Page 1

TransCore

P/N 411002-009

SmartPass® Integrated Reader

System Guide

2450 MHz (High Voltage)

8600 Jefferson Street NE

Albuquerque, NM 87113

June 2014

Page 2

Information in this document is subject to change and does not represent a commitment on the part

of TC License, Ltd.

1996 TC License, Ltd. All rights reserved. TRANSCORE, TOLLTAG, AMTECH, and

SMARTPASS are registered trademarks of TC License, Ltd. All other trademarks listed are the

property of their respective owners. Printed in the U.S.A.

For further information, contact:

TransCore

8600 Jefferson Street NE

Albuquerque, NM 87113

Technical Support

Web: transcore.com/rfidsupport

Phone: (505) 856-8007

Page 3

WARNING TO USERS IN THE UNITED STATES

FEDERAL COMMUNICATIONS COMMISSION (FCC) RADIO FREQUENCY

INTERFERENCE STATEMENT

47 CFR §2.105

NOTE: This equipment uses 2450-MHz frequency and thus does NOT comply with FCC U.S. frequency

allocation requirements.

NOTE: Users in all countries should check with the appropriate local authorities for licensing

requirements.

TransCore, LP

USA

Page 4

Page 5

Contents

Introduction

Preparing the Site

Overview .......................................................................................................... 1-3

System Description ......................................................................................... 1-3

Licenses ........................................................................................................... 1-4

Choosing and Ordering Equipment ............................................................... 1-4

SmartPass Model AI1611 ....................................................................................................... 1-4

Accessories .................................................................................................................................... 1-4

Communications Interface ............................................................................................................ 1-4

Input Power Supply ....................................................................................................................... 1-5

Communications Cables ................................................................................................................ 1-5

Power Cables ................................................................................................................................. 1-5

Tags ......................................................................................................................................... 1-6

Tag Models .................................................................................................................................... 1-6

Tag Data Formats .......................................................................................................................... 1-6

Determining the Location to Install SmartPass ............................................ 2-3

Reflection, Refraction, and Diffraction of RF Signals .............................................................. 2-3

RF Reflectors ................................................................................................................................. 2-4

RF Refraction ................................................................................................................................. 2-4

RF Diffraction ................................................................................................................................ 2-4

Existing Interference .............................................................................................................. 2-4

Page 6

SmartPass and Tag Mounting Locations ...................................................... 2-4

Quick SmartPass

Gate Configuration ................................................................................................................. 2-5

Parking Garage Configuration ................................................................................................ 2-6

Overhead Mounting Configuration ........................................................................................ 2-7

Open Lane Configuration ....................................................................................................... 2-8

Area Layout and Traffic Flow .................................................................................................. 2-9

Other SmartPass Units in the Area ....................................................................................... 2-10

Junction Box .................................................................................................. 2-10

Electrical Power Sup p ly ................................................................................ 2-11

Communications ........................................................................................... 2-11

Input/Output Circuit Requirements for Outside Equipment ............................................... 2-11

®

Test

Overview .......................................................................................................... 3-3

Materials Supplied ........................................................................................... 3-3

Additional Material s N eeded ........................................................................... 3-4

Testing with the Audible Circuit Tester ......................................................... 3-4

Testing With a PC and the Software Diskette ............................................... 3-6

Connecting an RS–232 Interface ............................................................................................ 3-6

Connecting an RS–422 Interface ............................................................................................ 3-7

Connecting a Wiegand Interface ............................................................................................ 3-7

Testing Procedures ................................................................................................................. 3-8

Page 7

Installing T ags on Vehicles

Installing SmartPass

Overview .......................................................................................................... 4-3

Locations for Installing Interior Tags ............................................................ 4-3

Tag Mounting Instructions.............................................................................. 4-5

Mounting Interior Tags ........................................................................................................... 4-5

Mounting Exterior Tags .......................................................................................................... 4-7

Mounting Tag to Bumper with Tape ............................................................................................. 4-7

Mounting Tag to Metal Bumper with a Blind Rivet ...................................................................... 4-8

®

Overview .......................................................................................................... 5-3

Additional Material s R equ ir ed ........................................................................ 5-4

Installation Instructions .................................................................................. 5-4

Installing SmartPass on a Round Pole .................................................................................... 5-5

Installing SmartPass on a Flat Surface .................................................................................... 5-7

Installing SmartPass on a Flat Surface Without Using the Accessory Bracket .............................. 5-7

Installing SmartPass on a Flat Surface Using the Accessory Bracket ............................................ 5-8

Marking the Read Zone ................................................................................. 5-10

Changing the Read Zone ....................................................................................................... 5-12

Communications Wiring Tables ................................................................... 5-12

Connecting Power from SmartPass to the Junction Box .......................... 5-12

Connecting Communications ....................................................................... 5-14

Connecting Communications to the Junction Box ............................................................... 5-14

Page 8

Connecting Input and Output Circuits .................................................................................. 5-14

General Software Information

Input Circuits ............................................................................................................................... 5-14

RF Control ................................................................................................................................... 5-15

Output Circuits ............................................................................................................................ 5-16

Grounding the Communications Cable Drain Wires .................................. 5-19

Testing With Host System ............................................................................ 5-19

Overview .......................................................................................................... 6-3

Communications Port ..................................................................................... 6-3

Error Messages ................................................................................................ 6-4

Flow Control ..................................................................................................... 6-5

ID Separation ................................................................................................... 6-5

Input Circuits ................................................................................................... 6-5

Operating Parameters ..................................................................................... 6-6

Output Circuits ................................................................................................ 6-6

Power Fail......................................................................................................... 6-6

Program Download .......................................................................................... 6-6

Download Considerations ...................................................................................................... 6-6

Download Procedure .............................................................................................................. 6-7

Page 9

Reports ............................................................................................................. 6-7

Modes of Operation

Communication Protocols

Reset Command .............................................................................................. 6-8

Startup .............................................................................................................. 6-8

Sign-On Message .................................................................................................................... 6-8

Boot Failure Message ............................................................................................................. 6-9

Tag/Message Buffer ............................................................................................................... 6-9

Time and Date ........................................................................................................................ 6-9

Overview .......................................................................................................... 7-3

Data Mode ........................................................................................................ 7-3

Command Mode ............................................................................................... 7-4

Buffer Control Mode ........................................................................................ 7-5

Download Mode ............................................................................................... 7-6

Overview .......................................................................................................... 8-3

Basic Protocol ................................................................................................. 8-4

Error Correcting Protocol ............................................................................... 8-4

Error Correcting Method ........................................................................................................ 8-4

Data Inquiry Protocol ...................................................................................... 8-5

Basic and ECP Protocol Formats ................................................................... 8-5

Reader Transmissions ............................................................................................................. 8-5

Page 10

ECP Host ACK/NAK Response ................................................................................................. 8-6

Switch to Command Mode Request ....................................................................................... 8-7

Host Transmission .................................................................................................................. 8-8

Reader Command Response .................................................................................................. 8-9

Sample Messages ................................................................................................................... 8-9

Reader Transmissions ................................................................................................................... 8-9

Host Command Transmissions .................................................................................................... 8-10

Timing and Synchronization ................................................................................................. 8-11

Reader Addressed Failure Conditions .................................................................................. 8-12

Illegal Sequence Number (Not in the Range 0–9, A–F) ............................................................... 8-12

Wrong Sequence Number ........................................................................................................... 8-12

Bad CRC ....................................................................................................................................... 8-12

Illegal Command ......................................................................................................................... 8-13

Transmission Timeout ................................................................................................................. 8-13

Receive Timeout.......................................................................................................................... 8-13

Asynchronous Message/Command Message Collision ............................................................... 8-13

