Page 1

Quality Refrigeration

INTELA-TRAUL

®

MASTER SERVICE MANUAL

For All Full Size Undercounter, G-Series and

R&A Series Refrigerator, Freezer, Dual-Temp

and Hot Food Unit Controllers

4401 Blue Mound Road - Fort Worth, Texas 76106

Phone: (800) 825-8220 or (817) 625-9671

Traulsen

Fax-Service (817) 740-6757

Form Number TR35705, revised 10/04

Page 2

TABLE OF CONTENTS

I. General Information

a) How To Use This Manual Page 2

b) About INTELA-TRAUL Page 2

c) Operating The Controller Page 2

II. Basic Service Procedures

a) Adjusting The Temperature Page 3

b) Starting A Manual Defrost Cycle (R & A Series) Page 4

c) Starting A Manual Defrost Cycle (G-Series) Page 5

III. Troubleshooting

a) Checking For Defective Sensors Page 6

b) Checking For Failed Relays Page 7

c) Checking For Other Failed Components Page 8

d) Checking For Iced Evaporator Coil Page 9

e) Proper Sensor Placement Page 10

IV. Control Architecture

a) R & A Series Refrigerator & Freezer Vertical Controllers Page 11-14

b) Undercounter Refrigerator & Freezer Horizontal Controllers Page 15

c) G-Series Refrigerator & Freezer Vertical Controllers Page 16-17

d) R & A Series Heated Cabinet Vertical Controllers Page 18-20

V. Removal/Installation

a) All Vertical Controllers Pages 21-22

b) All Horizontal Controllers Page 23

VI. Problem Diagnosis

a) How To Use Troubleshooting Trees Page 24

b) Hi-Temp Alarm (all HT/RI & LT/IF models) Page 25

c) Lo-Temp Alarm (all HT/RI & LT/IF models) Page 26

d) Door Open Alarm (all HT/RI, LT/IF HF/IH models) Page 27

e) Power Loss Alarm (all HT/RI, LT/IF HF/IH models) Page 28

f) System Leak Alarm (all HT/RI & LT/IF models) Page 29

g) Condenserclean Alarm (all HT/RI & LT/IF models) Page 30

VII. Accessing The Engineering Level Page 31

VIII. Control Parameters

a) Parameter Descriptions Page 32-33

b) Parameter Access & Units Of Measurement Page 34

c) G-Series Parameter Settings Page 35

d) R-Series Parameter Settings - Refrigerator Models Page 36

e) R-Series Parameter Settings - Freezer Models Page 37

f) Undercounter Parameter Settings Page 38

-1-

Page 3

I. GENERAL INFORMATION

I. a - HOW TO USE THIS MANUAL:

Traulsen provides this manual as an aid to the service technician in installation,

operation, and maintenance of INTELA-TRAUL® Controllers. When used

properly, this service manual can help the service technician maintain,

troubleshoot and diagnose most of the problems and malfunctions that may occur

with the Controllers.

This manual covers the four different types of Controllers (Full Size Undercounter,

G-Series, R&A Series Refrigerator & Freezer, and R&A Series Hot Food). These

vary slightly from one another, all exceptions are noted, and where appropriate

separate sections are provided.

While we believe that most aspects of the controllers are covered in this manual,

should you encounter a condition not addressed, or require a wiring diagram please

contact:

4401 Blue Mound Road Fort Worth, TX 76106

Phone: (800) 825-8220 or (817) 625-9671

All service communication must include:

Model Number & Serial Number Of Unit

A detailed explanation of the problem

I. b - ABOUT INTELA-TRAUL:

The Traulsen INTELA-TRAUL and G-Series microprocessor controls are

microprocessor based systems which replace several electromechanical

components typically built into refrigeration products, such as: time clocks,

thermometers, defrost limit switches and temperature controls, all combined into

one solid state modular unit.

These microprocessor controls both monitor a cabinet air sensor and a coil

sensor. The INTELA-TRAUL on the R & A Series also includes a discharge line

sensor and a relative humidity sensor (H1 versions only). In conjuction with the

programmed parameters of the control, and the information received, it cycles the

refrigeration system ON and OFF at set temperatures, initiates and/or terminates

defrost cycles, and initiates one of several alarm features if a problem is sensed

(R & A Series only). R & A Series controls also allow the operator to cycle the door

perimeter heaters ON/OFF as needed.

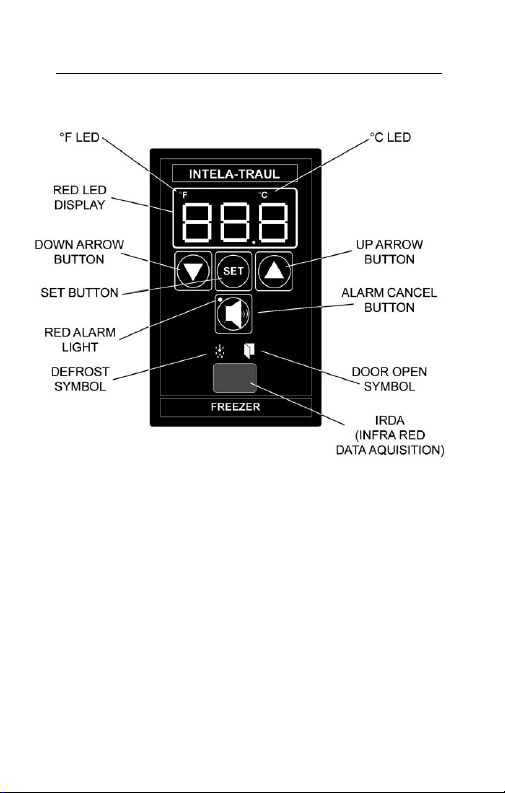

I. c - OPERATING THE CONTROLLER:

When operating the controller it is important to note that you only have

approximately 20-30 seconds between button pushes. If you take longer than 30

seconds, the controller will revert back to displaying the cabinet temperature.If you

enter the wrong security code, the controller will revert back to displaying the

cabinet temperature. You can exit the parameters at any time by waiting 20-30

seconds for the control to return to normal operation.

Traulsen

Attn: Service Department

Fax: (817) 740-6757

-2-

Page 4

II. BASIC SERVICE PROCEDURES

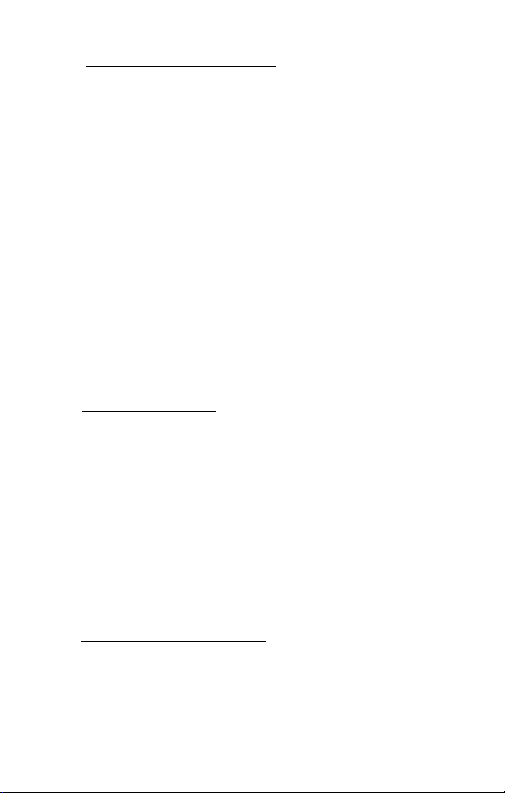

II. a - ADJUSTING THE TEMPERATURE:

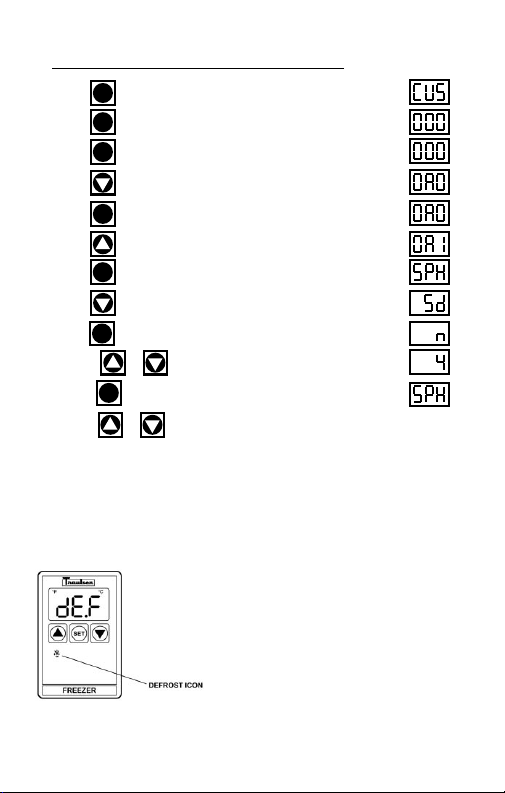

Step 1: Press . Display will read “CUS.”

