Page 1

Quick Start Guide

Full Manual available online at

www.transtechsys.com/pdf/PQI380Manual.pdf

1

Page 2

Table of Contents

Contents 3

Charging Batteries 4

Starting the Software 5

GPS Setup 6

Control Menu 7

Unit Settings 8

Data Logging 9

Mix Details 10

Edit Mix 11

Stone Size 12

Depth 13

MTD (Max Theoretical Density) 14

Operator 16

Accepting Mix Change 17

Project Details 18

Edit Project 19

Reading Modes 21

Oset 22

Reading Mode (Detailed) 28

Single Mode 29

Average Mode 31

Continuous Mode 34

Segregation Mode 35

Data Management 37

Replacement Parts 38

2

1-800-724-6306 • www.transtechsys.com

Page 3

Contents

Fold open

compartment

contents

Charger

AC Cord

DC Cord

CD Manual

Handle

Slot for

PQI 380 and

Standardization

Plate

Case

PQI380

DC Cord

Handle

CD Manual

Standardization

Plate

AC Cord

Charger

3

Page 4

Charging Batteries

1. Turn the PQI 380 unit OFF.

2. Connect the charger to the charger connector located on the back of

the PQI 380.

3. Plug the charger into a standard AC outlet.

4. The red indicator lamp will turn green to indicate that the batteries are

charged. (approx. 4hrs)

5. Unplug the charger from the power source before disconnecting the

charger from the PQI 380.

