Page 1

Multiprotocol

Reader Extreme (MPRX)

System Guide

16-0079-001 Rev A 11/16

TransCore’s Multiprotocol Reader Extreme (MPRX) is a radio frequency

identification (RFID) reader that is specifically designed for harsh

environment applications.

Purpose of This Guide

This guide provides site planning and testing, installing, and operating instructions for

TransCore’s Multiprotocol Reader Extreme (MPRX) System, which reads Association of

American Railroads (AAR) formatted tags and TransCore Super eGo® (SeGo) protocol tags.

Before you begin installing the MPRX, TransCore recommends that you familiarize yourself

with this manual.

Intended Audience

This document is intended for use by authorized TransCore MPRX dealers, installers,

and service personnel. Because the MPRX has no operator or end-user serviceable

components or features, no end-user manual or operator guide exists. Once the system

is set up and tested by the authorized installer, MPRX operation requires no end-user

intervention. Information in this document is subject to change and does not represent a

commitment on the part of TransCore, LP.

Trusted Transportation Solutions

Page 2

System Guide

© 2016 TransCore, LP. All rights reserved. TRANSCORE, AMTECH, EGO, TRU, and ENCOMPASS are

registered trademarks and are used under license. All other trademarks are the property of their respective

owners. Contents are subject to change. Printed in the U.S.A.

For further information, contact:

TransCore

8600 Jeerson Street NE

Albuquerque, New Mexico 87113 USA

TransCore Technical Support

Web: www.transcore.com/rfidsupport

Phone: (505) 856-8007

ii

TransCore Proprietary

Page 3

MPRX

WARNING TO USERS IN THE UNITED STATES

FEDERAL COMMUNICATIONS COMMISSION FCC

LOCATION AND MONITORING SERVICE STATEMENT

47 CFR §90.351

NOTE: The user is required to obtain a Part 90 site license from the Federal Communications

Commission (FCC) to operate this radio frequency identification (RFID) device in the United States.

The FCC ID number is FIHMPRX. Access the FCC website at www.fcc.gov to obtain additional

information concerning licensing requirements.

NOTE: Users in all countries should check with the appropriate local authorities for licensing

requirements.

FCC RADIO FREQUENCY INTERFERENCE STATEMENT

47 CFR §15.105A

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate RF energy and may cause harmful

interference to radio communications if not installed and used in accordance with the instruction

manual. Operating this equipment in a residential area is likely to cause harmful interference, in

which case, depending on the laws in eect, the user may be required to correct the interference

at their own expense.

NO UNAUTHORIZED MODIFICATIONS

47 CFR §15.21

CAUTION: This equipment may not be modified, altered, or changed in any way without

permission. Unauthorized modification may void the equipment authorization from the FCC and will

void the warranty.

USE OF SHIELDED CABLES AND GROUNDING

47 CFR §15.27A

NOTE: Shielded cables and earth grounding the unit is recommended for this equipment to comply

with FCC regulations.

TRANSCORE, LP

USA

TransCore Proprietary

iii

Page 4

System Guide

REMARQUE : L’utilisateur est tenu d’obtenir une licence d’utilisation sur site Partie 90 auprès de

la Federal Communications Commission (FCC) afin de pouvoir utiliser ce dispositif RFID (radioidentification) aux États-Unis ou au Canada. Le numéro d’identification de la FCC est FIHMPRX.Pour

obtenir de plus amples informations concernant les exigences relatives aux licences, prière de

consulter le site web de la FCC à www.fcc.gov.

REMARQUE : Il est recommandé à tous les utilisateurs, quel que soit leur pays, de consulter les

autorités locales compétentes sur les exigences de licence.

AVERTISSEMENT À L’ATTENTION DES

UTILISATEURS AUX ÉTATSUNIS

DÉCLARATION 47 CFR §90.351 CODE DES

RÈGLEMENTS FÉDÉRAUX DE LA FEDERAL

COMMUNICATIONS COMMISSION FCC SUR LES

SERVICES DE LOCALISATION ET DE CONTRÔLE

DÉCLARATION 47 CFR §15.105A DE LA FCC SUR

LES INTERFÉRENCES DES FRÉQUENCES RADIO

REMARQUE : Cet appareil a été testé et déclaré conforme à la catégorie d’un appareil numérique

de classe A en accord avec la partie 15 des directives de la FCC. Ces normes visent à assurer

une protection raisonnable contre les interférences nuisibles lorsque l’appareil est utilisé dans

un environnement commercial. Cet appareil génère, utilise et peut émettre de l’énergie RF et

peut être à l’origine d’interférences nuisibles aux communications radio s’il n’est pas installé et

utilisé en suivant les directives du manuel d’instructions. Si cet appareil est utilisé dans une zone

résidentielle, il est probable qu’il cause des interférences nuisibles. Dans ce cas, l’utilisateur

pourrait être amené à remédier aux interférences à ses propres frais, selon les lois du pays en

vigueur.

AUCUNE MODIFICATION NON AUTORISÉE

47 CFR §15.21

MISE EN GARDE : Il est interdit de modifier, d’altérer ou d’apporter des changements à cet appareil

de quelque manière que ce soit sans autorisation. Toute modification non autorisée peut annuler

l’autorisation d’utilisation accordée par la FCC et annulera la garantie.

iv

UTILISATION DE CÂBLES BLINDÉS ET MISE À LA TERRE

47 CFR §15.27A

REMARQUE : Il est recommandé d’utiliser des câbles blindés et une mise à la terre avec cet

appareil afin de répondre aux réglementations de la FCC

TRANSCORE, LP

ÉTATSUNIS

TransCore Proprietary

Page 5

MPRX

WARNING TO USERS IN CANADA

INDUSTRY CANADA IC INDUSTRY CANADA’S RADIO STANDARD SPECIFICATIONS RSS137 LOCATION

AND MONITORING SERVICE IN THE BAND 902928 MHZ SECTION 2.1

NOTE: The user is required to obtain a license from Industry Canada (IC), to operate this radio

frequency identification (RFID) device in Canada. The IC ID number is 1584A-MPRX, access the IC

website at www.ic.gc.ca to obtain additional information concerning licensing requirements.

Industry Canada (IC) Industry Canada’s Radio Standard Specifications General Requirements

(RSS-GEN) for Compliance of Radio Apparatus Statement Section 8.4

This device complies with Industry Canada’s license-exempt RSSs. Operation is subject to the

following two conditions:

1 ) This device may not cause interference; and

2 ) This device must accept any interference, including interference that may cause

undesired operation of the device.

AVERTISSEMENT AUX UTILISATEURS AU CANADA

INDUSTRIE CANADA IC INDUSTRIE CANADA RADIO STANDARD SPECIFICATIONS CNR137

EMPLACEMENT ET SERVICE DE SURVEILLANCE DANS LA BANDE 902928 MHZ, SECTION 2.1

Remarque : L’utilisateur est tenu d’obtenir une licence d’Industrie Canada (IC), afin d’exploiter

ce dispositif d’identification par radiofréquence au Canada. Le numéro d’identification d’IC est

1584A-MPRX. Pour obtenir de plus amples informations concernant les exigences relatives aux

licences, prière de consulter le site web de d’IC à www.ic.gc.ca .

Radio Standard Spécifications exigences générales Industrie Canada (IC) Industrie Canada

(CNR-GEN) pour s’acquitter du Radio appareil déclaration article 8.4

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio

exempts de licence. L'exploitation est autorisée aux deux conditions suivantes :

1 ) l'appareil ne doit pas produire de brouillage, et

2 ) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

TransCore Proprietary

v

Page 6

System Guide

Several agencies (OSHA, FCC, IC) have environmental guidelines regulating maximum permissible

exposure (MPE) or “safe” exposure levels that this product falls under. To ensure that proper safety

guideline for the end users of this product, i.e. Occupational (Controlled) and General Population/

Public (Uncontrolled), the recommended levels for each of the agencies are presented in the next

sections with TransCore’s recommendations for safety in the last section.

OSHA (Occupational Safety and Health Administration)

OSHA (an agency of The United States of America) legislates in the Code of Federal Regulations

(CFR) Title 29 Part 1910 Subpart G 1910.97 titled “Nonionizing radiation”, a maximum safe exposure

limit of 10 milliwatts per square centimeter (mW/cm2) during any 0.1-hour period (i.e. 6 minutes).

Using the frequency (in the middle of the band of operation of this equipment) of 915 MHz and the

highest antenna gain that this equipment is certified for use in a final installation, the minimum safe

distance was calculated to be 8in (20cm).

RADIO FREQUENCY HEALTH LIMITS FOR MPRX READER

USING AN EXTERNAL ANTENNA IN FREQUENCY BAND

OF 902.25 TO 903.75 AND 910.00 TO 921.50 MHZ

FCC (Federal Communication Commission)

FCC (an agency of The United States of America) legislates in the Code of Federal Regulations

(CFR) Title 47 Chapter I Subchapter A Part 1 Subpart I Section 1.1310 titled “Radiofrequency radiation

exposure limits” that the maximum permissible exposure (MPE) is the following:

Occupational/Controlled Exposure

Power density = frequency (in MHz)/300 mW/cm2 with an Averaging time of 6 Min

General Population/Uncontrolled Exposure

Power density = frequency (in MHz)/1500 mW/cm2 with an Averaging time of 30 Min

Using the frequency (in the middle of the band of operation of this equipment) of 915MHz and the

highest antenna gain that this equipment is certified for use in a final installation, the minimum

safe distance was calculated. The MPE minimum distances are 14in (36cm) for the Occupational/

Controlled environment, and 31.5in (80.5cm) for the General Population/Uncontrolled environment.

Industry Canada (Innovation, Science and Economic Development Canada)

vi

Industry Canada (a Department of the Government of Canada) sets out the requirements in Radio

Standards Specification RSS-102, Issue 5 guidelines, recommending a maximum safe

TransCore Proprietary

Page 7

power density in W/m2. Thus, the maximum permissible exposure for general population/

uncontrolled exposure at 915MHz is 2.77 W/m2. The average time is 6 minutes. The maximum

permissible exposure (MPE) is the following:

Controlled Environment

MPRX

Power density = 0.6455*frequency (in MHz)

0.5

W/m2 with a Reference Period time of 6 Min

General Public/Uncontrolled Environment

Power density = 0.02619*frequency (in MHz)

0.6834

W/m2 with a Reference Period time of 6 Min

Using the frequency (in the middle of the band of operation of this equipment) of 915MHz and the

highest antenna gain that this equipment is certified for use in a final installation, the minimum

safe distance was calculated. The MPE minimum distances are 18in (45cm) for the Controlled

environment and 47in (120cm) for the General Public/Uncontrolled environment.

