Page 1

Hardware Installation Guide

Ranger 7-RNGR-04X

Ver 5.4

Copyright © 2008 Mentor Engineering Inc. All rights reserved.

Page 2

Table of ConTenTs

Safety & After-Market Equipment ........................................4

Qualified Installer ...............................................................5

Introduction .......................................................................7

Cautions .......................................................................8

Before You Begin ................................................................8

Parts List ...........................................................................9

Supplied .......................................................................10

Supplied (Optional) ........................................................11

Not Supplied .................................................................11

Mounting Locations ............................................................12

Placement .....................................................................12

Ranger Mounting Examples .................................................13

Examples of Suitable Mounting Locations .........................13

Installing The Ranger Cover Plate ........................................14

Wiring - Ranger Back View .................................................17

Connection Points ..............................................................19

1) Splicing ...................................................................19

2) Power ......................................................................19

3) Ground ....................................................................19

4) Switched Ignition Power ............................................19

5) VSS (Vehicle Speed Sensor for Odometer Pulses) .........21

6) Emergency Switch (optional) ......................................22

Cabling ..............................................................................23

1) Routing....................................................................23

2) Strain Relief .............................................................23

3) Labeling ..................................................................24

4) Connection Types ......................................................24

5) Wire Types ...............................................................25

6) Electrical Measurements ............................................25

Antennas ...........................................................................26

2

Page 3

Table of ConTenTs

1) Internal Antennas .....................................................26

2) External Antennas .....................................................26

3) Cable Routing...........................................................27

4) Connectors ...............................................................28

Ranger Specs 7-RNGR-04X...............................................29

General Description ........................................................29

Standard Features ..........................................................29

Compliance and Testing ..................................................30

Optional Features ...........................................................30

Key Specifications ..........................................................30

Appendix A - Conformity .....................................................33

1) FCC Class B Part 15 .................................................33

2) IEC 60950 3rd Edition (2000) Safety of Information Tech-

nology Equipment .....................................................35

3) ISO 7637-1 Load Dump Transient ..............................35

4) MIL STD 810F: General Vibration ...............................35

5) MIL STD 810F: Shock Test ........................................35

6) IEC 60529 - IP54 ....................................................35

Appendix B - RF Radiation Specs ........................................36

RF Exposure ..................................................................36

Appendix C - Approvals .......................................................37

1) CDMA/EVDO ............................................................37

2) GSM/HSDPA ............................................................37

3) WIFI/Bluetooth Only ..................................................37

3

Page 4

WARNING

FAILURE TO INSTALL THE EQUIPMENT

AS RECOMMENDED COULD CAUSE OR

CONTRIBUTE TO AN ACCIDENT AND RESULT

IN DAMAGE TO PROPERTY OR PERSONS.

safeTy & afTer-MarkeT equipMenT

The use of after-market equipment in motor vehicles can

compromise a vehicle’s safety-related design characteristics,

including but not limited to:

• Airbags, including but not limited to potential obstruction of air-

bag deployment;

• Passenger compartment, including but not limited to potential for

ergonomic problems, physical obstacles, etc.; and

• Trunk/gas tank protection, including but not limited to the poten-

tial for trunk-mounted equipment to exacerbate tank vulnerability

in a rear collision.

4

Page 5

WARNING

This product is to be installed by

qualified installation personnel only.

Incorrect installation may result in FIRE

or contribute to an ACCIDENT

qualified insTaller

This product is to be installed by qualified installation personnel only.

The installer must be trained in industry best practices for this type of

installation. The training would include but not be limited to:

1. The appropriate methods for installing cables such that:

• The operation of the vehicle is not interfered with.

• The installation process does not damage or interfere with other

vehicle components and/or systems.

• Wiring is kept clear of sharp objects, sources of heat and any

other hazard that could damage the cable or wire.

• Wiring is secured such that it does not cause damage to other equip-

ment, itself, or interfere with the operation of other systems and

devices.

• Wiring through bulkheads is performed such that wiring does not

chafe, and a seal is maintained between compartments.

• Appropriate and industry standard fasteners, splices, connectors

and ties are used for the vehicle environment.

• Appropriate slack is in place to prevent straining of the wire, cable

or connectors.