Battery Care Tips

• Whenever uncertain about the battery charge level or condition,

recharge it

• The battery will self-discharge and should NOT be left uncharged for

more than 30 days

• An occasional complete discharge followed by a full recharge is

recommended

• NEVER drop the battery as this can damage the internals

• DO NOT store in freezer or expose to extreme heat

• Battery should be fully charged before use

4

1-800-724-6306 • www.transtechsys.com

Page 5

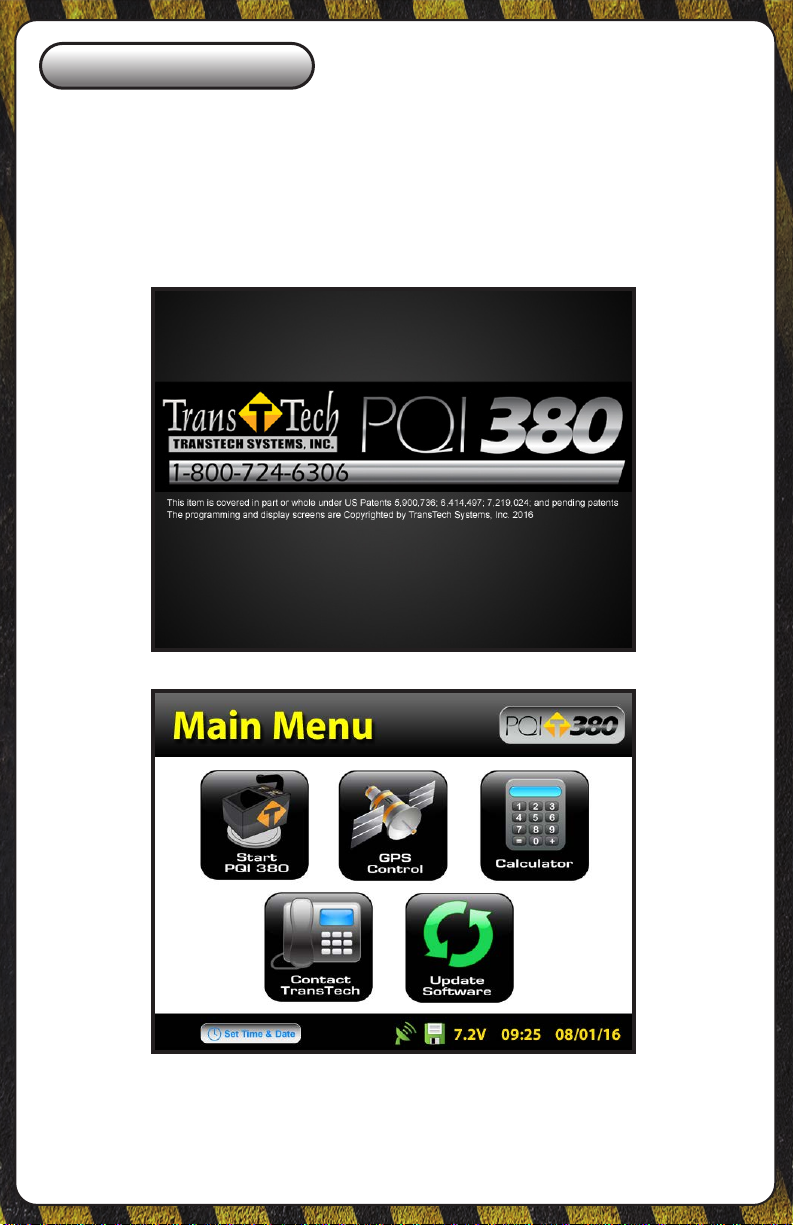

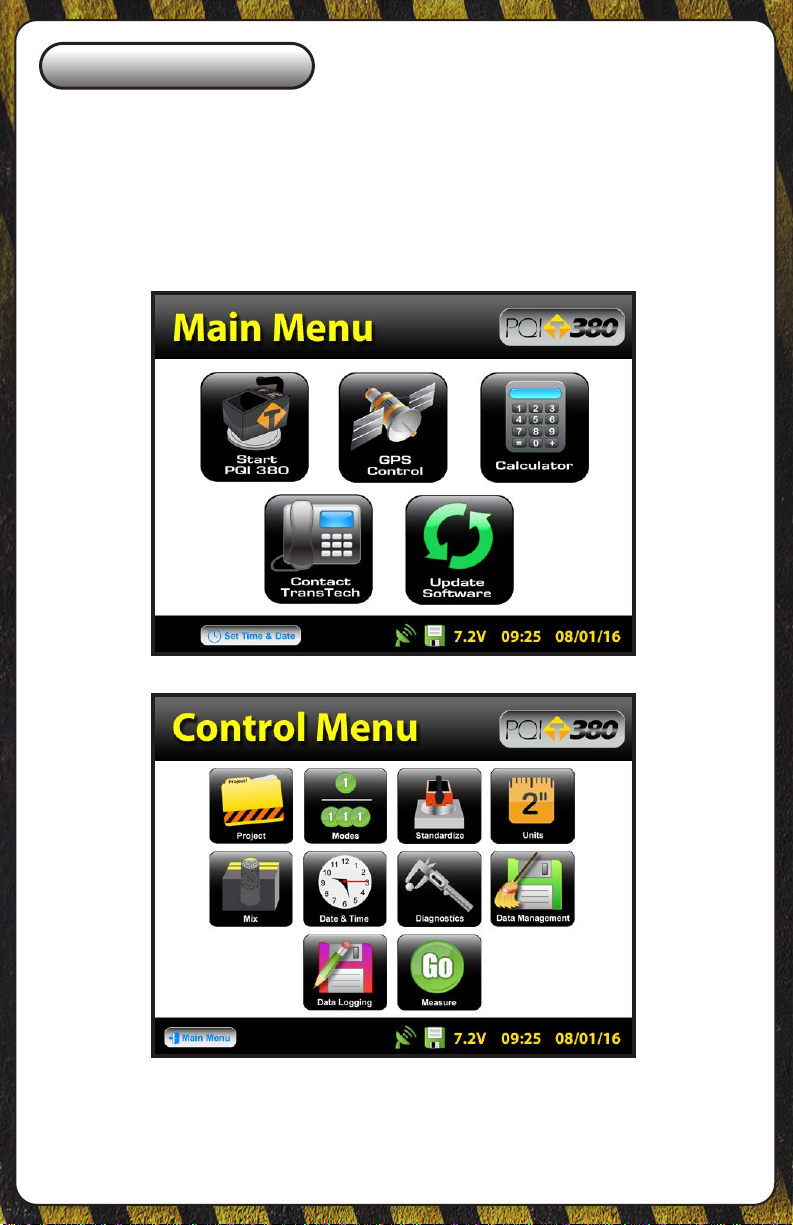

Starting the Software

Pressing the ON button will power on the PQI 380. After a few seconds

the TransTech splash screen will appear followed by the Main Menu

screen. The Main Menu screen will display ve options, Start PQI380,

GPS Control, Calculator, Contact TransTech and Update Software.

5

Page 6

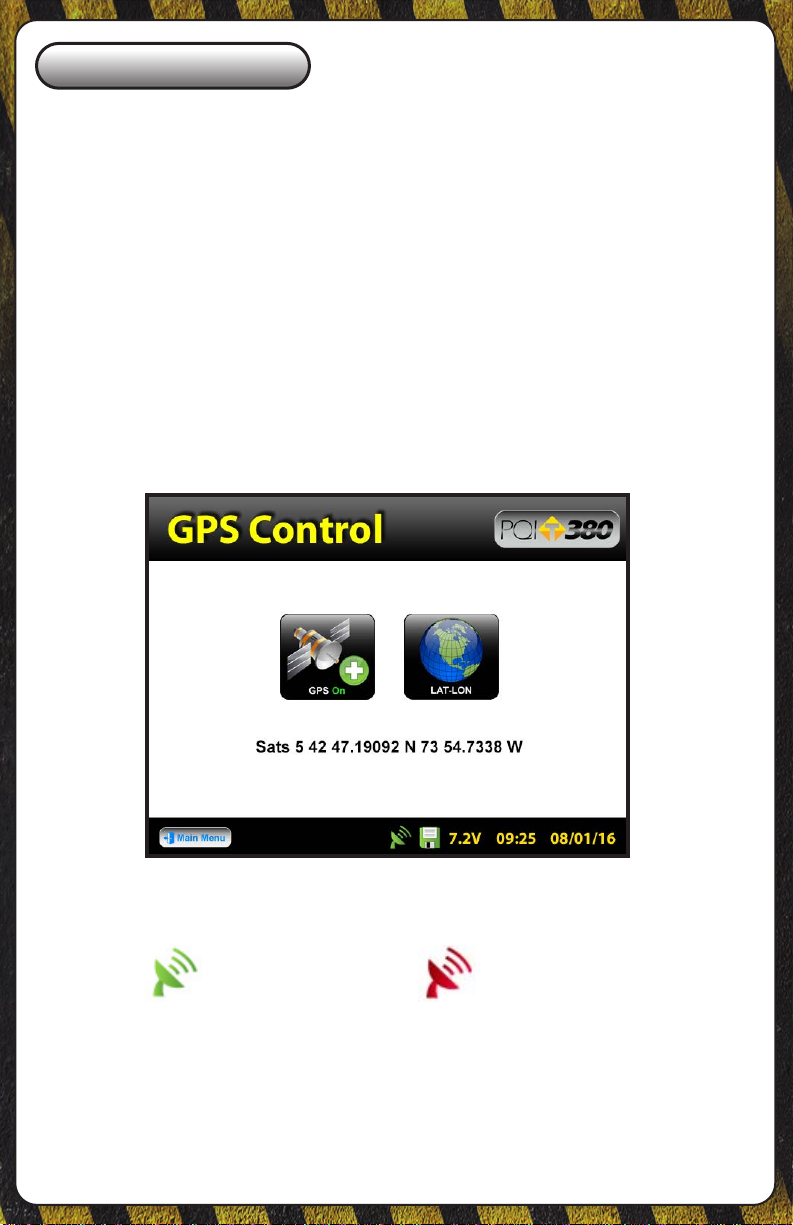

GPS Setup

From the Main Menu, press GPS CONTROL. GPS status can be toggled

ON or OFF. When enabled the satellite dish icon on the status bar at the

bottom of the display turns from red to green.

GPS formatting can also be toggled from the Universal Transverse

Mercator (UTM) grid to Latitude/Longitude (LAT-LON). Initially the

display will read Sats 0 for both formats until connections have been

made. The below example shows a connection to ve satellites (Sats 5).

GPS locations will appear on the bottom left corner of all reading mode

screens and will store with each reading when data logging is enabled.

Press Main Menu to return to the Main Menu.

GPS Enabled GPS Disabled

6

1-800-724-6306 • www.transtechsys.com

Page 7

Control Menu

From the Main Menu, press Start PQI 380 to enter the Control Menu.

From this menu, you will select units, enable data logging, enter mix

information and select a measurement mode. As a quick start, the option

is yours whether to input project details if data logging is enabled or just

begin taking readings.