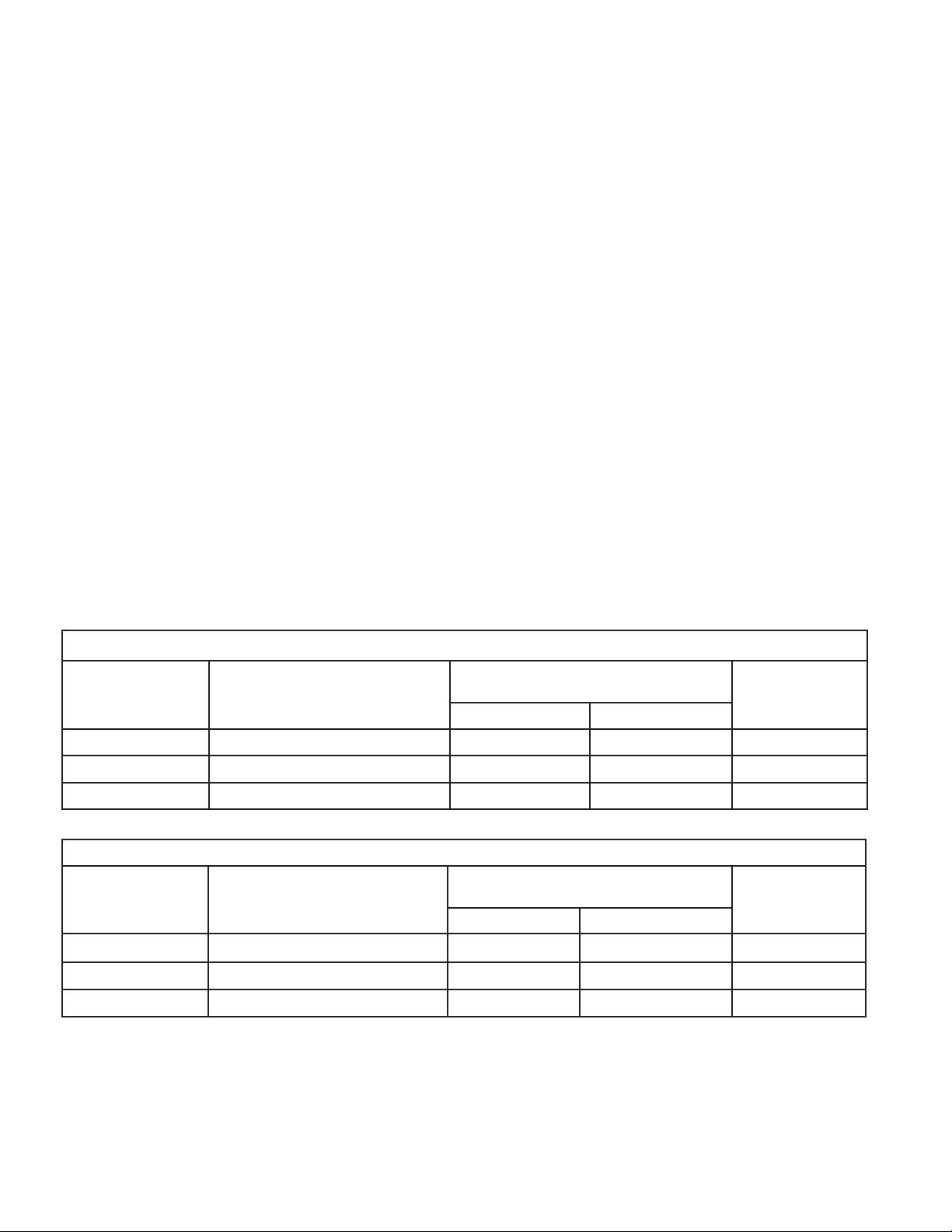

TransCore Recommendation on MPE (Maximum Permissible Exposure)

The calculated power densities and MPE distance for each of the agencies respective to the

environment is shown below.

Occupational/Controlled Environment

Agency Power Density (mW/cm2) MPE minimum distance Time (min)

in cm

OSHA 10 7 18 6

FCC 3.05 13 32 6

IC 1.95 16 40 6

General Population/Public/Uncontrolled Environment

Agency Power Density (mW/cm2) MPE minimum distance Time (min)

In cm

OSHA 10 7 18 6

FCC 0.61 28 72 30

IC 0.28 42 106 6

TransCore Proprietary

vii

Page 8

System Guide

With the equipment installed and running at the maximum transmit power of 1.6W (32dBm),

0dB transmit attenuation, using the highest gain antenna that the equipment is certified for, the

recommendation for each of the operation environments is as follows:

1 ) The antenna should be installed at least 42in (106cm) from the General Population/

Public i.e. Uncontrolled Environment.

2 ) Maintenance personnel (i.e. Occupational/Controlled Environment) must remain at least

16in (40cm) from the antenna and limit their time in the environment to 6 minutes when

the system is operating.

viii

TransCore Proprietary

Page 9

MPRX

LIMITES D’EXPOSITION AUX RADIOFRÉQUENCES POUR LE LECTEUR MPRX

UTILISANT UNE ANTENNE EXTERNE SUR LA BANDE

DE FRÉQUENCES DE 902.25 À 903.75 ET DE 910.00 À 921.50 MHZ

Plusieurs organismes (OSHA, FCC, IC) publient des directives environnementales qui

recommandent des limites d’exposition maximale autorisée (normes MPE) ou des niveaux

d’exposition «sûrs» auxquels cet appareil se conforme. Pour faire en sorte que chaque utilisateur

final ait connaissance des directives de sécurité qui le concerne, que ce soit dans son travail

(accès contrôlé) ou pour la population générale/le grand public (accès non contrôlé), TransCore

présente les niveaux recommandés par chaque organisme dans ses recommandations sécuritaires

détaillées dans la dernière section.

OSHA (Occupational Safety and Health Administration)

Dans le Code des réglementations fédérales (CFR), Titre 29, Partie 1910, Sous-partie G 1910.97,

intitulée «Nonionizing radiation» (Rayonnements non ionisants), l’OSHA (organisme américain)

recommande un plafond d’exposition maximale de 10 milliwatts par centimètre carré (mW/cm2)

pendant une période de 0,1 heure (soit 6 minutes). En utilisant la fréquence de 915 MHz (milieu de

la bande de fréquences de cet appareil) et le gain d’antenne maximal pour lequel cet appareil a

reçu une certification d’utilisation dans une installation finale, la distance minimale sécuritaire est

de 20 cm (8 po).

FCC (Federal Communication Commission)

Dans le Code des réglementations fédérales (CFR), Titre 47, Chapitre I, Sous-chapitre A, Partie

1, Sous-partie I, Section 1.1310 intitulée «Radiofrequency radiation exposure limits» (Limites

d’exposition aux rayonnements de radiofréquence), la FCC (organisme américain) établit les limites

d’exposition maximale autorisée (normes MPE) comme suit :

Exposition professionnelle/contrôlée

Densité de puissance = fréquence (en MHz)/300 mW/cm2 avec une durée moyenne de 6 min.

Exposition de la population générale/non contrôlée

Densité de puissance = fréquence (en MHz)/1500 mW/cm2 avec une durée moyenne de 30 min.

En utilisant la fréquence de 915 MHz (milieu de la bande de fréquences de cet appareil) et le

gain d’antenne maximal pour lequel cet appareil a reçu une certification d’utilisation dans une

installation finale, la distance minimale sécuritaire est la suivante : les distances MPE minimales

sont de 36 cm (14 po) pour l’environnement professionnel/contrôlé et de 80,5 cm (31,5 po) pour la

population générale/environnement non contrôlé.

TransCore Proprietary

ix

Page 10

System Guide

Industrie Canada (Innovation, Sciences et Développement économique Canada)

Le Cahier des charges sur les normes radioélectriques 102, 5e édition, d’Industrie Canada (un

ministère du Gouvernement du Canada) établit des recommandations pour une densité de

puissance maximale sécuritaire en W/m2. Ainsi, l’exposition maximale admissible pour la population

générale/non contrôlée à 915 MHz est calculée à 2,77 W/m2. La durée moyenne est de 6 minutes.

Les limites d’exposition maximale autorisée (normes MPE) sont les suivantes :

Environnement contrôlé

Densité de puissance = 0,6455*fréquence (en MHz)

0,5

W/m2 avec une durée de référence de 6 min.

Grand public/environnement non contrôlé

Densité de puissance = 0,02619*fréquence (en MHz)

0,6834

W/m2 avec une durée de référence de 6 min.

En utilisant la fréquence de 915 MHz (milieu de la bande de fréquences de cet appareil) et le

gain d’antenne maximal pour lequel cet appareil a reçu une certification d’utilisation dans une

installation finale, la distance minimale sécuritaire est la suivante : les distances MPE minimales

sont de 45 cm (18 po) pour l’environnement professionnel/contrôlé et de 120 cm (47 po) pour le

grand public/environnement non contrôlé.

