Page 1

DPM-3

DIGITAL PANEL MOUNT METER

PLUG AND PLAY IEEE 1451.4 COMPLIANT

OPERATOR MANUAL

4006497

Transducer

Techniques

R

Page 2

TABLE OF CONTENTS

REVISED 07/2017

1. TEDS IEEE 1451.4 INTRODUCTION .......................................................................... 3

2. GENERAL INTRODUCTION ....................................................................................... 3

3. RECEIVING & UNPACKING ....................................................................................... 4

4. SAFETY CONSIDERATIONS ...................................................................................... 4

5. CONNECTOR WIRING INFORMATION ..................................................................... 6

6. MECHANICAL ASSEMBLY ......................................................................................... 8

7. FRONT PANEL SETUP KEYS .................................................................................... 10

8. ENABLING AND LOCKING OUT MENU ITEMS ......................................................... 12

9. TEDS SIGNAL CONDITIONER IN TEDS MODE ........................................................ 13

10. SETUP OF NON-TEDS TRANSDUCERS ................................................................... 17

11. METER SCALING BY APPLYING KNOWN LOADS .................................................. 18

12. TEDS SIGNAL CONDITIONER WITH NON-TEDS TRANSDUCERS ......................... 19

13. LOAD CELL & MICROVOLT SIGNAL CONDITIONER ............................................... 23

14. DUAL RELAY OUTPUT OPTION ............................................................................... 25

15. ANALOG OUTPUT OPTION ....................................................................................... 28

16. SERIAL COMMUNICATION OPTIONS ....................................................................... 29

17. EXCITATION OUTPUTS & POWER SUPPLY ............................................................ 34

18. DIGITAL CONTROL INPUTS ...................................................................................... 35

19. INSTRUMENT SETUP VIA PC .................................................................................... 36

20. CUSTOM CURVE LINEARIZATION ............................................................................ 39

21. METER CALIBRATION ............................................................................................... 41

22. SPECIFICATIONS ....................................................................................................... 41

23. GLOSSARY OF TERMS .............................................................................................. 44

24. ACCESSORIES ........................................................................................................... 50

25. WARRANTY & REPAIR POLICY ................................................................................. 52

- 2 -

Page 3

1. TEDS IEEE 1451.4 INTRODUCTION

The DPM-3 is a TEDS IEEE 1451.4 Plug and Play Smart Load Cell Meter. TEDS, or

Transducer Electronic Data Sheet, is a set of electronic data in a standardized format

defined within the IEEE 1451.4 standard. Stored in an EEPROM, this data specifies what

type of sensor is present, describes its interface, and gives technical information such as

sensitivity, bridge type, excitation, etc.

The DPM-3 automatically detects when a TEDS IEEE 1451.4 compliant Load Cell / Torque

Sensor has been connected to it by using a built-in EEPROM detector. Once such a sensor

has been detected, the DPM-3 displays a front panel TEDS indicator light, reads the

EEPROM, stores the information in memory, and performs an automatic configuration. The

built-in, sensor-related EEPROM may be of any of the following types: DS1973/DS2433,

DS2431 or DS1971/DS2430A. The automatic system configuration function performs all

steps needed to calibrate the TEDS IEEE 1451.4 compliant Load Cell / Torque Sensor and

DPM-3 as a system. This includes the configured precision of 32 bits, 19 bits or 11 bits and

the configured excitation voltage. Using the DPM-3 with a TEDS IEEE 1451.4 compliant

Load Cell / Torque Sensor is as easy as plugging a mouse into a computer, making it a true

plug and play experience.

The DPM-3 is safety certified to UL 61010-1 and to CSA C22.2#61010-1. It carries the ETL

certification mark for the USA and Canada.

2. GENERAL INTRODUCTION

DPM-3 digital panel meters are a versatile, cost-effective solution to a wide variety of

monitoring and control applications. They are easily set up to produce an accurate display

of weight, load or direct reading of microvolts. Setup can be via front panel pushbuttons or

the meter’s serial interface. Digital scaling of zero and span provides direct readout in engineering units. Digital calibration of all ranges eliminates drift associated with potentiometers

found in non-microcomputer-based meters. Selective security lockout of the front panel keys

protects against accidental changes to the meter setup.

A unique method of analog-to-digital conversion provides 60 conversions per second (50 for

50 Hz operation), while integrating the signal over a full line cycle for maximum noise

rejection. Self-calibration cycles reduce the average reading rate to 56 per second (47 for

50 Hz). This fast read rate provides an accurate display of peak signal input and quick

response in control applications.

An adaptive auto-filter automatically selects a time constant appropriate for the encountered

signal noise level. This ensures stable displayed readings and outputs while responding

rapidly to changes of the input signal that exceed a selected threshold value. Input signal

polarity may be selected as normal or reverse.

The DPM-3 uses a lightweight, high-efficiency switching power supply that operates from

either AC or DC voltages and complies with safety regulations. The meter can be powered

worldwide without changes to the supply. An optional low voltage supply operates on 10 to

48 Vdc from batteries or 12 to 32 Vac from sources such as 400 Hz aircraft power. Both

supplies have an isolated 10 Vdc excitation supply to power transducers.

- 3 -

Page 4

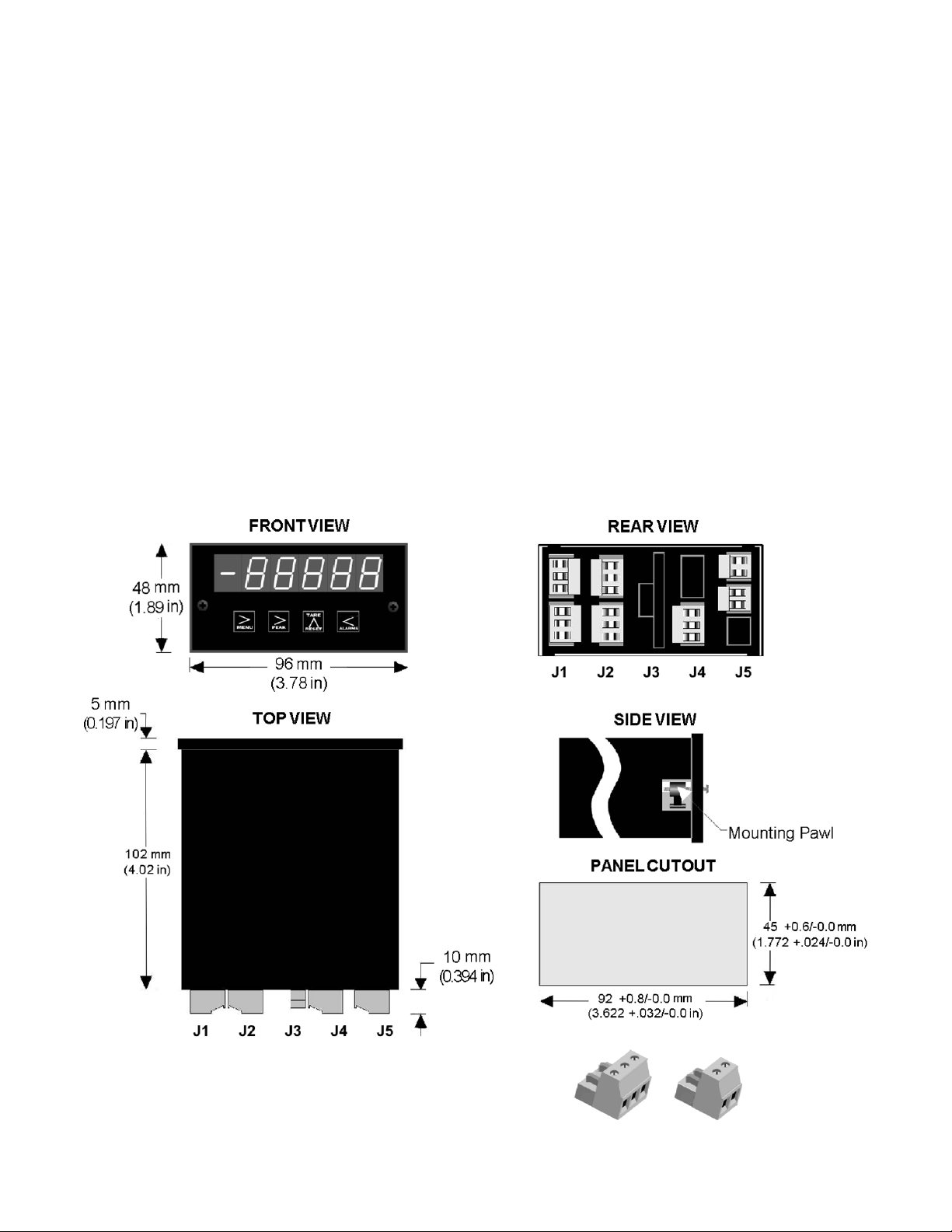

The NEMA-4 (IP65) 1/8 DIN case is made of high impact 94V-0 UL-rated plastic. Mounting

is from the front of the panel and requires less than 110 mm behind the panel. All wiring is

by removable plugs conforming to UL61010C safety standards. All output options are

isolated from meter and power ground by 250 Vac minimum.

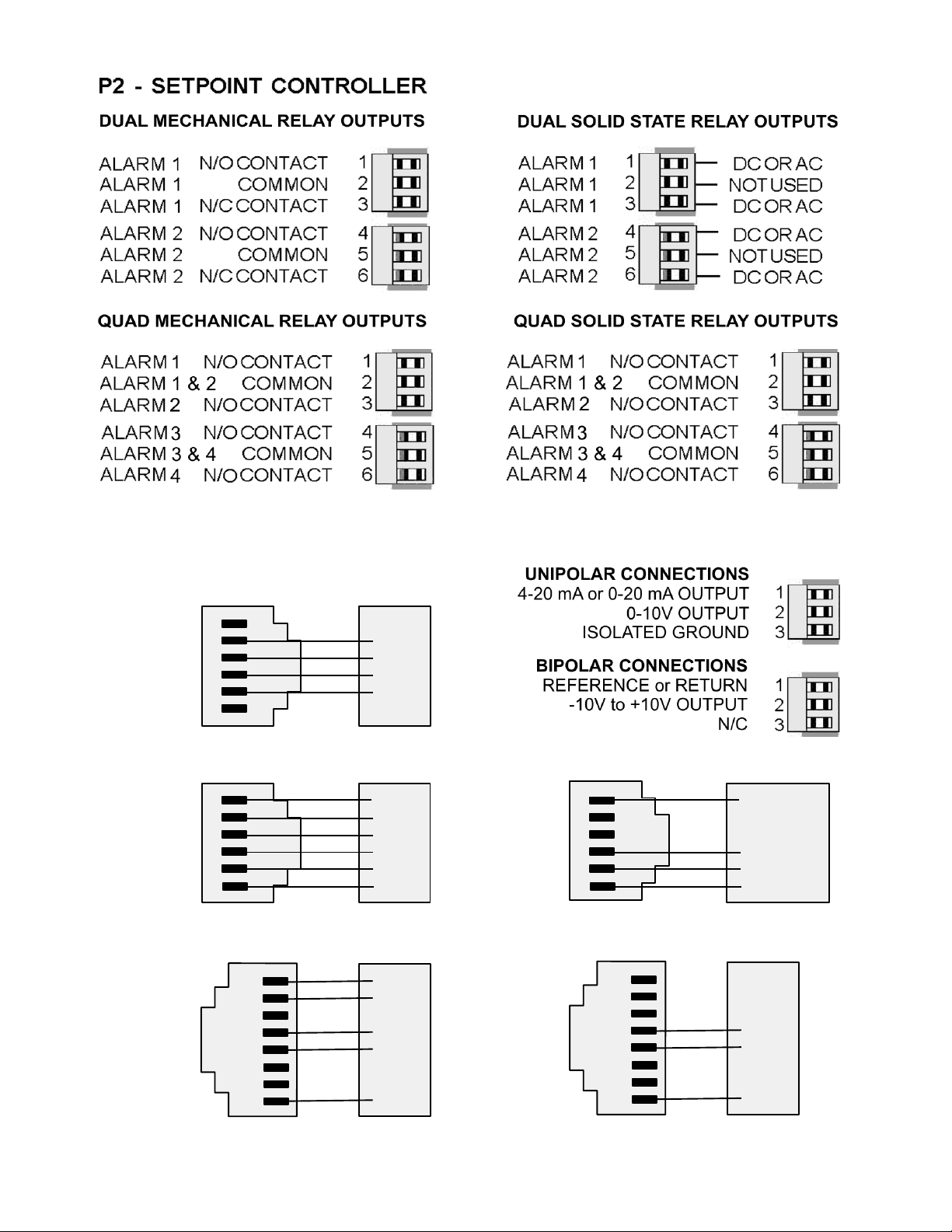

Alarm or setpoint control is provided by an optional relay board with two or four Form C 8A

mechanical relays or two or four Form A 120 mA solid state relays. The setpoints may be

latching or non-latching, be energized above or below the setpoint, or operate in a fail-safe

mode. The relays can operate from the filtered signal to reduce relay chatter or from the

unfiltered signal for fastest response. Snubber circuits and a programmable relay switching

time delay extend relay contact life.

