Page 1

AI1422 Half-Frame Reader

User Guide

TransCore, Inc.

19111 Dallas Parkway, Suite 300

Dallas, Texas 75287-3106

October 2004

P/N 411237-003

Page 2

Page 3

©

2004 TC IP, Ltd. All rights reserved. TRANSCORE is a registered trademark. The trademark is used under

license. All other trademarks listed are the property of their respective owners. Contents are subject to change.

Printed in the U.S.A.

Products covered by this document are protected by one or more of the following U.S. patents 4,739,328;

4,864,158; 4,999,636; and foreign equivalent patents. Other patents pending.

For further information, contact:

TransCore

19111 Dallas Parkway, Suite 300

Dallas, Texas 75287-3106 USA

Phone: (972) 733-6600

Fax: (972) 733-6699

TransCore Action Center (TrAC)

19111 Dallas Parkway, Suite 300

Dallas, Texas 75287-3106 USA

Phone: (800) 755-0378

Fax: (972) 733-6695

Page 4

WARNING TO USERS IN THE UNITED STATES

FEDERAL COMMUNICATIONS COMMISSION (FCC) RADIO FREQUENCY

INTERFERENCE STATEMENT

47 CFR §15.105(a)

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of the Federal Communications Commission (FCC) rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency (RF) energy and

may cause harmful interference to radio communications if not installed and used in accordance with the

instruction manual. Operating this equipment in a residential area is likely to cause harmful interference, in

which case, depending on the laws in effect, the users may be required to correct the interference at their

own expense.

NO UNAUTHORIZED MODIFICATIONS

47 CFR §15.21

CAUTION: This equipment may not be modified, altered, or changed in any way without permission

from TransCore, Inc. Unauthorized modification may void the eq uip m ent authorization from the FCC and

will void the TransCore warranty.

USE OF SHIELDED CABLES IS REQUIRED

47 CFR §15.27(a)

Shielded cables must be used with this equipment to comply with FCC regulations.

A license issued by the FCC is required to operate this RF identification device in the United States.

Contact TransCore, Inc. for additional information concerning licensing requirements for specific devices.

TransCore, Inc.

USA

Page 5

Contents

Page 6

Page 7

1 Before You Begin

Purpose of This Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Guide Topics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2 System Overview

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Transponder Interrogator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Reader Power Regulation and Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Transponders (Tags) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Contents

3 Interface Connections

Description of AI1422 Reader System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Antenna Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Main RS–232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Aux RS–232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Customer I/O Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Lock LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Main Power LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

RF Power LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Trigger Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Channels A, B, and C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

vii

Page 8

AI1422 Half-Frame Reader System User Guide

4 System Test Procedures

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Testing Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Measuring RF Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Measuring System Noise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Reading the Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

5 Command Codes

Default Command Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Asynchronous Reader Data Telegram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Health Status Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Retransmit Request. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Diagnostic Command Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Diagnostic Command Code Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Diagnostic Command Code Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

6 Troubleshooting

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Failure Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Unit Will Not Read Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Unit Will Not Retain Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Maintenance Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