• Any other issue that could affect the integrity of the wiring or the

safe operation of the vehicle is addressed appropriately.

5

Page 6

qualified insTaller

2. The appropriate methods for mounting equipment in vehicles such

that:

• The safe operation of the vehicle is not interfered with.

• The equipment is attached to the vehicle as securely as possible to

minimize the risk of the equipment breaking free in an accident situation.

• The installed device does not interfere with the deployment of air

bags.

• The installed device does not obscure displays or interfere with the

ability of the driver to operate other vehicle systems and components.

• The installation process does not damage other vehicle systems or

components.

• Compartments remain sealed against the elements.

3. The correct use and operation of the required tools.

Further:

• The installer must have the ability to read, understand and follow

the instructions in the installation manual.

• The installer must be equipped with the correct tools for perform-

ing each installation operation.

The Customer must ensure that the installation of all equipment provided for this project is safe, used for its intended purpose, and is in

continual accordance with all applicable codes, rules, regulations and

guidelines provided by motor vehicle and equipment manufacturers, as

well as any state, local or jurisdictional bodies.

6

Page 7

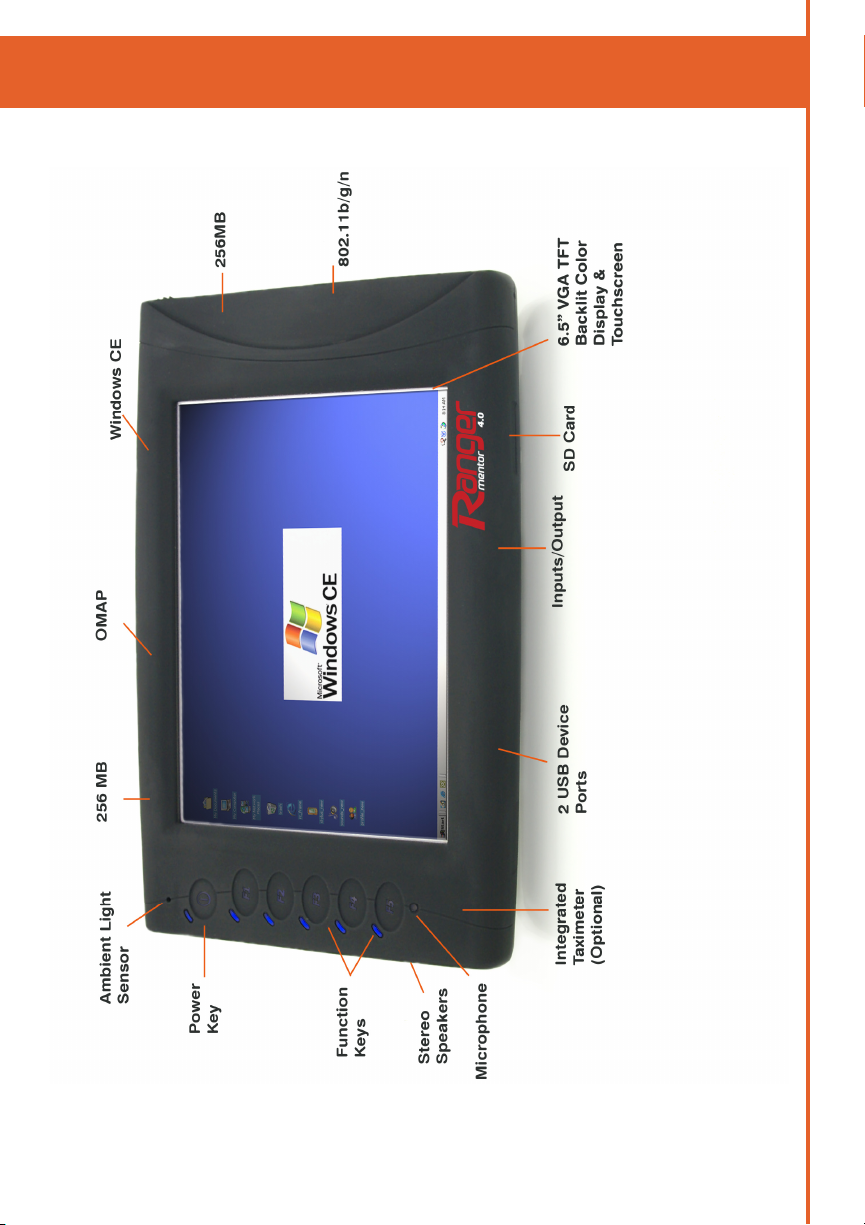

inTroduCTion

Mentor Ranger® v4.0 is a Windows CE fixed-mount computer

for two-way wireless communication, electronic dispatching, invehicle navigation, and more.

