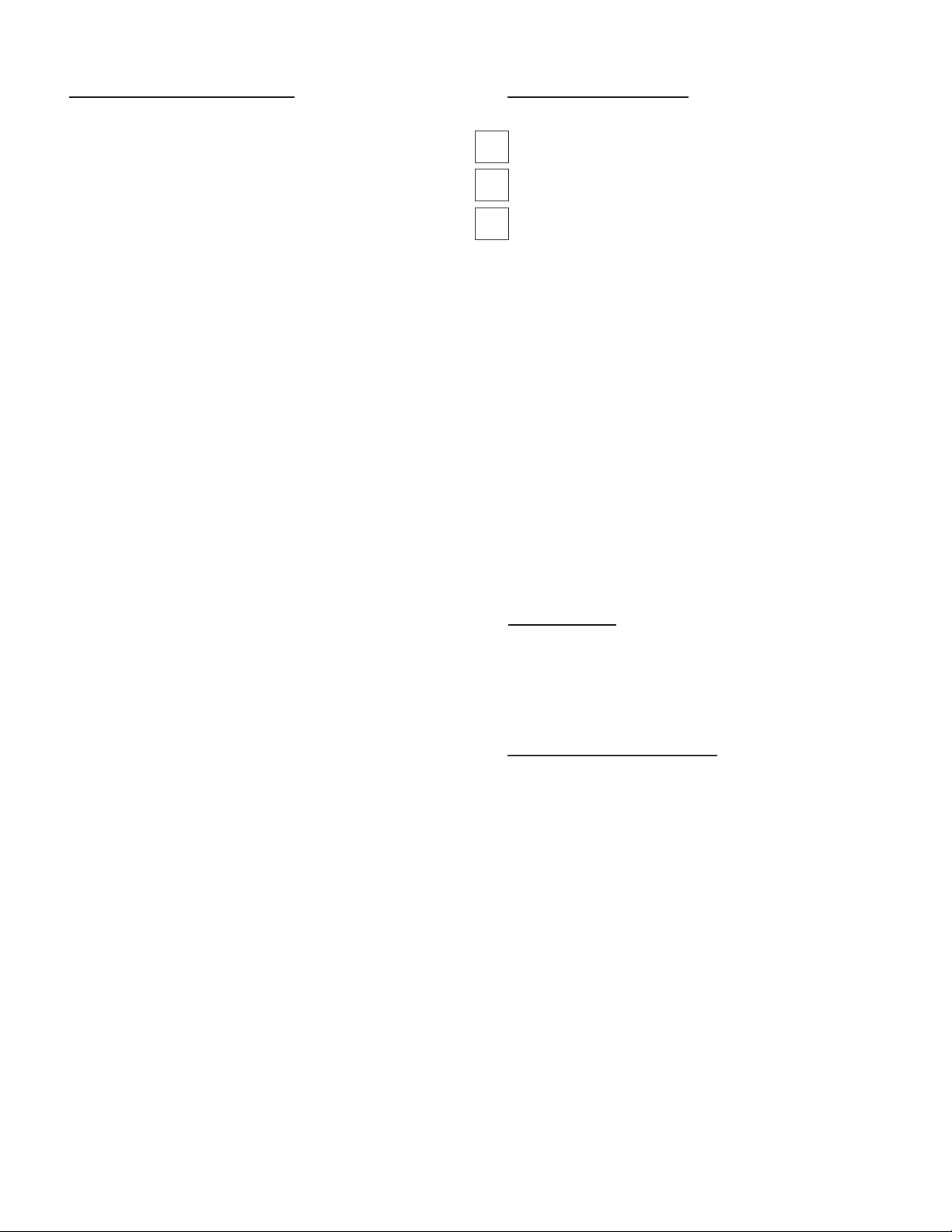

V. c - REPLACING THE GASKETS:

To remove the gasket to be replaced, grasp it rmly by

one corner and pull it out. Before attempting to install

a new gasket, both the unit and the gasket itself must

be at room temperature. Insert the four corners rst by

using a rubber mallet (or hammer with a block of wood).

V. c - REPLACING THE GASKETS:

After the corners are properly inserted, work your way

towards the center from both ends by gently hitting with

a mallet until the gasket is completely seated in place

(see gure 11 for proper gasket placement).

Fig. 11

NOTE: The gasket may appear too large, but if it is

installed as indicated above it will slip into place.

V. d - CLEANING THE EXTERIOR:

Exterior stainless steel should be cleaned with

warm water, mild soap and a soft cloth. Apply with a

dampened cloth and wipe in the direction of the metal

grain.

Avoid the use of strong detergents and gritty, abrasive cleaners as they may tend to mar and scratch the

surface. Do NOT use cleansers containing chlorine, this

may promote corrosion of the stainless steel.

Care should also be taken to avoid splashing the unit

with water, containing chlorinated cleansers, when

mopping the oor around the unit.

For stubborn odor spills, use baking soda and water

(mixed to a 1 TBSP baking soda to 1 pint water ratio).

V. e - CLEANING THE INTERIOR:

For cleaning both stainless steel and anodized

aluminum interiors, the use of baking soda as described

in section “V. d” is recommended. Use on breaker

strips as well as door gaskets. All interior ttings are

removable without tools to facilitate cleaning.

V. f - ADJUSTING THE SHELVES:

For shelves mounted on pins, rst select the desired

location and remove the white plastic covers in the

interior back and sides by rotating them counter-

clockwise. Remove the shelf pins by rotating them

counter- clockwise. Install the pins in the desired

location by rotating clockwise. Make sure the pin is

securely tightened down. Do not over tighten. Slide the

shelf into its new position, and replace the white plastic

covers into the holes vacated by the shelf pins.

