1422E Reader

User Guide

16-0058-001 Rev B (X3) 9/17

Purpose of This Guide

This user guide is intended for skilled personnel (including trained technicians and

engineers) to provide information for initializing the AI1422E Reader System. This

guide provides on-site test procedures useful in troubleshooting, as well as AI1422E

command codes and information on character translation.

Trusted Transportation Solutions

User Guide

Information in this document is subject to change and does not represent a commitment on the part of

TransCore, LP.

© 2017 TransCore, LP. All rights reserved. TRANSCORE, AMTECH, EGO, and ENCOMPASS are registered

trademarks and are used under license. All other trademarks are the property of their respective owners.

Contents are subject to change. Printed in the U.S.A.

For further information, contact:

TransCore

8600 Jeerson Street NE

Albuquerque, New Mexico 87113 USA

TransCore Technical Support

Web: www.transcore.com/rfidsupport

Phone: (505) 856-8007

Lantronix ® Technical Support (Ethernet Support)

Web: www.lantronix.com/support/

Phone: (949) 453-7198

TransCore Proprietary ii

Licensing Requirements

To operate a radio frequency (RF) system in a given country, the user must first obtain permission from the

regulatory agency that controls radio operations in that country. Most countries require type and safety

approval, as well as licensing for RF transmitters. Users in all countries should check with the appropriate

local authorities for licensing requirements.

U.S. Licensing

This AI1422E Reader System requires an FCC Part 90 license to operate in the U.S. The

authorized frequency bands in the U.S. are 902 to 904 MHz and 909.75 to 921.75 MHz.

The user is responsible for filing the FCC license according to FCC regulations. Access the

FCC Web site at https://www.fcc.gov/licensing-databases/forms or at wireless.fcc.gov/index.

htm?job=online_filing to obtain additional information concerning licensing requirements.

An FCC license provides the user with the legal authorization to operate the RFID systems on the

licensed frequencies at the site specified in the license. Only an authorized installer or service

technician can set the frequency for the AI1422E Reader System to that specified in the FCC site

license.

AI1422E Reader

The FCC license also provides the user with protection and authorization to maintain the system

should any other RFID be used in the licensed area after the AI1422E Reader System is installed.

TransCore Proprietary

iii

User Guide

WARNING TO USERS IN THE UNITED STATES

FEDERAL COMMUNICATIONS COMMISSION FCC

LOCATION AND MONITORING SERVICE STATEMENT

47 CFR §90.351

NOTE: The user is required to obtain a Part 90 site license from the Federal Communications Commission

(FCC) to operate this radio frequency identification (RFID) device in the United States. The FCC ID number is

FIHAI1422E. Access the FCC website at www.fcc.gov to obtain additional information concerning licensing

requirements.

NOTE: Users in all countries should check with the appropriate local authorities for licensing requirements.

FCC RADIO FREQUENCY INTERFERENCE STATEMENT

47 CFR §15.105A

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate RF energy and may cause harmful interference to radio communications if

not installed and used in accordance with the instruction manual. Operating this equipment in a residential

area is likely to cause harmful interference, in which case, depending on the laws in eect, the user may be

required to correct the interference at their own expense.

NO UNAUTHORIZED MODIFICATIONS

47 CFR §15.21

CAUTION: This equipment may not be modified, altered, or changed in any way without permission.

Unauthorized modification may void the equipment authorization from the FCC and will void the warranty.

USE OF SHIELDED CABLES AND GROUNDING

47 CFR §15.27A

NOTE: Shielded cables and earth grounding the unit is recommended for this equipment to comply with FCC

regulations.

TRANSCORE, LP

USA

TransCore Proprietary iv

AI1422E Reader

AVERTISSEMENT À L’ATTENTION DES

UTILISATEURS AUX ÉTATSUNIS

DÉCLARATION 47 CFR §90.351 CODE DES

RÈGLEMENTS FÉDÉRAUX DE LA FEDERAL

COMMUNICATIONS COMMISSION FCC SUR LES

SERVICES DE LOCALISATION ET DE CONTRÔLE

REMARQUE : L’utilisateur est tenu d’obtenir une licence d’utilisation sur site Partie 90 auprès de la Federal

Communications Commission (FCC) afin de pouvoir utiliser ce dispositif RFID (radio-identification) aux

États-Unis ou au Canada. Le numéro d’identification de la FCC est FIHAI1422E.Pour obtenir de plus amples

informations concernant les exigences relatives aux licences, prière de consulter le site web de la FCC à

www.fcc.gov.

REMARQUE : Il est recommandé à tous les utilisateurs, quel que soit leur pays, de consulter les autorités

locales compétentes sur les exigences de licence.

DÉCLARATION 47 CFR §15.105A DE LA FCC SUR

LES INTERFÉRENCES DES FRÉQUENCES RADIO

REMARQUE : Cet appareil a été testé et déclaré conforme à la catégorie d’un appareil numérique de

classe A en accord avec la partie 15 des directives de la FCC. Ces normes visent à assurer une protection

raisonnable contre les interférences nuisibles lorsque l’appareil est utilisé dans un environnement

commercial. Cet appareil génère, utilise et peut émettre de l’énergie RF et peut être à l’origine

d’interférences nuisibles aux communications radio s’il n’est pas installé et utilisé en suivant les directives

du manuel d’instructions. Si cet appareil est utilisé dans une zone résidentielle, il est probable qu’il cause

des interférences nuisibles. Dans ce cas, l’utilisateur pourrait être amené à remédier aux interférences à ses

propres frais, selon les lois du pays en vigueur.

AUCUNE MODIFICATION NON AUTORISÉE

47 CFR §15.21

MISE EN GARDE : Il est interdit de modifier, d’altérer ou d’apporter des changements à cet appareil de

quelque manière que ce soit sans autorisation. Toute modification non autorisée peut annuler

l’autorisation d’utilisation accordée par la FCC et annulera la garantie.

UTILISATION DE CÂBLES BLINDÉS ET MISE À LA TERRE

47 CFR §15.27A

REMARQUE : Il est recommandé d’utiliser des câbles blindés et une mise à la terre avec cet appareil afin de

répondre aux réglementations de la FCC

TRANSCORE, LP

ÉTATSUNIS

TransCore Proprietary

v

User Guide

RADIO FREQUENCY HEALTH LIMITS FOR AI1422 READER

USING AN EXTERNAL ANTENNA IN FREQUENCY BAND

OF 902.25 TO 903.75 AND 910.00 TO 921.50 MHZ

Several agencies (OSHA, FCC, IC) have environmental guidelines regulating maximum permissible exposure

(MPE) or “safe” exposure levels that this product falls under. To ensure that proper safety guideline for

the end users of this product, i.e. Occupational (Controlled) and General Population/Public (Uncontrolled),

the recommended levels for each of the agencies are presented in the next sections with TransCore’s

recommendations for safety in the last section.

OSHA OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION

OSHA (an agency of The United States of America) legislates in the Code of Federal Regulations (CFR)

Title 29 Part 1910 Subpart G 1910.97 titled “Nonionizing radiation”, a maximum safe exposure limit of 10

milliwatts per square centimeter (mW/cm2) during any 0.1-hour period (i.e. 6 minutes). Using the frequency

(in the middle of the band of operation of this equipment) of 915 MHz and the highest antenna gain that

this equipment is certified for use in a final installation, the minimum safe distance was calculated to be 8in

(20cm).

FCC FEDERAL COMMUNICATION COMMISSION

FCC (an agency of The United States of America) legislates in the Code of Federal Regulations (CFR) Title 47

Chapter I Subchapter A Part 1 Subpart I Section 1.1310 titled “Radiofrequency radiation exposure limits” that

the maximum permissible exposure (MPE) is the following:

Occupational/Controlled Exposure

Power density = frequency(in MHz)/300 mW/cm2 with an Averaging time of 6 Min

General Population/Uncontrolled Exposure

Power density = frequency(in MHz)/1500 mW/cm2 with an Averaging time of 30 Min

Using the frequency (in the middle of the band of operation of this equipment) of 915MHz and the highest

antenna gain that this equipment is certified for use in a final installation, the minimum safe distance was

calculated. The MPE minimum distances are 14in (36cm) for the Occupational/Controlled environment, and

31.5in (80.5cm) for the General Population/Uncontrolled environment.

INDUSTRY CANADA INNOVATION, SCIENCE AND ECONOMIC DEVELOPMENT CANADA

Industry Canada (a Department of the Government of Canada) sets out the requirements in Radio Standards

Specification RSS-102, Issue 5 guidelines, recommending a maximum safe power density in W/m2. Thus, the

maximum permissible exposure for general population/uncontrolled exposure at 915MHz is 2.77 W/m2. The

average time is 6 minutes. The maximum permissible exposure (MPE) is the following:

Controlled Environment

Power density = 0.6455*frequency(in MHz)

General Public/Uncontrolled Environment

TransCore Proprietary vi

0.5

W/m2 with a Reference Period time of 6 Min

AI1422E Reader

Power density = 0.02619*frequency(in MHz)

0.6834

W/m2 with a Reference Period time of 6 Min

Using the frequency (in the middle of the band of operation of this equipment) of 915MHz and the highest

antenna gain that this equipment is certified for use in a final installation, the minimum safe distance was

calculated. The MPE minimum distances are 18in (45cm) for the Controlled environment and 47in (120cm)

for the General Public/Uncontrolled environment.

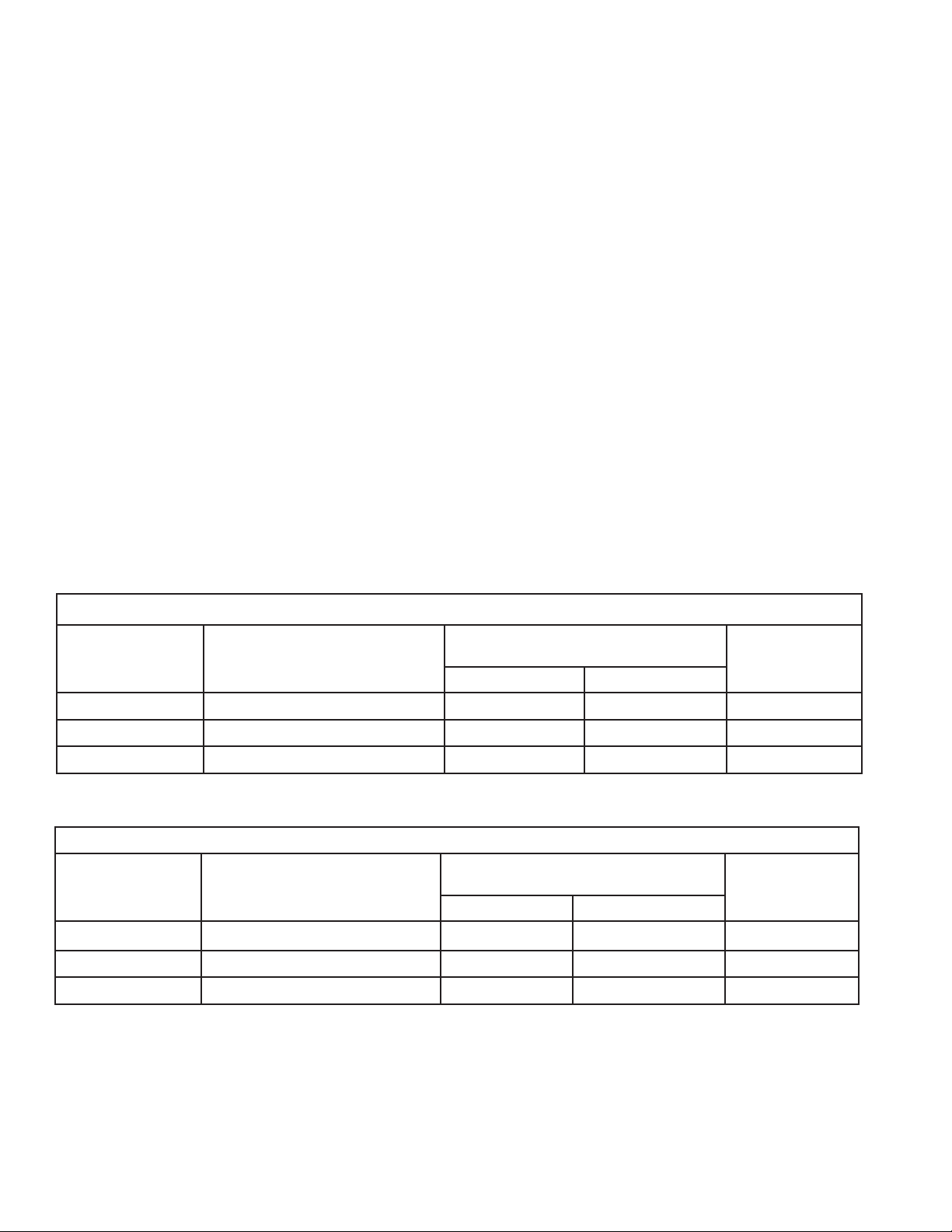

TRANSCORE RECOMMENDATION ON MPE MAXIMUM PERMISSIBLE EXPOSURE

The calculated power densities and MPE distance for each of the agencies respective to the environment

is shown below.