This Ranger Installation guide includes directions for successfully

installing and interfacing a Ranger into a vehicle. Specific wiring

and installation procedures may change from customer to

customer and should be discussed prior to installation. If any

questions remain after reading this guide,please contact Mentor

Engineering, (403) 777-3760 ext. 3, for more information.

4.0

7

Page 8

before you begin

CAUTIONS

a) Carefully read the Installation Guide before installing this

product. If anything is unclear please contact Mentor

Engineering for support.

b) Ensure that the NEGATIVE battery connection is disconnect-

ed before beginning work.

NOTE: Some components may lose short-term memory (i.e.

engine or transmission adaptive parameters, and radio presets) after a protracted time without battery power.

c) Ranger should be serviced by qualified, trained personnel

only. Attempting to remove the cover or disassemble the

device could expose you to dangerous high voltage points.

d) Only use a damp cloth for cleaning. Never use any type of

liquid/aerosol cleaner or any type of organic solvent to clean

this product.

e) Do not attempt to install or operate a damaged device. If the

unit has been exposed to excessive amounts of water; shows

evidence of physical damage; or is not operating properly;

unplug it from the power source and contact qualified service

personnel.

f) Use of thread-locking compounds such as Loctite may cause

serious damage to plastic enclosures. Many thread-locking

compounds are not compatible with thermoplastics and can

lead to stress cracking. This will require the unit to be returned to replace the ABS enclosures.

ENSURE THAT YOU HAVE ALL OF THE ITEMS LISTED IN

THE PARTS LIST

8

Page 9

ranger overview

9

Page 10

parTs lisT

Please verify that you have everything that you need to

complete the Ranger installation. NOTE: Not all parts

are provided by Mentor.

SUPPLIED

• Ranger

• Ranger Interface Cable

4-CAS-CGRDMMLX18-31

• Ranger Power Pigtail

• Ranger Mount

10

• In-line Cable Fuse(s)

Page 11

parTs lisT

SUPPLIED (OPTIONAL)

• Emergency switch

NOT SUPPLIED

• Zip Ties

• Glued Heat Shrink

• Tools as Required

• Grommets

• Loom

• Fasteners

11

Page 12

MounTing loCaTions

PLACEMENT

1) Ensure that the driver’s view of the road will not be

impacted.

2) Ensure that the equipment will not be in the path of any

active airbags.

3) Ensure that the driver will still have access to all controls on

the dash.

4) Ensure that the driver has a clear view of the terminal from

the seated driving position.

5) Ensure that the terminal is within easy reach of the driver

from the seated driving position.

6) Ensure that the mounting location is a solid surface.

Locations that allow even small amounts of initial movement

will loosen over time.

12

7) Before drilling any holes or using screws, check for vehicle

wiring under the carpet or behind the instrument panel which

could be pinched, cut or otherwise damaged.

8) If mounting through the floor, put body sealer over the

underbody projections. Stamped acorn nuts, filled with

sealer, are available at most body shops for this purpose.

This will keep moisture out of the carpet and insulation and

will forestall rust in this area.

9) If mounting under the instrument panel, be sure that there is

no interference with proper operation of the foot controls.

10) Inquire if the vehicle will be cleaned with a high pressure

water wand. If so, ensure that all equipment is installed

somewhere that will be protected from this type of cleaning.

Page 13

ranger MounTing exaMples

EXAMPLES OF SUITABLE MOUNTING LOCATIONS

Figure 1

Ranger Installed in an

Orion II Bus

Figure 2

Ranger Installed in a

Ford E-Series Cutaway

Figure 3

Ranger Installed in a

Chevrolet 3500 Series Cutaway

13

Page 14

insTalling The ranger Cover plaTe

SUPPLIES REQUIRED TO INSTALL COVER

In order to install the Ranger Cover, the following items

will be used. Most items are included in your shipment of

Ranger equipment:

- Ranger Cover Plate

- 6mm hex head screw (Quantity 2)

- 2mm hex head screw (Quantity 2)

- Hex bit, for 2mm hex head screws

- 5/16” wrench (torque wrench preferred) **

**Not included

Ranger Back View

sTep 1

Connect the Ranger power cable

to the power input as shown. Use

2mm screws and fasten cover. This

requires a 2mm Hex bit.