Host Addressed Failure Conditions ...................................................................................... 8-13

Illegal or Wrong Sequence Number ............................................................................................ 8-13

Bad CRC ....................................................................................................................................... 8-13

Transmission Timeout ................................................................................................................. 8-13

Receive Timeout.......................................................................................................................... 8-13

Asynchronous Message/Command Message Collision ............................................................... 8-14

Page 11

Error Correcting Protocol Reliability ........................................................... 8-14

Commands

CRC Calculation ............................................................................................ 8-14

Command Listings ..................................................................................................................... 3

Command Information ............................................................................................................ 18

00 Switch to Data Mode (Factory Default) .................................................................................... 18

01 Switch to Command Mode ....................................................................................................... 18

05 Switch to Download Mode ....................................................................................................... 18

06 Transmit Buffer Entry ............................................................................................................... 19

100N Select Baud Rate .................................................................................................................. 20

101N Select Stop Bits .................................................................................................................... 20

102N Select Parity ......................................................................................................................... 20

20 Set Time .................................................................................................................................... 21

21 Set Date .................................................................................................................................... 21

22 Display Time and Date .............................................................................................................. 21

30N Append Time and Date Selection .......................................................................................... 22

31N Append Auxiliary Information Selection ................................................................................ 23

40 Transmit All ID Codes ............................................................................................................... 23

410N Anti-Passback (Select Unique ID Code Criteria) .................................................................... 24

43 Buffer All ID Codes .................................................................................................................... 24

450 Disable Wiegand Mode (Factory Default) .............................................................................. 25

451 Enable Wiegand Mode ........................................................................................................... 25

452 Disable Tag Translation Mode (Factory Default) .................................................................... 25

453 Enable Tag Translation Mode ................................................................................................. 25

46NN Set Wiegand Retransmit Interval ........................................................................................ 26

Page 12

48N Select Dual-Frame Processing Mode ..................................................................................... 26

505 Display Software Version ....................................................................................................... 27

506 Display Hardware Configuration Information ........................................................................ 27

520 Display Power Fail Bit ............................................................................................................. 27

521 Display Reader ID Number ...................................................................................................... 27

522 Display Communication Port Parameters .............................................................................. 28

524 Display Appended Information Status ................................................................................... 28

525 Display Communication Protocol Status ................................................................................ 29

526 Display I/O Status ................................................................................................................... 30

527 Display RF Status .................................................................................................................... 31

529 Display Presence Input Status ................................................................................................ 32

530 Display RF0 Filter Status ......................................................................................................... 33

532 Display Wiegand Mode Status ............................................................................................... 33

533 Display Wiegand Retransmit Interval ..................................................................................... 33

534 Display Tag Translation Mode Status ..................................................................................... 34

535 Display Buffer Control Status ................................................................................................. 34

536 Display Dual-Frame Processing Mode .................................................................................... 34

537 Display Echo Status ................................................................................................................ 35

540 Display Flash Checksum.......................................................................................................... 35

543 Display Boot Checksum .......................................................................................................... 35

550 Display Periodic Check Tag Status .......................................................................................... 35

551 Display Selected Check Tag Option ........................................................................................ 36

560 Display Input Status Change Report Options ......................................................................... 36

60NN Set Reader ID Number ......................................................................................................... 36

610 Select Basic Protocol (Factory Default) .................................................................................. 37

611 Select Error Correcting Protocol ............................................................................................. 37

612NN Select Error Correcting Protocol Timeout ......................................................................... 37

Page 13

613 Select Data Inquiry Protocol ................................................................................................... 38

614N Select Flow Control Option .................................................................................................. 38

6160 Disable Buffer Control Mode (Factory Default).................................................................... 39

6161 Enable Buffer Control Mode ................................................................................................ 39

6170 Disable Echo Mode ............................................................................................................... 39

6171 Enable Echo Mode (Factory Default).................................................................................... 40

620N Output Control ..................................................................................................................... 40

621 Predefined Output Control (Factory Default)......................................................................... 40

63 Reset Reader ............................................................................................................................ 40

640N RF Control ............................................................................................................................ 41

641 Select RF-by-Input Control (Factory Default) ......................................................................... 41

65 Reset Power Fail Bit .................................................................................................................. 42

660 Test External RAM .................................................................................................................. 42

661 Display Diagnostic Results ...................................................................................................... 42

664 Test Real-Time Clock .............................................................................................................. 43

667 Verify Boot ROM Checksum ................................................................................................... 43

668 Verify Flash Memory Checksum ............................................................................................. 43

669 Perform All Diagnostics .......................................................................................................... 43

66F Load Default Operating Parameters ....................................................................................... 44

67N Set Output Pulse Duration ..................................................................................................... 44

690N Select Presence Without Tag Report Option ....................................................................... 45

692N Select RF Control Algorithm ................................................................................................. 45

693N Select RF Timeout Period ..................................................................................................... 45

694N Select Input Inversion Option .............................................................................................. 46

695 Set Serial Number ................................................................................................................... 47

696S...S Store Hardware Configuration String .............................................................................. 47

810 Disable Periodic Check Tag (Factory Default) ......................................................................... 47

Page 14

8110 Perform System Check Tag Test ........................................................................................... 47

Troubleshooting

Glossary

System Specificati

Wiring Tables

8120 Enable Periodic Check Tag .................................................................................................... 48

8160 Select Internal Check Tag (Factory Default) ......................................................................... 48

8161 Select External Check Tag ..................................................................................................... 48

82N Select Input Status Change Report Option ............................................................................ 48

90 Load Program Block .................................................................................................................. 49

91 Verify Flash Checksum .............................................................................................................. 49

96 Erase Flash Memory ................................................................................................................. 50

97 Perform Destructive Flash Test ................................................................................................ 50

99 Exit Download Mode ................................................................................................................ 50

Need Help? ................................................................................................................................ 4

Need Marketing Support? ......................................................................................................... 5

Find Something Wrong with SmartPass or Want to Suggest an Improvement? ...................... 5

Terms and Definitions .................................................................................... A-3

ons

Specifications ................................................................................................. B-3

Specifications ................................................................................................. C-3

Page 15

List of Figures

Figure 1-1 SmartPass System Diagram ...................................................................................................................... 1-3

Figure 2-1 Gate Configuration with Center Island ..................................................................................................... 2-5

Figure 2-2 Incorrect Mounting of SmartPass ............................................................................................................. 2-6

Figure 2-3 Parking Garage Configuration .................................................................................................................. 2-6

Figure 2-4 Left-Side Tag Mounting Locations ........................................................................................................... 2-7

Figure 2-5 SmartPass Mounted Overhead................................................................................................................. 2-7

Figure 2-6 Tag Mounting Positions for SmartPass Mounted Overhead .................................................................... 2-8

Figure 2-7 Open Lane Configuration .......................................................................................................................... 2-9

Figure 3-1 Wiring for Buzz Box .................................................................................................................................. 3-4

Figure 4-1 Left Side Tag Mounting Locations ............................................................................................................ 4-4

Figure 4-2 Top Center Tag Mounting Location .......................................................................................................... 4-4

Figure 4-3 Improper Tag Mounting Location ............................................................................................................ 4-5

Figure 4-4 Interior Tags with Hook and Loop Material ............................................................................................. 4-6

Figure 4-5 Exterior Tag with Adhesive Tape ............................................................................................................. 4-7

Figure 5-1 Front and Top View of SmartPass ............................................................................................................. 5-5

Figure 5-2 Side View of SmartPass ............................................................................................................................ 5-6

Figure 5-3 SmartPass Installed on a Flat Surface ....................................................................................................... 5-7