With the equipment installed and running at the maximum transmit power of 2.0W (33dBm), 0 dB transmit

attenuation, using the highest gain antenna that the equipment is certified for, the recommendation for

each of the operation environments is as follows:

1 ) The antenna should be installed at least 47in (120cm) from the General Population/Public i.e.

Uncontrolled Environment.

2 ) Maintenance personnel (i.e. Occupational/Controlled Environment) must remain at least 18in

(45cm) from the antenna and limit their time in the environment to 6 minutes when the system

is operating.

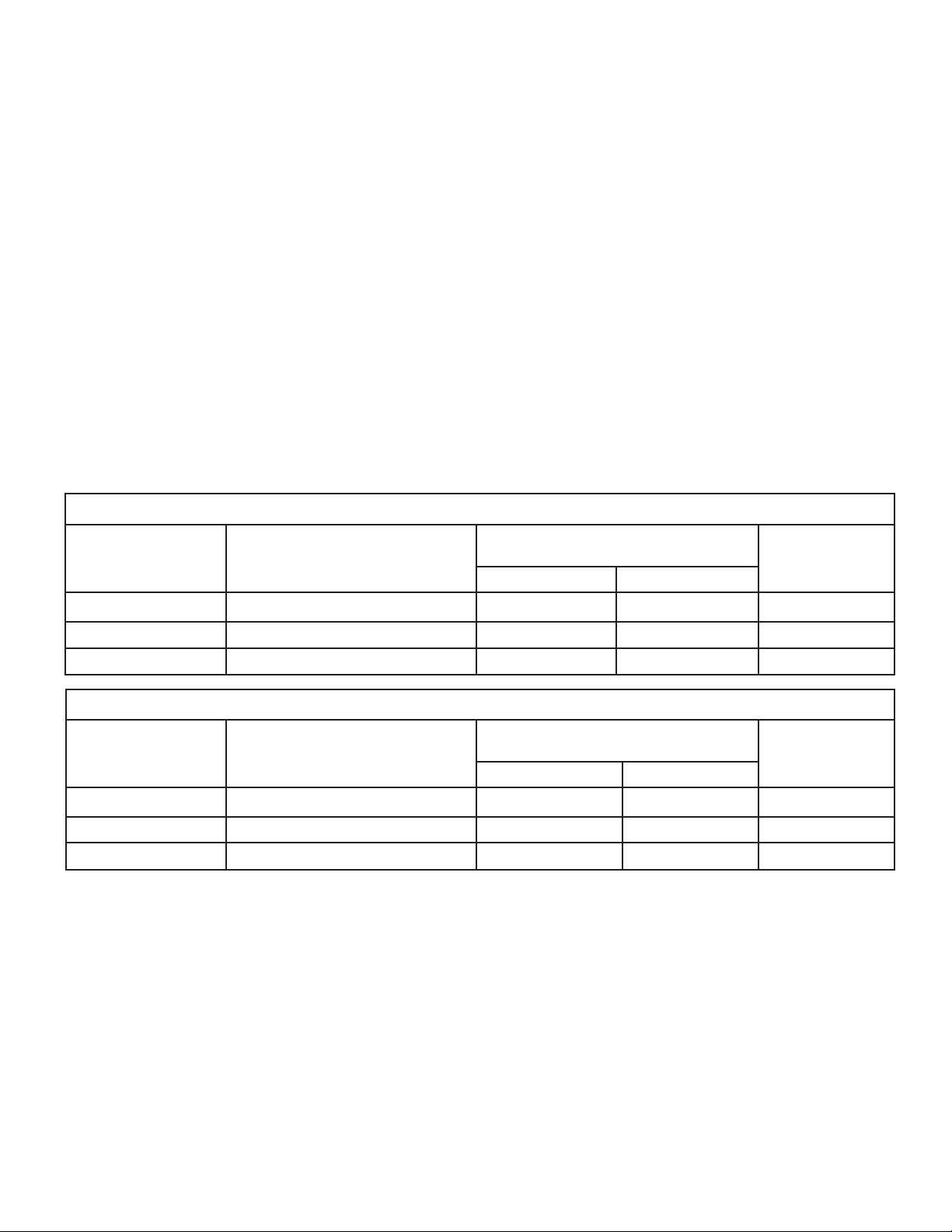

Occupational/Controlled Environment

Agency Power Density (mW/cm2) MPE minimum distance Time (min)

in cm

OSHA 10 8 20 6

FCC 3.05 14 36 6

IC 1.95 18 45 6

General Population/Public/Uncontrolled Environment

Agency Power Density (mW/cm2) MPE minimum distance Time (min)

In cm

OSHA 10 8 20 6

FCC 0.61 31.5 80 30

IC 0.28 47 120 6

TransCore Proprietary

vii

User Guide

LIMITES D’EXPOSITION AUX RADIOFRÉQUENCES POUR LE LECTEUR AI1422

UTILISANT UNE ANTENNE EXTERNE SUR LA BANDE

DE FRÉQUENCES DE 902.25 À 903.75 ET DE 910.00 À 921.50 MHZ

Plusieurs organismes (OSHA, FCC, IC) publient des directives environnementales qui recommandent des

limites d’exposition maximale autorisée (normes MPE) ou des niveaux d’exposition «sûrs» auxquels cet

appareil se conforme. Pour faire en sorte que chaque utilisateur final ait connaissance des directives de

sécurité qui le concerne, que ce soit dans son travail (accès contrôlé) ou pour la population générale/le

grand public (accès non contrôlé), TransCore présente les niveaux recommandés par chaque organisme

dans ses recommandations sécuritaires détaillées dans la dernière section.

OSHA OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION

Dans le Code des réglementations fédérales (CFR), Titre 29, Partie 1910, Sous-partie G 1910.97, intitulée

«Nonionizing radiation» (Rayonnements non ionisants), l’OSHA (organisme américain) recommande un

plafond d’exposition maximale de 10 milliwatts par centimètre carré (mW/cm2) pendant une période de

0,1 heure (soit 6 minutes). En utilisant la fréquence de 915 MHz (milieu de la bande de fréquences de cet

appareil) et le gain d’antenne maximal pour lequel cet appareil a reçu une certification d’utilisation dans une

installation finale, la distance minimale sécuritaire est de 20 cm (8 po).

FCC FEDERAL COMMUNICATION COMMISSION

Dans le Code des réglementations fédérales (CFR), Titre 47, Chapitre I, Sous-chapitre A, Partie 1, Sous-partie

I, Section 1.1310 intitulée «Radiofrequency radiation exposure limits» (Limites d’exposition aux rayonnements

de radiofréquence), la FCC (organisme américain) établit les limites d’exposition maximale autorisée (normes

MPE) comme suit :

Exposition professionnelle/contrôlée

Densité de puissance = fréquence (en MHz)/300 mW/cm2 avec une durée moyenne de 6 min.

Exposition de la population générale/non contrôlée

Densité de puissance = fréquence (en MHz)/1500 mW/cm2 avec une durée moyenne de 30 min.

En utilisant la fréquence de 915 MHz (milieu de la bande de fréquences de cet appareil) et le gain

d’antenne maximal pour lequel cet appareil a reçu une certification d’utilisation dans une installation finale,

la distance minimale sécuritaire est la suivante : les distances MPE minimales sont de 36 cm (14 po) pour

l’environnement professionnel/contrôlé et de 80,5 cm (31,5 po) pour la population générale/environnement

non contrôlé.

INDUSTRIE CANADA INNOVATION, SCIENCES ET DÉVELOPPEMENT ÉCONOMIQUE CANADA

Le Cahier des charges sur les normes radioélectriques 102, 5e édition, d’Industrie Canada (un ministère

du Gouvernement du Canada) établit des recommandations pour une densité de puissance maximale

sécuritaire en W/m2. Ainsi, l’exposition maximale admissible pour la population générale/non contrôlée à

915 MHz est calculée à 2,77 W/m2. La durée moyenne est de 6 minutes. Les limites d’exposition maximale

autorisée (normes MPE) sont les suivantes :

TransCore Proprietary viii

Environnement contrôlé

AI1422E Reader

Densité de puissance = 0,6455*fréquence (en MHz)

0,5

W/m2 avec une durée de référence de 6 min.

Grand public/environnement non contrôlé

Densité de puissance = 0,02619*fréquence (en MHz)

0,6834

W/m2 avec une durée de référence de 6 min.

En utilisant la fréquence de 915 MHz (milieu de la bande de fréquences de cet appareil) et le gain

d’antenne maximal pour lequel cet appareil a reçu une certification d’utilisation dans une installation finale,

la distance minimale sécuritaire est la suivante : les distances MPE minimales sont de 45 cm (18 po) pour

l’environnement professionnel/contrôlé et de 120 cm (47 po) pour le grand public/environnement non

contrôlé.

RECOMMANDATIONS DE TRANSCORE SUR LES LIMITES D’EXPOSITION MAXIMALE AUTORISÉE

NORMES MPE

Les densités de puissance et la distance MPE calculées par chaque organisme pour un

environnement donné sont présentées ci-dessous.

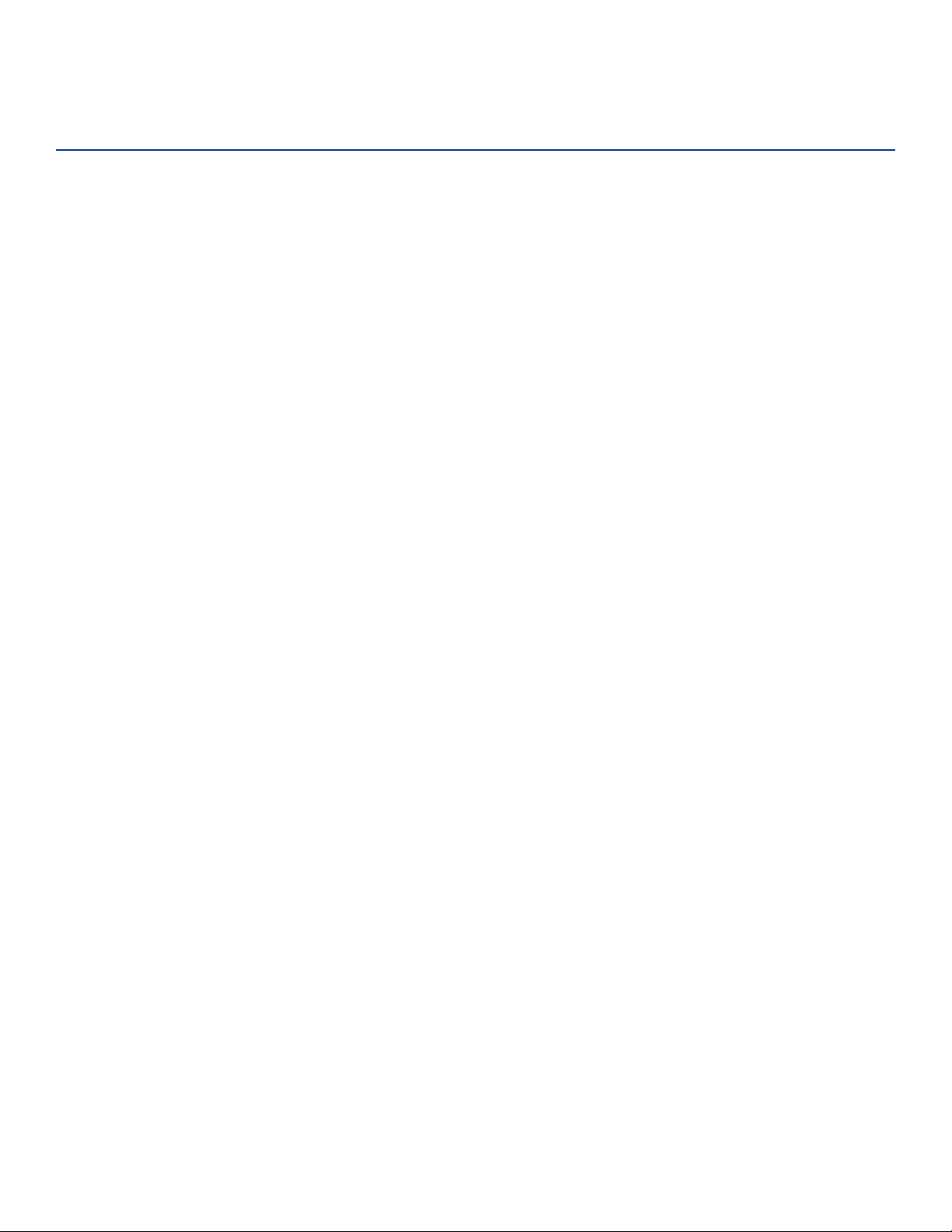

Exposition professionnelle/environnement contrôlé

Organisme

Densité de puissance (mW/

cm2)

Distance MPE minimale

po cm

Durée (en

min.)