A Character Conversion

B Technical Specifications

C Diagnostic Command Codes List

viii

Page 9

Contents

List of Figures

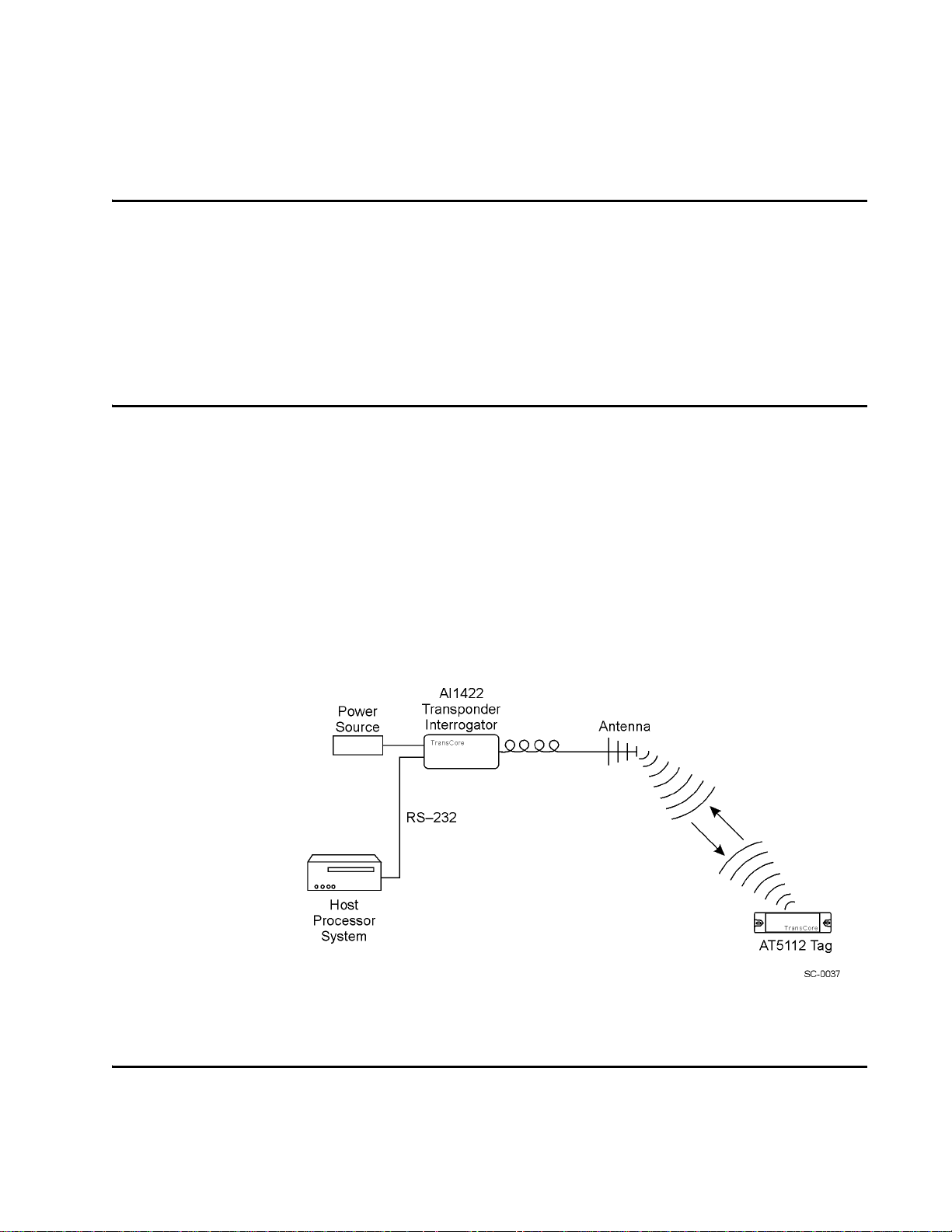

Figure 2-1 Typical Reader System Configuration 2-3

Figure 3-1 Front Panel of AI1422 Transponder Interrogator 3-3

Figure 3-2 RS–232, DB25 Interface Connector Pin-outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Figure 3-3 Customer I/O Interface Pin-outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure 4-1 Power Source Connections 4-4

Figure 4-2 Locations for DC Voltage Adjustment Measuring RF Power . . . . . . . . . . . . . . . . . . 4-5

Figure 4-3 Antenna Interface on Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Figure 4-4 Typical Waveform with a Tag in the Reader Field . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Figure 4-5 Typical Quiescent Noise Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Figure 4-6 Typical Beat Frequency Interference Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

List of Tables

Table 1-2 Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 4-1 System Noise Test Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Table A-1 TransCore 6-Bit-Per-Character Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Table B-1 AI1422 Half-Frame Reader System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . B-3

ix

Page 10

AI1422 Half-Frame Reader System User Guide

x

Page 11

1

Before You Begin

Page 12

Page 13

The AI1422 Half-Frame Reader User Guide provides information

necessary for interfacing the AI1422 Half-Frame Reader System to a host

computer system.

Purpose of This Guide

This user guide provides information for interfacing the AI1422 Half-Frame Reader

System with a host processor system, also called a host computer system. This guide

also provides on-site test procedures useful in troubleshooting any problems

encountered after installation. Command codes, which allow the user to configure the

reader system for communicating with the host computer, are discussed in Chapter 4.

The ASCII character conversion to TransCore 6-bit character codes is provided in

Appendix A.

Intended Audience

Chapter 1

Before You Begin

The intended audience for the AI1422 Half-Frame Reader User Guide is engineers

and technicians. These people are involved in the design, specification, and

installation of AI1422 Half-Frame Reader Systems.

Related Documents

AP4110 Programmer’s Guide

Guide Topics

This document presents the following information:

Chapter 1 – Before You

Begin

Chapter 2 – AI1422 Half-

Frame Reader System

Overview

Chapter 3 – Interface

Connections

Describes the purpose, intended audience, guide topics, related

documentation, and document conventions.

Provides an overview of the AI1422 Half-Frame Reader System’s features,

options, and accessories.

Describes the AI1422 Half-Frame Reader System interface connectors and

identifies their primary functions.

Chapter 4 – System Test

Procedures

Provides testing procedures that the user can use to fine-tune the AI1422

Half-Frame Reader System.

1-3

Page 14

AI1422 Half-Frame Reader System User Guide

Chapter 5 – Firmware

Command Codes

Chapter 6 – Maintenance

and Troubleshooting

Appendix A – Character

Conversions

Discusses the firmware command code that are used to configure the AI1422

Reader for communication with a personal computer or other host computer.

Provides maintenance procedures and troubleshooting indications that are

used to keep the AI1422 Half-Frame Reader System operating.