-6-

Page 8

V. CARE & MAINTENANCE (cont’d)

VI. OTHER

V. g - REPLACING THE LIGHT BULB:

All Traulsen R & A Series models are supplied with

incandecent lighting unless optional fluorescent

lighting was ordered (except for sliding glass door

models for which fluorescent lights are supplied

standard).

The bulb is a 115 volt/40 watt, T-61⁄2 intermediate clear

refrigerator lamp. It is mounted at the top front of the

cabinet at the center, and is located behind a plastic light

cover on refrigerator and freezer model.

Heated units (RHF/AHF/RIH/AIH/RDH/ADH/RIDH/AIDH)

are equipped with a similar type bulb, however this is

shatterproof because these models do not include a

plastic light cover.

To replace the bulb, rst remove the light cover (if so

equipped). This can be accomplished by squeezing it

together on both sides until it comes free. Replace the

light bulb, then squeeze both sides of the light cover

together and replace in its original position.

VI. a - SERVICE INFORMATION:

Before calling for service, please check the following:

Is the electrical cord plugged in?

Is the fuse OK or circuit breaker on?

Is the power switch “ON”?

If after checking the above items and the unit is still

not operating properly, please contact an authorized

Traulsen service agent. A complete list of authorized

service agents was provided along with your Traulsen

unit. If you cannot locate this, you may also obtain the

name of a service agent from the SERVICE & PARTS

button from our website: www.traulsen.com.

If service is not satisfactory, please contact our in-house

service department at:

Traulsen

4401 Blue Mound Road

Fort Worth, TX 76106

(800) 825-8220

Traulsen reserves the right to change specications or

discontinue models without notice.

VI. b - SPARE PARTS:

Spare or replacement parts may be obtained through a

parts supplier or one of our authorized service agents.

A complete list of authorized service agents is posted

on our company’s ofcial website www.traulsen.com,

under the SERVICE & PARTS button.

VI. c - WARRANTY REGISTRATION:

For your convenience, the warranties on your new

Traulsen unit may be registered with us on-line at www.

traulsen.com, under the SERVICE & PARTS button.

-7-

Page 9

VII. The INTELA-TRAUL® Control System

Your new Traulsen Refrigerator, Freezer or Hot Food cabinet is equipped with a state-of-the-

art electronic microprocessor INTELA-TRAUL® control, which precisely regulates opera-

tion and provides alarms when problems occur. It is supplied from the factory completely

ready for use and requires no adjustment (except Hot Food units which are set in the “OFF”

position, see page for 19 for more info), but without the audible alarms activated. See pages

9 thru 19 for more information.

VII. a - INTELA-TRAUL® CONTROL FEATURES:

1- Internal Time Clock

• Defrost cycle can be quickly adjusted to suit individual location and use.

• Must be set at power-up.

• Will automatically update for Daylight Savings Time.

2- Water Resistant Housing - The face of the control is water resistant to provide for protection during cleaning.

3- Parameter/Service Levels

• See “Customer / Service Parameters” on Page 10.

4- Defrost Lockouts - See “Setting Defrost Lockouts” on page 16 (refrigerator and freezer models only).

• Customers can set up to 4 different defrost lockout periods. The lockout prevents the unit from going into a defrost

cycle during peak kitchen use. Note: The 24-hour clock must be set for this feature to operate correctly.

5- Anti-Condensate Door Perimeter Heater Control (refrigerator and freezer models only)

“No-Sweat” feature is an energy savings system that allows the customer to set the percent of time for the door heater as

needed for the prevailing ambient conditions (from 0 - 100% of the time each day). It is used to prevent condensation from

forming around the perimeter of the doors.

6- Alarms (See the following pages for explanations)

• High Cabinet Air Temperature

• Low Cabinet Air Temperature

• Loss Of Power

• Sensor Failure

• Door Open*

• Clean Condenser (refrigerator and freezer models only)*

• New Compressor Run Time, Defrost Error

* Not available on remote models.

** Not available on Fire-Rated or Sliding Door models.

7- Display Features

• Door Open Icon

• 3-Digit LED Display

• Defrost in Progress Icon

• Fahrenheit or Celsius Temperature Scale In Use

-8-

Page 10

VII. INTELA-TRAUL® (continued)

VII. a - ALARM EXPLANATIONS:

*NOTE: Explanation of alarms assume the audible alarm style is set at a 3-second burst or a continuous audible alarm.

References to the audible alarm do not apply if the audible alarm style is set to OFF (Refer to page 18 for setting the

audible alarm style).

High Cabinet Air Temperature: The audible alarm* will sound and the display will read

cHI when the temperature inside the cabinet rises above a pre-programmed limit. The limit is

determined by the type of unit being operated (i.e.: refrigerator/freezer). To turn off the audible

alarm*, press the alarm cancel button. The visual alarm text will continue to display until the cabinet air temperature falls below the limit. If the temperature does not fall below the limit within 5

minutes, the audible alarm* will sound again and an additional Call Service message will display.

POSSIBLE CAUSES (for Refrigerator & Freezer Models):

• Doors open for extended periods of time.

• Large amounts of hot product placed inside the cabinet.

• Condenser coil dirty.

Low Cabinet Air Temperature: The audible alarm* will sound and the display will read cLO

when the temperature inside the cabinet falls below a pre-programmed limit. The limit is deter-

mined by the type of unit being operated (i.e.: refrigerator/ freezer). To turn off the audible alarm*,

press the alarm cancel button. The visual alarm text will continue to display until the cabinet

air temperature rises above the limit. If the temperature does not rise above the limit within 5

minutes, the audible alarm* will sound again and an additional Call Service message will display.

POSSIBLE CAUSES (for Refrigerator & Freezer Models):

• No product in unit.

• Failed sensors.

Loss Of Power: The audible alarm* will sound and the display will read Electrical Loss, when

the unit regains power after an outage. To turn off the audible alarm* and/or clear the visual

text, press the alarm cancel button.

