Transcend TS4GCF220I User Manual

CF220I -

CompactFlash Card

Description

Transcend’s CF220I is a high speed industrial

Compact Flash Card with high quality flash memory

assembled on a printed circuit board.

Features

Compliant with CF 6.0 specification with LBA48 support

RoHS compliant

Single Power Supply: 3.3V±5% or 5V±10%

Operating Temperature: -40oC to 85oC

Storage Temperature: -55oC to 100oC

Humidity (Non condensation): 0% to 95%

Built-in BCH ECC (Error Correction Code) functionality

and global wear-leveling algorithm to ensure data transfer

Operation Modes:

PC Card Memory Mode

PC Card IO Mode

True IDE Mode

True IDE Mode supports:

Ultra DMA Mode 0 to 5 (Ultra DMA mode 5 must

supply with 3.3V)

Multi-Word DMA Mode 0 to 4

PIO Mode 0 to 6

True IDE Mode: Fixed Disk (Default)

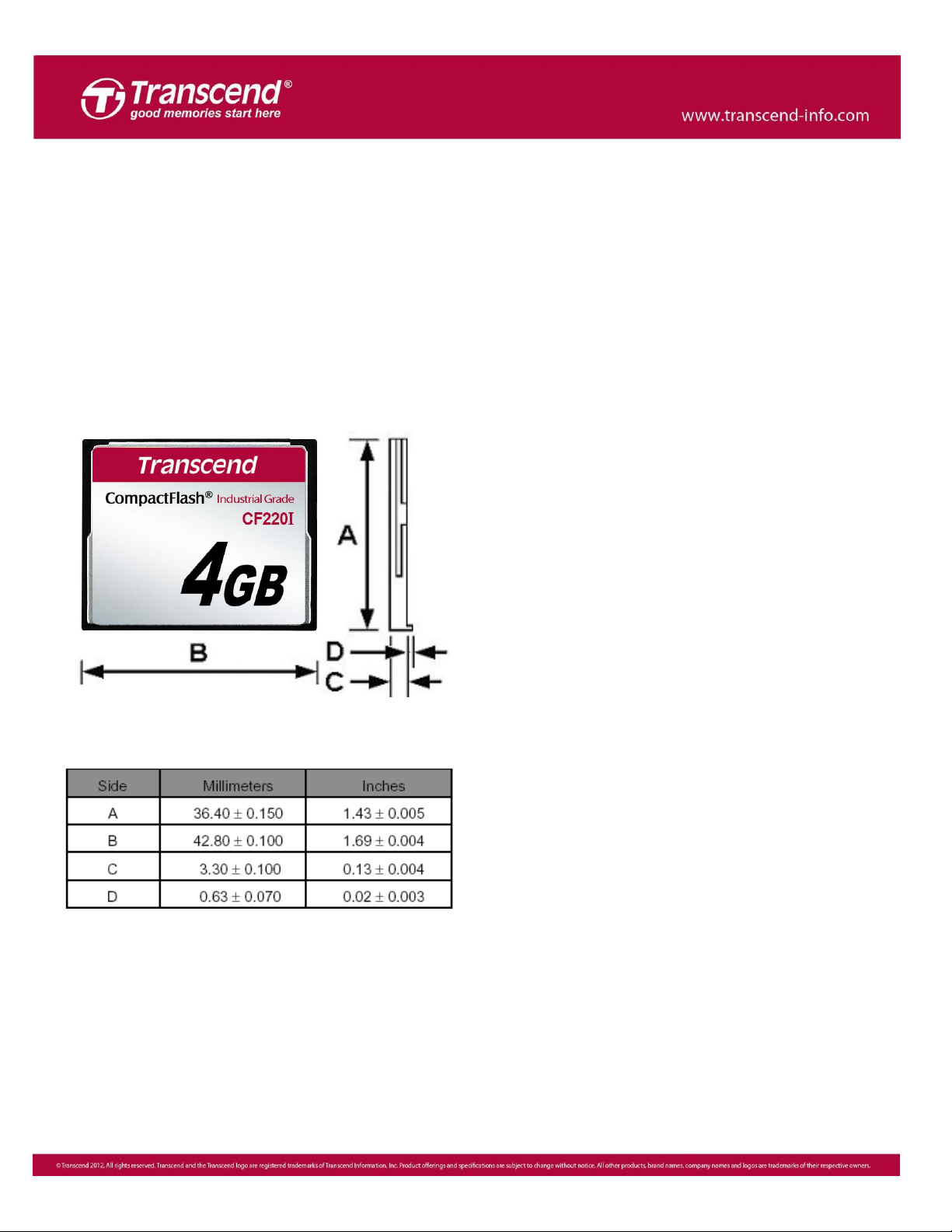

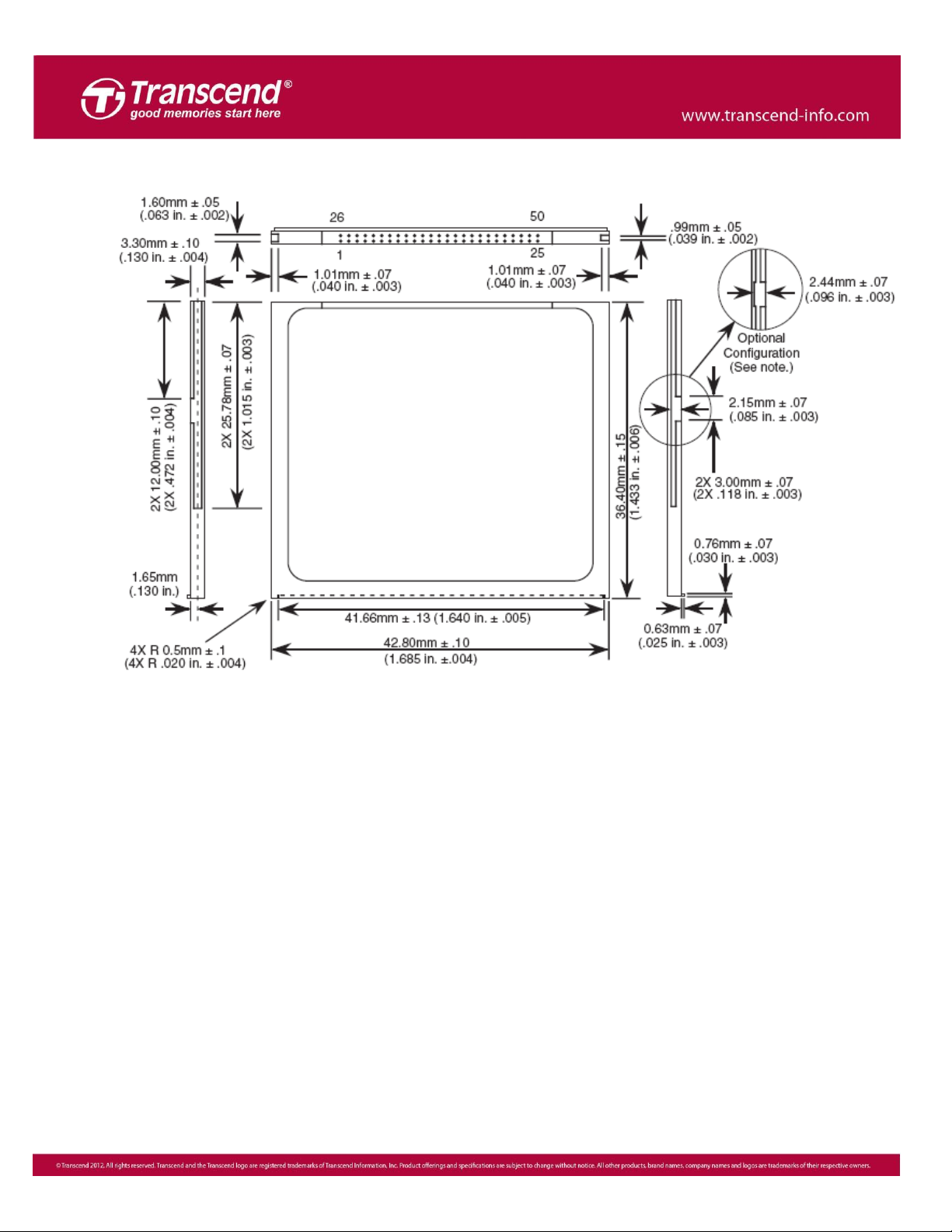

Dimensions

PC Card Mode: Fixed Disk (Default)

Durability of Connector: 10,000 times

MTBF: 4,000,000 hours (in 25 oC)

Support Global Wear-Leveling, Static Data Refresh,

Early Retirement, and Erase Count Monitor functions to

extend product life

Supports S.M.A.R.T (Self-defined)

