Page 1

Encompass®4 Reader System Guide

TransCore

3410 Midcourt Road, Suite 102

Carrollton, Texas 75006

January 2009

P/N 412066

Page 2

Encompass 4 Reader System Guide

For comments or questions about this document, e-mail tech.pubs@transcore.com.

Information in this document is subject to change and does not represent a commitment on the part of

TC IP, Ltd.

©2009 TC IP, Ltd. All rights reserved. TRANSCORE, AMTECH, EGO, and ENCOMPASS are registered

trademarks of TC IP, Ltd., and are used under license. All other trademarks listed are the property of their

respective owners. Contents are subject to change. Printed in the U.S.A.

Products covered by this document are protected by one or more of the following U.S. patents 4,739,328;

4,782,345; 4,786,907; 4,816,839; 4,853,705; 4,864,158; 4,999,636; 5,030,807; 5,528,222; 5,550,547;

5,606,323; 5,673,037; 5,889,489; 5,912,632; 5,942,987; 6,097,347; 6,121,880; 6,275,157; 6,975,228; and

foreign equivalent patents. Other patents pending.

For further information, contact:

TransCore

3410 Midcourt Road, Suite 102

Carrollton, Texas 75006 USA

Phone: (214) 461-4031

Fax: (214) 461-6478

Technical Support

Web: transcore.com/rfidsupport

Page 3

WARNING TO USERS IN THE UNITED STATES

FEDERAL COMMUNICATI ONS COMMISSION (FCC)

LOCATION AND MONITORING SERVICE STATEMENT

47 CFR §90.351

NOTE: The user is required to obtain a Part 90 site license from the FCC to operate this radio frequency

identification (RFID) device in the United States. See product label for FCC ID number. Access the FCC

Web site at www.fcc.gov/Forms/Form601/601.html for additional information concerning licensing

requirements.

NOTE: Users in all countries should check with the appropriate local authorities for licensing

requirements.

FCC RADIO FREQUENCY INTERFERENCE STATEMENT

47 CFR §15.105(a)

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate RF energy and may cause harmful interference to radio communications if

not installed and used in accordance with the instruction manual. Operating this equipment in a residential

area is likely to cause harmful interference, in which case, depending on the laws in effect, the user may be

required to correct the interference at their own expense.

NO UNAUTHORIZED MODIFICATIONS

47 CFR §15.21

CAUTION: This equipment may not be modified, altered, or changed in any way without permission

from TransCore, LP. Unauthorized modification may void the equipment authorization from the FCC and

will void the TransCore warranty.

USE OF SHIELDED CABLES IS REQUIRED

47 CFR §15.27(a)

NOTE: Shielded cables must be used with this equipment to comply with FCC regulations.

TransCore, LP

USA

Page 4

Encompass 4 Reader System Guide

Health Limits for Encompass 4 Reader Using Integrated Antenna (902 to 928 MHz)

Within the United States, environmental guidelines regulating safe exposure levels are issued by the Occupational Safety and Health Administration (OSHA).

Section 1910.97 of OSHA Safety and Health Standards 2206 legislates a maximum safe exposure limit of 10 milliwatts per square centimeter (mW/cm

aged over 6 minutes at 902 MHz.

Although not binding, other organizations such as the American National Standards Institute (ANSI) have issued similar guidelines that are more restrictive than

the OSHA limits (ANSI C95.1). ANSI guidelines recommend a maximum safe

power density in mW/cm

2

of:

2

) aver-

Frequency

(in MHz)

1500

Thus, the maximum permissible exposure for general population/ uncontrolled

exposure at 902 MHz is 0.60 mW/cm

2

. The power limit is a six-minute average.

The RF power density generated by the Encompass 4 Reader was calculated using

a maximum antenna gain of 9.5 dBi, equivalent to the antenna gain of the integrated antenna.

Warning

At 2 W transmitted power and a distance of 19.3 inches (49 cm) from the read er,

the maximum power density calculated was less than 0.60 mW/cm

2

. Install the

reader at least 19.3 inches (49 cm) from the general public. Maintenance personnel must remain at least 8.66 inches (22 cm) from reader when system is

operating.

The data confirms that the TransCore Encompass 4 Reader effectively meets

OSHA requirements and thus does not represent an operating hazard to either the

general public or maintenance personnel.

Page 5

Encompass 4 Reader System Guide

Health Limits for Encompass 4 Reader Using External Antenna (902 to 928 MHz)

Within the United S tates, environmental guidelines regulatin g safe exposure levels are

issued by the Occupational Safety and Health Administration (OSHA).

Section 1910.97 of OSHA Safety and Health Standards 2206 legislates a maximum

safe exposure limit of 10 milliwatts per square centimeter (mW/cm

minutes at 902 MHz.

Although not binding, other organizations such as the American National Standards

Institute (ANSI) have issued similar guidelines that are more restrictive than the

OSHA limits (ANSI C95.1). ANSI guidelines recommend a maximum safe power

density in mW/cm

2

of:

2

) averaged over 6

Frequency

(in MHz)

1500

Thus, the maximum permissible exposure for general population/ uncontrolled exposure at 902 MHz is 0.60 mW/cm

2

. The power limit is a six-minute average.

The RF power density generated by the Encompass 4 Reader was calculated using a

maximum antenna gain of 9.5 dBi, equivalent to the antenna gain of the external

antenna.