Door Open: The display will read Door Open and the audible alarm will sound, after the door

or doors have been open for 15 minutes. To turn off the alarm, close the door or press the

alarm cancel button. If the door remains open for an additional 5 minutes, the audible alarm*

will sound again (n/a on re-rated and sliding glass door models).

CONDENSER CLEAN™: The audible alarm* will sound and the display will read Clean

Filter, when the operating pressures and temperatures exceed a safe operating range. As

the load on the condenser decreases, the alarm will turn off by itself. As the pressures on the

condenser continues to rise, the audible alarm* will stay on for longer periods of time. To turn

off the audible alarm*, press the alarm cancel button. The visual alarm text will remain until the

lter/condenser has been cleaned. If the condition remains for 24 hours, the audible alarm* will

sound again and visual display will read Call Service.

POSSIBLE CAUSES:

• Inadequate air ow through condenser unit.

• Discharge sensor has failed high.

Sensor Failures: The audible alarm* will sound and the display will read SN1, SN2, SN3 when

any of the unit sensors fail to operate. To turn off the audible alarm*, press the alarm cancel

button. The visual alarm text will remain until the sensor has been replaced. Depending on

the function of the sensor, the audible alarm* will sound again in either 5 minutes or 24 hours.

*Not available on remote models.

Run Error: The audible alarm will sound and the display rUn Err when the compressor has run

continuously for over 24 hours. To turn off the audible alarm, press the alarm cancel button.

The visual text will remain until the issue is xed.

Defrost Error: The audible alarm will sound and the display will read DEF Err when defrost

does not terminate on temperature during a 36 hour period.

-9-

Page 11

VII. INTELA-TRAUL® (continued)

VII. c - CONTROL PANEL:

LED FOR ° F

INTELA-TRAUL

3-DIGIT (RED)

LED DISPLAY

°F

ALARM CANCEL

BUTTON

DEFROST ICON

W / LED

SET

)

)

)

FREEZER

DOOR OPEN ICON

W / LED

VII. d - NOTES TO THE USER:

You only have 20-30 seconds between button pushes. If you take longer than 30 seconds, the controller will revert back to

displaying the cabinet temperature. If you enter the wrong security code, the controller will revert back to displaying the cabinet temperature. You can exit the parameters at any time by pressing the alarm cancel button or by waiting 20-30 seconds.

VII. e - ENTER THE CUSTOMER ACCESS: This is required to set any of the control parameters

Use the security code 0, A, 1 and the following instructions:

Press the set button . The display will read Customer/Service Access.

Press the set button .

SET

S E T

The display will show three zeros with the left zero ashing .

Press the set button .

S E T

The display will show three zeros with the center zero ashing .

Press the down arrow key to sequence through F, E, d, C, b, A, 9, 8, 7,…etc.

When you reach A press set .

S E T

The display will show zero, A, zero with the right zero ashing .

Press the up arrow key to sequence through 1, 2, 3, 4, 5, 6, 7, 8, 9, A, b,…etc.

When you reach 1 press set .

The display will read Thermostat Set Point. Press to view and again to exit.

S E T

S E T S E T

You are now in the CUSTOMER / SERVICE PARAMETERS.

-10-

Page 12

VII. INTELA-TRAUL® (continued)

VII. f - CUSTOMER SERVICE PARAMETERS:

Listed below are the available parameters in the order they appear, using the down arrow key on the

controller. You can use either the up or down arrow keys to scroll through the options.

Thermostat Set Point Defrost Lockout 2

Set Point Differential Defrost Lockout 3

Temperature Scale* Defrost Lockout 4

Audible Alarm Style* Dew Point Compensation Factor*

Time (24-hour clock)* Room Temperature Offset

Date (month - day - year)* Evaporator Coil Sensor

Daylight Savings * Discharge Line Sensor

Defrost Lockout 1 Start Manual Defrost

Cabinet Air Sensor Temp

VII. g - ADJUSTING THE THERMOSTAT SET POINT:

*Available on Hot Food units.

This parameter sets the low point of the desired cabinet temperature range. Typically, freezers will range

from -4° F to 0° F (-19° C to -18° C) and refrigerators will range from 36° F to 40° F (2° C to 4° C) for

this parameter setting. This parameter is preset at the factory and does not have to be adjusted unless

the customer chooses to do so.

Follow the instructions to enter the customer access code on page 10. When the control

display reads Thermostat Set Point. Press the set button .

SET

Use the arrow keys to adjust the temperature to your desired setting.

When the display shows the temperature you want press the set button .

SET

The display will then read Thermostat Set Point.

You can use the up or down arrow keys to scroll to the next parameter

)

)

or press the alarm cancel button to exit .

)

-11-

Page 13

VII. INTELA-TRAUL® (continued)

VII. h - ADJUSTING THE THERMOSTAT SET POINT Differential:

This parameter sets the set point differential of the desired cabinet temperature range. Typically, freezers

and refrigerators will range from 2° F to 5° F for this parameter setting. This parameter is preset at the

factory and does not have to be adjusted unless the customer chooses to do so. Set point differential

determines the cabinet temperature at which the compressor come on.

Follow the instructions to enter the customer access code on page 10. When the control

displays Thermostat Set Point, press the down arrow key until the control

display reads Thermostat Set Point Differential. Press the set button .

SET

Use the arrow keys to adjust the temperature to your desired setting.

When the display shows the temperature you want press the set button .

SET

The display will then read Thermostat Set Point.

You can use the up or down arrow keys to scroll to the next parameter

)

)

or press the alarm cancel button to exit .

VII. i - CHANGING THE TEMPERATURE SCALE:

)

The temperature scale determines if the temperature displayed will be in degrees

Fahrenheit or degrees Celsius.

Follow the instructions to enter the customer access code on page 10. When the control

displays Thermostat Set Point, press the down arrow key until the control

display reads Temperature Scale. Press the set button .