Step 2: Press . Display will read “000” with the left digit flashing.

Step 3: Press . Display will read “000” with the center digit flashing.

SET

SET

SET

Step 4: Press until the center digit changes to an “A”.

Step 5: Press . Display will read “0A0” with the right digit flashing.

SET

Step 6: Press until the right digit changes to an “1”.

Step 7: Press . Display will read “SPH”.

Step 8: Press again.

SET

SET

Step 9: Press or to adjust temperature to desired setting.

(NOTE: SPH should be set at 38 to 40°F for refrigerators and 0°F for freezers)

Step 10: When display reads the desired temperature press .

SET

Step 11: Press until display reads “SPL”.

Step 12: Press .

SET

Step 13: Press or to adjust temperature to desired setting.

(NOTE: SPL should be set at 34°F for refrigerators and -4°F for freezers)

Step 14: Press .

SET

Step 15: Press to exit (R & A Series only). On G-Series models the

controller will automatically revert back to normal temperature display operation

after a delay of approximately 20-30 seconds.

The Display

Will Read

-3-

Page 5

II. BASIC SERVICE PROCEDURES

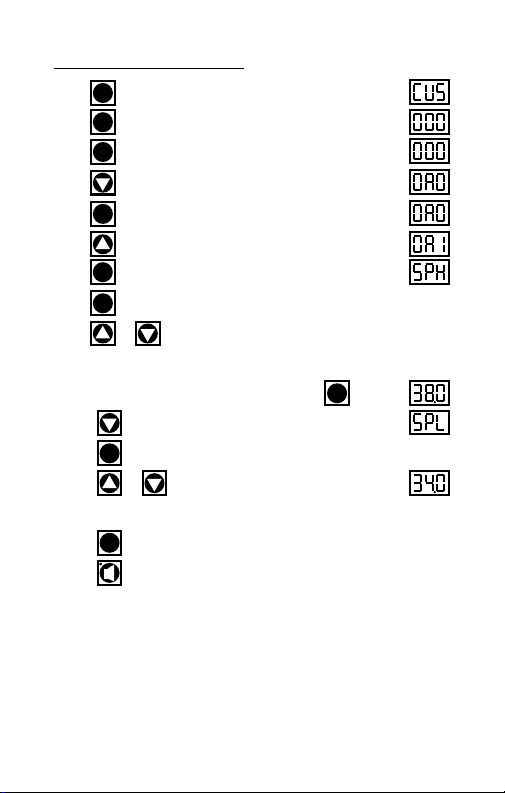

II. b - STARTING A MANUAL DEFROST CYCLE (R & A Series):

Step 1: Press . Display will read “CUS.”

Step 2: Press . Display will read “000” with the left digit flashing.

Step 3: Press . Display will read “000” with the center digit flashing.

SET

SET

SET

Step 4: Press until the center digit changes to an “A”.

Step 5: Press . Display will read “0A0” with the right digit flashing.

SET

Step 6: Press until the right digit changes to an “1”.

Step 7: Press . Display will read “SPH”.

SET

Step 8: Press until the control reads “Sd,” Start Manual Defrost.

Step 9: Press . Display will read “n” (NO).

SET

Step 10: Press or . Display will read “4” (YES).

Step 11: Press . Controller will display “SPH” for 30 seconds and

SET

then “DEF” will appear.

NOTE: The controller will automatically revert back to normal operation

after a delay of approximately 20-30 seconds.

NOTE:

Traulsen R & A Series refrigerator models also include an offcycle defrost feature, which occurs once an hour. This is

indicated by the control display, is time or temperature

terminated, and generally is of 3 - 10 minutes in duration.

The Display

Will Read

-4-

Page 6

II. BASIC SERVICE PROCEDURES

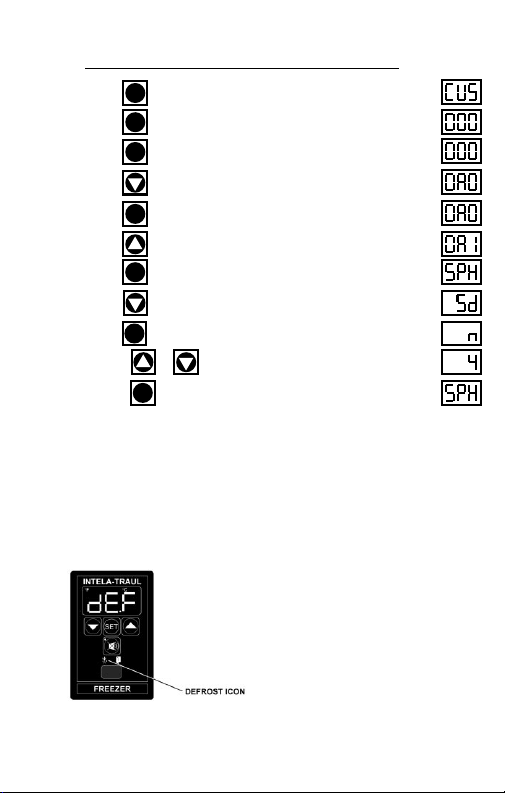

II. c - STARTING A MANUAL DEFROST CYCLE (G-Series):

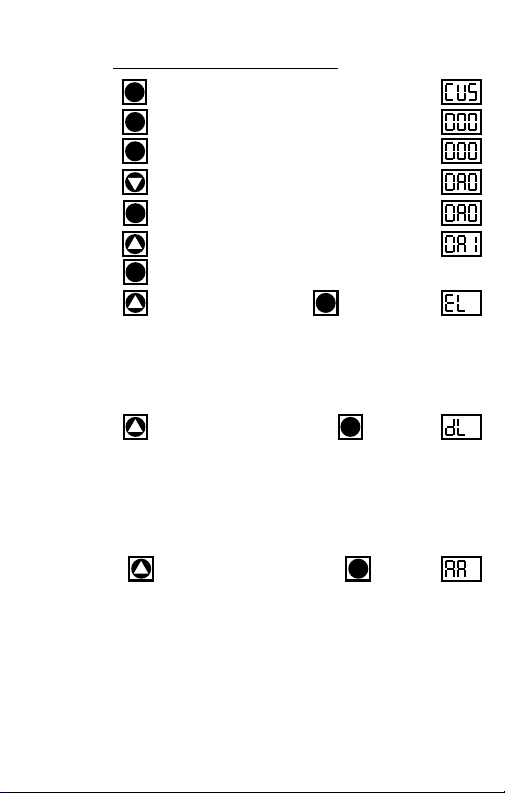

Step 1: Press . Display will read “CUS.”

Step 2: Press . Display will read “000” with the left digit flashing.

Step 3: Press . Display will read “000” with the center digit flashing.

SET

SET

SET

Step 4: Press until the center digit changes to an “A”.

Step 5: Press . Display will read “0A0” with the right digit flashing.

SET

Step 6: Press until the right digit changes to an “1”.

Step 7: Press . Display will read “SPH”.

SET

Step 8: Press until the control reads “Sd,” Start Manual Defrost.

Step 9: Press . Display will read “n” (NO).

SET

Step 10: Press or . Display will read “4” (YES).

Step 11: Press . Display will then read “SPH,” Start Manual Defrost.

SET

Step 14: Press or to scroll to the next parameter, otherwise the

controller will automatically revert back to normal operation after a delay of

approximately 20-30 seconds.

NOTE:

Traulsen G-Series refrigerator models also include an off-cycle

defrost feature, which occurs once an hour. This is

indicated by the control display, is time terminated, and is

generally of 3 - 10 minutes in duration.

The defrost cycle on Traulsen G-Series freezer models can

be either time or temperature terminated.

The Display

Will Read

-5-

Page 7

III. TROUBLESHOOTING

III. a - CHECKING FOR DEFECTIVE SENSORS:

Step 1: Press . Display will read “CUS.”

Step 2: Press . Display will read “000” with the left digit flashing.

Step 3: Press . Display will read “000” with the center digit flashing.

SET

SET

SET

Step 4: Press until the center digit changes to an “A”.

Step 5: Press . Display will read “0A0” with the right digit flashing.

SET

Step 6: Press until the right digit changes to an “1”.

Step 7: Press .

Step 8: Press until display reads “EL”. Press .

