Page 1

Pavement Quality Indicator

Model 301

Page 2

2.0 Controls and Components

4

4

3

7.0 Warranty

FAQ’s

Page 3

TransTech’s third generation Pavement Quality Indicator™ (PQI)

utilizes state

primary features are:

moisture.

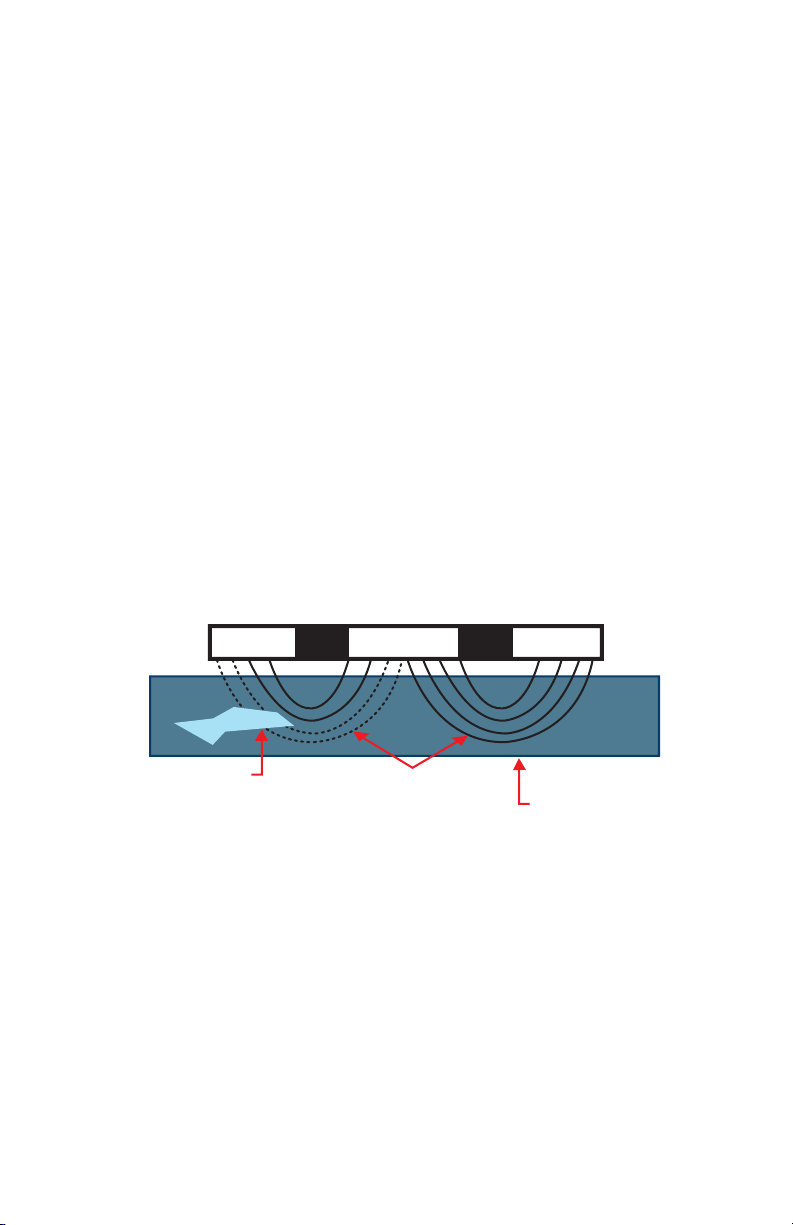

The density of asphalt pavement is directly proportional to the

measured

uses electrical waves to measure dielectric constant using an innovative, toroidal

PQI convert the field signals into material density readings and displays the

results. Once calibrated direct density readings can be consistently obtained.

This handbook is intended to be both a training manual and a

reference source

for the operation, care and maintenance of the TransTech Pavement Quality

Indicator. You must read through the entire manual completely to familiarize

yourself with the unit’s features, controls and operating modes before starting to

take readings and analyze data.

The PQI is intended primarily for use on newly-laid asphalt

pavements with lift

thickness ranging from 1 inch to 6 inches. Once calibrated the PQI will provide

reliable and consistent density measurements.

Page 4

Every effort has been made to make the Pavement Quality Indicator

to use and inherently safe. The PQI uses no nuclear elements, and is instead

based on a safe, low-voltage direct current electrical measurement techniques.

Like any instrument, however, the user should exercise care and common sense

in its use to prevent mishaps.

Warning- Do not use the unit on or near exposed electrical wiring. A shock

hazard potential exists if contact is made with the exposed wiring.