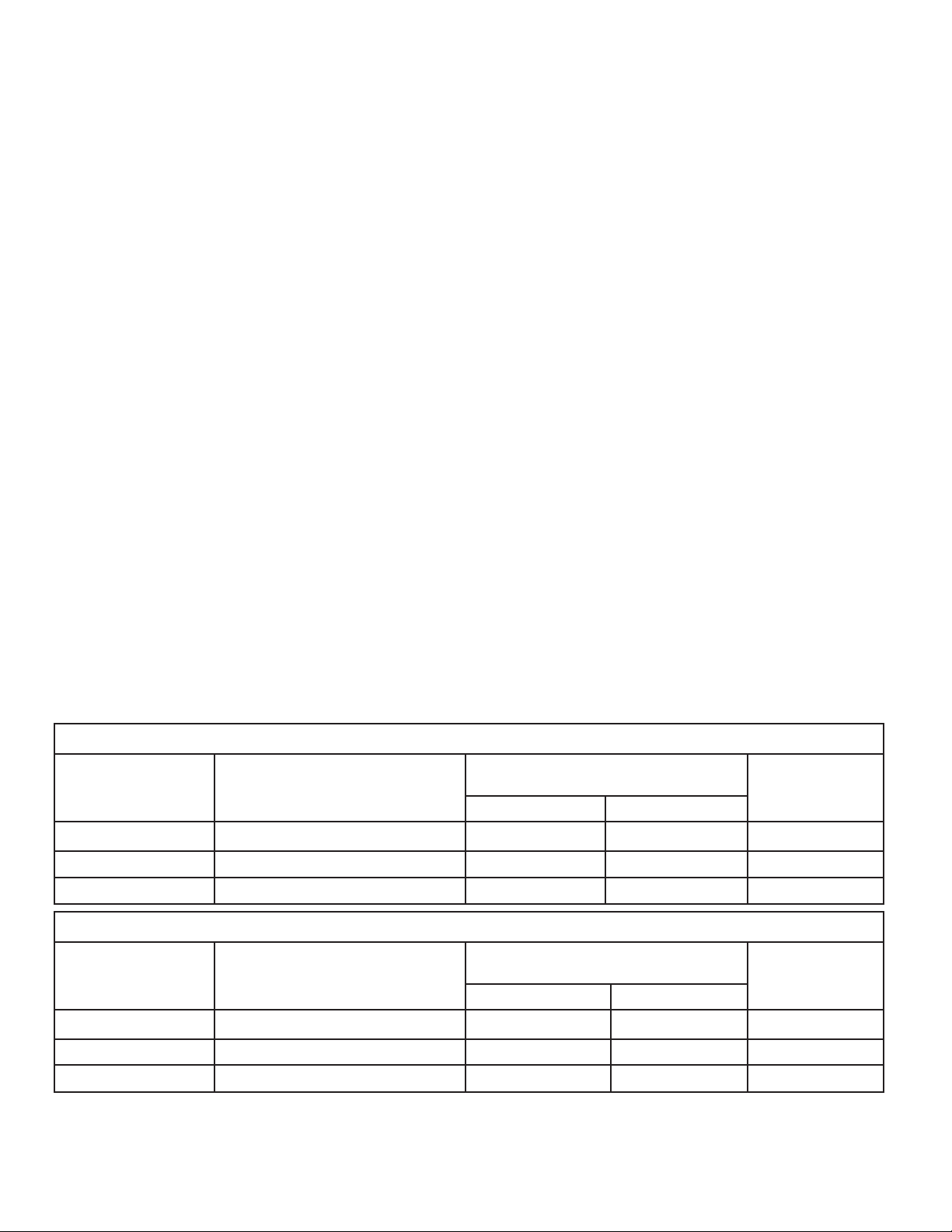

Recommandations de TransCore sur les limites d’exposition maximale autorisée (normes MPE)

Les densités de puissance et la distance MPE calculées par chaque organisme pour un

environnement donné sont présentées ci dessous.

Exposition professionnelle/environnement contrôlé

Organisme

Densité de puissance (mW/

cm2)

Distance MPE minimale

Durée (en min.)

po cm

OSHA 10 7 18 6

x

FCC 3,05 13 32 6

IC 1,95 16 40 6

Population générale/environnement non contrôlé

Organisme

Densité de puissance (mW/

cm2)

Distance MPE minimale

Durée (en min.)

po cm

OSHA 10 7 18 6

FCC 0,61 28 72 30

IC 0,28 42 106 6

TransCore Proprietary

Page 11

MPRX

Avec l’appareil installé et fonctionnant à la puissance de transmission maximale de 1,6W (32dBm),

0dB d’atténuation de transmission, et en utilisant le gain d’antenne maximal pour lequel l’appareil

a reçu une certification, les recommandations pour chaque environnement d’exploitation sont les

suivantes :

1 ) L’antenne devrait être installée à au moins 106 cm (42 po) de la population générale/du

grand public, c’est-à-dire d’un environnement non contrôlé.

2 ) Le personnel d’entretien (c’est-à-dire dans un environnement professionnel/contrôlé)

doit rester à au moins 40 cm (16 po) de l’antenne et limiter son temps d’exposition à 6

minutes lorsque l’appareil est en fonctionnement.

-

TransCore Proprietary

xi

Page 12

Table of Contents

Purpose of This Guide ................................................i

Intended Audience .................................................... i

Chapter 1 Introduction ..........................................1–2

Licensing Requirements ........................................... 1–4

Technical Support................................................. 1–4

Chapter 2 Developing the Site Plan ...............................2–2

System Description ...............................................2–2

Overview of Site Planning..........................................2–3

Reading of Mixed Population Tags.......................................2–3

Antenna and Tag Alignment ........................................2–4

Antenna Selection ................................................2–6

MPRX

Site Layout and Trac Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Electrical and Communications Requirements.........................2–9

Chapter 3 Choosing, Installing, Removing Tags .....................3–2

Compatible Tag Types ................................................3–2

Recommended Mounting Locations .................................3–2

Locomotive Mounting Guidelines ...................................3–6

Rail Car Mounting Guidelines.......................................3–8

Tank Car Mounting Guidelines .....................................3–10

Chapter 4 Installing the MPRX.............................................4–2

Installation Process ...............................................4–2

Pre-installation Testing of the MPRX .................................4–3

Mounting the MPRX...............................................4–9

Mounting the Antenna Rail-Side ....................................4–11

Connecting the Power Supply ......................................4–11

Connecting Communications ...................................... 4–12

Connecting Sense Input and Sense Output Circuits................... 4–12

Marking the Read Zone ........................................... 4–13

Chapter 5 General Software Information ..........................5–2

Command Entry Conventions........................................ 5–2

Command Response Conventions ................................... 5–3

TransCore Proprietary

i–i

Page 13

System Guide

Operating Parameters .............................................. 5–3

Power Fail ......................................................... 5–4

Program Download ...............................................5–4

Startup ..........................................................5–4

Tag/Message Buer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

Chapter 6 Communications Protocols .............................6–2

Introduction......................................................6–2

Basic Protocol ....................................................6–3

Error Correcting Protocol...........................................6–3

Data Inquiry Protocol ..............................................6–4

Basic Protocol and ECP Format .....................................6–4

Host-Addressed Failure Conditions..................................6–11

ECP Reliability...................................................6–12

CRC Calculation .................................................6–12

Manually Disabling ECP for Maintenance............................ 6–15

Chapter 7 Commands ...........................................7–2

Introduction......................................................7–2

Operating Modes .................................................7–2

Command List....................................................7–4

Chapter 8 Configuring the MPRX..................................8–2

Configuring the Reader ............................................8–2

Configuring Parameters with Terminal Emulation Software..............8–3

Configuring MPRX Parameters.......................................8–11

Chapter 9 Troubleshooting and Maintenance ......................9–1

Error Messages ................................................... 9–1

MPRX Repair .....................................................9–4

Technical Support .................................................9–4

Marketing Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–5

Chapter 10 Interface to Train Recording Unit .....................10–2

TRU System Overview............................................10–2

MPRX to TRU Connection.........................................10–3

Chapter 11 AT5720 Check Tag-to-MPRX Assembly.................. 11–2

ii

TransCore Proprietary

Page 14

Required Supplies ................................................11–2

Appendix A Glossary............................................A–2

Appendix B Technical Specifications...............................B–2

Reader Specifications .............................................B–2

Appendix C Wiring Information ...................................C–2

Appendix D Command Quick Reference ...........................D–2

Command Syntax .................................................D–2

Factory Default Settings ...........................................D–2

Numerical Command List ..........................................D–3

Alphabetical Command List .......................................D–14

MPRX

Appendix E Compatible Tag Information ...........................E–2

Tag Configurations ...............................................E–2

Tag Data Formats .................................................E–4

TransCore Proprietary

iii

Page 15

System Guide

List of Figures

Figure 2 – 1 MPRX End Views ........................................................................................................ 2–2

Figure 2 – 2 Tag and Antenna Orientation (horizontal polarization) ..................................... 2–4

Figure 2 – 3 Horizontally Polarized Tag ........................................................................................................2–5

Figure 2 – 4 Antenna Location Relative to Tag Position ..........................................................2–6

Figure 2 – 5 Location of Host Port on MPRX..............................................................................2–11

Figure 2 – 6 Pin Assignments for Host Connector ...................................................................2–11

Figure 2 – 7 Location of Sense Port on MPRX .......................................................................... 2–12

Figure 2 – 8 Pin Assignments for Sense Connector ............................................................... 2–12

Figure 3 – 9 Clear Zone –Side View ............................................................................................. 3–4

Figure 3 – 10 Clear Zone –End View ............................................................................................ 3–4

Figure 3 – 11 Mounting Location Examples ..................................................................................3–5

Figure 3 – 12 Tag Placement Window for Locomotives – Right Front ..................................... 3–6

Figure 3 – 13 Right Front Placement of Tag on Locomotive .................................................... 3–7

Figure 3 – 14 Tag Placement Window Location for Locomotives — Left Rear ......................3–7

Figure 3 – 15 Optimal Tag Placement for Locomotives ........................................................... 3–8

Figure 3 – 16 Tag Placement Window Location for Rail Cars –“A” Right Side ...................3–9

Figure 3 – 17 Tag Placement Window Location for Rail Cars -“B” Left Side ........................... 3–9

Figure 3 – 18 Optimal Tag Placement for Rail Cars ................................................................... 3–10

Figure 3 – 19 Tag Placement Window Location for Tank Cars –“B” Left Side ...................3–11

Figure 3 – 20 Optimal Tag Placement for Tank Cars ..............................................................3–11

Figure 4 – 1 Wiring for Audible Circuit Tester ........................................................................... 4–4

Figure 4 – 2 Connect RF N-type Load or Attenuator to Reader Cable End .......................4–5

Figure 4 – 3 Short Load to Earth Ground ..................................................................................... 4–5

Figure 4 – 4 MPRX Showing Antenna Ports ................................................................................ 4–6

Figure 4 – 5 Location of MPRX Ground Stud .............................................................................. 4–7

Figure 4 – 6 Location of Communications/Power Port on MPRX .........................................4–8

Figure 4 – 7 MPRX Outer Dimensions and Mounting Hole Locations (not to scale) ....... 4–10

iv

Figure 4 – 8 Sample Read Zone Marking Pattern ..................................................................... 4–15

Figure 8 – 1 Connection Description Dialog Box ........................................................................... 8–4

Figure 8 – 2 Phone Number Dialog Box ........................................................................................... 8–4

Figure 8 – 3 COM 1 Properties Dialog Box ........................................................................................ 8–5

Figure 8 – 4 Hyper Terminal Main Screen....................................................................................8–6

Figure 8 – 5 Sign-on Message ........................................................................................................ 8–7

TransCore Proprietary

Page 16

Figure 8 – 6 Tag and Antenna Orientation (horizontal polarization) ..................................... 8–9

Figure 8 – 7 Successful Tag Read ................................................................................................. 8–10

Figure 8 – 8 Second Successful Tag Read ................................................................................ 8–10

Figure 8 – 9 MPRX RF Control Options ....................................................................................... 8–14

Figure 10 – 1 TRU Front Panel Showing Operational LEDs..................................................10–2

Figure 10 – 2 TRU-MPRX Communications Interface Cable Port (bottom of TRU) .......... 10–3

Figure 10 – 3 MPRX-TRU Communications Interface Cable .................................................. 10–4

Figure 11 – 1 Place Nut and Grommet Over Exposed Check Tag Wires ............................. 11–3

Figure 11 – 2 Feed Check Tag Wires through Plastic Housing Connector ........................... 11–3

