Transtector I2R SuperHy 120 Installation Instructions Manual

Warning

Thank you for your recent purchase of our surge protection solution.

Your satisfaction with our product and service is important to us.

If you have any questions, comments or concerns, please contact us

at 800.882.9110 or visit our website at www.Transtector.com.

We look forward to continuing to serve your protection needs.

Installation Instructions

800.882.9110 | 208.772.8515 | www.ProtectionGroup.com

Risk of Electric Shock or Burn

• Install only in restricted access enclosure or control cabinet that

requires a key or tool to open.

• This SPD should only be installed and serviced by qualied electrical

personnel.

• All National and Local Electric Codes must be observed.

• Conrm that the SPD is rated for the voltage of the application.

• Before installation, turn off all power to equipment to prevent accidental

electric shock or injury.

• Replace all covers and doors prior to restoring power to this

equipment.

I²R SuperHy 120

Installation Instructions

800.882.9110 | 208.772.8515 | www.Transtector.com

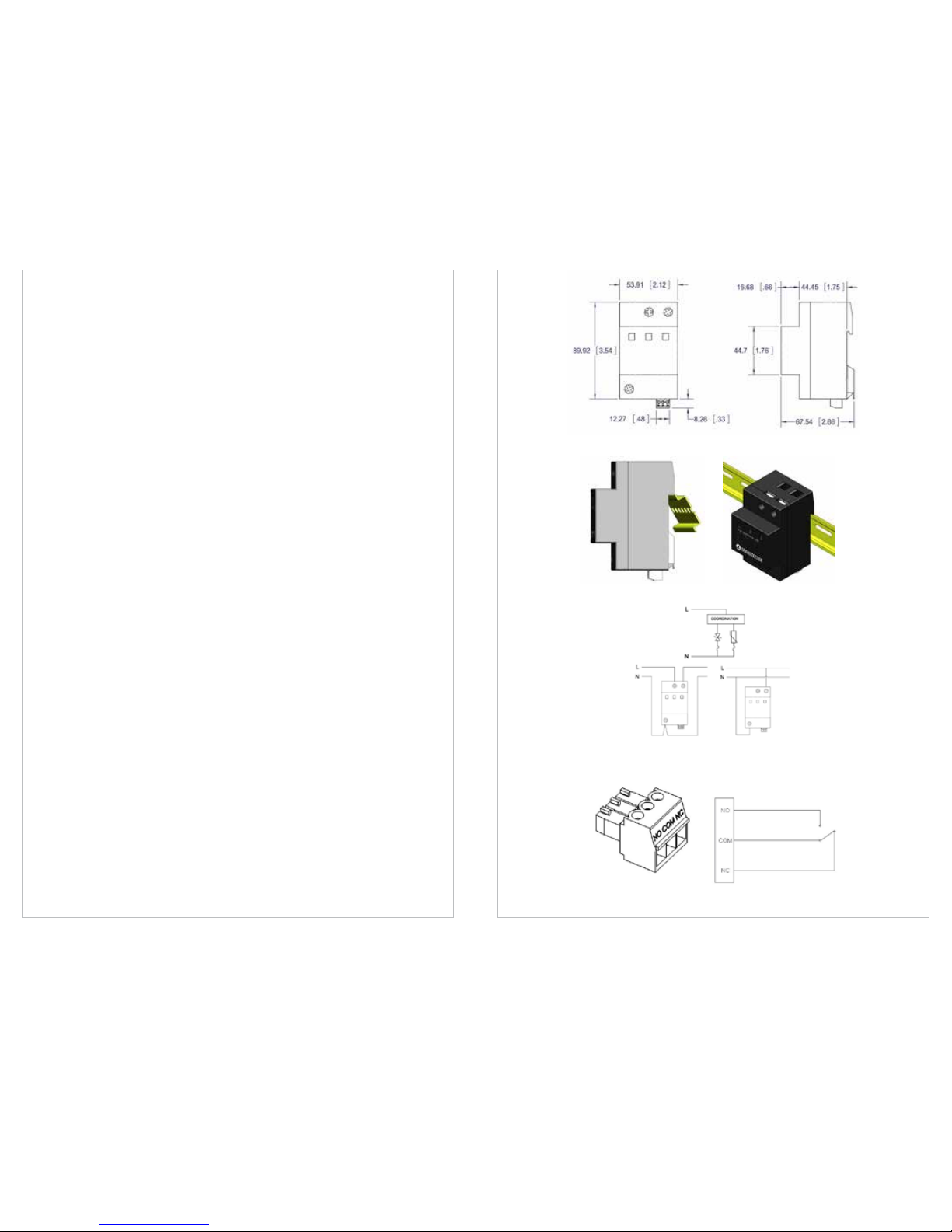

Figure 1 - Mechanical Outline Drawing (mm)

Figure 4 - Remote Contact Connections

Figure 3 - Wiring Diagram

Figure 2 - Installation

I²R SuperHy 120

INSTALLATION NOTES

The I²R SuperHy 120 is used to protect power supplies from over-voltage

caused by transients. This Surge Protection Device (SPD) offers hybrid

bidirectional silicon avalanche diode and metal oxide varistor suppression

technology and is intended for installation on the load side of the service

equipment over current device. The SPD is installed in parallel with the

load. If the lightning protection zone concept is used, this SPD installs

at the boundary of LPZ1 and LPZ2. The SPD features visual status

indication. The normally black indicator turns red if the module needs

replacement. Electrically isolated Form C dry contacts provide remote

monitoring capability. The SPD is designed to be installed in a restricted

access enclosure.

INSTALLATION INSTRUCTIONS

1. Mounting: Position the SPD as close to the equipment being protected

as possible in order to minimize the conductor length. The SPD should

be attached to a securely mounted 35mm DIN rail. The SPD shall be

mounted by positioning the terminal block end on the top edge of the DIN

rail and pressing downward until a ‘click’ is heard (see Figure 2).

2. Wiring: The SPD shall be installed in parallel with the load or electrical

system wiring using #6 - #14 AWG wire. The maximum torque to be

applied to the terminal screws is 1.6 Nm (15 lb-in). Interconnecting wire

should be no longer than 500mm (20”) in total length with a maximum bend

radius of 100mm (4”). Strip the wire insulation 8mm (5/16”). Do not loop

or twist the interconnecting wire. Determine the electrical conguration

and wire as shown in Figure 3.

3. Remote Annunciation: Electrically isolated Form C dry contacts provide

remote monitoring capability. The removable plug accepts #16 - #30

AWG wire. The continuous current rating for the remote indicator is

3A @ 125 VAC maximum. Strip the wire 6mm (1/4”), and torque the

terminal screw 0.2 Nm (1.8 lb-in). The terminal is labeled with Normally

Open (NO), Normally Closed (NC) and Common (COM). Install signal

wiring as shown in Figure 4.

USAGE AND MAINTENANCE

The SPD should be scheduled for periodic inspection to ensure the SPD is

operational and all wire connections are tight.

If the SPD is damaged, contact Transtector for replacement.

1104-15-300-M Rev A

Loading...

Loading...