Warning

At 2 W transmitted power and a distance of 19.3 inches (49 cm) from the antenna,

the maximum power density calculated was less than 0.60 mW/cm

2

. Install the

antenna at least 19.3 inches (49 cm) from the general public. Maintenance personnel must remain at least 8.66 inches (22 cm) from antenna when system is operating.

The data confirms that the TransCore Encompass 4 Reader effectively meets OSHA

requirements and thus does not represent an operating hazard to either the general

public or maintenance personnel.

Page 6

Encompass 4 Reader System Guide

Page 7

Contents

Page 8

Page 9

Health Limits for Encompass 4 Reader Using Integrated Antenna. . . . . . . . . . . . . iv

Health Limits for Encompass 4 Reader Using External Antenna . . . . . . . . . . . . . . . v

1 Introduction

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Guide Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Contents

Licensing Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2 Developing the Site Plan

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Reading of Mixed Population Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Reader and Tag Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Polarization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Unobstructed Line of Sight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Antenna Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

AA3100 Yagi (without radome) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

AA3101 Yagi (with radome). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

AA3110 Parapanel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

AA3140 PCB Log Periodic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

AA3152 Universal Toll Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

AA3153 Toll Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Antenna and Tag Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Polarization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Unobstructed Line of Sight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

ix

Page 10

Encompass 4 Reader System Guide

Site Layout and Traffic Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

The Encompass 4 Reader Read Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Other Encompass 4 Readers in the Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Lane Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Gate with Center Island Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Parking Garage with Ticket Island Configuration . . . . . . . . . . . . . . . . . . . . . . . 2-14

Overhead Reader Installation Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Lane Configurations for Encompass 4 Readers Using an External Antenna . . . . 2-15

Reflection, Refraction, and Diffraction of RF Signals . . . . . . . . . . . . . . . . . . . . . . 2-15

Existing Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Electrical and Communications Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Power and Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Power Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Host Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

RS–232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

RS–422 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Wiegand Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Input/Output Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Antenna Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

3 Choosing, Installing, and Removing Tags

Compatible Tag Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Reader and Tag Model Interoperability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

TransCore’s eGo Plus Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

eGo Plus Sticker Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

eGo Plus Security Sticker Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

eGo Plus License Plate Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

TransCore’s eGo Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

eGo Windshield Sticker Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

eGo License Plate Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Installing eGo Plus Sticker Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Positioning eGo Plus Sticker Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Mirror Post Attached on Windshield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Mirror Post Attached on Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Large Truck with No Inside Mirror. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

eGo Plus Sticker Tag Installation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Removing eGo Plus Sticker Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Installing eGo Plus Security Sticker Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

eGo Plus Security Sticker Tag Installation Procedures. . . . . . . . . . . . . . . . . . . . . 3-11

Removing eGo Plus Security Sticker Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

x

Page 11

Contents

Installing eGo Plus License Plate Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Positioning eGo Plus License Plate Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

eGo Plus LPT Installation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Installing eGo Windshield Sticker Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Positioning eGo Windshield Sticker Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Mirror Post Attached Low On Windshield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Mirror Post Attached High on Windshield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Mirror Post Attached to Headliner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Mounting the eGo Windshield Sticker Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Removing eGo Windshield Sticker Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Installing eGo LPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Installing Interior ATA Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Positioning ATA Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Interior Driver’s or Passenger’s Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Interior Center Windshield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

ATA Interior Tag Installation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Removing Interior ATA Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Installing ATA License Plate Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Positioning ATA License Plate Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

ATA License Plate Tag Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Types of Bumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Alternate Mounting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Installation Procedures Using Tape. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Installation Procedures Using Blind Rivets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Removing Exterior Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

4 Installing the Encompass 4 Reader

Installation Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Materials Supplied by TransCore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Contents of Shipping Carton. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Installation Accessory Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Additional Materials Needed for Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

xi

Page 12

Encompass 4 Reader System Guide

Pre-installation Testing of the Encompass 4 Reader . . . . . . . . . . . . . . . . . . . . . . . 4-5

Testing the Encompass 4 Reader Using an Audible Circuit Tester . . . . . . . . . . . . 4-5

Connecting the Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Connecting the AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Connecting the DC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Connecting Communications for Bench Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Connecting for Bench Testing with RS–232 Interface . . . . . . . . . . . . . . . . . . . . 4-8

Connecting the Encompass 4 Reader Colored-Wire Pair Cable . . . . . . . . . . 4-9

Connecting for Bench Testing with RS–422 Interface . . . . . . . . . . . . . . . . . . . 4-10

Bench Testing the Encompass 4 Reader Before Installation . . . . . . . . . . . . . . . . 4-10

Mounting the Encompass 4 Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Mounting the Encompass 4 Reader on a Round Pole . . . . . . . . . . . . . . . . . . . . . 4-12

Required Materials To Be Supplied by Customer. . . . . . . . . . . . . . . . . . . . . . . 4-12

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Mounting the Encompass 4 Reader to a Wall or Flat Surface . . . . . . . . . . . . . . . 4-16

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Mounting the Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Mounting the Antenna Curb-Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Mounting the Antenna Overhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Connecting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Connecting Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Connecting the Encompass 4 Reader to the PC. . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

RS–232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Connecting the Encompass 4 Reader Colored-Wire Pair Cable . . . . . . . . . 4-24

RS–422 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Wiegand Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Connecting Sense Input and Sense Output Circuits . . . . . . . . . . . . . . . . . . . . . . 4-26

Sense Input Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Sense Output Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Marking the Read Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

5 General Software Information

Command Entry Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Command Response Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

xii

Page 13

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Power Fail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Program Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Download Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Download Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Sign-On Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Boot Failure Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Tag/Message Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