Warning-

Use care in handling the unit. Personal injury can occur through

improper handling. Take proper precautions to prevent accidental dropping of

the unit.

Caution- Turn the unit off when not in use and during transport.

Caution- Unauthorized disassembly of the unit will void the warranty.

2.1 External Controls and Components

Prior to learning how to operate the PQI, we recommend that you

familiarize

yourself with the PQI unit’s operating controls and components. Illustrations and

listing of the main components and their basic functions are shown below.

Display

3

Page 5

2.2 Receipt

The PQI shipment package includes the items listed below. Report

12 VDC - Fast Charge

2.3 Charging The Battery

Important- Before using the unit for the first time the internal battery must be

fully charged. Follow the unpacking and setup instructions below.

The third generation PQI unit is powered by nickel metal hydride

batteries

which weigh less and are smaller than equivalent lead-acid cells. The new

microprocessor controlled battery charger will usually charge the PQI unit

in a couple of hours. For first use and after a fully discharged battery pack a

minimum of 5 hours should be allowed

for charging.

Under normal operation, the PQI unit can operate in excess of 13 hours

Warning- Attempting to recharge the unit in any other way than with the

recharger

supplied with the unit can result in damage to the unit and can present

a safety hazard. Use of any charging means other than the recharger supplied

with the unit will void the unit’s warranty.

The figure below shows the battery charger supplied with the PQI.

Page 6

PQI unit.

4. When charging is complete, unplug the charger from the power source

first then from the connector on the PQI unit.

Battery Voltage is displayed on the Continuous Reading Mode Screen. A fully

charged battery will read approximately 12.9-13 volts. The battery voltage will

go down as the PQI is used. At 11.5 volts, it is time to get the PQI re-charged.

When the PQI voltage gets to 11.0 volts, the PQI will display a “low battery

warning” and will not take any further readings. It is important to re-charge the

battery after each use.

3.1 General Operation Overview

The Pavement Quality Indicator is designed to be an extremely flexible

unit,

with several useful modes of operation. Each mode of operation is accessed

through the keypad controls. The number, letter and arrow keys have several

functions. The immediate function is shown by the text in the display panel.

The display can show four lines of text at a time called a page. The display tells

the operator what the PQI unit is ready to do or indicates that a reading is being

taken or that more key setting information is needed from the operator. Pressing

TransTech Systems

PQI V3.3ae1

Initializing………

Figure 3.1 first or “bootup” screen display.

