Page 1

Soil Density Gauge

Operator’s Handbook

Page 2

Table of Contents

Introduction 3

Measurement Technology 3

Application Summary 4

Safety 4

Operating Requirements 4

Controls & Components 5

Contents 5

Gauge Features 6

External Controls 7

Power Save/Auto Shut Down 8

Part 1: Setting up the SDG 8

Installing/Charging the Battery 9

Start Software 10

Main Menu 11

Local Time and Change Date Format 12

Setup GPS 13

Control Menu 14

Select Measurement Units 15

Data Logging 15

Project Details 15

Define, Edit or Upload Material Properties 17

Define and Editing a Material 18

Setting Measurement Offsets 20

Determining Offset Values 22

Upload Material 23

Part 2: Running a Test 24

Measurement Pattern 24

Surface Preparation 24

Measure Density 25

Select a Different Material to Test 28

Part 3: Data Storage and Downloading Data 29

Measurement Data 29

Diagnostic Data 29

Storage Capacity 30

Downloading Data 30

Deleting a Project File 30

Part 4: Maintenance and Troubleshooting 31

Maintenance 31

Troubleshooting 33

Part 5: Definitions and Calculations 33

Measurement Results 33

Definition of Material Properties 34

Part 6: Standardization of SDG 35

Part 7: Explanation of Gradation and Compaction Reports 36

SDG Unit Warranty 44

2

Page 3

Introduction

TransTech’s Soil Density Gauge (SDG) utilizes state of the art technology to get accurate soil density readings.

It’s primary features are:

• No special license or radioactive materials required.

• Lightweight and easy to use.

• 12 hours of portable operation.

• Measures density in common units (pcf or kg/m³).

• Measures percent moisture.

• Stores volumes of readings on internal data logger.

• Data download via USB flash drive (semicolon delimited text file format).

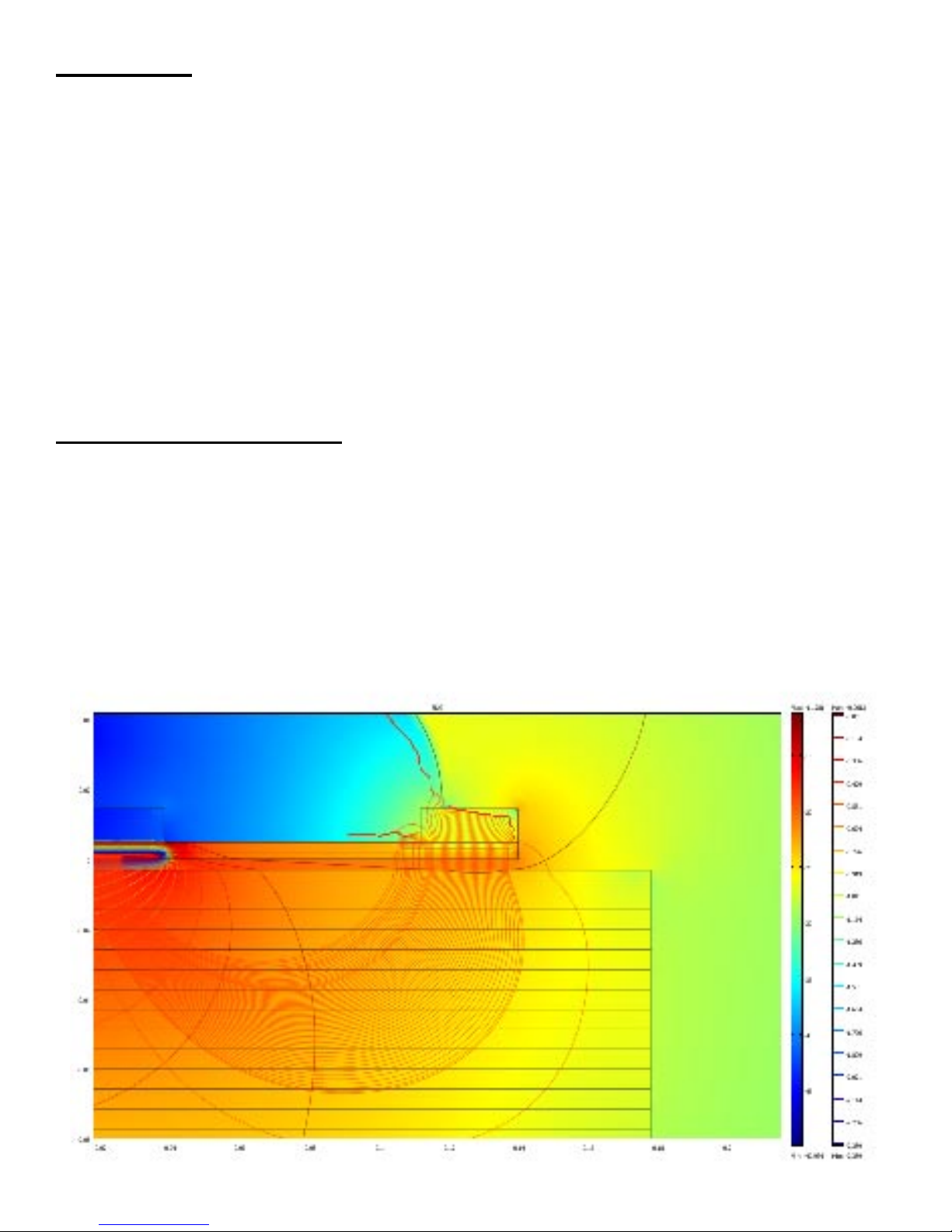

Measurement Technology

Using electrical impedance spectroscopy (EIS) the SDG 200’s measurement permits separation of the effects of

density and moisture content on the response of the soil to electromagnetic probing. The density, or compaction

level, is measured by the response of the SDG 200’s electrical sensing field to changes in electrical impedance

of the material matrix. Since the dielectric constant of air is much lower than that of the other soil constituents,

as density/compaction increases, the combined dielectric constant increases because the percentage of air in the

soil matrix decreases. The SDG 200 performs a calculation on the measurement data that enables the device to

report the soil’s density and moisture content.

3

Page 4

Application Summary

The SDG 200 is intended primarily for making density measurements on a standard 12 inch lift of soil during

or after compaction. It is designed to measure coarse and fine grained materials common in standard soils used

in civil construction projects. After configuring the gauge with soil properties from a standard particle size

distribution report (ASTM D422) and Proctor test (ASTM D698 and D1557) the gauge will provide reliable and

consistent measurements.

Safety

Every effort has been made to make the Soil Density Gauge SDG 200 convenient to use and inherently safe.

The SDG 200 uses non-nuclear, low-voltage direct current to obtain measurements, therefore, there are no

badges, licensing, storage or transport concerns. Like any instrument, however, the user should exercise care

and common sense in its use to prevent mishaps.

Warning

Do not use the unit on or near electrical wiring.

A potential shock hazard exists if contact is made with the exposed wiring.

Warning

Use care in handling the unit. Personal injury can occur through improper handling.

Take proper care to avoid accidentally dropping the unit.

Warning

Unauthorized disassembly of the unit will void the warranty.

Warning

Shipping the gauge with the batteries inside is not recommended.

Caution

Charging the gauge overnight or unattended is not recommended

Caution

Turn the unit off when not in use and during transport.

Caution

Be sure not to switch standardization plates with other gauges. Check the

Serial Numbers located on the gauge and on the plate to be sure they match.

Operating Requirements

Temperature: -4° to 104° F (-20° to 40° C)

Relative Humidity: 10% to 90% noncondensing

Maximum operating altitude: 10,000 feet (3,050 m)

Disclaimer: TransTech reserves the right to change or modify product design, construction, specifications, or

materials without prior notice and without incurring any obligation to make such changes and modifications on

TransTech products previously or subsequently sold.

4

Page 5

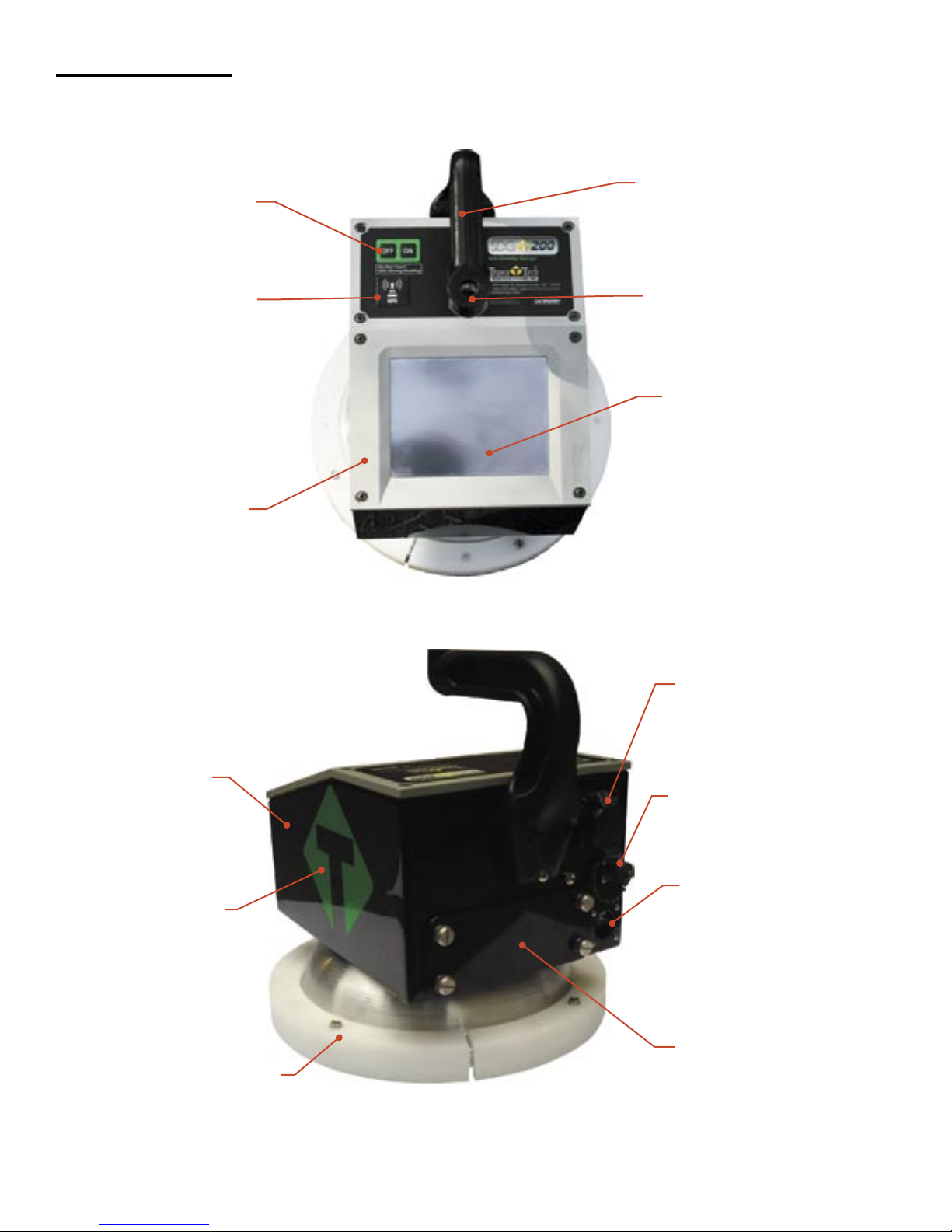

Controls and Components

Contents

The SDG200 is packaged and shipped with the following components. Contact TransTech Systems Inc.