Figure 5-4 Accessory Bracket ..................................................................................................................................... 5-8

Figure 5-5 SmartPass With Three Mounting Brackets ............................................................................................ 5-10

Figure 5-6 Sample Read Zone Marking Pattern ....................................................................................................... 5-11

Figure 5-8 SmartPass RF Control Options ............................................................................................................... 5-16

Figure 5-9 Example Circuit Connections ................................................................................................................. 5-17

Page 16

List of Tables

Table 1-1 Tag Models Available with SmartPass AI1611 ........................................................................................... 1-6

Table 2-1 Communications Interfaces and Conductors .......................................................................................... 2-11

Table 3-1 Three-Letter Reader Configuration Code .................................................................................................. 3-3

Table 3-2 RS–232 Interface Signal Wiring ................................................................................................................. 3-6

Table 3-3 RS–422 Interface Signal Wiring ................................................................................................................. 3-7

Table 3-4 Wiegand Interface Signal Wiring .............................................................................................................. 3-7

Table 3-5 Factory Defaults for SmartPass ................................................................................................................. 3-9

Table 5-1 AC Cable Connections .............................................................................................................................. 5-14

Table 5-2 External Interface Signal Wiring .............................................................................................................. 5-18

Table 6-1 Error Codes ............................................................................................................................................... 6-4

Table 7-1 BCM Commands ....................................................................................................................................... 7-6

Table 8-1 Example of Routine to Calculate CRC...................................................................................................... 8-15

Table 8-2 Example of Routine to Calculate CRC-CCITT without Lookup Table ....................................................... 8-15

Table 8-3 Example of Routine to Calculate CCITT-CRC with Lookup Table ............................................................. 8-16

Table 8-4 Example of Routine to Create Lookup Table .......................................................................................... 8-18

Table 9-1 Factory Default Settings ................................................................................................................................ 4

Table 9-2 SmartPass Command List (Ordered by Command Number) ........................................................................ 5

Table 9-3 SmartPass Command List (Ordered by Command Name) .......................................................................... 12

Table 9-4 Baud Rate specified by the N Variable ........................................................................................................ 20

Table 9-5 Stop Bits specified by the N Variable .......................................................................................................... 20

Table 9-6 Parity specified by the N Variable ............................................................................................................... 20

Table 9-7 Commands selecting Options of Appending Tme and Data ....................................................................... 22

Table 9-8 Commands Selecting the Option of Appending Auxiliary Information ....................................................... 23

Table 9-9 Commands for Buffering and Transmitting ID Codes ................................................................................. 24

Table 9-10 Output0 and Output1 Open/Closed Conditions for the Output Status Displays ...................................... 31

Table 9-11 Input0 and Input1 Open/Closed Conditions for the Input Status Displays ............................................... 31

Table 9-12 Select Flow Control Options ..................................................................................................................... 38

Table 9-13 Output Control Option Commands ........................................................................................................... 40

Table 9-14 RF Control Commands .............................................................................................................................. 41

Table 9-15 Commands for setting Output Pulse Duration ......................................................................................... 44

Table 9-16 Select Presence Without Tag Report Option Commands ......................................................................... 45

Table 9-17 Select RF Control Algorithm Commands ................................................................................................... 45

Table 9-18 Select RF Timeout Period Commands ....................................................................................................... 46

Table 9-19 Select Input Inversion Option Commands ................................................................................................ 46

Table 9-20 Select Input Status Change Report Option Commands ............................................................................ 49

Table 10-1 Symptoms and Remedies............................................................................................................................ 3

Page 17

A

Glossary

Page 18

Page 19

Appendix A

Glossary

This Appendix provides definitions for t er m s used t hr oughout t he

®

SmartPass

System Guide.

Terms and Definitions

The following table defines special terms used in this document.

AAR Association of American Railroads

AC alternating current

ACK acknowledge (data valid)

antenna passive device that converts RF energy into magnetic energy (RF signal)

ARC Amtech Response Center

ASCII American Standard Code for Information Interchange

ASIC application-specific integrated circuit

ATA American Trucking Associations

aux auxiliary

backscatter portion of an RF signal that is modulated by a tag and radiated back to the reader

baud measure of number of bits per second of a digital signal; for example, 9600 baud = 9600

bits per second

BCKS boot checksum

BCM buffer control mode

BIT built-in test

bps bits per second

byte a binary character; for example, one 8-bit ASCII character

CCITT Consultive Committee on International Telegraphy and Telephony

check tag tag mounted inside SmartPass assembly, or in an external antenna, that is used to check

operation of SmartPass.

cmd command

CTRL control

comm communications

command data set that is recognized by the receiving device as intending to elicit a specific response

conduit flexible steel pipe use for electrical wiring

cps characters per second

A-3

Page 20

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

CR carriage return

CRC cyclic redundancy check

CTS clear to send

data information that is processed by a computing device

DC direct current

DIAG diagnostic

ECP error correcting protocol

ECPS error correcting protocol status

EOL end of line

EOM end of message

EPROM erasable programmable read-only memory

field physical area/space in which a tag can be read by the reader; also, an element of a data

record/frame. For example, division within a tag's data frame.

frames consecutive bits of data in memory that are read and written as a group

frequency bands a range of RF frequencies assigned for transmission by an RF device

hex hexadecimal

hexadecimal base 16 numbering system that uses the characters 0–9 and A–F to represent the digits 0–

16

host device, generally a computer, that is connected to SmartPass through the communications

port

I/O or IO circuits input/output circuits

ID identification; encoded information unique to a particular tag

interface connection/connection point for communication with another device

IOST I/O status

ISO International Standards Organization

LF line feed

m meter

MHz megahertz

mode method of operation

ms milliseconds

NAK negative acknowledgment (data not valid)

passback used to refer to a tag ID that is not passed on to the tag buffer

PC personal computer

A-4

PCKS EPROM flash checksum

protocol specified convention for the format of data messages communicated between devices

PRST presence status

PWRB power fail bit

RAM random access memory

Page 21

Glossary

RDID reader ID

read process of acquiring data from a device; for example, from a tag or from computer memory

reader controlled interrogating device capable of acquiring data from a device; for example,

acquiring and interrupting data from a tag

read zone the physical area in which a tag can be read by the SmartPass system

RF radio frequency

RFST RF status

RFID radio frequency identification

RMA return material authorization

ROM read-only memory

RTC real-time clock

RTS request to send

SCTS status of check tag status

SSTC input status change reporting options

SOM start of message

SN serial number

tag small self-contained device acting as an identifying transponder

Tau timeout delay

TT tag translation

V volts

Ver version (software)

write process of recording data; for example, writing to computer memory or to a tag’s memory.

Writing writes over (erases) previous data stored at the specified memory locations.

WTI Wiegand retransmit interval

A-5

Page 22

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

A-6

Page 23

B

System Specifications

Page 24

Page 25

This Appendix provides specifications thr oughout t he Sm ar t Pass®

System Guide.