Page 7

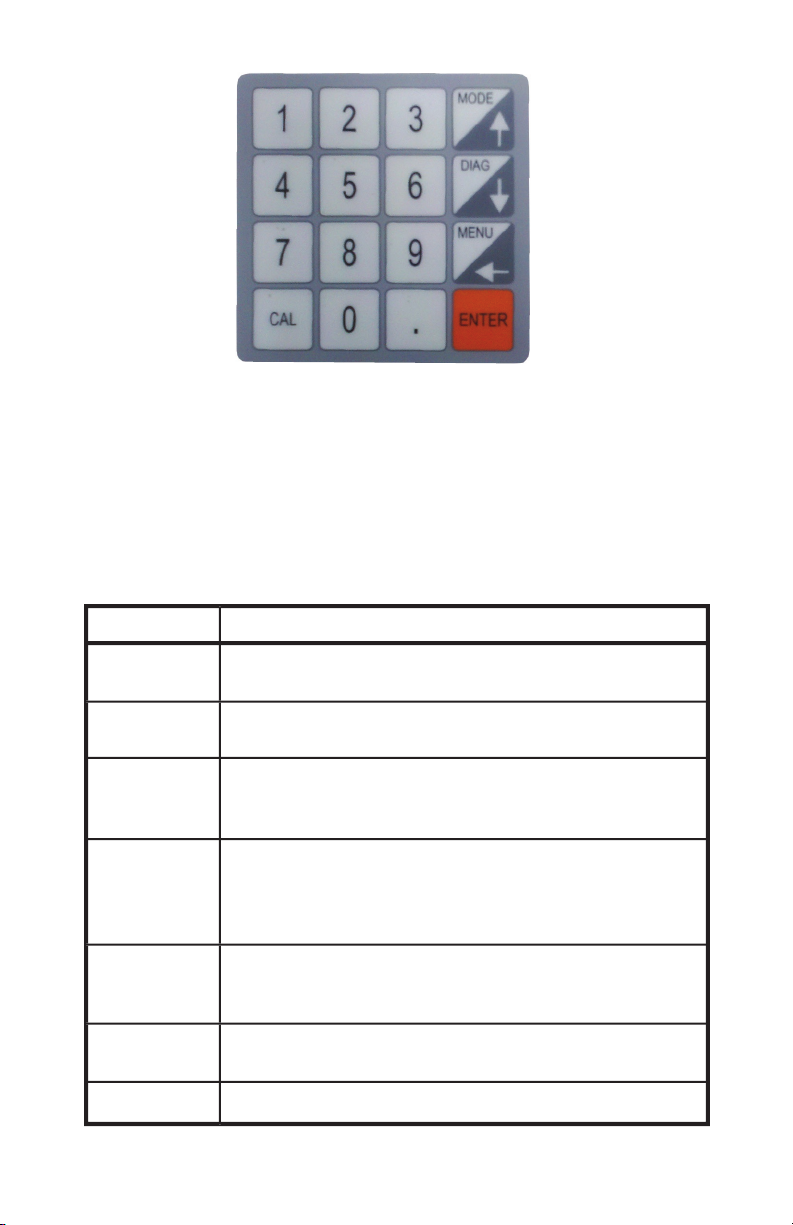

Figure 3.2 Keypad

A summary of the keypad codes used to set date and time, change measurement

modes, enter values for the Maximum Theoretical Density (MTD) value and

following sections of this handbook.

Function

The number keys have different

upon the menudisplay.

Mode/↑

Used as to switch among the four

measurement

modes or to scroll in the up direction.

Diag/↓

Used to display the DIAGNOSTICS

in the down direction.

Menu/←

This key brings the unit back to the

MAIN MENU.

Works as a back space key when it’s necessary to

Enter

The ENTER key functions like a return key

in that

it tells the PQI unit to accept information or to take

Used to enter calibration mode when in one

measurement modes.

Works as a decimal point when entering

values.

Page 8

3.2 Starting and Self Test

Important

Before using the unit for the first time the internal battery must be fully charged.

Follow the setup instructions in Section 2.2 above.

3.2.1 Starting the PQI unit for the first time.

A.

Turn the PQI on by flipping the POWER switch. After a few seconds

the

display will show the TransTech boot up screen. After the boot up screen

clears the PQI will display the SELECT PAVEMENT TYPE screen. From the

main menu option #2 also allows changing of this setting. The selection of a

“Pavement Type” / stone size in the mix which the PQI is going to be used on

is required as part of the initial calibration of the unit.

B.

The PQI will prompt the user for the correct unit of measurement

inches or mm. The PQI 301 asks the user to input the depth of the pavement

being laid out by the paver.

Lift Thickness

Enter Units

Lift Thickness

Enter Thickness ( in or mm)

Press the number 1 to show the first page of the MAIN MENU (also called

setup menu). Press 2 to return to an operating mode if setup was performed

earlier in the day.

Page 9

ENT) Exit (Scroll)

D.

Press the Down arrow to show the second MAIN MENU page.

4) Data Log

ENT) Exit (Scroll)

E.

Press ENT) Exit or (Scroll) Press the Down arrow to return the display to the

first page of the MAIN MENU as above.

3.3 Setting the Date and Time

The following steps check the date and time of the clock inside the PQI.

At the

first screen of the MAIN MENU, pressing the 1 key enters the Date and Time

mode.

ENT) Exit

3.3.1 Setting the Date

A. Pressing the 1 key prepares the PQI for setting the month, day and

year. The

first line of the display indicates the date presently stored in the PQI. If this date

MENU.

Enter Date

MM/DD/YYYY

XX/XX/XXXX

ENT) OK “.” ) Cancel

The MM is the first portion of a two digit month representing the 12 months of

the year. For example 01 is January.

Page 10

The DD is the second portion of a two digit day indication with a value from 01

to 31.

The YYYY is the third portion of the date representing a four digit year.

For

B.

Notice the flashing cursor beneath the MM letters. Using number keys

enter the value for the current month, 01, 02, etc. At this time using the

(backspace) key will move the cursor between the two MM spaces so

that the month value can be changed.

See that the underline cursor has moved to the DD position. Using

number keys enter a two digit value for the current day of the month,

01, 02, etc. Using the ← (backspace) key will move the cursor between

the two DD spaces so that the day value can be changed if a mistake is

made.

D.

The underline cursor has moved to the YYYY position. Using number

keys, enter a four digit value for the year. Using the ← (backspace) key

will move the cursor between the four spaces so that the year value can

be changed if a mistake is made. Pressing the ENT key sets the new

date. Pressing the “.” key cancels and returns the PQI to the change

date or the time screen without making any changes to the current

date.

Option #3 “Date Format” allows the date format to be changed from

M/D/Y to D/M/Y.

