Trapeze Software Group RAN45728, RAN49110, RAN48790 Installation Manual

Hardware Installation Guide

Ranger 7-RNGR-04X

Ver 5.4

Copyright © 2008 Mentor Engineering Inc. All rights reserved.

Table of ConTenTs

Safety & After-Market Equipment ........................................4

Qualified Installer ...............................................................5

Introduction .......................................................................7

Cautions .......................................................................8

Before You Begin ................................................................8

Parts List ...........................................................................9

Supplied .......................................................................10

Supplied (Optional) ........................................................11

Not Supplied .................................................................11

Mounting Locations ............................................................12

Placement .....................................................................12

Ranger Mounting Examples .................................................13

Examples of Suitable Mounting Locations .........................13

Installing The Ranger Cover Plate ........................................14

Wiring - Ranger Back View .................................................17

Connection Points ..............................................................19

1) Splicing ...................................................................19

2) Power ......................................................................19

3) Ground ....................................................................19

4) Switched Ignition Power ............................................19

5) VSS (Vehicle Speed Sensor for Odometer Pulses) .........21

6) Emergency Switch (optional) ......................................22

Cabling ..............................................................................23

1) Routing....................................................................23

2) Strain Relief .............................................................23

3) Labeling ..................................................................24

4) Connection Types ......................................................24

5) Wire Types ...............................................................25

6) Electrical Measurements ............................................25

Antennas ...........................................................................26

2

Table of ConTenTs

1) Internal Antennas .....................................................26

2) External Antennas .....................................................26

3) Cable Routing...........................................................27

4) Connectors ...............................................................28

Ranger Specs 7-RNGR-04X...............................................29

General Description ........................................................29

Standard Features ..........................................................29

Compliance and Testing ..................................................30

Optional Features ...........................................................30

Key Specifications ..........................................................30

Appendix A - Conformity .....................................................33

1) FCC Class B Part 15 .................................................33

2) IEC 60950 3rd Edition (2000) Safety of Information Tech-

nology Equipment .....................................................35

3) ISO 7637-1 Load Dump Transient ..............................35

4) MIL STD 810F: General Vibration ...............................35

5) MIL STD 810F: Shock Test ........................................35

6) IEC 60529 - IP54 ....................................................35

Appendix B - RF Radiation Specs ........................................36

RF Exposure ..................................................................36

Appendix C - Approvals .......................................................37

1) CDMA/EVDO ............................................................37

2) GSM/HSDPA ............................................................37

3) WIFI/Bluetooth Only ..................................................37

3

WARNING

FAILURE TO INSTALL THE EQUIPMENT

AS RECOMMENDED COULD CAUSE OR

CONTRIBUTE TO AN ACCIDENT AND RESULT

IN DAMAGE TO PROPERTY OR PERSONS.

safeTy & afTer-MarkeT equipMenT

The use of after-market equipment in motor vehicles can

compromise a vehicle’s safety-related design characteristics,

including but not limited to:

• Airbags, including but not limited to potential obstruction of air-

bag deployment;

• Passenger compartment, including but not limited to potential for

ergonomic problems, physical obstacles, etc.; and

• Trunk/gas tank protection, including but not limited to the poten-

tial for trunk-mounted equipment to exacerbate tank vulnerability

in a rear collision.

4

WARNING

This product is to be installed by

qualified installation personnel only.

Incorrect installation may result in FIRE

or contribute to an ACCIDENT

qualified insTaller

This product is to be installed by qualified installation personnel only.

The installer must be trained in industry best practices for this type of

installation. The training would include but not be limited to:

1. The appropriate methods for installing cables such that:

• The operation of the vehicle is not interfered with.

• The installation process does not damage or interfere with other

vehicle components and/or systems.

• Wiring is kept clear of sharp objects, sources of heat and any

other hazard that could damage the cable or wire.

• Wiring is secured such that it does not cause damage to other equip-

ment, itself, or interfere with the operation of other systems and

devices.

• Wiring through bulkheads is performed such that wiring does not

chafe, and a seal is maintained between compartments.