OSHA 10 8 20 6

FCC 3,05 14 36 6

IC 1,95 18 45 6

Population générale/environnement non contrôlé

Organisme

Densité de puissance (mW/

cm2)

Distance MPE minimale

po cm

Durée (en

min.)

OSHA 10 8 20 6

FCC 0,61 31,5 80 30

IC 0,28 47 120 6

Avec l’appareil installé et fonctionnant à la puissance de transmission maximale de 2,0 W (33 dBm), 0 dB

d’atténuation de transmission, et en utilisant le gain d’antenne maximal pour lequel l’appareil a reçu une

certification, les recommandations pour chaque environnement d’exploitation sont les suivantes :

1 ) L’antenne devrait être installée à au moins 120 cm (47 po) de la population générale/du grand

public, c’est-à-dire d’un environnement non contrôlé.

2 ) Le personnel d’entretien (c’est-à-dire dans un environnement professionnel/contrôlé) doit

rester à au moins 45 cm (18 po) de l’antenne et limiter son temps d’exposition à 6 minutes

lorsque l’appareil est en fonctionnement.

TransCore Proprietary

ix

User Guide

Table of Contents

Purpose of This Guide ............................................. i

Licensing Requirements............................................iii

System Overview

System Overview .................................................2

Transponder Interrogator ...........................................3

Interface Connections

Description of AI1422E Reader System...............................6

Antenna Interface .................................................6

Ethernet (M12) Interface............................................6

Customer I/O Interface.............................................7

Power Connector .................................................8

Interface Selection Switch ..........................................8

Main RS–232 Interface.............................................8

Aux RS–232 Interface .............................................9

Installation Instructions

General ......................................................... 11

Mechanical ..................................................... 11

Electrical Power.................................................. 11

Installing Wires into Connector.....................................14

Protective Earth Ground Terminal ..................................16

System Test Procedures

System Test Procedures...........................................18

Required Tools and Equipment .....................................18

Testing Basic Operation ...........................................18

Reading the Tag..................................................19

Communications Protocols

Communications Protocols ........................................22

Basic Protocol ...................................................22

Command Codes

Command Codes.................................................25

TransCore Proprietary x

Operating Modes ................................................25

Command List ...................................................31

Reader Mode Control .............................................32

Communications Port Control......................................32

Real-time Clock ..................................................34

Append Information ..............................................35

ID Filtering ......................................................37

Reader Status....................................................43

Reader Control Functions .........................................54

Auxiliary Reader Control ..........................................68

Troubleshooting and Maintenance

Required Tools and Equipment .....................................71

Troubleshooting .................................................71

AI1422E Reader

Error Messages ..................................................73

AI1422E Reader Repair............................................74

Technical Support ................................................74

Character Conversion

Appendix A......................................................76

Technical Specifications

Appendix B......................................................78

Lantronix® Ethernet Module Configuration

Appendix C......................................................81

Interface through Ethernet Port ....................................82

Command Quick Reference

Appendix D.....................................................88

TransCore Proprietary

xi

User Guide

List of Figures

Figure 1 Typical Reader System Configuration . . . . . . . . . . . . .2

Figure 2 Antenna-to-Tag Centerline Tolerance . . . . . . . . . . . . . .4

Figure 3 Front Panel of an AI1422E Reader . . . . . . . . . . . . . . .6

Figure 4 Pin Designations for M12 Connector . . . . . . . . . . . . .6

Figure 5 Customer I/O Interface Pin-out . . . . . . . . . . . . . . . .7

Figure 6 RS–232, DB–9 Interface Connector Pin-outs. . . . . . . . .9

Figure 7 AI 1422E Dimensions . . . . . . . . . . . . . . . . . . . . . 11

Figure 8 Power Connector . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9 Remove Plug from Receptacle . . . . . . . . . . . . . . . . 11

Figure 10 Remove Screw and Plug Insert . . . . . . . . . . . . . . . 12

Figure 11 Remove Wire Harness from Insert Clip . . . . . . . . . . . 12

Figure 12 Cable Gland Assembly - Rear of Plug . . . . . . . . . . . 12

Figure 13 Pin Numbering: Plug Wire Harness . . . . . . . . . . . . . 12

Figure 14 Thread Wires Through Assembly . . . . . . . . . . . . . . 13

Figure 15 Insert Wires into Pins. . . . . . . . . . . . . . . . . . . . . 13

Figure 16 Insert Wire Harness into Insert Clip. . . . . . . . . . . . . 13

Figure 17 Reassemble and Tighten Set Screw . . . . . . . . . . . . 13

Figure 18 Reassemble Cable Gland Assembly . . . . . . . . . . . . 14

Figure 19 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 20 Reinstall Power Connector . . . . . . . . . . . . . . . . . 14

Figure 21 Power the Unit to ON . . . . . . . . . . . . . . . . . . . . 15

Figure 22 Power the Unit to OFF. . . . . . . . . . . . . . . . . . . . 15

Figure 23 Connector Latch . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 24 Remove Plug from Receptacle . . . . . . . . . . . . . . . 16