SET

The display will start with the current setting either for degrees Fahrenheit

or for degrees Celsius. Use the arrow keys to toggle between the options.

When the display shows the scale you want press the set button .

SET

The display will then read Thermostat Set Point.

You can use the up or down arrow keys to scroll to the next parameter

)

)

or press the alarm cancel button to exit .

)

-12-

Page 14

VII. INTELA-TRAUL® (continued)

VII. j - SETTING THE 24-HOUR CLOCK:

The internal timeclock must be set in order for the data storage memory to correctly log events and to

allow any defrost lockout to occur at the correct time of day. If the clock is not set, the control assumes

the time is 12 a.m. at the time power is supplied to the unit. The hours on a 24-hour time clock read the

following way:

H01 = 1:00 a.m. H07 = 7:00 a.m. H13 = 1:00 p.m. H19 = 7:00 p.m.

H02 = 2:00 a.m. H08 = 8:00 a.m. H14 = 2:00 p.m. H20 = 8:00 p.m.

H03 = 3:00 a.m. H09 = 9:00 a.m. H15 = 3:00 p.m. H21 = 9:00 p.m.

H04 = 4:00 a.m. H10 = 10:00 a.m. H16 = 4:00 p.m. H22 = 10:00 p.m.

H05 = 5:00 a.m. H11 = 11:00 a.m. H17 = 5:00 p.m. H23 = 11:00 p.m.

H06 = 6:00 a.m. H12 = 12:00 p.m. H18 = 6:00 p.m. H24 = 12:00 a.m.

Follow the instructions to enter the customer access code on page 10. When the control

displays Thermostat Set Point, press the down arrow key until the control

display reads Clock. Press the set button .

SET

The display will show Hours. The right two numbers will be ashing.

Use the arrow keys to set the hour.

When the correct hour is displayed, press the set button .

SET

The display will show Minutes. The right two numbers will be ashing.

Use the arrow keys to set the minutes .

When the correct minutes are displayed, press the set button .

SET

The display will then read Thermostat Set Point.

You can use the up or down arrow keys to scroll to the next parameter

or press the alarm cancel button to exit .

)

)

)

-13-

Page 15

VII. INTELA-TRAUL® (continued)

VII. k - SETTING THE DATE:

The date must be set in order for the data storage memory to correctly log events. Follow the instruc-

tions to enter the customer access code on page 10. When the control displays Thermostat

Set Point, press the down arrow key until the control display reads Date. Press the set

button . The display will show (year). The right two numbers will be ashing. Press

SET

the arrow keys to set the year. When the correct year is displayed, press the set button

SET

. The display will show (month). The right two numbers will be ashing. Use the

arrow keys to set the month. When the correct month is displayed, press the set button

SET

. The display will show (day). The right two numbers will be ashing. Press the

arrow keys to set the day. When the correct day is displayed, press the set button

SET

. The display will then read Thermostat Set Point. You can use the up or down arrow

)

)

keys to scroll to the next parameter, press the alarm cancel button to exit .

VII. l - SETTING DAYLIGHT SAVINGS TIME:

)

This parameter is preset at the factory to automatically adjust the 24-hour clock for Daylight Savings

Time. Follow the instructions to enter the customer access code on page 10. When the control dis-

plays Thermostat Set Point, press the down arrow key until the display reads

Daylight Savings Time. Press the set button . The display will show Day-

SET

light Savings Time (Yes, automatically adjust for Daylight Savings Time). For “YES,” press the

set button , for “NO” press the up or down arrow key . The display will read

Daylight Savings Time (no). Press the set button . The display will read Thermostat

SET

SET

Set Point. You can press the the up or down arrow keys to scroll to the next parameter

)

)

or press the alarm cancel button to exit .

)

-14-

Page 16

VII. INTELA-TRAUL® (continued)

VII. m - STARTING A MANUAL DEFROST CYCLE:

This parameter allows a service technician to start a defrost cycle at any time. This parameter

will override any lockout settings.

Follow the instructions to enter the customer access code on page 10. When the control

displays Thermostat Set Point, press the down arrow key until the control

display reads Start Manual Defrost.

Press the set button .

SET

The display will show (OFF).

Press either arrow key (ON).

The display will show .

Press the set button .

SET

The display will then read and start the defrost cycle immediately.

Reach-In/Roll-In Models

INTELA-TRAUL

The defrost icon will be lit,and the display will read

°F °C

when the unit is in defrost.

SET

)

)

)

FREEZER

DEFROST ICON

NOTE: Traulsen refrigerator units also have an off-cycle defrost once an hour, at which time the

control will read . This defrost is time terminated and can last 10 minutes (dEF will be

displayed for 22-27 minutes).

-15-

Page 17

VII. INTELA-TRAUL® (continued)

VII. n - SETTING THE DEFROST LOCKOUTS:

The defrost lockout parameters allow the customer to prevent the unit from going into a defrost cycle for

two hours during a set timeframe. Customers can set up to four defrost lockout parameters. They are all

programmed the same way. The parameters will be set for the time the lockout is to start. The controller

automatically calculates 2 hours from that setting. The options are similar to the 24-hour clock settings

and are in 30-minute increments. Each of the lockout parameters covers 6 hours of the 24-hour clock.

Note: The 24-hour clock must be set for this feature to operate at the correct time of day. See “Setting

the 24-Hour Clock” on page 13.

Sample:

OFF OFF OFF OFF

020 = 2:00 a.m. 080 = 8:00 a.m. 140 = 2:00 p.m. 200 = 8:00 p.m.

023 = 2:30 a.m. 083 = 8:30 a.m. 143 = 2:30 p.m. 203 = 8:30 p.m.

030 = 3:00 a.m. 090 = 9:00 a.m. 150 = 3:00 p.m. 210 = 9:00 p.m.

033 = 3:30 a.m. 093 = 9:30 a.m. 153 = 3:30 p.m. 213 = 9:30 p.m.