Specifications

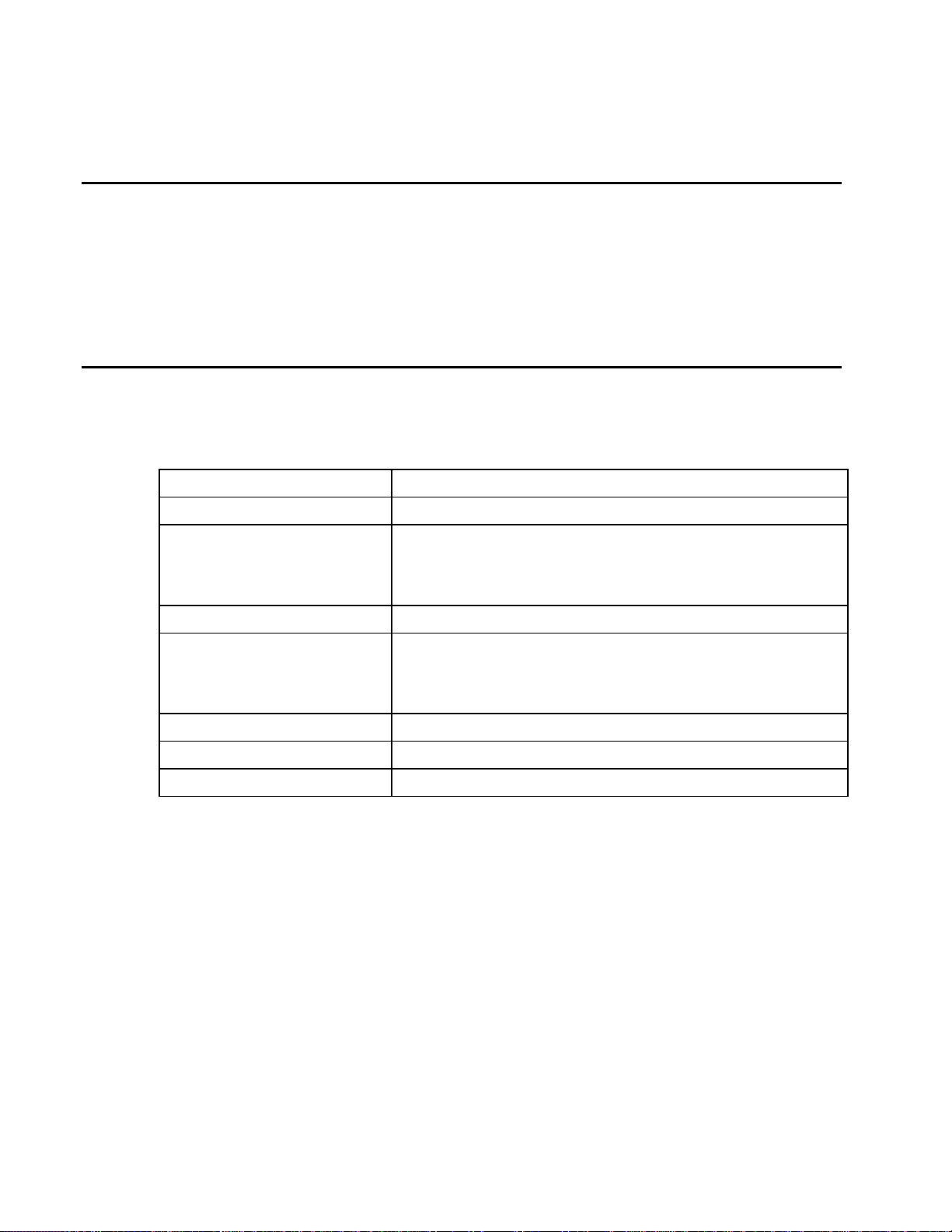

The following table shows the specifications for SmartPass Model AI1611.

Table B-1 SmartPass System Specifications

Size 38.1 x 41.7 x 10.2 cm (without mounting brackets)

Weight Less than 7.2 kg (without mounting brackets)

Appendix B

System Specifications

Input power

High voltage

AC

Output power 250–500 mW

Wire sizes

Power

Communications

Frequency (factory adjustable) 2400–2500 MHz

Emission designator N0N

Antenna gain 10 dBi nominal

Less than 25 W

90–260 V AC

47–63 Hz

3 conductors, 18 gauge

11 twisted, individually shielded pairs, 22 gauge

B-3

Page 26

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

B-4

Page 27

C

Wiring Tables

Page 28

Page 29

Appendix C

Interface

Number of Conductors

RS–232

3

handshake signals

RS–422

4

Wiegand

3

SmartPass

Pin

SmartPass

Receive from PC

Red/black

Red

Pin 3

Pin 2

Logic ground

Yellow/black

Yellow or black

Pin 5

Pin 7

Request to send

Yellow/red

Yellow

Pin 4

Pin 4

Clear to send

Yellow/red

Red

Pin 8

Pin 5

W iring Tables

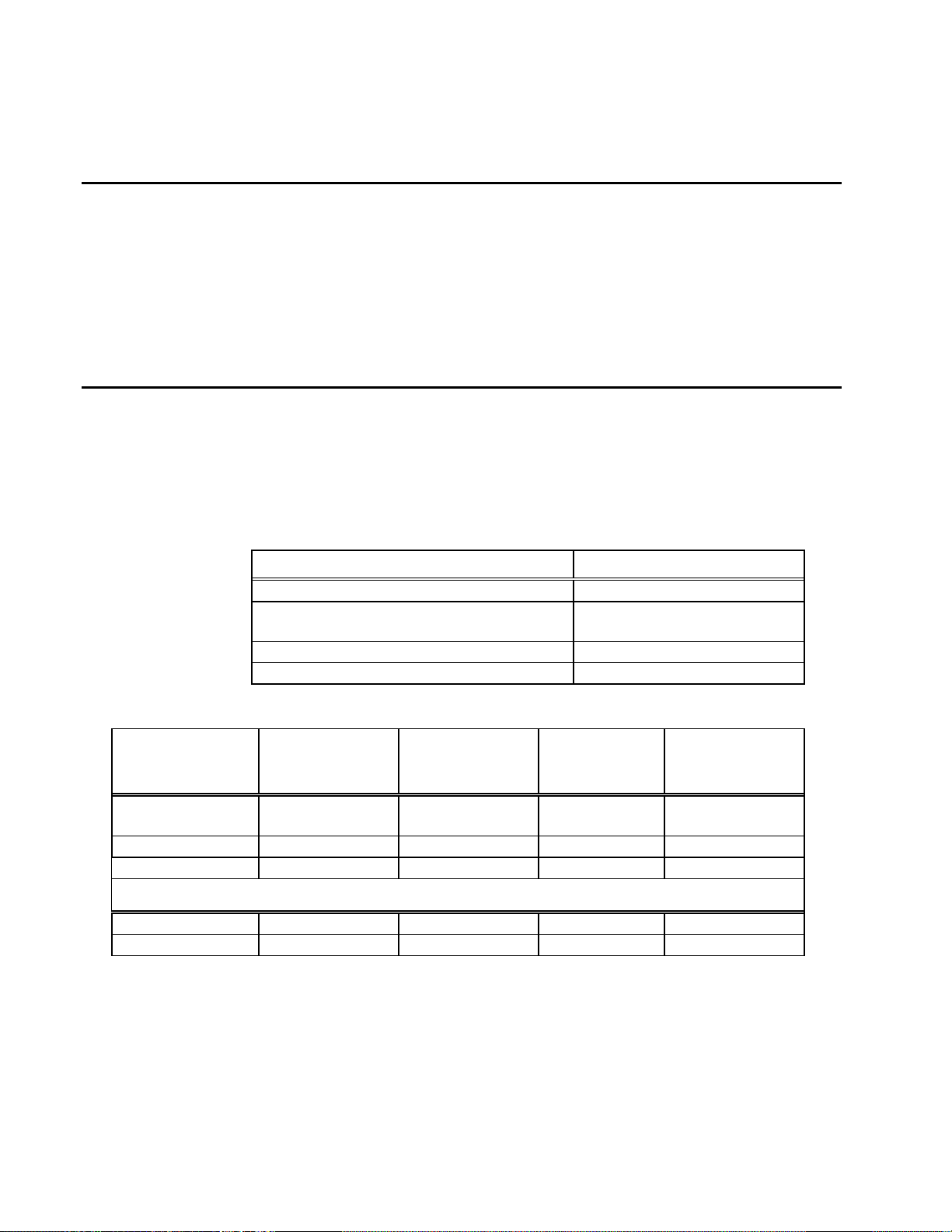

This Appendix provides tables showing the wiring connections used in

installing and testing Smart Pass t hr oughout t he Sm artPass

Guide.

