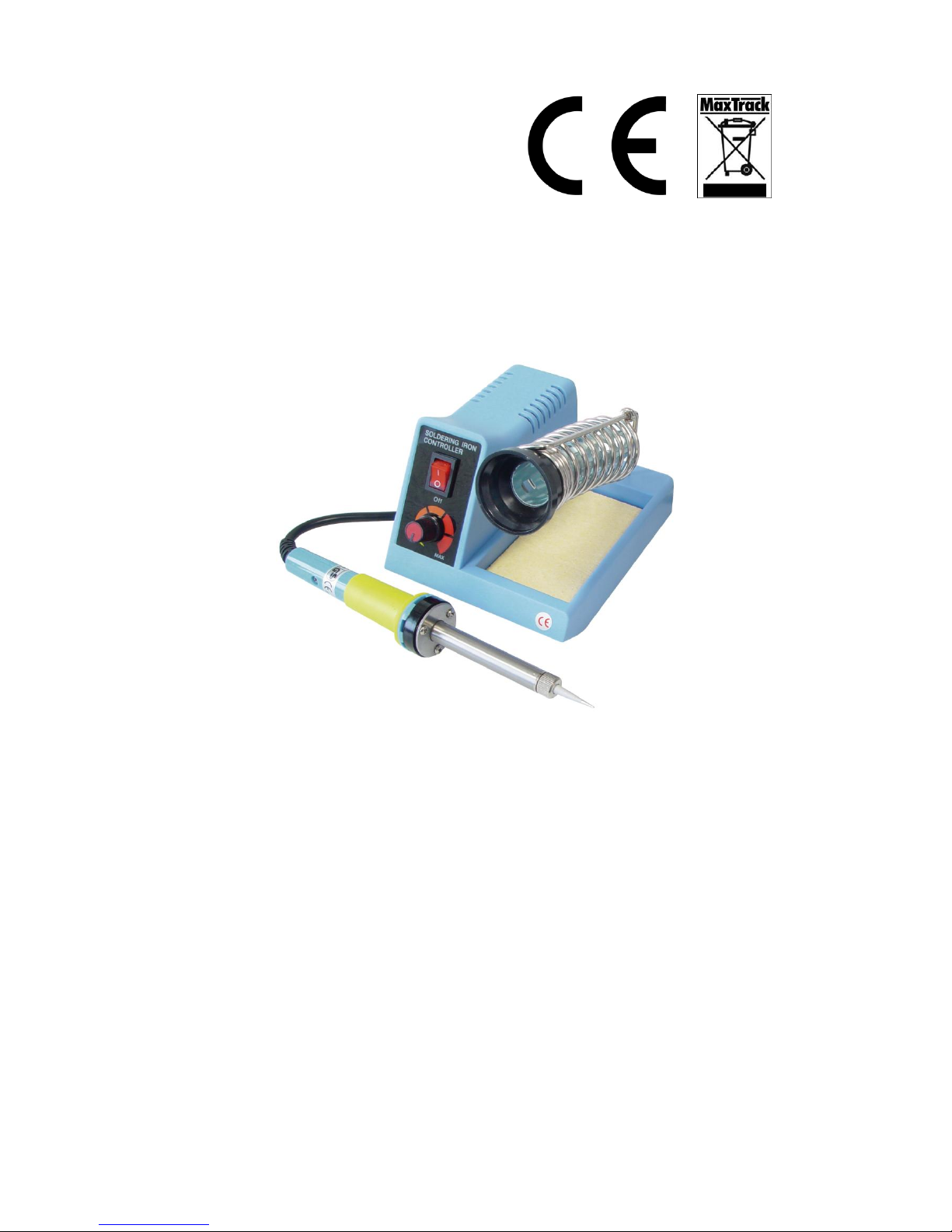

Transmedia ZLS 6 L User Manual

Temperature Controlled

Soldering Station

ZLS 6 L

WORKING TEMPERATURE

Soldering at the correct temperature is very important to ensure proper solder connections. If the

temperature is too low, the solder will not flow correctly and may cause cold solder joints, commonly

known as “dry joints”. If the temperature is too high, the flux will be burned and not allow the solder to

flow correctly. High temperatures can also cause damage to the PC Board and other sensitive

components. When the working temperature of the tip is set to the correct value for the type of the

solder being used, a good solder connection will result.

The most common solder alloys used in the electric industry are 60 % tin, 40 % lead (60/40).

The common tip working temperature of 60/40 solder is specified as below (this may vary from

manufacturer to manufacturer):

Melting point 419 °F (215 °C)

Normal operation 419 to 572 °F (215 to 300 °C)

Production line operation 608 to 716 °F (320 to 380 °C)

Desoldering operation for small joint 599 °F (315 °C)

Desoldering operation for larger joint 752 °F (400 °C)

CARE OF THE TIP

The tip supplied is plated copper and will last a long time. Please observe the following conditions:

1. Always keep the tip tinned before switching off or storing for any period of time, wipe only

before use.

2. Do not keep the iron set at a high temperature for long periods of time as this will break down

the surface of the tip.

3. Never clean the tip with a file or coarse abrasive materials.

4. If, however, an oxide film does form on the tip, it can be cleaned by lightly rubbing with a 600800 grit emery cloth, isopropyl alcohol or equivalent. Once this is done, immediately reheat

and re-tin the tip to prevent further oxidation.

5. If used continuously, remove the tip and clean every twenty hours, or at least once a week.

Also, remove any loose build up that may appear in the barrel.

6. Do not use fluxes containing chlorides or acids. Use only rosin or activated resin fluxes.

7. Do not use any anti-seize materials or compounds on the wettable surface of the tip.

MAINTENANCE

The soldering iron must be placed on the stand when not in use.

If the supply cord is damaged in any way it must be replaced immediately in order to avoid a hazard. A

suitably qualified person or service agent must carry this out.

TIP REPLACEMENT AND DRESSING

Note: Tip replacement or cleaning should be done only when the iron is at room temperature. The tip

can be changed or replaced simply by unscrewing the knurled nut barrel assembly. It is essential that

the station be switched off and allowed to cool before and during this operation, as damage may result

if the system is left on without the tip inserted.

After removing the tip, blow out any oxide dust that may have formed in the tip retaining area of the

barrel.

Care should be exercised to avoid getting dust in your eyes. Replace the tip and tighten the knurled

nut barrel assembly using only hand pressure. Pliers should only be used to tighten the nut, as this

may damage the element.

GENERAL CLEANING

The outer case of the iron or station may be cleaned with a damp cloth using small amounts of liquid

detergent. Never submerse the unit in liquid or allow any liquid to enter the case of the station. Never

use solvents to clean the case.

Loading...

Loading...