Provides TransCore 6-bit-per-character conversions from the standard ASCII

character set.

Typographical Conventions

Table 1-2 lists the conventions used in this manual.

Table 1-2 Typographical Conventions

Convention Indication

This procedure might cause harm to the equipment and/or

the user.

Concerns about a procedure

1-4

Code

Dialog Box Title

Function

Menu Item

Note

NUL Zero-value ASCII character or a zero-value byte

NULL Zero-value pointers. Null-terminated string refers to strings

Code, including keywords and variables within text and as

separate paragraphs, and user-defined program elements

within text appear in courier typeface.

Title of a dialog box as it appears on screen

Start with the characters, G4, and are in mixed case with no

underscores, and include parentheses after the name, as in

G4FunctionName().

Appears on a menu. Capitalization follows the interface.

Auxiliary information that further clarifies the current

discussion. These important points require the user’s

attention. The paragraph is in italics and the word Note is

boldface.

of printable ASCII characters with a zero-value byte placed

in memory directly after the last printable character of the

string.

Page 15

2

System Overview

Page 16

Page 17

The AI1422 Half-Frame Reader System is a microprocessor-controlled,

single-antenna unit that uses a unique communications protocol to

interface with vehicle identification (ID) equipment.

System Overview

This reader system uses radio frequency (RF) energy to read data from tags. The

AI1422 Half-Frame Reader System then decodes the tag ID information, validates the

ID code, and transmits tag data directly to a host processor for real-time data process

ing and use.

Communications (terminal) programs usually do not provide adequate data processing

capability. Your host computer software can be customized to provide the required

capabilities.

The AI1422 Half-Frame Reader System consists of the AI1422 Transponder Interrogator, which consists of a reader and RF module, combined with a TransCore antenna,

a TransCore tag, a host processor system, and a power source.

typical reader system configuration.

Chapter 2

System Overview

-

Figure 2-1 illustrates a

Figure 2-1 Typical Reader System Configuration

Transponder Interrogator

The transponder interrogator reads 60 bits of user-programmable data in the transponder.

2-3

Page 18

AI1422 Half-Frame Reader System User Guide

The transponder interrogator is operated in a continuous read mode, and any tag entering its read field has its data automatically read and relayed to the host computer. In

many applications this function is implemented by installing the reader on a vehicle

with restricted movement, such as a railcar or monorail bus. The tags are imbedded in

the roadway at various locations in the vehicle’s path. The data read from the tag

allows the host computer to assess the vehicle’s location and make any appropriate

response to that information.

The transponder interrogator is an independent tag decoder that combines a reader and

RF source to provide automatic identification and data storage within a single,

compact unit. The transponder interrogator includes the following components:

• 19-inch rack-mount design

• Serial input/output (I/O) link

• Real-time clock

• 32K buffer storage in static random access memory (SRAM) with battery backup

• Reader and RF module, combined in one unit

Reader Power Regulation and Filtering

The reader system uses an input voltage ranging from 8V DC to 140V DC. The

AI1422 Reader System incorporates a high-performance, DC-to-DC power supply

that converts voltage in this range to 13.5V DC. TransCore offers three input voltage

options, 8V DC to 32V DC, 28V DC to 140V DC, and 14V DC to 70V DC.

Antenna

TransCore has two antennas that can operate with the AI1422 Half-Frame Reader System, the AA3233 Rail Antenna and the AA3234 Light Rail Antenna. The AA3233

Rail Antenna can be used where high shock and vibration conditions exist. The

AA3234 Light Rail Antenna can be used for light rail applications that require a low

profile for mounting on the carriage of commuter trains and people-mover systems.

Transponders (Tags)

The AI1422 Half-Frame Reader System can use TransCore’s half-frame read-only

tags.

2-4

Page 19

3

Interface Connections

Page 20

Page 21

Interface Connections

This chapter describes the interface connections and their primary

functions.

Description of AI1422 Reader System

Because the AI1422 Half-Frame Reader System combines a reader and radio frequency (RF) module into a single unit, you must connect the following items to the

system: the external DC power, the customer input/output (I/O), the main and auxil

iary RS–232 interfaces, and the antenna. These interface connectors are located on the

AI1422 Half-Frame Reader System front panel as shown in

Chapter 3

-

Figure 3-1.

Figure 3-1 Front Panel of AI1422 Transponder Interrogator

Antenna Interface

Attach the antenna cable directly to the antenna interface on the front panel of the

AI1422 Half-Frame Reader System. The antenna cable length depends on the installa

tion.

Main RS–232 Interface

The main RS–232 interface is a standard DB25 plug connector used with a host processor. During operation, a host processor system uses the reader system functions in

real-time operating mode. In real-time mode, tag IDs are read and passed on to the

host processor.

Figure 3-2 illustrates the RS–232, DB25 plug connector pin-outs.