Specifications

The following table shows the wiring connections used in installing and testing

SmartPass. For more information on testing SmartPass, refer to Chapter 3, “Quick

SmartPass Test.” For information on installing SmartPass, refer to Chapter 5,

“Installing SmartPass.”

Table C-1 Communications Interfaces and Conductors

Table C-2 RS–232 Interface Signal Wiring

RS–232 with RTS and CTS hardware

5

®

System

Signal

Transmit from

Wire Pair

From

Red/black Black Pin 2 Pin 3

Optional for hardware handshaking

Wire Color

Used From Pair

Connect Wire

to PC DB9

Connect Wire

to PC DB25 Pin

C-3

Page 30

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

SmartPass

From Pair

to Signal

Transmit B (+) data

from SmartPass

Yellow/red

Yellow

Receive

(+)

SmartPass

)

SmartPass

(+)

Receive A (-) data to

SmartPass

Red/black

Red

Transmit

(-)

Signal

Data0

Blue/red

Blue

Data1

Data1

Blue/red

Red

Data0

Logic ground

Yellow/black

Yellow or black

Ground

Cable Colors

Colors

Brown

Black

AC hot (90–260 V AC)

Green and

yellow

Green or red

Safety ground

Table C-3 RS–422 Interface Signal Wiring

Signal

Transmit A (-) data

Receive B (+) data to

Wire Pair From

Yellow/red Red Receive (-

Red/black Black Transmit

Wire Color Used

Table C-4 Wiegand Interface Signal Wiring

Signal Wire Pair Wire Color

Connect

Wiegand

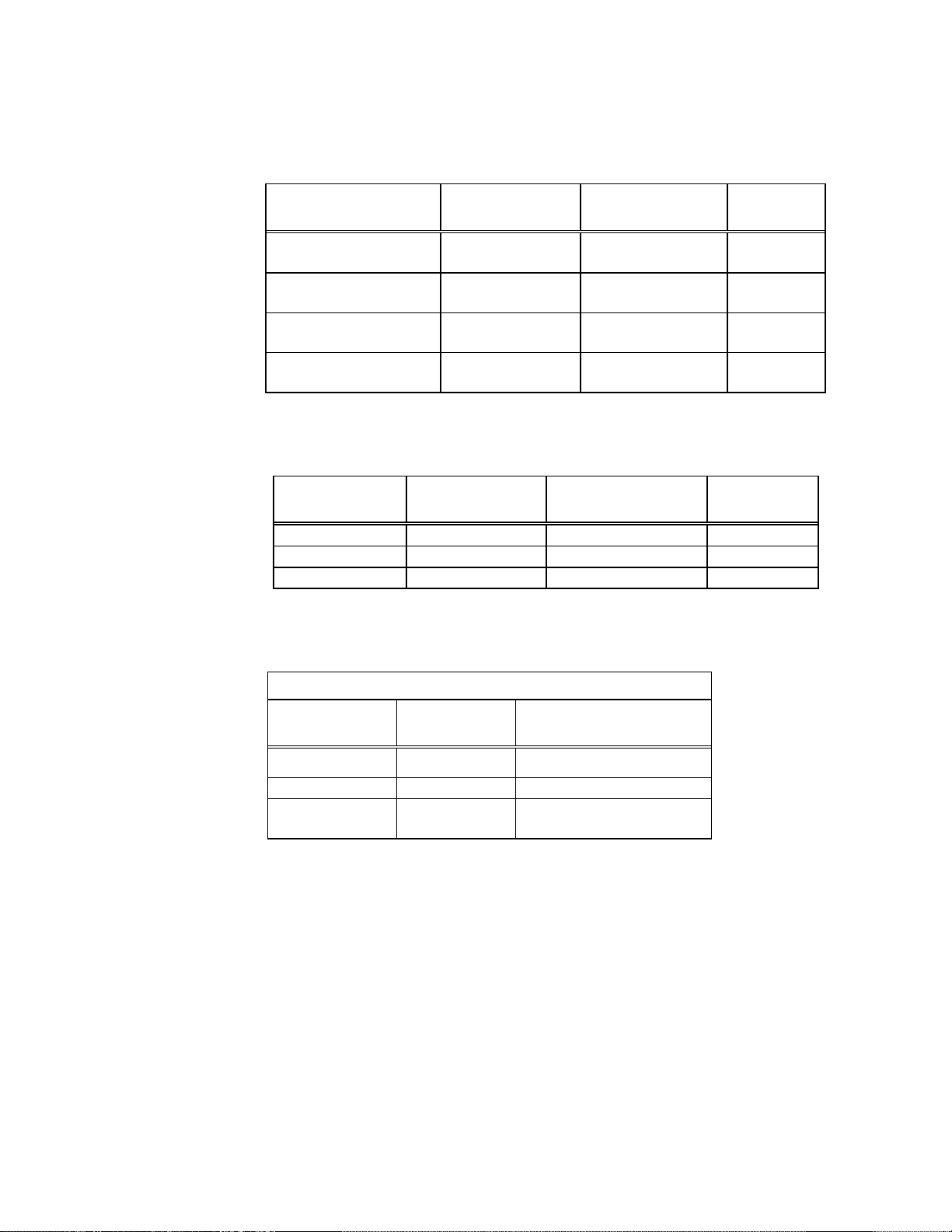

Table C-5 AC Cable Connections

International

Blue White AC neutral

U.S. Colors Connection Use

C-4

Page 31

Wiring Tables

Wire Pair

Wire Color

Signal

Typical Function

Blue/red

Blue

Wiegand data0

Parking/access control

applications

applications

White/red

White

Lock common

Testing maintenance

Red

Lock normally open

Testing maintenance

Green/red

Green

Input0

Loop and presence detect

Red

Input0 return

Loop and presence detect

Yellow/black

Yellow

Logic ground

Ground (not used with

RS–422)

RS–422)

available with Wiegand)

Black

Input1 return

A general purpose input; not

available with Wiegand)

buzzer, etc.)

buzzer, etc.)

Brown/black

Brown

Output0 normally open

Switches output to control

gate

gate

with Wiegand)

Black

Output1 common

Switches output (not available

with Wiegand)

Green/black

Green

Output1 normally open

Switches output (not available

with Wiegand)

with Wiegand)

Table C-6 External Interface Signal Wiring

Red Wiegand data1 Parking/access control

Black Logic ground Ground (not used with

Blue/black Blue Input1 A general purpose input; not

used to detect presence (not

used to detect presence (not

Orange/black Orange Output0 normally closed Switches output for any

external control (light, gate,

Black Output0 common Switches output for any

external control (light, gate,

Black Output0 common Switches output to control

White/black White Output1 normally closed Switches output (not available

Black Output1 common Switches output (not available

C-5

Page 32

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

C-6

Page 33

1

Introduction

Page 34

Page 35

Overview

Chapter 1

Introduction

This SmartPass® System Guide provides you w ith the information and

instructions for install ing a SmartPass Integrated Reader System,

called SmartPass. TransCore recommends that you r ead t hi s ent ire

manual. You should also read the READ.ME file t hat is on the

SmartPass software diskette befor e you begi n installing the SmartPass

system.

This chapter provides information for preparing to install SmartPass. This chapter

also addresses the most frequently asked questions about SmartPass:

• What is the SmartPass Integrated Reader System?