6 Communications Protocols

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Contents

Basic Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Error Correcting Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Basic Protocol and ECP Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Reader Transmissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

ECP Host ACK/NAK Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Switch to Command Mode Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Host Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Reader Command Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Sample Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Reader Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Host Command Transmissions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Timing and Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Reader-Addressed Failure Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Illegal Sequence Number (not in the range 0–9, A–F) . . . . . . . . . . . . . . . . . . . 6-12

Wrong Sequence Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Incorrect CRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Illegal Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Transmission Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Receive Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Asynchronous Message/Command Message Collision . . . . . . . . . . . . . . . . . . 6-13

Host-Addressed Failure Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Illegal or Wrong Sequence Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Incorrect CRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Transmission Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Receive Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Asynchronous Message/Command Message Collision . . . . . . . . . . . . . . . . . . 6-13

xiii

Page 14

Encompass 4 Reader System Guide

ECP Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

CRC Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Manually Disabling ECP for Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

7 Commands

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Data Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Command Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Download Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Reader Mode Control — Command Group 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

00 Switch to Data Mode (Factory Default) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

01 Switch to Command Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

06 Transmit Buffer Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Communications Port Control — Command Group 1 . . . . . . . . . . . . . . . . . . . . . . . 7-6

100N Select Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

101N Select Stop Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

102N Select Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Command Group 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

20 Set Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

21 Set Date. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

22 Display Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Append Information — Command Group 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

30N Append Time and Date Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

31N Append Auxiliary Information Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

ID Filtering — Command Group 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

40 Transmit All ID Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

410N Select Unique ID Code Criteria (Anti-passback Feature) . . . . . . . . . . . . 7-11

420N Select Valid ID Code Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

43 Buffer All ID Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

440 Reset Uniqueness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

44N Set Uniqueness Timeout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

450 Disable Wiegand Mode (Factory Default) . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

451 Enable Wiegand Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

452 Disable Tag Translation Mode (Factory Default). . . . . . . . . . . . . . . . . . . . 7-13

453 Enable Tag Translation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

454 Disable Multi-tag Sort (Factory Default). . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

455 Enable Multi-tag Sort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

456 Enable eGo Plus Tag Initialization During Multi-tag Sort (Factory Default) 7-14

457 Disable eGo Plus Tag Initialization During Multi-tag Sort . . . . . . . . . . . . . 7-14

458 Disable Second Alternate Group Select (Factory Default) . . . . . . . . . . . . 7-15

459 Enable Second Alternate Group Select. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

46NN Set Wiegand Retransmit Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

480 Disable ATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

xiv

Page 15

Contents

481 Enable ATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

482 Disable eGo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

483 Enable eGo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

484 Disable SeGo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

485 Enable SeGo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

486 Disable IAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

487 Enable IAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

488 Disable eATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

489 Enable eATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

490 Disable Third Alternate Group Select (Factory Default) . . . . . . . . . . . . . . 7-16

491 Enable Third Alternate Group Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

492 Disable Fourth Alternate Group Select (Factory Default) . . . . . . . . . . . . . 7-16

493 Enable Fourth Alternate Group Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

494 Disable Fifth Alternate Group Select (Factory Default) . . . . . . . . . . . . . . . 7-17

495 Enable Fifth Alternate Group Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

496 Disable Alternate Group Select (Factory Default) . . . . . . . . . . . . . . . . . . . 7-17

497 Enable Alternate Group Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Reader Status — Command Group 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

505 Display Software Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

506 Display Hardware Configuration Information . . . . . . . . . . . . . . . . . . . . . . . 7-18

510 Display RF Transceiver FPGA Version . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

511 Display RF Transceiver I Filter Chip Version. . . . . . . . . . . . . . . . . . . . . . . 7-18

512 Display RF Transceiver Q Filter Chip Version . . . . . . . . . . . . . . . . . . . . . . 7-18

513 Display DSP Board Actel Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

520 Display Power Fail Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

521 Display Reader ID Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

522 Display Communications Port Parameters . . . . . . . . . . . . . . . . . . . . . . . . 7-19

524 Display Appended Information Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

525 Display Communications Protocol Status . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

526 Display I/O Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

527 Display RF Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

529 Display Presence Input Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

530 Display RF0 Filter Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

532 Display Wiegand Mode Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

533 Display Wiegand Retransmit Interval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

534 Display Tag Translation Mode Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

535 Display Buffer Control Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

536 Display Dual-Frame Processing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

537 Display Echo Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

540 Display Flash Checksum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

543 Display Boot Checksum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

550 Display Periodic Check Tag Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

551 Display Selected Check Tag Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

560 Request Sensor Status Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

570 Display Operating Mode Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

577 Report Buffered Handshakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Reader Control Functions — Command Group 6 . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

60NN Set Reader ID Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

610 Select Basic Communication Protocol (Factory Default) . . . . . . . . . . . . . . 7-30

xv

Page 16

Encompass 4 Reader System Guide

611 Select Error Correcting Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

612NN Select Error Correcting Protocol Timeout. . . . . . . . . . . . . . . . . . . . . . . 7-30

613 Enable Data Inquiry Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

614N Select Flow Control Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

6160 Disable Buffer Control Mode (Factory Default) . . . . . . . . . . . . . . . . . . . . 7-31

6161 Enable Buffer Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Buffer Control Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