040 = 4:00 a.m. 100 = 10:00 a.m. 160 = 4:00 p.m. 220 = 10:00 p.m.

043 = 4:30 a.m. 103 = 10:30 a.m. 163 = 4:30 p.m. 223 = 10:30 p.m.

050 = 5:00 a.m. 110 = 11:00 a.m. 170 = 5:00 p.m. 230 = 11:00 p.m.

053 = 5:30 a.m. 113 = 11:30 a.m. 173 = 5:30 p.m. 233 = 11:30 p.m.

060 = 6:00 a.m. 120 = 12:00 p.m. 180 = 6:00 p.m. 240* = 12:00 a.m.

063 = 6:30 a.m. 123 = 12:30 p.m. 183 = 6:30 p.m. 243* = 12:30 a.m.

070 = 7:00 a.m. 130 = 1:00 p.m. 190 = 7:00 p.m. 010 = 1:00 a.m.

073 = 7:30 a.m. 133 = 1:30 p.m. 193 = 7:30 p.m. 013 = 1:30 a.m.

080 = 8:00 a.m. 140 = 2:00 p.m. 200 = 8:00 p.m. 020 = 2:00 a.m.

* Denotes not available.

A lockout cannot be programmed to start at 12:00 a.m. or 12:30 a.m. due to conicts with other internal programs. The defrost lockouts cannot be programmed to run back-to-back. For example, if dL1

is set to 080, then a defrost cycle would be locked out from 8:00 a.m. to 10:00 a.m. Because of the

dL1 setting the dL2 parameter would not let the user choose a lockout start time before 10:30 a.m. All

lockouts are preset at the factory to OFF.

Follow the instructions to enter the customer access code on page 10. When the control

displays Thermostat Set Point, press the down arrow key until the control the

S E T

control display reads or . Press the set button .

The display will show Off. Press the arrow keys to set the start time.

When the correct time is displayed, press the set button .

S E T

The display will then read Thermostat Set Point.

You can press the up or down arrow keys to scroll to the next parameter

)

)

or press the alarm cancel button to exit .

)

-16-

Page 18

VII. INTELA-TRAUL® (continued)

VII. o - ADJUSTING THE ROOM TEMPERATURE OFFSET:

The room temperature offset parameter allows a service technician or end user the ability to have the

display show a temperature that is within three degrees of the actual temperature being read by the

cabinet air sensor. This allows for continuity of reading between different temperature reading devices.

(i.e.: thermistor Vs thermocouple Vs hand held thermometer) This parameter is preset at the factory to

“0” or no offset.

Follow the instructions to enter the customer access code on page 10. When the control displays

Thermostat Set Point, press the down arrow key until the control display reads

Room Temperature Offset. Press the set button . Use the arrow keys to adjust the

offset to your desired setting. When the display shows the offset you want press the set button .

S E T

S E T

The display will then read Thermostat Set Point. You can use the up or down arrow keys

)

)

to scroll to the next parameter or press the alarm cancel button to exit .

VII. p - SETTING THE AUDIBLE ALARM STYLE:

)

This parameter will allow the customer to turn on/off the audible alarm feature on the

INTELA-TRAUL® control. The audible alarm is preset from the factory to OFF. The customer can

choose between an audible alarm that sounds for 3 seconds then automatically turns off, or a

continuous audible alarm that must be manually acknowledged. Regardless of this feature’s setting,

visual alarm text will display when conditions warrant.

To adjust this setting, follow the instructions to enter the customer access code on page 10. When

the control displays Thermostat Set Point, press the up arrow key until the display

reads Audible Alarm Style. Press the set button . The display will read OFF.

S E T

Use the arrow keys to scroll between for the 3-Second Audible Alarm Burst

or for Continuous Audible Alarm. When the display shows your choice of style, press the set

button . The display will then read thermostat Set Point. Use the arrow keys

to scroll to the next parameter or press the Alarm Cancel Button to exit.

S E T

-17-

)

)

)

Page 19

VII. INTELA-TRAUL® (continued)

VII. q - VIEWING SENSOR TEMPERATURES:

These parameters allow a service technician or customer to view the temperature of all sensors within

the unit. The temperatures cannot be adjusted.

Follow the instructions to enter the customer access code on page 10. When the control displays

Thermostat Set Point , press the DOWN arrow key unit the display reads

Cabinet Air Sensor, Evaporator Coil Sensor, and Disharge Line Sensor or

press the SET button . The display will read Thermostat Set Point .

S E T

Press the UP or DOWN arrow keys to scroll through the parameters or press the ALARM

)

)

CANCEL button to exit.

VII. r - DOOR OPEN ICON:

)

The door open icon is located on the control face, directly below the Alarm Cancel button (On/Off button

for heated cabinet models). This feature illuminates on all solid and hinged glass door models1 whenever

one or more of the doors is opened, and stops illuminating upon all doors being closed. There are no

operator adjustable parameters for this feature.

1= This feature is not included on either re-rated or sliding glass door models.

VII. s - HOT FOOD UNITS, ADJUSTING THE THERMOSTAT & TURNING THE UNIT OFF/ON:

This parameter sets the desired cabinet temperature. Please note that hot food units are delivered

from the factory set to the OFF position.

Follow the instructions to enter the customer access code on page 10. When the control reads

Thermostat Set Point, press the set button .

SET

Use the arrow keys to adjust the temperature to your desired setting. When the display

shows the temperature you want press the set button . The display will then read

SET

Thermostat Set Point. You can use the up or down arrow keys to scroll to the

next parameter or press the alarm cancel button to exit.

-18-

Page 20

VII. INTELA-TRAUL® (continued)

VII. t - HOT FOOD UNITS, TURNING THE UNIT OFF/ON:

After the temperature has been set, the customer can continuously turn the unit OFF and then back

ON to the same temperature. To turn the unit ON /OFF press the alarm cancel button , (please

note that this feature is not available on versions of the control manufactured prior to September

2000), or if an alarm warning condition is present, use the alternative ON/OFF activation method.