3.3.2 Setting the Time

A. From the Main Menu press the 1 key. Press the 2 key and the PQI is

ready

to have the time set. The HH is the hour portion of the time in a 24 hour format

Enter Time

HH:MM:SS

XX:XX:XX

ENT) OK “.” ) Cancel

The MM is the minute portion of the time display with a range of 00 to 59

minutes.

The SS is the seconds portion of the time also with a range of 00 to 59 seconds.

B.

See that the underline cursor is under one of the HH letters. Use number

keys to enter the new hour of the day. Using the ← (backspace) key will move

the cursor between the four spaces so that the year value can be changed if a

mistake is made.

Page 11

The underline cursor has moved to the MM letters. Use the number keys

to enter a new minute value. Using the ← (backspace) key will move the cursor

between the two paces so that the minute value can be changed if a mistake is

made.

D.

The underline cursor has moved to the SS letters. Use the number keys to

enter the new seconds values. Using the ← (backspace) key will move the

cursor between the two spaces so that the seconds value can be changed if a

mistake is made.

E.

Pressing ENTER sets the new time. Pressing the “.” key cancels and returns

the PQI to the change date or time screen without making any changes to the

current time. Pressing Enter returns the PQI to the Main Menu Screen

ENT) Exit (Scroll)

3.4 Setting the Mix Information

A. From the MAIN MENU press the 2 key.

ENT) Exit

3.4.1 Setting the MTD value

The Maximum Theoretical Density (MTD) value is provided from the asphalt

mix designer.

A.

Pressing the 1 key prepares the PQI unit to accept or change the current MTD

value.

B.

Pressing the 1 key will return the display to the Mix Information MENU

without any change to the stored MTD value. Pressing the 2 key changes the

display to the Set MTD menu.

Page 12

At this display, if the ENTER key is pressed a 0.0 MTD value will occur and

the display will return to the Main Menu.

D.

Use the keypad to enter a new 4 digit MTD value. At this time the

key can

be used to back space and change any of the digits. When the new MTD

value is set pressing the ENTER key sets the new MTD value in the PQI. The

display will return to the M ix Information Menu. The “.” key is used to enter

the decimal point.

3.4.2 Setting the Lift Thickness

A.

Pressing the 2 key prepares the PQI unit to accept or change the current Lift

thickness value.

New:

Lift Thickness

Enter Thickness (in)

At this display, if the ENTER key is pressed a 0.0 Lift Thickness value will

B.

Use the keypad to enter a new Lift thickness value. At this time the

key

can be used to back space and change any of the digits. When the new value

is set pressing the ENTER key sets the new Lift value in the PQI. The display

will return to the M ix Information Menu. The “.” key is used to enter the

decimal point.

3.4.3 Setting Pavement Type

A.

Pressing the 3 key prepares the PQI unit to accept or change the current

Pavement Type.

Page 13

At this display, choose option 1,2, or 3 depending on the type of pavement/stone

Information Menu.

Pressing

ENTER

returns the PQI to the Main Menu Screen

ENT) Exit (Scroll)

3.5 Changing Displayed Units

A.

From the MAIN MENU press the 3 key.

ENT) Exit

At this display, by pressing the corresponding #, the unit of measurement will be

Item 3 allows you to set the PQI to read % compaction or % voids. depending

Using the PQI on the road

take it out onto the road and perform a simple calibration.

Page 14

3.6 Calibration

be calibrated for each asphalt mat at each job site. The PQI determines

HMA density by measuring a property of the HMA mat and comparing it

to a measurement of that property at a known density. The property that the

PQI measures varies for different HMA mixes. Therefore, to obtain accurate

measured. Once calibrated for a specific mix, the calibration factors (called

used again.

The PQI provides a number of different calibration methods which can be used

under different circumstances. The following table briefly describes the different

methods:

Method

Description

Normal

PQI readings have been taken and cores have

been obtained from those reading areas. Simply

high or low relative to the core readings.

taking a reading of the unrolled mat and

that point.

Two Point Method

by taking readings of the unrolled mat and a

peaked area of the finished mat entering the

Manual Slope

Allows you to type in a numeric value for the

ENT) Exit

To access the calibration methods, press the “CAL” key while the PQI is

Page 15

3.6.1 Preparation

Pick a location on the asphalt that is dry. Designate an area approximate 10 feet

long and 5 feet wide on the asphalt mat. Divide the area into five data locations.

3.6.2 Calibration Readings

Use the PQI in the Single Reading Mode.

Place the PQI in the first location on the asphalt mat. Using a crayon marker

Press the ENT key,

and wait for a reading to

HINT: Better readings are taken if no hands or objects are in contact with

the PQI.