Ranger Back Cover Plate

14

Page 15

insTalling The ranger Cover plaTe

sTep 2a

Align the back cover

plate with the Ranger as

shown.

sTep 2b

If there are external cables connected to the Ranger, ensure to

thread the cables through the

holes in the cover.

The cables must be threaded

in such a way that they are

not pinched by the cover when

fastened to the Ranger.

sTep 3

Secure the cover to the

Ranger with the screws

provided. This will require

6mm and 2mm hex head

screws (2 of each).

15

Page 16

insTalling The ranger Cover plaTe

Torque Settings

There are a number of items that may need to be installed to a specific torque level. This includes the Main Cable Cover, Mounting Ball,

RF Cable Cover and antennas. The following Table lists the recommended torque settings for installing these items. Over and under

torquing can lead to product damage and/or failure.

We recommend using a calibrated torque screwdriver for tightening

all screws. A Huber Suhner SMA torque wrench (74Z-0-0-21) is

recommended for tightening the Antenna cable.

Recommended Torque

Description Mentor Part Number

Main Cable Cover 3-ENC-RNGRP226-XX 80-90 55-65

Mounting Ball 6-MNT-RAMCMN3X-XX 80-90 55-65

RF Cable Cover 3-ENCRNGRP301-XX 80-90 55-65

R-SMA Antenna Cable 6-ANT-XXXXXXXX-XX 140 100

Oz.In N.cm

16

Page 17

wiring - ranger baCk view

17

Page 18

wiring - ranger baCk view

18

4-CAS-PIGTVEHCXX-XX

REQUIRED

Green (Ignition Sense, 12/24V, 2A fuse) 6

White (Odometer - typically not used) 7

Red (Vin, 12/24V, 3A fuse) 8

Black (Ground) 16

Page 19

ConneCTion poinTs

1) SPLICING

T-Taps are not a suitable form of splicing into existing

cabling. All splices must be soldered and glued. Heat

shrink must be used for protection.

2) POWER

Power connections should be made directly to the bat-

tery and fused as close to the battery as possible. Avoid

using a cigarette lighter or “Power Point” receptacles

as power sources. Mentor does not recommend wiring power directly to a vehicle kill switch because the

Ranger will not power down correctly. Appropriate fuses

are provided with the installation equipment.

3) GROUND

The ground point should be that point where the (-)

terminal from the battery is connected to the body. This

connection to the battery is typically a 6 or 8 AWG black

wire connected to the wheelhouse or radiator support.

Do not fuse the ground lead. If the ground-side fuse were

to open, the entire supply current would be conducted

by an alternate current return path, which may cause

the feed line to overheat possibly resulting in damage.

4) SWITCHED IGNITION POWER

It is important to utilize an unused ignition point. Con-

necting to an ignition point that is currently being used

to switch other devices can cause improper operation of

those devices.

There are two methods for interfacing to the vehicle igni-

tion. If neither of these options are possible, then contact

your Mentor project manager and alternate ignition options can be discussed and approved.

19

Page 20

ConneCTion poinTs

It is highly preferable to find an ignition source that goes high only

when the engine is actually on. If this source cannot be found, an

ignition source that goes high only when the ignition is in the ON

position is the next recommended source.

a) Auxiliary Electrical Panel (Preferred)

Many bus manufacturers will include an auxiliary electrical

panel for interfacing peripheral devices. Below is an example of a common location in buses with a Ford chassis.

One of these terminals will typically be a switched ignition

point. A ring terminal should be used when connecting to

this type of ignition interface point. Ask the local maintenance personnel if you need assistance to find this panel.