To turn the unit ON/OFF using the alternative method, press both arrows at the same time,

the set temperature will remain in memory.

VII. v - HOT FOOD UNITS, TEMPERATURE ADJUSTMENT:

Press the SET button and the UP ARROW button at the same time. The display will

SET

ash the current temperature setting or OFF (if the unit is turned off). Use the UP or DOWN

ARROW buttons to adjust your desired temperature setting (temperature range is 140° - 180°

F, and OFF) then press the SET button . The display will go back to reading cabinet

SET

temperature. If OFF is selected the display will then read OFF. NOTE: If you wish to change the

set temperature at anytime follow this procedure.

These models also include a “One-Time Temperature Setting Adjustment” feature. Upon start-up,

the unit will warm-up to the last temperature you had set for it, unless changed.

-19-

Page 21

VIII. TROUBLE SHOOTING GUIDE

FIND YOUR PROBLEM HERE REMEDY

1. Condensing unit fails to start. a. Check if cord & plug has been disconnected.

b. Check INTELA-TRAUL® temperature setting.

2. Condensing unit operates for a. Are doors closing properly?

prolonged periods or continuously. b. Dirty condenser or lter. Clean properly.

c. Evaporator coil iced. Needs to defrost. See

instructions for setting a manual defrost cycle

on page 15.

d. Shortage of refrigerant, call service.

3. Food compartment is too warm. a. Check door(s) and gasket(s) for proper seal

b. Perhaps a large quantity of warm food has

recently been added or the door was kept

open for a long period of time, in both

cases, allow adequate time for the cabinet

to recover its normal operating temperature.

c. INTELA-TRAUL® setting too high, readjust

per instructions on page 11.

4. Food compartment is too cold. a. Perhaps a large quantity of very cold or frozen

food has recently been added. Allow adequate

time for the cabinet to recover its normal operating

temperature.

b. Adjust the INTELA-TRAUL® to a warmer

setting, see page 12.

5. Condensation on the exterior surface. a. Check door alignment and gaskets for proper seal.

b. Condensation on the exterior surface of the

unit is perfectly normal during periods of

high humidity. However, to alleviate the

condition, adjust the INTELA-TRAUL®

“Dewpoint Compensation Factor,” see page 17.

6. Compressor hums but does not start. a. Call for service.

7. Door open icon continually illuminated. a. Door open, close door.

b. Faulty door switch, replace door switch.

8. Door open icon does not illuminate. a. Faulty door switch, replace door switch.

9. Evaporator fans not operating. a. Defrost cycle in progress (freezers only).

b. Other, contact service.

-20-

Page 22

XI. SPARE PARTS LIST

PART PART # DESCRIPTION

Bulb, Fluorescent 337-27690-00 Replacement bulb for uorescent light models

Bulb, Incandescent 378-29776-00 Replacement bulb for incandescent light models

Bulb Cover 337-30858-00 Replacement bulb cover for incandescent light models

Caster, 6” High 344-13140-01 Optional caster for all reach-in models

Caster, 4” High W/O Brake SMO-28627-00 Optional lower height caster

Caster, 4” High W/Brake SMO-28628-00 Optional lower height caster

Caster Bolt (4 req’d per caster) 351-25542-00 Bolt for above

Door Handle, Stainless Steel 344-37690-00 Replacement handle for solid door units

Door Lock, Sliding Glass 346-60005-00 Jewelers type door lock for sliding glass door model

Hinge Cam 344-28488-00 Replacement hinge cam

Hinge Cover 344-28486-00 Replacement hinge cover

Hinge, Spring Assist SER-29021-03 Alternative hinge, spring assist

Hinge Assembly W/Stop Feature SER-40677-02 Alternative hinge, stop feature

Hinge Assembly SER-28583-00 Replacement hinge assembly

Key, Master 346-29467-00 Replacement key for solid door units

Leg, 4” High Adjustable 344-29558-00 Replacement or optional leg

Leg, 6” High Adjustable 344-13168-01 Replacement leg

Shelf Pin 344-24759-02 Replacement shelf pin

Shelf Clip 344-08982-00 Replacement shelf clip for pilasters

Tray Slide, #4 Chrome Rod Type 340-04842-00 Tray slide for rim support of 18” x 26” pan

Tray Slide, Universal 719-07805-00 Tray slide for 18” x 26”, 14” x 18” or 12” x 20” pan

Tray Slide, #1 719-20236-00 Tray slide for 18” x 26” or 14” x 18” pan

Coil Sensor 337-60071-02 Coil Sensor For Microprocessor Control

Discharge Sensor 337-60072-02 Discharge Line Sensor For Microprocessor Control

Cabinet Sensor 337-60069-02 Cabinet Sensor For Microprocessor Control

Horn 337-60070-00 Horn For Audible Control Alarms

-21-

Page 23

XII. STAINLESS STEEL OVERVIEW

XII. a - INTRODUCTION:

All Traulsen R & A Series Refrigerator, Freezer, DualTemp and Heated Cabinet models are constructed

with a high quality 430 series, 20 gauge stainless steel

exterior nish (front, sides and doors). The interior

nish on these same R-Series models are constructed

using 300 series stainless steel (anodized aluminum is

used for A-Series).

The stainless steel nish on Traulsen R & A Series should

retain its appearance throughout the products usable

lifetime. However, some care is required to maintain

this appearance. The following paragraphs will provide

a guideline on proper care of the exterior/interior nish,

as well as some suggestions on how to repair a nish

which has been marred due to adverse environmental

conditions or improper jobsite care.