An isolated analog output of 4-20 mA, 0-20 mA, 0-10V or -10 to +10V can be provided by an

optional analog output board. The output is linearized to the display and can operate from

the filtered or unfiltered signal input. It can be scaled via front panel pushbuttons or the

meter’s serial interface.

Optional RS232, RS485, or USB serial interfaces allow the DPM-3 to communicate bidirectionally with computers, PLC’s or other digital devices. An optional USB-to-RS485 converter

board allows a primary DPM-3 to be interfaced to a computer and to be the device server for

a network of up to 31 other DPM-3’s on an RS485 bus, while itself retaining all capabilities

of a meter.

Windows-based software is available from Transducer Techniques to program our meter

and transmitters via a PC using the serial interface. This software can be downloaded at no

charge from www.transducertechniques.com/online-manuals.aspx. Please see Section 19

for details.

3. RECEIVING & UNPACKING

Your DPM-3 meter was carefully tested and inspected prior to shipment. Should the meter

be damaged in shipment, notify the freight carrier immediately. In the event the meter is not

configured as ordered or the unit is inoperable, return the unit to Transducer Techniques for

repair or replacement. Please include a detailed description of the problem.

4. SAFETY CONSIDERATIONS

Visually inspect the instrument for signs of damage. If damaged, do not attempt to operate.

Warning: Use of this equipment in a manner other than specified may impair the protection of the device and subject the user to a hazard. Visually inspect the unit for signs of

damage. If the unit is damaged, do not attempt to operate.

Caution:

This unit must be powered with AC (mains) from 85-264 Vac with the high voltage power

supply option, or 12-32 Vac (10-48 Vdc) with the low voltage power supply option. Verify

- 4 -

Page 5

that the proper power option is installed for the power to be used. This meter has no AC

4006497

ETL Mark. Indicates that product conforms to UL Std. 61010-1 and is certified

to CAN/USA Std. C22.2 No. 61010-1

CE Mark. Indicates that product meets EU safety, health and environmental

requirements.

Caution (refer to accompanying documents)

Caution, risk of electric shock.

Earth (ground) terminal.

Equipment protected throughout by double insulation or reinforced insulation.

Both direct and alternating current.

RoHS Symbol. Indicates that product is free from hazardous substances defined

in EC directive 2002/95/EC.

WEEE Symbol. Indicates that product should be recycled and not disposed of as

general waste.

(mains) switch. It will be in operation as soon as power is connected.

The 85-264 Vac mains connector (P1 Pins 1-3) is colored Green to differentiate it from

other input and output connectors. The 12-32 Vac (10-48 Vdc) mains connector is colored

Black.

Do not make signal wiring changes or connections when power is applied to the instru-

ment. Make signal connections before power is applied. If reconnection is required,

disconnect the AC (mains) power before such wiring is attempted.

To prevent electrical or fire hazard, do not expose the instrument to excessive moisture.

Do not operate the instrument in the presence of flammable gases or fumes; such an

environment constitutes a definite safety hazard.

This meter is designed to be mounted in a metal panel. Verify the panel cutout dimen-

sions, and mount according to instructions.

Symbols applicable to this product:

Operating environment:

The meter is Class II (double insulated) equipment designed for use in Pollution degree 2.

- 5 -

Page 6

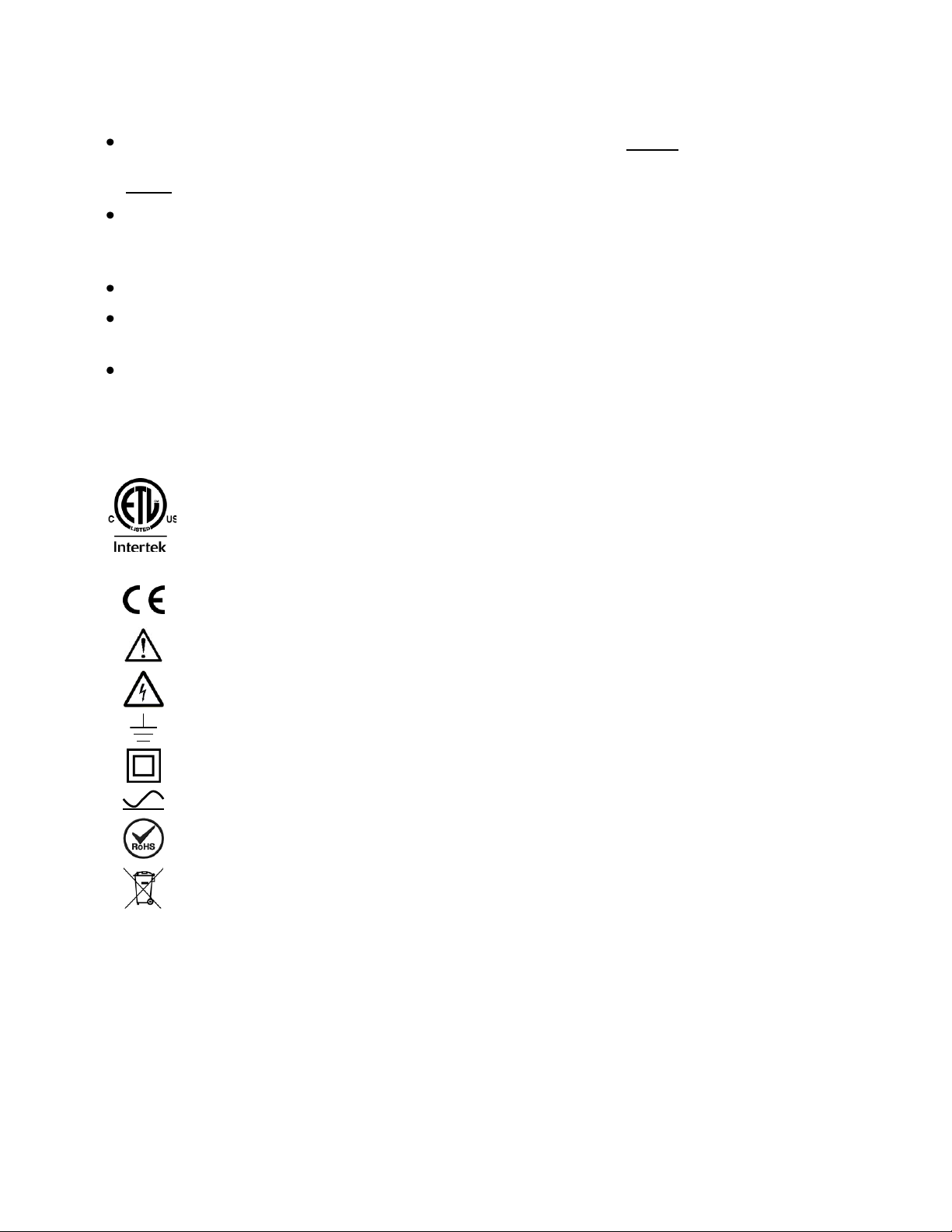

5. CONNECTOR WIRING INFORMATION

5.1 CONNECTOR LOCATION

Connectors for signal and power are UL-rated screw-clamp terminal blocks that plug into

mating jacks on the printed circuit board. Communication connectors can be a USB jack, a

single RJ11 jack for RS232, dual RJ11 jacks for RS485, or dual RJ45 jacks for RS485.

Note: For wiring color, refer to Load Cell Calibration Certificate or to

www.transducertechniques.com/wiring-color-code.aspx

- 6 -

Page 7

P3 - SERIAL COMMUNICATIONS P4 - ANALOG OUTPUT

6

5

4

3

2

1

N/C

ISO GND

RX

TX

RTS

N/C

GND

TX

RX

RTS

RS232 INTERFACE Computer

6

5

4

3

2

1

ISO GND

BRX

ARX

ATX

BTX

ISO GND

GND

BTX

ATX

ARX

ARX

GND

RS485 INTERFACE - FULL DUPLEX

6

5

4

3

2

1

ISO GND

ATX / ARX

BTX / BRX

ISO GND

GND

ATX / ARX

BTX / BRX

GND

RS485 INTERFACE - HALF DUPLEX

1

2

3

4

5

6

7

8

(A') RXD0

(B') RXD1

(B) TXD1

(A) TXD0

ISO GND

TXD0

TXD1

RXD1

RXD0

GND

RS485-MODBUS - FULL DUPLEX RS485-MODBUS - HALF DUPLEX

1

2

3

4

5

6

7

8

(B) TX/RXD1

(A) TX/RXD0

ISO GND

D1

D0

GND

- 7 -

Page 8

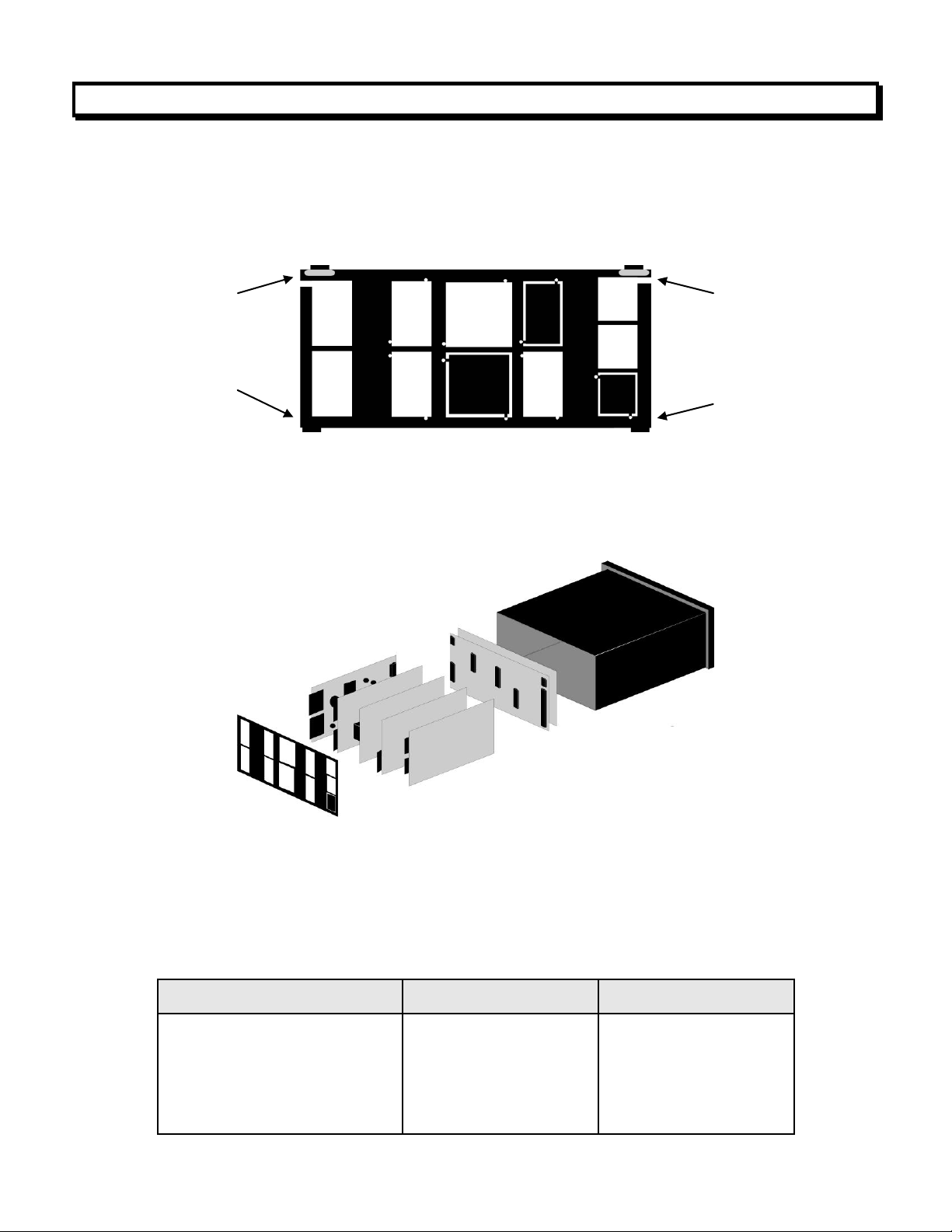

6. MECHANICAL ASSEMBLY

Rear Panel

Option Board

Main Board Jack

Rear Panel Jack

Power supply

Relay board

Serial interface board

Analog output board

Signal conditioner board

P11

P12

P13

P14

P15

J1

J2

J3

J4

J5

Retaining tab

with tab release

Retaining tab

with tab release

Retaining tab

Retaining tab

REMOVING THE REAR PANEL

First remove any connectors. Use one hand to press in the two sides of the rear of the

case, and the other hand to press down the two protruding tab releases at the top of the

rear panel (see figure below). This will unhook the rear panel from the case.

REMOVING THE ELECTRONICS

With the rear panel removed, grasp the power supply board to the left and signal conditioner board to the right, and carefully slide the electronic assembly out through the rear of

the case (see figure below).