• Appropriate and industry standard fasteners, splices, connectors

and ties are used for the vehicle environment.

• Appropriate slack is in place to prevent straining of the wire, cable

or connectors.

• Any other issue that could affect the integrity of the wiring or the

safe operation of the vehicle is addressed appropriately.

5

qualified insTaller

2. The appropriate methods for mounting equipment in vehicles such

that:

• The safe operation of the vehicle is not interfered with.

• The equipment is attached to the vehicle as securely as possible to

minimize the risk of the equipment breaking free in an accident situation.

• The installed device does not interfere with the deployment of air

bags.

• The installed device does not obscure displays or interfere with the

ability of the driver to operate other vehicle systems and components.

• The installation process does not damage other vehicle systems or

components.

• Compartments remain sealed against the elements.

3. The correct use and operation of the required tools.

Further:

• The installer must have the ability to read, understand and follow

the instructions in the installation manual.

• The installer must be equipped with the correct tools for perform-

ing each installation operation.

The Customer must ensure that the installation of all equipment provided for this project is safe, used for its intended purpose, and is in

continual accordance with all applicable codes, rules, regulations and

guidelines provided by motor vehicle and equipment manufacturers, as

well as any state, local or jurisdictional bodies.

6

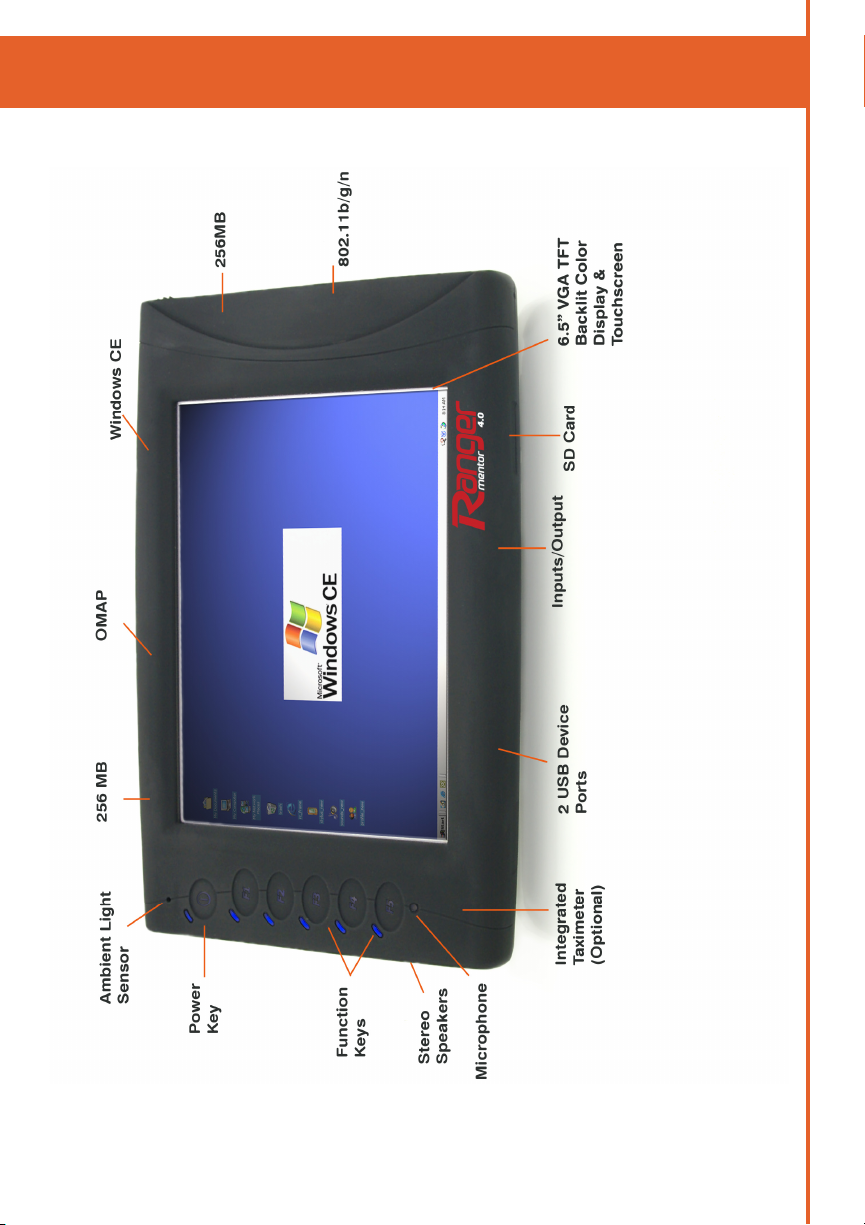

inTroduCTion

Mentor Ranger® v4.0 is a Windows CE fixed-mount computer

for two-way wireless communication, electronic dispatching, invehicle navigation, and more.

This Ranger Installation guide includes directions for successfully

installing and interfacing a Ranger into a vehicle. Specific wiring

and installation procedures may change from customer to

customer and should be discussed prior to installation. If any

questions remain after reading this guide,please contact Mentor

Engineering, (403) 777-3760 ext. 3, for more information.

4.0

7

before you begin

CAUTIONS

a) Carefully read the Installation Guide before installing this

product. If anything is unclear please contact Mentor

Engineering for support.

b) Ensure that the NEGATIVE battery connection is disconnect-

ed before beginning work.

NOTE: Some components may lose short-term memory (i.e.

engine or transmission adaptive parameters, and radio presets) after a protracted time without battery power.

c) Ranger should be serviced by qualified, trained personnel