Customer Service if any of the parts are missing.

• SDG200 unit

• Storage/shipping case

• Operators Quickstart Guide

• SDG handle

• 120/220V AC to 12V DC battery charger

• 12V DC Car Charger

• 3 battery packs

5

Page 6

Gauge Features

USB Port

Used to allow

communication between a

flash drive and the gauge

Charger Port

used to connect the ac

or dc charger to gauge

Infrared

Temperature

Sensor

Used to measure the

surface temperature of

the asphalt

Shroud with

10” Sensor Plate

Location where sensor

plate is located

Battery Door

where the battery

is located

Gauge Shell

Body of the gauge

Handle

Used to carry the gauge

TouchScreen

Used to input and

interact with the

gauge

Faceplate

Protective bezel

for touchscreen

GPS Module

Location of GPS

unit on the gauge

(Accurate to

5+- Meters)

On\Off Button

Turns gauge

on and off

Handle Extension

Used to connect handle

extension

Reflective

Vinyl

safety feature for

operation in dark

areas

6

Page 7

External/Internal Controls

External controls on the SDG 200 consist of an ON/

OFF switch and 480x640 VGA touch screen display

for navigating through the user interface and entering

alpha/numeric data.

Be sure not to drag your finger from one button to

the next. A firm yet light touch is all that is needed to

navigate from screen to screen.

Unique yet consistent icons are located on most screens for easy one touch navigation. When data input is

required of the operator the screen will display the above keyboard. Toggle from upper to lower case letters

using the Shift button The upper case keyboard gives the option of a minus sign while the lower

case keyboard gives the plus sign Once editing is completed simply Press Enter to store and return

to the previous screen.

7

Page 8

The numeric keypad as shown in this example allows for only numbers and a decimal point.

Press Accept to store your entry and in most cases return to the previous screen.

The Status Bar is located at the bottom of the screen (excluding the keyboard screens) and will continuously

update the remaining voltage of the batteries while displaying the date, time and status of the GPS and Data

Logging features.

Prior to using the SDG 200 for the first time the gauge will need to be configured to make measurements and

record data correctly.

The following steps must be completed before operating the SDG 200:

1. Installing and Charging the Batteries

2. Starting the Software

3. Set the Local Time/Set Date

4. Set up the GPS

5. Select Units of Measurement

6. Define the material being tested (Material Details)

8. Define Project Details

Setting up the SDG 200

External/Internal Controls

8

The SDG Model 200 has a built in power saving mode. If there are no buttons pressed after approximately 20

minutes the unit will go into a power saving mode. Pressing any key will “Wake” the SDG up for continued

use. If the SDG is left “On” for an hour without any buttons being pressed, it will shut itself down, to conserve

battery run time

Power Save/Auto Shut Down

Page 9

Installing/Charging the Batteries

To charge the unit, proceed as follows:

1) Turn the SDG 200 unit OFF.

2) Connect the charger to the charger connector located on the back of the SDG 200.

3) Plug the charger into a standard AC outlet.

4) The red indicator lamp will turn green to indicate that the batteries are charged.

5) Unplug the charger from the power source before disconnecting the charger from the SDG 200.

9

You will find a plate on the back of the SDG 200 with 4 spring loaded bolts.

• Turn each bolt approx. 2 full turns until the spring releases

• Remove the plate from the gauge

• Next you will find a wire with a connector, disconnect the battery from the gauge

• Then pull the nylon strap to slide the battery out of the compartment.

(Do Not pull the battery by the connector wire, doing so could cause damage to the battery)

Plug the gauge in and allow the LED to go from red to green for a full charge.

Approximate charge time is 4 hours.

Page 10

Battery voltage can be viewed on the Status Bar located at the bottom of all screens. A fully charged battery

will display over 8 volts. The battery voltage will decrease as the SDG 200 is used. A low battery icon will be

displayed at approximately 6.5 volts.

The gauge will continue to operate until the battery can not supply enough voltage to complete a measurement.

Once this happens, the gauge will automatically shut down and will not restart until charged. Depending on the

condition of the batteries, once the voltage drops below 6 volts, the gauge may be able to take about 12 to 15

additional readings. It is important to re-charge the battery after each use.

Starting the Software

Turn the SDG 200 on by pressing the ON button. After a few seconds the TransTech splash screen will

appear followed by the Main Menu Screen. The Main Menu screen will display six options. Start SDG200,

Internet (Coming Soon), Calculator, Contact TransTech, GPS Control and Update

Software.

Installing/Charging the Batteries

10

Page 11

Main Menu

Start button when pressed will

open the Control Menu Screen.

The Internet button when pressed will

open a new screen. The new screen

indicates that this will be an option in

the future. It is not active at this time.

The Calculator button when

pressed will open a screen

which functions as a calculator.

The GPS Control button when

pressed will open a screen

which will allow you to enable

or disable the GPS.

Local Time and Change Date Format

The Contact button when pressed

displays TransTech and distributor

contact information.

The Update Software button will

be used in the event that TransTech

releases an update to the software

You may set the date and time in two locations. From the Main Menu, Press Set Time & Date

located on the status bar or from the Control Menu press Date & Time.

11

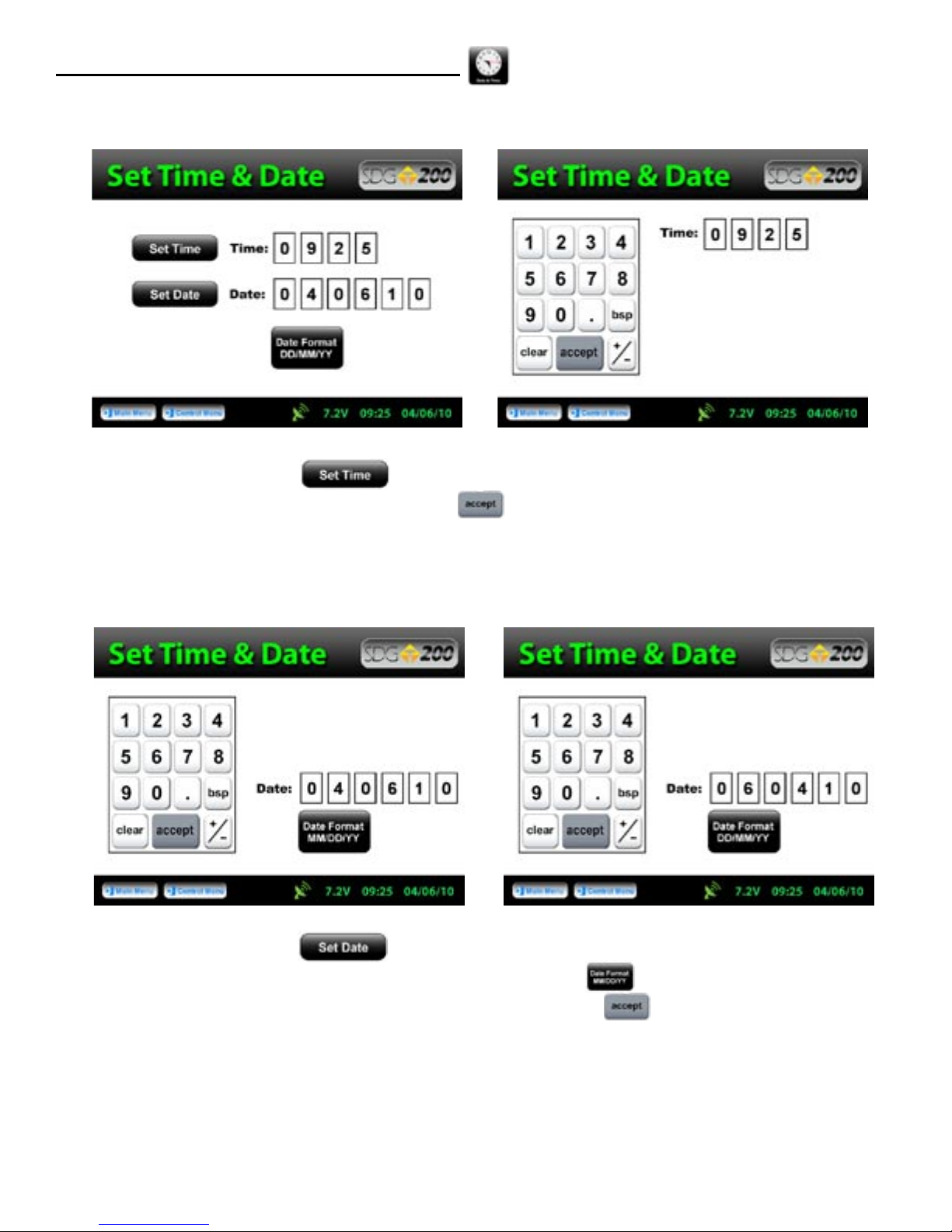

Page 12

Local Time and Change Date Format

To set the time, Press Set Time. Press the appropriate numbers for the time in 24 hour format.

Once you are satisfied with your entry, Press Accept to store and return to the previous screen.

To set the date, Press Set Date. The date will display in either the DD/MM/YY or MM/DD/YY

format which may be toggled from the button located on both screens. As you did with the time, press

the appropriate numbers for the date in the format chosen. Press Accept to store and return to the

previous screen. (Note: Date will be preset by the factory)

12

Page 13

Setup the GPS

Setting up the GPS is nothing more than turning it on and waiting to connect to satellites. It can

take up to 15 minutes to connect to satellites depending on your location.