If the display now reads “-40,” check for loose connection on the EVAPORATOR

sensor. If the display has a very high reading such as “266,” replace the evaporator

sensor.

NOTE: Erroneous readings may be the result of a faulty sensing circuit (open or

Step 9: Press until the display reads “DL1”. Press .

In the event that the display now reads “-40,” check for a loose connection on the

DISCHARGE LINE sensor. If the display has a reading of “220” or higher, check for lack

of adequate air-flow through the condenser, a bad condenser motor, or any other

condition around the unit which could cause a high temperature, such as a steam

table or a crossdraft. Otherwise, proceed with replacing the DISCHARGE LINE sensor.

NOTE: Erroneous readings may be the result of a faulty sensing circuit (open or

Step 10: Press until the display reads “AA2”. Press .

Display should read the approximate ambient air temperature behind the louver panel.

If the display reads “111” check for a loose connection on the RH/AMBIENT AIR sensor.

If the display reads “32.0” check the sensor for a short circuit.

NOTE: If display reads -40 or 266 the cabinet sensor is defective and requires

SET

SET

shorted) in the Controller.

SET

shorted) in the Controller.

SET

replacement.

NOTE: Ambient Air Sensor not included on MIT version controllers.

NOTE: Erroneous readings may be the result of a faulty sensing circuit (open or

shorted) in the Controller (on H1 control version only).

1= DL is not included on G-Series controllers.

2= AA is not available with MIT version controllers.

-6-

The Display

Will Read

Page 8

III. TROUBLESHOOTING

III. b - CHECKING FOR FAILED RELAYS:

Checking For A Failed Internal Controller Relay:

1. Gain access to Controller compressor relay (see REMOVAL

INSTRUCTIONS within this service manual for the specific type of

controller your are servicing).

2. Locate the connector with the black/blue/purple wires and unplug it.

Refer to the schematic on the side of the controller, or refer to the

appropriate wiring diagram (to obtain this please contact the factory,

referencing the serial numberof the unit involved).

3. Using a volt/ohm meter (VOM) with the power OFF, check the resistance

across the black to blue wires of the Controller connector. If completed

circuit is indicated (with no power to the Controller), the contacts are

stuck closed and the Controller should be replaced (on MIT versions

either the relay box or one of the other relays within the unit need to be

replaced).

Checking For A Failed External “Slave” Relay or Solid State Relay (SSR),

p/n 337-60360-01 (MIT II Only):

1. Gain access to the controller compressor relay (see REMOVAL

INSTRUCTIONS within this service manual for the specific type of

controller your are servicing).

2. Locate the external “slave” relay and unplug the harness connectors.

3. Using a volt/ohm meter (VOM), check the resistance from the “COM”

terminal to the “NO” terminal. If a completed circuit is indicated, the

contacts are stuck closed and the slave relay should be replaced.

4. For the SSR, remove the black and blue wires from terminals 3 & 4. Using

a volt/ohm meter, and with the power OFF, measure the resistance across

the terminals. A completed circuit indicates that the circuit is closed and

that the relay should be replaced. A reading of 25 mΩ to 35 mΩ is

considered normal for an open circuit in the SSR.

Checking For A Failed Door/Light Relay (R & A Series models only):

1. Gain access to Controller door relay (see REMOVAL INSTRUCTIONS

within this service manual for the specific type of controller your are

servicing).

2. Remove the wire from the door relay coil.

3. Using a volt/ohm meter (VOM), check across the relay contacts. If an

open across the contacts is not indicated, replace the door relay.

NOTE: Equipment manufactured with the MIT II controller version do not

include a Door/Light relay).

4. Physically check the switch for evidence of water. If switch has water in

it, proceed with replacing the switch.

-7-

Page 9

III. TROUBLESHOOTING

III. c - CHECKING FOR OTHER FAILED COMPONENTS:

Checking For A Failed Door Switch:

1. Remove the door(s) from the unit involved.

2. Locate the door switch, which is located behind the top door hinge(s).

3. Remove the switch from the cabinet.

4. Using a volt/ohm meter (VOM), check across the switch contacts. “COM”

to “NO” should read open. If not, replace the switch.

5. Reinstall the switch and hinge onto the cabinet.

NOTE: If the unit has more than one door, check ALL door switches in the

same manner as described in steps 1 thru 5 above.

Checking For A Failed Controller Transformer

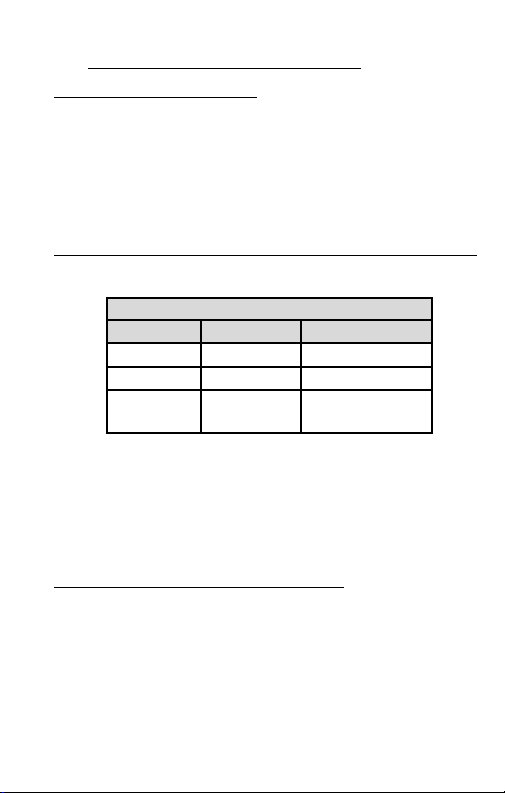

1. Check incoming voltage. Voltage at the unit must be within the ranges

shown in the table below.

VOLTAGE

MIN MAX STANDARD

104 VAC 126 VAC 115/60/1

187 VAC 253 VAC 208-230/60/1

10.2 Volts 13.8 Volts Transformer

(MIT 12.4) (MIT 14.7) Output Voltage

2. If the controller display does not come back on, use a volt/ohm meter

(VOM) and check the output voltage of the controller transformer.

3. If the output voltage from the transformer is not within the range

shown in the table above, replace the transformer. If the transformer

tests OK, replace the controller instead.

4. For equipment manufactured with the MIT II controller version the

transformer is mounted inside the relay module. Check between 17 and

8 on 18 pin connector on relay module for 12V DC.

Checking Cabinet, Coil or Discharge Line Sensors:

1. Gain access to CABINET, COIL or DISCHARGE LINE sensor and

disconnect it.

2. Place tip if sensor probe in a mixture of icewater for several minutes.

Allow enough time for sensor probe to aclimate to the icewater.

3. At 32°F, probe resistance shoud be 32.7K Ohms, +/- 10%. If resistance

is not within this range, repalce the sensor.

(H1 & MIT I control versions only)

:

-8-

Page 10

III. TROUBLESHOOTING

III. d - CHECKING FOR ICED EVAPORATOR COIL:

With

evaporator

clear of ice is

there proper

air-flow?

YES

Check DEF settings in

controller parameters.

Go to pages 33-36.

OK

Check coil sensors.

Go to pages 6, 7 & 8.

OK

Check evaporator

NO NOT OK

blower motor for

proper operation.

NOT OK

Reset

control

parameters

NOT OK

Remove restriction.

Replace

failed

sensor.

Replace

evaporator

blower motor.

Evap’r

or ducting

restriction.

Will unit

enter manual

defrost cycle?

Will control

cycle unit at set

temps?

YES

Problem

with ref’n

system.

YES

compressor

OK

Check defrost heater.

Check cabinet sensor.

Go to pages 6, 7 & 8.

cabinet sensor.

Does

shut-off in

defrost?

YES

NOT OK

Replace

failed

-9-

NO

OK

Replace

compressor

relay or module.

Replace

controller*

(see note below).

*NOTE: See the corresponding pages to

remove and replace the controller:

• R & A Series Refrigerator & Freezer

Pages 21 - 22.

• G-Series Refrigerator & Freezer

Pages 21 - 22.

• Undercounter Refrigerator & Freezer

Page 23.

• R & A Series Hot Food Cabinets

Pages 21 - 22.