7

Page 8

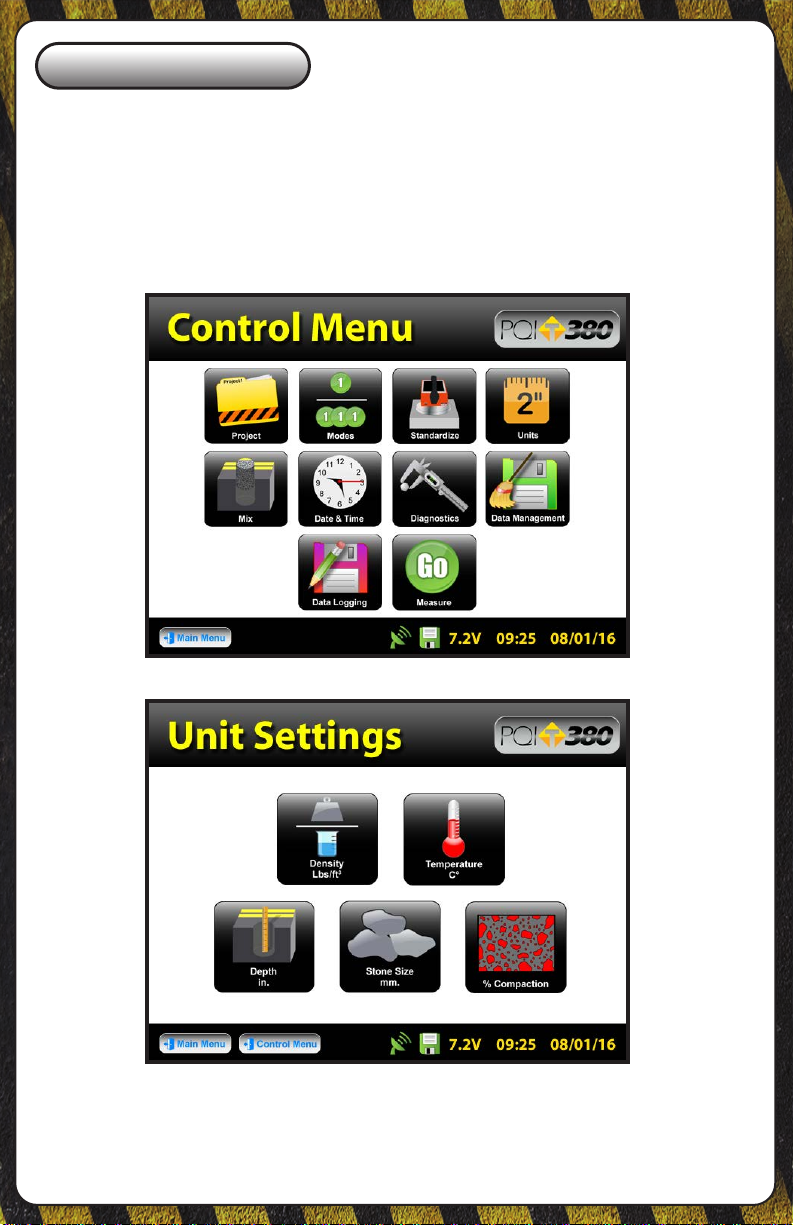

Unit Settings

From the Control Menu, press Units. Density, Temperature, Depth, Stone

Size and % Compaction can be toggled independently between system

international (SI “metric”) and U.S. customary units. For example, you can

set the density to lb/ft3 while temperature is set to celsius, depth is set to

inches while stone size is set for millimeters.

8

1-800-724-6306 • www.transtechsys.com

Page 9

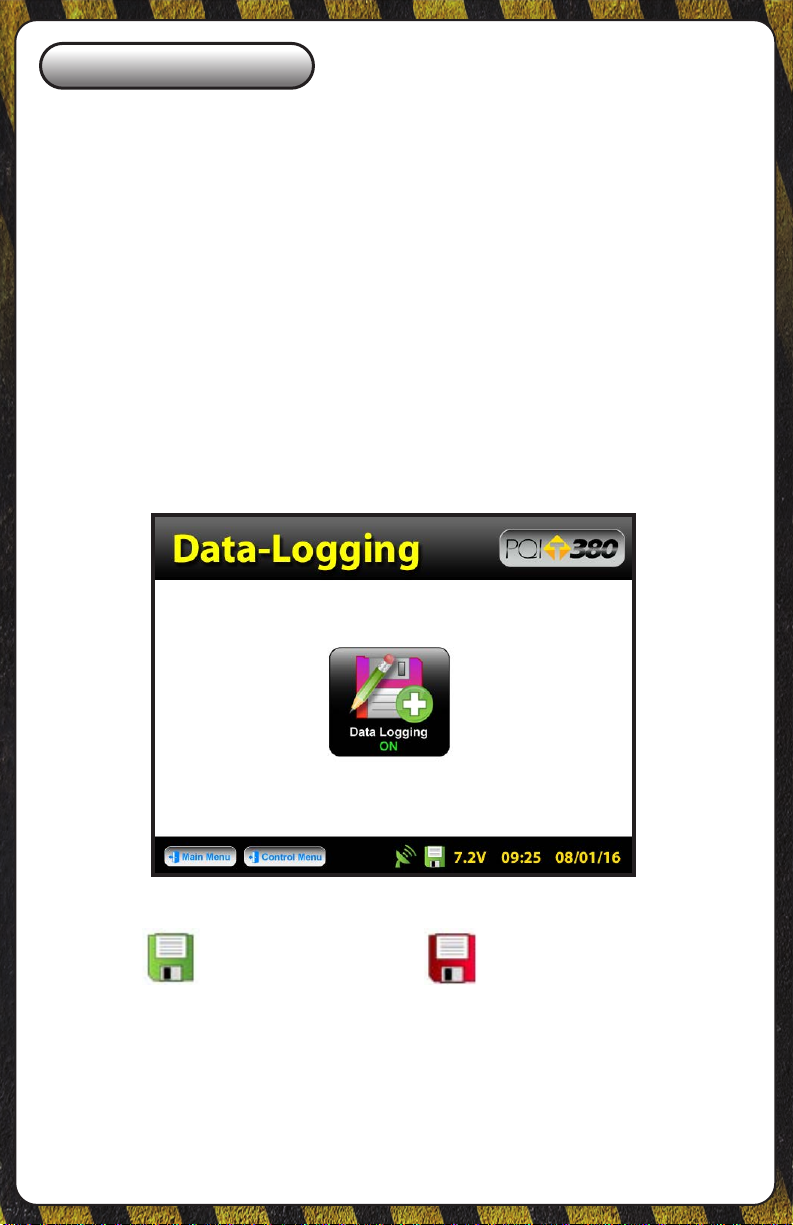

Data Logging

From the Control Menu, press Data Logging. If you wish to save your

data, you must enable the data logging feature by toggling the button to

ON. The oppy disk icon on the status bar will turn from red to green when

data logging is enabled. In the example below data logging is enabled.