From the Main Menu, Press GPS CONTROL. GPS status can be toggled ON or OFF.

When the GPS is ON the satellite dish on the status bar turns from red to green.

GPS formatting can also be toggled from the Universal Transverse Mercator (UTM) grid to Latitude/

Longitude (LAT-LON). Initially the display will read Sats 0 for both formats until connections have been

made. The above examples show a connection to five satellites (Sats 5) in both formats. GPS locations will

appear on the bottom left corner of all Reading Mode screens and will store with each reading when Data

Logging is ON.

13

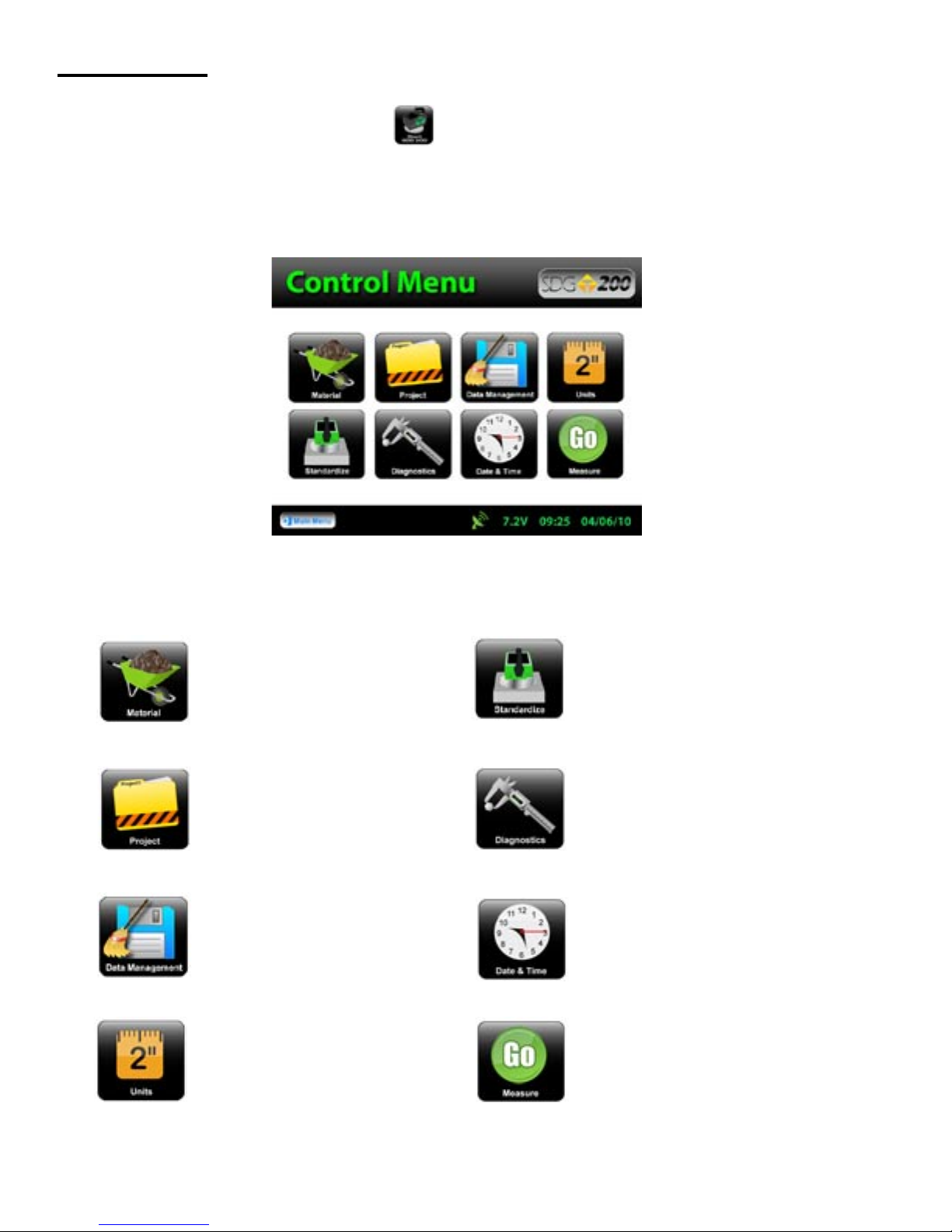

Page 14

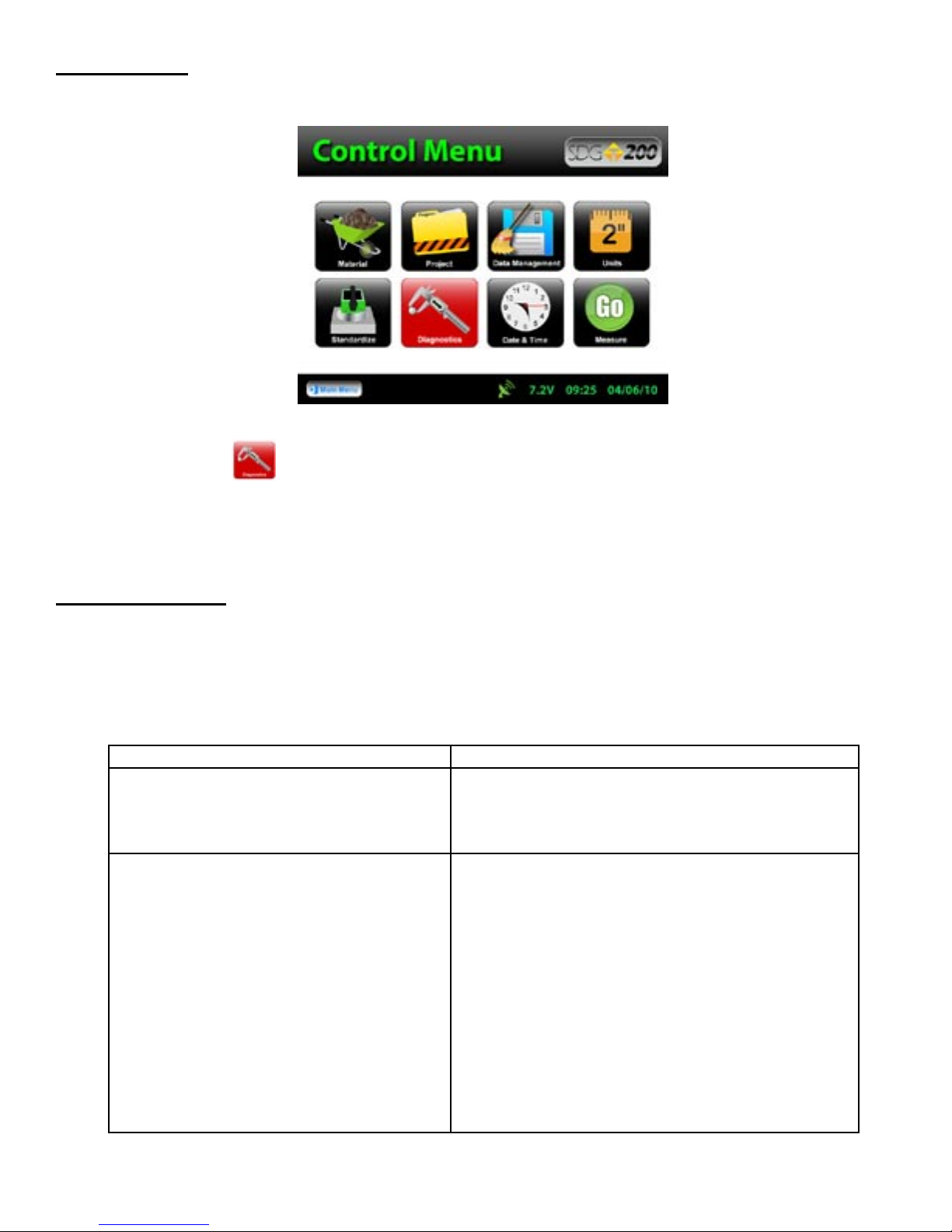

Control Menu

From the Main Menu Press Start SDG 200 to obtain the Control Menu. From this menu, you will find

the icons listed below.