Page 11

III. TROUBLESHOOTING

III. e - PROPER SENSOR PLACEMENT:

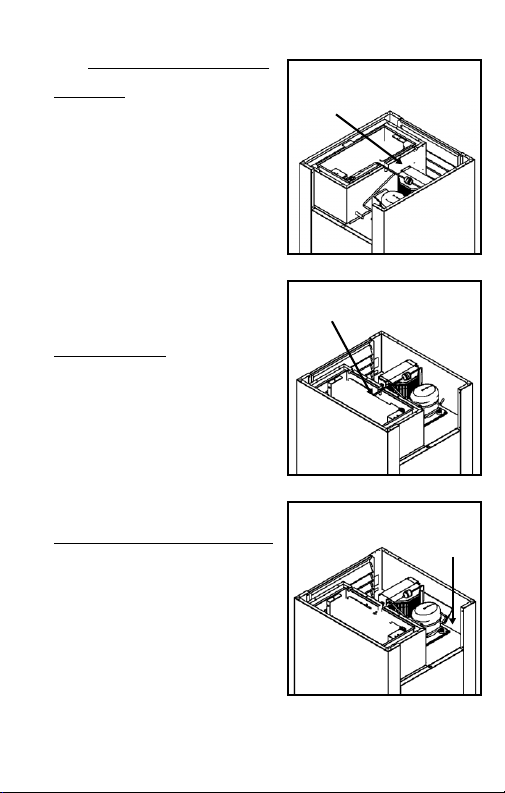

Coil Sensor:

The coil sensor should be inserted into

the return air side of the evaporator coil.

On freezer models only this sensor

should be centered approximately 2”

(two inches) from the top (horizontally

through coil - centered in coil).

On refrigerator models this sensor

should be mounted on top of the coil.

Cabinet Air Sensor:

The cabinet air sensor should be

mounted inside the evaporator housing

(hump) on the return air side of the

evaporator coil.

Correct

Sensor

Location

Correct

Sensor

Location

Discharge Sensor (R & A Series Only):

The discharge air sensor should be

mounted on the hot gas side of the

compressor. Placement should be as

close to the compressor as possible

and must be placed prior to the

beginning of the hot gas loop. Please

note that discharge sensors must be

insulated.

-10-

Correct

Sensor

Location

Page 12

IV. CONTROL ARCHITECTURE

IV. a -

R & A SERIES REFRIGERATOR & FREEZER VERTICAL CONTROLLER:

NOTES: IRDA not included on equipment

manufactured with the MIT II control

version.

See parts assembly on pages 12-13.

-11-

Page 13

IV. CONTROL ARCHITECTURE

DEFROST COMPRESSOR

RELAY POWER LINE IN 2

DOOR RELAY

EVAP BLOWER

RELAY

POWER LINE IN 1

TRANSFORMER/

RS485

DOOR

RELAY

1= Set of two (can be ordered separately).

2= Requires unit model number and serial

number to place order.

COIL SENSOR

P/N 337-60071-02

GREEN

SHRINK TUBE

CABINET

BLUE SHRINK TUBE

3

CABINET SENSOR

P/N 337-60069-02

RH/AMBIENT

AIR

DISCHARGE SENSOR

P/N 337-60072-00

3

(control versions H only)

H1 CONTROLLER

AIR

EVAP

COIL

RH SENSOR

P/N 337-60080-00

-12-

HOLDER CLIP

P/N 337-60038-00

2

HORN

DISCHARGE LINE

HOLDER CLIP

P/N 337-60038-00

YELLOW SHRINK TUBE

3

3

HORN

P/N 337-60070-00

3

3= Component can be ordered separately.

1

1

Page 14

IV. CONTROL ARCHITECTURE

IV. b -

R & A SERIES REFRIGERATOR & FREEZER VERTICAL CONTROLLER:

Parts assembly for H1 thru MIT control versions only

CABINET SENSOR - 337-60069-02

COIL SENSOR - 337-60071-02

DISCHARGE SENSOR - 337-60072-00

TO TRANSFORMER

HOLDER CLIP

337-60038-00

(set of two)

CONTROL HEAD

R/A 337-60318-00

G 337-60319-00

HF 337-60320-00

UC/UL 337-60321-00

HORN

337-60070-00

ADAPTER HARNESS

333-60249-00

TO DOOR RELAY

(door switch & line neutral)

TO DOOR HEATERS

(evap blower relay

power line in 1)

TO COMPRESSOR

& DEFROST RELAY

(power line in 2)

(not included for MIT II versions)

CONTROL CABLE

333-60250-00

337-60360-01 - see below

RELAY BOX

337-60162-02

TO SSR COIL

CIRCUIT (MIT II ONLY)

MIT CONTROL TROUBLE SHOOTING DIAGRAM

Remove the 4 screws (one

in each corner) & remove

the relay box cover to

expose pin connections &

transformer with voltage

setting jumper.

1 Defrost

DC 12-2001

2 12 VDC Coil

1 12 VDC Coil

*Voltage should

not be more than

5 DC when

measured to

ground (pin 8).

Part numbers may

vary according to

model type.

PIN connections may

not be available for

all model types.

337-60317-00

6 Door Switch

5 Line Neutral

4 Door Heater

3 Blower

2 Line Voltage

Date code will be listed

as the week-year (01-52)-

(2001-2100) when the

control is manufactured.

-13-

NOTE

All pins in this connection should

not read more than 20 VAC

Connector

Pin No. Color Signal

1Gray Blower*

2 Orange Door Heater*

3 Green Alarm From Controller

4

5

6 Brown

7White/Purple -RS485

8Black Ground

9Yellow/Red 12 VAC

10 Blue Compressor*

11 Purple Defrost*

12 Yellow Door Open Signal

13 Red Power to Horn

14 Orange

15 White

16 Pink +RS485

17 Red 12 VDC to Controller

18

Page 15

IV. CONTROL ARCHITECTURE

IV. c -

UC & UL (UNDERCOUNTER) HORIZONTAL CONTROLLER:

DEFROST COMPRESSOR

RELAY POWER LINE IN 2

DOOR HEATER EVAP

BLOWER RELAY

POWER LINE IN 1

TRANSFORMER/RS485

NOT

USED

CABINET

COIL SENSOR

P/N 337-60071-02

GREEN

SHRINK TUBE

AIR

NOT

USED

EVAP

COIL

BLUE SHRINK TUBE

3

CABINET SENSOR

P/N 337-60069-02

DISCHARGE

LINE

DISCHARGE SENSOR

P/N 337-60072-00

3

-14-

1= Set of two (can be ordered separately).

2= Requires unit model number and serial

number to place order.

HOLDER CLIP

P/N 337-60038-00

1

CONTROLLER

HORN

1

3

HOLDER CLIP

P/N 337-60038-00

HORN

YELLOW SHRINK TUBE

3

P/N 337-60070-00

3= Component can be ordered separately.

2

Page 16

IV. CONTROL ARCHITECTURE

IV. c -

UC & UL (UNDERCOUNTER) HORIZONTAL CONTROLLER:

Parts assembly for MIT control version only

CABINET SENSOR - 337-60069-02

COIL SENSOR - 337-60071-02

HOLDER CLIP

337-60038-00

(set of two)

HORN

337-60070-00

ADAPTER HARNESS

HT = 333-60240-00

LT = 333-60225-00

Part numbers may

vary according to

model type.

PIN connections may

not be available for

all model types.

CONTROL HEAD

UC/UL 337-60321-00

MIT CONTROL TROUBLE SHOOTING DIAGRAM

337-60172-02

6 Door Switch

5 Door Switch

Date code will be listed

as the week-year (01-52)-

(2001-2100) when the

control is manufactured.

EVAP BLOWER RELAY

Revision Level

4 Door Heater

3 Blower

2 Line Voltage

1 Defrost

UNUSED

(power line in 1)

TO COMPRESSOR

& DEFROST RELAY

(power line in 2)

Remove the 4 screws (one

in each corner) & remove

the relay box cover to

expose pin connections &

transformer with voltage

setting jumper.

DC 12-2001

2 Compressor

1 Line Voltage

-15-

Connector

Pin No. Color Signal

2 Orange Door Heater*

3 Green Alarm From Controller

5

6

*Voltage should not be more than 5 DC when

measured to ground (pin 8).

DISCHARGE SENSOR - 337-60072-00

TO TRANSFORMER

(not included for MIT II versions)

CONTROL CABLE

333-60228-00

RELAY BOX

337-60172-02

NOTE

All pins in this connection should

not read more than 20 VAC

1Gray Blower*

4Black Return From Horn

7White/Purple -RS485

8Black Ground

9White 12 VAC

10 Blue Compressor*

11 Purple Defrost*

12 Yellow Door Open Signal

13 Red Power to Horn

14

15

16 Pink +RS485

17 Red 12 VDC to Controller

18 Black 12 VAC

Page 17

IV. CONTROL ARCHITECTURE

IV. d -

G-SERIES REFRIGERATOR & FREEZER VERTICAL CONTROLLER:

-16-

Page 18

IV. CONTROL ARCHITECTURE

IV. d -

G-SERIES REFRIGERATOR & FREEZER VERTICAL CONTROLLER:

-17-

Page 19

IV. CONTROL ARCHITECTURE

IV. e -

R-SERIES HEATED CABINET VERTICAL CONTROLLER:

NOTES: IRDA not included on equipment

manufactured with MIT II control

version.