• Is a license needed to operate SmartPass?

• What equipment should be ordered?

System Description

SmartPass consists of an antenna, a check tag, a radio frequency (RF)

transmitter/receiver (called the RF module), a reader logic board (also called a tag

decoder), and a power supply. The components of SmartPass are contained in one

highly reliable, compact, and easy-to-install package. The integrated reader system is

shown in Figure 1-1. Appendix B contains the system specifications.

Figure 1-1 SmartPass System Diagram

1-3

Page 36

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

SmartPass generates an RF signal that is reflected from an TransCore radio

frequency identification (RFID) tag. The tag is programmed with identification

information. SmartPass receives and decodes the tag data carried by the reflected

signal and then transmits this data to a local host computer for processing.

Licenses

You should ask local and national authorities if your company needs to apply for a

license to use this product.

Choosing and Ordering Equipment

This section helps you determine the equipment for your site. In addition to

SmartPass, you need the appropriate communications interface, input power supply,

and power and communications cables. When choosing tags, you need to determine

the tag data format and the tag type. Refer to the Order Administration section of

your SmartPass Dealer’s Guide for the information on these topics:

• How to place an order

• How to change an existing order

• TransCore's credit and return policy

• TransCore's warranty and return policy

• Order Entry Form for SmartPass reader and tag

SmartPass Model AI1611

SmartPass Model AI1611 uses the 2450 MHz frequency. This model is also

available in a European version for customers whose applications must meet CE

mark requirements. You must indicate on the SmartPass Order Entry Form if you

require the CE mark version.

Accessories

TransCore recommends Part No. 54-1600-001, the accessory bracket kit, if you need

more flexibility when defining the read zone. The accessory bracket allows

SmartPass to be adjusted up, down, left, and right. You can use this kit if SmartPass

will be mounted to a flat surface, such as a wall, ceiling, or overhead structure.

1-4

Communications Interface

The SmartPass system communicates with the external host computer through an

asynchronous serial line or a Wiegand interface. SmartPass receives commands to

set up the system configuration and transfers information from the tag to the host

computer. This serial line can be an RS–232 interface or an RS–422 interface. Select

Page 37

Introduction

one of the following communications interface based on the specific needs of your

site.

Use an RS–232 interface if one or more of the following items apply to your site:

• The host computer system is less than 15.2 m from SmartPass

• The host computer system is more than 15.2 m from SmartPass and a pair of RF

modems or limited distance modem/line drivers over copper wire are used for

communications between SmartPass and the host. The distance from the RF

modem to SmartPass should not exceed 15.2 m.

• Other common communications devices that use RS–232 have been selected, such

as fiber optics

Use an RS–422 interface if one or more of the following items apply to your site:

• The host computer is more than 15.2 m from SmartPass

• The host computer has an external limited-distance modem

The standard RS–422 connection has a maximum distance of 1.2 km.

Use a Wiegand interface, which includes an RS–232 interface, if SmartPass must

interface with equipment requiring the Wiegand +5 V DC data0-data1-gnd interface.

Note: You must order tags programmed with Wiegand-formatted data when using

Wiegand-compatible readers.

Input Power Supply

The input power supply configurations should be based on the specific needs of your

site. SmartPass Model AI1611 uses 90–260 V AC, 47–63 Hz power.

Communications Cables

The appropriate communications cable length depends on the physical characteristics

of the SmartPass installation site. Select one of the following options for SmartPass

communications cable length.

• Select the short cable option if SmartPass will be located less than 1.2 m from the

junction box.

• Select the long cable option if SmartPass will be located more than 1.2 m from the

junction box. This cable is approximately 6.1 m long.

Power Cables

The appropriate power cable length depends on the physical characteristics of the

SmartPass installation site. Select one of the following options for SmartPass power

cable length.

• Select the short cable option if SmartPass will be located less than 1.2 m from the

junction box.

1-5

Page 38

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

Characters

Bits

window

AT5414

Transportation,

exterior

10-year

battery

10

26–54

exterior

battery

interior

battery

applicable

AT5988

TollTag,

interior

5-year

battery

20

Not

applicable

power

• Select the long cable option if SmartPass will be located more than 1.2 m from the

junction box. This cable is approximately 6.1 m long.

Tags

TransCore offers numerous tag models and four tag data formats to complete your

SmartPass system. The information below will assist you in determining which tag

and the tag data format are best for your system.

Note: If any of the vehicles already have tags, such as those used in toll

applications, contact TransCore at 2142)4613-4031 for information about

mixed-tag installations before you plan tag type, location, and

programming.

Tag Models

Use Table 1-1 to determine which tags will be best suited for your site requirements.

TransCore recommends battery-powered tags for use with the SmartPass Model

AI1611. Interior-mounted tags can be ordered from the factory with hook and loop

material already applied to the tag, or they can be ordered with double-sided tape.

Exterior-mounted tags can be ordered from the factory with double-sided tape or

with blind rivet mounting.

Table 1-1 Tag Models Available with SmartPass AI1611

Tag Model

Number

AT5406 Access control,

AT5910 Transportation,

AT5944 TollTag,

AT5704 Dynamic tag,

Tag Type Power

Source

10-year

interior inside

exterior

battery

10-year

10-year

DC

external

Number of

6-Bit ASCII

10 26–54

20 26–54

20 Not

Up to 4608 Not

Number

of Wiegand

applicable

Tag Data Formats

The TransCore factory programs tags with the tag model number, date of

manufacture, and data format. Consult the special order entry procedures in your

1-6

Page 39

Introduction

SmartPass Dealer’s Guide for ordering the format that applies to your system. Four

formats can be used for tag data:

• 10-character alphanumeric ASCII — Four alphanumeric characters are fixed and

can be used to identify either the dealer or the user. TransCore test tags are

typically programmed with PASS in these four positions. The remaining six

positions are numeric and should be unique for each tag issued. For example, the

entry ACME000001 might be used for the first tag in an order for ACME

Security.

• 20-character alphanumeric ASCII — A tag formatted with 20-character

alphanumeric ASCII data typically has four fixed positions. The remaining 16

positions are numbered sequentially.

• Wiegand — You must indicate the data to be programmed into the tags. A

Wiegand Format Worksheet is attached to the SmartPass Order Entry Form for

your use. Wiegand-formatted tags are labeled with a W prefix, followed by a

facility code and an identification number. For example, a Wiegand-formatted

TransCore tag with a facility code of 10 and an identification number of 253

would be labeled as W10 253.

Note: Not all tags can be Wiegand-formatted.

• ISO — For requirements for this format, refer to ISO 10374.

1-7

Page 40

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

1-8

Page 41

2

Preparing the Site

Page 42

Page 43

Chapter 2

Preparing the Site

Before installing SmartPass, you need t o devel op a site plan. Several

factors to consider when developing this site plan include the

following:

• SmartPass mounting locations

• Junction box requirements

• Electrical power requirement s

• Communications requirements

• Input/output circuit requirements for outside equipment

Warning

All construction work required for installing SmartPass must be completed before

installing SmartPass. Additionally, communications and power cables must be

installed through outdoor-grade, flexible steel conduit. Local building code

requirements should be followed.

Determining the Location to Install SmartP ass

The location of SmartPass and the location of the tags must be compatible. Each tag

must be in a direct line of sight to the reader.

You should also consider the following factors when determining a SmartPass

installation location:

• Reflection, refraction, and diffraction of RF energy

• Existing interference at the site that may need to be shielded or removed, such as

fluorescent lights, neon signs, nearby radio stations, or power lines

• Site area layout and traffic flow

• Location and read zone of other SmartPass units in the area

Reflection, Refraction, and Diffraction of RF

Signals

The RF signal can be reflected, refracted, or diffracted by metal objects, walls, and

even wet pavement or ice. When designing your site, you must take into account any

permanent structures that may reflect RF signals, as well as transient factors.