20

Figure 6

Example of an Auxiliary

Electrical Panel on a

Ford Van

b) Fuse Panel

An unused ignition activated position in the fuse panel is

another option. This installation requires an Add-A-Circuit

fuse holder as pictured below. It is not acceptable to use a

“fuse sleeve”

Page 21

ConneCTion poinTs

Figure 7

Add-A-Circuit Installation

5) VSS (VEHICLE SPEED SENSOR FOR ODOMETER PULSES)

Many vehicles have a VSS point which provides a pulse

train from the transmission. Vehicles that do not have a

VSS point with adequate signal characteristics will require

the installation of a transducer. It is the responsibility of the

installer and customer to locate a VSS point or determine

the appropriate location for a transducer. Your Mentor

Systems Engineer may be able to assist in locating suitable

VSS point. He/She can also provide information on the type

of signal that is required for accurate odometer tracking.

21

Page 22

ConneCTion poinTs

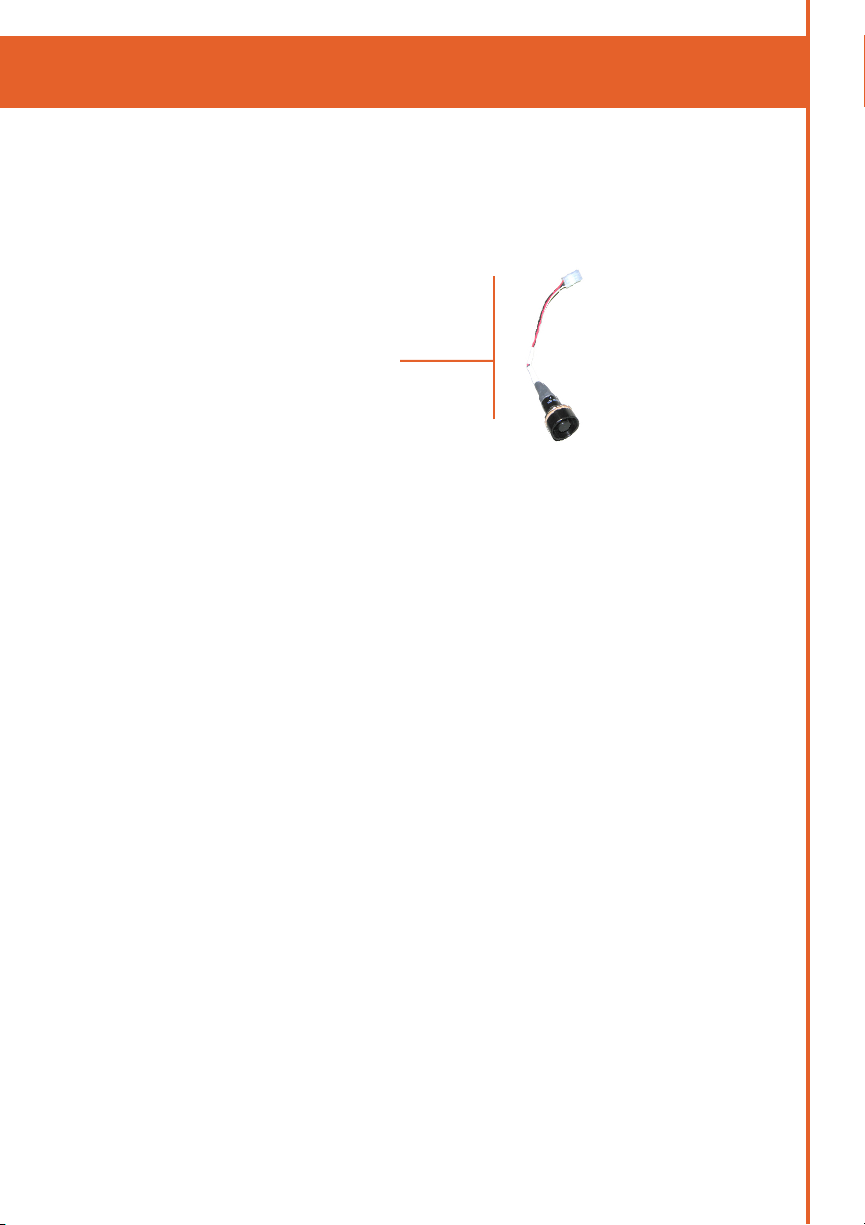

6) EMERGENCY SWITCH (OPTIONAL)

The emergency switch is usually installed somewhere that

would allow for covert operation. This location needs to

be chosen by the customer prior to the start of installation. Mentor will provide a switch if one is required. It is

sometimes possible to use an existing switch already on the

vehicle. Ranger 4.0 requires a normally closed momentary

push button switch with one side connected to the blue

wire (or the wire corresponding to Pin 14 ) on the Ranger

Power Pigtail input/output cable (Part Number 4-CAS-PIGTVEHC24-45_R05).

