traub TNX65 Technical Data

CNC-

Turn-mill center

TNX65/42

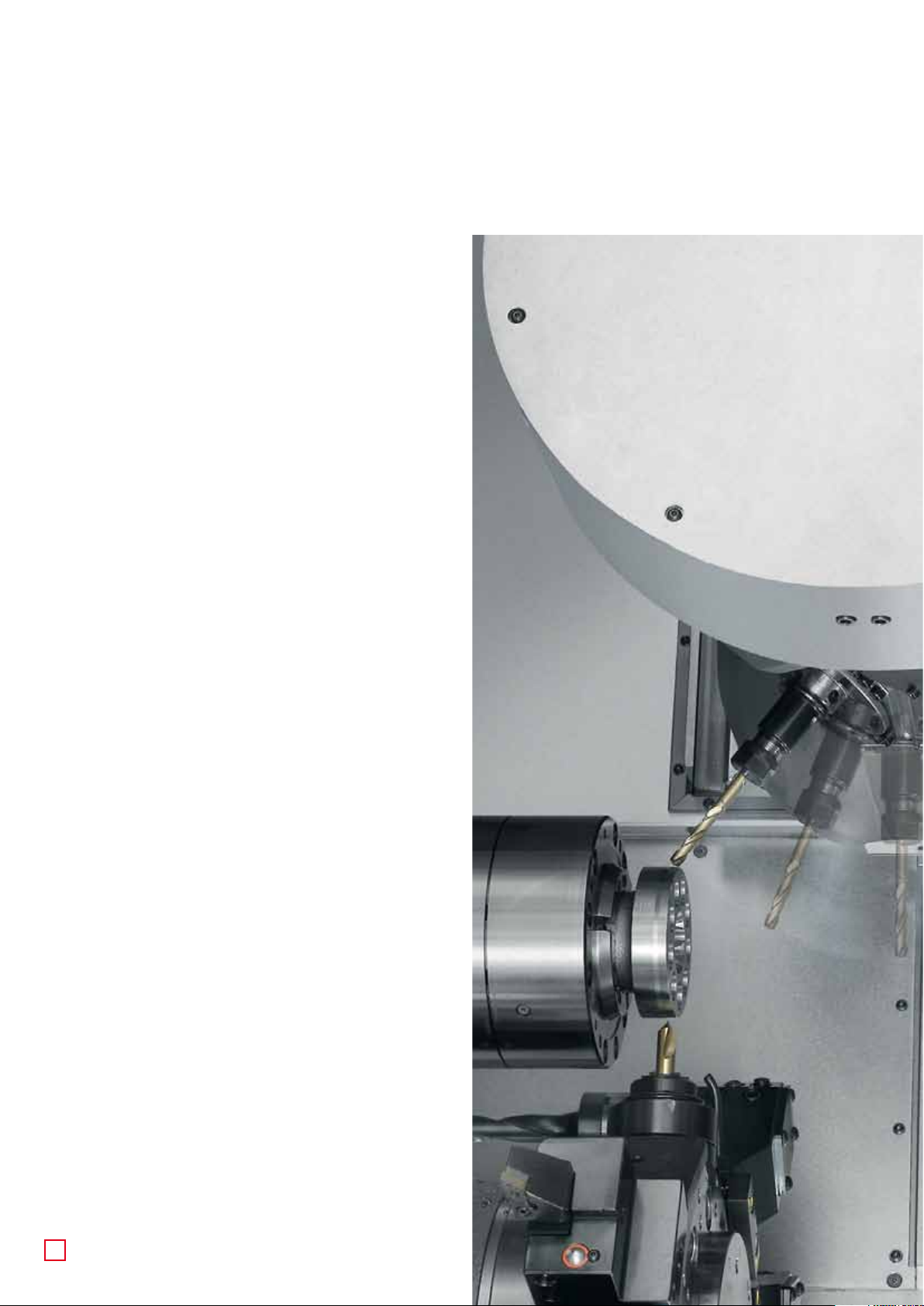

TRAUB'S TNX65/42 sets new

standards in high-performance

machining.

Its future-oriented machine

concept comprising a new,

unique milling unit offers

previously unexpected oppor-

tunities of integrating machi-

ning processes. This concept

stands for previously unknown

flexibility and productivity.

The new milling unit impres-

ses by its chip-to-chip times,

such as previously only known

of tool turrets.