2-3

Page 44

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

Transient factors could include passing traffic, local weather conditions, chain link

fences, and gates that could temporarily reflect RF signals.

RF Reflectors

The most common RF reflectors are metallic surfaces. RF signals are also somewhat

reflected by nonconducting materials such as dirt, wood, ice, asphalt, and cured

concrete. When nonconducting materials in the system environment become wet,

they reflect more RF signals.

Aiming and placing Smartpass are the two best controls of RF reflections. When

these actions alone cannot adequately control reflections, other techniques may be

needed. These techniques could include shielding, absorbing, handshake counts, or

barriers.

RF Refraction

When an RF signal enters any material, its direction of travel is altered by a few

degrees. Refraction of RF signals rarely affects system performance, except when

tags are mounted on or under surfaces where nonconducting materials are placed or

can accumulate between the tag and the antenna.

RF Diffraction

Diffraction occurs when RF signals are bent around objects allowing RF into areas

that would normally receive little or no signal. Metal poles, corners of buildings, and

metal housings in industrial environments often diffract signals.

Existing Interference

Interference from RF and electrical sources can degrade system performance. This

type of interference must be considered in the site design.

Existing interference at the site may be shielded, removed, or positioned further from

the source. Filters may be added to the system. Fluorescent lights, neon signs, nearby

radio stations, or power lines can interfere with the optimal functioning of the

system. Even the magnetic impulse noise from relays, whose opening and closing

control the operation of a gate, can disrupt the RF signal.

SmartPass and Tag Mounting Locations

SmartPass can be installed in many positions to provide the most accurate field, or

read zone, for the tags. SmartPass can be mounted to a round pole or to a flat surface,

such as a wall, ceiling, flat pole, or an overhead structure. The following sections

provide more information for different site configurations and show the preferred tag

mounting locations.

2-4

Page 45

Preparing the Site

Gate Configuration

Figure 2-1 illustrates a gate configuration. Two SmartPass units are located on a

center island. SmartPass is placed to allow time for the gate to open so the vehicle

can continue without stopping.

Figure 2-1 Gate Configuration with Center Island

2-5

Page 46

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

Figure 2-2 shows an incorrect mounting of SmartPass. Do not install SmartPass

behind a gate. Vehicles might pull up too close to the gate, damaging the vehicle or

the gate.

Figure 2-2 Incorrect Moun ting of SmartPass

Parking Garage Configuration

Figure 2-3 illustrates a parking garage configuration with each SmartPass on the

ticket island. SmartPass is placed so that the vehicle stops before the gate opens.

2-6

Figure 2-3 Parking Garage Configuration

Page 47

Preparing the Site

In the gate configuration and the parking garage, interior tags are mounted on the

inside of the windshield on the left side of the vehicle. Exterior tags are mounted on

the left side of the bumper. Figure 2-4 shows interior and exterior tag mounting

locations for use with a left-side gate configuration and a parking garage

configuration.

Figure 2-4 Left-Side Tag Mounting Locations

Overhead Mounting Configuration

SmartPass can be mounted to an overhead structure as shown in Figure 2-5.

Figure 2-5 SmartPass Mounted Overhead

2-7

Page 48

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

When SmartPass is mounted overhead, the preferred tag mounting position is inside

the windshield, behind the rearview mirror. If an exterior tag must be used when

SmartPass is mounted overhead, place the tag on the front bumper in the center.

Figure 2-6 illustrates interior and exterior positions of tags used with SmartPass

mounted overhead.

Figure 2-6 Tag Mounting Positio ns for SmartPass Mounted Overhead

Open Lane Configuration

Figure 2-7 illustrates an open lane configuration. For this configuration, tags are

mounted on the inside of the windshield on the right side of the vehicle

2-8

Page 49

Preparing the Site

Figure 2-7 Open Lane Configuration

For additional information on installing SmartPass, refer to Chapter 5, “Installing

SmartPass.” Chapter 5 has illustrations for mounting SmartPass on a pole or to an

overhead structure. Chapter 4, “Installing Tags On Vehicles,” provides additional

information on selecting the proper tag mounting location and has examples of tags

mounted on vehicles.

Area Layout and Traffic Flow

SmartPass must be able to read a tag’s data properly within the read zone without

reading any other tags nearby. SmartPass must be positioned to allow the RF signal

2-9

Page 50

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

to reach and return from a tag within the designated range. Also, if the antenna

becomes misaligned or some nearby permanent structure is added or removed,

system operation can be seriously affected. SmartPass should be placed in an area

where it is not likely to be bumped out of alignment.

Other SmartPass Units in the Area

If multiple SmartPass readers are installed near each other, they must be configured

with a frequency separation of at least 3 MHz.

Note: Never install two SmartPass reader systems directly facing each other, or

SmartPass receiver circuitry and decoder will not operate reliably

Junction Box

A junction box is needed at the site. TransCore recommends a NEMA Type 4 or IEC

IP54 junction box with a back plate. The junction box will house the terminal strip

for communications and power.

The junction box must be a watertight box that meets applicable local and national

building codes. It must have watertight conduit for any cables that will attach to

SmartPass. SmartPass will be used with a 90–260 V AC power supply. The box must

have conduit on both the supply and reader sides. SmartPass is fitted with a 1.3-cm

pipe NPT-threaded connector that allows watertight conduit to be installed.

Caution

Power and communications lines must use separate conduits.

Vorsicht

Strom- und Kommunikationsleitungen müssen durch getrennte Kabelkanäle

geführt werden.

Precaución

Se deben emplear conductos separados para las líneas de alimentación y de

comunicaciones.

Précaution

Les lignes d'alimentation et de communications doivent emprunter des conduits

différents.

Attenzione

Le linee dell’alimentatore e di comunicazione devono usare condutture separate.

2-10

Page 51

Electrical Power Su pply

Interface

Conductors

RS–232

3

RS–232 with RTS and CTS hardware

handshake signals

5

RS–422

4

Wiegand

3

An electrical power supply must be present at the site. SmartPass Model AI1611 is

supplied with 90–260 V AC, 47–63 Hz power, which is less power than a 25 W

incandescent light bulb. Consult your local and national electrical codes for

installation and safety requirements.

Communications

Your site design must include the communications required for installing SmartPass.

Your host computer must be able to accept one of the interfaces shown in Table 2-1.

Consult the requirements for the host interface for the number of conductors, type,

and size of cable required for the junction box. The distance between the host

computer and SmartPass must also be considered.

Table 2-1 Communications Interfaces and Conductors

Preparing the Site

Number of

Input/Output Circuit Requirements for Outside

Equipment

You will need input and output circuits if you will use any additional equipment,

such as a loop detector or traffic control light. If you are connecting SmartPass to

such equipment, wires from these circuits should be installed at the junction box.

The input circuit of SmartPass connects to a dry contact closure. SmartPass output

circuits are single-pole, double-throw relays providing dry contact closures. These

closures are rated at 125 V AC or DC at 1 A.

2-11

Page 52

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

2-12

Page 53

3

Quick SmartPass® Test

Page 54

Page 55

Overview

First Character

Second Character

Third Character

6.1 m

Chapter 3

Q uick Sm artPass® Test

This chapter provides instructions f or t est ing SmartPass.

Before installing SmartPass at the site, you should perform two tests on SmartPass to

ensure that it will work properly. The first test is done using an audible circuit tester.

This test confirms that SmartPass has power, is communicating with the software

loaded inside the SmartPass reader, and can read a tag presented in the tag read zone.