Supports Security Command

Compliant with CompactFlash, PCMCIA, and ATA

standards

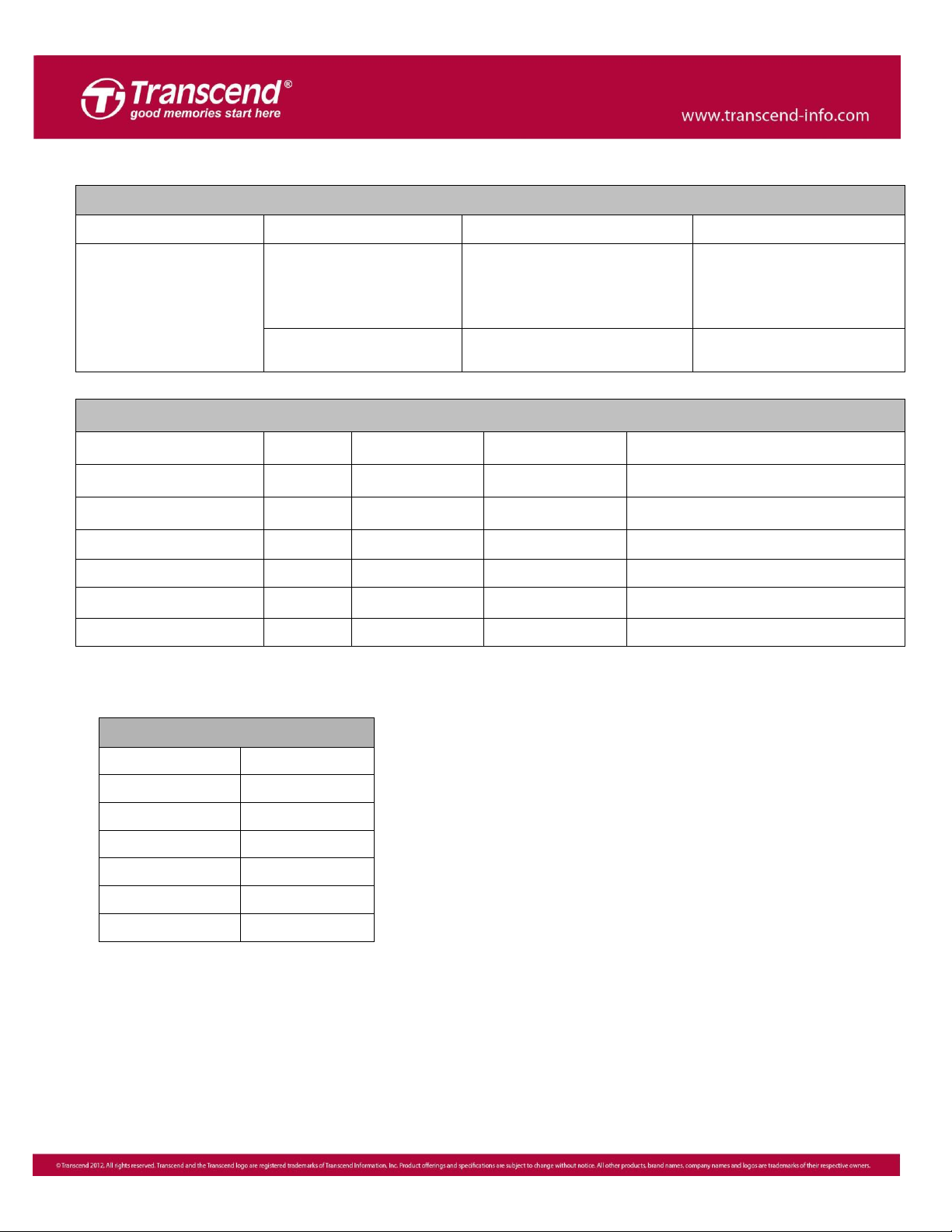

Ordering Information

Part Number

Interface

Transfer Mode

Disk Type

TS128M~4GCF220I

True IDE mode

Ultra DMA mode 0~5

Multi-Word DMA Mode 0~4

PIO Mode 0 ~ 6

Fixed Disk (Default)

PC Card mode (PCMCIA)

80ns, 100ns, 120ns, 250ns

Fixed Disk (Default)