only. Attempting to remove the cover or disassemble the

device could expose you to dangerous high voltage points.

d) Only use a damp cloth for cleaning. Never use any type of

liquid/aerosol cleaner or any type of organic solvent to clean

this product.

e) Do not attempt to install or operate a damaged device. If the

unit has been exposed to excessive amounts of water; shows

evidence of physical damage; or is not operating properly;

unplug it from the power source and contact qualified service

personnel.

f) Use of thread-locking compounds such as Loctite may cause

serious damage to plastic enclosures. Many thread-locking

compounds are not compatible with thermoplastics and can

lead to stress cracking. This will require the unit to be returned to replace the ABS enclosures.

ENSURE THAT YOU HAVE ALL OF THE ITEMS LISTED IN

THE PARTS LIST

8

ranger overview

9

parTs lisT

Please verify that you have everything that you need to

complete the Ranger installation. NOTE: Not all parts

are provided by Mentor.

SUPPLIED

• Ranger

• Ranger Interface Cable

4-CAS-CGRDMMLX18-31

• Ranger Power Pigtail

• Ranger Mount

10

• In-line Cable Fuse(s)

parTs lisT

SUPPLIED (OPTIONAL)

• Emergency switch

NOT SUPPLIED

• Zip Ties

• Glued Heat Shrink

• Tools as Required

• Grommets

• Loom

• Fasteners

11

MounTing loCaTions

PLACEMENT

1) Ensure that the driver’s view of the road will not be

impacted.

2) Ensure that the equipment will not be in the path of any

active airbags.

3) Ensure that the driver will still have access to all controls on

the dash.

4) Ensure that the driver has a clear view of the terminal from

the seated driving position.

5) Ensure that the terminal is within easy reach of the driver

from the seated driving position.

6) Ensure that the mounting location is a solid surface.

Locations that allow even small amounts of initial movement

will loosen over time.

12

7) Before drilling any holes or using screws, check for vehicle

wiring under the carpet or behind the instrument panel which

could be pinched, cut or otherwise damaged.

8) If mounting through the floor, put body sealer over the

underbody projections. Stamped acorn nuts, filled with

sealer, are available at most body shops for this purpose.

This will keep moisture out of the carpet and insulation and

will forestall rust in this area.

9) If mounting under the instrument panel, be sure that there is

no interference with proper operation of the foot controls.

10) Inquire if the vehicle will be cleaned with a high pressure

water wand. If so, ensure that all equipment is installed

somewhere that will be protected from this type of cleaning.

Loading...

Loading...