Data will not save for continuous or segregation reading modes.

Data stored includes all project and mix details, as well as the compaction,

density, temperature and date and time of each reading. If the GPS is

enabled and it is connected to satellites, the location in the format chosen

as well as GPS date and GPS time for each reading will also be recorded.

Press Control Menu on the status bar to return to the Control Menu.

Data Logging

Enabled

Data Logging

Disabled

9

Page 10

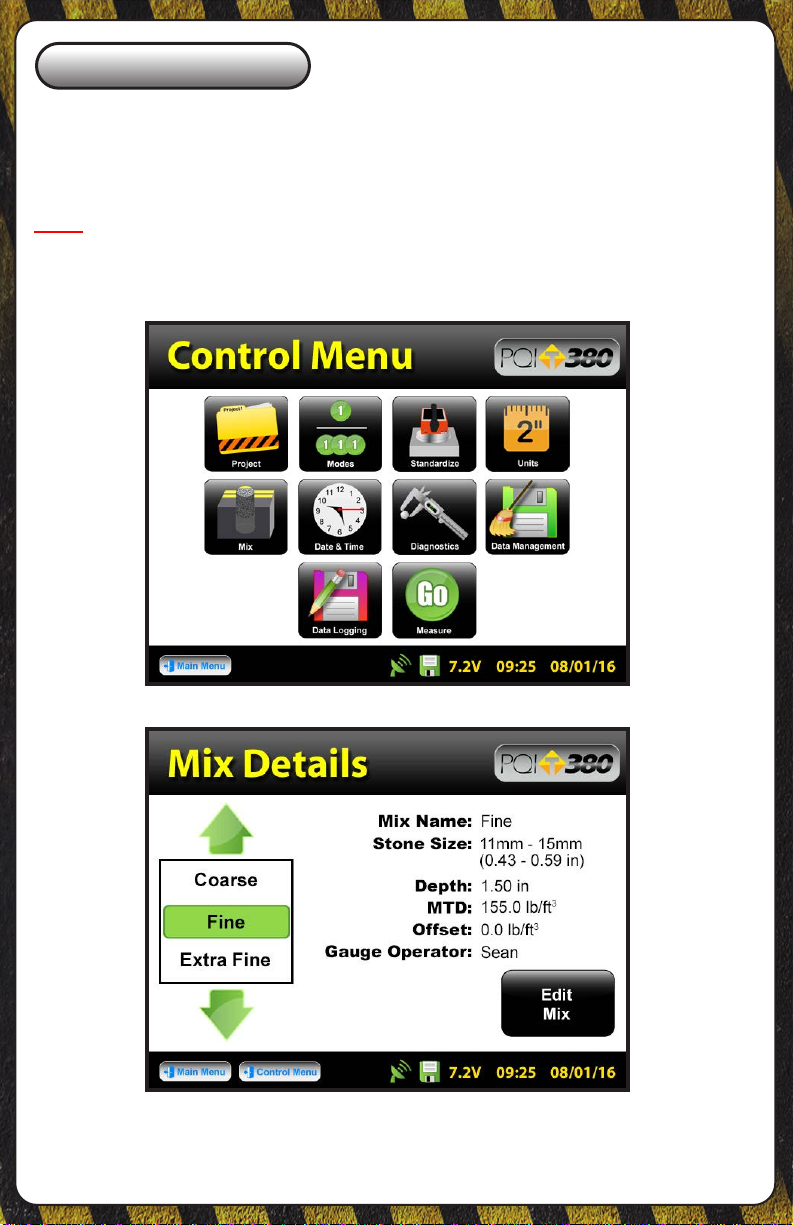

Mix Details

From the Control Menu, press Mix. The PQI 380 will store twenty detailed

mixes. The mix highlighted in green on the left is displayed in detail on the

right. To edit the details of this mix, press Edit Mix.

Note: Readings taken prior to accurately setting up the mix details

will result in incorrect density and compaction results.