Figure 11 – 3 Connect Check Tag Wires ........................................................................................11–3

Figure 11 – 4 Two Check Tag Assemblies Connected to Terminal Strip .................................11–4

Figure 11 – 5 Securing Terminal Strip into Connector Housing .............................................. 11–5

Figure 11 – 6 Plastic Nuts with Grommets ....................................................................................11–5

MPRX

Figure 11 – 7 Nylon Cap Securely Fastened in Unused Port ..................................................11–6

Figure 11 – 8 Check Tag Assembly Secured to MPRX Port .....................................................11–6

TransCore Proprietary

v

Page 17

System Guide

List of Tables

Table 1 – 1 MPRX System Guide Overview .................................................................................. 1–2

Table 1 – 2 Typographical Conventions .........................................................................................1–3

Table 2 – 1 Staggered Reader Frequencies for AAR-formatted Tag Operation ................. 2–8

Table 2 – 2 Staggered Reader Frequencies for Tag Operation Outside the U.S. .............. 2–8

Table 2 – 3 Connector Cabling Accessory Kits ........................................................................2–10

Table 2 – 4 Power Supply Current Requirements ...................................................................... 2–10

Table 2 – 5 Reader to Antenna Cable Performance ................................................................. 2–13

Table 3 – 1 Tags Read by the MPRX ................................................................................................3–2

Table 4 – 1 Installation Accessories................................................................................................4–3

Table 4 – 2 MPRX-to-Host Communications Cable Pin Designations .................................. 4–8

Table 4 – 3 Commands for Testing RF Port-0 ............................................................................. 4–14

Table 4 – 4 Commands for Testing RF PORT-1 ......................................................................................4–16

Table 4 – 5 Commands for Testing RF PORT-2 ....................................................................................4–16

Table 4 – 6 Commands for Testing RF PORT-3 .........................................................................4–16

Table 5 – 1 Four-Character Command Structure ........................................................................ 5–1

Table 5 – 2 Sample Command Sequence....................................................................................5–2

Table 7 – 1 Select Baud Rate Commands ..................................................................................... 7–6

Table 7 – 2 Select Stop Bits Commands ......................................................................................7–6

Table 7 – 3 Select Parity Commands ............................................................................................. 7–7

Table 7 – 4 Append Time and Date Commands ....................................................................... 7–9

Table 7 – 5 Append Auxiliary Information Commands ............................................................. 7–10

Table 7 – 6 Unique ID Code Criteria .............................................................................................. 7–11

vi

Table 7 – 7 Select Valid Code Commands and Frames ........................................................... 7–12

Table 7 – 8 Flow Control Commands ...........................................................................................7–25

Table 7 – 9 RF Control Commands ...............................................................................................7–26

Table 7 – 10 RF Attenuation Command Variables .....................................................................7–27

Table 7 – 11 Select RF Frequency Commands ............................................................................7–29

TransCore Proprietary

Page 18

Table 7 – 12 Presence Without Tag Report Commands .......................................................... 7–30

Table 7 – 13 RF Control Algorithm Commands .......................................................................... 7–31

Table 7 – 14 Timeout Period Values ..................................................................................................... 7–32

Table 7 – 15 Input Inversion Options .............................................................................................7–33

Table 8 – 1 MPRX Default Configuration Settings ..................................................................... 8–2

Table 8 – 2 Command Sequence to Verify Communications ................................................ 8–8

Table 9 – 1 Error Messages ............................................................................................................. 9–1

Table 9 – 2 Symptoms and Remedies ..........................................................................................9–2

Table 10 – 1 MPRX-to-TRU Interface Cable Pin and Signal Designations ......................... 10–4

Table 11 – 1 Check Tag Kit Parts List ............................................................................................... 11–2

Table 11 – 2 Check Tag 0 Wire Assignments ................................................................................ 11–4

MPRX

Table 11 – 3 Check Tag 1 Wire Assignments ................................................................................. 11–4

Table C – 1 Communications Interfaces and Conductor Requirements ............................... C–2

Table C – 2 MPRX Host Communications Cable Pin Designations ......................................C–2

Table C – 3 MPRX SENSE Communications Cable Pin Designations ..................................C–4

Table D – 1 MPRX Default Configuration Settings ......................................................................D–2

Table D – 2 MPRX Commands Listed Numerically .................................................................... D–4

Table D – 3 MPRX Commands Listed Alphabetically ............................................................... D–14

Table E – 1 SeGo Protocol Tags ...................................................................................................... E–2

Table E – 2 AAR-formatted Tags ..................................................................................................................E–3

TransCore Proprietary

vii

Page 19

Chapter 1

Introduction

Page 20

System Guide

Chapter 1 Introduction

This chapter presents an overview of the MPRX System Guide.

Table 1 – 1 describes the contents of each chapter.

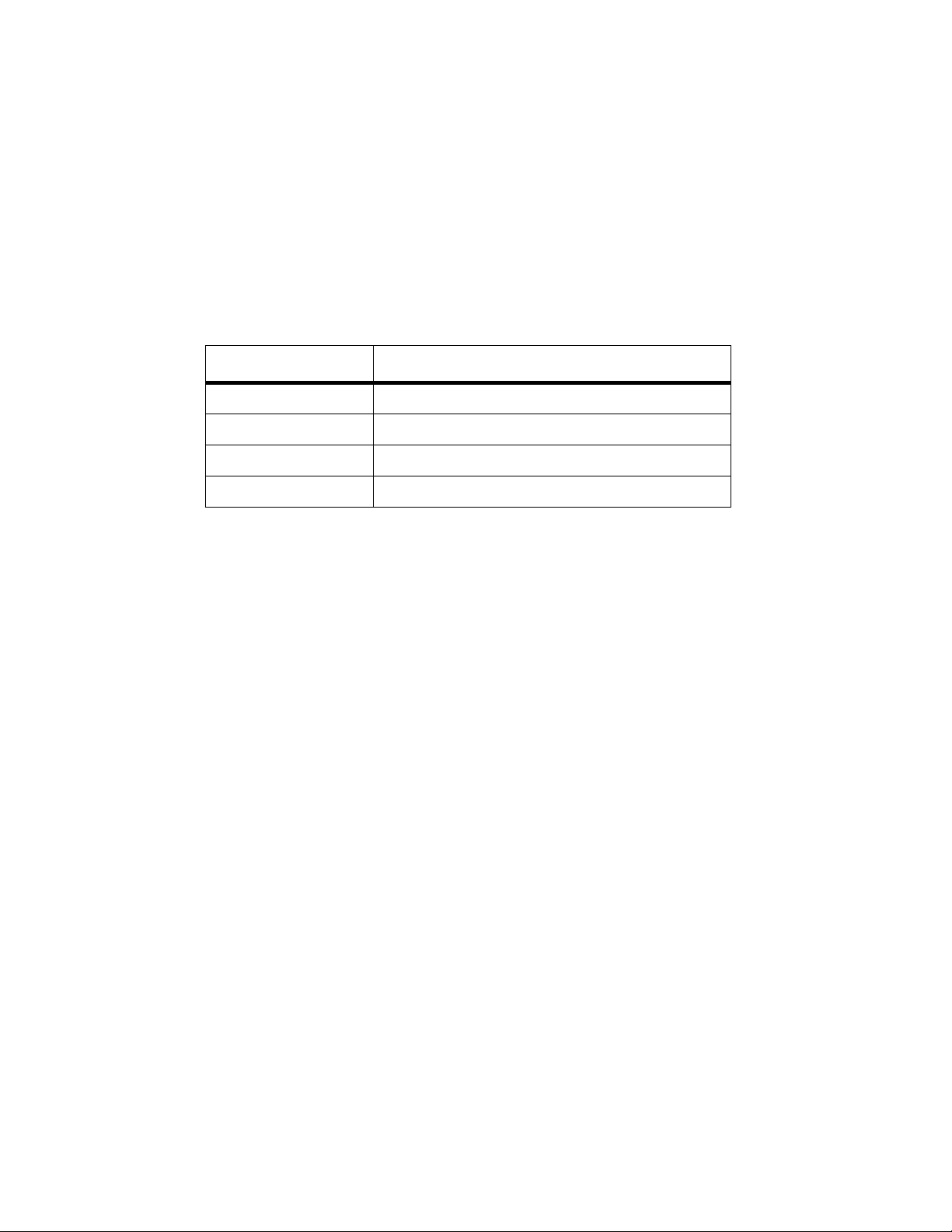

Table 1 – 1 MPRX System Guide Overview

Chapter Number

and Title

Chapter 1 – Introduction Outlines the manual’s organization, provides a brief description of the

MPRX, and discusses Federal Communications Commission (FCC) licensing

requirements.

Chapter 2 – Developing

the Site Plan

Chapter 3 – Choosing,

Installing, and Removing

Tags

Chapter 4 – Installing

the Multiprotocol Reader

Extreme

Chapter 5 – General

Software Information

Chapter 6 –

Communications

Protocols

Chapter 7 – Commands Discusses the host-transmitted commands that are used to control MPRX

Chapter 8 – Configuring

the Multiprotocol Reader

Extreme

Chapter 9 –

Troubleshooting and

Maintenance

Chapter 10 –Interface to

Train Recording Unit

Chapter 11 – Connecting

AT5720 Check Tag-toMPRX Assembly

Discusses factors to be considered when developing the site plan and before

ordering equipment and installing the MPRX. These considerations include

antenna and tag alignment, site layout and trac flow, and electrical and

communications requirements.

Contains information on compatible tag models and provides procedures

for installing tags onto, and removing tags from, railcars where the MPRX is

installed.

Lists the materials needed and provides procedures to install the MPRX,

including pre-installation testing, installing the MPRX in a railside hut or NEMA

enclosure, connecting power and communications, connecting to TransCore’s

Train Recording Unit (TRU™), and marking the read zone

Provide reference information on various software-related topics

Provide reference information on various communications protocols.

configuration and operation.

Provides procedures for configuring and fine-tuning the MPRX after installing

it at the site, including marking the read zone.

Answers the most commonly asked questions about installing and maintaining

the MPRX.

Describes the interoperability between the MPRX and the TRU.

Explains how to connect one or two check tags to the MPRX.

Description

1–2

TransCore Proprietary

Page 21

MPRX

Chapter Number

and Title

Appendix A – Glossary Contains frequently used terms.

Appendix B – Technical

Specifications

Appendix C – Wiring

Information

Appendix D – Command

Quick Reference

Appendix E – Compatible

Tag Information

Index Provides an alphabetical listing of guide topics.

Provides the MPRX specifications.

Shows the wiring connections for the communications interfaces, electrical

cable connections, and the external interface signal wiring.

Lists the MPRX factory default configuration settings and provides host

software commands in numerical and alphabetical order.

Provides helpful information about tags that are compatible with the MPRX.