INSTALLING NEW OPTION BOARDS

Options boards plug into the main board at the front of the meter. These are plug-and-play

and may installed in the field. They will be recognized by the software, which will provide

access to the menu items associated with that board. If necessary, remove rear panel

knockouts for new boards. Boards plug into connectors as follows:

- 8 -

Page 9

Note: Corresponding main board and option board connectors have the same number of

The DPM-3 uses UL / VDE rated detachable

screw terminal connectors for signal and power.

electrical lines. When an option board is correctly installed, the top and bottom edges of

the main board and option board are aligned.

REASSEMBLING YOUR METER

Slide the electronics assembly into the case until the display board is seated flush against

the front overlay. Insert the bottom tabs of the rear panel into the case, then carefully align

the board connectors with the openings in the rear panel. If necessary, remove any rear

panel knockouts for new option boards that may have been installed. Ensure that all option

boards are properly aligned with the molded board retaining pins on the inside of the rear

panel. With the rear panel in place, reinstall the input/output screw clamp terminal plugs.

PANEL MOUNTING

Ensure that the panel mounted gasket is in place against the back of the bezel. Turn the

two mounting screws counterclockwise until the space between the mounting pawl and the

rear of the gasket is greater than the panel thickness. Insert the meter in the panel cutout.

Turn the mounting screws clockwise until the meter is securely mounted in the panel. Do

not overtighten.

- 9 -

Page 10

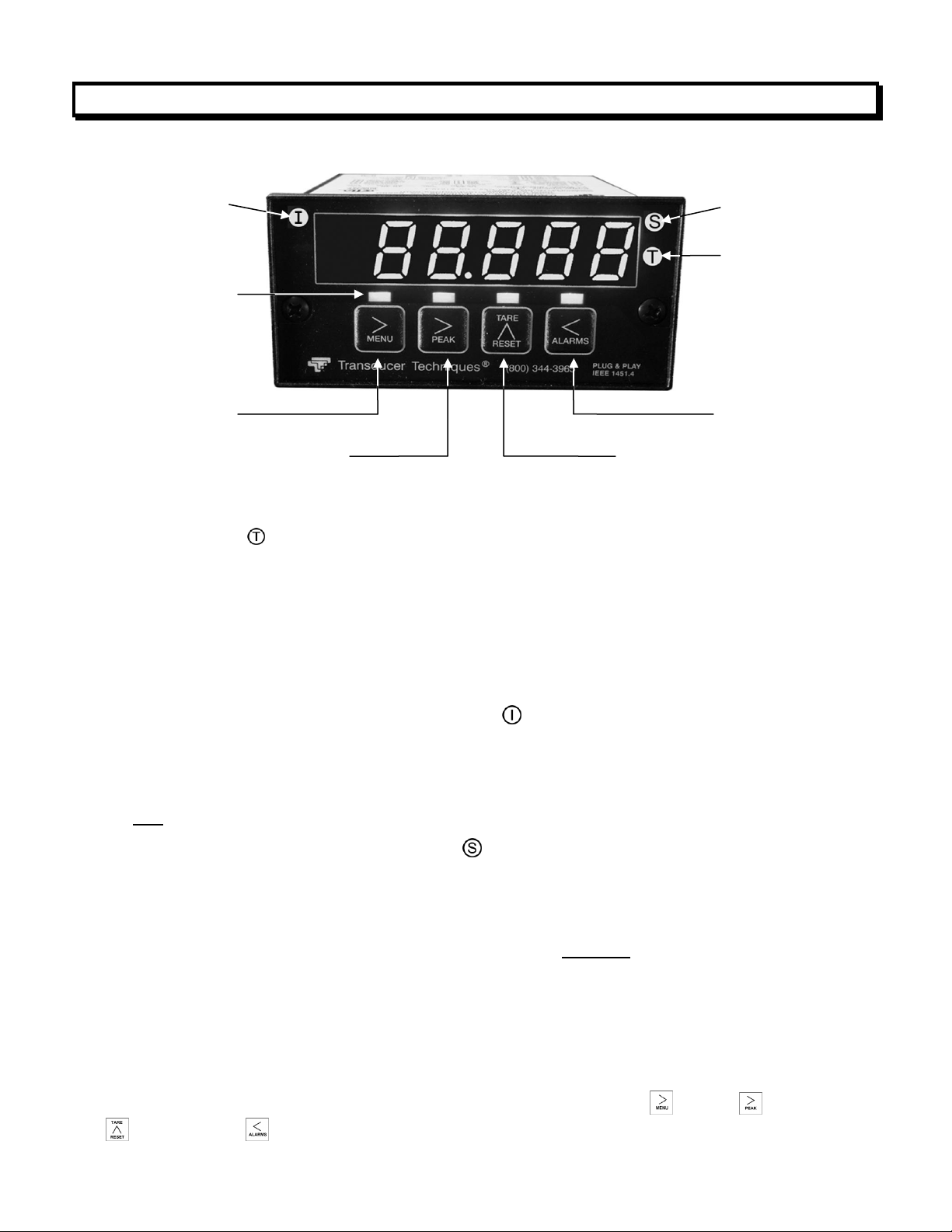

7. FRONT PANEL INDICATORS AND SETUP KEYS

Alarms key

(Reverse menu)

Alarms status

indicators

1 through 4

Menu key

Peak display key

(Digit select)

Reset/Tare key

(Value select)

Sensor Calibration

indicator

Instrument

Calibration

indicator

TEDS indicator

TEDS INDICATOR

Meter Front Panel

On steady when DPM-3 has detected a TEDS sensor, has read the EEPROM, and has

performed an automatic meter configuration.

CALIBRATION INDICATORS

The following two indicators are active when the Calibration indicators are enabled by the

tArE menu item:

1. INSTRUMENT CALIBRATION INDICATOR

Flashing indicates either that the instrument is due for calibration or will be due in less

than 30 days. On steady when instrument is past due for calibration. Stops flashing when

acknowledged from the front panel by selecting the CALrt menu item and changing the

first digit from a 1 to a 0.

2. SENSOR CALIBRATION INDICATOR

Active when a TEDS Plug-and-Play Sensor is detected in Plug-and-Play mode, otherwise stays dark. Flashing indicates either that the sensor is due for calibration or will be

due in less than 30 days. Stops flashing when acknowledged from the front panel by

selecting the CALrt menu item and changing the second digit from a 1 to a 0. Once

acknowledged, it is on steady when the TEDS Plug-and-Play sensor is past due for

calibration.

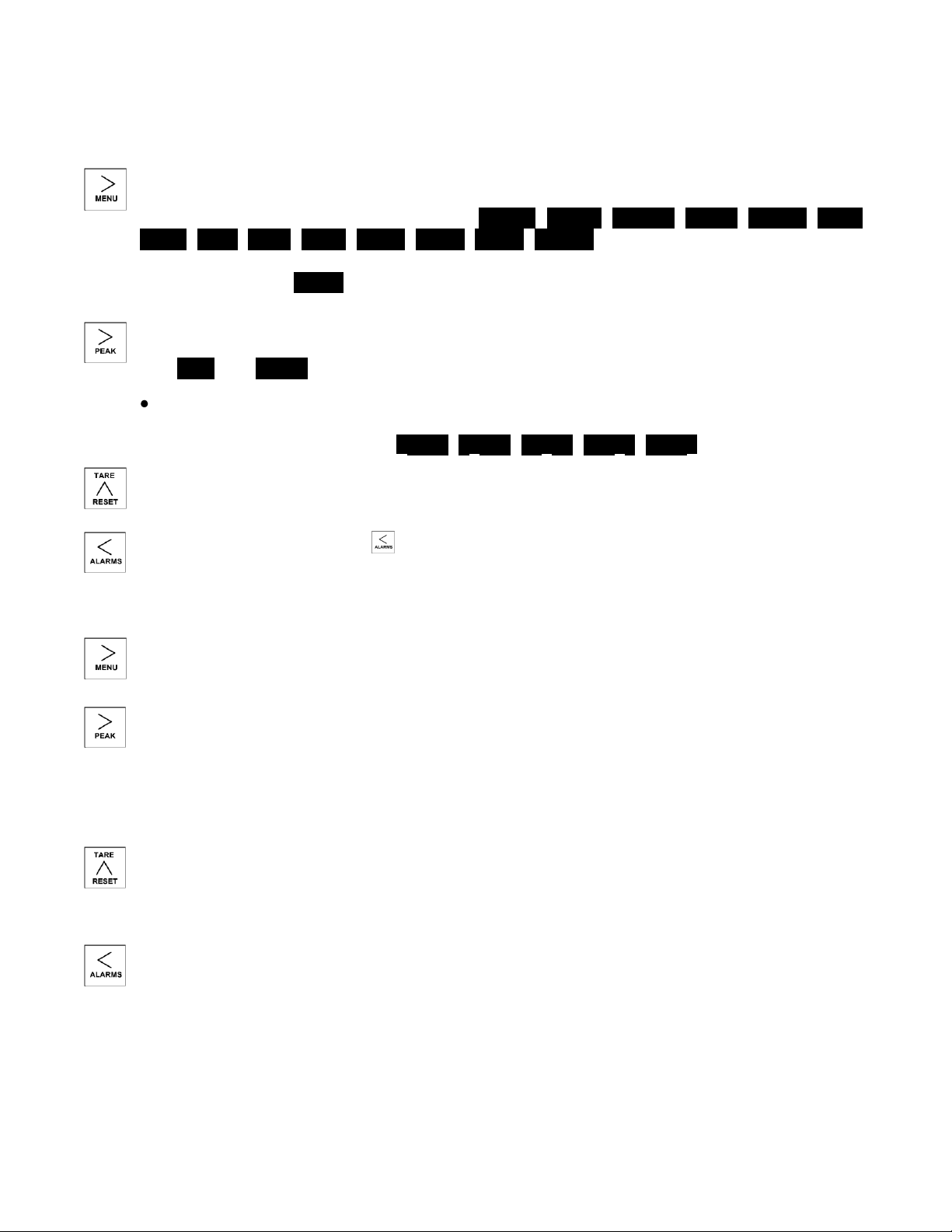

FRONT PANEL KEYS

There are four front panel keys, which change function for the Run Mode and Menu Mode,

effectively becoming eight keys. The keys are labeled with alphanumeric captions (MENU,

PEAK, RESET, ALARMS) for the Run Mode and with symbols ( Menu, Digit select,

Value select, Reverse menu) for the Menu Mode.

- 10 -

Page 11

KEYS IN MENU MODE

In the Menu Mode, pressing a key momentarily advances to the next menu item. Holding

down a key automatically advances through multiple menu items for fast menu navigation.

(Menu). Pressing MENU steps the meter through all menu items that have been

enabled and then back to the Run Mode. With the DC signal conditioner board and no

option boards, available menu items are _InPut, SEtuP, ConFG, _FiLtr, dEc.Pt, Lo in,

Lo rd, Hi in, Hi rd, tArE, Loc 1, Loc 2, Loc 3, Loc 4 . If a change has been made to a

menu item, that change is saved to non-volatile memory when the MENU key is

pressed next, and StorE is displayed briefly.

(Digit Select). Pressing digit select from the InPut menu brings up all meter functions

available with the meter's signal conditioner. For the Load cell signal conditioner, these

are, Strn and _dC u.

Pressing digit select from the SEtuP, ConfFG, FiLtr, Lo in, Lo rd, Hi in, Hi rd, tArE,

Loc 1, Loc 2 or Loc 3 menus items sequentially selects digit positions 1 - 5, as

indicated by a flashing digit: 00000, 00000, 00000, 00000, 00000.

(Value Select). Pressing value select for a flashing item (digit position or decimal point

position) will increment that item. Pressing MENU will save any changes.

(Reverse Menu). Pressing has the same effect as the MENU key, except that menu

items are brought up in reverse order.

KEYS IN RUN MODE

MENU Key. Pressing MENU from the Run Mode enters the Menu Mode. Pressing

MENU repeatedly will step the meter through the various menu items (if these have not

been locked out) and then back to the Run Mode.

PEAK Key. Pressing PEAK normally causes the peak value of the input signal to be

displayed. The peak display then blinks to differentiate it from the normal present value

display. Pressing PEAK again returns the display to the present value. The PEAK key

can also be programmed to display Valley, alternating Peak or Valley, or to Tare the

reading to zero. When Peak or Valley is selected, periodic horizontal bars at the top of

the display indicate Peak, and periodic horizontal bars at the bottom indicate Valley.

RESET/TARE Key. Pressing RESET with PEAK resets peak and valley values.

Pressing RESET with ALARMS resets latched alarms. Pressing RESET with MENU

performs a meter reset (same as power on). Meter reset can also be applied via a rear

panel connector. Pressing and releasing RESET/TARE tares the meter value to zero.

ALARMS Key. Pressing ALARMS once displays the setpoint for Alarm 1. Pressing it

again displays the setpoint for Alarm 2. Pressing it again returns to the present value.