10

1-800-724-6306 • www.transtechsys.com

Page 11

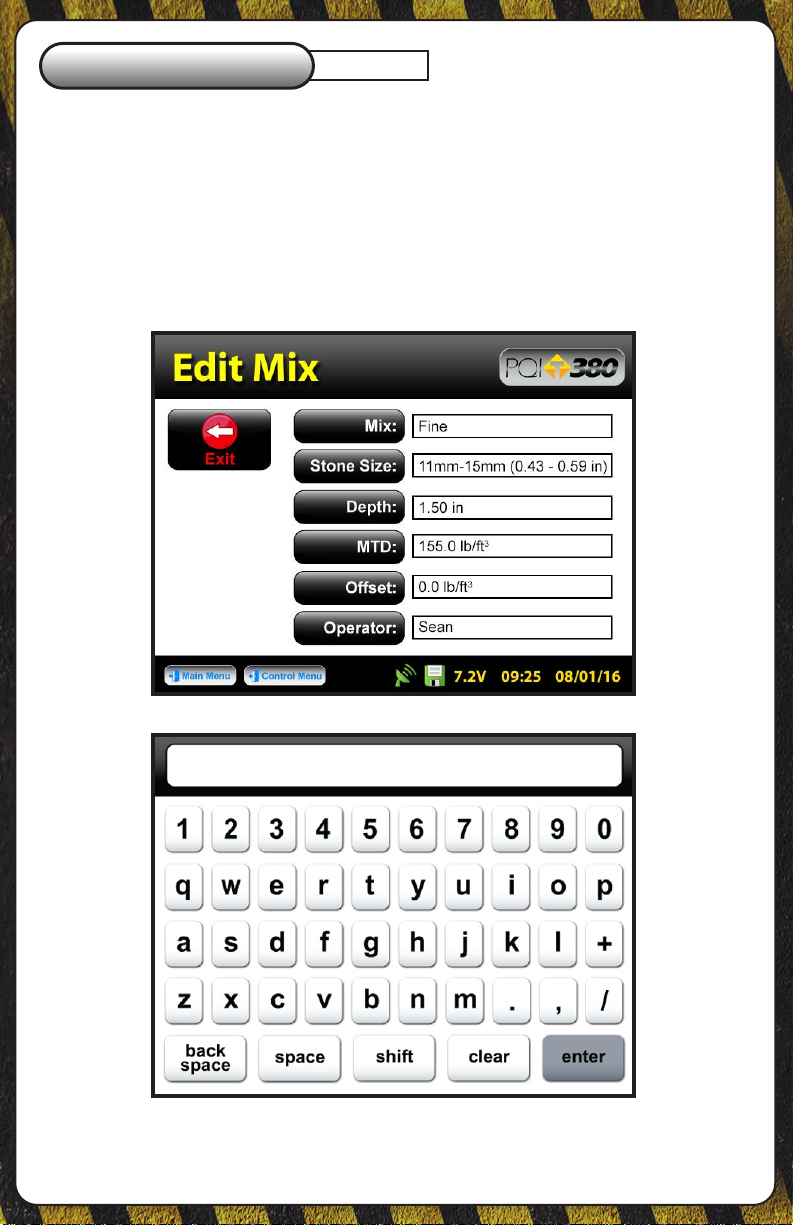

Edit Mix

There are six black buttons labeled Mix, Stone Size, Depth, MTD, Oset,

and Operator. By pressing one of these black labeled buttons, you will

enter the screen that allows you to store the information described by the

button. For example, press Mix, the keyboard will open allowing you to

change the default mix name. Press Clear if you would like to start over

with a new name. Press Shift to toggle from lowercase to uppercase

letters. Once editing has been completed press Enter.

Mix Name

Fine

11

Page 12

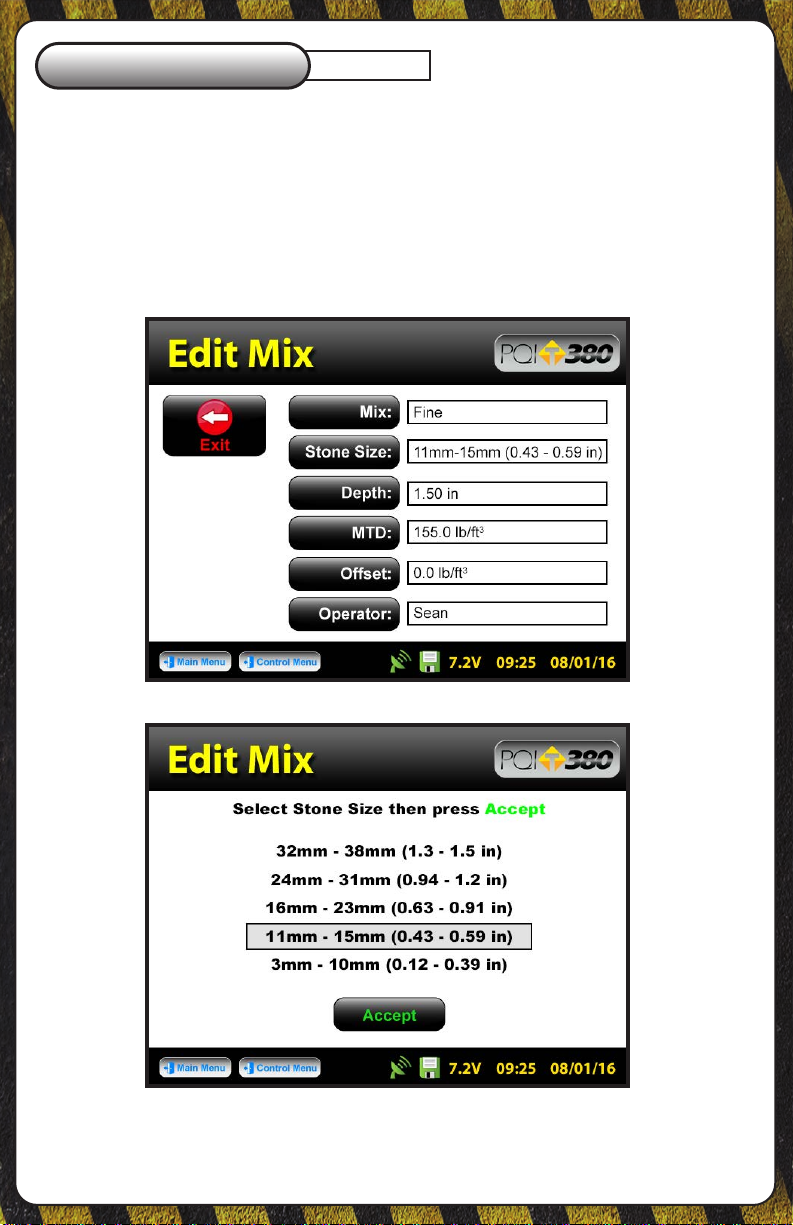

Edit Mix

Press Stone Size. There are ve options of aggregate sizes listed in

millimeters (inches). If, however, you do not see your specic stone size

listed choose the closest stone size available.

For example, if your mix has an aggregate size of 20mm (0.79in), select

16mm - 23mm (0.63 - 0.91). Press Accept after you made your selection.

Stone Size

12

1-800-724-6306 • www.transtechsys.com

Page 13

Edit Mix

Press Depth. Enter the depth of the asphalt mat on the numeric keypad in

the units you previously selected for the depth. Once the correct value has

been entered, press Accept.

An out of range Warning will display for depths entered outside of

the following range: 0.75in - 6.0in (19.05mm - 152.4mm)

Depth

13

Page 14

Edit Mix

MTD (Max Theoretical Density)

Press MTD. Enter the Maximum Theoretical Density (MTD) of the mix

on the numeric keypad in the units you previously selected. The MTD is

provided from the asphalt mix designer and is a key value in determining

the percent compaction. Once the correct value has been entered, press

Accept.

An out of range Warning will display for an MTD entered outside of

the following range: 100lb/ft

3

- 200lb/ft3 (1601.8kg/m3 - 3203.7kg/m

3

)

14

1-800-724-6306 • www.transtechsys.com

Page 15

Edit Mix

The oset for this material can be adjusted at a later time. Measurements

takenpriortoadjustingtheosetwillnotincludetheoset. You will

need to take a measurement to determine the oset. The oset feature will

be revisited later in the calibration section of this document.

Oset

15

Page 16

Edit Mix

Press Operator. Enter your name as the operator of the gauge, press

Enter. The gauge will return to the edit mix screen. Verify all mix

information on this screen. Once you have veried the results of the mix,

press Exit to save the mix.