Move the PQI approximately 2 inches up and to the right on the outside of the

Move the PQI clockwise around the marked circle to about the 4 o’clock

position. Press the ENT key to take another reading and record it in the table.

Following the pattern in Fig. 3.6.2, move the PQI to the next circle location,

record a density reading in the center and at each clock position, in turn, until the

table is complete.

Figure 3.6.1 Reading Location Layout

Figure 3.6.2 PQI Measurement Pattern

Page 16

3.6.3 Calibration Comparison

A.

Arrange to have physical core samples taken from the center of each marked

circle location in the 10 foot strip.

B.

Enter the density value from each core sample on the data table.

Calculate the numeric difference between the average PQI readings and the

core density lab reports. Add or subtract to obtain a small number which

represents the difference between the density value that the PQI is reading

versus the actual density values from the core samples. These numbers are

used to adjust the calibration offset value stored in the PQI so that the unit

can indicate readings that are very close to the actual density values for the

asphalt mix at the job site.

From the Calibration Menu, press ‘1’ to access the normal calibration function,

which will display the following screen:

ENT) Exit

The function is used when you have obtained a number of PQI readings,

PQI is reading too high or low. The first step is to press a key to indicate whether

the PQI is reading too high or low. After pressing the key, the following screen

will appear:

Adjustment:

At this point you should enter the difference in the PQI and core readings.

For example, if the average core reading was 142.3 lb/ft3 and the average PQI

reading at those locations was 143.1 lb/ft3, then the PQI is reading 0.8 lb/ft3 too

high, relative to the cores and you would enter “0.8” or “.8” at the “Adjustment”

prompt.

Note that the calibration should be entered in the current density units. If

the PQI is set to kg/m3, the adjustment should be entered in to kg/m3.

Page 17

After entering the adjustment, the following screen will be displayed to confirm

your entry. The adjustment amount you entered will be shown (the value will

be negative if you said that the PQI was reading too high), along with the new

Adjustment = -1.0

New Offset = -1.0

If you choose option #1 the new offset will be saved in the PQI.

The PQI is now calibrated using this method.

Note: You must first enter the mix MTD before using this method.

Many users have found that their screeds obtain a fairly uniform compaction. If

this compaction is known, it can be used to perform a quick offset calibration of

the PQI using the One Point Method. To use this method, first press ‘2’ (Special)

from the Calibration Menu. After displaying a message recommending that you

first read this guide, the following menu will be displayed:

ENT) Exit

After entering ‘2’, to select the One Point Method, you will be prompted to enter

the expected percent compaction as follows:

Enter % Compaction

After entering the percent compaction you expect from the screed, you will be

prompted as follows:

Page 18

Place PQI on

Unrolled Mat

At this point, you should place the PQI on a fresh unrolled portion of the mat,

press the ENT key, and remove your hand from the PQI. Follow the pattern in

figure 3.6.2 in order to obtain 5 readings. After the 5th reading the PQI will

keep the old offset.

The Two Point Calibration Method is similar to the One Point Method but

it uses an additional measurement of the finished mat in order to obtain a

instructions for performing the calibration and entering the readings.

Note:

The worksheet calls for a reading to be taken on a finished (or “peaked”)

followed:

Reduce the water spray on the roller to the minimum setting

2.

Allow the roller to pass by the sample location

3.

Place the PQI on the mat in a visibly dry location and mark the location for

reference

4.

Take a PQI reading and record the density value

Pick up the PQI and check the probe bottom for signs of moisture

If moisture is present, wipe off the bottom of the probe

7.

Have the roller roll back over the location and begin the next PQI

measurement

Continue this process until the density reading on the PQI dose not rise any

further and has reached its peaked value.

Page 19

Manual Slope (Factory Use Only)

The Manual Slope Method allows you to type in a numeric value for the

was previously calibrated because you can simply reenter the slope that was

previously used.

The first line will be either “Set D_Slope” or “Set S_Slope”, depending on the

lift thickness that you entered. The second line displays the current value of the

To enter a new slope value, presumably a value that you recorded the last time

the mix was used), press ‘2’ and enter the new value as instructed. The new slope

value will be used immediately when you return to one of the run modes.

3.7 The Operating Modes

Average, Single, and Segregation. If the PQI is not in one of the run modes (e.g.

it might be displaying the Setup Menu), you can switch to the last Run Mode

used by pressing the ‘Mode’ key. If the PQI is already operating in one of the

run modes, pressing the ‘Mode’ key will cause the PQI to switch to the next run

mode.