2

TNX65/42

A passion for

high performance

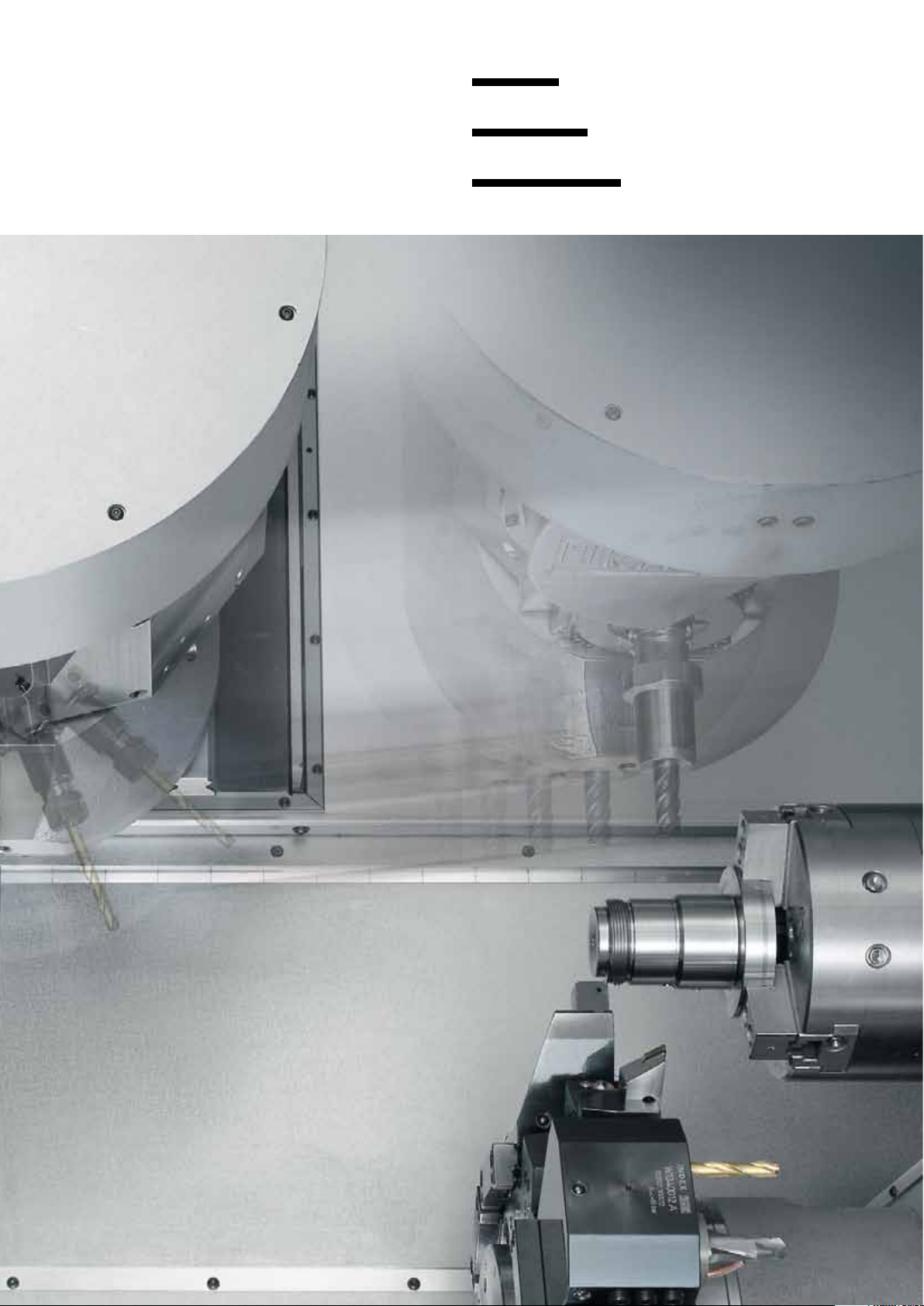

The TNX65/42

economical with

2, 3 or 4 turrets

The machine concept of

the TNX65/42 has been

tailored to the wide range

of requirements needed by

users. The result offers many

advantages:

quadruple functional symmetry,

i. e. 4 identical turrets with

independent Y axis, with identical

tool change areas and identical

number of tool stations

free allocation of the tool

carriers to the two spindles

high-powered drives on main and

counter spindles provide optimum

metal-cutting performance

powerful tool drives on all

turrets for perfect complete

machining

Wide application spectrum

for high utilization of the

machine

suitable for all different

workpieces and lot sizes

highly productive due to the

simultaneous use of up to 4 tool

carriers

high integrability for different

machining methods

bar, chuck or shaft machining

Less setup efforts

precise tool change repetitive

accuracy of the tool holders

(TRAUB patent)