6170 Disable Echo Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

6171 Enable Echo Mode (Factory Default). . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

620N Set Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-33

621 Select Predefined Output Control (Factory Default) . . . . . . . . . . . . . . . . . 7-34

63 Reset Reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

640N RF Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

641 Select RF-by-Input Control (Factory Default) . . . . . . . . . . . . . . . . . . . . . . 7-35

642NN Select RF Operating Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

643NN Select ATA Operating Range (Distance) . . . . . . . . . . . . . . . . . . . . . . . 7-38

644NN Set RF Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

645NN Set eGo and eGo Plus Operating Range (Distance) . . . . . . . . . . . . . . 7-39

646XX Set IAG RF Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

647XXX Select RF Operating Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

65 Reset Power Fail Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

66F Load Default Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

67N Set Output Pulse Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

690N Select Presence Without Tag Report Option . . . . . . . . . . . . . . . . . . . . . 7-42

692N Select RF Control Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

693N Select RF Timeout Period. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

694N Select Input Inversion Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

695S...S Set Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

696S...S Store Hardware Configuration String. . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Auxiliary Reader Control — Command Group 8 . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

82N Select Input Status Change Report Option. . . . . . . . . . . . . . . . . . . . . . . . 7-45

830 Disable Automatic Periodic RF Status Report (Factory Default) . . . . . . . . 7-45

831 Enable Automatic Periodic RF Status Report . . . . . . . . . . . . . . . . . . . . . . 7-46

8 Configuring the Encompass 4 Reader

Configuring the Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

General Configuration Labeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Default Operating Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Configuring Parameters with Terminal Emulation Software . . . . . . . . . . . . . . . . . 8-5

Starting the Terminal Emulation Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Verifying Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Verifying Tag Read Capability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Configuring Encompass 4 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Appended Tag Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

ID Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

xvi

Page 17

Contents

Reset Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Radio Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

RF Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Vehicle Detector Controlling RF Transmission . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Host Controlling RF Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Continuous RF Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Sense Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Sense Output Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Serial Port Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Port Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Communications Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Software Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Fine-Tuning and Verifying the Read Zone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Physically Orienting the Encompass 4 Reader . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Physically Orienting the Encompass 4 Reader Antenna . . . . . . . . . . . . . . . . . 8-20

Fine-Tuning the Read Zone by Lowering Output Power . . . . . . . . . . . . . . . . . 8-20

Fine-tuning the Read Zone by Adjusting Sensitivity Range . . . . . . . . . . . . . . . 8-21

9 Troubleshooting and Maintenance

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Encompass 4 Reader Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Marketing Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Find a Problem with the Encompass 4 Reader or Have Suggestions? . . . . . . . . 9-7

A Glossary

B Technical Specifications

Reader Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Physical Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Environmental Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

xvii

Page 18

Encompass 4 Reader System Guide

C Wiring Tables

Communications Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Cable Supplied with the Encompass 4 Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

RS–232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

RS–422 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Wiegand Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Power Supply Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Low-Voltage DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Input/Output Cabling Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Summary Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

D Command Quick Reference

Command Syntax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Factory Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Numerical Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Alphabetical Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-17

E Compatible Tag Information

Tag Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Tag Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

xviii

Page 19

List of Figures

Figure 1-1 Encompass 4 Reader System Front and Side Views . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 2-1 Tag and Reader Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-2 Encompass 4 Reader Location Relative to Tag Position . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-3 Typical Tag Positions for U.S. Driver’s Side Reader . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-4 Typical Tag Positions for U.S. Passenger’s Side Reader . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-5 Typical Tag Positions Used with Overhead Reader . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 2-6 Gate Application with Center Island . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-7 Parking Garage Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-8 Overhead Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Figure 3-1 eGo Plus Windshield Sticker Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-2 eGo Plus Security Sticker Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 3-3 eGo Plus License Plate Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-4 eGo Windshield Sticker Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-5 eGo License Plate Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-6 eGo Plus Sticker Tag Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-7 eGo Plus Sticker Tag Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-8 eGo Plus Sticker Tag Placement in Large Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-9 Applying eGo Plus Sticker Tag to Windshield . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-10 Second Step of eGo Plus Sticker Tag Application . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 3-11 Applying eGo Plus Security Sticker Tag to Windshield . . . . . . . . . . . . . . . . . . . . 3-12

Figure 3-12 Second Step of eGo Plus Security Sticker Tag Application . . . . . . . . . . . . . . . . . 3-12

Figure 3-13 Correct Mounting Location for LPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Figure 3-14 Correct Tag Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Figure 3-15 Upper Placement Over the Top Area of the License Plate . . . . . . . . . . . . . . . . . . 3-15

Figure 3-16 eGo Windshield Sticker Tag Placement Option A . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Figure 3-17 eGo Windshield Sticker Tag Placement Option B . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Figure 3-18 eGo Windshield Sticker Tag Placement Option C . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Figure 3-19 Driver’s or Passenger’s Side (U.S.) Interior Windshield Tag Location . . . . . . . . . 3-19

Figure 3-20 Upper Center Interior Windshield Tag Location . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Figure 3-21 Hook-and-Loop Material on Interior Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Figure 3-22 Proper Tag Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Figure 3-23 Correct Exterior Tag Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Figure 3-24 Upper Placement In License Plate Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Figure 3-25 Obstruction-Free Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Figure 3-26 Spacer Positioned Behind Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Figure 3-27 Exterior Tag with Double-Sided Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Figure 4-1 Wiring for Audible Circuit Tester . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-2 Back of Encompass 4 Reader Showing Antenna Connector . . . . . . . . . . . . . . . . . . 4-6

Figure 4-3 Pin Assignments for Signal to Host Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Figure 4-4 Back of the Encompass 4 Reader (reader shown has integrated antenna) . . . . . . 4-13