C.H.S Table

Capacity

C H S

Physical Capacity

128MB

246

16

63

126,959,616 bytes

256MB

493

16

63

254,435,328 bytes

512MB

987

16

63

509,386,752 bytes

1GB

1974

16

63

1,018,773,504 bytes

2GB

3949

16

63

2,038,063,104 bytes

4GB

7899

16

63

4,076,642,304 bytes

Endurance

Model P/N

Tera Byte Write

TS128MCF220I

5.5 TBW

TS256MCF220I

5.5 TBW

TS512MCF220I

11 TBW

TS1GCF220I

22 TBW

TS2GCF220I

44 TBW

TS4GCF220I

88 TBW

*Note: FAT format for <4GB, FAT32 format for 4

*Note: Based on JEDEC JESD218A specification, Client Application

Class and the following scenario: Active use: 40oC, 8hrs/day; Retention

Use: 30oC, 1year.

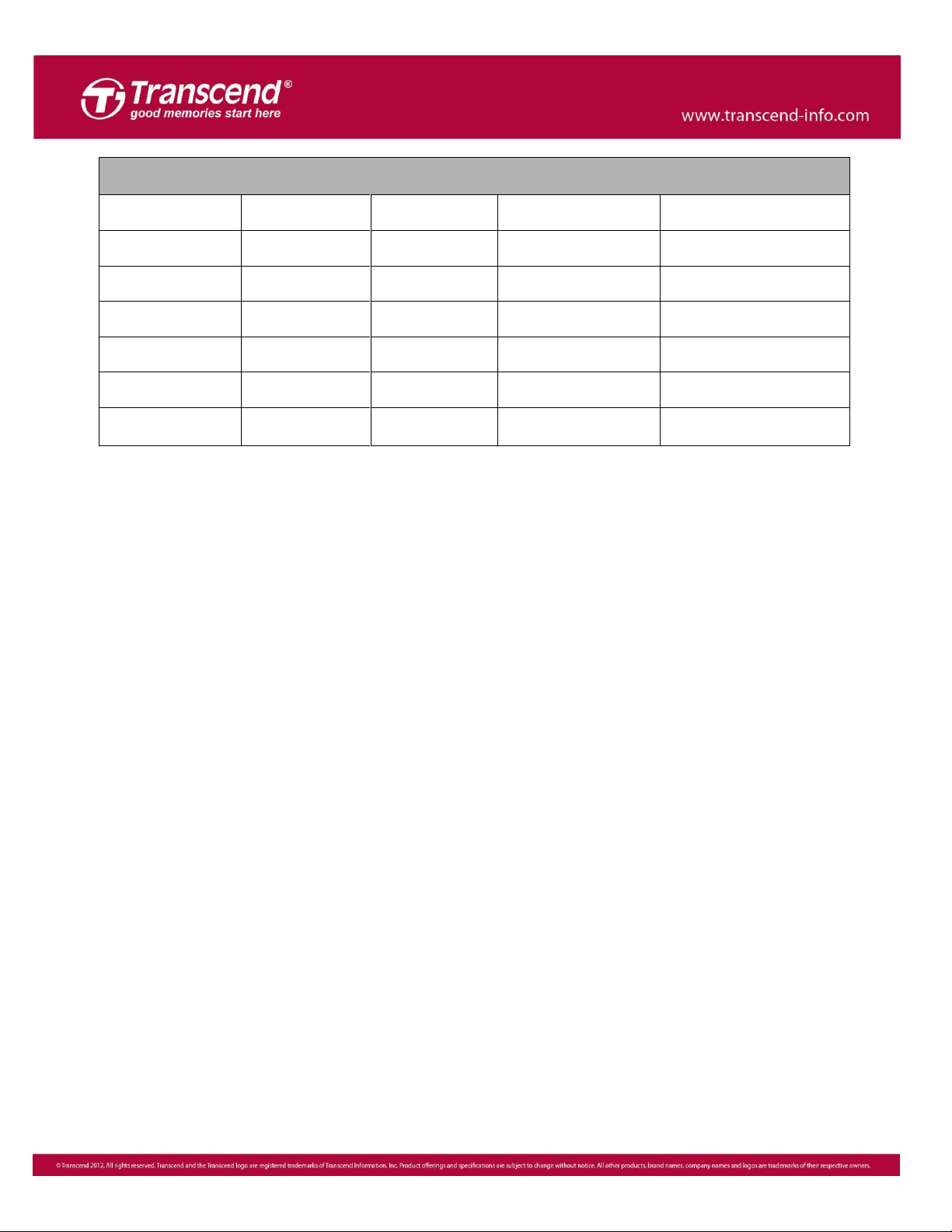

Performance

Model P/N

Read (MB/s)