Description

Typographical Conventions

The conventions listed in Table 1 – 1 are used in this manual.

Table 1 – 2 Typographical Conventions

Convention Indication

Concerns about a procedure.

Code

Dialog Box Title

Menu Item

Factory Default Settings

Note Auxiliary information that further clarifies the current

NUL

NULL

Caution

Code, including keywords and variables within

text and as separate paragraphs, and user-defined

program elements within text appear in courier

typeface.

Title of a dialog box as it appears on screen.

Appears on a menu. Capitalization follows the

interface.

Identifies factory default settings

discussion. These important points require the user’s

attention. The paragraph is in italics and the word

Note is bold.

Zero-value ASCII character or a zero-value byte.

Zero-value pointers. Null-terminated string refers to

strings of printable ASCII characters with a zero-value

byte placed in memory directly after the last printable

character of the string.

This procedure might cause harm to the equipment

and/or the user.

TransCore Proprietary

1–3

Page 22

System Guide

Licensing Requirements

An FCC license provides the user with the legal authorization to operate the MPRX on the

licensed frequencies at the site specified in the license. Only an authorized installer or

service technician can set the RF frequency of the MPRX to the frequency specified in the

FCC site license. No end-user-operated controls exist on the MPRX.

The FCC license may provide the user with protection and authorization to maintain

the system should any other RFID product be used in the licensed area after the MPRX

equipment is installed.

Users of the MPRX in the United States must obtain a license from the FCC. In the United

States, the authorized modulated (SeGo protocol operation) frequency band for this

product is 911.75 to 919.75 MHz and the authorized continuous wave (AAR-formatted

operation) frequency band is 902.25 to 903.75 MHz and 910.00 to 921.50 MHz.

The user is responsible for filing the FCC license according to FCC regulations, but the

TransCore dealer will provide assistance and support as necessary to complete these

forms. Forms are available online at the FCC internet site http://wireless.fcc.gov/uls. For

further information on obtaining the license contact TransCore.

Caution

This equipment can be set to frequency ranges outside those authorized for use in

the U.S. by the FCC. Users in all countries should check with the appropriate local

authorities for licensing requirements.

Technical Support

Authorized dealers and distributors are responsible for the direct support of all customers.

Authorized dealers and distributors needing technical support can contact:

Technical Support: Phone: (505) 856-8007

Web: transcore.com/rfidsupport

Please be prepared to answer a series of questions that are designed to direct you to the

best support resource available.

1–4

TransCore Proprietary

Page 23

MPRX

TransCore Proprietary

1–5

Page 24

Chapter 2

Developing the Site Plan

Page 25

System Guide

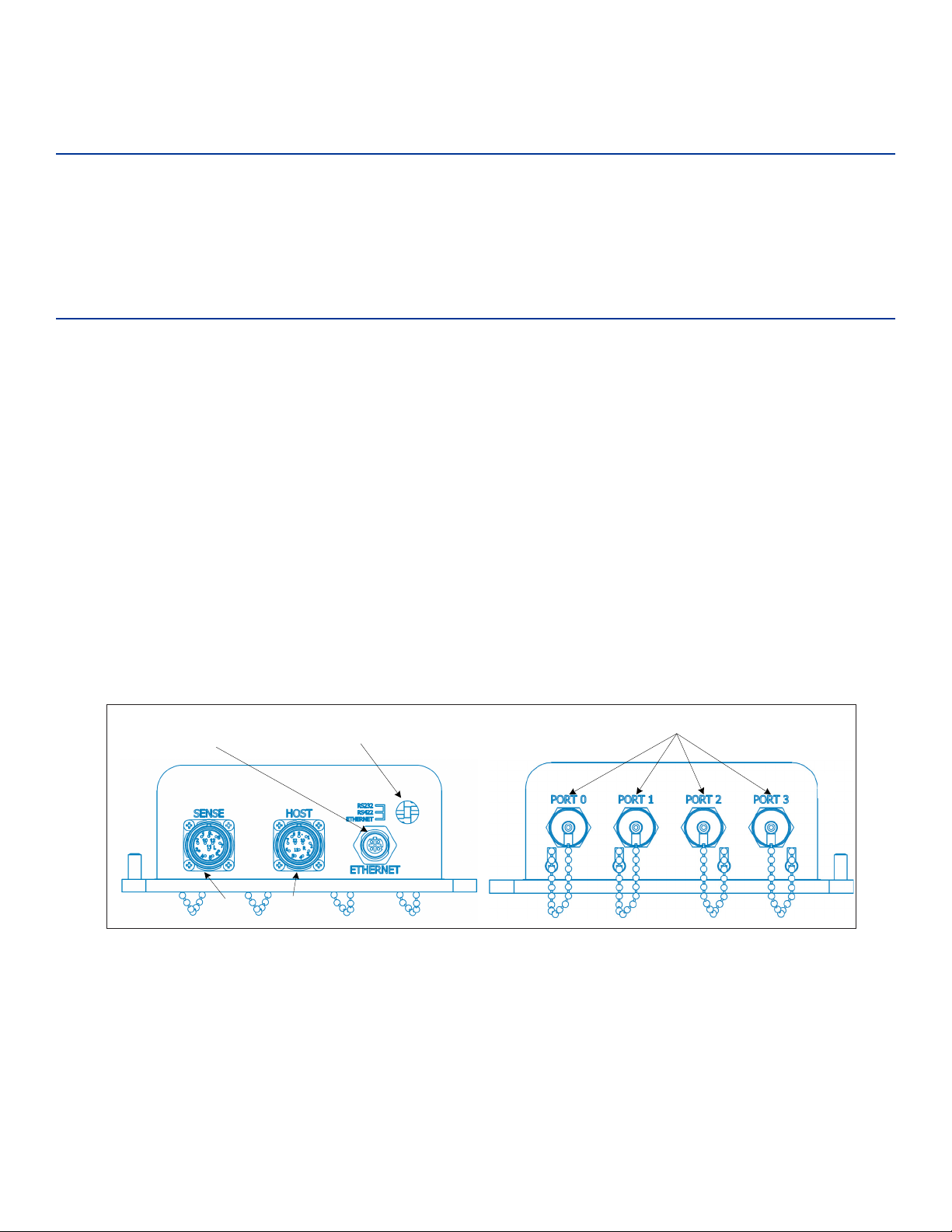

Antenna Ports

Interface Selection Switch

Host Port

Sense Port

Ethernet Port

Chapter 2 Developing the Site Plan

This chapter provides a brief description of the Multiprotocol Reader

Extreme (MPRX) and discusses site plan development for installing the

MPRX System.

System Description

The MPRX is a reader that supports Association of American Railroads (AAR) formatted

tags and TransCore’s low-cost, high-performance Super eGo® (SeGo) radio frequency

identification (RFID) technology.

The MPRX is a high-power unit that reads full frame tags. The reader output power can be

adjusted using reader commands.

The MPRX can multiplex up to four antennas, which allows a single reader to be used for

two tracks. The MPRX can support up to two AT5720 Check Tags.

Reader

The MPRX consists of an input/output (I/O) module, a power supply, a reader logic board

(also called a tag decoder), and a radio frequency (RF) transmitter/receiver (called the RF

module) in a compact enclosure. These MPRX components are contained in a highly

reliable, compact, and easy-to-install package. Figure 2 – 1 shows the Host connector,

Sense connector, Ethernet connector, Interface Selection Switch, and antenna ports

locations on opposite ends of the MPRX.

Figure 2 – 1 MPRX End Views

2–2

TransCore Proprietary

Page 26

Tags

The MPRX has the capability to read TransCore AAR formatted read-only full frame tags and

TransCore SeGo protocol tags, for example, the AT5118 Harsh Environment Transportation

Tag and the AT5120 Transportation Tag.

How It Works

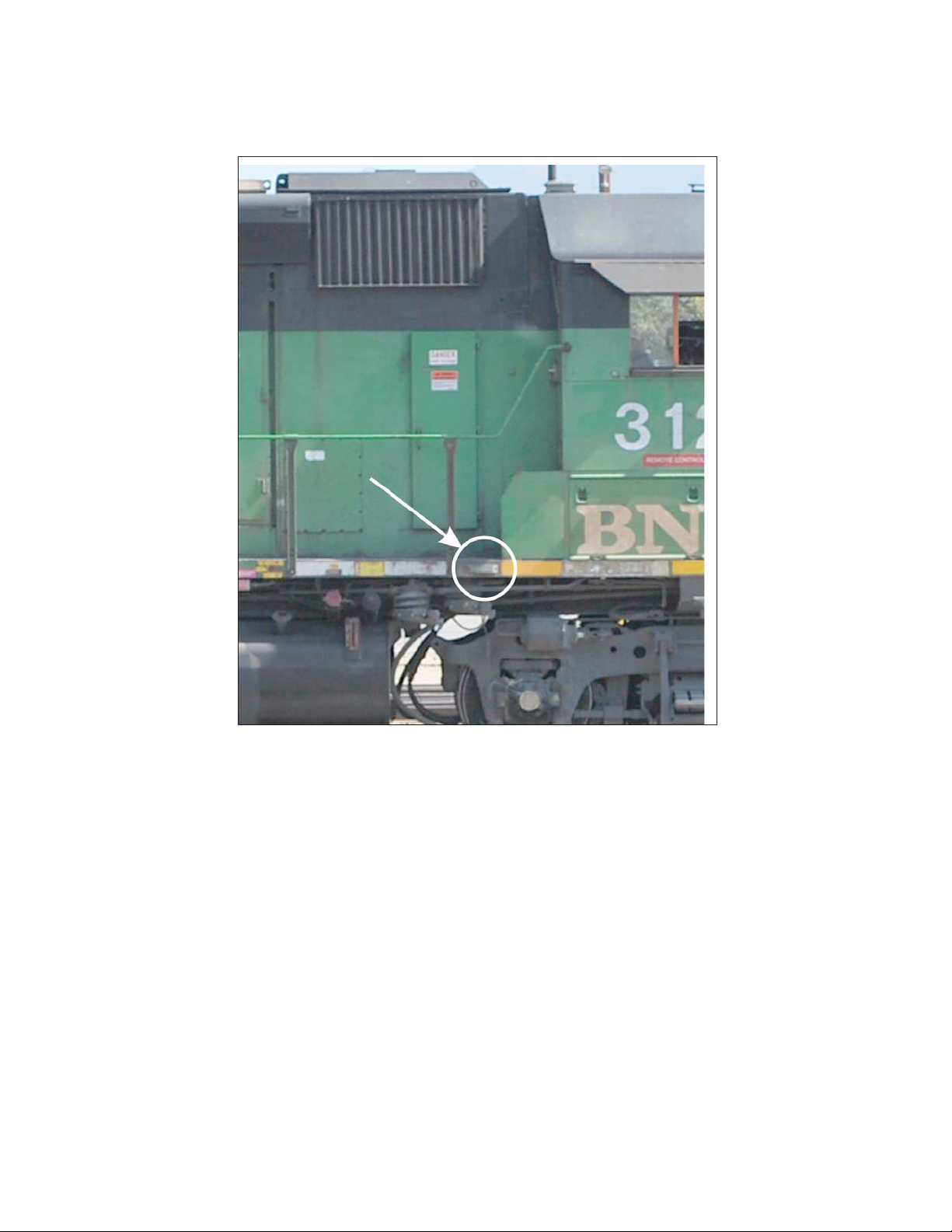

The MPRX directs the RF module to generate an RF signal, which is broadcast through

the external antenna mounted railside. Entering the MPRX’s reading range, a TransCore

RFID tag installed on a railcar or other asset to be tracked adds its programmed

identification information to the signal and reflects the signal back to the MPRX. The

MPRX receives this modified, or modulated signal, and decodes the tag data carried by

the reflected signal and transmits this data to the Train Recording Unit (TRU) or local host

computer for processing.