Figure 25 Location of Ground Stud . . . . . . . . . . . . . . . . . . 16

Figure 26 Proper Single Ground Screw Diagram. . . . . . . . . . . 16

Figure 27 Power Source Connections. . . . . . . . . . . . . . . . . 18

Figure 28 AI1422E Reader Mechanical Dimensions . . . . . . . . . 79

TransCore Proprietary xii

AI1422E Reader

Figure 29 Install the Stand-alone DeviceInstaller. . . . . . . . . . . 82

Figure 30 Launch DeviceInstaller from the Start Menu . . . . . . . 82

Figure 31 Change IP Address and Submet Mask of NIC Card. . . . 83

Figure 32 Prompt if Computer has Multiple NIC cards . . . . . . . 83

Figure 33 NIC Card Options Screen . . . . . . . . . . . . . . . . . .84

Figure 34 Check for Updates Prompt . . . . . . . . . . . . . . . . . 84

Figure 35 Disable Firewall to Allow Access. . . . . . . . . . . . . . 84

Figure 36 Lantronix DeviceInstaller Menu . . . . . . . . . . . . . . 85

Figure 37 Finding the IP address of a Reader. . . . . . . . . . . . . 85

Figure 38 PuTTY Configuration Screen . . . . . . . . . . . . . . . .86

Figure 39 PuTTY Connection Screen . . . . . . . . . . . . . . . . . 86

TransCore Proprietary

xiii

User Guide

List of Tables

Table 1 Data Mode Commands . . . . . . . . . . . . . . . . . . . . 26

Table 2 Asynchronous Interrogator Tag Data Message Fields . . . 27

Table 3 Status Request Message Fields . . . . . . . . . . . . . . . . 28

Table 4 Status Response Message Fields . . . . . . . . . . . . . . . 29

Table 5 Retransmit Request Message Fields . . . . . . . . . . . . .30

Table 6 Retransmit Response Message Fields . . . . . . . . . . . .30

Table 7 Select Baud Rate Commands . . . . . . . . . . . . . . . . .33

Table 8 Select Stop Bits Commands . . . . . . . . . . . . . . . . . . 33

Table 9 Select Parity Commands. . . . . . . . . . . . . . . . . . . . 34

Table 10 Append Time and Date Commands . . . . . . . . . . . . . 36

Table 11 Append Auxiliary Information Commands . . . . . . . . . 37

Table 12 Unique ID Code Criteria. . . . . . . . . . . . . . . . . . . . 39

Table 13 Select Valid Code Commands and Frames . . . . . . . . . 39

Table 14 Open/Closed Conditions for Output Status . . . . . . . . . 47

Table 15 Open/Closed Conditions for Output Status (IAG). . . . . . 47

Table 16 Open/Closed Conditions for Input Status . . . . . . . . . . 48

Table 17 Output Control Commands . . . . . . . . . . . . . . . . . . 56

Table 18 RF Control Commands . . . . . . . . . . . . . . . . . . . .57

Table 19 RF Attenuation Command Variables. . . . . . . . . . . . . 58

Table 20 Select RF Operating Frequency Commands. . . . . . . . 59

Table 21 Output Pulse Duration Commands . . . . . . . . . . . . . 62

Table 22 Presence Without Tag Report Commands. . . . . . . . . 63

Table 23 RF Control Algorithm Commands . . . . . . . . . . . . . .64

Table 24 Timeout Period Values . . . . . . . . . . . . . . . . . . . .65

Table 25 Input Inversion Options. . . . . . . . . . . . . . . . . . . . 66

Table 26 Input Status Change Report Options . . . . . . . . . . . . 68

Table 27 Error Messages . . . . . . . . . . . . . . . . . . . . . . . .73

Table 28 TransCore 6-Bit-Per-Character Conversion . . . . . . . . 76

Table 29 AI1422E Reader System Specifications . . . . . . . . . . . 78

TransCore Proprietary xiv

AI1422E Reader

Table 30 AI1422E Default Configuration Settings . . . . . . . . . . 88

Table 31 Legacy Commands . . . . . . . . . . . . . . . . . . . . . . 90

Table 32 AI1422E Commands Listed Numerically . . . . . . . . . . 91

Table 33 AI1422E Commands Listed Alphabetically . . . . . . . . 102

TransCore Proprietary

xv

1

System Overview

User Guide

Power

Source

AI1422E

Host Processor

System

RS232

RS422

Ethernet

Antenna

TAG

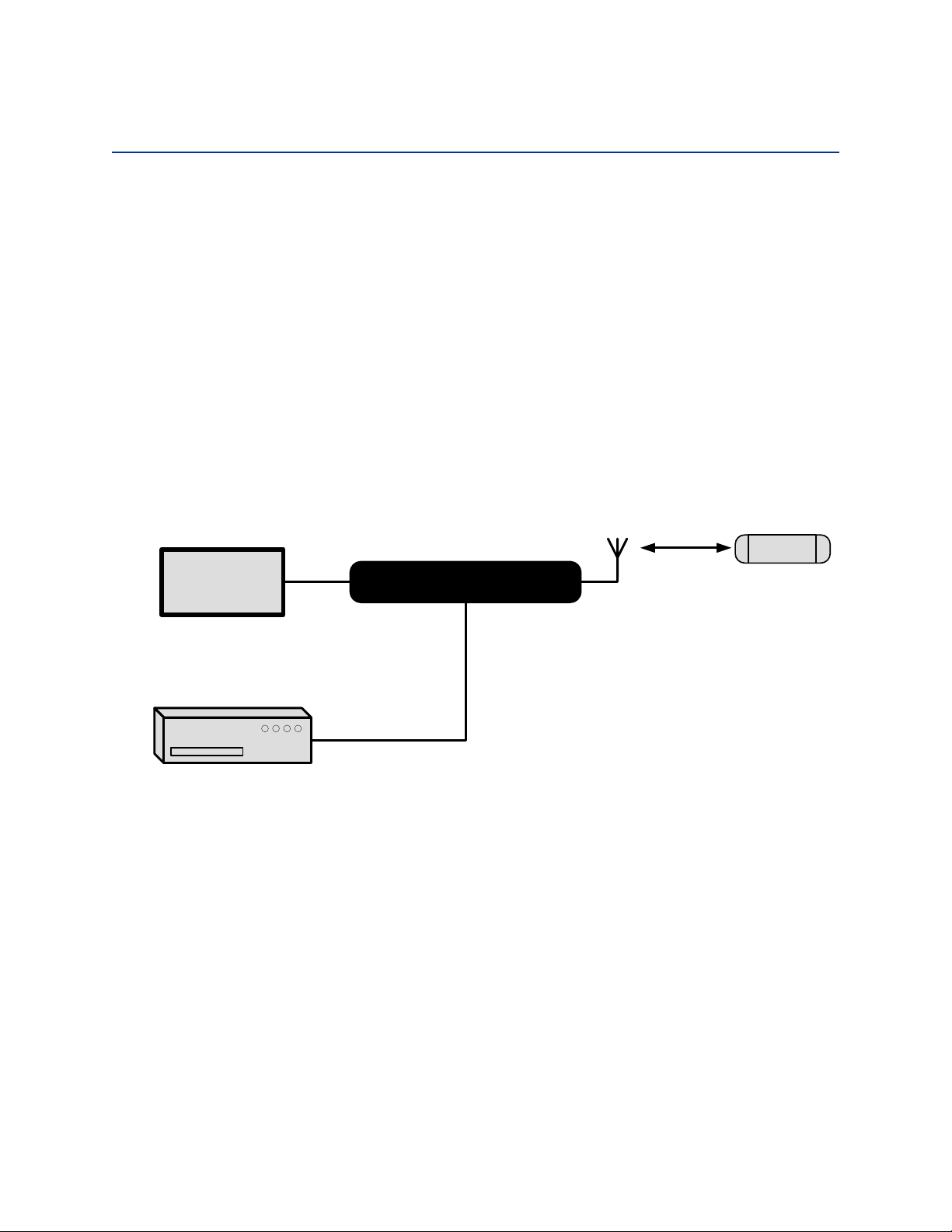

System Overview

The AI1422E Reader System is a microprocessor-controlled, single-antenna unit that

uses a unique communications protocol to interface with vehicle identification (ID)

equipment.

This reader system uses radio frequency (RF) energy to read data from tags. The AI1422E

Reader System then decodes the tag ID information, validates the ID code, and transmits

tag data directly to a host processor for real-time data processing and use.

Communications (terminal) programs usually do not provide adequate data processing

capability. Your host computer software can be customized to provide the required

capabilities.

The AI1422E Reader System consists of the AI1422E Reader, which consists of a reader and

RF module, combined with a TransCore antenna, a TransCore tag, a host processor system,

and a power source. Figure 1 illustrates a typical reader system configuration.

Figure 1 Typical Reader System Configuration

TransCore Proprietary 2

Transponder Interrogator

The transponder interrogator reads 60/120 bits of user-programmable data in the

transponder.

The transponder interrogator is operated in a continuous read mode, and any tag

entering its read field has its data automatically read and relayed to the host computer. In

many applications this function is implemented by installing the reader on a vehicle with

restricted movement, such as a railcar or monorail bus. The tags are embedded in the

roadway at various locations in the vehicle’s path. The data read from the tag allows the

host computer to assess the vehicle’s location and make any appropriate response to that

information.

The transponder interrogator is an independent tag decoder that combines a reader and

RF source to provide automatic identification and data storage within a single, compact

unit. The transponder interrogator includes the following components:

• 19-inch rack-mount design (1U)

• RS232/RS422/Ethernet input/output (I/O) link

AI1422E Reader

• Real-time clock

• Reader and RF module, combined in one unit

Reader Power Regulation and Filtering

The reader system uses an input voltage ranging from 24VDC to 110VDC (12VDC to

150VDC Min/Max). The AI1422E Reader System incorporates a high-performance, DC-toDC power supply that converts voltage in this range to 24VDC. This voltage conversion is

internal to the unit, and should be transparent to the end-user.

Antenna

TransCore has multiple antennas for use with the AI1422E Reader, covering multiple

applications such as heavy rail, light rail, European regions, and more. Contact TransCore

for assistance with antenna selection.

Tags (Transponders)

The AI1422E Reader System can use TransCore’s half-frame or full-frame read-only tags.

When selecting a tag for an application that requires the tag to be placed on the road bed,

several design elements need to be kept in mind.

Beam-powered tags have a shorter footprint than battery or switch-powered tags, and thus

the maximum top speed of the vehicle will be less, all other factors equal.

Battery tags have an inherently larger footprint, but the battery life limitation will require the

operating company to replace the tags every 8 to 10 years. The presence of the battery

and its reactive mass reduces the reliability of the tag, particularly when the tag is placed

near high shock or vibration locations such as switches.

Switch-powered tags have RF characteristics similar to battery tags, and the tags are

powered by inductive power derived from railway switch power.

TransCore Proprietary

3

User Guide

Tag Mounting

All tags used with the AI1422E must be mounted on a flat metal plate. The internal

antennas of these tags are tuned for the backplane of the tag to be in contact with a

flat metal surface. This metal surface does not need to be extended beyond the outer

dimensions of the tag, and having a larger metal surface will not aect the immediate

performance of the tag.

Metal located to the sides or above the tag can aect the tag’s performance. Metal

surfaces or objects should not be placed closer than 1 inch (2.5 cm) to the side edges

of the tag to ensure that the tag’s antenna tuning remains within design criteria. Metal

placed above the tag can cause shadowing of the RF beam, both in the incident and

return directions, and should be avoided. The only exception to this rule would be metal

placed for the purpose of aecting the read range of the tag or footprint of the system, and

the placement of such metal should be done with careful planning and testing to ensure

proper system performance. With battery-powered tags, the arrangement of intentional

metallic obstructions may be the best way to limit the broad footprint of these tags, as

well as improve the repeatability of the TLS signal with respect to its absolute position

relative to the tag. These tag mounting details would need to be made by the customer on

the basis of each customer’s overall system design and requirements. Keep in mind that

metal placed too close in proximity to the tag will aect the tag’s antenna tuning, and may

unintentionally aect principal design parameters such as VSWR or the impedance match

of single paths internal to the tag, to name a few examples.

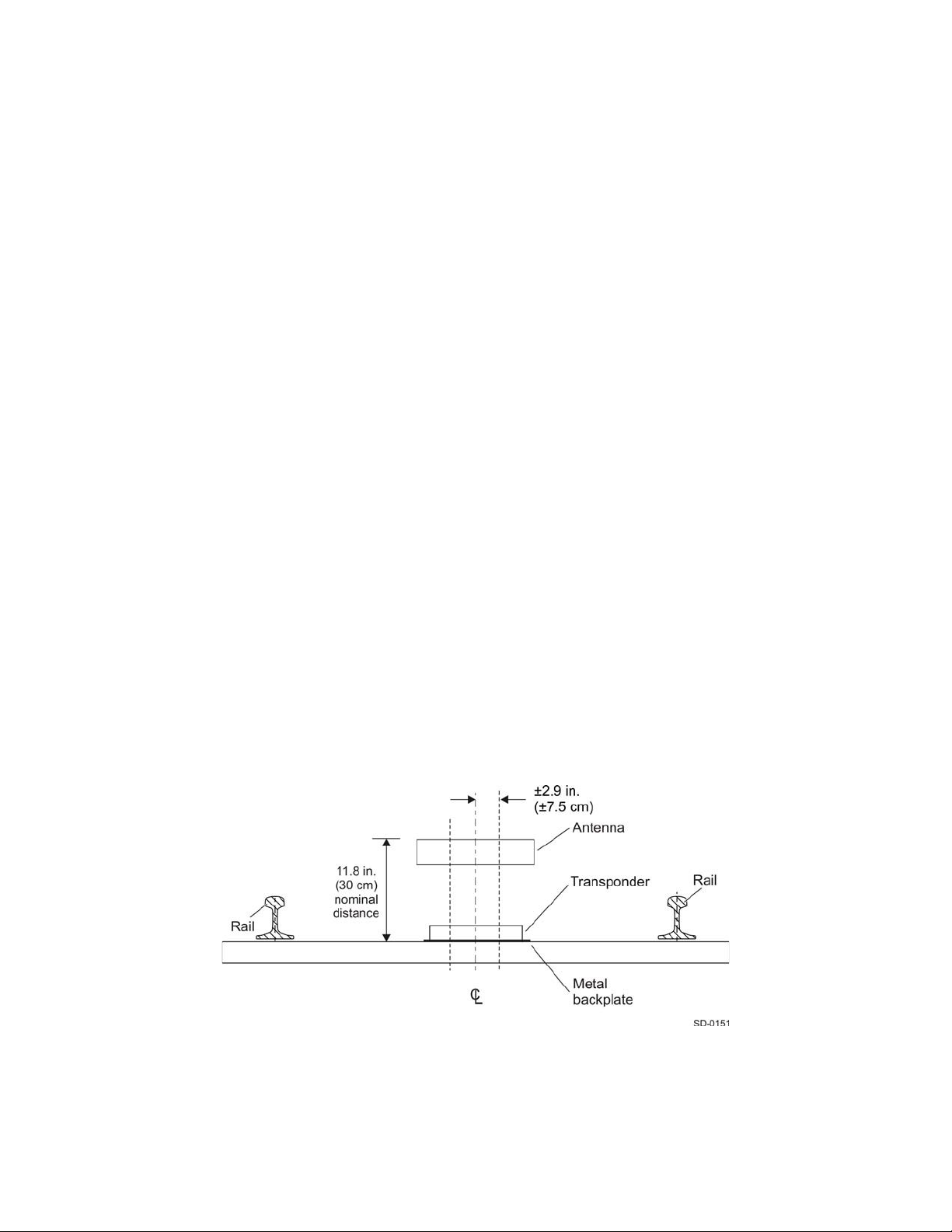

Antenna-to-Tag Centerline Alignment

For best performance, mount tags so that the centerline of the tags and the centerline of

the reader antennas are within ±2.9 inches (±7.5 cm) of each other (Figure 2).

Antenna-to-tag Distance

Many installations have been installed with a nominal 11.8-inch (30-cm) distance from the

backplane of the reader antenna to the back edge of the tag (Figure 2).

Figure 2 Antenna-to-Tag Centerline Tolerance

TransCore Proprietary 4

2

Interface Connections

User Guide

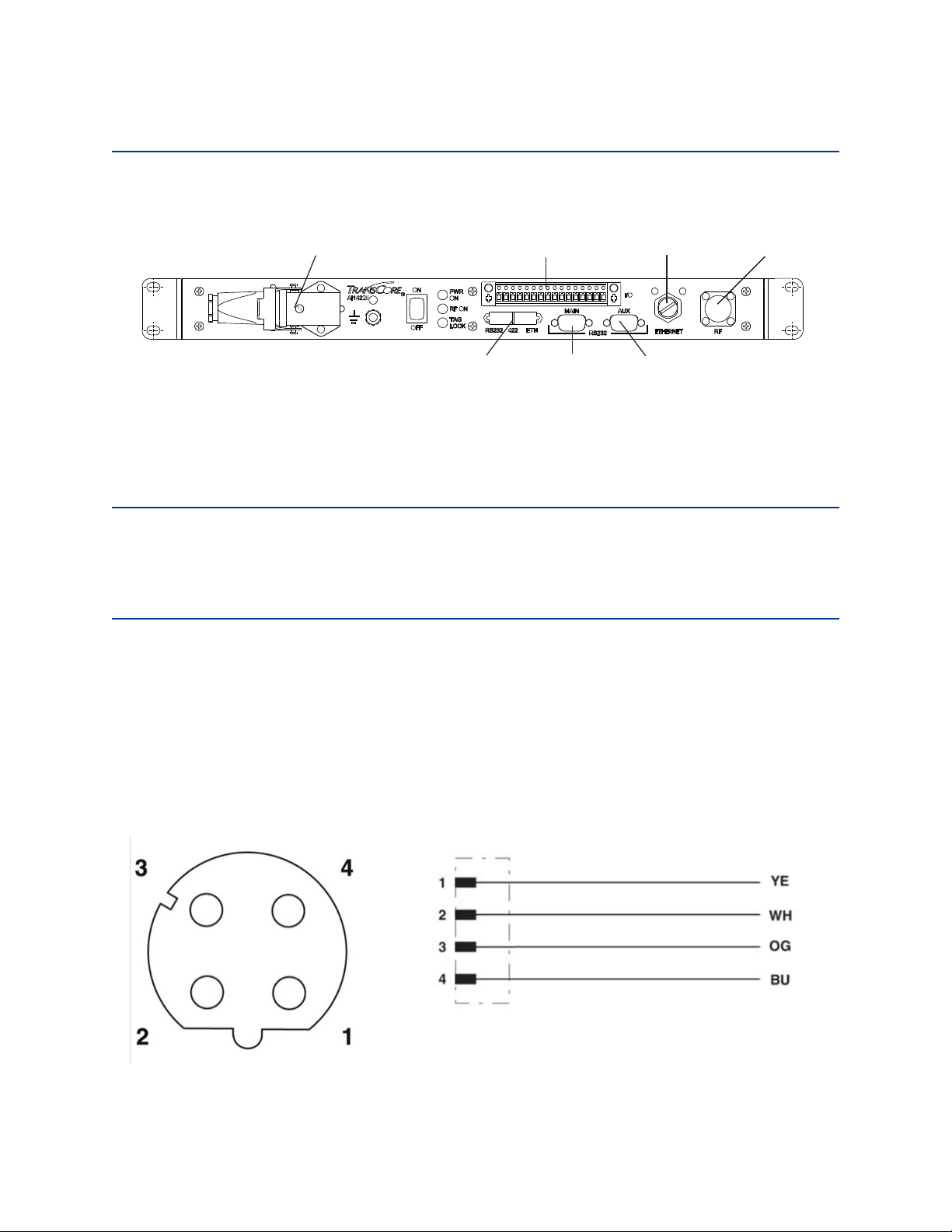

Description of AI1422E Reader System

The interface connectors are located on the AI1422E Reader System front panel as shown