Figure 4-5 Factory-Mounted Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Figure 4-6 Pole-Mount Bracket Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Figure 4-7 The Encompass 4 Reader Attached to the Pole Mount Bracket . . . . . . . . . . . . . . 4-14

Figure 4-8 Front and Top Views of the Encompass 4 Reader Position . . . . . . . . . . . . . . . . . . 4-15

Figure 4-9 Wall Mount Bracket Accessory (part number 54-1620-001) . . . . . . . . . . . . . . . . . . 4-16

Figure 4-10 Wall Mount Bracket Attached to the Encompass 4 Reader . . . . . . . . . . . . . . . . . 4-17

Figure 4-11 Factory-Mounted Bracket Attached to Wall Mount Bracket . . . . . . . . . . . . . . . . . 4-18

Contents

xix

Page 20

Encompass 4 Reader System Guide

Figure 4-12 Pole Mount Bracket Attached to Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Figure 4-13 Connecting the Encompass 4 Assembly to Pole Mount Bracket . . . . . . . . . . . . .4-19

Figure 4-14 Front and Top Views of the Curb-Side Antenna Position . . . . . . . . . . . . . . . . . . .4-21

Figure 4-15 Encompass 4 Reader Installation with Overhead Antenna . . . . . . . . . . . . . . . . . .4-22

Figure 4-16 Sample Circuit Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Figure 4-17 Sample Read Zone Marking Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

Figure 8-1 Connection Description Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Figure 8-2 Phone Number Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

Figure 8-3 COM 1 Properties Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

Figure 8-4 Hyper Terminal Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

Figure 8-5 Sign-on Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Figure 8-6 Successful Tag Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

Figure 8-7 Second Successful Tag Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-12

Figure 8-8 Encompass 4 Reader RF Control Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-16

Figure C-1 DB9 and DB25 Connector Pin Assignments for Signal to Host. . . . . . . . . . . . . . . . C-4

xx

Page 21

List of Tables

Table 1-1 Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 2-1 Examples of Staggered Reader Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Table 2-2 Connector Cabling Accessory Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Table 2-3 Power Supply Current Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Table 2-4 Recommended Cable Length from Transformer to the Encompass 4 Reader . . . . 2-18

Table 2-5 Communications Interfaces and Conductor Requirements . . . . . . . . . . . . . . . . . . . 2-18

Table 2-6 Reader to Antenna Cable Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Table 3-1 Tags Read by the Encompass 4 Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Table 3-2 eGo Plus Tag Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Table 3-3 eGo Tag Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Table 4-1 Installation Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Table 4-2 AC Transformer Connections for Colored-Wire Pair Cable . . . . . . . . . . . . . . . . . . . . 4-6

Table 4-3 Low Voltage DC Cable Connections for the Colored-Wire Pair Cable . . . . . . . . . . . 4-7

Table 4-4 RS–232 Interface Signal Wiring for Colored-Wire Pair Cable . . . . . . . . . . . . . . . . . . 4-9

Table 4-5 Commands for Bench Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Table 4-6 RS–232 Interface Signal Wiring for Colored-Wire Pair Cable . . . . . . . . . . . . . . . . . 4-24

Table 4-7 RS–422 Interface Signal Wiring for Colored-Wire Pair Cable . . . . . . . . . . . . . . . . . 4-25

Table 4-8 Wiegand Interface Signal Wiring for Colored-Wire Pair Cable . . . . . . . . . . . . . . . . 4-26

Table 4-9 Sense Input/Output Cabling Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Table 5-1 Four-Character Command Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table 5-2 Sample Command Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Table 7-1 Select Baud Rate Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Table 7-2 Select Stop Bits Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Table 7-3 Select Parity Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Table 7-4 Append Time and Date Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Table 7-5 Append Auxiliary Information Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Table 7-6 Unique ID Code Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Table 7-7 Select Valid Code Commands and Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Table 7-8 Open/Closed Conditions for Output Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Table 7-9 Open/Closed Conditions for Input Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Table 7-10 Flow Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Table 7-11 Output Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Table 7-12 RF Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Table 7-13 RF Frequency Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Table 7-14 RF Attenuation Command Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Table 7-15 Select RF Frequency Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

Table 7-16 Output Pulse Duration Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Table 7-17 Presence Without Tag Report Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Table 7-18 RF Control Algorithm Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Table 7-19 Timeout Period Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-43

Table 7-20 Input Inversion Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Table 7-21 Input Status Change Report Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-45

Table 8-1 Encompass 4 Reader Configuration Label Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Table 8-2 Encompass 4 Reader Default Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Table 8-3 Command Sequence to Verify Communications . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Table 9-1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Table 9-2 Symptoms and Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Table C-1 Communications Interfaces and Conductor Requirements . . . . . . . . . . . . . . . . . . . . .C-3

Contents

xxi

Page 22

Encompass 4 Reader System Guide

Table C-2 RS–232 Interface Signal Wiring for Colored-Wire Pair Cable . . . . . . . . . . . . . . . . . . C-5

Table C-3 RS–232 Interface Signal Wiring for Alternate Wire Cable . . . . . . . . . . . . . . . . . . . . . C-5

Table C-4 RS–422 Interface Signal Wiring for Colored-Wire Pair Cable . . . . . . . . . . . . . . . . . . C-6

Table C-5 RS–422 Interface Signal Wiring for Alternate Wire Cable . . . . . . . . . . . . . . . . . . . . . C-6

Table C-6 Wiegand Interface Signal Wiring for Colored-Wire Pair Cable . . . . . . . . . . . . . . . . . C-7