See parts assembly on pages 17-18.

HOT FOOD CABINET START-UP (pre-MIT version):

When power is first applied to the unit, you must set the temperature by pressing

the “SET” and “UP ARROW” buttons at the same time using equal pressure with

both thumbs, until the temperature appears on the display. Next, use the “UP”

button to reach the desired temperature (maximum 180°), then press and release

the “SET” button to lock it in.

After this is done you can turn the control ON and OFF by pressing and releasing

the “ALARM CANCEL” button.

Be aware to watch for the display constantly reading “OFF”. This is an indication of

a possible faulty cabinet sensor. To remedy, replace the sensor and reset the

operating temperature.

HOT FOOD CABINET START-UP (MIT version):

The MIT control offers an additional means of turning the cabinet heaters ON and

OFF. After the operating temperature has been set, the operator can continuously

turn the unit OFF and then back ON again to the same operating temperature by

pressing the “ON/OFF” button on the face of the control.

Please note that this feature will not function if the control is in an alarm state with

the alarm LED illuminated.

-18-

Page 20

IV. CONTROL ARCHITECTURE

IV. e -

R-SERIES HEATED CABINET VERTICAL CONTROLLER:

Parts assembly for H1 control versions only

1= Set of two (can be ordered separately).

2= Requires unit model number and serial

number to place order.

2

HORN

337-60070-00

1

-19-

Page 21

IV. CONTROL ARCHITECTURE

IV. e -

R-SERIES HEATED CABINET VERTICAL CONTROLLER:

Parts assembly for MIT control versions only

CABINET SENSOR - 337-60069-02

HOLDER CLIP

337-60038-00

(set of two)

HORN

337-60070-00

ADAPTER HARNESS

CONTROL HEAD

HF 337-60320-00

333-60225-00

TO DOOR RELAY

UNUSED

TO HEATERS

UNUSED

UNUSED

TO TRANSFORMER

(not included for MIT II versions)

CONTROL CABLE

333-60228-00

RELAY BOX

337-60171-02

MIT CONTROL TROUBLE SHOOTING DIAGRAM

Remove the 4 screws (one

in each corner) & remove

the relay box cover to

expose pin connections &

transformer with voltage

setting jumper (MIT II

version only).

Revision Level

1 Defrost

DC 12-2001

2 12 VDC Coil

1 12 VDC Coil

*Voltage should

not be more than

5 DC when

measured to

ground (pin 8).

Part numbers may

vary according to

model type.

PIN connections may

not be available for

all model types.

337-60371-00

6 Door Switch

5 Line Neutral

4 Door Heater

3 Blower

2 Line Voltage

Date code will be listed

as the week-year (01-52)-

(2001-2100) when the

control is manufactured.

-20-

NOTE

All pins in this connection should

not read more than 20 VAC

Connector

Pin No. Color Signal

1Gray Blower*

2 Orange Door Heater*

3 Green Alarm From Controller

4Black Return To Horn

5

6

7White/Purple -RS485

8Black Ground

9White 12 VAC

10 Blue Compressor*

11 Purple Defrost*

12 Yellow Door Open Signal

13 Red Power to Horn

14

15

16 Pink +RS485

17 Red 12 VDC to Controller

18 Black 12VAC

Page 22

V. REMOVAL/INSTALLATION

V. a -

ALL VERTICAL CONTROLLERS:

To remove INTELA-TRAUL® (p/n’s 337-60090-00, 337-60091-00 and

337-60092-00) and G-Series (p/n’s 337-60093-00, 337-60094-00 and

337-60095-00) Vertical Controller from the unit in which it is installed, proceed as

follows (If unable to access the unit from the rear perform steps 1 through 3,

otherwise, proceed to step 4):

1. At front of unit,

remove two (2)

slot head thumb

screws from

bottom corners of

louver

assembly. Set

thumbscrews

aside.

2. Swing louver

assembly up and

away from front of

unit until it stops.

3. Remove two (2)

Slot head thumbscrews from top of

louver assembly.

Set thumbscrews

and louver

assembly aside.

-21-

Page 23

V. REMOVAL/INSTALLATION

WARNING: DISCONNECT ALL POWER BEFORE PROCEEDING

4. At the top of the junction box,

remove three (3) Phillips head

screws. Set screws aside.

5. Locate one (1) Phillips head

screw at bottom of junction box,

and remove. Set screw aside.

6. Carefully slide junction box

away from front of unit until all

wiring and connections to the

controller are exposed.

7. Locate all nine (9) Controller

connections (five for G-Series),

then carefully disconnect each

one.

JUNCTION

BOX

REAR VIEW

OF UNIT

CONNECTIONS

CONTROLLER

(3) PHILLIPS

HEAD SCREWS

(1) PHILLIPS

HEAD SCREW

JUNCTION

BOX

(relay junction

box shown

turned 90

degrees)

8. Firmly grasp and compress the

rounded portion of the middle

prong on each holder clip.

Slowly slide each holder clip off

the controller. Set clips aside.

NOTE:

Be sure ALL components

have been disconnected

from the Controller before

performing the next step.

9. Slowly pull Controller through

mounting hole and set aside.

TO RE-INSTALL CONTROLLER,

REVERSE THE PRECEEDING

PROCEDURE.

-22-

HOLDER

CLIP

CONTROLLER

PULL CONTROLLER

IN THIS DIRECTION

MIDDLE

PRONG

HOLDER

CLIP

Page 24

V. REMOVAL/INSTALLATION

V. a -

ALL HORIZONTAL CONTROLLERS:

To remove INTELA-TRAUL® (p/n’s 337-60096-00 and 337-60097-00) Horizontal

Controller from the unit in which it is installed, proceed as follows:

WARNING: DISCONNECT ALL POWER BEFORE PROCEEDING

LOUVER ASSEMBLY

MIDDLE

PRONG OF

HOLDER CLIP

(one on each side

of the controller)

GUIDE SLOTS

(one on each side

of the controller)

MIDDLE

PRONG OF

HOLDER CLIP

(one on each side

of the controller)

(4) PHILLIPS

HEAD SCREWS

(4) BLACK PLASTIC

PLUGS

MOUNTING

BRACKET

(2) PHILLIPS

HEAD SCREWS

MOUNTING

BRACKET

(2) PHILLIPS

HEAD SCREWS

1. Check to make sure that the

power cable is disconnected

from the wall.

2. Remove the four (4) black

plugs that are located in each

corner of the power pack

louver assembly. Set plugs

aside.

3. Remove the four (4) Phillips

head screws holding the louver

assembly in place. Set screws

and louver assembly aside.

4. Remove the two (2) Phillips

head screws thathold the

Controller and the bracket

assembly to the condenser fan

assembly. Set screws aside.

5. Locate all nine (9) Controller

connections, then carefully

disconnect each one.

6. Firmly grasp and compress the

rounded portion of the middle

prong on each holder clip.

Slowly slide each holder clip off

the Controller. Set clips aside.

TO RE-INSTALL CONTROLLER,

REVERSE THE PRECEEDING

PROCEDURE.

-23-

Page 25

VI. PROBLEM DIAGNOSIS

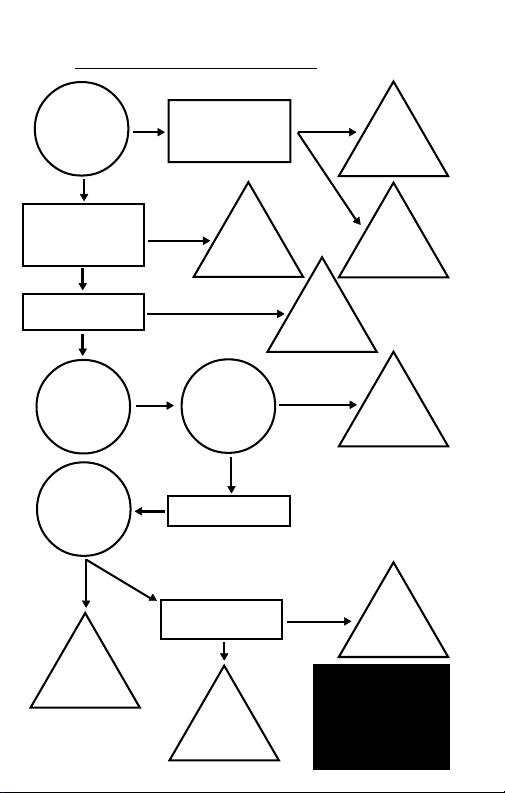

VI. a - HOW TO USE THE TROUBLESHOOTING TREES:

The troubleshooting trees on the following pages were developed as an aid to the

service technician in determining the exact solution to a certain problem or malfunction. When used as designed, the troubleshooting trees can lead you from a

general symptom to the most likely component to suspect as the cause of the

problem.