XII. b - STAINLESS STEEL, HOW IT WORKS:

The process by which stainless steel retains its

appearance is a result of its type of metal alloy. Steel is

a composite of metals combined in a specic industrial

process. Stainless steel contains a high percentage

of chromium, the addition of which provides both its

appearance, and a microscopic surface layer protecting the steel underneath from corrosion. This external

layer acts as a barrier, preventing typical oxidation of

the steel. Remove this barrier, and the environment will

eventually corrode the metal, marring its appearance.

XII. c - UNDERSTANDING THE CAUSES OF CORROSION:

Corrosion to stainless steel can only be caused in one

of four specic ways:

1) ABRASION

Abrasion can be caused during routine cleaning of the

metal, either by use of an abrasive cleanser, or use

of an abrasive device, such as a metal scouring pad.

Abrasion can also be caused by contact with other hard

surfaces, such as nearby equipment, walls or tools.

Special care should be taken to position your unit

properly to prevent accidental dents and scratches.

2) WATER

Water everywhere contains various deposits, or solids,

which as the water drys or evaporates, can leave spots

behind. The spots may eventually cause corrosion if

not removed.

3) CHEMICALS OR WATER CONTAINING CHLORIDES

Chlorides, such as found in water or many cleaning

materials are especially corrosive to stainless steel.

Daily janitorial duties, such a oor mopping, can splash

water containing chlorinated cleansers against the front

and sides of a Traulsen refrigeration product, resulting in

corrosion. Avoid use of these on or around a Traulsen

refrigeration product if at all possible.

XII. c - UNDERSTANDING THE CAUSES OF CORROSION:

4) PROLONGED CONTACT WITH FOOD PRODUCT

Many food products, such as milk and carbonated

sodas, contain acids which may damage the protective

layer of stainless steel. All food and beverage spills

should be cleaned up promptly to avoid possible stains

and corrosion.

XIII. CARE OF STAINLESS STEEL

XIII. a - USING THE PROPER TOOLS:

Use of proper cleaning materials will do much to

prolong the appearance of your Traulsen refrigeration product. We particularly encourage the use of

either plastic scouring pads or soft cloths for cleaning

stainless steel.

Soft nylon scouring pads can also be used, however care

has to used to insure that all scrubbing is done in the

direction of the metals “GRAIN.” Because metals are

chrystalline in nature, when they are in a solid state the

individual ions line up to form visible grain lines. Use

of a soft nylon scouring pad in a direction opposite of

the grain will mar its luster. Always do so “PARALLEL”

to the grain.

There are several types of tools which should NEVER BE

USED when cleaning stainless steel, these include:

• WIRE BRUSHES

• METAL SCOURING PADS

• SANDPAPER

• SCRAPERS & PUTTY KNIVES

Use of any of these tools will result in scratches or

removal of the stainless steel’s protective layer, which

will eventually lead to corrosion and rust.

XIII. b - USING THE RIGHT CLEANSER:

Avoid all cleaning products containing chloride

ingredients. Use of a cleanser specically designed

for stainless steel is highly recommended. You may

nd yourself in a situation where you are uncertain if a

particular cleaning product contains any chlorides. If

unsure, its probably best to just assume that it does

and avoid its use in cleaning a Traulsen refrigeration

product.

Also to be avoided are cleaning products which contain “QUATERNARY SALTS.” These salts can literally

attack the stainless steel’s protective layer, leading to

corrosion and pitting of the steels surface.

After cleaning, it is important to always rinse the cleaned

area thoroughly with cool, clean water (do not use hot

water) and wipe completely dry using a paper towel or

soft absorbent cloth.

Use of cleaning products designed for use on stainless

steel, in conjunction with the proper tools, as outlined

above will help retain the appearance of your Traulsen

refrigeration product for years and years.

-22-

Page 24

XIII. CARE OF STAINLESS STEEL

(cont’d)

XIV. CORROSION REMEDIES

XIII. c - CLEANING SUMMARY - DO’S & DONT’S:

To summarize the proper cleaning of Traulsen

refrigeration products, always follow the below

guidelines.

DO use only cleaning products designed for

stainless steel, or cleaning products which do

not contain chlorides.

DO use only non-abrasive cleaning materials, such

as soft cloths or plastic scouring pads.

DO clean-up food and beverage spills ASAP.

DO scrub only in the direction of the grain when

using soft nylon scouring pads.

DON’T use chlorinated cleansers or cleansers

containing quaternary salts.

DON’T use abrasive cleaning materials or tools

which can scratch the stainless steel’s surface.

XIII. d -

In the daily routine of a busy foodservice operation,

your Traulsen refrigeration product may occasionally

come in contact with chlorinated cleaners, such as when

being splashed during mopping. Stain and corrosion

problems resulting from this can be avoided by prompt

action to remove this cleanser. Rinse the affected area(s)

thoroughly with cool, clean water (do not use hot water)

and wipe completely dry using a paper towel or soft

absorbent cloth.

DEALING WITH ACCIDENTAL CHLORIDE CONTACT

:

XIV. a - DEALING WITH RUST AFTER THE FACT (cont’d):

STEP THREE - Apply a preservative polish, such as

“Sheila Shine,” to the affected area (see section II. e).

XIV. b - DEALING WITH EXTREME RUST SITUATIONS:

In the event that rust and corrosion were not dealt with

promptly, more acute situations can be remedied as

follows:

NOTE: PROCEDURE REQUIRES USE OF AN ACID

BASED SOLUTION - USE OF PROTECTIVE GLOVES AND

EYEWEAR ARE REQUIRED BEFORE PROCEEDING

STEP ONE - In a clean spray bottle combine water with

“Zep FS Lime Remover” to make a 5 parts to 1 solu-

tion.

STEP TWO - Apply this solution to the affected area with

either a clean cloth or sponge.

STEP THREE - After application, wipe the same area

thoroughly clean with water only to remove any

residue.