Table C-7 Wiegand Interface Signal Wiring for Alternate Wire Cable . . . . . . . . . . . . . . . . . . . . C-7

Table C-8 AC Transformer Connections for Colored-Wire Pair Cable . . . . . . . . . . . . . . . . . . . . C-7

Table C-9 AC Transformer Connections for Alternate Wire Cable . . . . . . . . . . . . . . . . . . . . . . . C-8

Table C-10 Low Voltage DC Cable Connections for Colored-Wire Pair Cable . . . . . . . . . . . . . C-8

Table C-11 Low Voltage DC Cable Connections for Alternate Wire Cable . . . . . . . . . . . . . . . . C-8

Table C-12 Sense Input/Output Cabling Assignments for Colored-Wire Pair Cable . . . . . . . . . C-9

Table C-13 Sense Input/Output Cabling Assignments for Alternate Wire Cable . . . . . . . . . . . C-10

Table C-14 All Cabling Assignments for Colored-Wire Pair Cable or Alternate Wire Cable. . . C-12

Table D-1 Encompass 4 Reader Default Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . D-3

Table D-2 Encompass 4 Reader Commands Listed Numerically . . . . . . . . . . . . . . . . . . . . . . . D-5

Table D-3 Encompass 4 Reader Commands Listed Alphabetically . . . . . . . . . . . . . . . . . . . . . D-17

Table E-1 SeGo Protocol Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Table E-2 eGo Protocol Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Table E-3 ATA Protocol Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

xxii

Page 23

1

Introduction

Page 24

Page 25

Purpose

Audience

Chapter 1

Introduction

This chapter is the introduction to this manual and provides information

pertaining to the audience, organization, document conventions, system

®

description, and license information for the Encompass

System.

This guide provides site planning and testing, installing, and operating instructions for

TransCore’ s Encompass 4 Reader System, a dual-protocol reader that reads TransCore

®

Super eGo

International Organization for Standardization (ISO), and Inter-Agency Group (IAG)

tag protocols. Before you begin installing the Encompass 4 Reader System, TransCore

recommends that you read this entire manual.

(SeGo), Intellitag®-based eGo, American Trucking Associations (ATA)/

4 Reader

This document is intended to be used by authorized TransCore Encompass 4 Reader

System dealers, installers, and service personnel. Because the Encompass 4 Reader

System has no operator- or end-user serviceable components or features, no end-user

manual or operator guide exists. Once the system is set up and tested by the

authorized installer, Encompass 4 Reader System operation requires no end-user

intervention.

System Guide Organization

Note: TransCore offers the Encompass 4 Reader in two models: one with an integrated antenna and one that r equir es connection to an external antenna. In this system

guide, information and instructions for both Encompass 4 Reader models are presented. Where separate instructions dictate, a section detailing one Encompass 4

Reader model is followed immediately with a section detailing the other reader model.

In this system guide, the reader with an integrated antenna is listed first. In cases

where the information does not warrant a separate section, the addition of "...or

antenna" distinguishes between the Encompass 4 Reader models.

The chapters of this guide and a description of the contents are listed below.

• Chapter 1, “Introduction,” explains the purpose and describes the audience for the

guide, outlines the manual’s organization, provides a brief description of the

Encompass 4 Reader system, and discusses Federal Communications Commission (FCC) licensing requirements.

1-3

Page 26

Encompass 4 Reader System Guide

• Chapter 2, “Developing the Site Plan,” discusses factors to be considered when

developing the site plan and before ordering equipment and installing the Encompass 4 Reader System. These considerations include reader or antenna and tag

alignment, site layout and traffic flow, and electrical and communications requirements.

• Chapter 3, “Choosing, Installing, and Removing Tags,” contains information on

compatible tag models and provides procedures for installing tags onto, and

removing tags from, vehicles that use the facility where the Encompass 4 Reader

System is installed.

• Chapter 4, “Installing the Encompass 4 Reader System ,” lists the material s needed

and provides procedures to install the Encompass 4 Reader System. Steps include:

• Pre-testing

• Installing the Encompass 4 Reader System on a round pole or flat surface

• Connecting power and communications

• Marking the read zone.

• Chapter 5, “General Software Information,” and Chapter 6, “Communications

Protocols,” provide reference information on various software-related topics and

communications protocols.

• Chapter 7, “Commands,” discusses the host-transmitted commands that are used

to control Encompass 4 Reader System configuration and operation.

• Chapter 8, “Configuring the Encompass 4 Reader System,” provides procedures

for configuring and fine-tuning the Encompass 4 Reader System after installing it

at the site.

• Chapter 9, “Troubleshooting and Maintenance,” answers the most commonly

asked questions about installing and maintaining the Encompass 4 Reader System.

• Appendix A, “Glossary,” contains frequently used terms.

• Appendix B, “Technical Specifications,” provides the Encompass 4 Reader Sys-

tem specifications.

• Appendix C, “Wiring Tables,” shows the wiring connections for the communica-

tions interfaces, electrical cable connections, and the external interface signal wiring.

• Appendix D, “Command Quick Reference,” lists the Encompass 4 Reader System

factory default configuration settings and provides host software commands in

numerical and alphabetical order.

1-4

• Appendix E, “Compatible Tag Information,” provides helpful information about

tags that are compatible with the Encompass 4 Reader System.

• Index provides an alphabetical listing of guide topics.