The PQI also has a Diagnostics Mode, which is primarily used by factory

personnel. You can switch to Diagnostics Mode by pressing the ‘Diag’ key.

Each of the run modes will be described in the following sections.

3.7.1 Continuous Reading Mode

Page 20

Batt: 12.7V

H2O: 3.2 187.6 F

D: 156.5 Lb (87.8%)

Line 1:

Always reads “Continuous Mode”. [ ] Indicate pavement type selected.

Line 2:

Displays the battery voltage. A fully charged battery will usually read

approximately 13.8 V and the voltage will decrease as the battery is

discharged. The PQI should be recharged if the battery voltage is less

than 11.6 volts. If the battery voltage is less than 11.0 volts the PQI will

stop operating and simply display a “Battery Low” message.

Line 3:

Displays the moisture index and the mat temperature.

The moisture

index gives a relative indication of the amount of moisture in the mix or

on the surface of the mat.

Line 4:

Displays the density in actual units and in percent.

The density will be

displayed either in lbs/ft3 or kg/m3.To change the units, go to the

Setup Menu and select ‘Displayed Units’ and the select ‘Density’. The

percent density will be displayed in either percent compaction or percent

voids. If displaying percent compaction, the value will be enclosed in

“( )”. If displaying percent voids, the value will be enclosed in “[ ]”.

To change between these units, go to the Setup Menu and select

‘Displayed Units’ and the select ‘%’. Remember that the percentage

values will not be accurate unless you have properly entered the MTD

value of the mix you are currently measuring.

If the PQI is running in Continuous Mode and no keys have been pressed for

the last 5 minutes, the PQI Mode will enter a Power Save Mode. Much of the

Note: While the PQI will take continuous readings in Continuous Mode, the

readings are only valid when the PQI is properly positioned and the

operator is not touching the PQI.

3.7.2 Single Reading Mode

The single reading mode takes a density reading within five seconds. This mode

requires the Enter key to be pressed to start each reading. When the PQI is not

to the Continuous Mode.

Example of Continuous Mode Screen

Page 21

Single Mode

Press ENT to Read

Example of Single Mode Screen

3.7.3 Average Reading Mode

The average reading mode allows the PQI to perform calculations to determine

the average density of five readings from one location on the mat. This mode

hold 99 average readings with station location information along with time and

Avg Mode (5)

ENT) Take Reading # 1

Eample of Average Mode Screen

A.

Press

Enter

B.

Move the PQI and follow the instructions on the display for the next reading.

(Press Enter to start next reading)

After reading number 5 is complete press

Enter

to have the PQI calculate the

Avg Mode (5)

ENT) Display Average

H2O: 3.2

D: 156.5 Lb

The next screen displays the average of the 5 readings and indicates that the PQI

is ready to be moved to a new location for the next density reading. The PQI will

20

Page 22

Avg Mode (5)

ENT) Continue

H2O: 3.2

D: 155.5 Lb

Log the last avg?

Logging the average allows the user to enter a station location.

For example;

the Station Number from a site map may be give as “300 + 050.“

Enter 300 as the first# press

Enter

key can be used to “backspace” and correct numbers. Put in the numbers for the

Enter

Bypass the Set Location screen by pressing

Enter twice

Enter Station #

Example: 300 +50

First #:

Data Added to Log

Press any key

Note: If you choose not to log an average the PQI returns to the first

Average Mode screen and is ready to begin a new set of readings.

3.7.4 Stored Data

From the MAIN MENU press the Down arrow until the screen below appears.

4) Data Log

ENT) Exit

Page 23

Press Key 4 once to display the DATA LOG CONTROL screen

ENT) Exit

Warning!!!! Pressing key 1 will clear all the readings from the Data Logger

Press key 2 to view all the data in the data log on the PQI display screen.

Data Log Size: 22

Up/Down to select

ENT to exit

Pressing the Up or Down arrow keys displays the previous or next set of

readings.

Loc 0300+0150

H2O: 3.1

T:186.4

DENS: 156.7Lb

Pressing the

Enter

key returns the display to the previous menu.

3.7.5 Segregation Mode

finished mat. The PQI’s Segregation Mode can be used to conveniently measure

the density variations that result from mix segregation.

The operation of Segregation Mode is patterned after test procedures used by a

number of testing organizations. The PQI is used to take a number of readings

Page 24

The first screen you will see in Segregation Mode appears as follows:

The code at the end of the first line tells which location and reading are about

to be performed. For example, the “1A” on the previous screen indicates that

you are at the first location and are taking the first, or ‘A’, reading there. Two

readings (‘A’ and ‘B’) are taken at each location and the average value is used.