Operator

16

Sean

1-800-724-6306 • www.transtechsys.com

Page 17

Edit Mix

After exiting the Edit Mix screen, the gauge will return to the Mix Details

screen. Here you may use the green up or down arrows to select a new

mix for editing or change an existing mix. The green highlighted mix is

the CURRENT MIX that the gauge will use when taking readings. Prior to

exiting this screen, be sure this is the mix you want and the information to

the right has been veried. Press Control Menu to return to the Control

Menu.

17

Page 18

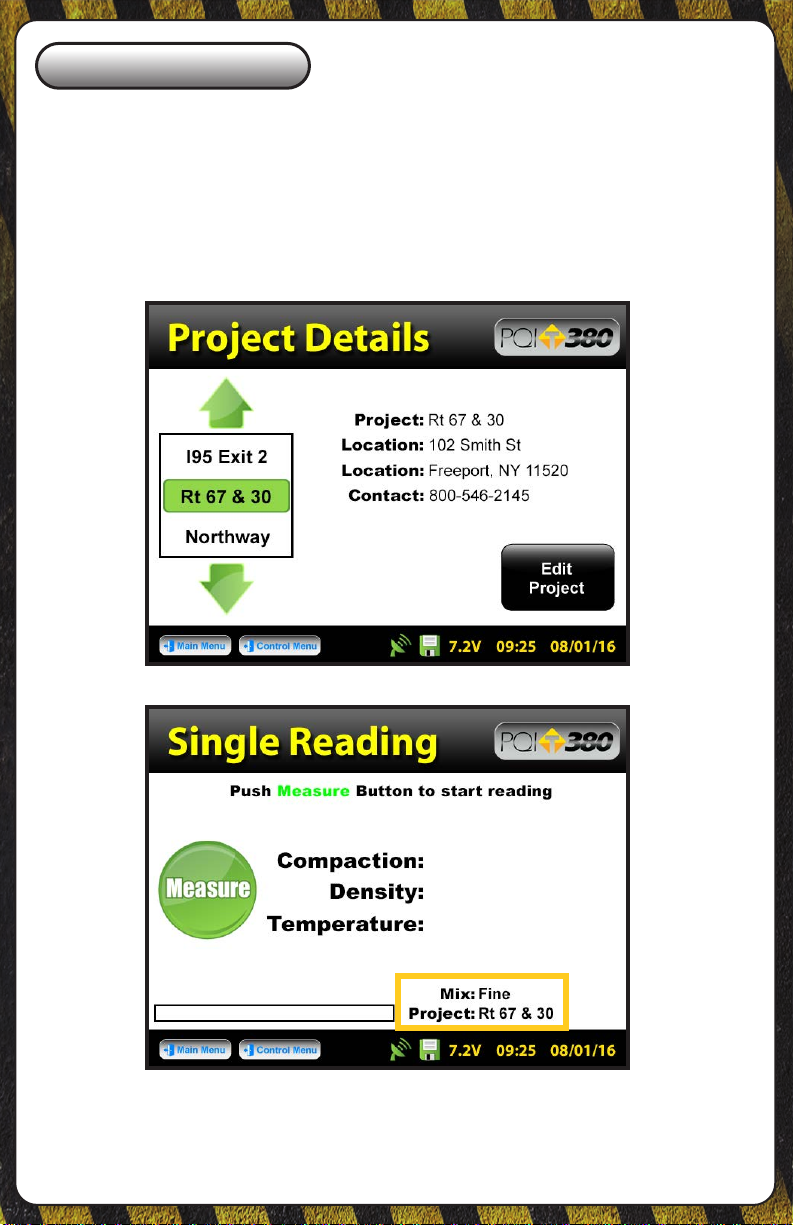

Project Details

If you wish to save data and you have data logging enabled, press

Project, otherwise skip to Reading Modes. The PQI 380 will store ten

detailed projects. The project details screen will resemble the mix details

screen such that you are able to select your project using the up and

down arrows. The green highlighted project is the CURRENT PROJECT.

Readings taken will store on a dat le using the CURRENT PROJECT

NAME. You may revisit each project at any given time to continue taking

readings. Data within each project will store in the order of which it was

taken. To edit a project, press Edit Project.

18

1-800-724-6306 • www.transtechsys.com

Page 19

Edit Project

There are four black buttons labeled Project, Location, Location and

Contact. By pressing one of these black labeled buttons, you will enter

the screen that allows you to store information for that project. For

example, press Project, the keyboard will open allowing you to change

the default name. Press Clear if you would like to start over with a new

name. Press Shift to toggle from lowercase to uppercase letters. Once

editing is complete, press Enter. Verify the information then press Exit to

save the project information and return to the project details screen. Press

Control Menu to return to the Control Menu.

Rt 67 & 30

19

Page 20

Edit Project

If you took readings with data logging enabled but did not set up a

project, data will store on the default project name (ex. Project1).

Always take note of the project and mix names displayed on your

reading mode screens.

20

1-800-724-6306 • www.transtechsys.com

Page 21

Reading Modes

From the Control Menu, press Modes. There are four reading modes

(Single, Average, Continuous and Segregation). Continuous and

segregation modes will not save data. Single and average modes will

save data when data logging is enabled. Press the button of the mode you

would like to use. The active mode button will appear larger than the rest.

For example, single reading mode has been selected below. Select either

continuous mode or single mode in order to take a quick reading to

determine the oset. Once your selection has been made, press Control

Menu to return to the Control Menu.

Detailed instructions on page 28

21

Page 22

Oset

Prior to cores being taken, you may want to adjust the PQI 380 to the

asphalt mat. After choosing the continuous or single reading mode as

described on the previous page, from the Control Menu, press Measure.

Take note and verify the mix and project names. Continuous mode

will continuously display and update the Compaction, Density and

Temperature until the STOP button is pressed. This data will not be saved.

Single mode will take one measurement, display the results and await

another reading if data logging is disabled.