Page 27

Typographical Conventions

The conventions listed in Table 1-1 are used in this manual:

Table 1-1 Typographical Conventions

Convention Indication

Concerns about a procedure.

Introduction

Code

Dialog Box Title

Menu Item

Note

NUL Zero-value ASCII character or a zero-value byte.

NULL Zero-value pointers. Null-terminated string refers to strings

System Description

Code, including keywords and variables within text and as

separate paragraphs, and user-defined program elements

within text appear in courier typeface.

Title of a dialog box as it appears on screen.

Appears on a menu. Capitalization follows the interface.

Auxiliary information that further clarifies the current

discussion. These important points require the user’s

attention. The paragraph is in italics and the word Note is

bold.

of printable ASCII characters with a zero-value byte placed

in memory directly after the last printable character of the

string.

This procedure might cause harm to the equipment and/or

the user.

The Encompass 4 Reader System is a dual-protocol reader supporting the low-cost,

high-performance SeGo radio frequency identification (RFID) technology . SeGo technology provides the capability to read miniature RFID tags in a myriad of options

including rugged, durable, or thin flexible forms such as the eGo Plus S ticker Tag. The

Encompass 4 Reader System also supports legacy transportation applications such as

gated toll, parking, or security gate access and is designed to be compatible with exist-

®

ing TransCore SmartPass

parking access control applications certified for licensed

use. The Encompass 4 Reader System also supports the TransCore eGo and TransCore

ATA/ISO tag types, as well as the IAG tag protocol.

1-5

Page 28

Encompass 4 Reader System Guide

The Encompass 4 Reader System is a high-power unit that can read both half-frame

and full-frame tags. The reader output power can be adjusted using reader commands.

Reader

The Encompass 4 Reader System consists of an input/output (I/O) module, a power

supply, a reader logic board (also called a tag decoder), a radio frequency (RF) transmitter/receiver (called the RF module), and a patch antenna.

A second version of the Encompass 4 Reader is designed to be used with a high-performance external antenna. These Encompass 4 Reader System components are contained in a highly reliable, compact, and easy-to-install environmentally-sealed

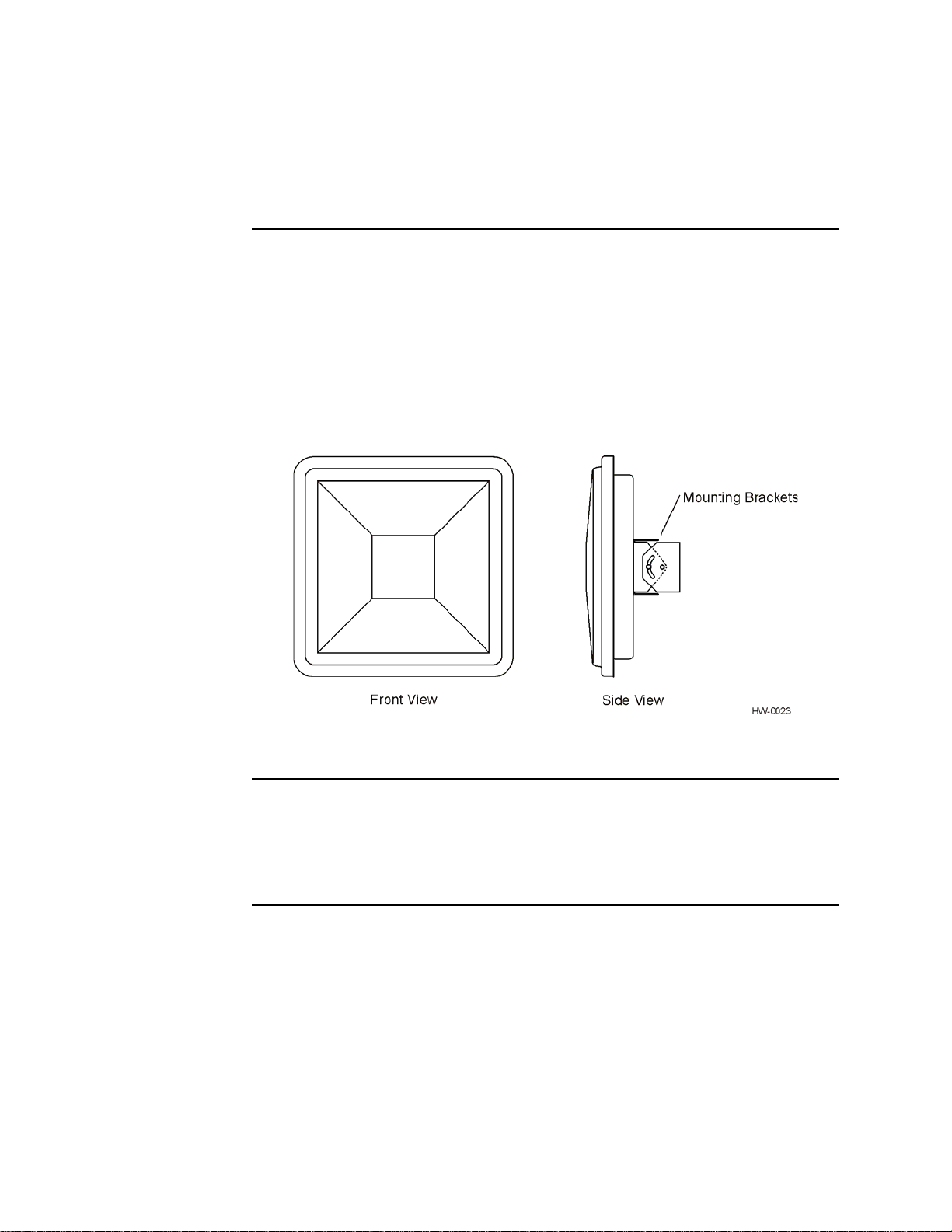

package. Figure 1-1 shows the front and side views of an Encompass 4 Reader System.