Taking the average of two readings is required for nuclear gauges, which exhibit

poor repeatability. The PQI has excellent repeatability so two readings should

not be required, but two readings are taken for compatibility with existing

nuclear test procedures.

4) Wait for the reading to be taken (this will take approximately 5

seconds).

After the reading has been taken, the screen will appear similar to the following

H2O 2.7

D: 147.4Lb

take reading “1B”, the second reading at location #1. After accepting the reading

After you have taken all the readings, press ‘2’ to calculate the results. The

results will be displayed on a screen similar to the following:

Results

Lo: 142.7lb

23

Page 25

From this screen you can press ‘1’ to display the lowest density reading, highest

readings can also be transferred to a personal computer using the PQI’s Remote

Mode).

Pressing ‘2’ will complete the set of readings and display the starting screen with

the location/reading reset to ‘1A’.

Correction

3.8.1 Moisture correction

The third generation PQI has a built in moisture correcting formula. Care should

Excessive moisture can affect the accuracy of the PQI. DO NOT take a reading

where there is signs of excessive surface moisture, ie puddles. The Relative

Water Value is displayed as “H2O” in all measurement modes of the PQI.

The third generation PQI has a built in moisture correcting formula. Care should

Batt: 12.7V

H2O: 3.2

D: 156.5 Lb

Example of H2O being displayed

The PQI shows H2O values up to three digits.

Hint: Always wipe the sensor disk with a clean dry cloth before taking

another reading.

3.8.2 Automatic Temperature Compensation

The third generation PQI comes equipped with an infrared temperature probe

the asphalt mat.

Temperature readings are displayed during all of the measurement modes.

Batt: 12.7V

H2O: 3.2

D: 156.5 Lb

Example of temperature being displayed

Page 26

3.9 Power Save Mode/Auto Shutoff

The PQI Model 301 has a built in power saving mode when using the PQI in the

the unit will go into a power saving mode. Pressing any key will “Wake” the

PQI up for continued use. If the PQI is left “On” for an extended period of time

without any keys being depressed, it will shut itself down, to conserve battery

run time.

4.0 Remote Mode

The PQI has a remote mode which allows you to connect it to a personal

Mode readings. To enter Remote Mode, choose selection #6 on the Setup Menu.

To exit Remote Mode, press any key on the PQI keypad.

with a serial (COM) port and terminal emulation software, such as Windows

HyperTerminal. Using a suitable nine-pin serial cable, you should first connect

the PQI to one of your personal computer’s serial ports, making sure to note

which port (e.g. COM1, COM2, etc.).

After connecting the cable, start the communications program on your PC. The

program should be configured to use the COM port that you connected to, with

the following parameters:

Baud Rate:

Data Bits:

Parity:

None

If you are configuring Windows HyperTerminal, you would first select

have connected to. Then select “Configure” to display the remaining parameters.

25

Page 27

Clear (erase) the PQI’s Data Log

N:

Print the number of entries in the PQI’s Data Log

L:

Print all Data Log entries in a readable format

X:

Print all Data Log entries in a spreadsheet-readable format so the

data can be easily imported into a spreadsheet such as Microsoft

Excel.

Print the last set of readings taken in Segmentation Mode.

Enter a new title for the PQI. The title is displayed on the PQI when

power is first applied. To change the title, type ‘T’ and then type the

title. This is a simple title entry function and backspacing is not

allowed. If you make a mistake, you must reenter the correct title.

H:

Print a list of all the commands

E:

Instruct the PQI to exit Remote Mode.

is suggested that 5 or more readings be taken at each site following the reading

pattern of Fig. 3.6.2 .

For accurate readings, the PQI should have a clean, dry, smooth interface with

the mat. Therefore, you should wipe the PQI probe surface dry and clean after

would prevent the PQI from seating properly. If a buildup of asphalt begins to

form on the probe surface, clean the surface with WD-40.

While the PQI contains moisture correction algorithms, the most accurate

readings will be obtained if areas with low moisture levels are measured. If a

measurement area has noticeable surface moisture, you should either wait for the

moisture to evaporate or remove the moisture with an absorbent cloth.

26

Page 28

Watch for suspicious readings

If a reading seems unusual or suspicious, check for possible measurement

Best results are obtained when moisture levels for a series of readings are kept

relatively constant. If the moisture level for a reading is more than a percentage

point higher or lower than the previous readings, the reading should be treated as

Don’t touch the PQI while it is making a measurement

Touching any part of the PQI while it is performing a measurement can distort

the reading.