- 11 -

Page 12

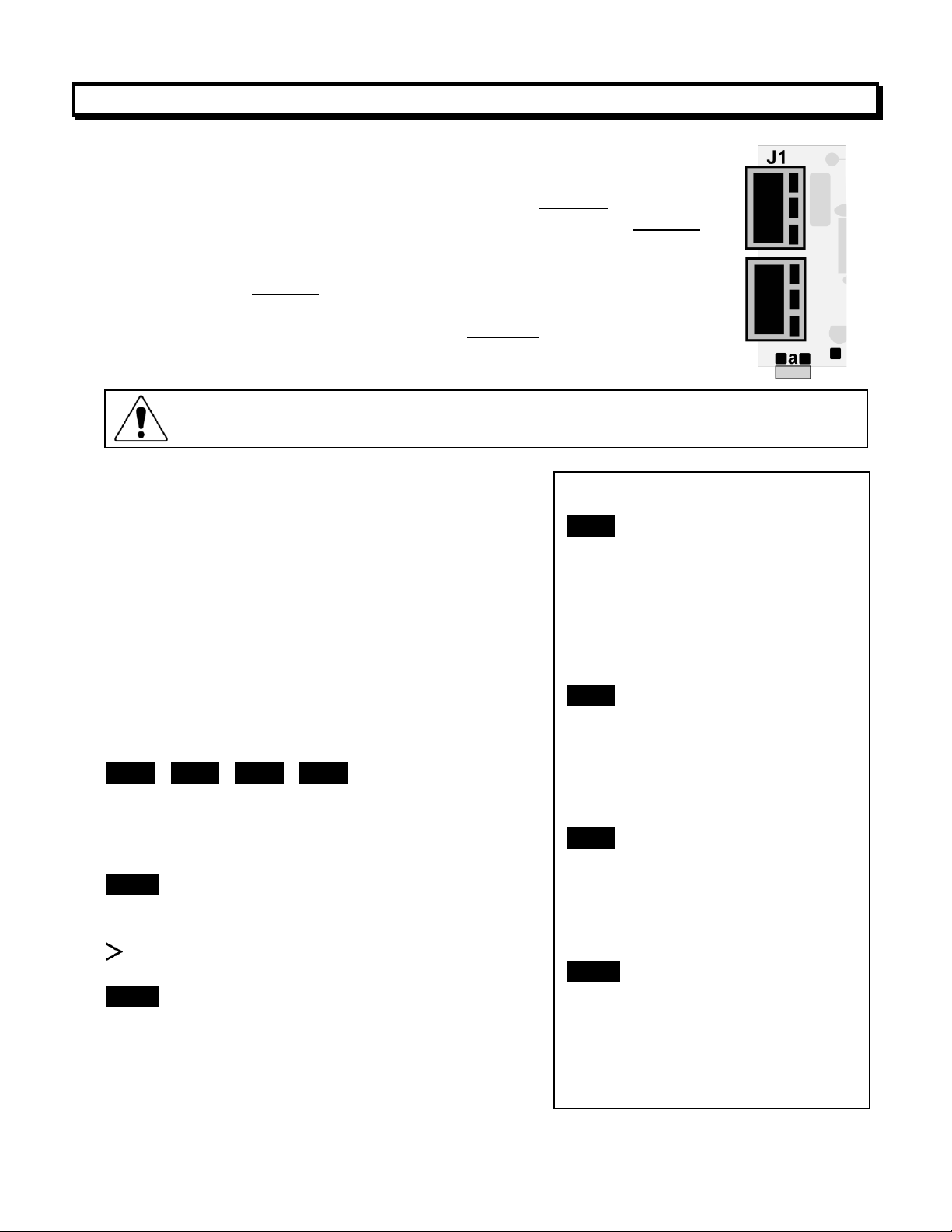

8. ENABLING & LOCKING OUT MENU ITEMS

Check lockout status. DPM-3 meters may have lockouts in place. This causes

menu items described in this manual not to appear.

Enabled or Disabled Menu Items

Loc 1

1 - Input type selection.

2 - Meter setup, configuration &

decimal point

3 - Filter selection.

4 - Scale or Lo, Hi input.

5 - Offset or Lo, Hi reading

Loc 2

2 - Alarm setup.

3 - Alarm setpoint value

programming.

4 - Analog output scaling.

5 - Serial interface setup.

Loc 3

2 - View peak value

3 - View alarm setpoints

4 - Reset (peak & latched alarms)

5 - Reset (meter reset)

Loc 4 (TEDS only)

1 - dAtE

2 – SerNo of sensor & Units

3 - Calibration dates and CALrt

4 - Calibrator’s initials & bridge ID

5 - Calibration Period

For security reasons and ease of meter operation, any or all menu

items may be disabled or "locked out" so that they are no longer

accessible from the front panel. Each function to be disabled can be set

to "1" under menu headers Loc 1-4, while each function to be enabled

can be set to "0." Access to the menu headers Loc 1-4 can in turn be

locked out by installing a hardware jumper on the power supply board.

With the jumper installed, the operator only has access to previously

enabled menu items, not to the menu headers Loc 1-4 and hence not to

the menu items below. With the jumper removed, the operator has

access to menu headers Loc 1-4 and hence to the menu items below.

SETTING HARDWARE LOCKOUT JUMPER

To access the lockout jumper, remove the rear

panel per Section 6 and locate jumper “a” in the

lower portion of the power supply board next to the

input connectors (see figure above).

SETTING SOFTWARE LOCKOUTS

When setting up the meter, it may be necessary to

enable specific menu items by setting the corresponding lockout digit to 0. Be sure to reset the

lockout digit to "1" if you do not want the menu item

to be changed by an operator.

Loc 1 Loc 2 Loc 3 Loc 4

Press the MENU key until Loc 1, Loc 2 Loc 3 or Loc

4 is displayed. Note: Hardware lockout jumper “a”

must be removed (see above).

11111

Press the PEAK to display the lockout status, con-

sisting of 1’s and 0’s. The left digit will flash. Press

again to step to the next digit, which will flash.

00000

12345

Press RESET to set the flashing digit to "0" to

enable the menu item or to "1" to disable. Press

MENU to enter. See the table to the right for list of

menu items that can be enabled or disabled.

- 12 -

Page 13

9. TEDS SIGNAL CONDITIONER IN TEDS MODE

9.1 INTRODUCTION

The DPM-3 is a TEDS IEEE 1451.4 Plug and Play Smart Load Cell Meter. TEDS, or

Transducer Electronic Data Sheet, is a set of electronic data in a standardized format

defined within the IEEE 1451.4 standard that is stored in an EEPROM. This data specifies

what type of sensor is present, describes its interface, and gives technical information such

as sensitivity, bridge type, excitation, etc. The DPM-3 will automatically detect when a

TEDS IEEE 1451.4 compliant Load Cell / Torque Sensor is connected to it, each and every

time, by a built in EEPROM detector. Once a TEDS Sensor has been detected, the DPM-3

displays a front panel TEDS indicator light, reads the EEPROM and stores the information

in memory and performs an automatic configuration. The automatic system configuration

function performs all steps needed to calibrate the TEDS IEEE 1451.4 compliant Load Cell

/ Torque Sensor and DPM-3 as a system, including selecting the correct sensor excitation.

Using the DPM-3 with a TEDS IEEE 1451.4 compliant Load Cell / Torque Sensor is as

easy as plugging a mouse into a computer, making it a true plug and play experience.

9.2 SCALING

When a DPM-3 connected to a TEDS transducer is powered on, the meter reads the data

stored in the transducer. The excitation supply is automatically set to the correct value and

the DPM-3 calculates the correct scaling to calibrate the meter and the transducer as a

system. The jumper on the signal conditioner board must be set for the 50 mV range. See

Section 13.1. If the Maximum Physical Value of the TEDS sensor exceeds 100,000, the

calculated scale and offset are divided by 10 and the reading is in 10's of units.

If the full scale of the transducer is 50 pounds, the meter will display 50 at full scale output.

If more resolution is desired, the meter decimal point can be set so that the meter will read

50.0, 50.00, or 50.000. In this example, if another unit of measure, such as kilograms, is

desired, there are two alternatives.

If the meter has a serial communication board installed, TEDS Reader_Editor software

can be used (see Section 24 "Accessories" for information). The electronic data sheet for

your transducer can then be read electronically and be displayed on a computer screen.

The values can be modified (e.g., to display kilograms instead of pounds), and then written

back to the transducer.

The meter Menu item "Tare," digits 4 and 5, can be set to 1 to configure the meter as a

non-TEDS transducer type.

9.3 Error Messages

If there is a problem with the TEDS connection between the meter and the TEDS trans-

ducer, one of the following error messages will be displayed at power on or when plugging

in a TEDS transducer while the power is on:

Err 1 - TEDS data line shorted

Err 2 - No Presence pulse from TEDS

Err 3 - Improper Presence pulse width

Err 4 - TEDS family code in ROM in error

Err 5 - TEDS checksum error in the first or second 32 bytes

- 13 -

Page 14

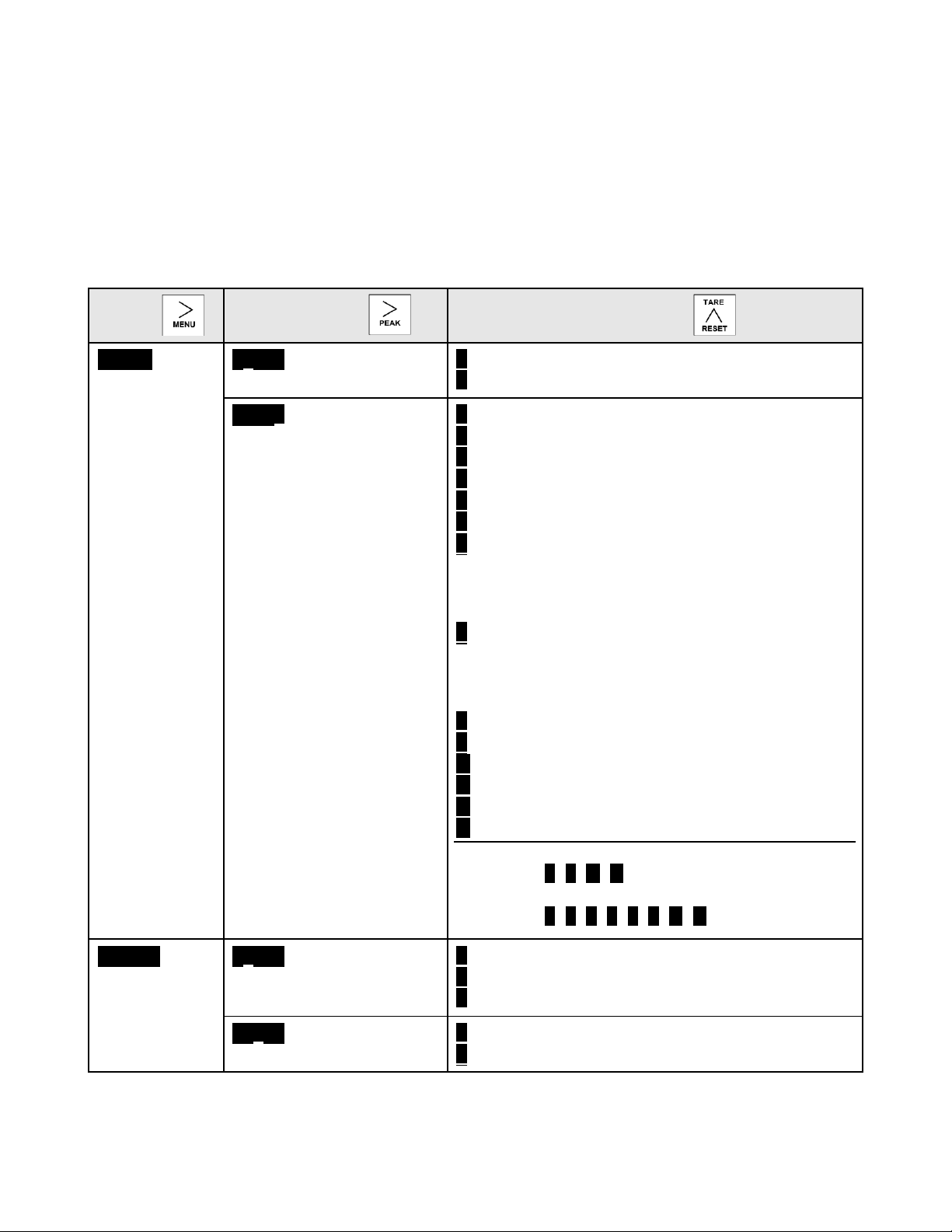

9.4 Software

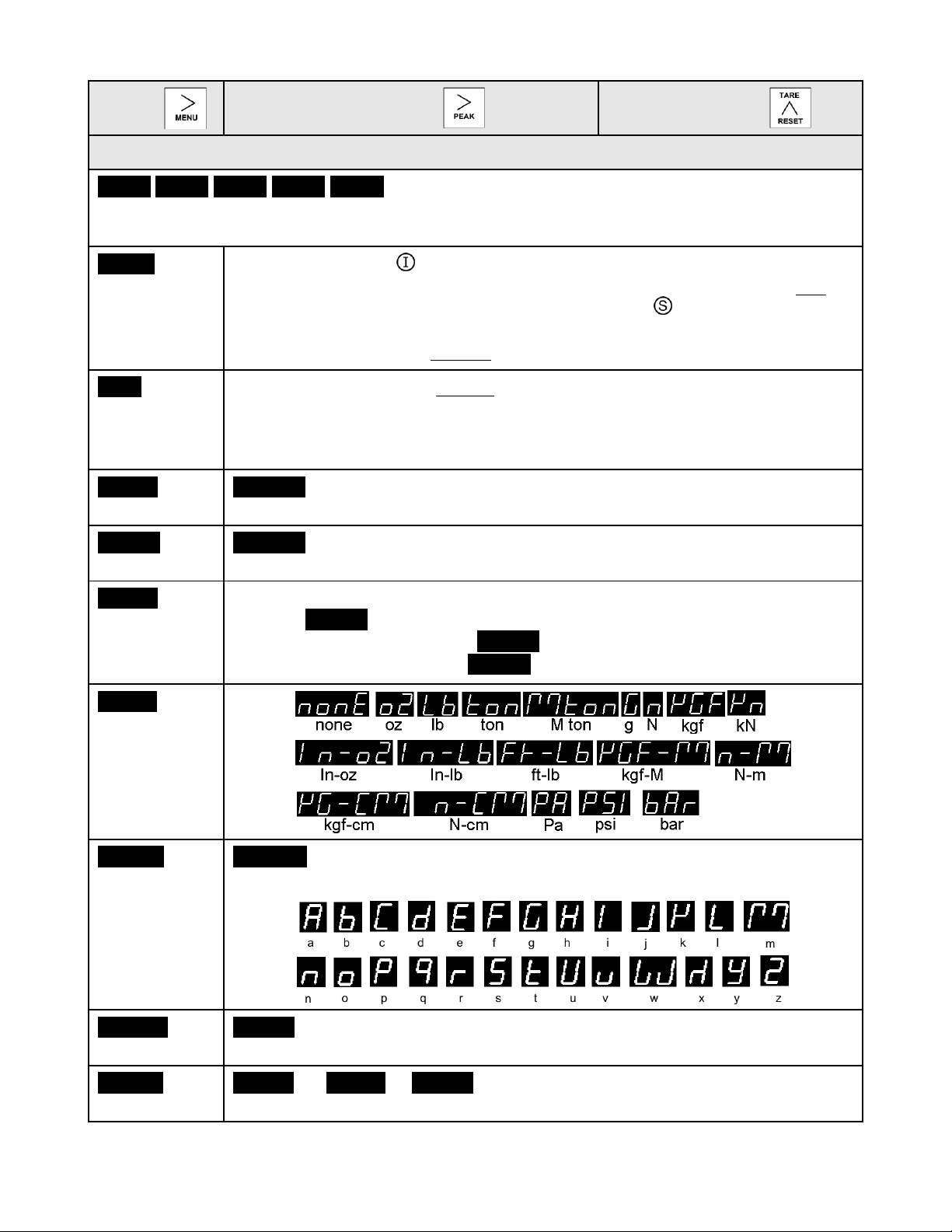

MENU

KEY

DIGIT

SELECT KEY

VALUE

SELECT KEY

SEtuP

Meter Setup

_0__0

Power line frequency

0 Noise minimized for 60 Hz

1 Noise minimized for 50 Hz

_0__0

Rear control inputs

A & B

True = logic 1 (0V or

tied to digital ground)

False = logic 0 (5V or

open)

0 A = Reset, B = Meter Hold

1 A = Function Reset B = Peak or Valley Displ.

2 A = Meter Hold B = Peak or Valley Displ.

3 A = Meter Hold B = Tare

4 A = Peak or Valley B = Tare

5 A = Tare B = Reset

6 A = 0, B = 0, decimal point 1= XXXXX

A = 1, B = 0, decimal point 1 = XXXX.X

A = 0, B = 1, decimal point 1 = XXX.XX

A = 1, B = 1, decimal point 1 = XX.XXX

7 A = 0, B = 0, decimal point 2 = XXXX.X

A = 1, B = 0, decimal point 2 = XXX.XX

A = 0, B = 1, decimal point 2 = XX.XXX

A = 1, B = 1, decimal point 2 = X.XXX.X

8 A = Function Reset B = Display Blank

9 A = Hold B = Display Blank

A A = Peak or Valley B = Display Blank

B A = Tare B = Display Blank

C A = Valley Display B = Peak Display

D A = Tare B = Tare Reset

Both control inputs A and B set to logic 1 for

selections 2, 4, A, C = Function Reset.

Both control inputs A and B set to logic 1 for

selections 0, 1, 3, 5, 8, 9, B, D = Meter Reset.

ConFG

Meter

Configuration

_00___

Operation of front panel

PEAK button

0 Peak Display (max reading)

1 Valley Display (min reading)

2 Peak (1st push), Valley (2nd push)

_00___

Signal polarity

0 Normal Input Signal Polarity

1 Reverse Signal Polarity

TEDS Reader-Editor Software, P/N DPM-3-TRES, is available from Transducer Techniques. This software allows the user to read and edit information stored in the TEDS

transducer. See Section 24 "Accessories" for ordering information.

9.5 Meter Setup

When setting up the meter, it may be necessary to enable some of the menu items.

See Section 8 “Enabling and Locking Out Menu Items” for the procedure.

- 14 -

Page 15

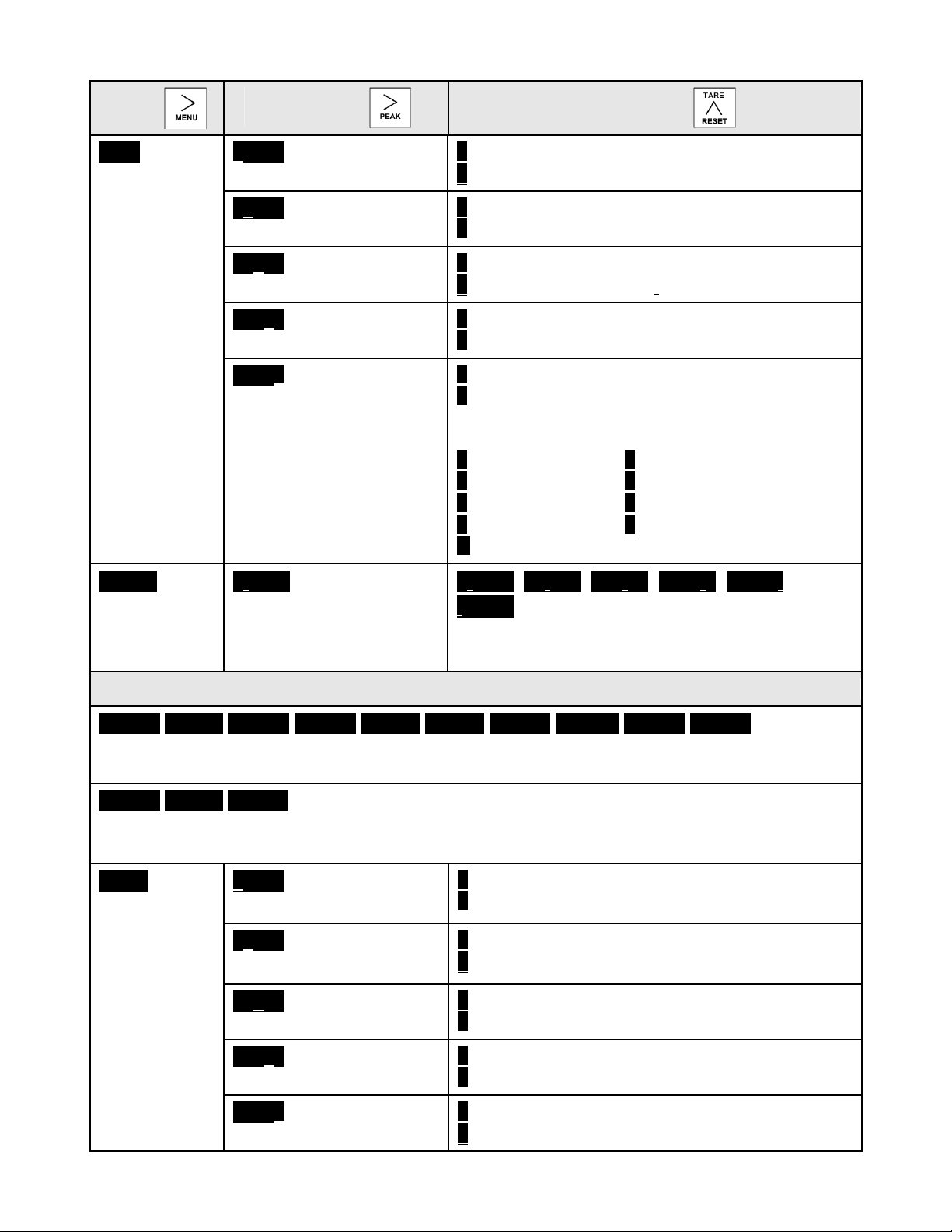

MENU

KEY

DIGIT

SELECT KEY

VALUE

SELECT KEY

FiLtr

Filtering

00000

Alarm filtering

0 Alarm unfiltered

1 Alarm filtered

00000

Peak & Valley filtering

0 Peak & Valley unfiltered

1 Peak & Valley filtered

00000

Display filtering

0 Display batch average every 16 readings

1 Display filtered signal

00000

Adaptive filter threshold

0 Low adaptive filter threshold level

1 High adaptive filter threshold level

00000

Input signal filtering.

Can be applied to display, setpoint, analog

output, data output.

0 Autofilter

1 Batch average, 16 readings.

Moving averages with equivalent RC time

constants:

2 0.08 sec. 3 0.15 sec.

4 0.3 sec. 5 0.6 sec.

6 1.2 sec. 7 2.4 sec.

8 4.8 sec. 9 9.6 sec.

A Unfiltered

dEc.Pt

Decimal point

selection.

d.dddd

Determines decimal

point position & reading

resolution.

d.dddd dd.ddd ddd.dd dddd.d ddddd.

.ddddd Press ^ key to shift decimal point.

Decimal point is stored in TEDS memory.

Display shows TEds instead of StorE.

Option board dependent menu items

ALSEt. ALS34 dEU1H dEU2H dEU1b dEU2b dEU3H DEU4H DEU3b DEU4b

Menu items related to alarm setup These will only appear if a relay board is detected. If

so, please see Section14.

AnSEt. An Lo. An Hi..

Menu items related to analog output setup. These will only appear if an analog output

board is detected. If so, see Section 15.

tArE_

Tare & TEDS

selections.

00000 Calibration due

indicator.

0 Calibration due indicators enabled

1 Calibration due indicators disabled

00000 Front panel

pushbutton Tare.

0 Front panel tare enabled

1 Front panel tare disabled

00000

Auto-Tare.

0 Tare after meter reset

1 No tare after meter reset

00000 TEDS Plug and

Play indicator.

0 TEDS Plug and Play indicator enabled

1 TEDS Plug and Play Indicator disabled

00000

TEDS Plug and Play.

0 TEDS Plug and Play enabled

1 TEDS Plug and Play disabled

- 15 -

Page 16

MENU

KEY

DIGIT

SELECT KEY

VALUE

SELECT KEY

Option board dependent menu items

SEr 1. SEr 2. SEr 3. SEr 4. _Addr

Menu items related to serial communications. These will only appear if an RS232,

RS485, or USB I/O board is detected. If so, see Section 16.

CAL rt

Cal Reset

The Cal Instrument indicator starts flashing 30 days before instrument

calibration is due. To acknowledge and turn off flashing, change the first

digit of this menu item from 1 to 0. The Cal Sensor indicator starts

flashing 30 days before sensor calibration is due. To acknowledge and turn

off flashing, change the second digit of this menu item from 1 to 0.

dAtE

Current date

Use keypad to enter the current date in MM.DD.YY format. This menu item

can also appear as an error message when the battery has just been

replaced, or in other instances where the instrument date is not correct.

The meter remains non-functional until the current date has been entered.

CALd II

Instr cal date

00.00.00 Meter calibration date in MM.DD.YY format. Read-only.

CALdS

Sens cal date

00.00.00 Sensor calibration date in MM.DD.YY format. Read-only.

SEr no

Transducer

Serial No.

If the serial number is 6 digits or less, press the Peak key once to display

all digits 123456. If the serial number is greater than 6 digits, press Peak

once to display the first digits 12–___, and press the Peak key again to

display the remaining digits 345678. Read only.

UnitS_

Units of measure. Read

only.

CALInL

Cal initials

_A_ b_C Initials of the person who performed the transducer calibration.

Read only. Characters used are:

CALPEr

Cal period

___365 Required transducer calibration interval in days. Read only.

-M – Id-

Bridge ID

brdg-A or brdg-b or brdg-C Identifies whether meter is monitoring

bridge A, bridge B, or bridge C.