22

1-800-724-6306 • www.transtechsys.com

Page 23

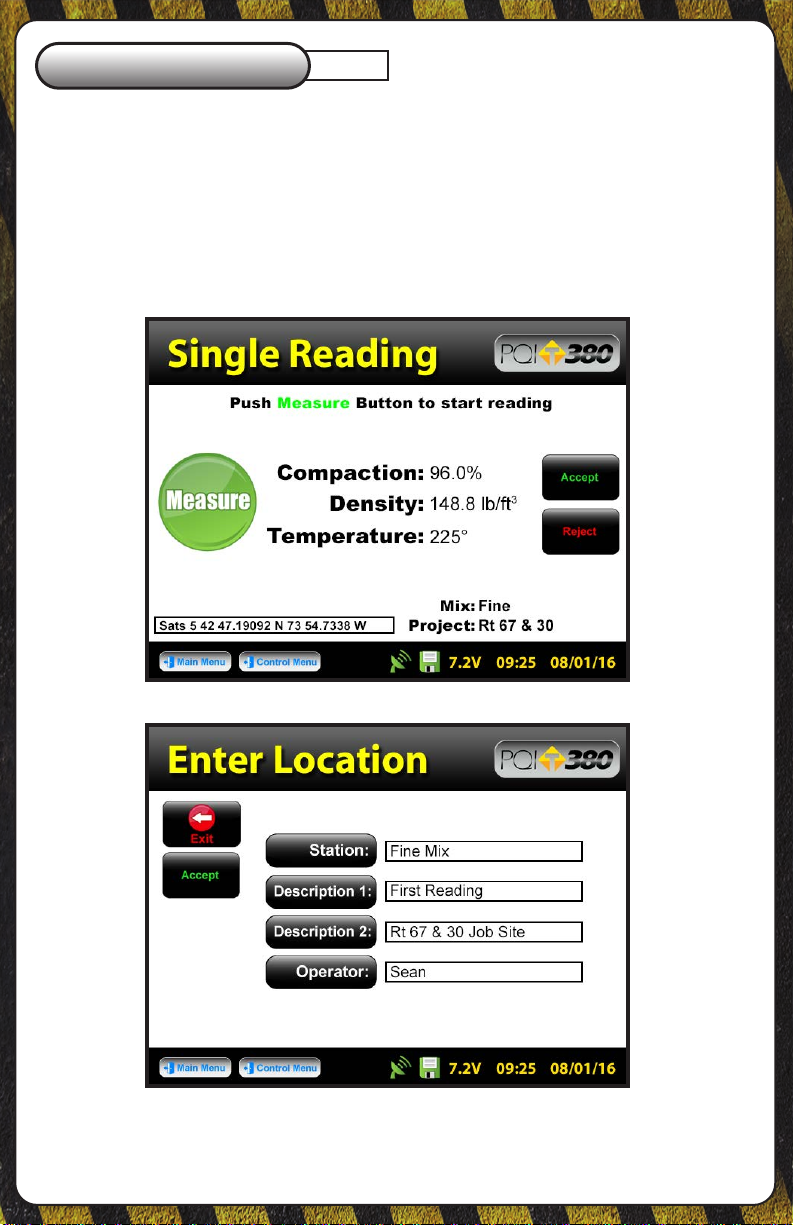

Oset

If data logging is enabled, the PQI 380 will display Accept and Reject

buttons for that reading. Once accepted, the Enter Location screen will

load which will allow specic information to be stored for that reading.

Press Accept to immediately bypass this screen or when you have

nished entering information for that reading. Once you are satised with

the density result, press Control Menu then press Mix to return to the

Mix Details screen.

23

Page 24

Oset

Be sure that the green highlighted mix is the mix you wish to apply the

oset. Press Edit Mix then press Oset. Using the value of the density

you previously measured, compare that to the value of density desired.

Once the numeric dierence is calculated, determine whether the PQI 380

is reading too high or too low. For example, if the PQI reads 155lb/ft3,

and you would like it to read 150lb/ft3, the PQI is reading too high and the

adjusted value for the oset is 5.

24

1-800-724-6306 • www.transtechsys.com

Page 25

Oset

Press PQI is reading too High or Low depending on your situation. For

our example, we are going to press PQI is reading too HIGH. The next

screen will contain a numeric keypad as well as the values for the mix

name and the current oset for that mix. Type in the adjusted value for the

oset which we previously determined would be 5. Press 5, then press

Enter.

25

Page 26

Oset

The adjusted value and new oset will be the same if the current oset

was originally zero. If the current oset had been -1 and the adjusted

value 5, then the new oset would be -6 for a PQI that was reading too

high. Press Accept. You will be brought to the Edit Mix screen where you

can verify the updated oset information for that mix. Once veried, press

Exit to save your results, then press Control Menu on the status bar to

return to the Control Menu.

26

1-800-724-6306 • www.transtechsys.com

Page 27

Oset

Theosetforeachmixcanbeadjustedatanytime.Readings

takenpriortoaspecicadjustmentwillnotreectthatadjustment.

Dataleswillrecordeachosetusedtocalculatedensityforeach

reading.

27

Page 28

Reading Modes

To change reading modes, from the Control Menu, press Modes. Select

the reading mode you would like to use, then press Control Menu. From

the Control Menu, press Measure to begin taking readings. The heading

of the screen will display the active mode (Single, Average, Continuous,

Segregation). For all reading modes, take note and verify the mix and

project names displayed in the bottom right corner. Do not touch or hover

over the gauge when it is taking a reading. Place the gauge on a at and

dry surface whenever possible.

Detailed

28

1-800-724-6306 • www.transtechsys.com

Page 29

Reading Modes

Single Reading Mode - Press Measure. If data logging is disabled, the

gauge will display the results of the rst reading and await another.

Single

29

Page 30

Reading Modes

If data logging is enabled, the gauge will display Accept and Reject

buttons for that reading. Once accepted, the Enter Location screen will

load which will allow specic information to be stored for that reading.

Press Accept to immediately bypass this screen or when you have

nished entering information for that reading.