MPRX

Overview of Site Planning

Developing a site plan provides the foundation for the site’s system design and

establishes the following system configuration parameters:

• Number and general location of primary components

• Number of dierent radio frequencies required

Gathering relevant site information is crucial before applying for Federal Communications

Commission (FCC) or regulatory agency approval from the country where the equipment

is to be used and ordering and installing MPRX(s) and tags.

Also, consider the following factors when developing a site plan:

• Type of tags used

• Antenna and tag alignment

• Site layout and rail trac flow

• MPRX and/or antenna mounting requirements

• MPRX electrical requirements

• MPRX communications requirements

These factors provide relevant information regarding each site’s physical and

electromagnetic environment and the conditions under which the system must perform.

Reading of Mixed Population Tags

The MPRX reads AAR-formatted tags and TransCore’s SeGo protocol tags. The factors

that influence the readability include, but are not limited to, physical orientation and

configuration, type of read-only tag, ratio of backscatter cross-section of the tags, and

whether the tag is battery powered or beam powered.

TransCore Proprietary

2–3

Page 27

System Guide

Antenna and Tag Alignment

The position of the antenna and placement of the tag on the vehicle must be compatible.

Two primary criteria must be satisfied to achieve the highest read reliability:

• Tag and the antenna polarization, they must be aligned in the same direction —

both horizontal.

• The installed tag must be in a direct, unobstructed line of sight to the antenna.

Caution

A tag may not be reliably read unless the preceding criteria are met.

Polarization

The polarization of the tag must be aligned in the same direction as the antenna.

Figure 2 – 2 shows a horizontally polarized antenna and tag.

Note: Matching the tag and antenna polarization is critical to obtain optimal system

performance.

2–4

Figure 2 – 2 Tag and Antenna Orientation (horizontal polarization)

TransCore Proprietary

Page 28

Figure 2 – 3 shows a tag in correct polarization for the antenna.

MPRX

Figure 2 – 3 Horizontally Polarized Tag

Unobstructed Line of Sight

For optimum readability, install the MPRX and antenna(s) and the railcar’s tag so that when

the railcar approaches the antenna(s), the tag is directly facing the antenna and the line of

sight is clear between the antenna and the tag. If there is a physical obstruction between

the tag and the antenna(s), the MPRX cannot reliably read the tags. Figure 2 – 4 illustrates

possible installation locations of an antenna in relation to a tag’s mounting location on a

railcar.

TransCore Proprietary

2–5

Page 29

System Guide

Figure 2 – 4 Antenna Location Relative to Tag Position

Antenna Selection

This section contains guidelines to assist in antenna selection for an MPRX installation. The

following antennas are compatible with the MPRX installation.

AA3110 Parapanel

Appropriate for installations with the following requirements and conditions:

• 902 to 928 MHz operation

• Exposure to harsh environments

• Broad radiation pattern in one dimension, narrow in the other

• Low antenna profile

• Horizontal polarization

AA3140 PCB Log Periodic

Appropriate for installations with the following requirements and conditions:

• 845 to 950 MHz operation

• Exposure to harsh environments

• Maximum coverage at close range (<20 ft [6.1 m])

• Vertical or horizontal polarization

Site Layout and Trac Flow

The following site layout and trac flow considerations are critical when determining MPRX

installation locations:

• The MPRX read zone

2–6

TransCore Proprietary

Page 30

• Other MPRXs and antennas in the area

• Reflection, refraction, and diraction of RF signals

• Existing signal interference at the site

The MPRX Read Zone

The MPRX must be able to read the tag data properly within a specified area, called the

read zone, without reading other nearby tags or interfering with other MPRXs at the site.

The following are some of the factors that aect the size and shape of the read zone:

• Mounting method used for the antenna

• Mounting location of the antenna

• Height from the ground and mounting angle of the antenna

• RF output attenuation

• Range discrimination setting

• Other sources of interference and reflection

MPRX

The railside antenna must be positioned so that the RF signal travels to and return from the

tags within the designated range and must be placed in an area where it is not likely to be

bumped out of alignment. If the antenna becomes misaligned or some nearby structure is

added or removed, system operation can be seriously aected.

For instructions on setting the read zone, refer to “Fine-Tuning and Verifying the Read

Zone” on page 8–17

Other MPRXs and Antennas in the Area — AAR-Formatted Tag

Operation

For AAR-formatted (continuous wave) tag operation, sites with more than one MPRX in

proximity should be configured with a frequency separation of at least 2 MHz from adjacent

readers. If more than one MPRX is in a multiple track application, the frequencies should

be staggered. MPRX antennas can face each other across a rail track as long as they are

multiplexed and controlled by the same MPRX. For installations where multiple antennas

are controlled by a host processor with multiple MPRXs, or where multiple MPRXs are

used in close proximity, ensure that there is adequate frequency separation between the

antennas. Contact TransCore Technical Support with any questions. Table 2 – 1 shows

examples of staggered reader frequencies in a site with up to seven readers.

TransCore Proprietary

2–7

Page 31

System Guide

Table 2 – 1 Examples of Staggered Reader Frequencies for AAR-formatted Tag Operation

Caution

TransCore advises locating antennas controlled by an MPRX at least 24 feet (7.3

meters) away from antennas that are controlled by another MPRX. There is no

minimum spacing for antennas connected to the same MPRX.

Rail Number Reader Frequency

1 911.50

2 918.50

3 913.00

4 915.00

5 921.50

6 917.00

7 910.00

Table 2 – 2 shows examples of staggered reader frequencies in a site outside the U.S. with

up to four readers.

Table 2 – 2 Examples of Staggered Reader Frequencies for Tag Operation Outside the U.S.

Rail Number

1 865.25

2

3

4 866.50

5

6

7 866.00

Reader

Frequency*

866.25

865.50

865.75

866.75

Reflection, Refraction, and Diraction of RF Signals

2–8

RF signals can be reflected, refracted, or diracted by metal objects, walls, and even wet

pavement or ice. Any of these factors can alter or degrade system performance. When

designing your site plan, you must consider permanent structures and transient factors in

the vicinity that may aect RF signals being generated by the MPRX. Permanent structures

include buildings, chain link fences, guard shacks, and gates. Transient factors include

passing trac and local weather conditions, such as rain or snow. Symptoms of reflection,

TransCore Proprietary

Page 32

refraction, and diraction include reading tags that are out of the desired read zone or tags

being read from another track.

The most common RF reflectors are metallic surfaces. RF signals may also be partially

reflected by nonconducting materials such as dirt containing high concentrations of

metallic rail dust, wood, ice, asphalt, and concrete. When nonconducting materials in the

system environment become wet, they increase reflection of RF signals.

The antenna mounting location, aiming, and range control adjustment, and use of presence

detectors can reduce interference from RF reflections. When these actions cannot

adequately control reflections, other techniques such as shielding, absorbing, range

sensitivity adjustment, or barriers can also be used. Refer to “Chapter 9 Troubleshooting

and Maintenance” for information about troubleshooting and maintenance.

Existing Signal Interference at the Site

Interference from RF and electrical sources can degrade system performance and also

must also be considered in the site design. Fluorescent lights, neon signs, nearby radio

stations, or power lines can interfere with the optimal operation of the system.

MPRX

Interference may degrade both reader and tag performance. Existing sources of

interference at the site should be shielded, removed, or positioned farther from the

antenna. In some cases, changing the operating frequency of the MPRX may provide a

simple solution. Readers in proximity should have at least a 2 MHz frequency separation.

Refer to “Other MPRXs and Antennas in the Area — AAR-Formatted Tag Operation” on

page 2–7. Strong RF sources of any frequency, in proximity to the tag, can preclude

the tag receiving the reader interrogation. Refer to “Chapter 4 Installing the MPRX” for

information about troubleshooting and maintenance.

Electrical and Communications Requirements

All construction work at the site must be completed before installing the MPRX. Electrical

and communications cables should be installed according to all applicable local and

federal building code requirements. Specific instructions for positioning and installing the

MPRX are discussed in “Chapter 4 Installing the MPRX”.

Power and Communications Cables

Cable length for power and communications depends on the physical characteristics of the

MPRX installation site. Table 2 – 3 lists accessory kits available for cabling options based

on your site’s requirements.

TransCore Proprietary

2–9

Page 33

System Guide

Table 2 – 3 Connector Cabling Accessory Kits

Part Number Description

MPRX-to-TRU™ six-foot (1.8-m) cable assembly

MPRX-to-TRU 20-foot (6.1-m) cable assembly

MPRX cable assembly six feet (1.8 m), no TRU

MPRX cable assembly 20 feet (6.1 m), no TRU

Electrical Power

When connecting the MPRX to a TRU in a trackside hut, the MPRX draws its power directly

from the TRU. A dedicated power supply is only required when a MPRX is not connected to

a TRU.

The dedicated power must be 24-110VDC (Option 1) or 12-24VDC (Option 2). Consult your

local and national electrical codes for installation and safety requirements.

It is the installer’s responsibility to supply conversion equipment and wiring. Table 2 – 4

contains power supply current requirements.

Table 2 – 4 Power Supply Current Requirements

(RF On)

Supply

24 to 110VDC (Option 1) 1.7A at 24VDC 1A at 24VDC

12-24VDC (Option 2) 2.1A at 12VDC 1.4A at 12VDC

Power circuits are protected internally against power surges (±30%).

Worst Case

Maximum Current

at 68°F (20°C)

Maximum Current

Host Communications

Your site design must include communications between the MPRX and the TRU or other

host device. The MPRX communicates with the TRU or other host device through an

asynchronous RS-232, RS-422, or Ethernet interface. Figure 2 – 5 shows the MPRX

communications ports and Figure 2 – 6 shows the connector pin designations.