Write (MB/s)

Random Read (MB/s)

Random Write (MB/s)

TS128MCF220I

39.43

8.615

10.60

0.178

TS256MCF220I

39.23

8.657

10.19

0.182

TS512MCF220I

20.79

7.637

8.139

0.338

TS1GCF220I

20.85

13.75

6.382

0.237

TS2GCF220I

20.57

22.45

6.308

1.091

TS4GCF220I

39.14

42.08

9.278

1.279

* Note : 25 oC, according to CF to IDE connector test on P5K-VM, 1GB RAM * 2, IDE interface support UDMA5,

Windows® XP Version 2002 SP3, benchmark utility CrystalDisk (version 3.0)

SHOCK & Vibration Test

Condition

Standard

Mechanical Shock Test

1500G, 0.5ms, 3 axes

IEC 60068-2-27

Vibration Test

20G (Peak-to-Peak)

20Hz to 2000Hz (Frequency)

IEC 60068-2-6

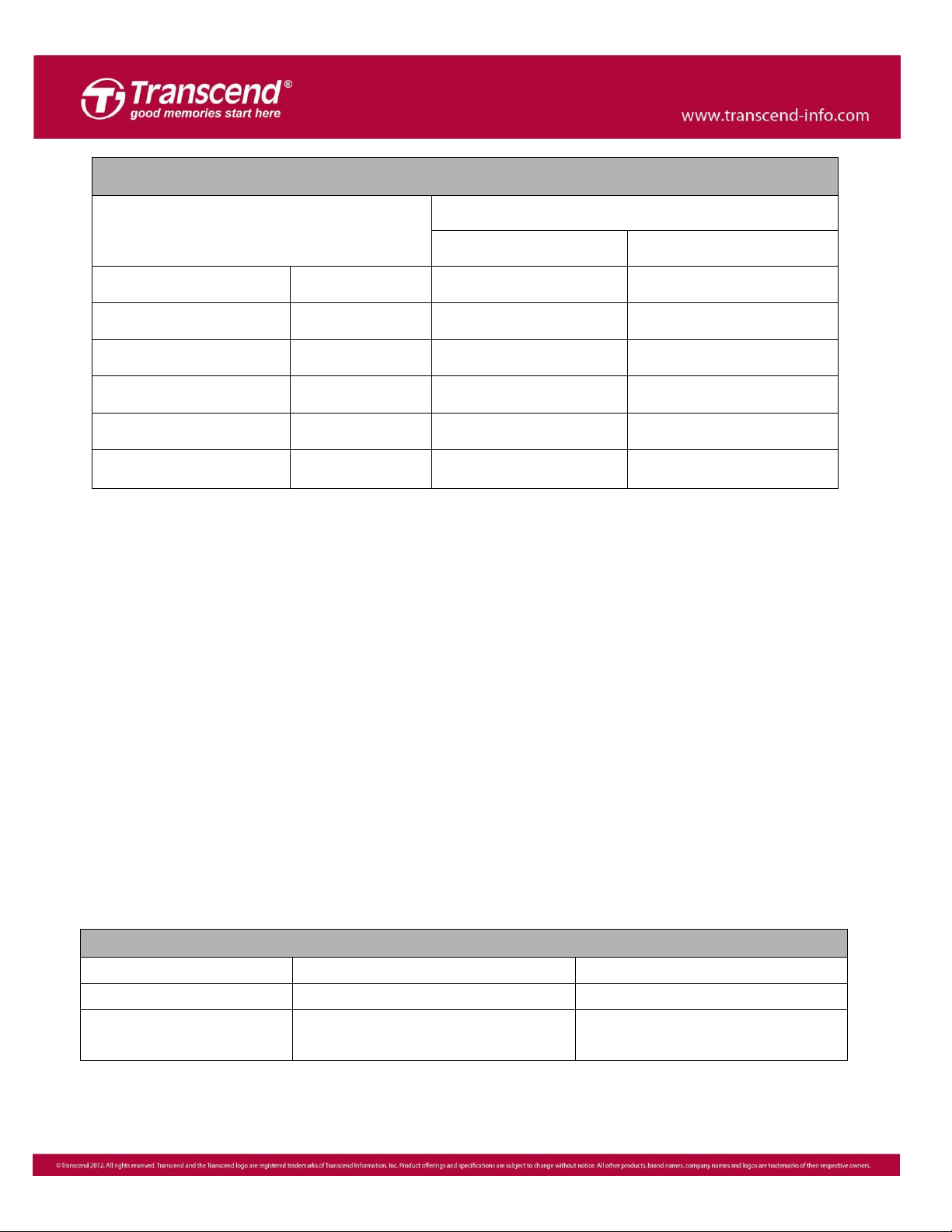

Power Requirements (DC 5V, 3.3V @25℃)