-

3-3

Page 22

AI1422 Half-Frame Reader System User Guide

Figure 3-2 RS–232, DB25 Interface Connector Pin-outs

Aux RS–232 Interface

The auxiliary RS–232 interface is used as a backup monitoring system to the main

RS–232 interface. The auxiliary interface monitors data from the transponder interro

gator. The auxiliary RS–232 interface is a standard DB25 plug connector. This port is

not wired to receive data and cannot accept commands.

Customer I/O Interface

A mating connector for the customer I/O interface is supplied with each unit. This

connector allows a screw terminal, point-to-point wiring interface.

the pin-outs on the customer I/O interface connector.

-

Figure 3-3 shows

3-4

Page 23

Interface Connections

Figure 3-3 Customer I/O Interface Pin-outs

The customer I/O interface connector contains the lock light-emitting diode (LED),

main power LED, RF power LED, the trigger signals, and channels A, B, and C.

Lock LED

The transistor-transistor-logic (TTL) lock si gnal shows the presence of a tag. The lock

signal goes active high when a valid tag is in the RF field of the antenna and may be

connected to an LED for monitoring purposes.

Main Power LED

The TTL main power signal goes active high when the ON/OFF switch on the front

panel is switched to on. The switch is connected to +5V through a 300 ohm resistor

and is connected to an LED on the front panel, which may be used for power monitor

ing purposes.

RF Power LED

The TTL RF power LED goes active high when the reader system is configured for

the RF power to be on and the ON/OFF switch is set to on. It is connected to +12V

through a resistor and may be connected to a LED for RF power monitoring purposes.

-

Tri gg er Signals

The trigger connection turns on the RF power when a ground is applied and the

AI1422 Reader System has been programmed with the RF Follows T r igger command

(!642).

3-5

Page 24

AI1422 Half-Frame Reader System User Guide

Channels A, B, and C

The analog intermediate frequency channe l A, B, and C signals represent the three

channels generated by the AI1422 Reader System. These channels can be used to

measure tag signal quality.