- 16 -

Page 17

10. SETUP OF NON-TEDS TRANSDUCERS

10.1 SCALING METHODS

Three methods are selectable for scaling the meter, as follows:

Scale and Offset Method (using calculated scale and offset). This method requires that you

calculate the required scale and offset values and enter them into memory when the meter

displays SCALE and OFFst. No calibration signals need to be applied to the meter.

Coordinates of 2 Points Method (using values from sensor's calibration certificate). With this

method, you enter the low input signal value, the display value for the low signal, the high input

signal value, and the display value for the high input signal value. These values are entered

when menu items Lo In, Lo rd, HI In and HI rd are displayed. No calibration signals need to

be applied to the meter with this method, which is the most commonly used.

Reading Coordinates of 2 Points Method (applying a known weight or load). When using

this method, the meter calculates the proper scaling and offset values, entering them into

memory. The meter is connected to your sensor and looks at the values of the input signals to

calibrate the meter and transducer as a system.

10.2 Implementing Scale and Offset Method (using calculated scale factor and offset)

Apply power and press the MENU key until SEtuP appears on the display.

Press the PEAK key, and four digits will appear on the display. Continue pressing the PEAK

key until Digit 4 begins to flash _00_00. Make this digit a 0 by pressing the RESET key until 0

appears. Store the change by pressing the left MENU key. Perform any other programming

changes are required for your application.

10.3 Implementing Coordinates of 2 Points Input Method (using values from the sensor's

calibration certificate)

Apply power and press the MENU key until SEtuP appears on the display.

Press the PEAK key, and four digits will appear on the display. Continue pressing the PEAK

key until Digit 4 begins to flash _00_10. Make this digit a 1 by pressing the RESET key until 1

appears. Store the change by pressing the MENU key. Reset the meter.

Press the MENU key until Lo In appears. Using the PEAK and RESET keys, enter the low

input value. Push the MENU key until Lo rd appears. Using the PEAK and RESET keys, enter

the low reading to be displayed. Repeat this procedure for HI In and HI rd. Perform any other

programming changes that are required for your application.

10.4 Implementing Reading Coordinates of 2 Points Method (applying a known load)

Apply power and press the left MENU key until SEtuP appears on the display.

Press the PEAK key, and four digits will appear on the display. Continue pressing the PEAK

key until the Digit 4 begins to flash _00_20. Make this digit a 2 by pressing the RESET key

until 2 appears. Store the change by pressing the left MENU key. Reset the meter.

Go to Section 11 and perform the procedure of applying known low and high loads. Perform

any other programming changes that are required for your application.

- 17 -

Page 18

11. METER SCALING BY APPLYING KNOWN LOADS

MENU KEY

DIGIT SELECT

KEY

VALUE

SELECT KEY

_Lo In_ Press the key.

Lo In will appear on the

meter display. Apply the low

known load.

_0.021 Press the key.

The meter will begin to take

readings and display the low

signal value.

_0.021 Press the key to

store the Lo In (low signal)

value.

_Hi In_ Press the key.

Hi In will appear on the

meter display. Apply the high

known load.

20.094 Press the key.

The meter will begin to take

readings and display the high

signal value.

20.094 Press the key to

store the Hi In (high signal)

value.

_Lo rd_ Press the key.

Lo Rd will appear on the me-

ter display. Enter the desired

low load reading value.

_0001.5 Press the key

to select a digit, which will

flash.

0.0000 0.0000 0.0000

0.0000 0.0000

0000.0 Press the key to

select a value from 0 to 9 for

the flashing digit. The decimal is fixed by dEC.Pt.

_Hi rd_ Press the key.

Hi Rd will appear on the me-

ter display. Enter the desired

high load reading value.

_1000.0 Press the key

to select a digit, which will

flash.

0.0000 0.0000 0.0000

0.0000 0.0000

5000.0 Press the key to

select a value from 0 to 9 for

the flashing digit. The decimal is fixed by dEC.Pt.

Apply power and press the left MENU key until SEtuP appears on the display. Press the

PEAK key, and 4 digits will appear on the display. Continue pressing the PEAK key until

the Digit 4 begins to flash _00_20. Make this digit a 2 by pressing the RESET key until 2

appears. Store the change by pressing the left MENU key. Reset the meter. Connect the

meter to your sensor or transducer. Use the procedure below to scale your meter by

applying known loads.

- 18 -

Page 19

MENU

KEY

DIGIT SELECT

KEY

VALUE SELECT KEY

InPut

Input signal

type

_Strn_

Load cells. Factory default scaling is 50 mV FS

__20.0 __50.0 _100.0 _250.0 _500.0

20, 50, 100, 250, 500 mV full scale.

_dC u

DC millivolts

SEtuP

Meter Setup

00_00

Display type

0 4-1/2 digit meter, counts by 1

1 5-digit remote display (±99,999)

2 4-1/2 digit meter, counts by 10

3 3-1/2 digit meter

00 _00

Power line frequency

0 Noise minimized for 60 Hz

1 Noise minimized for 50 Hz

_0_00

Meter scaling method

0 Scale and offset method

1 Coordinates of 2 points method

2 Reading coordinates of 2 points method

00_00

Rear connector control

inputs 1 & 2

True = logic 1 (0V or

tied to digital ground)

False = 0 (5V or open)

0 1 = Reset, 2 = Meter Hold

1 1 = Function Reset 2 = Pk or Valley Disp.

2 1 = Meter Hold 2 = Pk or Valley Disp.

3 1 = Meter Hold 2 = Tare

4 1 = Peak or Valley 2 = Tare

5 1 = Tare 2 = Reset

6 1 = 0, 2 = 0, decimal point 1= XXXXX

1 = 1, 2 = 0, decimal point 1 = XXXX.X

1 = 0, 2 = 1, decimal point 1 = XXX.XX

1 = 1, 2 = 1, decimal point 1 = XX.XXX

7 1 = 0, 2 = 0, decimal point 2 = XXXX.X

1 = 1, 2 = 0, decimal point 2 = XXX.XX

1 = 0, 2 = 1, decimal point 2 = XX.XXX

1 = 1, 2 = 1, decimal point 2 = X.XXX.X

8 1 = Function Reset 2 = Display Blank

9 1 = Hold 2 = Display Blank

A 1 = Peak or Valley 2 = Display Blank

B 1 = Tare 2 = Display Blank

C 1 = Valley Display 2 = Peak Display

D 1 = Tare 2 = Tare Reset

Both control inputs 1 & 2 set to 1 for selections

2, 4, A, C = Function Reset.

Both control inputs 1 & 2 set to 1 for selections

0, 1, 3, 5, 8, 9, B, D = Meter Reset.

12. TEDS SIGNAL CONDITIONER WITH NON-TEDS TRANSDUCERS

- 19 -

Page 20

MENU

KEY

DIGIT SELECT

KEY

VALUE SELECT KEY

ConFG

Meter

Configuration

000_0

Operation as a rate of

change meter.

Extended meter only.

0 Not rate of change

1 Rate x 0.1

2 Rate x 1

3 Rate x 10

4 Rate x 100

5 Rate x 1000

6 Rate x 10000

000_0

Operation of front panel

PEAK button and rear

connector for Peak or

Valley Display

0 Peak Display. Also selects “Peak” in

“Peak or Valley” at connector above.

1 Valley Display. Also selects “Valley” in

“Peak or Valley” at connector above.

2 Peak (1st push), Valley (2nd push)

000_0_

Signal polarity.

0 Normal signal polarity

1 Reverse signal polarity

000_0_

Nonlinear input scaling

Extended meter only..

0 Linear input

1 Custom curve linearization

FiLtr

Filtering

00000

Alarm filtering

0 Alarm unfiltered

1 Alarm filtered

00000

Peak & Valley filtering

0 Peak & Valley unfiltered

1 Peak & Valley filtered

00000

Display filtering

0 Display batch average every 16 readings

1 Display filtered signal

00000

Adaptive filter threshold

0 Low adaptive filter threshold level

1 High adaptive filter threshold level

00000

Input signal filtering.

Can be applied to display, setpoint, analog

output, data output.

0 Autofilter

1 Batch average, 16 readings

2 Moving average, 0.08 sec.

3 Moving average, 0.15 sec.

4 Moving average, 0.3 sec.

5 Moving average, 0.6 sec.

6 Moving average, 1.2 sec.

7 Moving average, 2.4 sec.

8 Moving average, 4.8 sec.

9 Moving average, 9.6 sec.

A Unfiltered

dEc.Pt

Dec. point

selection

d.dddd

Decimal point flashes.

d.dddd dd.ddd ddd.dd dddd.d ddddd.

.ddddd

- 20 -

Page 21

MENU

KEY

DIGIT SELECT

KEY

VALUE SELECT KEY

Scaling method “Scale and Offset” if selected under SEtuP

SCALE

Scale factor

0.0000 0.0000 0.0000

0.0000 0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Select decimal point

location when decimal point is flashing.

OFFst

Offset value

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point location

is selected by dEC.Pt.

Scaling method “Coordinates of 2 points” if selected under SEtuP

Lo In.

Low signal

input.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set by

input range chosen.

Lo rd

Desired reading at Lo In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set by

dEC.Pt.

Hi In.

High signal

input.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set by

input range chosen.

Hi rd.

Desired reading at Hi In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set by

dEC.Pt.

Scaling method “Reading coordinates of 2 points” if selected under SEtuP

Lo In.

Low signal

input.

_0.021

Apply a low reference

signal to the meter.

_0.021

Press to store the low signal input in the

meter.

Hi In.

High signal

input.

_20.094

Apply a high reference

signal to the meter.

_20.094

Press to store the high signal input in the

meter.

Lo rd

Desired reading at Lo In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

0.0000

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set by

dEC.Pt.

Hi rd.

Desired reading at Hi In.

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

6.7500

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Decimal point is set by

dEC.Pt.

- 21 -

Page 22

Option board dependent menu items

ALSEt. ALS34 dEU1H dEU2H dEU1b dEU2b dEU3H DEU4H DEU3b DEU4b

Menu items related to alarm setup These will only appear if a relay board is detected. If so,

please see Section14.

AnSEt. An Lo. An Hi..

Menu items related to analog output setup. These will only appear if an analog output

board is detected. If so, see Section 15.

MENU

KEY

DIGIT SELECT

KEY

VALUE SELECT KEY

tArE_

Tare selections.

00000 Calibration

due indicator.

0 Calibration due indicators enabled

1 Calibration due indicators disabled

00000 Front panel

pushbutton Tare.

0 Front panel tare enabled

1 Front panel tare disabled

00000

Auto-Tare.

0 Tare after meter reset

1 No tare after meter reset

Option board dependent menu items

SEr 1. SEr 2. SEr 3. SEr 4. _Addr

Menu items related to serial communications. These will only appear if an RS232,

RS485, or USB I/O board is detected. If so, see Section 16.

CAL rt

Cal Reset

The Cal Instrument indicator starts flashing 30 days before instrument

calibration is due. To acknowledge and turn off flashing, change the first

digit of this menu item from 1 to 0. The Cal Sensor indicator starts

flashing 30 days before sensor calibration is due. To acknowledge and

turn off flashing, change the second digit of this menu item from 1 to 0.

dAtE

Current date

Use the keypad to enter the current date in MM.DD.YY format. This

menu item appears as an error message when the battery has just been

replaced, or in other instances where the date in the instrument cannot

be correct. The meter remains non-functional until the current date has

been entered.

CALd II

Calibration date of instrument in MM.DD.YY format.

Menu lockout items

Loc 1. Loc 2. Loc 3.

Menu items used to enable or lock out (hide) other menu items. Loc menu items may in

turn be locked out by a hardware jumper. Please see Section 8.

- 22 -

Page 23

13. LOAD CELL & MICROVOLT SIGNAL CONDITIONER

Input span = Hi signal in – Lo signal in

Input ratio =Input range / Input span

Input span = 20 mV – 0 mV = 20 mV

Input ratio = 20 mV / 20 mV = 1.00

Display span = Hi display – Lo display

Display ratio = FS Display / Display span

Display span = 10000 – 0000 = 10000

Display ratio = 20000 / 10000 = 2.00

Scale Factor = Input ratio / Display ratio

Scale Factor = 1.00 / 2.00 = 0.5000

Offset = – (Lo signal in / Input span) x

Display span + Lo display

Offset = – (0 mV / 20 mV x 10000) + 0000

= 0000

Input

Range

Jumpers

Full Scale

Display

± 20 mV

± 50 mV

± 100 mV

± 250 mV

± 500 mV

e

a

b

c

d

± 20000

± 50000

± 10000

± 25000

± 50000

This section provides setup instructions to set up the DPM-3 signal conditioner for use with

load cells or strain gauges, or as a microvolt meter. The meter’s built-in, isolated 10 Volt,

120 mA excitation supply will power up to four 350 ohm load cells in parallel.

13.1 RANGE SELECTION VIA JUMPERS

Notes 1. See Section 17 to select 10V excitation.

2. Jumpers are 2.5 mm (0.1”).

3. If a TEDS sensor is connected, jumper for ± 50 mV.

13.2 MENU SELECTION

Display in engineering units can be programmed by either the Scale and Offset Method,

Coordinates of 2 Points Method, or Reading Coordinates of 2 Points Methods.