in Figure 3.

POWER

CONNECTOR

INTERFACE

SELECTION

SWITCH

Figure 3 Front Panel of an AI1422E Reader

Antenna Interface

Attach the antenna cable directly to the antenna interface on the front panel of the AI1422E

Reader System. The antenna cable length depends on the installation.

Ethernet (M12) Interface

The AI1422E Reader incorporates a Lantronix® Ethernet to Serial conversion module, which

is used to add full Ethernet compatibility into the reader. This module is located on the

interface board internal to the reader, and is addressable through Lantronix host software.

More details on this module can be found in “Appendix C” on page 81.

I/O

INTERFACE

MAIN RS–232

INTERFACE

ETHERNET

INTERFACE

AUX RS–232

INTERFACE

ANTENNA

INTERFACE

The Ethernet Interface utilizes a 4-pin, D-coded M12 connector (defined in IEC 61067-2-101

Amendment 1 as the Industrial Ethernet standard). This connector is pin-to-pin compatible

with RJ45 10/100Mbps Ethernet.

Figure 4 shows the connector pin designations.

Figure 4 Pin Designations for M12 Connector

TransCore Proprietary 6

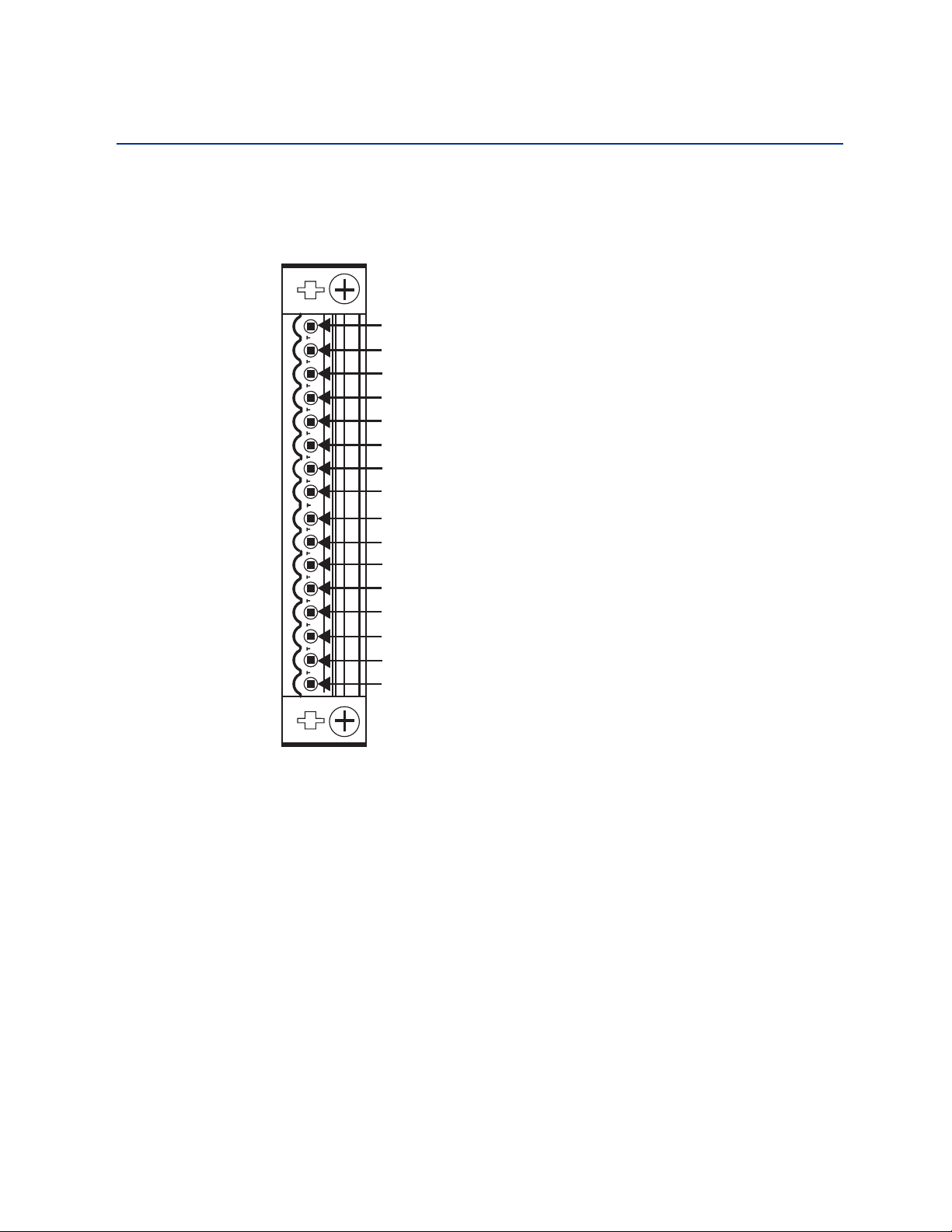

Customer I/O Interface

Pin 1 – I/O Ground

Pin 2 – Trigger Signals

Pin 3 – I/O Ground

Pin 4 – N/C

Pin 5 – RS422 Ground

Pin 6 – RS422 RXPin 7 – RS422 RX+

Pin 8 – RS422 TXPin 9 – RS422 TX+

Pin 10 – N/C

Pin 11 – Wiegand 1

Pin 12 – I/O Ground

Pin 13 – Wiegand 0

Pin 14 – RF Power Output

Pin 15 – Main Power Output

Pin 16 – Tag Lock Output

The customer I/O interface connector contains the tag lock, main power, RF Power outputs

(solid state), trigger signals (solid state), and RS–422 (Figure 5).

A mating connector for the customer I/O interface is supplied with each unit. This

connector allows a screw terminal, point-to-point wiring interface.

AI1422E Reader

Figure 5 Customer I/O Interface Pin-out

Trigger Signals (Pin 2)

RS–422 Interface (Pins 5-9)

The trigger connection turns on the RF power when shorted to I/O ground and the AI1422E

Reader System has been programmed with the RF Follows Trigger command (!642).

The RS–422 interface is a terminal block connector. In real-time mode, tag IDs are read

and passed on to the host processor.

RF Power Output (Pin 14)

The TTL RF power LED goes active high when the reader system is configured for the

RF power to be on and the ON/OFF switch is set to ON. The RF power signal may be

connected to an LED for monitoring purposes.

The main power relay is referenced to 5V

and I/O Ground.

iso

TransCore Proprietary

7

User Guide

Main Power Output (Pin 15)

The TTL main power signal goes active high when the ON/OFF switch on the front panel

is switched to on. The main power signal may be connected to an LED for monitoring

purposes.

The main power relay is referenced to 5V

iso

Tag Lock Output (Pin 16)

The transistor-transistor-logic (TTL) lock signal shows the presence of a tag. The lock signal

goes active high when a valid tag is in the RF field of the antenna and may be connected to

an LED for monitoring purposes.

The tag lock relay is referenced to 5V

signal can be increased by using a 10K ohm resistor.

and I/O Ground. The falling edge of the tag lock

iso

Power Connector

The power connector on the front panel of the AI1422E Reader System is a panel mount,

right angle, EPIC ® HA-3 style 3 pin plus ground rectangular connector.

Interface Selection Switch

The AI1422E Reader incorporates a communications interface selection switch, which

allows on-the-fly changes to the communications mode. This switch allows selecting the

reader’s receive communications interface. All communications interfaces are configured

for simultaneous transmit, but only the interface selected by the switch is active for

commands transmitted into the reader.

and I/O Ground.

Main RS–232 Interface

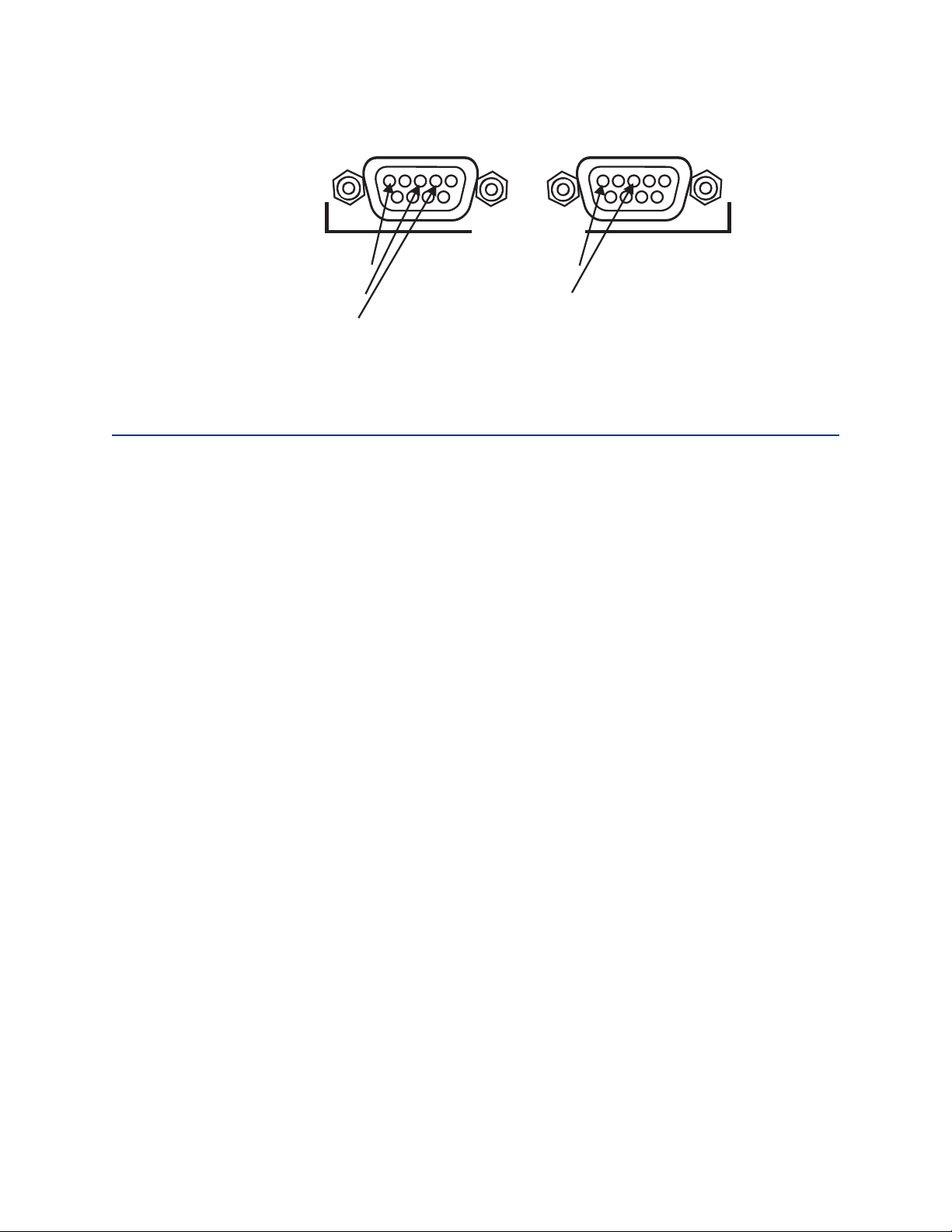

The main RS–232 interface is a standard DB–9 plug connector used with a host processor.