Power Connection

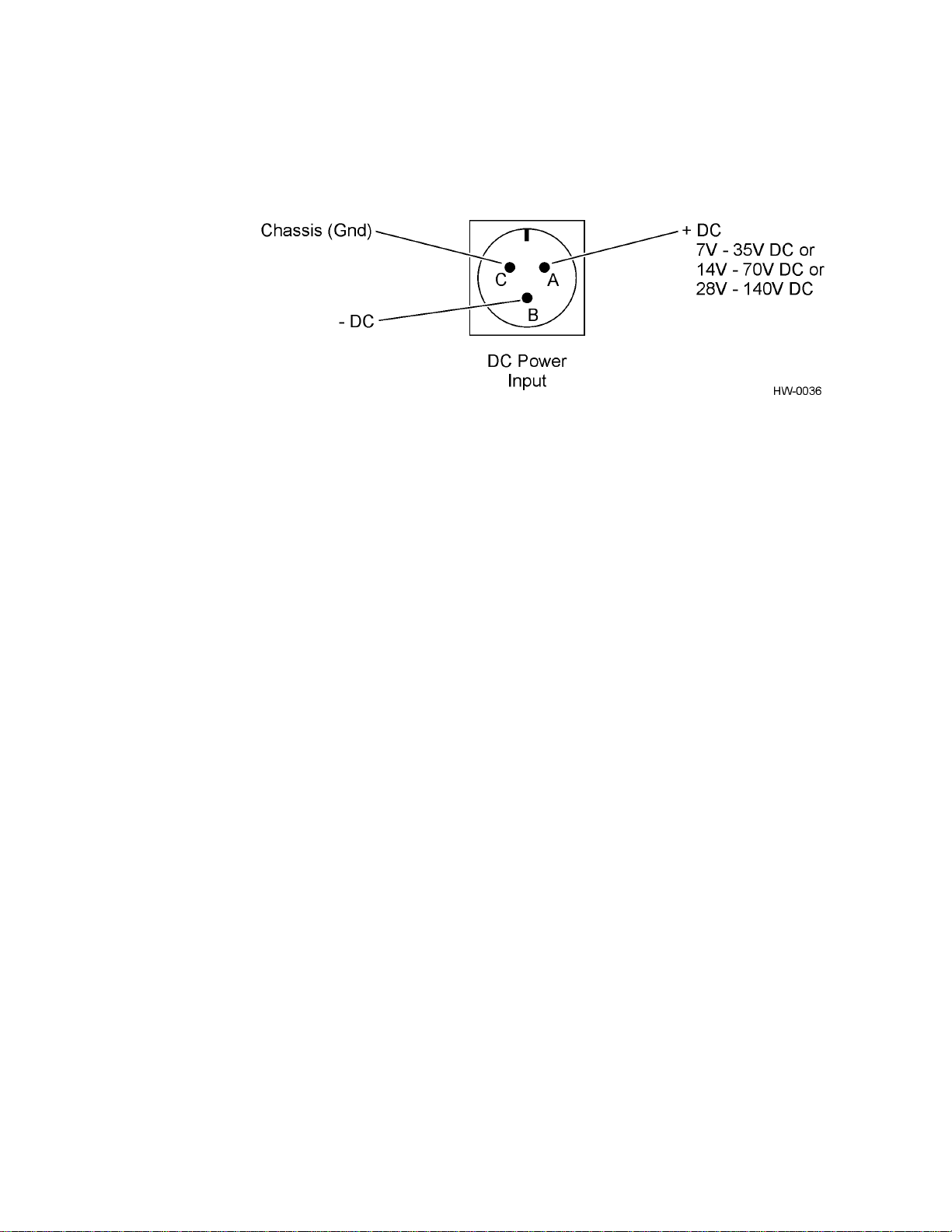

The power connector on the front panel of the AI1422 Half-Frame Reader System is a

panel mount circular connector of type Cannon CA 3100 E16-10P-F80-T12.

3-6

Page 25

4

System Test Procedures

Page 26

Page 27

System Test Procedures

This chapter provides testing procedures that will help you fine-tune

your reader system and test basic operation, measure radio frequency

(RF) power, measure system noise, read tags, and monitor the system.

Required Tools and Equipment

The following tools and equipment are required:

• 50-ohm, 5-watt (W) load (N-type connector)

• Personal computer (PC) with terminal emulator software

• Appropriate power source for your reader

• Digital multimeter

• RF power meter

Chapter 4

• 100 MHz oscilloscope

• Antenna, cable, and connectors

Testing Basic Operation

To test the system operation, configure the reader system as outlined in the following

steps.

CAUTION

The following procedures will cause RF power to be turned on and off at various

times. Do not operate the system without a 50-ohm, 5-W load attached to the RF

output. When any RF cable is disconnected, the associated RF power measurement

unit must be turned off.

1. Connect a 50-ohm, 5-W load (termination) to the antenna interface located on the

front panel of the reader system.

2. Configure a terminal emulator (a PC running communications software) to 2400

or 9600 baud, no parity, 8 data bits, and 1 stop bit.

3. Connect the emulator to the main RS–232 interface located on the front panel of

the reader system.

4. Switch off the ON/OFF switch located on the front panel of the reader system.

4-3

Page 28

AI1422 Half-Frame Reader System User Guide

5. Connect a power source to pins A (+) and B (-) on the DC power input front

panel connector (

Figure 4-1 Power Source Connections

Figure 4-1).

6. Switch on the ON/OFF switch located on the front panel of the reader system.

7. Type the command ~~CC (CC must be entered in upper case) and press

Enter.

Note: For information on entering command codes, refer to Chapter 5, Command

Codes.

8. Type !22 and press Enter. The time and date will be returned.

If the time and date are not received, check communications connections, cycle

power, and repeat.

If the time and date are incorrect, use !20 and/or !21 to correct this information,

then type the following commands.

!20hh:mm:ss sets time

!21MM/DD/YY sets date

!642 sets RF to follow the trigger

!41 enables tag reporting

The entered command and !Done response will be returned after each properly

executed command.

9. Connect a jumper between pins 14 (ground) and 15 (trigger) on the customer

input/output (I/O) connector to turn on the RF power.

Figure 3-3 on page 3-5 in

Chapter 3 shows the location of pins 14 and 15.

10. Connect a voltage output meter to pins 20 (+) and 23 (-) at the back of the

Melcher DC-DC converter.

Figure 4-2 shows the location of pins 20 and 23.

11. Adjust the R1 knob (Figure 4-2) to obtain 13.5V DC.

4-4

Page 29

System Test Procedures

Figure 4-2 Locations for DC Voltage Adjustment Measuring RF Power

Measuring RF Power

To measure the RF power

1. Set the ON/OFF switch located on the front panel of the reader system to off.

2. Connect an RF power meter of known accura cy to the antenna interface on the

front panel of the reader system (

connector should be 0.8 W (29 dBm).

Figure 4-3). Power measured at the antenna

Figure 4-3 Antenna Interface on Front Panel

Caution

Some RF power meters have input power restrictions, and 0.8 W can severely damage the RF meter if applied directly. Use supplemen tal attenuators of known accuracy with these types of meters and add the attenuation amount to the resulting RF

power measurement.

4-5

Page 30

AI1422 Half-Frame Reader System User Guide

3. If a cable is used with the power meter, the cable loss must be determined by

measuring all cables with an RF power meter of known accuracy. Calculate the

resultant RF power levels using the formula dB = 10

the meter reading to determine the actual RF power output.

4. Set the ON/OFF switch located on the front panel of the reader system to on.

5. Repeat steps 6 through 8 under the section “Testing Basic Operation” on page 43 to configure the unit to operating conditions.The RF power measurement

should read greater than 0.8 W.