Opens the material details screen

Opens the project details screen

Opens the data management

screen. Here you can delete, download and print job files

Opens the units screen. Here you

can toggle, kg/m3-lbs/ft3, F°-C°,

in-mm

Starts the standardization process

Opens the diagnostics screen

Opens the date and time screen

Starts the measurement process

14

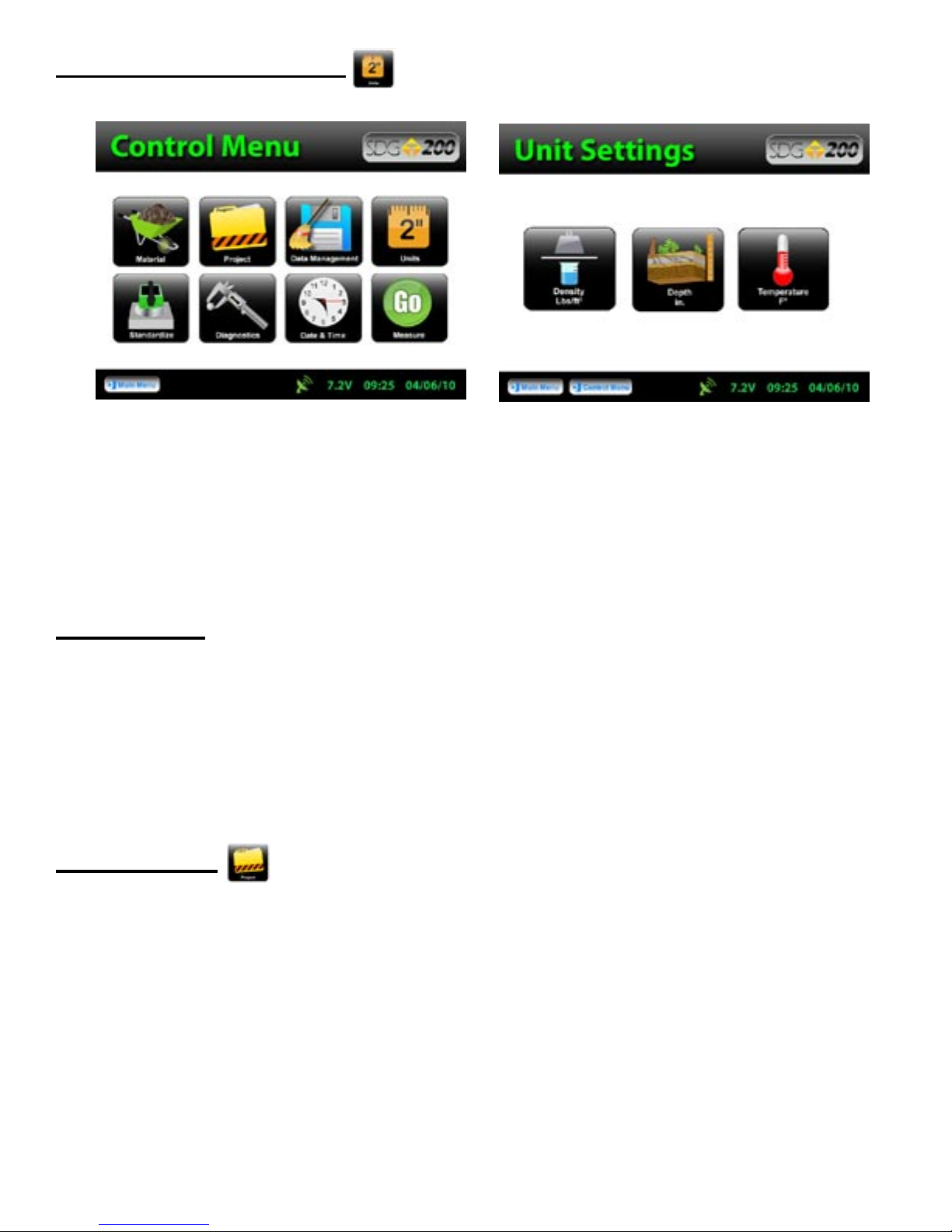

Page 15

Select Measurement Units

From the Control Menu, Press Units. Density, Temperature and Depth can be toggled independently between

System International (SI “metric”) and U.S. Customary Units. For example, you can set your Density in lb/ft3

while the Temperature is set for Celsius and Depth set to Inches. Press Control Menu on the taskbar to return to

the Control Menu.

Data Logging

The SDG 200 saves data automatically under the Project name that is current while readings are being taken.

Data stored includes all Project and Mix details as well as Dry Density, Wet Density, Percent Moisture,

Volumetric Moisture, Percent Compaction, Soil Temperature, Date, Time, GPS Position, GPS Time and GPS

Date.

Project Details

The SDG 200 is configured to store 10 unique projects that are identified by user entered descriptions. If 10

projects have been defined in the SDG 200 and an 11th project is required, one of the original 10 will need to

be modified to reflect the new project. The details of the new project will need to be input by editing the details

of a previously stored project. Once the old projects are overwritten with new information, the old information

is gone and the new information is saved in the gauge. Previously store data files with the old material

information, however, will not be overwritten.

You may revisit each Project at any given time to continue taking readings. Data from readings taken within

each project will store in the order of which they were taken. If material details change within a project or

project details are added, data for readings taken after the changes will continue to store in the same data file

in the order of which they were taken. Only by changing the Project Name itself will the data be stored in a

separate data file.

15

Page 16

Project Details

The default Projects stored in a new SDG 200 will have generic Project names (i.e. Project1, Project2, etc)

along with generic Project details (i.e. My Street, My Road, Contact). Project Detail screens will resemble the

Material Detail screen such that you are able to select your Project using the up and down arrows.

The green highlighted project is the CURRENT PROJECT. Readings taken will store in a data

file using the CURRENT PROJECT NAME. If the gauge is shutdown, the current project prior to shutdown

will remain the current project when started back up.

Keep track of your projects by entering detailed information into Project Details.

Editing Project Details

From the Control Menu, Press Project for the Project Details screen. The project highlighted in green

on the left is displayed in detail on the right. To edit the details of this project, Press Edit Project.

16

Page 17

Editing Project Details

There are four black buttons labeled

Project Location Location Contact.

By pressing one of these labeled buttons, you will enter the screen that allows you to store information

for that Project.

For example Press Project, a keyboard allowing you to change the default name will appear. Press

Clear if you would like to start over with a new name. Press Shift to toggle from lower

to upper case letters. Once editing has been completed, Press Enter.

Define, Edit or Upload Material Properties

The density determined by the SDG 200 is highly material dependent so it is extremely important that the

material properties from the Proctor Test and Gradation Report for the soil being tested are input accurately into

the gauge.

The SDG 200 is configured to store 20 unique materials that are identified by user entered descriptions. If 20

materials have been defined in the SDG 200 and a 21st material is required, one of the original 20 will need to

be modified to reflect the material properties of the new material. The properties of the new material will need

to be input by editing the properties of a previously defined material. Once the old material properties are

overwritten with new information, the old information is overwritten and the new information is saved in the

gauge.

The SDG 200 will have default defined materials stored in each of the 20 unique locations. The following

sequence explains how to input new material properties through the keypad or by USB upload and how to edit

previously input material definitions.

17

Page 18

Define, Edit or Upload Material Properties

Note: Be sure that the units of the gauge are set for the same units as the material you are uploading.

If, for example, the gauge was set in U.S. Customary units (ex: 150 lb/ft3) and you were to upload the

material in SI units (2402.8 kg/m3) the gauge will notify you that the density is out of range. However, it

will continue to load the material. If you were to switch to SI units AFTER the material has been loaded,

the density would convert the 2402.8 as if it were in lb/ft3 and result in 38,489.2 kg/m3. Correct this

by deleting the material, change the units of the gauge and reload the material or by simply editing the

density in the material setup.

See Part 5 for explanations of the Material Properties.

See Part 6 for explanations of gradation and Proctor test reports.

See Appendix A for explanations of the MTL Generator

Defining and Editing a Material

Here you may use the green up or down errors to select a new material for editing or change an existing

material. The green highlighted material is the CURRENT MATERIAL that the gauge will use when

taking readings. Prior to exiting this screen, be sure this is the material you want and the information to

the right has been verified. Press Control Menu on the Status Bar (bottom middle) to return to the Control

Menu. If the gauge is shutdown, the current material prior to shutdown will remain the current material when

started back up.

!! Note: The sum of %Greater the 3 inches, %Gravel, %Sand, and %Fines must add up to 100%. The

default values programmed in the SDG software add up to 100%. As soon as one of those values is

edited, the sum will no longer add up to 100% and an error message will be displayed, however, after the

initial error the gauge will allow you to exit and begin taking readings. THIS IS NOT RECOMMENDED

AND WILL GIVE INACCURATE RESULTS!!

!! Note that Max Dry Density and Dry Density Offset must be entered in the same units in which the

gauge is configured to output results. Example: If the gauge is configured to measure in pcf, input Max

Dry Density in pcf !!

18

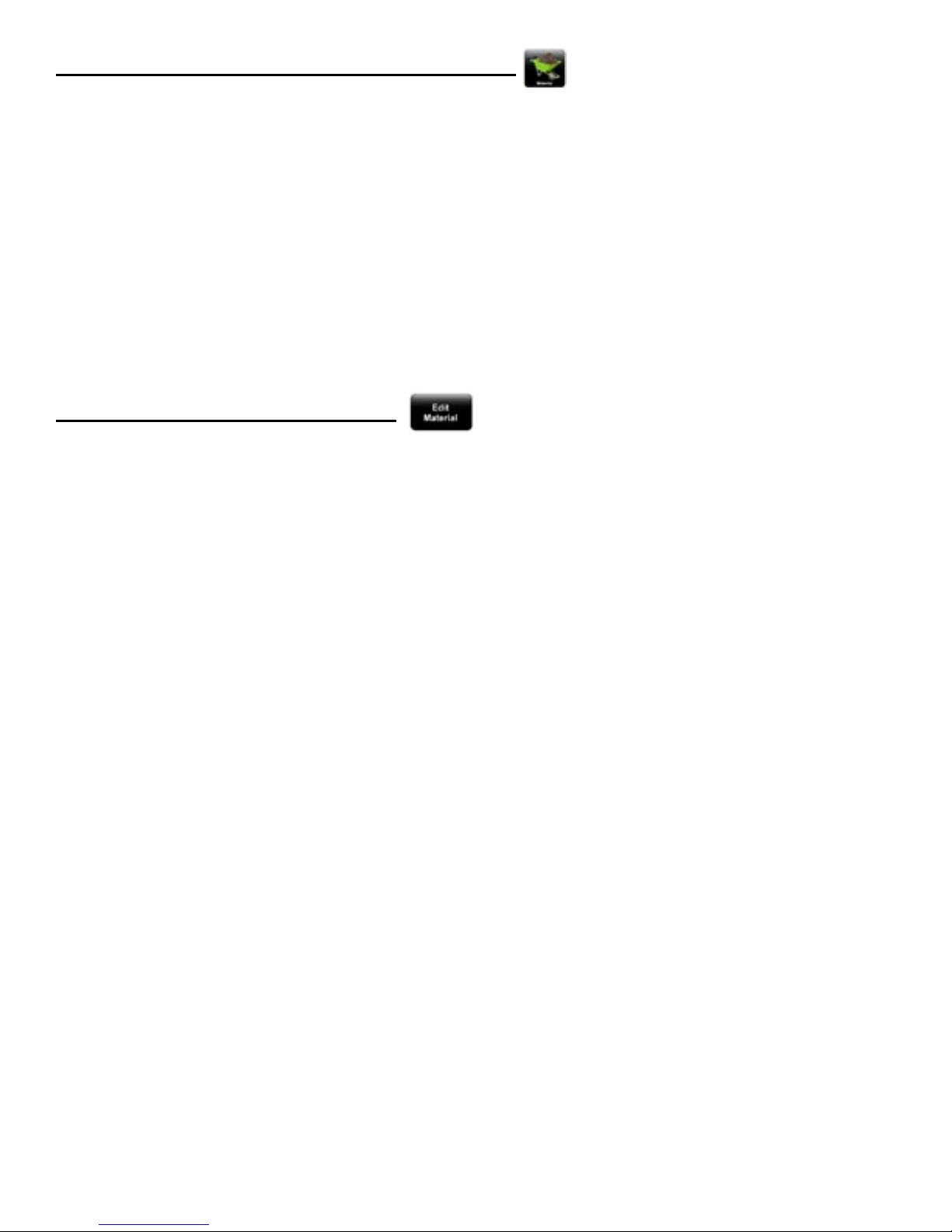

Page 19

Defining and Editing a Material

From the Control Menu, Press Material for the Material Details screen. The material highlighted in

green on the left is displayed in detail on the right. To edit the details of this material, Press

Edit Material.