In real-time mode, tag IDs are read and passed on to the host processor. Figure 6

illustrates the RS–232, DB–9 plug connector pin-outs.

TransCore Proprietary 8

RS232

AI1422E Reader

AUXMAIN

PIN5 – GROUND

PIN3 – RX DATA

PIN2 –TX DATA

Figure 6 RS–232, DB–9 Interface Connector Pin-outs

Aux RS–232 Interface

The auxiliary RS–232 interface is used as a backup monitoring system to the main RS–232

interface. The auxiliary interface monitors data from the transponder interrogator. The

auxiliary RS–232 interface is a standard DE09 plug connector. This port is not wired to

receive data and cannot accept commands.

PIN5 – GROUND

PIN3 – TX DATA

TransCore Proprietary

9

3

Installation Instructions

General

Equipment should be installed and serviced only by skilled, qualified personnel. Equipment

should be installed only in RESTRICTED ACCESS LOCATIONS.

Mechanical

The AI1422E has a standard 1U sized hole pattern. For installation, use No. 10 rack US

screws and torque to 25-30 in-lbs. For metric, use M6 screws and torque to 3-4 N-m. Refer

to Figure 7 for diagram and dimensions.

1.25

AI1422E Reader

18.35

Figure 7 AI 1422E Dimensions

Electrical Power

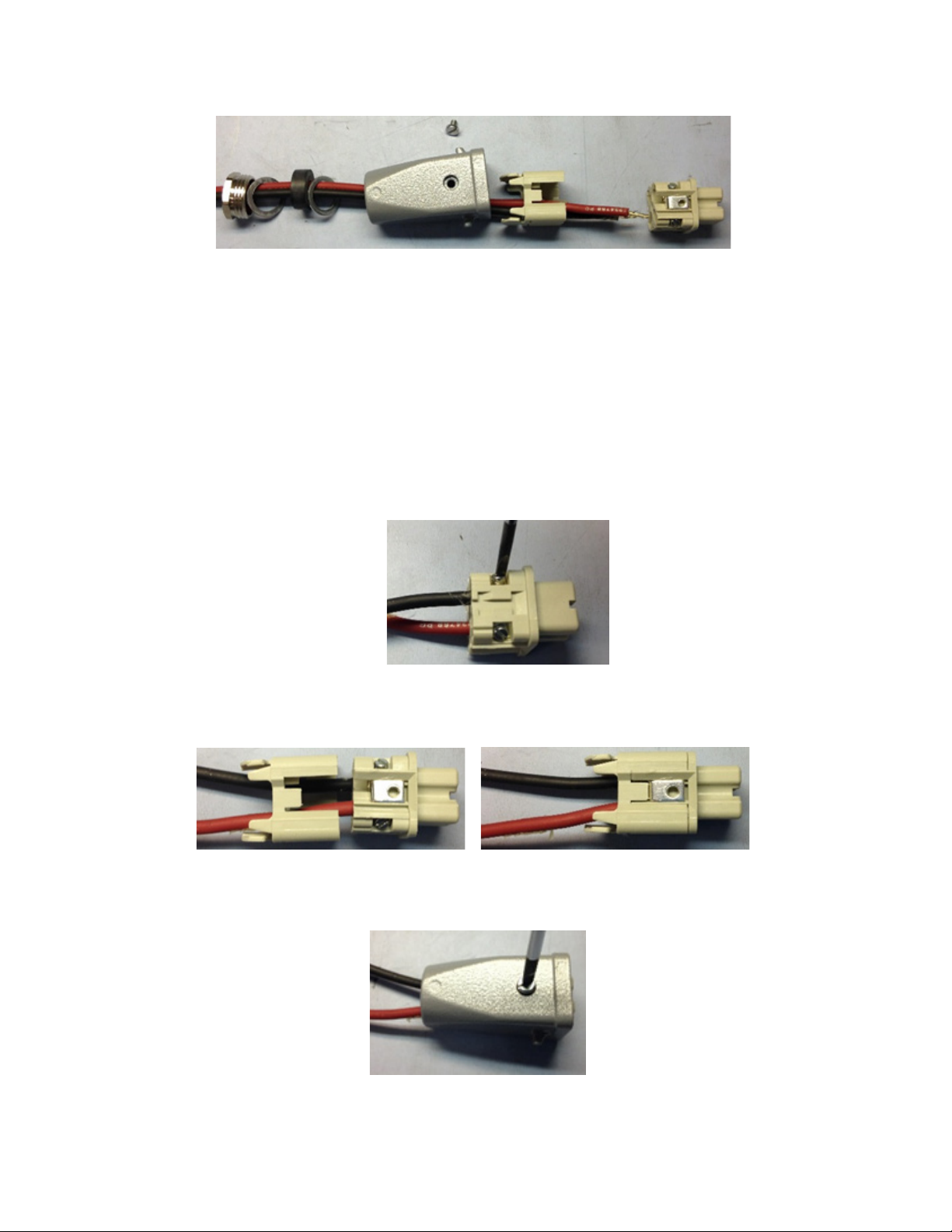

Assembling the Power Connector

WARNING: Ensure that the ON/OFF switch is in the OFF position and the PWR

ON indicator is not illuminated before servicing the unit.

1. Unpack the unit from the shipping crate and locate the power connector on the front

panel (Figure 8).

Figure 8 Power Connector

2. Unlatch the plug from the receptacle on the unit and remove it (Figure 9).

Figure 9 Remove Plug from Receptacle

TransCore Proprietary

11

User Guide

3. Locate the set screw on the plug housing. Remove the screw and plug-insert from the

housing (Figure 10).

Figure 10 Remove Screw and Plug Insert

4. Locate the tabs on the plug insert. Squeeze the tabs to remove the wire harness from

the insert clip (Figure 11).

Figure 11 Remove Wire Harness from Insert Clip

5. Remove the cable gland assembly from the rear of plug (Figure 12).

Figure 12 Cable Gland Assembly - Rear of Plug

6. Locate the wiring diagram label on the top panel of the 1422E and note the

corresponding pin numbering on the plastic of the plug wire harness (Figure 13).

Figure 13 Pin Numbering: Plug Wire Harness

7. Thread the +Vin and -Vin wires through the cable gland, housing, and insert assemblies

(Figure 14).

TransCore Proprietary 12

AI1422E Reader

Figure 14 Thread Wires Through Assembly

NOTE: The Power cable requires an 18 AWG stranded wire or larger, with a minimum

insulation rating of 70C and 150V. Wire must meet EN 60950-1 or other applicable

component standards.

An external 10A-rated overcurrent protection device is required in-line with positive

terminal for proper system operation and protection. Device must meet EN60950-1

or applicable component standard(s).

8. Loosen the wire retention screws on the wire harness. Insert the wires into their

respective pins and tighten the retention screws to ensure wires cannot be removed

(Figure 15).

Figure 15 Insert Wires into Pins

9. Insert the wire harness into the insert clip until the tabs click into place (Figure 16).

Figure 16 Insert Wire Harness into Insert Clip

10. Place the insert back into the plug housing and tighten the set screw (Figure 17).

Figure 17 Reassemble and Tighten Set Screw

TransCore Proprietary

13

User Guide

Installing Wires into Connector

NOTE: If the set screw will not tighten, remove the insert and ensure the set screw is

properly aligned with the hole on the plug housing.

11. Insert the cable gland assembly back into the plug housing. Using a wrench, tighten the

gland nut. Connect +Vin and -Vin to the power source (Figure 18).

Figure 18 Reassemble Cable Gland Assembly

NOTE: Unit MUST be installed as close to the power source as possible.

WARNING: Ensure ON/OFF switch is in OFF position and the PWR ON indicator is

not illuminated before connecting/disconnecting from the power supply.

Connecting power

1. Ensure that the ON/OFF switch is in the OFF position (Figure 19).

2. Reinstall the power connector. Press the latch firmly to ensure proper connection

(Figure 20).

Figure 19 Power Switch

Figure 20 Reinstall Power Connector

TransCore Proprietary 14

3. Toggle the ON/OFF switch to the ON position and ensure the PWR ON indicator is

illuminated (Figure 21).

Disconnecting power

1. Toggle the ON/OFF switch to the OFF position and ensure that the PWR ON indicator

is not illuminated (Figure 22).

AI1422E Reader

Figure 21 Power the Unit to ON

Figure 22 Power the Unit to OFF

2. Unlatch the connector (Figure 23).

Figure 23 Connector Latch

TransCore Proprietary

15

User Guide

Protective Earth Ground Terminal

For safety and proper operation, the 1422E must be properly fastened to a protective earth ground.

The ground stud is located on the front panel of the 1422E between the power connector and ON/

OFF switch (Figure 25).

3. Gently remove plug from receptacle (Figure 24).

Figure 24 Remove Plug from Receptacle

Figure 25 Location of Ground Stud

For proper grounding, refer to the diagram in Figure 26.

NOTE: Grounding cable should be 16 AWG or larger

Earth Ground

Figure 26 Proper Single Ground Screw Diagram

TransCore Proprietary 16

4

System Test Procedures

User Guide

1

2 3

Chassis (GND)

-VDC

+12 to +150VDC

System Test Procedures

Required Tools and Equipment

This chapter provides testing procedures that will help you fine-tune your reader system

and test basic operation, measure radio frequency (RF) power, measure system noise, read

tags, and monitor the system.

The following tools and equipment are required:

• 50-ohm, 5-watt (W) load (N-type connector)

• Personal computer (PC) with terminal emulator software

• Appropriate power source for your reader

• Digital multimeter

• Antenna, cable, and connectors

Testing Basic Operation

To test the system operation, configure the reader system as follows:

1. Configure a terminal emulator (a PC using communications software) to 9600 baud, no

parity, 8 data bits, and 1 stop bit (factory default settings for the reader).

2. Connect the emulator to the main RS–232 interface located on the front panel of the

reader system.

3. Slide the Interface Selection switch on the front panel of the reader to RS–232.

4. Toggle the ON/OFF switch located on the front panel of the reader system to o.

5. Connect a power source to pins 1 (+) and 3 (-) on the DC power input front panel

connector (Figure 27).

Figure 27 Power Source Connections

6. Toggle the ON/OFF switch located on the front panel of the reader system to o.

7. Enter the command !01 or ~~CC (CC must be entered in upper case) and press

Enter.

TransCore Proprietary 18

AI1422E Reader

Note: For information on entering command codes, refer to “Communications

Protocols” on page 22.

8. Input !22 and press Enter. The time and date will be returned.

If the time and date are not received, check communications

connections, cycle power, and repeat.

If the time and date are incorrect, use !20 and/or !21 to correct this information, then input

the following commands:

!20hh:mm:ss sets time

!21MM/DD/YY sets date

!642 sets RF to follow the trigger

!41 enables tag reporting

NOTE: !41 command should be used in diagnostic mode only. Do not use in

normal system operation.

The entered command and !Done response will be returned after each properly

executed command.

Reading the Tag

To verify that the AI1422E Reader System is correctly reading tags:

1. Toggle the ON/OFF switch located on the front panel of the reader system to o.

2. Using your own cable, connect the laptop PC to the reader system at the main RS–232

interface.

3. Slide the Interface Selection switch on the front panel of the reader to RS–232.

4. Connect the antenna to the antenna interface on the front panel of the reader system.

5. Toggle the ON/OFF switch located on the front panel of the reader system to on.

6. Connect a jumper between pins 14 (Ground) and 15 (Trigger Input) on the customer I/O

interface to trigger the RF on (“Figure 6 Customer I/O Interface Pin-outs” on page

8).

7. Monitor the LEDs on the box and verify that the main power LED and the RF power LED

are illuminated.