Single

30

1-800-724-6306 • www.transtechsys.com

Page 31

Reading Modes

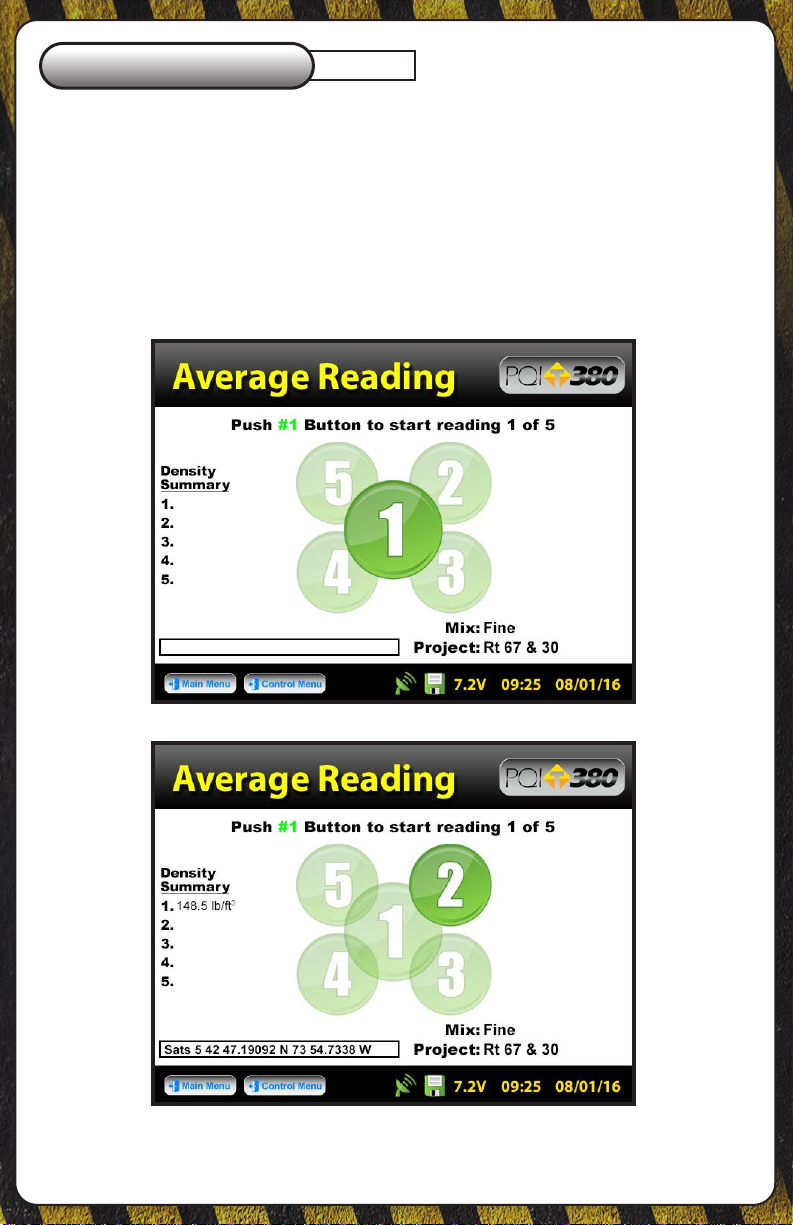

Average Reading Mode - The ve average readings are taken in a clover

leaf format. The gauge will highlight the reading number as well as the

position of the gauge. Once the gauge is positioned on a at surface,

press 1. When reading one is complete, the density summary list will

begin to populate and the gauge will prompt you to move to location 2.

Move the gauge to position 2 and press 2 to continue. Repeat these steps

for the remaining three measurements.

Average

31

Page 32

Reading Modes

After the fth reading the PQI 380 will display the ve individual readings

under density summary along with the average of the compaction, density

and temperature. If data logging is enabled, the gauge will display Accept

and Reject buttons for that reading. Once accepted, the Enter Location

screen will load which will allow specic information to be stored for that

reading. Press Accept to immediately bypass this screen or when you

have nished entering information for that reading.

Average

32

1-800-724-6306 • www.transtechsys.com

Page 33

Reading Modes

The PQI 380 will not store individual readings in average mode, only

theaverageofallvereadingswillbestored.Ifindividualreadings

are needed, this will be the last time the screen will display them.

If data logging is disabled the gauge displays the average and awaits the

next reading set.

Average

33

Page 34

Reading Modes

Continuous Reading Mode - Press Measure. Data will NOT store for

this mode. Continuous mode will continuously display and update the

Compaction, Density and Temperature until the STOP button is pressed.

Continuous

34

1-800-724-6306 • www.transtechsys.com

Page 35

Reading Modes

Segregation Reading Mode - Press Measure. Data will NOT store for

this mode. This mode mimics the PQI 300, where two readings (A and B)

are taken for each location. For every reading taken the option to Accept

or Reject will be given.

Segregation

35

Page 36

Reading Modes

After the last pair of readings has been taken, press Calculate. The

gauge will display % Compaction, Density and Temperature for the lowest,

highest and mean readings.

Segregation

36

1-800-724-6306 • www.transtechsys.com

Page 37

Data Management

From the Control Menu, press Data Management. This is where project

les will be saved, viewed, printed and downloaded.

Download Data - Use the up and down arrows to scroll, highlight the

desired project and press Download. Insert the USB ash drive into the

USB port, press Download. The gauge will ask if you inserted the USB

drive, once ready, press Download. When downloading is complete the

gauge will display READY.

Viewing a Project File - Use the up and down arrows to scroll, highlight

the desired project and press View. All of your tests saved to this project

will be listed in the order they were taken. Only the most pertinent

information will be shown in this view including: Test Number, Station,

Description1, Density, Compaction and Surface Temperature. Press the

Back button to exit the Project View screen.

Deleting a Project File - Use the up and down arrows to scroll, highlight

the desired project and press Delete. You will be prompted with a warning

asking if you are sure you wish to delete the le. Once conrmed and

deleted, you will no longer be able to retrieve the measurement data.

Printing a Project File - Plug in your TransTech printer, use the up and

down arrows to scroll, highlight the desired project and press Print.

37

Page 38

Replacement Parts

To order parts call the TransTech service department at 1-800-724-6306

7500-0320

PQI 380 AC Charger

7500-0292

PQI 380 DC Vehicle

Charger

7500-0235

PQI 380 Extension

Handle Kit

38

1400-0028

PQI 380 StrongHold

Carry Case

8000-0063

PQI 380 Generation 1

Battery (3 Pack)

7500-0354

PQI 380 Generation 1

Battery Cap with Spring

1-800-724-6306 • www.transtechsys.com

Page 39

Replacement Parts

To order parts call the TransTech service department at 1-800-724-6306

7500-0356

PQI 380 Generation 2

Battery

7000-0336

PQI 380 Generation 2

Replacement Battery Door

2100-0159

PQI 380 Charging Port

Dust Cap

39

Page 40

900 Albany Shaker Road, Suite 2

Latham, NY 12110

Phone: 518-370-5558

Toll Free: 1-800-724-6306

Fax: 518-370-5538

Email: inquiries@transtechsys.com

Web: www.transtechsys.com

Toll Free: TransTech.Systems.Inc01

Follow us on

Ver. 1.4

03/2019

40

Loading...

Loading...