There are fifteen material properties for each material. Eight of these material properties are listed on Page one

of the Edit Material Page and the remaining seven are listed on Page 2. Each can be edited individually by

pressing its corresponding label which prompts a numeric or alpha numeric keypad.

19

Page 20

Defining and Editing a Material

Once editing is complete, Press the Back button located on Page 2 to verify your changes on the

Material Details page.

Setting Measurement Offsets

The SDG 200 has been designed to determine the moisture and density in a compacted soil sample without

the need for any offsets. The ability to measure moisture and density is based on an empirical model that

was developed by studying common soil types at near optimum moisture contents with typical particle size

distributions. As the SDG 200’s measurement performance is based on this empirical model, there will be

occasions where the soil being measured is so different from one that has been studied previously that an offset

may be required to enable the SDG 200 to produce acceptable results.

20

Page 21

Setting Measurement Offsets

Offsets for Wet Density and % Moisture can be set manually by the operator in cases where the SDG 200

does not appear to be comparing favorably to collocated measurements. The offsets are simply added to

or subtracted from the Wet Density and % Moisture calculated by the SDG 200. Dry Density, Volumetric

Moisture, and % Compaction are then recalculated based on the offset values of Wet Density and % Moisture.

The Wet Density and % Moisture offsets are saved in each data record

with the results of the corresponding test in the .mnt file.

Wet Density and % Moisture offsets are entered into the SDG 200 as a material property and are displayed and

edited identically to other material properties.

Wet Density and % Moisture Offsets can be either negative or positive. To enter a positive offset simply type

in the offset value that will be added to the current measurement. To enter a negative offset, use the (-/+) key to

enter a negative sign then enter the value that will be subtracted from the measured value. After the offsets are

applied to the Wet Density and % Moisture, Dry Density and Volumetric Moisture are calculated by the SDG

200 as follows:

The % Moisture Offset is input as a percentage. For example, if the SDG 200 is consistently measuring %

moisture as 7.5% and a collocated reference measurement is consistently measuring 5%, inputting an offset of

-2.5 will adjust the SDG 200 to yield results similar to your reference measurement.

The Wet Density offset is input in units of mass/unit volume. If the gauge is set to operate in kg/m³, the offset

will need to be entered in kg/m³. If the SDG 200 is configured to operate in lb/ft³, the density offset will need

to be entered in lb/ft³.

The moisture, density, and compaction values displayed by the SDG 200

and logged in the .mnt file reflect the application of the user selected offsets

Failing to enter the Wet Density Offset in the same units that the

SDG 200 is Configured to measure in may result in significant errors.

21

Page 22

Determining Offset Values

Methods used to determine what offsets are appropriate will vary from application to application, but will all

generally follow the same steps. In order to determine an offset, a reference measurement will be required.

That reference may include one or more of the following: a Nuclear Density Gauge, Oven Dry Moisture

Measurements, Speedy Moisture Measurements, Sand Cone Apparatus, Balloon Density Apparatus, Density

Drive Cone or other applicable equipment.

Multiple measurements should be taken at three to five representative locations with both the SDG 200 (make

sure both offsets are set to 0) and your appropriate reference equipment. Note the results by each method at

each location and determine the average difference between the SDG 200 results and the reference measurement

results. This average difference will be your offset. If the SDG 200 measures lower than your reference

measurement your SDG 200 offset will be positive. If the SDG 200 measures higher than the reference gauge,

your SDG 200 offset will be negative.

At a particular location, if you are not able to get repeatable measurements with either the SDG 200 or your

reference equipment, there may be an anomaly in the soil that effects the equipment and a new location should

be selected.

!!Arbitrary selection of offsets is not recommended!!

Uploading a Material

A material definition that has been set up using the SDG 200 Gradation Calculator and saved on a USB flash

drive can be uploaded to the SDG 200.

From the Material Details screen choose the material name you wish to overwrite by pressing the up or down

arrows. The green highlighted material name displayed prior to uploading the material will be the

location the new material will be stored. The information that is stored in this location will be overwritten and

you will not be able to retrieve it again. Once you have made your choice, Press Upload Material.

Be sure to have your USB drive inserted into the USB port located on the back of the gauge. Press

Upload.

22

Page 23

Uploading a Material

The file name of the materials located on the USB drive will appear on the left and some details identifying that

specific material will be displayed on the right. Use the up or down arrows to highlight the material

you wish to upload. Once verified, Press Select to upload the material information into the gauge.

Continue to select additional materials to upload or Press Back to view the material in detail.

Note: Be sure that the units of the gauge are set for the same units as the

material you are uploading. If, for example, the gauge was set in U.S.

Customary units (ex: 150 lb/ft3) and you were to upload the material in

SI units (2402.8 kg/m3) the gauge will notify you that the density is out

of range. However, it will continue to load the material. If you were

to switch to SI units AFTER the material has been loaded, the density

would convert the 2402.8 as if it were in lb/ft3 and result in 38,489.2 kg/m3.

Correct this by deleting the material, change the units of the gauge and

reload the material or by simply editing the density in the material setup.

See Appendix A for explanations of the SDG MTL Generator

23

Page 24

Part 2: Running a Test

Measurement Pattern

A complete test consists of five individual measurements taken in a “cloverleaf” pattern at the test location.

Each of the five measurements takes about 10 seconds. The SDG 200 is placed in position 1 for the first

measurement and moved clockwise around position 1 as indicated in the illustration above. Upon completion

of each reading, the SDG 200 will prompt the operator to move to the next location.

Surface Preparation

While the SDG 200 unit stands off from the soil, surface condition is still important. It is necessary for the soil

surface to be free from any loose and disturbed material, stones, large air pockets or ‘divots’ and other debris.

It is also important that the soil surface be smooth. If it is not, smooth out the surface or move the unit to a

location where the surface is smoother. The SDG 200 should not rock side-to-side when placed in a location to

take a measurement; if it does, move to a new location or remove the obstacle that is causing the rocking being

careful to not measure on top of any ‘divot’ left by removal of the object.

Large metal objects should not be within three feet of the gauge or underneath the soil while taking

measurements. Measurements within ten feet of buried power lines should be avoided. When possible,

measurements taken with an SDG 200 near an edge or vertical obstruction should be taken at least three inches

from that edge.

When placing the SDG 200 at a location for a measurement, do not push down on the unit to ‘seat’ the

unit in place. Set the unit down on the surface and check to see if it rocks side-to-side.

Do not touch the SDG while it is taking a measurement.

24

Page 25

Measure Density

Turn the SDG 200 on by pressing the ON button. After a few seconds the TransTech splash screen

will appear followed by the Main Menu screen.

The Main Menu screen will display six options.

Start SDG200 Internet (Coming Soon) Calculator Contact TransTech GPS

Control and Update Software.

From the Main Menu, Press Start SDG 200 to get to the Control Menu. Press Material to

display and verify the details of the current material that will be used for this test. Once verified, Press Control

Menu from the status bar.

25

Page 26

Measure Density

Press Project to verify the Project Name that the data will store under as well as the Project Details.

Once verified, Press Control Menu from the status bar.

Press Measure, to enter into the Soil Reading screen. In the bottom left corner, the name of the material

to be tested and project are displayed for verification as well as the temperature of the soil. In the bottom right

corner, the GPS information is displayed. The cloverleaf pattern is also displayed for your convenience with the

highlighted position being the current position to measure.

26

Page 27

Measure Density

Position the gauge on the material in position 1 as it appears on the screen. Do not touch the gauge while it is

busy taking a measurement. When reading 1 is complete, the green 2 will be illuminated. Move the

gauge to position two and press 2. Repeat this for the five measurements. After the fifth measurement has been

taken, the in place density and moisture content will be calculated and displayed on the screen. Here you can

choose to “Accept” or “Reject” the recording of the averages into the data file.

After pressing “Accept”, the Enter Location screen will appear allowing for a Description of the

location to be entered as well as the Operator name. This information will be stored in the data file and will

remain for future readings until edited. Once editing is complete, Press Back to return to position one

of the Soil Reading screen to continue taking measurements. If you chose to press “Reject”

instead of “Accept”, the reading will not be stored and the gauge will return to position one of the Soil

Reading screen.

27

Page 28

Select a Different Material to Test

At any time you wish to go back and change the Material to be tested you may do so.

From the Control Menu, Press Material. By using the up or down arrows you can change

the material, return to the Soil Reading screen and begin testing. However, keep note that these readings will

be stored under the same Project Name that you were just using (the current Project). The data file name will

be the same as the Project Name and will consist of the details on any and all materials used while that Project

Name is current or active. Only by changing the current Project Name will you receive a separate data file.

28

Page 29

Part 3: Data Storage and Downloading Data

The SDG 200 saves two types of data files. One file contains information that is referred to as diagnostic data,

the other file contains information that is referred to as measurement data. Data files can be removed from the

SDG 200 via a USB flash drive.

Measurement Data

The measurement data is a record of all of the tests performed with the instrument (a test is made up of the 5

individual measurements taken in a cloverleaf pattern). It is a semi colon delimited text file containing the

following information:

Internal: Software Version; Gauge SN;

Results: Dry Density; Wet Density; Moisture Content (%);

Volumetric Moisture; % Compaction;

Special Features: Soil Temperature; SDG Time; SDG Date; GPS Position;

GPS Time; GPS Date;

Project Details: Project Name; Project Locations; Project Contact;

Description; Operator;

Material Details: Material ID; Description; Max Dry Density;

Optimum Moisture; %Greater than 3in; %Greater than in;

%Gravel; %Sand; %Fines; PL; LL; Cu; Cc; A coefficient;

B coefficient; Dry Density Offset; % Moisture Content Offset

When the measurement file is downloaded it is automatically named by the SDG 200. The following naming

format is used:

Project Name:month:month:day:day:hour:hour:minute:minute.mnt

Project 103061510.mnt for Project 1 of March 6, 3:10 PM

Diagnostic Data

The diagnostic data contains all of the measurement data as well as information that indicates how the SDG 200

is performing. This data is of little interest to gauge owners and operators but will be very helpful to TransTech

in the event of an instrument malfunction. Similar to the measurement data, the diagnostic data is saved at the

conclusion of a complete measurement. Data from partial measurements are not logged in memory.