8. Position a programmed TransCore half-frame rail tag with a backplate within 2 to 3 feet

(0.6 to 0.9 m) of the antenna. No other tag can be in this 2 to 3 foot (0.6 to 0.9 m) area

during this test.

9. Verify that the lock LED is illuminated and that the PC is acquiring the tag data.

Note: If the !41 command was issued prior to this test, the PC will be receiving a

continuous stream of tag data. If the !41 command was not issued, the reader

responds with only one response. The Lock LED remains illuminated as long as

there is a tag in the field, but only one response is forthcoming unless the !41

command has been issued.

TransCore Proprietary

19

User Guide

10. Remove the tag from the antenna field. The PC should stop reading the tag data.

11. Disable the trigger by disconnecting the jumper.

12. Toggle the on/o switch located on the front panel of the reader system to o.

Note: Repeat this test several times. Each time, the lock LED should be illuminated

and the PC should be reporting the tag data.

TransCore Proprietary 20

5

Communications Protocols

User Guide

Communications Protocols

The AI1422E Reader supports the following communications protocols:

• Basic

• Error correcting protocol (ECP)

The following protocol information provides reference information relevant to developing

host software.

Communications are performed using the 7-bit ASCII code with optional parity, thus

providing easy setup, testing, and diagnostics with standard ASCII terminals and serial

printers. Parity must be enabled to achieve the specified undetected error rate.

Each message is framed within the start-of-message (som) and end-of-message (eom)

characters so that the host computer can detect the beginning and end of each message.

This convention is most important under marginal communications conditions during which

the host may receive extraneous noise-induced characters between reader transmissions.

In such instances, the host is capable of ignoring any messages that do not conform to the

som...eom frame sequence.

Both data mode and command mode require a two-way message interchange when

using ECP. This interchange is completed by the message recipient returning a message

acknowledgment to the message sender.

With ECP, all transmissions require a message. If a message is not received, the sender will

time out with the same eect as if it had received a negative acknowledgment (from the

host) or an Error message from the AI1422E Reader.

Software (XON/XOFF) flow control is optionally supported. Be careful in the use of XON/

XOFF since noise-induced characters may be interpreted by the AI1422E Reader as the

XOFF character, which would suspend reader output without information reaching the host

computer. For more information refer to “525 Display Communications Protocol Status” on

page 40.

Note: TransCore recommends that XON/XOFF flow control be disabled while using ECP.

Basic Protocol

With basic protocol, messages sent to and from the AI1422E Reader and the host are

transmitted without error checking. For each host transmission, the AI1422E Reader returns

a Done or Error message to the host.

When the host computer is physically close to the AI1422E Reader and no sources of

interference exist, the basic protocol provides reliable communications.

The host must be ready to receive reader-transmitted messages because in basic

protocol the AI1422E Reader does not wait for the host to acknowledge a message before

transmitting the next message. If necessary, the host may halt reader transmissions by

using software or hardware. Refer to “Command Codes” on page 25 for flow control

information.

TransCore Proprietary 22

AI1422E Reader

Error Correcting Protocol

When the quality of data communications is imperative or may be suspect, you can invoke

ECP to ensure the integrity of data transmitted between the AI1422E Reader and the host.

Note: TransCore recommends that basic protocol (not ECP) be used when

commands are entered manually at the keyboard.

Wiegand output is automatically disabled when the reader is put into ECP mode.

Error correction is accomplished with the use of a cyclic redundancy check (CRC) value that

is based on the message data. The originator (reader or host) calculates the CRC value of a

message and includes it in the transmitted message.

The recipient (reader or host) also calculates a CRC value for the received message. If

the transmitted message data is correct, the CRC value calculated by the recipient will

agree with the CRC value calculated by the originator. If the CRC values do not agree, the

recipient rejects the message.

Message sequence numbers are also included when using ECP. These sequence numbers

are checked to determine if the message received has the correct sequence number; if

not, the recipient rejects the message.

Since the seven-bit ASCII code is used and there are eight data bits per character, the

eighth bit can optionally be used to support parity. Where parity is selected, the CRC value

calculation includes the parity of each character in the calculation of the CRC value.

Parity is required to achieve the most reliable communications. If parity is enabled, both the

AI1422E Reader and the host must issue a message if any received character has a parity

error. However, the message must not be transmitted before receipt of the eom character.

In this case, the AI1422E Reader will issue an Error message, and the host computer will

issue a negative acknowledgment message.

TransCore Proprietary

23

6

Command Codes

Command Codes

The AI1422E Reader is delivered from the factory with specified default settings that

determine how the reader operates. Commands transmitted by the host computer can

change the default settings and control additional features. The commands can be

transmitted by manually entering the commands at the host keyboard if the host is in

terminal emulation mode.

Note: If you are using Wiegand mode, you must connect the PC or laptop to the

AI1422E Reader using the RS–232 or RS–422 interface and a terminal emulation

program to send commands to the reader. You can leave the Wiegand interface

connected during this procedure.

Operating Modes

The AI1422E Reader has three modes of operation: Data Mode, Command Mode, and

Download Mode. The software for the AI1422E Reader contains two separate programs —

Boot and Application. The Boot program has control of the AI1422E Reader on startup and

when operating in download mode. The Application program has control of the AI1422E

Reader during a command mode operation and holds the application code. Together, they

control the AI1422E Reader in the three modes of operation.

AI1422E Reader

Data Mode

The AI1422E Reader is in Data Mode on power-up. While in Data Mode, the AI1422E

Reader sends all communications to the host computer as data messages, such as tag IDs

and reports. Reports provide information on Input 0 and Input 1 status changes, a presence

without tag report, and buer overflow information. The host computer can send only four

commands to the AI1422E Reader while in Data Mode (Table 1).

TransCore Proprietary

25

User Guide

Status Request

Retransmit Request

Enter Command Mode

Enter Command Mode

Table 1 Data Mode Commands

Data Mode Commands

Type Description Command

Causes the interrogator to respond with a message

containing information indicating the rolling transponder

seen count and the count of host error messages.

Requests the interrogator to retransmit the last tag ID

read. (BB must be entered in upper case).

Disables reading and reporting of tags and changes

the reader from Data Mode to Command Mode. (CC

must be entered in upper case). Refer to ”Switch to

Command Mode” on page 32.

Disables reading and reporting of tags and changes the

reader from Data Mode to Command Mode.

There is no carriage return or line feed required for any of the ~~ commands. Commands

!01 require a carriage return.

~~@@

~~BB

~~CC

!01

No Response is received with the ~~CC and !01 commands.

Note: The AI1422E Reader transmits ID codes to the host computer when the

AI1422E Reader is in Data Mode. If the AI1422E Reader remains in Command Mode

with tags passing through the read zone, all tag IDs are not reported.

Asynchronous Interrogator Data Message

The interrogator sends the transponder ID in 8-bit ASCII. The message format is as follows:

<7EH><7EH><01H><transponder count><transponder ID><CRC>

The interrogator transmits the most significant bit first. The CRC is calculated, starting with

the most significant byte.

No Response is received with the ~~CC and !01 commands.

Table 2 presents the field descriptions.

TransCore Proprietary 26

Table 2 Asynchronous Interrogator Tag Data Message Fields

Field Description Hex ASCII

Start of Message

Message Type

Transponder Seen

Count

Transponder ID

Cyclical Redundancy

Check

These two bytes, along with the Message

type byte, designate the start of the data

message.

An 01H indicates that this message is a tag

data message.

After power-up, this 8-bit count begins with

01 and is updated each time a tag with a

unique ID moves out of the RF field, then

back into the RF field. This field is useful in

determining whether a train has multiple tag

reads of a given ID due to a change in the

train’s direction.

The data that is programmed into

the transponder. The data within the

transponder is 6-bit ASCII but the

interrogator translates this data into

standard 8-bit ASCII.

An 8-bit cyclical redundancy check (CRC).

Includes the Start of Header, the Seen

Count and the Transponder ID. Refer to

Appendix D for a description of the CRC

algorithm. There is no carriage return or line

feed for this message.

AI1422E Reader

7E7E ~~

01 SOH

00 - FF N/A

- ID

00 - FF N/A

TransCore Proprietary

27

User Guide

Status Request

Start of Message

Message Type

Note: The Status Request should only be used when the train is stationary. Sending

this command simultaneous to tags being read can create a condition whereby the

interrogator will no longer report tags until power cycled.

The Status Request command causes the interrogator to respond with a message

containing information indicating the transponder seen count and host error messages.

The request command format is as follows:

<7EH><7EH><40H><CRC>

Table 3 Status Request Message Fields

Field Description Hex ASCII

These two bytes designate the start of the data

message.

Sending a 40H indicates that this message is a

status request.

7E7E ~~

40 @

The 8-bit cyclical redundancy check (CRC)

includes the Start of Message and Message Type.

Cyclical Redundancy

Check

The response is

<7EH><7EH><02H><Transponder count><host

computer messages-bad CRC><incomplete host message>

<Reserved><Reserved><Reserved><CRC>

See “Appendix D” for a description of the CRC

algorithm. This is a fixed value of 40 hexadecimal,

for this command. There is no carriage return or

line feed for this message.

40 @

TransCore Proprietary 28

AI1422E Reader

Table 4 Status Response Message Fields

Field Description Hex ASCII

Start of Message

Message Type

Transponder Seen

Count

Number of Messages

from Host with Bad

CRCs

Number of incomplete

Host Messages

Reserved Reserved 0 NUL

Reserved Reserved 0 NUL

Reserved Reserved 0 NUL

Cyclical Redundancy

Check

These two bytes, along with the Message Type

byte, designate the start of the data message.

An 02H indicates that this message is a status

response.

The Transponder Seen Count is a single byte,

hexadecimal field. At power-up, the interrogator

initializes this Seen Count byte to 00. This value

is incremented each time a tag with a unique ID

moves out of the RF field, then back into the RF

field. This field is useful in determining whether

a train has multiple tag reads of a given ID due

to a change in the train’s direction.

At power-up, the interrogator initializes this

byte with 00. It is incremented each time a

message with a bad CRC is received from the

Host.

At power-up, the interrogator initializes this

byte with 00. It is incremented each time an

incomplete message is received from the

Host.

This field is a single byte (8-bits) cyclical

redundancy check (CRC). Includes the Start

of Message, Message Type, Transponder

Seen Count, Number of Messages from Host

with bad CRCs, and Number of Incomplete

Host Messages. Refer to “Appendix D” for a

description of the CRC algorithm. There is no

carriage return or line feed for this message.

7E7E ~~

02 STX

00 - FF N/A

00 - FF N/A

00 - FF N/A

00 - FF N/A

Retransmit Request

Note: The Retransmit Request should only be used when the train is stationary.

Sending this command simultaneous to tags being read can create a condition

whereby the interrogator will no longer report tags until power cycled.

The Retransmit Request Command tells the transponder to retransmit the last tag ID. (BB

must be entered in upper case).

The request command format is as follows:

<7EH><7EH><

42H

><CRC>

TransCore Proprietary

29

User Guide

Start of Message

Message Type

Cyclical

Redundancy Check

Table 5 Retransmit Request Message Fields

Field Description Hex ASCII

These two bytes, along with the Message

Type byte, designate the start of the data

message.

Sending a 42H indicates that this message is

a retransmit request.

An 8-bit cyclical redundancy check (CRC)

Includes the Start of Message and Message

Type. Refer to “Appendix D” for a description

of the CRC algorithm. This is a fixed value

of 42 hexadecimal, for this command. There

is no carriage return or line feed for this

message.

The response is

<7EH><7EH><01H><transponder count><transponder ID><CRC>

7E7E ~~

42 B

42 B

Field Description Hex ASCII

Start of Message

Message Type

Transponder Seen

Count

Transponder ID

Cyclical Redundancy

Check

Table 6 Retransmit Response Message Fields

These two bytes, along with the Message

Type byte, designate the start of the data

message.

An 01H indicates that this message is a tag

data message.

After power-up, this 8-bit count begins with

01 and is updated each time a tag with a

unique ID moves out of the RF field, then

back into the RF field. This field is useful in

determining whether a train has multiple tag

reads of a given ID due to a change in the

train’s direction.

The data that is programmed into the

transponder. The data within the transponder

is 6-bit ASCII but the interrogator translates

this data into standard 8-bit ASCII.