(RF O)

Worst Case

at 68°F (20°C)

2–10

TransCore Proprietary

Page 34

Figure 2 – 5 Location of Host Port on MPRX

MPRX

Pin Number Operation

1

2

3 LOCK (Mechanical

4

5

6

7

8

9 COM_GND (RS232

10 COM_GND (RS422

11 +V In

12 +V Return

RS232_TX

RS232_RX

Relay)

LOCK_RTN

RS422_TX+

RS422_TX-

RS422_RX+

RS422_RX-

GND)

GND)

Figure 2 – 6 Pin Assignments for Host Connector

The standard RS-232/RS-422/Ethernet connection maximum distance depends on the

baud rate, cable type, and the receiving device at the other end.

TransCore Proprietary

2–11

Page 35

System Guide

Sense Connections

Figure 2 – 7 Location of Sense Port on MPRX

Pin Number Operation

1

2

3

4

5

6

7

8

9

10

11 SENSE 1

+12VDC

OUT1

I/O GROUND

I/O GROUND

PULSE OUT

OUT0

CTAG 0

CTAG 1

I/O GROUND

I/O GROUND

2–12

12 SENSE 0

Figure 2 – 8 Pin Assignments for Sense Connector

The MPRX’s two RF sense input circuits are TTL (Logic Level, 0V/5V), designed to be

shorted to I/O Ground (0V) to provide sense.

TransCore Proprietary

Page 36

The MPRX’s tag lock output circuit is a single-pole, double-throw relay providing a dry

contact closure. These contacts are rated at 42.2V AC peak (30V

) or 60V DC, at 1A

rms

maximum with non-inductive load.

Output circuit is not intended for the direct control of electromechanical devices such as

motorized barrier arms. For such applications, the MPRX output circuit should be used to

drive a secondary, appropriately rated high-power relay.

Antenna Interface

The site design must include interface cable(s) between the MPRX and the compatible

antenna(s) chosen for the site. The antenna interface is RF coaxial cable with male Type

N sockets on each end.

Table 2 – 5 is a summary of coaxial cable performance. Figures indicate maximum

lengths of cable in feet.

Note: 1.1dB of cable loss is required for proper FCC operation.

Table 2 – 5 Reader to Antenna Cable Performance

MPRX

Cable Length (ft.)

870MHz

Cable Type

Overall

a

Diameter

915 MHz

Cable Length (ft.)

(in.)

Minimum

Length

b

Maximum

Length

c

Minimum

Length

b

Maximum

Length

RG–223 0.216 7.9 21.6 8.2 22.5

RG–214 0.425 14.4 39.3 14.9 41.1

FSJ1–50 0.25 19.4 52.8 19.9 54.6

LDF2–50 0.375 32.8 89.4 33.7 92.7

FSJ4–50B 0.5 32.1 87.6 33.1 90.6

LDF4–50A 0.5 52 141.9 53.4 146.7

LDF5–50A 0.875 92.2 251.4 94.8 260.4

LDF6–50 1.125 135.6 369.6 139.5 383.1

LDF7–50A 1.625 156.4 426.3 161.1 442.2

a. Suxes 50, 50A, and 50B indicate 50-ohm cables available from the Andrew Corporation.

b. These cable lengths ensure optimal system performance (1.1 dB loss).

c. These cable lengths ensure adequate, but not optimal, system performance (3 dB loss).

c

TransCore Proprietary

2–13

Page 37

Chapter 3

Choosing, Installing and

Removing Tags

Page 38

System Guide

Chapter 3 Choosing, Installing, Removing Tags

This chapter describes the various tag types compatible with the

Multiprotocol Reader Extreme (MPRX) and the procedures for installing

and removing compatible external tags.

Compatible Tag Types

The MPRX provides the capability to read Association of American Railroads (AAR)

formatted tags and TransCore Super eGo (SeGo) protocol tags. Refer to “Appendix E

Compatible Tag Information” on page E–2 for information about the numerous tag

models.

Reader and Tag Model Interoperability

Table 3 – 1 lists the tags that are read by the MPRX. Refer to www.transcore.com/pdf/

Tag- Reader-Matrix.pdf for most current information concerning readers and supported

tag protocols.

Table 3 – 1 Tags Read by the MPRX

Beam Tags Battery Tags External Power Tags

AT5110, AT5112, AT5118, AT5120*,

AT5125, AT5133, AT5412, AT5413,

AT5415

*The AT5120 Transportation Tag is used for applications in the 860 to 880 MHz frequency range.

AT5114, AT5510, AT5414,

AT5549, AT5707, AT5910

AT5117, AT5119, AT5704

Recommended Mounting Locations

Each piece of rail equipment has a specific area or window for optimum tag placement.

Tag positioning in the tag placement window is based on the center of the tag in

reference to window physical specifications.

3–2

TransCore Proprietary

Page 39

Required Materials

• Torque wrench (in/lb. range)

• Bolts and nuts (#10-24 NC threaded studs and nuts)

• Aluminum pop rivets

• Pop rivet gun

Mounting Surface

The mounting surface must be metal, vertical, and smooth within the area of the tag. If the

mounting area does not meet this requirement, you must use a metal mounting bracket.

If the mounting surface is irregular or non-metal (e.g., fiberglass), the tag must be

attached to a metal bracket to provide an electrical reflector for the tag. Use a 1/8-inch

(0.32-cm) or thicker smooth metal bracket that is the same size or larger than the tag.

The mounting bracket and tag must be in contact with each other to avoid interference

with transmission of radio waves.

MPRX

Tag Positioning

Each piece of equipment has a specific area or tag placement window for optimum tag

placement. Tag positioning in the tag placement window is based on the center of the tag

in reference to window physical parameters.

The tag placement window is on opposite ends and opposite sides of the equipment.

The front and rear ends of the equipment are referred to as the “A” end and “B” end.

The “B” end represents the hand brake end and the “A” end represents the opposite

end looking forward. To determine left and right sides, stand at the “B” end and look

toward the front end of the equipment.

Refer to the appropriate section for tag placement window location on rail cars and

locomotive devices. Where possible, tags should be mounted in locations that minimize

the likelihood of damage from equipment such as forklifts, cranes, and other hazards.

Mount the tag on a plane perpendicular to the rail (back of the tag against the

equipment) with the long edge of the tag horizontal to the rail.

There is a clear zone surrounding the tag and toward the wayside that allows for

unobstructed data transmission. This zone must not be obstructed by any metallic

objects or protrusions.

TransCore Proprietary

3–3

Page 40

System Guide

As Figure 3 – 9 illustrates, there should be no obstructions in the area extending 45º from

the center line of the tag to one inch outside either narrow side of the tag. The side view

depicts the tag as viewed from the top of the equipment.

Figure 3 – 9 Clear Zone –Side View

Figure 3 – 10 illustrates that there should be no obstructions in the area extending 60º

from the center line of the tag to 1 inch outside either long side of the tag. The end view

depicts the tag as viewed from the end of the equipment.

3–4

Figure 3 – 10 Clear Zone –End View

Figure 3 – 11 shows examples of acceptable and unacceptable mounting locations based

on the clear zone. Any obstructions in the clear zone may introduce reading problems

TransCore Proprietary

Page 41

MPRX

with the tag. Refer to the mounting specifications chapters for each type of equipment for

tag placement window locations.

Figure 3 – 11 Mounting Location Examples

Surface Installation Techniques

Backing plates are preferred for attaching tags to equipment, but tags may be mounted

directly to the car at the owner’s discretion. Aluminum material is permitted as a

substitute for the mounting plate material specified, when required for compatibility with

the car surface.

When painting the backing plates, protect the studs from paint.

Two approved methods for mounting tags and backing plates on locomotives and

railcars are rivet and bolt mounting.

Note: Weld the backing plate to the freight car side sheet, but be certain the backing

plate is kept flat. If the car side sheet is deformed, spacing of welds may vary to

accommodate waviness of the freight car side.

Note: Allow the backing plate to cool after welding before mounting the tag.

Rivet/Bolt Mounting Guidelines

Select a means for mounting the tag that secures the tag but does not compromise the

tag case.

TransCore Proprietary

3–5

Page 42

System Guide

Aluminum pop rivets are permissible, but TransCore advises against using high- pressure

rivets for mounting the tag.

If using bolts and nuts to mount the tag, avoid using excessive torque, which may crack

or break the tag case. Tighten the nut until snug, then tighten an additional 1/2 turn

only.

Locomotive Mounting Guidelines

Install two tags on each locomotive on opposite ends and opposite sides of the

equipment. Install one on the right front (engineer’s side) and another on the left rear

(fireman’s side).

Tag Placement Window Location

Horizontally, the tag placement window extends from the center line of the truck to two

feet from the center line of the inside axle (measure toward the center of the vehicle).

Vertically, the tag placement window begins two feet above the top of the rail and extends

to a maximum of five feet above the top of the rail.

Figure 3 – 12 illustrates the tag placement window on the right front portion (engineer’s

side) of the locomotive.