The trees are made up of three different types of boxes:

QUESTION CHECK SOLUTION

QUESTION

Boxes ask a yes/no question and the answer will lead to either another question

box, a check box, or a solution box.

CHECK

Boxes will suggest a point to check for proper operation, and will often refer you to

a page in either the SERVICE INFORMATION or the REMOVAL/INSTALLATION

sections of this manual. The result of the check may lead to another box, or a

solution box.

SOLUTION

Boxes suggest the most likely component to cause the malfunction described in

the heading of the tree. When reaching a solution box, do not immediately

assume the component is defective. The final step is to use the SERVICE

INFORMATION section of this manual to verify that the component is defective.

To use the troubleshooting trees, first find the page with the heading describing the

type of problem occurring. Begin at the top of the page and follow the tree,

step-by-step. When a check box is reached, refer to the suggested section to

make the check suggested. Once a solution box is reached, refer to the

suggested section to verify that the component in the solution box is indeed

defective, and repair or replace per the direction in that section.

-24-

Page 26

VI. b- HIGH TEMPERATURE ALARM

Door(s) open

longer than 5

minutes?

NO

Excessive

amount of hot

product placed

in unit?

NO

Is evaporator

coil frozen up?

Check compressor

for low refrigerant.

Check that sensor

probe(s) properly

NO

IS OK

connected.

Replace

failed

sensor.

1

YES

YES

YES

YES

Close

door(s).

Reduce

volume of

hot product.

Defrost

evaporator

coil.

IS NOT OK

IS NOT OK

Add

refrigerant.

Connect

probe(s).

1= See procedure on page 9.

-25-

Page 27

VI. c- LOW TEMPERATURE ALARM

Is temperature

setting for unit

too low?

Is there food

product in the

unit?

Check for failed

compressor relay.

Check that sensor

probe(s) properly

connected.

Replace

sensor.

NOTE ON HOT FOOD UNITS ONLY

Hot food units are designed to hold hot food at set temperature.

The cabinet is not designed to heat cold products.

failed

NO

NO

IS OK

YES

YES

YES

Increase

operating

temperature.

Add

product

to the unit.

IS NOT OK

IS NOT OK

Replace

failed

controller or

slave relay.

Connect

probe(s).

-26-

Page 28

VI. d- DOOR OPEN ALARM

Door(s) open

longer than 5

minutes?

YES

1

NO

Checkfor a failed door/

light relay.

2

IS OK

Is there water

in the door

switch?

YES

NO

Check for mis-wired

door switch.

Close

door(s).

IS NOT OK

Replace

door

switch.

IS NOT OK

Replace

failed

relay.

Replace

door

switch.

1= H1 and MIT 1 control versions only.

2= See procedure on page 7.

-27-

Page 29

VI. e- POWER LOSS ALARM

Is unit

plugged

in?

YES

Has unit

suffered a loss

of power due to

bad weather?

NO

Is unit

receiving low

voltage input?

NO

Check for failed

controller transformer.

NO

YES

YES

1

Plug

unit in.

Full

operation

will return

when service

is restored.

Contact

local utility

provider.

IS NOT OK

Replace

controller

transformer.

1= See procedure on page 8.

-28-

Page 30

Does

discharge temp

rise 45°F within

5 min. of a ref’n.

cycle start?

YES

VI. f- SYSTEM LEAK ALARM

N

O

Check compressor

for low refrigerant.

IS OK

Check discharge

line sensor.

IS NOT OK

IS NOT OK

1

Add

refrigerant.

Replace

failed

sensor.

Are sensor

probes properly

connected?

YES

Check for disolocated

sensor probe(s).

1= See procedure on page 8.

NO

YES

Connect

Probes.

Relocate

probe(s) to

proper position.

-29-

Page 31

VI. g - CONDENSERCLEAN ALARM

Is

condenser

coil dirty?

condenser fan

disconnected?

Check forfailed

condenser fan.

Are there

any obstructions

at top or rear

of unit?

YES

NO

Is

NO

OK

YES

NO

YES

Clean

condenser

coil.

Properly

conenct fan.

IS NOT OK

Remove

obstructions.

Replace

fan.

Is the room

temperature

too warm?

NO

Is air-flow

restricted by

any objects?

YES

YES

Lower

the room

temperature.

Move

unit or

objects for

better air-flow.

-30-

Page 32

VII. ACCESSING THE ENGINEERING LEVEL

VII. a - ACCESSING THE ENGINEERING LEVEL:

Not all control parameters can be adjusted at the customers level of access.

To adjust these other parameters it is first necessary to gain access to the

ENGINEERING LEVEL. Please follow the below procedure in order to enter

this level.

Step 1: Press . Display will read “CUS.”

SET

Step 2: Press until “EnG” is displayed.

Step 3: Press . Display will read “000” with the left digit flashing.

SET

Step 4: Press until the left digit changes to an “9”.

Step 5: Press . Display will read “900” with the center digit flashing.

SET

Step 6: Press until the center digit changes to an “9”.

Step 7: Press . Display will read “990” with the right digit flashing.

SET

Step 8: Press until the right digit changes to an “E”.

Step 9: The display will read (99E), press .

SET

Step 10: Press . The display will now read “FOC” - See Note.

The Display

Will Read

NOTE: R & A Series Only, for G-Series models press for the

control to display “FOC.”

-31-

Page 33

VIII. CONTROL PARAMETERS

VIII. a - PARAMETER DESCRIPTIONS:

FOC 3-digit code which identifies the .hex file loaded at the factory.

ADR Device address for NAFEM networks.

BAU Communications rate when connected into a NAFEM network.

NAF Allow the control to communicate with a NAFEM network.

SPH High value of desired cabinet temperature range.

SPL Low value of desired cabinet temperature range.

SHL Lowest temperature of allowed range for setting of SPH.

SHH Highest temperature of allowed range for setting of SPH.

SLL Lowest temperature of allowed range for setting of SPL.

SLH Highest temperature of allowed range for setting of SPL.

RO Difference, in degrees, between displayed & measured temperature.

HI The highest temperature the cabinet air temperature is allowed to reach before

triggering a High-Temp alarm.

LO The lowest temperature the cabinet air temperature is allowed to reach before

triggering a Low-Temp alarm.

SCL Sets the temperature display scale (fahrenheit or celsius).

HAD Time, in minutes, that the controller delays triggering the High-Temp alarm at any

start-up or at the end of a defrost cycle.

LAD Time, in minutes, that the controller delays triggering the Low-Temp alarm if

cabinet air temperature equal or below SPL setting.

AC The amount of time, in minutes, that the compressor must be off between cycles.

DEF Defines the type of heat used to defrost the coil: Electric, Hot Gas, None or

Off-Cycle.

IBD The amount of time, in hours, between the end of the drip time& start of the next

defrost cycle.

DDC The maximum amount of time, in minutes, that the heat will be on during a defrost

cycle.

CDE The temperature of the evaporator coil that indicates the end of a defrost heat

cycle.

DDE The amount of time, in minutes, between the defrost heat being turned off and the

compressor turning on.

BDD The delay time, in minutes, between the end of the drip time and and before the

evaporator blower turns on.

BSD The temperature of the evaporator coil that triggers the evaporator blower to turn

on after drip time ends.

ODD The maximum amount of time, in minutes, that the display will read the last

temperature recorded before entering the defrost cycle.

SD Allows a techinician to start or stop a defrost cycle.

CFA Alows the customer to turn the clogged filter alram ON/OFF ( R & A Series only).

CCR The minium amount of time, in minutes, that the compressor must be running

before generating a clogged filter alarm.

CDL The discharge line temperature that will trigger a clogged filter alarm.

DOA Allows the customer to turn the door open alarm ON/OFF in units equipped with

the appropriate hardware.

DAD The time, in minutes, that a door must be open before triggering a door open

alarm.

-32-

Page 34

VIII. CONTROL PARAMETERS

VIII. a - PARAMETER DESCRIPTIONS (continued):

APD The amount of time, in seconds, that a visual alarm text will be displayed.

ATD Alarm temperature delay.

AAS Allows the customer to set the type of audible alarm style, either Blast, OFF or

Continuous.