22

Figure 8

Emergency Switch

The emergency switch is typically installed on the lower left

side of the driver seat.

Always ensure that the connector on the emergency switch

pigtail is strain reliefed off the floor to prevent shorts if water

enters the connector.

Page 23

Cabling

1) ROUTING

a) Use caution when routing wires between the passenger

and engine compartments to avoid chafing or pinching

the wires. Use grommets over any exposed sharp edges

and strain reliefs to keep wires in place. Seal all holes to

prevent moisture intrusion.

b) Route and secure all under-hood wiring away from mechan-

ical hazards such as exhaust manifolds and moving parts.

c) Maintain as great a distance as possible between mobile

radio power leads and the vehicle’s electronic modules

and wiring. Avoid running power leads in parallel with

vehicle wiring over long distances.

d) If cabling is routed under the instrument panel, be sure

that there is no interference with proper operation of the

foot controls.

2) STRAIN RELIEF

Ensure that there is no strain exerted on cable connectors where

they enter the unit. Avoid placing the unit in a position where

the cable connectors entering the back of the unit are under

pressure or strain of any kind. Ensure the power cable is fully

inserted before replacing the cable cover. In the event of undue

stress or strain on installed cables and connectors, permanent

damage may occur imparing the connections. This may result

in intermittent or complete loss of communication and or power.

Always include strain relief every 2-3 feet on long cable runs.

As the Ranger can be tilted and rotated freely by the driver/user,

cabling should be installed such that moving/adjusting the position

of the unit does not exert any significant stress on the cables.

23

Page 24

Cabling

3) LABELING

It is important to always label cabling at connection points.

This simplifies maintenance in the future. Using cables with

consistent coloring will also make maintenance easier.

4) CONNECTION TYPES

Acceptable Connection Types

a) Ring Terminals

b) Butt Splices with Self Contained Solder

and Shrink Tubing

24

1

1. Solder Sleeve

2. Crimp Splice (shown crimped)

3. Wire

3

4

4. Shrink Tubing

2

3

c) Soldered Connections with Shrink Tubing

Page 25

Cabling

Unacceptable Connection Types

a) T-Taps

b) Spade Terminals

c) Marrettes

d) Blade Connectors

e) Standard Butt Splices

5) WIRE TYPES

The following are the minimum specifications for hook-up

wire that should be used during the installation process:

a) Ranger Power and Ground

300V, 105°C PVC, 18AWG stranded

b) Ignition

300V, 105°C PVC, 22AWG stranded

c) Odometer Interface

300V, 105°C PVC, 22AWG stranded

d) Ranger Inputs (i.e. Emergency Input, etc.)

300V, 105°C PVC, 22AWG stranded

6) ELECTRICAL MEASUREMENTS

Always ensure that there is adequate voltage at the point

where Ranger is being powered. Compare this voltage to the

voltage at the battery. The two voltages should be almost the

same or a different power point should be chosen closer to

the battery.

25

Page 26

anTennas

1) INTERNAL ANTENNAS

Ranger 4.0 contains celullar, WIFI, Bluetooth and GPS antennas.

Cellular, WIFI and Bluetooth antennas are capable of transmitting.

Ranger should be installed and operated with a minimum distance of

20 cm (8”) between the radiator and the operator.

The orientation and mounting location of Ranger4.0 can have an

effect on antenna performace.

To optimize GPS performace, mount the Ranger vertically with a

clear view of the sky.

2) EXTERNAL ANTENNAS

If desired, external WIFI and/or GPS antennas can be used with

Ranger 4.0

26

Specific antenna selection depends on the individual system setup.

Contact Mentor Engineering for assistance in selecting an appropriate

antenna.

Use short lengths of low loss cabling whenever possilbe. WIFI

performace is especailly susceptible to cable losses.