3–6

Figure 3 – 12 Tag Placement Window for Locomotives – Right Front

TransCore Proprietary

Page 43

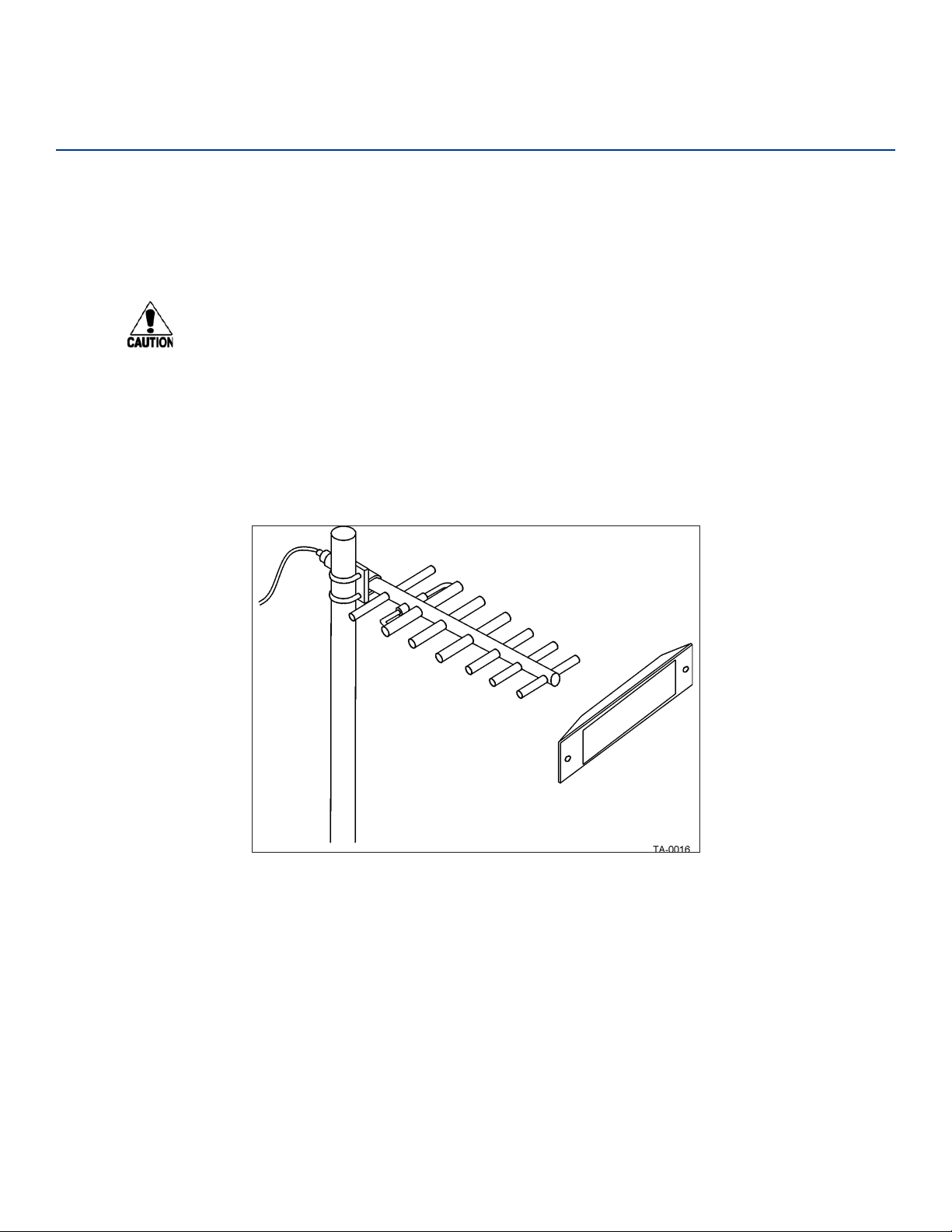

Figure 3 – 13 shows the right front location of a tag on a locomotive.

Figure 3 – 13 Right Front Placement of Tag on Locomotive

MPRX

Figure 3 – 14 illustrates the tag placement window on the left rear portion (brakeman’s

side) of the locomotive.

Figure 3 – 14 Tag Placement Window Location for Locomotives — Left Rear

Tag Placement

Optimal tag placement centers the tag on the left boundary line of the tag placement

window (Figure 3 – 15). Alternately, the center of the tag may be mounted anywhere

within the tag placement window, provided there are no obstructions to the tag’s clear

zone.

TransCore Proprietary

3–7

Page 44

System Guide

Figure 3 – 15 Optimal Tag Placement for Locomotives

Rail Car Mounting Guidelines

Install two tags on each rail car on opposite ends and opposite sides of the equipment.

Install one on the right front (“A” end) and another on the left rear (“B” end).

Tag Placement Window Location

Horizontally, the tag placement window extends from the center line of the truck to two feet

from the center line of the inside axle (measure toward the center of the vehicle). Vertically,

the tag placement window begins at two feet above the top of the rail end and extends to

a maximum of five feet above the top of the rail. The tag should not cover car stenciling.

3–8

TransCore Proprietary

Page 45

MPRX

Figure 3 – 16 illustrates the tag placement window on the right front portion (“A” end) of the

rail car.

Figure 3 – 16 Tag Placement Window Location for Rail Cars –“A” Right Side

Figure 3 – 17 illustrates the tag placement window on the left rear portion (“B” end) of the

rail car.

Figure 3 – 17 Tag Placement Window Location for Rail Cars -“B” Left Side

TransCore Proprietary

3–9

Page 46

System Guide

Tag Placement

Optimal tag placement centers the tag on the left boundary line of the tag placement

window (Figure 3 – 18). Alternately, the tag may be mounted so that the center

of the tag falls anywhere within the tag placement window, provided there are no

obstructions of the tag’s clear zone.

Figure 3 – 18 Optimal Tag Placement for Rail Cars

Tank Car Mounting Guidelines

Tank car mounting is essentially the same as that for rail cars, except that the tag

placement window area has been expanded 18 inches to the right of the center of the

truck.

Tag Placement Window Location

Horizontally, the tag placement window extends from 18 inches to the right of the

center line of the truck to two feet from the center line of the inside axle (measured

toward the center of the vehicle). Vertically, the tag placement window begins at two

feet above the top of the rail and extends to a maximum of five feet above the top of

the rail. The tag should not cover car stenciling.

3–10

TransCore Proprietary

Page 47

MPRX

Figure 3 – 19 illustrates the tag placement window on the left rear portion (“B” end) of the

tank car.

Figure 3 – 19 Tag Placement Window Location for Tank Cars –“B” Left Side

Tag Placement

Optimal tag placement positions the tag on the center line of the truck on the body bolster

(Figure 3 – 20). Alternately, the tag may be mounted so that the center of the tag falls

anywhere within the tag placement window, provided there are no obstructions of the tag’s

clear zone.

Figure 3 – 20 Optimal Tag Placement for Tank Cars

TransCore Proprietary

3–11

Page 48

Chapter 4

Installing the MPRX

Page 49

System Guide

This chapter lists the materials needed and presents the procedures to

pre-test and install the Multiprotocol Reader Extreme (MPRX).

Installation Process

After you have developed the site plan and identified the location to install the MPRX

and antennas1, if required, you are ready to install the equipment. Installation involves the

following tasks:

• Power and tag read capability testing prior to final installation of the MPRX

• Mounting the MPRX in a railside hut

• Mounting the railside antenna(s)

• Connecting the antenna(s)

Chapter 4 Installing the MPRX

• Connecting the MPRX to Earth Ground and power source

• Marking the read zone

• Connecting the MPRX host and sense input/sense output and communications

Materials Supplied by TransCore

You need the following materials to pre-test and install the MPRX. TransCore supplies

some of the materials; other materials must be obtained from other sources.

Contents of Shipping Carton

Ensure that you have received all parts before beginning your pre-installation MPRX tests.

Your MPRX is packaged with the following materials:

• One MPRX

• One Multiprotocol Reader Extreme Quick Start Guide

• Any accessories ordered as options as shown in Table 4 – 1

Required accessories are a power/communications cable harness and an AC/DC Converter

or a 24 to 110VDC/12 to 24VDC power source. You also require at least one MPRXcompatible antenna and an antenna RF cable. These may be ordered as accessories from

TransCore or obtained from other sources.

For MPRX installation with TransCore’s Train Recording Unit (TRU™), refer to “Chapter 10

Interface to Train Recording Unit” on page 10–2.-

Installation Accessory Options

Table 4 – 1 lists optional TransCore MPRX installation accessory items.

1 The MPRX is designed with RF cable connectors for use with N-type RF Cables

4–2

TransCore Proprietary

Page 50

Table 4 – 1 Installation Accessories

MPRX

Part No.

20-7001-001 MPRX check tag accessory kit

Description

MPRX Cable

MPRX Cable

MPRX Cable

MPRX Cable

Additional Materials Needed for Testing

You need these additional materials to perform the pre-tests on the MPRX:

• Test tags, supplied by the TransCore dealer or distributor.

Note: The test tag must be mounted flush against a metal backplane.

• Suitable 24 to 110VDC or 12 to 24VDC power wiring for the MPRX

• Audible circuit tester and 9V DC battery for circuit tester power

• Wire stripper

• At least one MPRX-compatible antenna

• Suitable RF interface coaxial cable

Pre-installation Testing of the MPRX

Before installing the MPRX permanently at the site, you should use an audible circuit

tester to confirm that the MPRX has power and can read a tag that is in the tag read

zone.

Testing the MPRX Using an Audible Circuit Tester

An audible circuit tester is also called a buzz box. These boxes are available at some

electronic parts supply stores, or you can make a buzz box, as shown in Figure 4 – 1.

The buzz box is powered by a 9V DC battery and is equipped with two alligator-clip

leads. When you touch the leads together, the box makes an audible sound.

TransCore Proprietary

4–3

Page 51

System Guide

9VDC

Battery

6-12VDC

Buzzer

+ -

Pin 4 on

Host Connector

Pin 3 on

Host Connector

- +

Figure 4 – 1 Wiring for Audible Circuit Tester

To test the MPRX, connect the antenna and power supply as described in the appropriate

sections that follow.

Discharging Voltage from the Antenna

Use these instructions to discharge high voltage from the antenna before proceeding with

further pre-installation testing of the reader connected to an antenna.

Required Equipment

This procedure requires the following equipment.

• MPRX

• External antenna

• Grounding RF cable (long enough to reach Earth Ground source)

• N-type load (e.g., 50 Ω) or RF attenuator (e.g., 20 dB)

Caution

During shipping and installation, an antenna can build up a very high voltage charge.

The voltage needs to be discharged before connecting the antenna to the reader.

1. Terminate the reader end of the grounding RF cable with any N-type load or RF

attenuator (Figure 4 – 2).

4–4

TransCore Proprietary

Page 52

MPRX

Figure 4 – 2 Connect RF N-type Load or Attenuator to Reader Cable End

2. Connect the grounding RF cable to the antenna (refer to Item 1 in Figure 4 – 3.

Figure 4 – 3 Short Load to Earth Ground

3. Short the outer metal case of the load or attenuator to Earth Ground for approximately

10 seconds (refer to Item 2 in Figure 4 – 3). In this example, the operator is using the

mounting pole that has been properly connected to Earth Ground.

TransCore Proprietary

4–5

Page 53

System Guide

Antenna Ports

4. Disconnect the grounding RF cable from the antenna and connect the permanent RF

cable to reader.

Once the antenna is discharged and properly connected to the reader, the reader

circuitry provides a DC path to keep any further charge from building up in the antenna.

Caution

TransCore does not recommend using a screwdriver or other tool to short the RF cable

center conductor to the outer ground of the cable. This grounding method can damage

the center pin or the threads of the connector.

TransCore strongly advises that you use adequate Earth Ground for this voltage

discharge procedure in accordance with the National Electric Code for the locale

where you are installing the MPRX.

Connecting the Antenna

This section explains the connection between the MPRX and antenna(s) (Figure 4 – 4).

4–6

Figure 4 – 4 MPRX Showing Antenna Ports

To connect the reader and antenna

1. Ensure the reader is turned o and unplugged.

2. Connect one end of the RF interface cable to the antenna.

3. Connect the other end of the RF interface cable to the appropriate antenna port on the

end of the MPRX (Figure 4 – 4).

4. For consistent performance, terminate unused antenna ports using a 50-Ohm, N–type

terminator.

TransCore Proprietary

Page 54

Connecting the MPRX to a Power Supply