CL Allows the customer to set the time of day.

DAY Allows the customer to set the date.

DS Sets daylight savings time On or OFF.

DL1 Selects the time to start a defrost lockout.

DL2 Selects the time to start a defrost lockout.

DL3 Selects the time to start a defrost lockout.

DL4 Selects the time to start a defrost lockout.

DCF Allows the customer to set the percentage of time that the door perimeter heaters

will operate, to control surface condensation.

CON The amount of time the compressor will run in the event of a cabinet air sensor

failure.

COF The amount of time, in minutes, that the compressor will be OFF in the event of a

cabinet air sensor failure.

EL Displays the evaporator temperature at the time (press set or the up arrow button

to display this feature).

DL Displays the discharge line temperature at the time (press set or the up arrow

button to display this feature).

CB When activated (by pressing the set or up arrow buttons), will display the cabinet

air temperature at the time the button is pressed.

PLn When activated will display the approximate line voltage.

RCO Will energize the compressor relay for 10 seconds when activated.

RdF Will energize the heater relay for 10 seconds when activated.

RFA Will energize the blower relay for 10 seconds when activated.

RDH Will energize the door heater relay for 10 seconds when activated.

Pro Parameter used only when reflashing the program memory.

CEP When activated, will return all of the parameters to the initial factory settings.

REF Displays the revision level of the software loaded into memory.

-33-

Page 35

VIII. CONTROL PARAMETERS

VIII. b - PARAMETER ACCCESS & UNITS OF MEASUREMENT:

Control Unit of

Parameter Description Access Measure

ADR* Device Address ENG

BAU* Comm. Baud Rate in K ENG KBaud

NAF* NAFEM Communications Enable ENG On/Off

SPH Temperature Set-Point High CUS Degree

SPL Temperature Set-Point Low CUS Degree

SHL Set-Point High/Low ENG Degree

SHH Set-Point High/High ENG Degree

SLL Set-Point Low/Low ENG Degree

SLH Set-Point Low/High ENG Degree

RO Room Offset CUS Degree

HI Upper Temperature Limit ENG Degree

LO Lower Temperature Limit ENG Degree

SCL Temperature Scale CUS F or C

HAD High-Temperature Alarm Delay ENG Minute

LAD Low-Temperature Alarm Delay ENG Minute

AC Anticylcing ENG Minute

DEF Defrost Type ENG Electric/Gas/Off

IBD Intervals Between Defrosts ENG Hours

DDC Maximum Defrost Duration ENG Minute

CDE Coil Temperature At End of Defrost Cycle ENG Degree

DDE Drip Time At End of Defrost Cycle ENG Minute

BDD Blower Delay At Drip Time ENG Minute

BSD BSD After Defrost End ENG Degree

ODD Display Hold After Defrost ENG Minute

SD Start/Stop Defrost CUS Start/Stop

CFA Clogged Filter Alarm n/a On/Off

CCR Clogged Filter Compressor Run Time n/a Minute

CDL Clogged Filter Alarm Temperature n/a Degree

DOA Door Open Alarm ENG On/Off

DAD Door Display Alarm Delay ENG Minute

APD Alarm Pause Delay ENG Second

ATD Alarm Temperature Delay ENG Second

AAS Audible Alarm Style CUS On/Off

CL Set The Clock Time CUS H/N/S

DAY Set The Clock Date CUS Y/N/D

DS Daylight Savings CUS On/Off

DL1 Defrost Lockout 1 CUS Time/Off

DL2 Defrost Lockout 2 CUS Time/Off

DL3 Defrost Lockout 3 CUS Time/Off

DL4 Defrost Lockout 4 CUS Time/Off

DCF Dewpoint Correction Factor CUS %

CON Compressor Default On Time ENG Minute

COF Compressor Off Time ENG Minute

EL Evaporator Coil Temperature CUS Degree

DL Discharge Line Temperature CUS Degree

CB Cabinet Air Temperature CUS Degree

PLn* Display Line Voltage ENG Volts

RCO* Cycle Compressor Relay ENG On/Off

RdF* Cycle Defrost Relay ENG On/Off

RFA* Cycle Blower/Fan Relay ENG On/Off

RDH* Cycle Door Heater Relay ENG On/Off

PRO* Go To Bootloader For Programming ENG

CEP* Clear EEPROM & Load Defaults ENG

REF* Software Version/Revision/Step n/a

*MIT II control version only.

H1, MIT I & MIT II CONTROL VERSIONS ONLY

-34-

Page 36

VIII. CONTROL PARAMETERS

VIII. c - G-SERIES PARAMETER SETTINGS (MIT II Control Version):

Control Freezer Models Refrigerator Models

Parameter GF1 GF2 GF3 GF4 GR1 GR2 GR3

ADR* 2 2 2 2 2 2 2

BAU* 9.6 9.6 9.6 9.6 9.6 9.6 9.6

NAF* ON ON ON ON ON ON ON

SPH -5.2 0.1 0.1 32 38.1 39.2 39.2

SPL -10 -4 -4 26.1 34 37 37

SHL -8 -3.1 -3.1 30.2 36 39.2 39.2

SHH -5.2 0.1 0.1 34 40 40 40

SLL -13 -6.2 -6.2 26.1 32 34 34

SLH -10 -4 -4 28 34 37 37

RO 0 000 000

HI 0.1 5 5 35.2 41 41 41

LO -18.4 -10 -10 20 30.2 30.2 30.2

SCL F FFF FFF

HAD n/a n/a n/a n/a n/a n/a n/a

LAD n/a n/a n/a n/a n/a n/a n/a

AC 3 333 333

DEF ELE ELE ELE ELE OFF ELE OFF

IBD 4.0 4.0 4.0 4.0 1.0 2.0 1.0

DDC 20 20 20 20 10 20 10

CDE 75 75 75 75 45.1 70 45.1

DDE 2 222 222

BDD 1 111 000

BSD 32 32 32 32 32 32 32

ODD 10 10 10 10 10 10 10

SD

Starts a new defrost cycle at any time or stops a current defrost cycle.

CFA n/a n/a n/a n/a n/a n/a n/a

CCR n/a n/a n/a n/a n/a n/a n/a

CDL n/a n/a n/a n/a n/a n/a n/a

DOA n/a n/a n/a n/a n/a n/a n/a

DAD n/a n/a n/a n/a n/a n/a n/a

APD n/a n/a n/a n/a n/a n/a n/a

ATD n/a n/a n/a n/a n/a n/a n/a

AAS n/a n/a n/a n/a n/a n/a n/a

CL Set the hours and minutes in military time.

DAY Set the year, month, day of the month and day of the week.

DS ON ON ON ON ON ON ON

DL1 OFF OFF OFF OFF OFF OFF OFF

DL2 OFF

DL3 OFF

DL4 OFF OFF OFF OFF OFF OFF OFF

DCF n/a n/a n/a n/a n/a n/a n/a

CON 19 19 19 19 11 11 11

COF 7 7 7 7 10 10 10

EL

DL

CB

PLn*

RCO*

RdF*

RFA*

RDH*

PRO* Set the controller in receiving mode for programming.

CEP* Clear all controller memories and reloads the factory default parameters.

REF*

*MIT II control version only.

11:30am

OFF OFF OFF OFF OFF

5:30pm

OFF OFF OFF OFF OFF

Will display evaporator coil temp in real time every time an arrow is pressed.

Will display discharge line temp in real time every time an arrow is pressed.

Will display cabinet air temp in real time every time an arrow is pressed.

Will display power line voltage in real time every time an arrow is pressed.

Turns ON/OFF the compressor relay for 10-seconds or until an arrow is pressed.

Turns ON/OFF the defrost relay for 10-seconds or until an arrow is pressed.

Turns ON/OFF the blower relay for 10-seconds or until an arrow is pressed.

Turns ON/OFF the door heater triac for 10-seconds or until an arrow is pressed.

Firmware revision in the format X9.9 (X=version, 9=major revision, 9=minor revision).