An 8-bit cyclical redundancy check (CRC).

Includes the Start of Message, Message

Type, Seen Count and Transponder ID. Refer

to for a description of the CRC algorithm.

There is no carriage return or line feed for

this message.

7E7E ~~

01 SOH

00 - FF N/A

- ID

00 - FF N/A

TransCore Proprietary 30

Command Mode

While the AI1422E Reader is in Command Mode, the host computer sends commands to

the AI1422E Reader that can be used to control the operation and configuration of the

reader. After the AI1422E Reader receives a command, it transmits a command response

message. Typically, the command message contains Error, Done, or data relating

specifically to the command request. These messages may be of variable length since

some commands require information as part of the message.

Communications can be lost if the host computer attempts to send certain commands

under marginal communications conditions. For example, if the host computer transmits the

command request to change the baud rate and the AI1422E Reader properly receives the

request and transmits the Done message, one of the two following conditions may occur:

1. If the host computer receives the Done message, then both the host and the AI1422E

Reader switch to the new baud rate, and communications are maintained.

Note: In many applications, the host must be set to the new baud rate as it will not

change automatically. The AI1422E Reader changes the baud rate immediately after

issuing the Done message.

AI1422E Reader

2. if the host does not receive the Done message transmitted by the AI1422E Reader, the

host assumes that the command was not properly sent and does not switch to the new

baud rate, causing a loss of communications.

Caution

The host computer should not attempt to change communications parameters

or protocols during marginal communications conditions; otherwise, a loss of

communications can result.

Download Mode

In Download Mode, the AI1422E Reader allows the host to download new software.

While in Download Mode, the reader communications port parameters are fixed at the

following factory-default settings: 38400 baud, 8 data bits, 1 stop bit, no parity, software

flow control (XON/XOFF), basic protocol.

While in Download Mode, the AI1422E Reader turns RF o, does not process tags, and

does not echo host commands.

Command List

Reader commands are divided into groups based on primary function. The following

sections provide information about each command in command number order. Refer to

TransCore Proprietary

31

User Guide

Reader Mode Control

00/662 Switch to Data Mode (Factory Default)

Command !00 switches the reader to Data Mode, which allows the reader to transmit

“Command Quick Reference” on page 80 for listings of commands in both numerical

and alphabetical order.

In the Command Quick Reference list, the symbols < and > represent variable message

data. These symbols are not part of the message syntax. Hex digits (0–9, A–F) in either

uppercase or lowercase characters may be used in data strings and for hex digits A–F.

Group 0 commands control reader mode. The mode determines whether the reader is

transmitting data to or receiving data from a host computer or terminal.

tag data (ID codes) to the host. In addition to switching the reader to

Data Mode, command !00 automatically saves to non-volatile memory

(NVRAM) any user parameters that had been changed during the

command mode session. The reader enters Data Mode on power up.

The command !662 is present for backward compatibility with

previous generation AI1422 readers, and is not recommended for use.

Caution

To save user parameter changes to NVRAM, you must send command

!00/!662 before powering down the reader.

Switch to Command Mode

While operating in Data Mode, the reader accepts the following commands:

Command !01 Switch to Command Mode

Reader response: No Response

Command ~~CC switches the reader to Command Mode, which allows the reader to

accept commands from a host or terminal. While in Command Mode,

the reader turns RF o and does not acquire tags.

Reader response: No Response

Communications Port Control

Group 1 commands configure the parameters used by the AI1422E Reader to communicate

with a host computer or terminal. These commands set baud rate, stop bits, parity, and endof-line delay.

TransCore Proprietary 32

AI1422E Reader

100N Select Baud Rate

Command !100N selects the reader baud rate. The factory-default setting is 9600 baud.

The N variable specifies the baud rate shown in Table 7.

Reader response: Done

Table 7 Select Baud Rate Commands

Command Baud Rate Selected

1002 1200

1003 2400

1004 4800

1005 9600 (factory default)

1006 19.2 K

1007 38.4 K

Caution

If ECP is enabled, ensure that the ECP timeout is sucient for the new baud

rate. Refer to “525 Display Communications Protocol Status” on page 45.

101N Select Stop Bits

Command !101N selects the number of stop bits for reader character transmission. The

factory default setting is 1 stop bit. The N variable specifies the number

of stop bits as indicated in Table 8.

Reader response: Done

Table 8 Select Stop Bits Commands

Command Stop Bits Selected

1010 1 (factory default)

1011 2

102N Select Parity

Command !102N selects the reader parity setting. The factory-default setting is parity

disabled. The N variable specifies parity as shown in Table 9.

Reader response: Done

TransCore Proprietary

33

User Guide

Real-time Clock

20 Set Time

Table 9 Select Parity Commands

Command Data Bits Parity Selected

1020 8 Disable parity (factory default)

1021 7 Select even parity

1022 7 Select odd parity

Group 2 commands control the real-time clock which maintains the AI1422E internal time

and date. This time and date can be appended to IDs, error messages, and sensor input

reports. An internal battery supports the clock, so time and date are preserved if main

power is lost.

Command !20 sets the time. Enter the time in the proper format: two-digit decimal

entries with no spaces between characters and using colons as

delimiters. The entry format is as follows:

20HH:MM:SS or 20HH:MM:SS:hh

where

HH represents hours (00 to 23).

MM represents minutes (00 to 59).

SS represents seconds (00 to 59).

hh represents hundredths of a second (00 to 99).

: is the time delimiter.

If hundredths of a second is not specified, the reader sets the

hundredths register to 00.

Reader response: Done

TransCore Proprietary 34

AI1422E Reader

21 Set Date

Command !21 sets the date. Enter the date in the proper format: two-digit decimal entries

with no spaces between characters and using forward slashes “/” as

delimiters. The entry format is as follows:

21MM/DD/YY

where

MM represents the month (01 to 12).

DD represents the day (01 to 31).

YY represents the last two digits of the year (00 to 99).

/ is the date delimiter.

Reader response: Done

22 Display Time and Date

Command !22 displays the reader’s current time and date. One space separates the

time and the date output.

Reader response: HH:MM:SS.hh MM/DD/YY

where

HH represents hours.

MM represents minutes.

SS represents seconds.

hh represents hundredths of seconds.

: is the time delimiter.

MM represents the month.

DD represents the day.

YY represents the last two digits of the year.

/ is the date delimiter.

Append Information

Group 3 commands append useful information to reader transmissions, such as IDs, error

messages, and sensor input reports. Auxiliary information such as reader number, antenna

number (or manual entry code), number of times the previous tag was read, and sensor

input status can be appended to the ID using the Group 3 commands.

30N Append Time and Date Selection

Command !30N selects the option of appending the time and date to transmitted

IDs, error messages, presence without tag reports, and input status

change reports. The factory default setting is time and date appended

(command !302).

TransCore Proprietary

35

User Guide

The reader returns an Error message if its tag buer contains

data. The reset reader command !63 may be transmitted to

clear the buer; however, tag ID data will not be reported. If this is

unacceptable, allow the buer to empty before reissuing append time

and date command !30N. Append Time and Date commands are

shown in Table 10.

The reader transmits messages with time and date appended as

follows. One space separates the time from the date.

<string>&<HH:MM:SS.hh MM/DD/YY>

where

string is a tag ID, error message, or report.

& separates <string> from the time and date.

HH:MM:SS is the time delimiter.

MM/DD/YY is the date delimiter.

Reader response: Done

Table 10 Append Time and Date Commands

Command Append Option

300 No time and date appended

302 Time and date appended (factory default)

31N Append Auxiliary Information Selection

Command !31N selects the option of appending auxiliary information to transmitted

IDs, presence-without-tag reports, and input status change reports.

Auxiliary information is not appended to error messages. The factory

default setting is no auxiliary information appended. The N variable

specifies whether or not auxiliary information is to be appended.

Append Auxiliary Information commands are shown in Table 11.

The reader transmits messages with auxiliary information appended

as:

<message data>%<xx-y-zz-q>

where

% separates the auxiliary information and signals the host

computer that auxiliary information is appended.

xx reader ID. Value can be set with command !60NN.

- auxiliary information delimiter

y antenna number. Value fixed at 0.

TransCore Proprietary 36

AI1422E Reader

zz number of reads (00 to FF hexadecimal) of the previous

tag

q current status of Input 0 and Input 1 (0 to 3). Refer to “525

Display Communications Protocol Status” on page 45

These values are inverted if input inversion is enabled with

command 6941.

Reader response: Done

Command Append Option

310 No auxiliary information appended (factory default)

311 Auxiliary information appended

Table 11 Append Auxiliary Information Commands

320 Disable EAC Page Append (Factory Default)

Command !320 is a factory-set default that disables the EAC (embedded application

code) page append.

Reader response: Done

321 Enable EAC Page Append

Note: This functionality was added to the Encompass® 2 Reader to handle a

special unique customer requirement, and is retained in the AI1422E Reader for full

backward compatibility.

Command !321 selects the option to append an additional predefined 8 bytes of data

to be read from an eGo® or eGo Plus tag when the reader is in ID only

mode (not eATA) and multitag sort is enabled. The additional bytes

that are read from the tag are in locations 10 through 17.

The reader transmits the message with EAC page append as follows:

The EAC append data occurs before time and date append data and

AUX append data if they are enabled.

<tag ID>&<EAC page data>

Reader response: Done

ID Filtering

Group 4 commands set criteria for filtering (buering or discarding) ID codes. These

commands are useful for eliminating duplicate ID codes and selecting the type of tags read

by the AI1422E Reader.

40 Disable Transmission All ID Codes

Command !40 instructs the reader to reinstate the previous uniqueness checks.

Reader response: Done

TransCore Proprietary

37

User Guide

41 Transmit All ID Codes

Command !41 instructs the reader to transmit all IDs without regard for uniqueness.

Reader response: Done

410N Select Unique ID Code Criteria (Anti-passback Feature)

Command !410N instructs the reader to buer and transmit ID codes according to the

This command can be useful when mapping the footprint or per

forming diagnostics.

After diagnostics are complete, you may want to reinstate the

uniqueness check using command !410N Select Unique ID Code

Criteria, or by using !40 to set reader back to its original setting.

following test: an ID is read if previously decoded IDs have changed

value at least N+1 times since the new ID was last received. IDs

that do not pass the test are not read. The factory-default setting is

command !4100, which selects a separation of one ID. Variable N

specifies ID separation as shown in Table 12.

Each time the reader receives a tag ID, it compares the ID with the

contents of a comparison register. This register contains the following

four items:

Item 1 Most recently acquired ID

Item 2 Second-most recently acquired ID

Item 3 Third-most recently acquired ID

Item 4 Fourth-most recently acquired ID

When the uniqueness filter is set to separation of one ID, the newly

acquired ID is transmitted only if it is dierent from the first item.

Separation of two IDs allows transmission if the new ID is dierent

from Items 1 and 2 in the comparison register.

Separation of three and four IDs transmit the new ID only if it is

dierent from the first three and the first four items, respectively.

Note: A new ID can fail the filter test and not be transmitted; however, it remains

stored in the comparison register.

The uniqueness test’s time limit is set by Command !441. If an ID is

buered, it will not be accepted again unless it arrives at the reader

more than the programmed time interval from the previous arrival or

until the receipt of one or more other IDs reset the uniqueness.

Reader response: Done

TransCore Proprietary 38

Table 12 Unique ID Code Criteria

Command Uniqueness Criteria

4100 Separation of 1 ID (factory default)

4101 Separation of 2 IDs

4102 Separation of 3 IDs

4103 Separation of 4 IDs

420N Select Valid ID Code Criteria

Command !420N directs the reader to validate an ID received only after it has been

obtained a specified number of times in sequence. Values for N are 0

through 3 (Table 13). The factory setting is one acquisition (N = 0).

The validation procedure is executed before the unique ID test (Select

Unique ID Code Criteria [!410N] commands). IDs that do not pass

the validation test are not reported.

AI1422E Reader

For example, command !4203 specifies that the same ID must

be obtained from the RF module 4 times in succession before

it is considered for the uniqueness test. This feature is useful in

installations where RF reflections may cause a single tag to be read

multiple times or where an occasional ID might be read from fringe

areas.

Table 13 Select Valid Code Commands and Frames

Command Valid Code Frames

4200 1 (Factory default)

4201 2

4202 3

4203 4

TransCore Proprietary

39