Example of RF power measurement with a 645-mW meter reading using a

cable:

10

645 +28.1 dBm

log

Test cable loss 0.9 dB

Total +29.0 dBm = 0.8 W

Measuring System Noise

P in/P out. Add this loss to

log

With the equipment configured the same as for the RF power measurement test

described above, connect a 100 MHz oscilloscope to the customer I/O interface

according to the parameters listed in

Table 4-1 System Noise Test Parameters

Channel Pins

A 8 (ground) and 9

B 10 (ground) and 11

C 12 (ground) and 13

Table 4-1.

Figures 4-4 through 4-6 depict waveforms generated at selected channels, as shown by

an oscilloscope.

Figure 4-4 illustrates the desired waveform generated during normal operation with a

valid tag in the reader field.

4-6

Page 31

System Test Procedures

Figure 4-4 Typical Waveform with a Tag in the Reader Field

Figure 4-5 depicts typical quiescent noise levels with the RF connector configured

with a 50-ohm, 5-W terminator. Quiescent noise levels vary from unit to unit with

channel C having the most representative noise level.

Figure 4-5 Typical Quiescent Noise Waveform

Figure 4-6 shows the typical beat frequency interference waveform caused by a similar frequency interrogator system connected to an antenna in proximity to the system

under test.

4-7

Page 32

AI1422 Half-Frame Reader System User Guide

Figure 4-6 Typical Beat Frequency Interference Waveform

Reading the Tag

To verify that the AI1422 Half-Frame Reader System is properly reading tags

1. Switch the ON/OFF switch located on the front panel of the reader system to off.

2. Using your own cable, connect the laptop PC to the reader system at the main

RS–232 interface.

3. Connect the antenna to the antenna interface on the front panel of the reader

system.

4. Connect three customer-supplied light-emitting diodes (LED) between the

ground pin and lock LED, the ground pin and the main power LED, and the

ground pin and the RF power LED. All of these pins are located on the customer

I/O interface on the front panel of the reader system.

5. Set the ON/OFF switch located on the front panel of the reader system to on.

6. Connect a jumper between pins 14 (ground) and 15 (trigger) on the customer

I/O interface to trigger the RF on (Figure 3-3 on page 3-5).

7. Monitor the LEDs on the box, and verify that the main power LED and the RF

power LED are lit.

8. Position a programmed TransCore half-frame rail tag with a backplate within 2 to

3 feet (0.6 to 0.9 m) of the antenna. No other tag can be in this 2 to 3 foot (0.6 to

0.9 m) area during this test.

4-8

9. Verify that the lock LED is lit and that the PC is acquiring the tag data.

10. Remove the tag from the antenna field. The PC should stop reading the tag data.

Page 33

System Test Procedures

11. Disable the trigger by disconnecting the jumper.

12. Set the on/off switch located on the front panel of the reader system to off.

Note: Repeat this test several times. Each time, the lock LED should be lit and the PC

should be reporting the tag data.

4-9

Page 34

AI1422 Half-Frame Reader System User Guide

4-10

Page 35

5

Command Codes

Page 36

Page 37

This chapter describes the default and diagnostic command codes that

enable you to develop host computer programs to control the functions

of the AI1422 Half-Frame Reader System.

Default Command Codes

The default command codes enable communications between the host computer and

the reader system. These codes, also referred to as the communications protocol, are in

a binary format. TransCore strongly recommends that a person with software writing

capabilities write this communications protocol.

The transponder identification (ID) can be 3 or 10 bytes, which corresponds to 2400 or

9600 baud, respectively. These bytes are 6-bits coded. See

Conversion,” of this user guide.

Asynchronous Reader Data Telegram

The reader system sends a data telegram when it reads a unique tag ID.

Chapter 5

Command Codes

Appendix A, “Character

<7EH><7EH><01H><transponder count><transponder ID<CR>

Health Status Request

You will need to write a script file to download the following binary string for the

health status request.

<7EH><7EH><40><CR>

The response is

<7EH><7EH><02H><Transponder count><host computer

telegrams-bad CRC><incomplete host telegram>

<Reserved><Reserved><Reserved>

<CR>

Retransmit Request

You will need to write a script file to download the retransmit request.

<7EH><7EH><42H><CR>

The response is

<7EH><7EH><01H><transponder count><transponder ID><CR>

5-3

Page 38

AI1422 Half-Frame Reader System User Guide

Diagnostic Command Codes

Diagnostic commands are used to check or fine-tune the reader system.

Diagnostic Command Code Syntax

Unlike default command codes that require a script file, diagnostic codes are typed by

the user. The general syntax of diagnostic commands is to begin with an exclamation

character, !, followed by the command code and a list of parameters. No spaces should

be between characters, and the command is sent by pressing Enter or carriage return

<CR>.