-35-

Page 37

VIII. CONTROL PARAMETERS

VIII. d - R-SERIES PARAMETER SETTINGS (MIT II Control Version):

Control Refrigerator Models

Parameter RA1 RA2 RA3 RA4 RA5 RA6 RA7 RA8

ADR 2 2222222

BAU 9.6 9.6 9.6 9.6 9.6 9.6 9.6 9.6

NAF ON ON ON ON ON ON ON ON

SPH 39.2 39.2 39.2 39.2 38.1 38.1 39.2 39.2

SPL 37 37 37 37 34 34 37 37

SHL 39.2 39.2 39.2 39.2 36 36 39.2 39.2

SHH 40 40 40 40 40 40 40 40

SLL 34 34 34 34 32 32 34 34

SLH 37 37 37 37 34 34 37 37

RO 0 0000000

HI 41 41 41 41 41 41 41 41

LO 30.2 30.2 30.2 30.2 30.2 30.2 30.2 30.2

SCL F FFFFFFF

HAD 15 15 15 15 15 15 15 15

LAD 2 2222222

AC 3 3333333

DEF OFF OFF OFF OFF OFF OFF ELE ELE

IBD 1.0 1.0 1.0 1.0 1.0 1.0 2.0 2.0

DDC 10 10 10 10 10 10 20 20

CDE 45.1 45.1 45.1 45.1 45.1 45.1 70 70

DDE 2 2222222

BDD 0 0000000

BSD 32 32 32 32 32 32 32 32

ODD 10 10 10 10 10 10 10 10

SD

Starts a new defrost cycle at any time or stops a current defrost cycle.

CFA OFF ON OFF ON ON ON OFF ON

CCR 20 20 20 20 20 20 20 20

CDL 220.1 220.1 220.1 220.1 220.1 220.1 220.1 220.1

DOA ON ON ON ON ON ON ON ON

DAD 15 15 15 15 15 15 15 15

APD 2 2222222

ATD 10 10 1 01010101010

AAS OFF OFF OFF OFF OFF OFF OFF OFF

CL Set the hours and minutes in military time.

DAY Set the year, month, day of the month and day of the week.

DS ON ON ON ON ON ON ON ON

DL1 OFF OFF OFF OFF OFF OFF OFF OFF

DL2 OFF OFF OFF OFF OFF OFF OFF OFF

DL3 OFF OFF OFF OFF OFF OFF OFF OFF

DL4 OFF OFF OFF OFF OFF OFF OFF OFF

DCF 100 100 100 100 100 100 100 100

CON 11 11 11 11 11 11 11 11

COF 10 10 10 10 10 10 10 10

EL

Will display evaporator coil temp in real time every time an arrow is pressed.

DL

Will display discharge line temp in real time every time an arrow is pressed.

CB

Will display cabinet air temp in real time every time an arrow is pressed.

PLn*

Will display power line voltage in real time every time an arrow is pressed.

RCO*

Turns ON/OFF the compressor relay for 10-seconds or until an arrow is pressed.

RdF*

Turns ON/OFF the defrost relay for 10-seconds or until an arrow is pressed.

RFA*

Turns ON/OFF the blower relay for 10-seconds or until an arrow is pressed.

RDH*

Turns ON/OFF the door heater triac for 10-seconds or until an arrow is pressed.

PRO* Set the controller in receiving mode for programming.

CEP* Clear all controller memories and reloads the factory default parameters.

REF*

*MIT II control version only.

Firmware revision in the format X9.9 (X=version, 9=major revision, 9=minor revision).

-36-

Page 38

VIII. CONTROL PARAMETERS

VIII. e - R-SERIES PARAMETER SETTINGS (MIT II Control Version):

Control Freezer Models

Parameter RF1 RF2 RF3 RF4 RF5

ADR 2 2222

BAU 9.6 9.6 9.6 9.6 9.6

NAF ON ON ON ON ON

SPH -15.4 -10 0.1 0.1 -5.2

SPL -20.2 -15.4 -4 -4 -10

SHL -15.4 -13.6 -2.2 -2.2 -8

SHH -10 -10 0.1 0.1 -5.2

SLL -20.2 -20.2 -6.2 -6.2 -13

SLH -17 -15.4 -4 -4 -10

RO 0 0000

HI 5.2 5.2 5 5 0.1

LO -25.6 -25.6 -10 -10 -17.8

SCL F FFFF

HAD 15 15 15 15 15

LAD 2 2222

AC 3 3333

DEF ELE ELE ELE ELE ELE

IBD 4.0 4.0 4.0 4.0 4.0

DDC 30 20 20 20 20

CDE 55 75 75 70 70

DDE 5 2222

BDD 1 1111

BSD -10 32 32 32 32

ODD 10 10 10 10 10

SD

Starts a new defrost cycle at any time or stops a current defrost cycle.

CFA ON OFF OFF ON ON

CCR 20 20 20 20 20

CDL 220.1 220.1 220.1 220.1 220.1

DOA ON ON ON ON ON

DAD 15 15 15 15 15

APD 2 2222

ATD 10 10 1 01010

AAS OFF OFF OFF OFF OFF

CL Set the hours and minutes in military time.

DAY Set the year, month, day of the month and day of the week.

DS ON ON ON ON ON

DL1 OFF OFF OFF OFF OFF

DL2 OFF OFF OFF OFF OFF

DL3 OFF OFF OFF OFF OFF

DL4 OFF OFF OFF OFF OFF

DCF 100 100 100 100 100

CON 19 19 19 19 19

COF 7 7777

EL

Will display evaporator coil temp in real time every time an arrow is pressed.

DL

Will display discharge line temp in real time every time an arrow is pressed.

CB

Will display cabinet air temp in real time every time an arrow is pressed.

PLn

Will display power line voltage in real time every time an arrow is pressed.

RCO

Turns ON/OFF the compressor relay for 10-seconds or until an arrow is pressed.

RdF

Turns ON/OFF the defrost relay for 10-seconds or until an arrow is pressed.

RFA

Turns ON/OFF the blower relay for 10-seconds or until an arrow is pressed.

RDH

Turns ON/OFF the door heater triac for 10-seconds or until an arrow is pressed.

PRO Set the controller in receiving mode for programming.

CEP Clear all controller memories and reloads the factory default parameters.

REF

Firmware revision in the format X9.9 (X=version, 9=major revision, 9=minor revision).

-37-

Page 39

VIII. CONTROL PARAMETERS

VIII. f - UNDERCOUNTER PARAMETER SETTINGS (MIT II Control Version):

Control

Parameter UF1 UF2 UP1 UP2

ADR 2 2 2 2

BAU 9.6 9.6 9.6 9.6

NAF ON ON ON ON

SPH 0.1 38.1 38.1 38.1

SPL -4 33.8 33.8 33.8

SHL -0.31 36 36 36

SHH 0.1 40 40 40

SLL -6.2 32 32 32

SLH -4 34 34 34

RO 0 0 0 0

HI 5 41 41 41

LO -10 30.2 30.2 30.2

SCL F F F F

HAD 15 15 15 15

LAD 2 2 2 2

AC 3 3 3 3

DEF GAS GAS OFF OFF

IBD 4.0 4.0 1.0 1.0

DDC 20 20 10 10

CDE 75 75 45.1 45.1

DDE 5 2 2 2

BDD 1 1 0 0

BSD -10 32 32 32

ODD 10 10 10 10

SD

Starts a new defrost cycle at any time or stops a current defrost cycle.

CFA OFF OFF N/A OFF

CCR 20 20 N/A 20

CDL 220.1 220.1 N/A 220.1

DOA OFF OFF N/A OFF

DAD 15 15 N/A 15

APD 2 2 2 2

ATD 10 10 N/A 10

AAS OFF OFF N/A OFF

CL Set the hours and minutes in military time.

DAY Set the year, month, day of the month and day of the week.

DS ON ON ON ON

DL1 OFF OFF OFF OFF

DL2 OFF OFF OFF OFF

DL3 OFF OFF OFF OFF

DL4 OFF OFF OFF OFF

DCF 100 100 100 100

CON 19 19 11 11

COF 7 7 10 10

EL

Will display evaporator coil temp in real time every time an arrow is pressed.

DL

Will display discharge line temp in real time every time an arrow is pressed.

CB

Will display cabinet air temp in real time every time an arrow is pressed.

PLn

Will display power line voltage in real time every time an arrow is pressed.

RCO

Turns ON/OFF the compressor relay for 10-seconds or until an arrow is pressed.

RdF

Turns ON/OFF the defrost relay for 10-seconds or until an arrow is pressed.

RFA

Turns ON/OFF the blower relay for 10-seconds or until an arrow is pressed.

RDH

Turns ON/OFF the door heater triac for 10-seconds or until an arrow is pressed.

PRO Set the controller in receiving mode for programming.

CEP Clear all controller memories and reloads the factory default parameters.

REF

Firmware revision in the format X9.9 (X=version, 9=major revision, 9=minor revision).

-38-

Page 40

HOURS OF OPERATION:

Monday thru Friday 7:30 am - 4:30 pm CST

Traulsen

4401 Blue Mound Road Fort Worth, TX 76106

Phone: (800) 825-8220 Fax-Svce: (817) 740-6757

Quality Refrigeration

Website: www.traulsen.com

Loading...

Loading...