1-6

Figure 1-1 Encompass 4 Reader System Front and Side Views

Tags

The Encompass 4 Reader System has the capability to read TransCore SeGo protocol

tags, the Intellitag-based eGo protocol tags, TransCore ATA protocol, and TransCore

ISO-compliant read-only full- and half-frame tags, as well as IAG protocol tags.

How It Works

The Encompass 4 Reader System directs the RF module to generate an RF signal,

which is broadcast through the integrated or external antenna. Entering the Encompass

4 Reader System’s reading range, a T ransCor e RFID tag installed on a vehicle or other

object to be tracked adds its programmed identification information to the signal and

reflects the signal back to the Encompass 4 Reader System. The Encompass 4 Reader

System receives this modified, or modulated signal, and decodes the tag data carried

by the reflected signal and transmits this data to a local host computer for processing.

Page 29

Licensing Requirements

An FCC license provides the user with the legal authorization to operate the Encompass 4 on the licensed frequencies at the site specified in the license. Only an authorized installer or service technician can set the RF frequency of the Encompass 4

Reader System to the frequency specified in the FCC site license. No end-user-operated controls exist on the Encompass 4 Reader System.

The FCC license may provide the user with protection and authorization to maintain

the system should any other RFID product be used in the licensed area after the

Encompass 4 equipment is installed.

Users of the Encompass 4 Reader System in the United States must obtain a license

from the FCC. In the United States, the authorized modulated frequency band for this

product is 911.75 to 91 9.75 MHz and the authorized continuous wave frequency band

is 902.25 to 903.75 MHz and 910.00 to 921.50 MHz.

The user is responsible for filing the FCC license according to FCC regulations, but

the TransCore dealer will provide assistance and support as necessary to complete

these forms. Forms are available online at the FCC internet site http://wire-

less.fcc.gov/uls. For further information on obtaining the license contact TransCore.

Introduction

Technical Support

Authorized dealers and distributors are responsible for the direct support of all

customers. Authorized dealers and distributors needing technical support can contact:

Technical Support

Web: transcore.com/rfidsupport

or

TransCore

3410 Midcourt Road, Suite 102

Carrollton, Te xas 75006 USA

Phone: (214) 461-4031

Fax: (214) 461-6478

Please be prepared to answer a series of questions that are designed to direct you to the

best support resource available.

1-7

Page 30

Encompass 4 Reader System Guide

1-8

Page 31

2

Developing the Site Plan

Page 32

Page 33

Overview

Chapter 2

Developing the Site Plan

This chapter discusses site plan development for installing the

®

Encompass

Note: In this section, unless specifically stated, "Encompass 4 Reader" applies

both to the Encompass 4 Reader with integrated antenna and Encomp ass 4

Reader with external antenna.

Developing a site plan provides the foundation for the site’s system design and establishes the following system configuration parameters:

• Number and general location of primary components

• Number of different radio frequencies required

Gathering relevant site information is crucial before applying for Federal Communications Commission (FCC) approval and ordering and installing Encompass 4

Reader(s) and tags.

4 Reader System.

Also, consider the following factors when developing a site plan:

• Type of tags used in the facility

• Reader and/or antenna and tag alignment

• Site layout and traffic flow

• Encompass 4 Reader and/or antenna mounting requirements

• Encompass 4 Reader electrical requirements

• Encompass 4 Reader communications requirements

These factors provide relevant information regarding each site’s physical and electromagnetic environment and the conditions under which the system must perform.

Reading of Mixed Population Tags

The Encompass 4 Reader reads TransCore’s Super eGo® (SeGo) protocol tags, the

American Trucking Association (ATA) and International Organization for Standardization (ISO) read-only tags, whether powered by battery or beam, application-specific integrated circuit (ASIC)-based tags with Intellitag technology, or Inter-Agency

2-3

Page 34

Encompass 4 Reader System Guide

Group (IAG) tags. The reader can read the ATA or ISO read-only tags in the presence

of Intellitag-based tags; however, attempting to read an Intellitag-based tag in the

presence of an ATA or ISO read-only tag is not recommended.

Caution

Attempting to read an Intellitag-based tag in the presence of an ATA or ISO read-only

tag may provide unreliable results.

The factors that influence the readability include, but are not limited to physical orientation and configuration, type of read-only tag, ratio of backscatter cross-section of the

tags, and whether the tag is battery- or beam-powered.

Reader and Tag Alignment

The position of the Encompass 4 Reader and placement of the tag on the vehicle must

be compatible. Also, consider any existing tagged vehicles now using the facility to

determine the optimal Encompass 4 Reader location and orientation at the site.

Note: If any of the vehicles using your facility already have tags, such as those used

in toll applications, contact TransCore for information about mixed-tag installations

before you plan tag type, location, and programming.

Three primary criteria must be satisfied to achieve the highest read reliability:

• Polarization of the tag and the Encompass 4 Reader must be aligned in the same

direction

— both horizontal.

• The installed tag must be in a direct, unobstructed line of sight to the Encompass 4