The second test uses a personal computer (PC) and the SmartPass software diskette.

In this test you will check the factory defaults on your SmartPass and change the

defaults if needed. A list of the factory default settings on SmartPass is shown in

Table 3-5 located at the end of this chapter.

Materials Supplied

The SmartPass shipping carton is labeled to indicate the reader’s configuration.

Table 3-1 lists the simple three-letter code used.

Table 3-1 Three-Letter Reader Configuration Code

T = RS–232

F = RS–422

W = Wiegand

This same three-letter code is stamped on the serial number plate on each SmartPass.

The code is followed by the frequency rate.

Example: A shipping carton labeled THS2450 contains a SmartPass that is

configured with RS–232, high-voltage power supply, and short cables and has an

operating frequency of 2450 MHz.

Your SmartPass is packaged with the materials listed below. Ensure you have

received all parts before beginning your quick test of SmartPass.

• One SmartPass unit

• One pole-mount bracket

H = High voltage

90–260 V AC

S = Short cables

1.2 m

L = Long cables

3-3

• Four machine screws and washers

Page 56

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

Additional Materials Needed

You need these additional materials to perform the two tests on SmartPass:

• SmartPass software diskette, which is supplied to TransCore dealers and

distributors

• PC with 1.44 MB floppy disk drive, MS DOS, RS–232 COM1 port, and a

communications cable with a DB9 or DB25 connector

• Two test tags, supplied by the TransCore dealer or distributor

• Other materials needed to connect the PC to SmartPass as described in the

software diskette READ.ME file

Testing with the Audible Circuit Tester

Testing with an audible circuit tester confirms that your SmartPass has power, is

communicating with the software loaded inside the SmartPass reader, and can read a

tag if it is in the read zone.

An audible circuit tester is also called a buzz box. These boxes are available at

electronic parts supply stores, or you may make a buzz box as shown below. The

buzz box is powered by a battery and equipped with two alligator-clip leads. When

you touch the leads together, the box makes an audible sound. Figure 3-1 shows the

wiring for a buzz box.

3-4

Figure 3-1 Wiring for Buzz Box

Page 57

Quick SmartPass® Test

To test SmartPass

1. Connect SmartPass to a 90–260 V, high-voltage power supply.

Warning

For safety, the power supply should be grounded. Consult your local electrical

authorities for proper grounding techniques.

Warning

Aus Sicherheitsgründen sollte die Stromversorgung geerdet sein. Wenden Sie sich

bitte an Ihren örtlichen Stromversorger für Informationen bezüglich einer

korrekten Erdung.

Advertencia

Por motivos de seguridad, se debe conectar la fuente de energía a tierra. Para

averiguar la manera correcta de efectuar la conexión a tierra, póngase en contacto

con las autoridades locales competentes en materia de instalaciones eléctricas.

Avertissement

Si ces lignes sont raccordées à des dispositifs externes, elles doivent être isolées

d'une façon ou d'une autre. Si elles ne sont pas correctement isolées, la carte

logique du lecteur risque d'être gravement endommagée.

Avvertenza

Se queste linee vengono collegate a dispositivi esterni, questi devono essere isolati

in qualche modo. Un isolamento sbagliato delle linee può causare gravi danni alla

scheda logica del lettore.

2. Connect the two leads from the batteries to the red and white pair of wires from

the SmartPass communications cable.

3. Twist the red and green wire pair from the SmartPass cable. Twisting the red

and green pair turns the RF on continuously.

4. Pass a tag in front of SmartPass. The buzz box should buzz when it reads the

tag.

5. Disconnect the buzz box from SmartPass.

You are ready to proceed with the second test.

Note: Save this buzz box for use when installing SmartPass at the site.

3-5

Page 58

SmartPass® Integrated Reader 2450 MHz (High Voltage) System Guide

Pin

Pin

Transmit from

SmartPass

Red/black

Black

Pin 2

Pin 3

Receive from PC

Red/black

Red

Pin 3

Pin 2

Logic ground

Yellow/black

Yellow or black

Pin 5

Pin 7

Optional for hardware handshaking

Request to send

Yellow/red

Yellow

Pin 4

Pin 4

Clear to send

Yellow/red

Red

Pin 8

Pin 5

Testing Wit h a PC and the Sof tware Diskette

Testing SmartPass with a PC and the software diskette verifies that SmartPass

hardware and software are working and that the communications hardware is

operating correctly.

SmartPass can interface with the host computer by using either an RS–232 interface,

an RS–422 interface, or with a Wiegand interface. Refer to the appropriate section

below to connect the interface you are using with your SmartPass. SmartPass does

not need to be powered down before attaching it to the PC. The power-up sequence

does not affect communications between SmartPass and the PC.

Connecting an RS–232 Interface

Follow these instructions if your SmartPass uses an RS–232 interface. RS–232

interface signals are supplied by five wires from the SmartPass communications

cable. The wire connections are shown in Table 3-2.

Table 3-2 RS–232 Interface Signal Wiring

Signal Wire Pair

From SmartPass

To connect an RS–232 Interface

1. Connect the black wire from the red and black wire pair from the SmartPass

cable to pin 2 of the DB9 connector or pin 3 of the DB25 connector.

2. Connect the red wire from the red and black wire pair from the SmartPass cable

to pin 3 of the DB9 connector or pin 2 of the DB25 connector.

3. Connect either the yellow or black wire from the yellow and black wire pair

from the SmartPass cable to pin 5 of the DB9 connctor or pin 7 of the DB25

connector.

4. Plug in the DB9 connector or DB25 connector to the PC.

Wire Color

Used From Pair

Connect Wire

to PC DB9

Connect Wire

to PC DB25

3-6

SmartPass is now connected to your PC.

Note: If you are using Windows 95, make sure you connect the DB9 connector or

the DB25 connector to COM1 or COM2 before powering up the PC.

Page 59

Quick SmartPass® Test

SmartPass

Pair

Transmit B (+) data

from SmartPass

Yellow/red

Yellow

Receive (+)

from SmartPass

SmartPass

(+)

Receive A (-) data to

SmartPass

Red/black

Red

Transmit (-)

Signal

Wire Pair

Wire Color

Wiegand Signal

Data0

Blue/red

Blue

Data 1

Data1

Blue/red

Red

Data0

Logic ground

Yellow/black

Yellow or black

Ground

Connecting an RS–422 Interface

Follow these instructions if your SmartPass is an RS–422 unit. RS–422 interface

signals are supplied by four wires from the SmartPass communications cable.

Your host must have an RS–422 interface, with either an internal converter or

with an external converter. Table 3-3 lists the RS–422 signals and their interface

wires.

Table 3-3 RS–422 Interface Signal Wiring

Signal

Transmit A (-) data

Receive B (+) data to

Wire Pair

From

Yellow/red Red Receive (-)

Red/black Black Transmit

Wire Color

Used From

Connect to

Signal

To connect an RS–422 interface

1. Connect the yellow transmit B (+) wire from the yellow and red wire pair from

the SmartPass cable to the host receive (+) signal.

2. Connect the red transmit A (-) wire from the yellow and red wire pair from the

SmartPass cable to the host receive (-) signal.

3. Connect the black receive B (+) wire from the red and black wire pair from the

SmartPass cable to the host transmit (+) signal.

4. Connect the red receive A (-) wire from the red and black wire pair from the

SmartPass cable to the host transmit (-) signal.

3-7

SmartPass is now connected to your PC.

Connecting a Wiegand Interface

Follow these instructions if your SmartPass uses a Wiegand interface. Wiegand

interface signals are supplied by three wires from the SmartPass communications

cable. Table 3-4 lists the Wiegand signals and the interface wires.