As characters are typed, they are automatically displayed on the terminal (except for

the ~~CC command). As soon as the command is terminated with Enter or a <CR>,

the reader system responds to the command as follows:

!Done command recognized and accepted

or

!Error command not recognized

The normal response is !Done. Other responses, for example, the time/date

response, provide a description of the entry made or command completed.

The reader system operates using two distinct command sets. The first command set

contains the system default commands when the system is turned on. The second

command set contains diagnostic and other fine-tuning codes.

Diagnostic Command Code Listing

The following commands are used for diagnostics or to fine-tune the reader system.

Escape Command

!~~CC

Pressing the escape command disables the reader system default command codes and

allows the reader system to accept the other diagnostic and fine-tuning command

codes.

The response is

No response is returned

5-4

Baud Rate Select

!100x

Command !100x selects the baud rate, where x = 0 to 6:

0 = 110 baud

1 = 300 baud

2 = 1200 baud

Page 39

Command Codes

3 = 2400 baud

4 = 4800 baud

5 = 9600 baud (factory setting)

6 = 19.2 kbaud

The response is

!Done or !Error

Note: The !Done response is issued at the setting that existed before invoking the new

command. All subsequent communications will be at the new baud rate.

Stop Bits

!101x

Command !101x selects the stop bits, where x = 0 or 1:

0= 1 stop bit (factory setting)

1 = 2 stop bits

The response is

!Done or !Error

Note: The !Done response is issued at the setting that existed before invoking the new

command. All subsequent communications will be at the stop bit mode.

Parity Select

!102x

Command !102x is used to select parity, where x = 0 to 2:

0 = disable parity (factory setting)

1 = enable even parity

2 = enable odd parity

The response is

!Done or !Error

Note: The !Done response is issued at the setting that existed before invoking the new

command. All subsequent communications will be at the new parity mode.

Set the Time in the Real-Time Clock

!20hh:mm:ss

where

hh = hours (00–23)

5-5

Page 40

AI1422 Half-Frame Reader System User Guide

mm = minutes (00–59)

ss = seconds (00–59)

The response is

!Done or !Error

Note: The time must be entered exactly as shown with no spaces between characters

and colons as delimiters. All entries use decimal characters 0 through 9.

Set the Date in the Real-Time Clock

!21MM/DD/YY

where

MM = month (01–12)

DD = day (01–31)

YY = year (00–99)

The response is

!Done or !Error

Note: The date must be entered exactly as shown with no spaces between characters

and with forward slashes (/) as delimiters. All entries use decimal characters 0

through 9.

Display Time and Date

!22

where

hh = hours (00–23)

mm = minutes (00–59)

ss = seconds (00–59)

dd = hundredths of seconds

MM = month

DD = day

YY = year

The response is

5-6

!hh:mm:ss.dd MM/DD/YY

or

!Error

Note: There are two spaces between the time and the date.

Page 41

Command Codes

Real-Time Transmission to Host Enabled (factory setting)

!305

When a tag identification (ID) is acquired by the radio frequency (RF) source, it is

immediately sent out on the RS–232 port. The tag ID is not stored in the data buffer.

The response is

!Done or !Error

Transmit All Tag ID Codes

!41

Command !41 transmits to the host computer all tag IDs received by the antenna.

The response is

!Done or !Error

Note: This command is to be used for diagnostic purposes only.

Return to Default Command Codes

!63

Command !63 returns the host computer to the default command codes.

The response is

No response is returned

RF Follows Trigger

!642

Command !642 switches RF power on continuously.

The response is

!Done or !Error

Note: This command is for diagnostic purposes only.

5-7

Page 42

AI1422 Half-Frame Reader System User Guide

5-8

Page 43

6

Troubleshooting

Page 44

Page 45

This section lists routine maintenance procedures to keep the AI1422

Half-Frame Reader System operating correctly and diagnostic

procedures for troubleshooting an improperly working reader system.

Required Tools and Equipment

The following tools and equipment are required:

• 50-ohm, 5-watt (W) load (N-type connector)

• Personal computer (PC) with terminal emulator software

• Appropriate power source for your reader

• Digital multimeter

• RF power meter

Chapter 6

Troubleshooting

• 100 MHz oscilloscope

• Antenna and cable

Troubleshooting

No loop-back mode to restore defaults, such as baud rate, means that troubleshooting

is required.

Failure Modes

No Communication — To determine if there is a problem in the communications

hardware, the following two commands should be repeated together for testing pur

poses:

!~~CC escape to diagnostic mode

!22 display time and date

If functioning properly, the time and date will be displayed after the second command,

which means that the reader is communicating. If the reader is not functioning prop

erly , then perform the following checks.

• Does the AI1422 Half-Frame Reader System have adequate power? If not, ensure

reader has 13.5V DC

-

-

±1.0V DC.