With the Scale and Offset Method, scale and offset are calculated as follows, and are

then entered manually. The example below is for 0 to 20 mV = 0 to 100.00.

With the Coordinates of 2 Points Method, values for low signal input, low display

reading, high signal input and high display reading must be entered manually. For

example, if the desired scaling is 0 to 30 mV = 0 to 500.0, the 50 mV full scale range

would be selected and values would be entered as follows:

Lo in = 00.000 Lo rd = 0000.0

Hi in = 30.000 Hi rd = 0500.0

In the Coordinates of 2 Points example below, 0 to 20 mV = 00000 to 50000. During

setup, it may be necessary to enable some menu items. See Section 8 for information.

- 23 -

Page 24

MENU KEY

DIGIT SELECT

KEY

VALUE SELECT KEY

_InPut

Press to display InPut

(input type).

_Strn

Press key until Strn

(ratiometric) is displayed.

_0020.0

Press to select 20.0,

50.0, 100.0, 250.0 or 500.0

mV.

_SEtuP

Press to display SEtuP

(basic setup). See Section

18 for description of digits

1 - 5.

_30_00

Press to select digit,

which will flash.

_00_10

12345

Press key to select value.

_ConFG

Press to display ConFG

(configuration). See Section

18 for description of digits 1 -

5.

_00000

12345

Press to select digit,

which will flash.

_00000

12345

Press to select value.

_dEc.Pt

Press to display dEcPt

(decimal point).

_d.dddd

Press to display decimal

point location.

_ddddd.

Press to change decimal

point location.

_Lo in

Press to display Lo in

(low signal input value).

_00.000

Press to select digit,

which will flash. Decimal

point is fixed by input range.

_00.000

Press to set digit values.

Set to 00.000 mV. Leftmost

digit may be set to 0 thru 9

and -0 thru -9.

_Lo rd

Press to display Lo rd

(desired meter reading at

low signal input).

_00000

Press to select digit,

which will flash. Decimal

point is fixed by dEc.Pt

_00000

Press to set digit values.

Set to 0.

_Hi in

Press to display Hi in

(high signal input value).

_00.000

Press to select digit,

which will flash. Decimal

point is fixed by input range.

_20.000

Press to set digit values.

Set to 20.000 mV.

_Hi rd

Press to display Hi rd

(desired meter reading at

high signal input).

_00000

Press to select digit,

which will flash. Decimal

point is fixed by dEc.Pt.

_50000

Press to set digit values.

Set to 0.

_rESEt

Press (or and simultaneously) until rESEt is displayed. The meter will go to the

operating mode and display the value of the input signal.

- 24 -

Page 25

14. DUAL OR QUAD RELAY OUTPUT OPTION

ALARMS KEY

DIGIT SELECT KEY

VALUE SELECT

KEY

300.24

Press , (Alarms)

to display Alarm 1

setpoint.

_200.00

Current setpoint 1 value blinks, and

Alarm 1 LED indicator lights. Press

to select a digit, which will blink.

_295.00

To change setpoint 1 value,

press to change

selected blinking digits.

395.00

Press , (Alarms)

to display Alarm 2

setpoint.

_395.00

Current setpoint 2 value blinks, and

Alarm 2 LED indicator lights. Press

to select a digit, which will blink.

_305.00

To change setpoint 2 value,

press to change

selected blinking digits.

395.00

Press , (Alarms)

to display Alarm 3

setpoint.

_395.00

Current setpoint 3 value blinks, and

Alarm 3 LED indicator lights. Press

to select a digit, which will blink.

_305.00

To change setpoint 3 value,

press to change

selected blinking digits.

395.00

Press , (Alarms)

to display Alarm 4

setpoint.

_395.00

Current setpoint 4 value blinks, and

Alarm 4 LED indicator lights. Press

to select a digit, which will blink.

_305.00

To change setpoint 4 value,

press to change

selected blinking digits.

300.24 Press , (Alarms) again. Meter will reset and display current reading.

Alarm status

indicators

1 through 4

An optional relay board may be installed in the

meter main board at plug position P2, adjacent

to the power supply board. Four board versions are available: 2 or 4 relays, mechanical

or solid state. Once installed, the relay board is

recognized by the meter software or PC-based

Instrument Setup software, which will bring up the appropriate menu items for it. These menu

items will not be brought up if a relay board is not detected. All relay boards offer a choice of

operating modes: normally off or on, latched or non-latched, hysteresis band, deviation band,

alarm based on the filtered or unfiltered signal, and selectable number of readings in alarm

zone to cause an alarm.

KEYSTROKES FOR VIEWING & CHANGING SETPOINTS

The (Alarms) key can be used to step through and view setpoints while the meter continues

to make conversions and performs setpoint control. If the (Peak) key is pressed while a

setpoint is displayed, conversion stops and the setpoint can be changed. After pressing ,

you have 30 seconds, or the meter reverts to the normal display. To view setpoints, menu item

Loc3, digit 2, must have been set to 0. To change setpoints, menu item Loc2, digit 2, must

have been set to 0.

- 25 -

Page 26

KEYSTROKES FOR SETPOINT SETUP

MENU KEY

DIGIT SELECT

KEY

VALUE SELECT KEY

ALSEt

Alarm Setup for

relays 1 & 2 if

detected.

Press until

ALSEt is displayed.

00000

Relay state when

alarm is active.

0 Relay 1 on Relay 2 on

1 Relay 1 off Relay 2 on

2 Relay 1 on Relay 2 off

3 Relay 1 off Relay 2 off

00000

Alarm latching or nonlatching (auto reset).

0 Alarm 1 auto reset Alarm 2 auto reset

1 Alarm 1 latching Alarm 2 auto reset

2 Alarm 1 auto reset Alarm 2 latching

3 Alarm 1 latching Alarm 2 latching

00000

Alarm operates at and

above setpoint (active

high) or at and below

setpoint (active low).

0 AL1 active high AL2 active high

1 AL1 active low AL2 active high

2 AL1 disabled AL2 active high

3 AL1 active high AL2 active low

4 AL1 active low AL2 active low

5 AL1 disabled AL2 active low

6 AL1 active high AL2 disabled

7 AL1 active low AL2 disabled

8 AL1 disabled AL2 disabled

00000

Hysteresis mode or

band deviation mode

0 AL1 band deviation AL2 band deviation

1 AL1 hysteresis AL2 band deviation

2 AL1 band deviation AL2 hysteresis

3 AL1 hysteresis AL2 hysteresis

4 No deviation or hysteresis in menu.

00000

Number of consecutive

readings in alarm zone

to cause an alarm.

0 After 1 reading 4 After 16 readings

1 After 2 readings 5 After 32 readings

2 After 4 readings 6 After 64 readings

3 After 8 readings 7 After 128 reading

ALS34

Alarm Setup for

relays 3 & 4 if

detected.

00000

Relay state when

alarm is active.

0 Relay 3 on Relay 4 on

1 Relay 3 off Relay 4 on

2 Relay 3 on Relay 4 off

3 Relay 3 off Relay 4 off

00000

Alarm latching or nonlatching (auto reset).

0 Alarm 3 auto reset Alarm 4 auto reset

1 Alarm 3 latching Alarm 4 auto reset

2 Alarm 3 auto reset Alarm 4 latching

3 Alarm 3 latching Alarm 4 latching

If the MENU key does not work, see Section 8 “Enabling & Locking Out Menu Items.”

- 26 -

Page 27

MENU KEY

DIGIT SELECT KEY

VALUE SELECT

KEY

ALS34

Alarm Setup for

relays 3 & 4

(continued)

00000

Alarm operates at and

above setpoint (active

high) or at and below

setpoint (active low).

0 AL3 active high AL4 active high

1 AL3 active low AL4 active high

2 AL3 disabled AL4 active high

3 AL3 active high AL4 active low

4 AL3 active low AL4 active low

5 AL3 disabled AL4 active low

6 AL3 active high AL4 disabled

7 AL3 active low AL4 disabled

8 AL3 disabled AL4 disabled

00000

Hysteresis mode or

band deviation mode

(see Glossary)

0 AL3 band deviation AL4 band deviation

1 AL3 hysteresis AL4 band deviation

2 AL3 band deviation AL4 hysteresis

3 AL3 hysteresis AL4 hysteresis

00000

Number of consecutive

readings in alarm zone

to cause an alarm.

0 After 1 reading 4 After 16 readings

1 After 2 readings 5 After 32 readings

2 After 4 readings 6 After 64 readings

3 After 8 readings 7 After 128 reading

dEU1H Alarm 1

hysteresis

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Alarms will activate

above the setpoint by the value entered and

deactivate below the setpoint by the value

entered.

DEU2H Alarm 2

hysteresis

DEU1b Alarm 1

band deviation

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Alarms will activate

above and below the setpoint by the value

entered and will deactivate in the middle of

the band.

DEU2b Alarm 2

band deviation

dEU3H Alarm 3

hysteresis

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Alarms will activate

above the setpoint by the value entered and

deactivate below the setpoint by the value

entered.

DEU4H Alarm 4

hysteresis

DEU3b Alarm 3

band deviation

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first digit, 0 thru 9

for other flashing digits. Alarms will activate

above and below the setpoint by the value

entered and will deactivate in the middle of

the band.

DEU4b Alarm 4

band deviation

- 27 -

Page 28

15. ANALOG OUTPUT OPTION

MENU KEY

DIGIT SELECT KEY

VALUE SELECT

KEY

AnSEt

Analog Output Setup.

Press until AnSEt is

displayed (requires

analog output board).

___00

Analog output signal

selection.

0 0-20 mA current output

1 0-10V voltage output

2 4-20 mA current output

3 -10 to +10V voltage output

___00

Analog output filtering.

0 Analog output unfiltered

1 Analog output filtered

An Lo

Low displayed value

for 0 mA, 4 mA, 0V, or

-10V output

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first

digit, 0 thru 9 for other flashing

digits. Decimal point location is

fixed by dEC.Pt selection.

An Hi.

High displayed value

for 20 mA or 10V output

0.0000 0.0000 0.0000

0.0000 0.0000

Select digit to flash.

Select -9 thru 9 for flashing first

digit, 0 thru 9 for other flashing

digits. Decimal point location is

fixed by dEC.Pt selection.

An optional analog board may be installed in the meter at rear panel jack position J4, adjacent

to the signal conditioner board. Once installed, this board is recognized by the meter, which

will bring up the appropriate menu items for it. These will not be brought up if an analog output

board is not installed.

The analog output can be a 0-20 mA, 4-20 mA or 0-10V unipolar signal with respect to isolated

ground, or a bipolar -10V to +10V voltage signal with respect to a reference return line.

Unipolar or bipolar operation is selected by a jumper. A unipolar current or voltage output is

selected at the connector. Unipolar 4-20 mA or 0-20 mA current is selected in software.

Unipolar current of voltage: Jumper a

Bipolar -10 to +10 voltage: Jumper b

The low analog output (0 mA, 4 mA, 0V, or -10V) may be set to correspond to any low

displayed reading An Lo. The high analog output (20 mA, 0V or 10V) may be set to correspond to any high displayed reading An Hi. The meter will then apply a straight line fit between

these two end points to provide an analog output scaled to the meter reading.

KEYSTROKES FOR SETUP

If the MENU key does not work, see Section 8 “Enabling & Locking Out Menu Items.”

- 28 -

Page 29

16. SERIAL COMMUNICATION OPTIONS

A serial communications board may be connected to the DPM-3 meter main board at plug

position P13 (middle position). Available boards are RS232, RS485 (with dual RJ11 connectors), RS485 Modbus (with dual RJ45 connectors), USB, and a USB-to-RS485 converter. The

dual connectors of RS485 boards are wired in parallel to allow daisy chaining of addressable

meters without the use of a hub. Three serial communication protocols are selectable for all

serial boards: Custom ASCII, Modbus RTU, and Modbus ASCII.

A USB-to-RS485 converter board allows a DPM-3 meter to be interfaced to a computer and

to be the device server for a network of up to 31 other meters on an RS485 bus, while itself

retaining all capabilities of a meter. The remote meters need to be equipped with our RS485

digital interface board DPM-3-OPT-TRS485. This board has dual 6-pin RJ11 jacks, which are

wired in parallel to allow multiple meters to be daisy-chained using readily-available 6-wire

data cables with no need for hand-wiring or an RS485 hub. The outer two wires are used for

ground.

Use 6-wire, straight-through data cables, not 4-wire telephone cables or crossover cables,

all the way from the device server to the last device on the RS485 bus. Connect ATX to ATX,

BTX to BTX, etc., with no crossover as you go from device to device.

To connect a meter with a USB board to a computer, use a USB cable with Type A and

Type B connectors. The computer will display “Found new Hardware” followed by “Welcome to

the Found new Hardware Wizard.” Follow the instructions for software installation from a CD.