large tool stock with up to

80 tools in 4 turrets

4

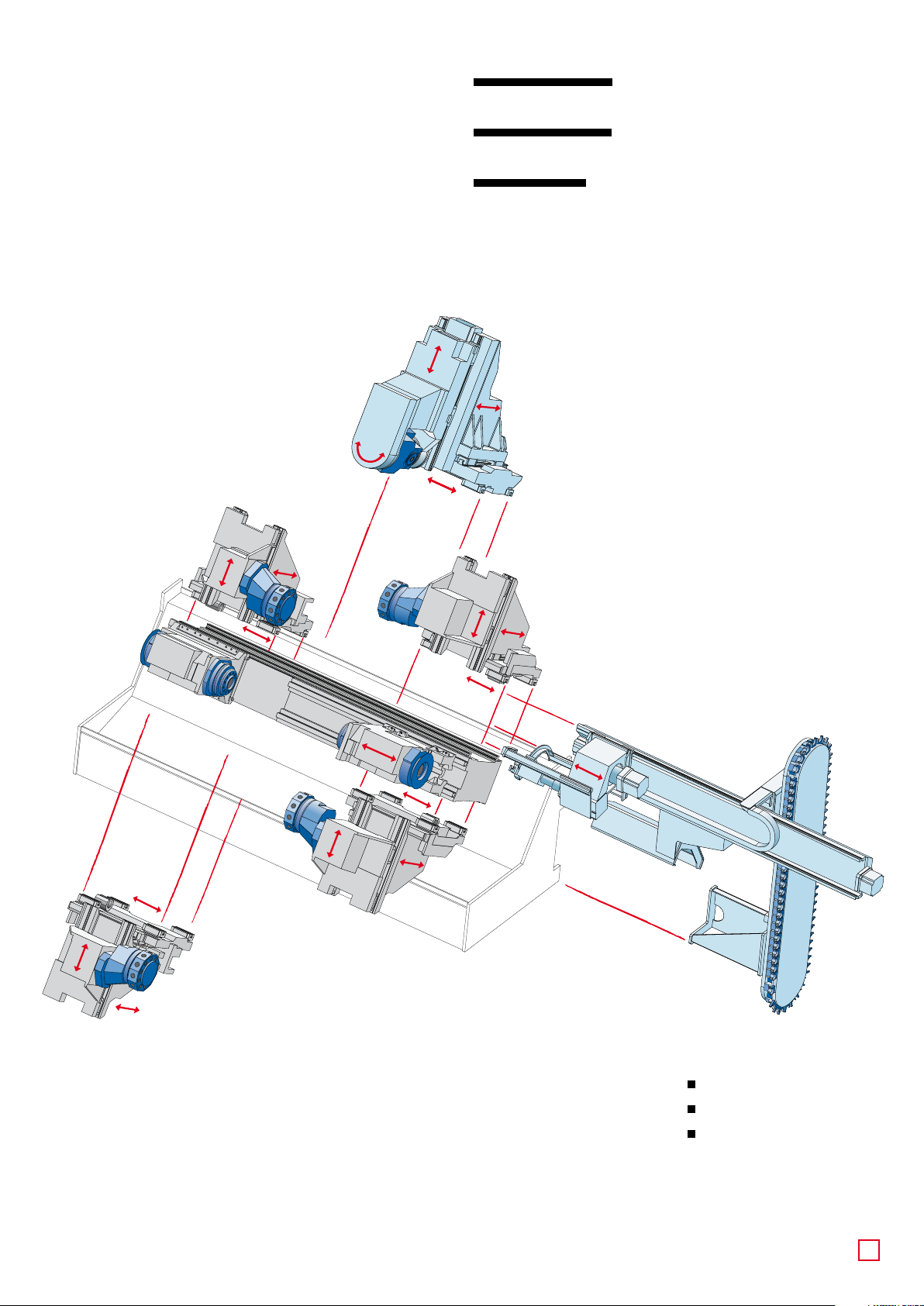

Modular system

for your specific

requirements

New: The milling unit

Features chip-to-chip times that

are as quick as with a turret.

Up to 80/120 tools in the

magazine are available for almost

limitless machining tasks.

The modular system

For optimal adaptation of the

machine equipment to your

specific needs.

The basic structure

The compact machine bed made

of heavily ribbed cast iron has high

torsional and bending stiffness.

It carries the thermo-symmetric

headstock and the linear guideways

for bed slides and counter spindle

slides. It offers excellent vibration

dampening, outstanding dynamic

stiffness and high thermal stability.

A bed inclination of 60° ensures

unhindered chip fall.

Machine dimensions

bar diameter up to 65 mm

chuck sizes up to 175 mm

turning lengths up to 650 mm

5

Loading...

Loading...