Some importance features to consider are:

Compact construction,

Durability

Weatherproofing

Temperature stability

Mode of Installation

Page 27

anTennas

Groundplane style antennas are ideally mounted on the centre of a

metal vehicle roof.

Glass mount antennas should be mounted away from metal objects.

When using an adhesive antenna, it is extremely important to make

sure that the surface of the mounting location has been thoroughly

cleaned. Use Isopropyl alcohol to clean the surface just before

securing the adhesive pad.

3) CABLE ROUTING

The antenna cabling has a minimum inside bend radius of 2”. Bending the cable tighter will cause degradation in antenna performance.

Avoid routing the antenna cable in parallel with the vehicle wiring

over long distances.

Do not coil excess antenna cable slack.

Figure 7

Antenna Routing

27

Page 28

anTennas

CONNECTORS

• R- SMA - The reverse SMA connector is used for WIFI and

requires a 1N-M torque wrench to properly secure

• QMA - The QMA connector is used for GPS and is a snap

on version of the SMA connector

28

Page 29

ranger speCs 7-rngr-04x

GENERAL DESCRIPTION

Mentor Ranger® v4 is a water resistant

vice that is equipped with color Touchscreen display,

Compact Flash, smart card/magnetic card readers and

USB host/device port. Application software can be

custom-designed making it adaptable to a wide variety

of applications. It has an optional internal wireless

modem for HSPDA or EVDO networks. Internal GPS

allows Ranger to be used for vehicle navigation, AVL

(Automatic Vehicle Location) and/or Computer Aided

Dispatch systems for fleet applications.

STANDARD FEATURES

• 256MB of Flash

• 256MB of DDR SDRAM

• 2 USB Device Ports

• Bluetooth 2.1

• WIFI 802.11b/g/n

• CANBUS J1939

• J1708

• Built in Odometer Signal Conditioner

• 4 Digital Input / Open Drain Output with soft

ware selectable pull up or pull down

• 6 Button Capacitive Touch Keypad

• 3W Stereo Speakers

• 6.5” TFT Color Display with Touchscreen

• External SD Card Socket

• Covert Microphone

• 2 RS-232 Com Ports

• Tactile Wear Resistant Coating

• Internal 50 Channel GPS

8

1,2

WinCE de-

29

Page 30

ranger speCs 7-rngr-04x

COMPLIANCE AND TESTING

• FCC Class B Part 15

• IEC 60950 3rd Edition (2000)

• ISO 7637-1 Load Dump Transient

• MIL STD 810F: General Vibration

• MIL STD 810F: Shock

• IP54: Environmental, Dust and Water exposure

OPTIONAL FEATURES

• Taximeter

• ISO 7811 Magnetic card reader/ISO 7816 Smart Card

Reader (combined module)

• Internal SD Card Socket (4GB max)

• Internal Wireless Data Modems

(HSDPA or EVDO or DSP Radio)

3

• Handset and/or Handsfree Voice Calls

KEY SPECIFICATIONS

• Supply Voltage

Typical 12 V

Min 6 V

Max 32 V

• Current Consumption

7

30

Input Voltage

Current Draw (mA)

(V)

Standby Idle

4

9 68 360 965

13.8 50 250 645

24 39 160 405

Maximum6 3.0 A

Typical

5

Page 31

ranger speCs 7-rngr-02x

• Operating Temperature

Min -30o C Max 65o C

• Storage Temperature

Min -30o C Max 70o C

• Size

8.25” x 2.0” x 5.75”

210mm x 57mm x 146 mm

• Weight

2.0 lbs / 0.9 kg

• 5% - 95% relative humidity non-condensing

Foot Notes

1) Ranger is designed to be splash resistant. It’s not designed to be immersed in

water.

2) Ranger may not be water resistant when some of the options are specified.

3) DSP Radio and Wireless Modem options cannot be specified at the same

time.

4) When diisplay is off, the unit is in idle without modem options

5) Unit Idle with full backlight with GPS, Wifi and Bluetooth. No modem

options

6) This is an absolute maximum which includes an installed

modem and all peripheral devices. Actual current draw will depend on system

design.

7) Unit is IP54 rated for water without Mag swipe, or Taximeter Options or DSP

modem.

31

Page 32

ranger speCs 7-rngr-02x

8) USB 2.0 High Speed; One port is for maintenance only.