When the installation is complete, use Device Manager to determine the COM port. To get to

Device Manger, go to the Windows Control Panel, click on System, click on the Hardware tab,

then click on Device Manager. Go down the device list and click on Ports (COM & LPT) and

USB serial port (COM #). Note the COM port # for use with communications to your meter,

then exit Control Panel. If you later need to change the COM port, right-click on USB serial port

(COM #), then on Properties, Port settings, and Advanced. Change port to the desired number,

click OK, then exit Control Panel.

DOWNLOADABLE SOFTWARE AND MANUALS

Windows-based software is available from Transducer Techniques to program our meters

and transmitters via a PC using the serial interface. This software can be downloaded at no

charge from www.transducertechniques.com/online-manuals.aspx. Please see Section 19 for

details.

Software manuals for the Custom ASCII and Modbus Protocols can also be downloaded from

www.transducertechniques.com/online-manuals.aspx.

- 29 -

Page 30

BOARD SETUP VIA JUMPERS

USB Board

No jumpers required.

RS232 Board

e - RTS enabled by external source (otherwise always

enabled).

f - Slave display to RS232 from another meter.

g - Required for RS232 operation.

Note: Board is shipped with jumpers e and g installed

RS485 Board, Full Duplex Operation

b & d - Installed on last meter in long cable run.

RS485 Board, Half Duplex Operation

a & c - Installed for half duplex operation.

d - Installed on last meter in line with long cable runs.

Note: Board is shipped with no jumpers installed.

RS485-Modbus Board, Full Duplex Operation

b & e - Bias jumpers should be installed on 1 board.

a & d - Installed on last meter in long cable run.

RS485-Modbus Board, Half Duplex Operation

b & e - bias jumpers installed on 1 board.

c & f - installed for half duplex operation.

a - installed on last meter in line with long cable runs.

Note: Board is shipped with no jumpers installed.

Modbus

b

a

cd

e

RJ45

RJ45

f

USB-to-RS485 Converter Board

Full Duplex Operation

No jumpers for short cable runs.

Add b & d for long cable runs.

Half Duplex Operation

a & c - Installed for half duplex operation.

d - Installed on last meter in line with long cable runs.

- 30 -

Page 31

KEYSTROKES FOR SETUP

MENU KEY

DIGIT SELECT

KEY

VALUE SELECT KEY

.SEr 1.

Fixed Parameters:

No parity

8 data bits

1 stop bit

__000

Output filtering

0 Send unfiltered signal

1 Send filtered signal

__000U

Baud rate

0 300 baud

1 600 baud

2 1200 baud

3 2400 baud

4 4800 baud

5 9600 baud

6 19200 baud

__000U

Output update rate

60 Hz 50 Hz

0 Line frequency Line frequency

1 0.28 sec 0.34 sec

2 0.57 sec 0.68 sec

3 1.1 sec 1.4 sec

4 2.3 sec 2.7 sec

5 4.5 sec 5.4 sec

6 9.1 sec 10.9 sec

7 18.1 sec 21.8 sec

8 36.6 sec 43.5 sec

9 72.5 sec 97 sec

.SEr 2.

Serial Setup 2

_0000U

Line feed

0 No line feed after carriage return

1 Line feed after carriage return

_0000U

Alarm data with readings

0 No alarm data

1 Alarm data with reading

_0000U

Control of data output

0 Continuous data output

1 Data output on ASCII command only

_0000U

Meter address with Custom

ASCII protocol

Select 1 thru F for addresses 1 thru 15.

Select 0. thru F. (with decimal point) for

addresses 16 thru 31.

.SEr 3.

Serial Setup 3

00000U

Half or full duplex

0 Full duplex

1 Half duplex

00000U

Special start & stop char.

0 Standard continuous mode

1 Special start & stop characters

00000U

RTS mode

0 Normal RTS

1 Single transmission

00000U

Termination characters

0 Only at end of all items

1 At end of each item

If the MENU key does not work, see Section 8 “Enabling & Locking Out Menu Items.”

- 31 -

Page 32

MENU KEY

DIGIT SELECT

KEY

VALUE SELECT KEY

.SEr 3.

Serial Setup 3

(continued)

00000U

Data sent in continuous

mode

0 Reading

1 Peak

2 Valley

3 Reading + peak

4 Reading + valley

5 Reading + peak + valley

SEr 4.

Serial Setup 4.

__000U

Modbus ASCII gap timeout

0 1 sec

1 3 sec

2 5 sec

3 10 sec

__000U

Serial protocol

0 Custom ASCII

1 Modbus RTU

2 Modbus ASCII

__000U

Parity

0 None, 2 or more stop bits

1 Odd, 1 or more stop bits

2 Even, 1 or more stop bits

_Addr

Modbus Address.

Appears only if the

Modbus protocol is

selected.

__000 __000 __000

Select digit to flash.

__247

Select 0 through 9 for flashing digit.

Address range is 1 to 247.

- 32 -

Page 33

SERIAL CONNECTION EXAMPLES

- 33 -

Page 34

17. EXCITATION OUTPUTS & POWER SUPPLY

Excitation output

Jumper locations

5 Vdc ±5%, 100 mA max

10 Vdc ±5%, 120 mA max

24 Vdc ±5%, 50 mA max

b, d, e

b, d, f

c

Three isolated transducer excitation output levels are available from the power supply board.

These are selectable via jumpers b, c, d, e, f in the upper right of the board, as illustrated.

In addition, the board provides three jumper positions for special features. The same jumper

locations apply to the universal power supply (85-264 Vac) and to the low voltage power

supply (12-32 Vac or 10-48 Vdc).

SELECTION OF OTHER JUMPERS

Jumper a - Front panel menu lockout, locked when installed. (See Section 8)

Jumper g - Provides +5V power output at P1-4 when installed.

Jumper h - Connects "Control Input 2" to P1-4 when installed.

- 34 -

Page 35

18. DIGITAL CONTROL INPUTS

Logical 0

Current display value is set to zero and is stored as offset value.

Logical 1

Displayed value equals signal input less tare value.

Valley Display

Logical 0

Peak or Valley value of input signal is displayed.

Logical 1

Current value of input signal is displayed.

Logical 0

Meter display and outputs are held at last reading prior to hold

going low.

Logical 1

Display and outputs are updated normally.

Logical 0

Microcomputer reads and resets meter to values stored in nonvolatile memory.

Logical 1

Meter display and outputs operate normally.

Logical 0

Microcomputer resets peak to current value, and resets alarms.

Logical 1

Meter display and outputs operate normally.

MENU

KEY

DIGIT

SELECT KEY

VALUE SELECT KEY

_SEtuP

Press the

until SEtuP

(meter setup)

is displayed.

_0___0

12345

Press to select digit

5, which will flash.

_0___0

12345

Press to set value for flashing digit.

0 A = Reset B = Meter Hold

1 A = Function Reset B = Peak or Valley Disp.

2 A = Meter Hold B = Peak or Valley Disp.

3 A = Meter Hold B = Tare

4 A = Peak Display B = Tare

5 A = Tare B = Reset

6 A = 1, B = 1, decimal point 1= XXXXX

A = 0, B = 1, decimal point 1 = XXXX.X

A = 1, B = 0, decimal point 1 = XXX.XX

A = 0, B = 0, decimal point 1 = XX.XXX

7 A = 1, B = 1, decimal point 2 = XXXX.X

A = 0, B = 1, decimal point 2 = XXX.XX

A = 1, B = 0, decimal point 2 = XX.XXX

A = 0, B = 0, decimal point 2 = X.XXX.X

8 A = Function Reset B = Display Blank

9 A = Hold B = Display Blank

A A = Peak or Valley B = Display Blank

B A = Tare B = Display Blank

C A = Valley Display B = Peak Display

D A = Tare B = Tare Reset

Both inputs A and B set to 1 for selections

2, 4, A, C = Function Reset

Both inputs A and B set to 1 for selections

0, 1, 3, 5, 8, 9, B, D = Meter Reset

External decimal DP1 & DP2 control the

decimal point positions and override the

decimal point selection in SEtuP.

18.1 FUNCTION OF DIGITAL INPUTS

18.2 MENU SELECTIONS

- 35 -

Page 36

19. INSTRUMENT SETUP & DATA DISPLAY VIA PC

DPM-3 Instrument Setup software is a PC program which is much easier to learn than front

panel programming. It is of benefit whether or not the meter is connected to a PC. With the

meter connected to a PC, it allows uploading, editing and downloading of setup data,

execution of commands under computer control, and the listing, plotting and graphing of

data. With the meter unconnected to a PC, it provides quick selection of jumper locations

and a printable display of menu selections for front panel setup.

SOFTWARE INSTALLATION

Download DPM-3 Instrument Setup software from www.transducertechniques.com/online-

manuals.aspx onto your PC. Double-click on the downloaded file to unzip it into a special

directory, such as c:\Program Files\DPM-3\IS. Within that directory, double-click on

setup.exe, which will install the software on your PC. Prerequisites for connected use are

the following:

DPM-3 meter with a DPM-3-OPT-T (RS232 option) or DPM-3-OPT-U (USB option).

PC-compatible computer with an available RS232 or USB port.

RJ11-to-DB9 RS232 cable (P/N DPM-3-RJ11AD9) or commercial USB cable to connect

the meter to the PC.

DPM-3 Instrument Setup software.

ESTABLISHING COMMUNICATIONS

Connect the meter to the PC. Apply power, and keep the meter in RUN Mode. To start the

software from Windows, click on Start > Programs > DPM-3 Digital Panel Meter > DPM-3

Instrument Setup. Select the proper COM port and baud rate. Click on RS232 > Establish.

The program will temporarily set the selected COM port to the required baud rate, parity,

data bits and stop bit. Once communications have been established, click on Main Menu.

- 36 -

Page 37

Plot

Graph

SETUP OF CONNECTED METER

A setup file can be retrieved from the meter (DPM => Get Setup), be edited (View =>

Setup), be saved to disk (File => Save Setup), be retrieved from disk (File => Open Setup),

and be downloaded into one or multiple meters (DPM => Put Setup). Downloading of setup

files from a PC can be a major time saving when multiple meters have to be set up in the

same way.

You will find that DPM-3 Instrument Setup software is very user friendly, with separate tabselectable windows for Input+Display, Scaling, Filter, Relay Alarms, Communications,

Analog Out, and Lockouts. If the required hardware, such as the analog output board, is not

sensed, the corresponding tab will be grayed out.

ADDITIONAL FEATURES

The Commands pull-down menu allows you to execute certain meter functions by using

your computer mouse. You can reset individual meter functions, display current or peak

readings, and enter numbers to be displayed remotely by the DPM. The first position of a

transmitted number must be a blank, + sign or - sign. Five digits and a decimal point must

be transmitted. Leading 0’s serve as blanks. The Commands pull-down menu will be grayed

out unless a Get Setup has been executed.

- 37 -

Page 38

The Readings pull-down menu provides three formats to display DPM data on the PC

monitor. Use the Pause and Continue buttons to control the timing of data collection, then

press Print for a hardcopy using your PC printer.

- List presents the latest readings in a 20-row by 10-column table. Press Pause at any

time to freeze the display. Press Print

for a hardcopy. List can capture peak

readings.

- Plot generates a plot of readings vs.

time in seconds. It effectively turns the

DPM-PC combination into a printing

digital oscilloscope.

- Graph generates a histogram, where

the horizontal axis is the reading and

the vertical axis is the number of

occurrences of readings. The display

continually resizes itself as the number of readings increases.

The Jumpers pull-down menu provides

jumper positions for the various meter boards, duplicating information in this manual.

METER SETUP WITH AN UNCONNECTED PC

DPM-3 Instrument Setup software is also of benefit

when the PC is not connected to a meter. Upon launching the software, click on None for Communications,

then on DPM-3 and Continue. Click on File => Default

Setup to retrieve a default setup file from disk, or on File

=> Open Setup to retrieve a previously saved setup file

from disk.

To enter new setup information, click on View => Setup,

then make your screen selections as if you were

connected to a meter. Tabs will be grayed out if you

have not selected the required hardware under the

Input+Display tab. When done, press on Main Menu,

then on View => Menu. The selections made under

Setup will now be shown in the form of the required front

panel programming sequence, where each row corresponds to a menu item selected by the key, and the

seven data columns correspond to values entered via the and keys.

Click on any step in the sequence to bring up a detailed help window. Click on Print for a

hardcopy, which you can then use as an instruction sheet to program your meter via its front

panel. Click on Main Menu => File => Save Setup As to save your setup to disk and have

an electronic record.

- 38 -

Page 39

20. CUSTOM CURVE LINEARIZATION

Curve.exe is a DOS-based, executable PC program used to set up an Extended meter so that

the readings have a user-defined, non-linear relationship with the input signal. The calculated

linearizing parameters are downloaded into non-volatile memory of the meter. For example, it

allows a meter to correct for transducer nonlinearity or to display volume of an irregularly

shaped tank based on pressure measured at the bottom of the tank. The

curve-fitting algorithm uses quadratic

segments of varying length and curvature, and provides diagnostics to estimate curve fitting errors. The program is

self-prompting, avoiding the need for a

detailed printed manual. This manual

section is only intended as an introduction.

PREREQUISITES