When the diagnostic file is downloaded it is automatically named by the SDG 200. The following naming

format is used:

Project Name:month:month:day:day:hour:hour:minute:minute.dat

Project 103061510.dat for Project 1 of March 6, 3:10 PM

29

Page 30

Storage Capacity

The SDG 200 has the capability to store up to twenty detailed projects and twenty detailed materials with an

overall storage capacity of over 1000 MB for all data files. Upon completion of a set of five measurements, the

complete details of the test will be written to a file and saved on the instrument ONLY AFTER THE ACCEPT

BUTTON HAS BEEN PRESSED. This feature is new to the SDG 200 where the older 100 series saved

automatically. With the 200 series, the gauge gives the operator the option to accept or decline.

On occasions that operators do not complete the series of five readings that make up a complete measurement

series and either exits out of the reading routine or turns off the instrument, that incomplete record will not be

stored. If the operator tries to exit out of the reading as it is being taken a warning will display: “Attention!

Measurement currently running; please stop measurement.” Simply wait for the measurement to complete.

If the operator decides to decline the completed set of readings, the gauge will not store that set.

Downloading Data

From the Control Menu, Press Data Management. Project files will be stored and downloaded here.

Scroll down to the Project you would like to download using the arrows located at the top left corner

of the screen. Insert the USB flash drive into the USB port located on the back of the gauge. Press “Download

DAT & MNT” if you wish to download the measurement data as well as the diagnostic data.

Press “Download MNT” if you wish to download the measurement data only. You will be

prompted to insert the USB flash drive if you haven’t already and then to press Download. The gauge

will return to the Data Management screen which now displays BUSY

in the top right hand corner. Downloading is complete when the gauge displays READY.

Deleting a Project File

When and if you wish to delete a Project, be sure to highlight the correct project and Press “Delete”.

A warning will display to be sure you wish to delete the file. Once deleted, you will no longer be able to

retrieve the measurement nor the diagnostics data.

30

BUSY

READY

Page 31

Part 4: Maintenance and Troubleshooting

In the event that the SDG 200 were to malfunction internal information about the gauge can be obtained and

relayed to the factory. In the event that a repair is required, it is strongly recommended that authorized factory

service be obtained. Unauthorized repair or maintenance by the user will void the unit’s warranty

From the Control Menu, Press Diagnostics and the internal information needed for the factory to track

your gauge will display. This information consists of the Serial Number, Software Version and the date the

gauge was last calibrated.

Maintenance

The SDG 200 has been designed to require a minimum of maintenance or service. Normal care in use should

insure long and trouble free operation.

Keep SDG bottom surface clean:

For accurate readings, the SDG 200 should have a smooth interface with the surface. Try not to place the SDG

200 on top of large rocks that would cause the gauge not to sit properly. Also, do not try to “dig” the gauge into

the material.

Touchscreen:

Do not clean the touchscreen with abrasive products, solvents or other harsh cleaners. Apply window cleaner to

a clean soft rag and wipe the surface clean.

Factory Calibration:

Yearly recalibration of the gauge is recommended to maintain consistency and accuracy for the electronic

components.

31

Page 32

Maintenance

The Diagnostic button on the Control Menu will turn red as a reminder. Only authorized distributors or

the factory are able to perform this type of calibration.

Troubleshooting

The chart below provides guidance to a few suspect conditions.

Problem

Buttons Sticking/Frozen Software

Incorrect Density Reading

Repress the frozen button firmly for three seconds.

Be sure not to drag your finger from one button to

the next. If this does not work, reset the gauge by

turning it off and then back on.

Clean off sensor plate

Check Current Material Details -be sure you have

entered all details correctly (ex. Does the %Gravel,

%Sand and %Fines add up to 100%?)

Check Offsets-if you entered a Dry Density Offset or

a %Moisture Offset be sure that the values selected

make sense (see the Definitions and Calculations

section of this manual)

Check Units-be sure all of the values for the Density

whether uploaded or entered, are in the same units

Call Factory

Remedy

32

Page 33

Troubleshooting

The chart below provides guidance to a few suspect conditions.

Problem

Battery Problems/Gauge Keeps Shutting

Down/Gauge Will Not Come On

Data is not recording Check Current Project Name-data readings will

GPS Communication Errors

Part 5: Definitions and Calculations

Measurement Results

Remedy

Ensure battery pack is plugged in

Check battery voltage-plug gauge into charger and

wait for the green LED to illuminate to indicate a full

charge

Call Factory

store on the Current Project only, be sure you have

the correct Project name set on the gauge (Verify the

name of the Project and Mix on each reading screen)

Call Factory

The following values are reported at the end of a measurement:

Wet Density is the total mass of material per unit volume in pcf or kg/m³

Volumetric Moisture is the mass of water per unit volume in pcf or kg/m³, measured by the SDG.

% Moisture = water content as percent of dry density =

Dry Density = Wet Density – Volumetric Moisture

% Compaction = Dry Density

Max Dry Density

33

Page 34

Definitions of Material Properties

The following descriptions and material properties need to be entered in the gauge for measurement or data

reporting purposes:

Material ID: Usually a numeric entry that will associate the soil being tested with the gradation and proctor

test report. Examples of soil or material ID’s may include ’33.1099’ or ‘776632. Material IDs are limited to 13

characters.

Description: Typically a brief description of the soil that allows the operator to visually identify the material

being tested. Examples may include ‘clayey sand red’, or ‘light brown silt’. Descriptions are limited to 13

characters.

Max Dry Density: This is the maximum dry density or target density or Proctor number for the material being

tested. It is input in pcf or kg/m³. Be sure the units of the gauge are in the same units you wish to enter.

This value can be found in a Proctor test report completed in accordance with ASTM D 1557 or ASTM D 698.

This is used by the SDG as the value against which the measured dry density is compared to calculate percent

compaction.

Opt Moisture: This is the optimum moisture content for the material being tested. This value can be found in

a compaction test report completed in accordance with ASTM D 1557 or ASTM D 698.

PL: Plastic Limit. This property describes soils with a high clay and silt content. It is defined as the moisture

content in percent at which the sample begins to exhibit plastic behavior as it transitions from having semi-solid

properties. This value is determined as outlined by ASTM D 4318.

LL: Liquid Limit. This property describes soils with a high clay and silt content. It is defined as the moisture

content in percent at which a sample begins to exhibit liquid behavior as it transitions from having plastic

properties. This value is determined as outlined by ASTM D 4318.

Cu: Coefficient of Uniformity. Cu is defined as the ratio of D60 / D10, where D

is the particle diameter of

60

which 60% of the sample is smaller, and D10 is the particle diameter of which 10% of the sample is smaller. Cu

can be calculated from values taken from a particle size distribution plot defined by ASTM D 422.

Cc: Coefficient of Curvature. Cc is defined as D

2

/ (D60 x D10). Cc can be calculated from values taken from a

30

particle size distribution plot defined by ASTM D 422.

% Gravel: The percentage of material by mass passing a 3 in. (75mm) sieve but retained on a #4 (4.75mm)

sieve. %Gravel can be taken from a particle size distribution report defined by ASTM D 422.

% Sand: The percentage of material by mass passing a #4 (4.75mm) sieve but retained on a #200 (75μm).

%Sand can be taken from a particle size distribution report defined by ASTM D 422.

% Fines: The percentage of material by mass passing a #200 (75μm) sieve. %Fines can be taken from a

particle size distribution report defined by ASTM D 422.

Note: Be sure that the % Greater than 3”, % Gravel, % Sand and the % Fines add up to 100%.

% Greater than in: The percentage of material by mass retained on a inch (19.0mm) sieve. % Greater

than inch can be taken from a particle size distribution report defined by ASTM D 422.

% Greater than 3 in: The percentage of material by mass retained on a 3 inch (75 mm) sieve. % Greater than

3 inches can be taken from a particle size distribution report defined by ASTM D 422.

34

Page 35

Part 6: Standardization of the SDG

To assure that the SDG 200’s ability to make consistent measurements has not been compromised, a daily

measurement should be taken on a reference material and tracked day to day for any unacceptable variations. A

metallic plate has been installed in the bottom of the SDG 200 carrying case that is suitable for this purpose.

Although this verification is referred to as a standardization of the gauge, the results of the

standardization in no way influence the measurement of the gauge, they only serve to alert the user to a

change in the way that the gauge is operating. Unexpected changes in the standardization values should

be noted and discussed with Product Service at TransTech.

Standardizations are performed inside the carry case. Located at the bottom of the case is a steel plate.

Position the gauge on top of the plate inside the case. Be sure the gauge screen is facing you, if it is placed

in the case backwards the handle will prevent proper seating you will get a false reading. The case should

not be on top of or around (10ft.) any large metal objects. Turn the gauge ON and proceed to the Control

Menu.

Press Standardize, to obtain the above screen. Press Start, and do not touch the gauge while it

is busy.

The acceptable range for the A and B values are displayed on the screen, however, the gauge will respond with a

PASS or Fail based on these ranges automatically.

35

Page 36

Part 6: Standardization of the SDG

If you receive a Fail, prior to calling the factory try the following:

1) Reposition the gauge/case to another location (outside preferably)

2) Be sure that you are testing the gauge inside the carry case that was provided with the SDG.

The gauge and case are paired during production to determain the standardization.

3) Do not place the case on the back or near an automobile as well as any other large metal

objects and/or wires

4) Be sure that no foreign objects have adhered to the bottom of the gauge or on the steel plate

5) Shut off all cell phones within 10ft of the gauge

WARNING: THE STANDARDIZATION OF THE SDG 200 WILL ONLY WORK WITH THE PLATE

IT HAS BEEN ISSUED TO. IF YOU RECEIVE A FAIL RESULT, CHECK TO BE SURE THE SERIAL

NUMBERS LOCATED ON THE GAUGE AND THE STANDARDIZATION PLATE ARE THE SAME.

WARNING: THE STANDARDIZATION OF THE SDG 200 MAY GIVE A FALSE “FAIL” IF TEST IS

TAKEN TOO CLOSE TO METAL OBJECTS, POWER LINES OR OTHER ELECTRICAL DEVICES

THAT MAY BE TOO CLOSE TO THE GAUGE. TURN THE GAUGE OFF AND MOVE THE GAUGE

ATLEAST 10 FEET FROM THESE OBJECTS. IF AFTER THESE PRECAUTIONS ARE TAKEN

THE GAUGE STILL DISPLAYS A “FAIL” CONTACT YOUR DISTRIBUTOR.