NOTE: Mentor Engineering Inc. reserves the right to change

circuitry and specifications without notice at any time.

Please ensure you have the most recent revision of this

document.

NOTE: Operation at Temperatures outside the ranges is not

recommended.

NOTE: Only use Mentor Engineering approved cables for

installation purposes. Refer to cable section of

the Hardware Installation Manual for additional

information.

32

Page 33

appendix a - ConforMiTy

1) FCC CLASS B PART 15

This device complies with Part 15 of FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference

2. This device must accept any interferenc

recceived, including interference that may cause

undesired operation.

INDUSTRY CANADA STATEMENT

Under Industry Canada regulations, this radio transmitter may

only operate using an antenna of a type and maximum (or

lesser) gain approved for the transmitter by Industry Canada. To

reduce potential radio interference to other users, the antenna

type and its gain should be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary

for successful communication.

This device complies with Industry Canada licence-exempt RSS

standard(s). Operation is subject to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including ...

interference that may cause undesired operation of the

device.

Conformément à la réglementation d’Industrie Canada, le

présent émetteur radio peut fonctionner avec une antenne

d’un type et d’un gain maximal (ou inférieur) approuvé pour

l’émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à l’intention des autres utilisateurs, il faut choisir le type d’antenne et son gain de sorte que

la puissance isotrope rayonnée équivalente (p.i.r.e.) ne dépasse

pas l’intensité nécessaire à l’établissement d’une communica-

33

Page 34

appendix a - ConforMiTy

tion satisfaisante.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation est

autorisée aux deux conditions suivantes :

(1) l’appareil ne doit pas produire de brouillage, et

(2) l’utilisateur de l’appareil doit accepter tout brouillage ra

dioélectrique subi, même si le brouillage est susceptible

d’en compromettre le fonctionnement.

NOTE: This equipment has been tested and found to

comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particulat

installation.

34

If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following

measues:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and

receiver.

Page 35

appendix a - ConforMiTy

- Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV

technician for help.

2) IEC 60950 3RD EDITION (2000) SAFETY OF INFORMATION

TECHNOLOGY EQUIPMENT

3) ISO 7637-1 LOAD DUMP TRANSIENT

Designed for ISO 7637-1 Load Dump Transient

4) MIL STD 810F: GENERAL VIBRATION

Tested to MIL-STD-810F Vibration Test Method 514.5 Procedure

I: General Vibration, Category 20 Ground Vehicles.

4.1) Highway Vehicle Endurance Testing

Each axis was exposed to 1 hour of vibration according to Figure

514.5C-1 U.S. Highway Truck Vibration Exposure Levels. This is

an accelerated fatigue test meant to test the unit’s life cycle. The

unit was functionally tested before and after the test.

5) MIL STD 810F: SHOCK TEST

Tested to MIL-STD-810F Shock Test Method 516.5 Procedure I:

Functional Shock. Functional Shock was performed on the vertical, transverse, and longitudinal axes with a pulse of 40gs. The

tests were performed to ensure the unit stays intact during vehicle

operation.

6) IEC 60529 - IP54

Tested to IEC 60529 IP54 for protection against ingress of water

with harmful effects splashing. Unit must not be equipped with

magnetic card reader or taximeter.

35

Page 36

appendix b - rf radiaTion speCs

RF EXPOSURE

This equipment complies with FCC radiation exposure limits

set forth for an uncontrolled environment. This equipment

should be installed and operated with minimum distance of 20

cm between the radiator and your body.

This transmitter must not be co-located or operating in conjunction with any other antenna or transmitter.

36

Page 37

appendix C - approvals

1) CDMA/EVDO - VOICE/DATA NETWORK CERTIFICATIONS

FCC ID: RZ3RAN45728

IC ID:2234A-RAN45728

Approvals: FCC, IC

2) GSM/HSDPA

FCC ID RZ3RAN48790

IC ID 2234A-RAN48790

Approvals: FCC, IC, PTCRB

3) WIFI/BLUETOOTH ONLY - NO CELLULAR MODEM

Contains Transmitter Module FCC ID: N7NMC8790

FCC ID RZ3RAN49110

IC ID 2234A-RAN49110

37

Loading...

Loading...