• Is the main power switch on? If not, switch it on.

6-3

Page 46

AI1422 Half-Frame Reader System User Guide

• Is the main power switch light-emitting diode (LED) lit? If not, turn on power

switch.

• Is the front panel fuse blown? If so, replace it with a 1.5 amp (A) slo-blo fuse.

• Is the reader’s DC-DC converter functioning? If so, the OK LED on upper left

corner of front panel will be lit.

• Are you using a null modem cable connection? If not, switch to a null modem

connection.

• Have you set the correct baud rate? If an incorrect baud rate is suspected, select

and send each baud rate in turn, using the !100x Baud Rate Select command, and

wait for a response.

Unit Will Not Read Tags

The suggestions listed here assume that the user has already verified proper serial

communications, and the command !305 has been entered successfully to enable

real-time transmission to the host computer. If RF POWER LED, which is recom

mended for customer I/O connector, is lit, the indication is that the AI1422 is querying

for tags. If the LOCK LED, which is recommended for the customer I/O connector, is

lit, the indication is that the reader system is retrieving tag data. If either LED is not lit,

then check the following items:

-

• Verify that the antenna connection is good.

• Verify that the antenna cable is in good condition.

• Verify that a single, known valid tag is in the antenna field.

• Verify that the trigger remains activated and the unit power is on.

• Verify that a tag being alternated with a tag containing different data to avoid

uniqueness filtering.

Unit Will Not Retain Settings

If the unit will not retain information, such as time and date stamp or baud rate

between power cycles, the internal battery backup has failed and the unit must be

returned for repair. Contact TransCore at the telephone number listed at the front of

this user guide.

Maintenance Procedures

Except for the 1.5-A slo-blo fuse in the front panel of the unit, there are no user-serviceable parts in the AI1422 Half-Frame Reader System.

6-4

Page 47

A

Character Conversion

Page 48

Page 49

Appendix A

Character Conversion

Table A-1 lists the TransCore 6-bit-per-character conversion from the standard ASCII

character set.

Table A-1 TransCore 6-Bit-Per-Character Conversion

spc 000000 6 010110 L 101100

! 000001 7 010111 M 101101

" 000010 8 011000 N 101110

# 000011 9 011001 O 101111

$ 000100 : 011010 P 110000

% 000101 ; 011011 Q 110001

& 000110 < 011100 R 110010

' 000111 = 011101 S 110011

( 001000 > 011110 T 110100

) 001001 ? 011111 U 110101

* 001010 @ 100000 V 110110

+ 001011 A 100001 W 110111

, 001100 B 100010 X 111000

- 001101 C 100011 Y 111001

. 001110 D 100100 Z 111010

/ 001111 E 100101 [ 111011

0 010000 F 100110 \ 111100

1 010001 G 100111 ] 111101

2 010010 H 101000 ^ 111110

3 010011 I 101001 _ 111111

4 010100 J 101010

5 010101 K 101011

A-3

Page 50

AI1422 Half-Frame Reader System User Guide

A-4

Page 51

B

Technical Specifications

Page 52

Page 53

Appendix B

Technical Specifications

Table B-1 lists the specifications of the AI1422 Half-Frame Reader System.

Table B-1 AI1422 Half-Frame Reader System Specifications

Specification Description

Size

Weight

Operating temperature

Power requirement

Available frequency range

Approved frequency range for

Federal Communications

Commission and Industry Canada

Receiver RF bandwidth

Receiver sensitivity

Transmitter frequency stability

Transmitter RF power

Communications port

Other features

19.0 x 5.25 x 9.0 in

(48.3 x13.34 x 22.9 cm)

12.0 lb (5.4 kg)

+32°F to +158°F (+0°C to +70°C)

13.5V DC ±1.0V DC @25W

902–928 MHz

902.25–903.75 MHz and

910.00–921.50 MHz

≅1.2 MHz

-48 dBm

±5.0 ppm over operating temperature

range

0.8W ±0.1W

RS–232, 110 to 19,200 baud

Real-time calendar clock

Optional 8V–32V DC, 14V–70V DC, or

28V-140V DC power supply

B-3

Page 54

AI1422 Half-Frame Reader System User Guide

B-4

Page 55

C

Diagnostic Command Codes List

Page 56

Page 57

Appendix C

Diagnostic Command Codes List

Command Function

!~~CC Escape (CC must be entered in upper case)

!100x Baud Rate Select

!101x Stop Bits

!102x Parity Select

!20hh:mm:ss Set the Time in the Real-Time Clock

!21MM/DD/YY Set the Date in the Real-Time Clock

!22 Display Time and Date

!305 Real-Time Transmission to Host Enabled (factory setting)

!41 Transmit All Tag ID Codes

!63 Return to Default Command Codes

!642 RF Follows Trigger

C-3

Page 58

AI1422 Half-Frame Reader System User Guide

C-4

Loading...

Loading...