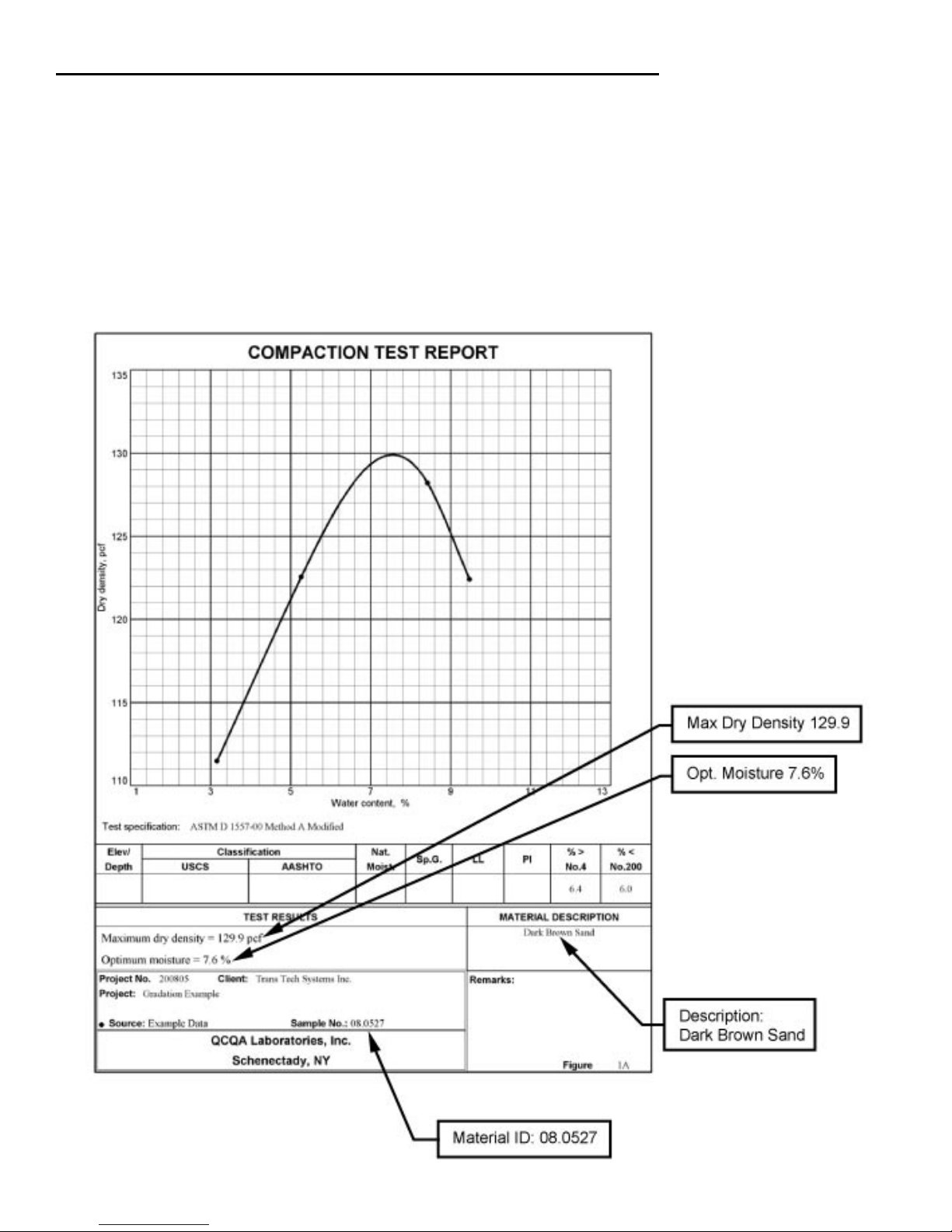

Part 7: Explanation of Gradation and Compaction Reports

All of the information needed to configure an SDG 200 to measure the density and moisture content of

a material is available on Compaction Test Reports (Proctor Test) and Particle Size Distribution Reports

(Gradation/Sieve Analysis) completed as outlined by ASTM D 422 and ASTM D 1557. In order to configure

the gauge to operate on materials that have high clay and silt contents, results from an Atterberg limits test

(ASTM D 4318) will be needed as well.

36

Page 37

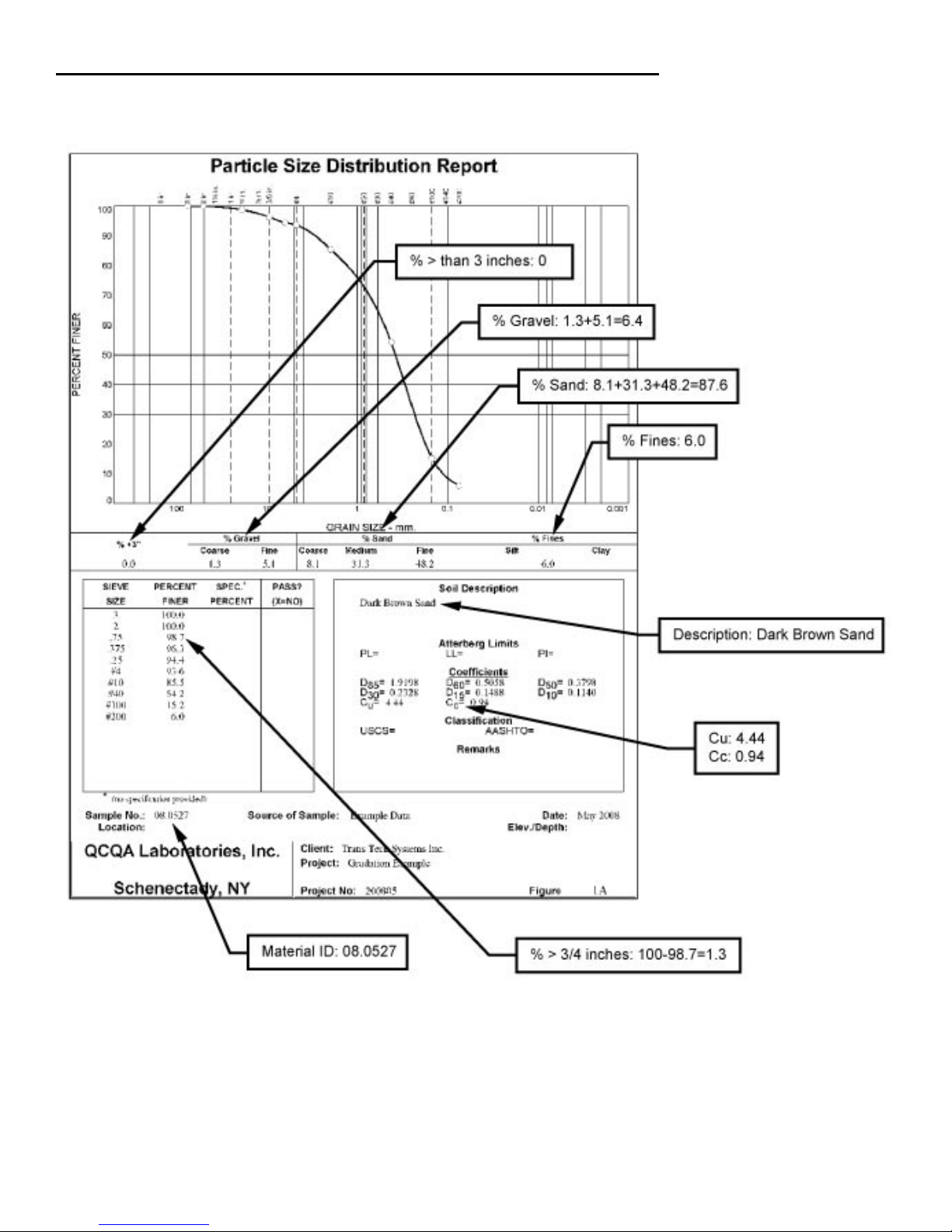

Part 7: Explanation of Gradation and Compaction Reports

The thirteen properties that will need to be entered through the SDG’s user interface are shown on the Material

Details screen above and defined below. Further definitions of these properties can be found in Part 5 of the

SDG Operators Handbook. Examples of a gradation report and compaction test are on the following pages.

The Material ID is any identifier that can associate the material being evaluated with its test report. A report

number or sample number should be entered here. For the example shown, 08.0527 is the Soil ID. Do not

enter letters or characters as part of the Soil ID.

The Description should be a used to describe the material and help make a visual association with the material

being tested. Dark Brown Sand is used for this example.

The Max Dry Density is the maximum practically achievable density a soil can have. This value is determined

experimentally by performing a “Proctor” Test (ASTM D 1557). 129.9 pounds per cubic foot is taken directly

from the example compaction test report.

The Optimum Moisture Content is the water content (%) at which the material can be compacted to its

maximum dry density. This is determined experimentally by performing a “Proctor” Test (ASTM D 1557).

7.6% is taken directly from the example compaction test report.

PL and LL are the plastic and liquid limits used to describe the plasticity of materials with a high silt and clay

content. They are determined by following the test procedure outlined by ASTM D 4318. This example is a

sandy material so PL and LL are input as 0.0. If plasticity tests had been performed on this material, the results

would be given on the gradation report.

Cu and Cc are the Coefficient of Uniformity and Coefficient of Curvature of the material. They are calculated

values that are typically used describe the particle size distribution a soil. In this example, Cu = 4.4 and Cc =

0.94

% Gravel is the summation of the coarse and fine gravel in a sample of material. Some gradation test results

will report this as a single value while others will break it down into the coarse and fine fractions. The SDG

only recognizes the total percentage of gravel so the coarse and fine fractions will need to be added together

before entering them. The gradation report shown breaks the gravel content out into Fine and Coarse fractions

so those will need to be added together. 1.3% + 5.1% = 6.4%

% Sand is the summation of the coarse, medium and fine sand in a sample of material. Some gradation

test results will report this as a single value while others will break it down into the coarse, medium and fine

fractions. The SDG only recognizes the total percentage of sand so the coarse, medium and fine fractions will

need to be added together before entering them. The gradation report shown breaks the sand down into coarse,

medium, and fine fractions, so the percent sand in the example shown is 8.1% + 31.3% +48.2% = 87.6%.

% Fines is the summation of the silt and clay in a sample of material. Some gradation test results will

report this as a single value while others will break it down into the fractions of silt and clay. The SDG only

recognizes the total percentage of fines so the coarse, silt and clay fractions will need to be added together

before entering them. In this example, the percent fines is 6.0%.