The PQI measures percentage of air voids in the area beneath the probe,

including the voids on the surface of the mat, while the AASHTO T-166 specific

the AASHTO T-166 method is measuring, PQI readings should be taken on

when the PQI is used on mixes containing larger aggregate.

Measurements should be made on the same day as paving

While the PQI has corrections algorithm for surface moisture, embedded

moisture which can occur after periods of rain, can adversely effect the PQI

readings. If you need to take PQI readings at exact coring locations and the cores

PQI readings on the day of paving.

Page 29

The PQI has been designed to require a minimum of maintenance or service.

Normal care in use should insure long and trouble free operation. The bottom of

the sensing probe is protected by a durable bottom. This material was chosen as

it is resistant to adhesion of pavement particles. If pavement materials begin to

The chart below provides guidance to a few suspect conditions.

Trouble Shooting Chart :

Problem

Incorrect Screen Display

Turn unit off and then back on (Reset)

Incorrect Density Reading

Battery Problems

Data is not being recorded

Review Data Logger procedure

28

Page 30

In the event that the PQI continues to malfunction an internal diagnostics mode

warranty period will void the unit’s warranty. From the

Main Menu option #5

is a diagnostic tool for factory use.

The Company warrants to the Purchaser that the product delivered hereunder

will be free from defects in material or workmanship and be the kind and quality

the Company.

If the product delivered hereunder does not meet the above warranty and if

the Purchaser promptly notifies the Company, the Company shall thereupon

product, replacing the product, or by making available the necessary repaired or

replacement parts.

The liability of the Company under this warranty, for any loss, whether the

whether written, oral, implied or statutory.

No warranty of merchantability or of fitness for purpose shall apply.

Unauthorized service shall void this warranty.

Factory authorized service and replacement items may be obtained directly from

TransTech’s factory or through an authorized representative.

For further information contact TransTech Customer Service:

Fax

E-mail

inquiries@transtechsys.com

Address

29

Page 31

Date

Job Site

Asphalt Mix

MTD Value

Core Comparison Calibration Work Sheet

PQI Readings

Avg. PQI Readings

Avg. Difference between cores &

PQI readings (Calibration Adjustment) value

Position Location1 Location2 Location3 Location4 Location5

4 o’clock

Average

by 5)

30

Page 32

PQI 301 Two Point Calibration Worksheet

FACTORY USE ONLY!!!!!

Enter MTD in PQI and record here

Display the Setup Menu either by

Startup Menu or

Run Mode

4. Press ‘2’ to “Enter a New Value”

Use the PQI’s Average Mode to obtain a low-density measurement from

repeated “Density Mismatch” errors, switch the PQI to Continuous Mode (by

pressing the ‘Mode’ key) and retake the reading. Record the reading here

Use the PQI’s Average Mode to obtain a high-density measurement from a

finished area of the mat. Record the reading here

To compute slope, the PQI requires an estimate of the actual percent

compaction behind the paver. This density is typically 82% of MTD but may

vary with mix and with paver type. In the following table, enter your estimate

To compute slope, the PQI also requires an estimate of the actual percent

compaction of the finished mat where the finished reading above was

taken. This density is typically 95% of MTD but may vary with mix. In the

following table, enter your estimate of percentage of MTD you would expect

in the finished mat.

Use the PQI Slope Calibration Function

4. Enter “Lo Reading”, “Hi Reading”, “Lo Estimate” and “Hi Estimate”

values from above when prompted

7. Press ‘Ent’ twice to return to Run Mode

Low

Reading

High

Reading

Low

Estimate

High

Estimate

New

31

Page 33

Worksheet to Calculate MTD

Density

Targets

Enter Maximum Theoretical,

rice gravity in (A) Lab values are

commonly in gcc ( i.e. 2.54)

3

pounds per cubic

foot ( i.e. 158.50) (A) x 62.4

Enter Density Target (B) In PQI

“See Entering

MTD in Manual”

32

Page 34

Is the PQI orange carry case watertight?

No, the case is not watertight and should not be left out in the rain.

2.

No, There are no user serviceable parts, it must be sent back to the

factory.

3.

Do you have to calibrate the PQI annually at the factory?

No, unless you experience a problem with the unit it does not need

to be sent back.

4.

At this time the PQI 301 is only designed for use on Asphalt Pavement.

How can I charge the PQI 301 in my car?

We suggest that you purchase a 12 volt DC to 120 volt AC power

inverter from a local retailer and plug the PQI charger into the inverter.

Follow the inverter instructions.

33

AC Charger

www.transtechsys.com/opencart

mobile device to go

Page 35

34

4000-0021

Vehicle Cord

www.transtechsys.com/opencart

Page 36

Loading...

Loading...