STEP FOUR - Once cleaned, apply a light coat of “Zep

Restore” to the surface area. This will serve to preserve

the metal and help prevent future rust from occuring.

STEP FIVE - Restore the remaining stainless steel

surfaces to their original shine using “Zep Stainless

Steel Polish.”

Repeat steps one thru ve if necessary for stubborn rust

and corrosion areas.

XIII. e - PROTECTING THE STAINLESS STEEL SURFACE:

Occasional use of a commercial stainless steel polish,

such as “Sheila Shine,” will help protect the surface of

stainless steel. Follow the directions on the spray can

for proper use.

XIV. CORROSION REMEDIES

XIV. a - DEALING WITH RUST AFTER THE FACT:

Although Traulsen strongly recommends proper care

and cleaning of stainless steel nishes in order to avoid

rust and corrosion before it occurs, we recognize that

it may occur occasionally as a result of the causes

described in section one of this booklet.

To remove small quantities of rust from the surface of

stainless steel, it is far preferable to deal with this when

it rst becomes visible. When rust occurs, do not allow

it to remain for any period of time, and remove it using

the following method:

STEP ONE - Use a lightly abrasive compound (free of

harmful chlorides), such as “Bon Ami,” on a soft cloth,

to remove the rust. Care must be taken to rub this on

the area of rust only in the direction of the stainless

steel’s grain.

STEP TWO - Once the rust is removed, clean the affected area thoroughly with a stainless steel cleaner (see

sections II. a & b).

XIV. c - RESTORING THE PROTECTIVE LAYER:

There are several products available on the market

today which can actually help restore the

“PASSIVATION” of stainless steel. “PASSIVATION”

refers to the protective qualities of the non-reactive

surface layer of stainless steel which prevents

oxidation. Contact your cleaning supplier for product

recommendations and more information.

-23-

Page 25

XV. WARRANTY INFORMATION

(this warranty applies to units manufactured after January 01, 2013)

TRAULSEN warrants new equipment to the original purchaser, when installed within the United States against

defective material and workmanship for three (3) years from the date of original installation. Under this

warranty, TRAULSEN will repair or replace, at its option, including service and labor, all parts found to be

defective and subject to this warranty. Warranty term begins upon the date of Installation, the date of End User

Invoice or the date of Dealer Invoice, whichever is proven to occur latest, not to exceed 18 months from Dealer

Invoice date (the “Warranty Period”). Warranty excludes components that are removable without tools.

The compressor part is warranted for an additional two (2) years. During this period TRAULSEN will supply

replacement compressor(s) if deemed defective, however all installation, recharging and repair costs will remain

the responsibility of the owner.

This warranty does not apply to damage resulting from fire, water, burglary,

of God, terrorism, attempted repairs, improper installation by unauthorized persons, and does not apply to food

loss.

For Traulsen units purchased with a remote feature, standard warranty will apply only to those components

contained within the unit to the point of connection of the refrigeration lines leading to the remote condenser.

“Defective Part Return” – All claimed defective replacement part(s) must be returned to TRAULSEN for

inspection within 30 days from the date of the repair. Failure to return all claimed defective part(s) to

TRAULSEN will invalidate the warranty claim, this warranty statement, and forfeit payment for those repairs

affected.

INTERNATIONAL COMMERCIAL WARRANTY

TRAULSEN warrants to the original purchaser the

defects in material and workmanship under normal use and service for a period of one (1) year from date of

shipment. Under this warranty, TRAULSEN will reimburse the purchaser for the replacement of any part of said

equipment (excluding dryers & refrigerant gas) which then proves to be defective. This warranty does not

apply to damage resulting from fire, water, burglary, accident, abuse, misuse, transit, acts of God, terrorism,

attempted repairs, improper installation by unauthorized persons, and will not apply to food loss.

TRAULSEN’S standard warranty does not apply to Export Sales. Rather, for a period of one (1) year from date

of original installation no

Traulsen’s sole discretion, replace or repair, F.O.B. factory, any defective parts normally subject to warranty and

will not cover the cost of packing, freight or labor, such costs being the sole responsibility of the dealer.

THERE ARE NO

LIMITED TO,

EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. TRAULSEN SHALL HAVE NO OBLIGATION OR LIABILITY

FOR CONSEQUENTIAL OR SPECIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO, INDIRECT, PUNITIVE

DAMAGES, LOSS OF USE, LOSS OF PRODUCT, DOWN TIME OR LOST PROFITS, GROWING OUT OF OR WITH

RESPECT TO THE EQUIPMENT OR ITS SALE, OPERATION OR USE, AND TRAULSEN NEITHER ASSUMES NOR

AUTHORIZES ANYONE ELSE TO ASSUME FOR IT ANY OBLIGATION OR LIABILITY IN CONNECTION WITH THE

EQUIPMENT OR ITS SALE, OPERATION OR USE OTHER THAN AS STATED HEREIN.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EITHER EXPRESSED OR IMPLIED AND

TRAULSEN’S FULL OBLIGATION AND LIABILITY. WARRANTIES NOT AVAILABLE ON REMOTE

ORAL, STATUTORY

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE WHICH

t to exceed Fifteen (15) months from date of shipment from factory, TRAULSEN: will, at

STANDARD DOMESTIC WARRANTY

Refrigeration Equipment shall be manufactured free from

OR

IMPLIED WARRANTIES

APPLICABLE TO TRAULSEN, INCLUDING BUT NOT

accident, abuse, misuse, transit, acts

CONSTITUTES

MODELS.

-24-

Page 26

HOURS OF OPERATION:

Monday thru Friday 7:30 am - 4:30 pm CST

Quality Refrigeration

Traulsen

4401 Blue Mound Road Fort Worth, TX 76106

Phone: (800) 825-8220 Fax-Svce: (817) 740-6757

Website: www.traulsen.com

© 2015 Traulsen - All Rights Reserved

Loading...

Loading...