37

Page 38

Part 7: Explanation of Gradation and Compaction Reports

% Greater than 3 inches is the percentage of the sample that is retained on the 3 inch sieve. Typical gradation

tests report the “percent finer” or percentage that passes a particular sieve. In this example the percent finer for

the 3 inch sieve is 100% so 0% of the sample is retained on the 3 inch sieve.

% Greater than 3/4 inch is the percentage of the sample that is retained on the 3/4 inch sieve. Typical

gradation tests report the “percent finer” or percentage that passes a particular sieve. In this example the percent

finer for the 3/4 inch sieve is 98.7% so 1.3% of the sample is retained on the 3/4 inch sieve.

38

Page 39

Part 7: Explanation of Gradation and Compaction Reports

!! Note: The sum of %Greater the 3 inches, %Gravel, %Sand, and %Fines must add up to 100%. The

default values programmed in the SDG software add up to 100%. As soon as one of those values is

edited, the sum will no longer add up to 100% and an error message will be displayed until all of those

gradation values are entered such that the sum is 100% again.!!

39

Page 40

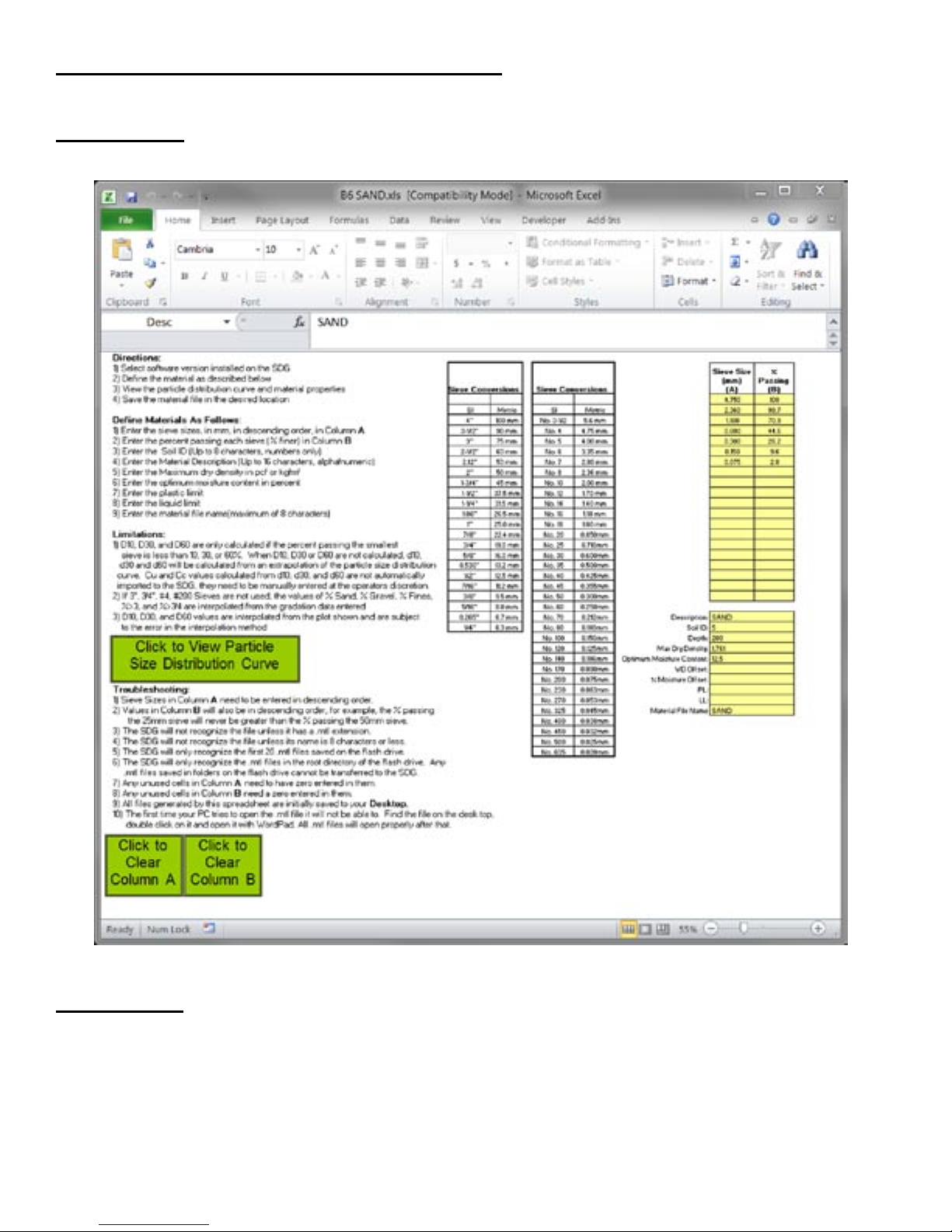

Appendix A: Using the SDG MTL Generator

The SDG MTL Generator is a spreadsheet based application developed to determine the gradation inputs that

the SDG needs to measure moisture and density of a soil in cases when the gradation performed was not done

in accordance with ASTM D 422. The MTL Generator will allow users to input the gradation information that

they have and will produce a particle size distribution curve from which the Cu, Cc, %Gravel, %Sand, %Fines,

%>3/4” and %>3” values will be taken. Those values will be organized in a text file that can be uploaded onto

the SDG via a USB flash drive.

There are two MTL applications. One application allows users to input any sieve size, in millimeters, that

was used in their gradation. The second application is useful when an ASTM D 422 type gradation report is

available and users simply want to type the report summary into their PC and generate a text file to upload into

the SDG.

Getting Started:

The MTL applications are Microsoft Excel spreadsheets that contain macros. For the applications to operate

properly, Excel will need to be configured to run macros on any computer you wish to use these on. To change

the macro settings on your computer, follow these steps.

1. Open up Excel

2. Select the Tools menu

3. Select the Macro option

4. Select the Security option

5. Select the Security Level Medium and select OK

Once this setting is selected, Excel will ask you to confirm that you want to allow these applications to enable

macros each time they are opened. Choose enable macros when prompted to do so.

The Gradation Calculator has two separate screens. Screen one explains the use of the calculator, contains

conversion tables for US customary and metric sieve sizes, contains the inputs for the sieve sizes and percent

passing those sieves and has inputs for the material descriptors that make up the material definition file.

40

Page 41

Appendix A: Using the SDG MTL Generator

Screen One:

Screen Two:

The second screen of the MTL displays the plot of the particle size distribution curve and displays a table of all

of the material properties that will be converted into a text file to upload to the SDG.

On Screen 1, input the sieves used in the gradation (in mm) and the percent of material passing each sieve in

columns A and B. The data must be entered in order of decreasing sieve sizes, and the first sieve entered should

be of a size such that 100% of the material passed that sieve.

41

Page 42

Appendix A: Using the SDG MTL Generator

Screen Two:

Once the gradation data is entered, fill in the rest of the material definition information in the yellow cells on

Screen 1. The explanations and limitations for those definitions are explained on Screen 1.

Clicking on the button to view the Particle size distribution curve displays Screen 2. The gradation curve will

be visible, as well as a table of all of the properties that define the material. Clicking on the button to save and

view the material properties file creates a text file with a .mtl extension of your PC’s desktop. (Note: the first

time you open a .mtl file on your PC, you will need to manually open it from the desktop with WordPad

or similar text file editor. After that, your PC will always open .mtl files automatically.)

The .mtl file can now be copied to a USB flash drive to be uploaded onto the SDG as explained on page 18.

The SDG will only recognize the first 20 .mtl files on the USB flash drive, and it will only recognize them

if they are in the root directory of the flash drive. If .mtl files are in sub folders on your flash drive, the

SDG will not recognize them.

42

Page 43

Appendix A: Using the SDG MTL File Tool

The MTL File Tool is designed to allow users to easily create .mtl files to upload into the SDG. If a gradation

report completed in accordance with ASTM D 422 is available, all of the information on that report can be

entered into the table on the Gradation file tool and a .mtl file will automatically be generated and saved to the

Desktop of your PC. This file can then be transferred to a USB flash drive and installed directly into the SDG

as explained on page 18.

43

Page 44

TransTech Systems Product Warranty

The Company warrants to the Purchaser that the product delivered hereunder will be free from

defects in material or workmanship and be the kind and quality designated or specified in the contract

or purchase order. This warranty shall apply only to defects appearing within one (1) year from the

date of shipment by the Company.

If the product delivered hereunder does not meet the above warranty and if the Purchaser promptly

notifies the Company, the Company shall thereupon correct any defect, including nonconformance

with the specifications, either (at the Company’s option) by repairing any defective or damaged parts

of the product, replacing the product, or by making available the necessary repaired or replacement

parts.

The liability of the Company under this warranty, for any loss, whether the claim is based on contract

or negligence, shall not in any case exceed the cost of correcting defects in the product as herein

provided, and upon the expiration of the warranty period, all such liability shall terminate. The

foregoing shall constitute the exclusive remedy of the Purchaser and the exclusive liability of the

Company. The foregoing warranty is exclusive and in lieu of all other warranties, whether written, oral,

implied or statutory.

No warranty of merchantability or of fitness for purpose shall apply. Unauthorized service shall void

this warranty.

TransTech Systems Product Non-Warranty Return Policy

Non-warranty returns for TransTech Systems Inc. products must be made within twenty (20) days

from the original date of shipment, unless otherwise indicated. Returned products must be in the

original packaging, unused and in undamaged condition. Proof of purchase is required. Upon receipt

of the product TransTech will inspect the product to the above mentioned criteria.

Unused products will be issued a credit to the Purchaser’s account that was used to purchase

the product. TransTech will not credit prepaid shipping cost. The original packing slip or invoice is

required to be sent back with the product to be returned.

The Purchaser is responsible for shipping the product back to TransTech, carefully package the

item(s) and include the packing slip and return manufacturing authorization number on the package.

Prepay shipping is required – TransTech will not accept C.O.D.s.

Returns will be credited within 10 working days.

Proper Process of Warranty or Non-Warranty Shipments to TransTech Systems

For product returns (warranty or non-warranty), please follow the instructions below to assure prompt

handling:

Call us for authorization (518-370-5558 or 800-724-6306), obtain a return manufacturing authorization

number (RMA), and the return shipping address.

Indicate to our representative the reason for returning the product.

For Warranty Returns, Purchaser is responsible for shipping to TransTech’s office. TransTech will pay

ground shipping return to the Purchaser.

44

Page 45

Notes:

45

Page 46

Notes:

46

Page 47

Notes:

47

Page 48

Loading...

Loading...