Part Number & Input Voltage

Current Magnitude (mA)

Read

Write

TS128MCF220I

3.3V 5%

121.3

84.1

TS256MCF220I

3.3V 5%

121.9

84.9

TS512MCF220I

3.3V 5%

87.7

70.3

TS1GCF220I

3.3V 5%

89.9

88.3

TS2GCF220I

3.3V 5%

92.1

111.0

TS4GCF220I

3.3V 5%

132.2

169.5

1. Read/Write operation is derived from IOMeter with 10MB file each operation.

2. StandBy Current : 5V : 2.8mA 3.3V : 2.2mA

3. All data above are maximum value of each measurement.

Regulations

Compliance

CE, FCC and BSMI

More Functions to extend product life

1. Global Wear Leveling – Advanced algorithm to enhance the Wear-Leveling Efficiency

Global wear leveling ensures every block has an even erase count. By ensuring all spare blocks in the

SSD’s flash chips are managed in a single pool, each block can then have an even erase count. This helps

to extend the lifespan of a SSD and to provide the best possible endurance.

There are 3 main processes in global wear leveling:

(1) Record the block erase count and save it in the wear-leveling table.

(2) Find the static-block and save it in wear-leveling pointer.

(3) Check the erase count when a block is pulled from the pool of spare blocks. If the erased block

count is larger than the Wear Count (WEARCNT), then the static blocks are leveraged against the

over-count blocks.

2. StaticDataRefresh Technology – Keeping Data Healthy

Many variants may disturb the charge inside a Flash cell. These variants can be: time, read operations,

undesired charge, heat, etc. Each variant would create a charge loss, which slightly influences the charge

levels. In our everyday usage, more than 60% are repeated read operations, and the accumulated charge

loss would eventually result in the data loss. Normally, the ECC engine corrections take place without

affecting normal host operations. Over time, the number of bit errors accumulated in the read transaction

exceeds the correcting capacity of the ECC engine, which results in corrupted data being sent to the host.

To prevent this, the controller monitors the bit error levels during each read operation; when the number of

bit errors reaches the preset threshold value, the controller automatically performs a data refresh to

“restore” the correct charge levels in the cell. Implementation of StaticDataRefresh Technology reinstates

the data to its original, error-free state, and hence, lengths the data’s lifespan.

3. EarlyRetirement – Avoiding Data Loss Due to Weak Block

The StaticDataRefresh feature functions well when the cells in a block are still healthy. As the block

ages over time, it cannot store charge reliably anymore, EarlyRetirement enters the scene.

EarlyRetirement works by moving the static data to another block (a health block) before the previously

used block becomes completely incapable of holding charges for data. When the charge loss error level

exceeds another threshold value (higher from that for StaticDataRefresh), the controller automatically

moves its data to another block. In addition, the original block is then marked as a bad block, which

prevents its further use, and thus the block enters the state of “EarlyRetirement.” Note that, through this

process, the incorrect data are detected and effectively corrected by the ECC engine, thus the data in the

new block is stored error-free.

4. Advanced Power Shield – Avoiding Data Loss during Power Failure

When a power failure takes place, the line voltage drops. When it reaches the first Logic-Freeze

Threshold, the core controller is held at a steady state. Here are some implications: Firstly, it ceases the

communication with the host. This prevents the host from sending in further address/instructions/data that

may be corrupted. During power disturbance, the host is likely experiencing a voltage drop, so the

transmission integrity cannot be guaranteed. Secondly, it stops sending the information to the Flash, which

prevents the controller from corrupting the address/data being transmitted to the Flash, and corrupting the

Flash contents inadvertently. Furthermore, Advanced Power Shield cuts off the connection of host power

and turns off the controller to reserve most of the energy for NAND Flash to complete programming. Owing

to the SLC structure, an interrupted programming may damage a paired page and cause the loss of the

previously written data.

Transcend

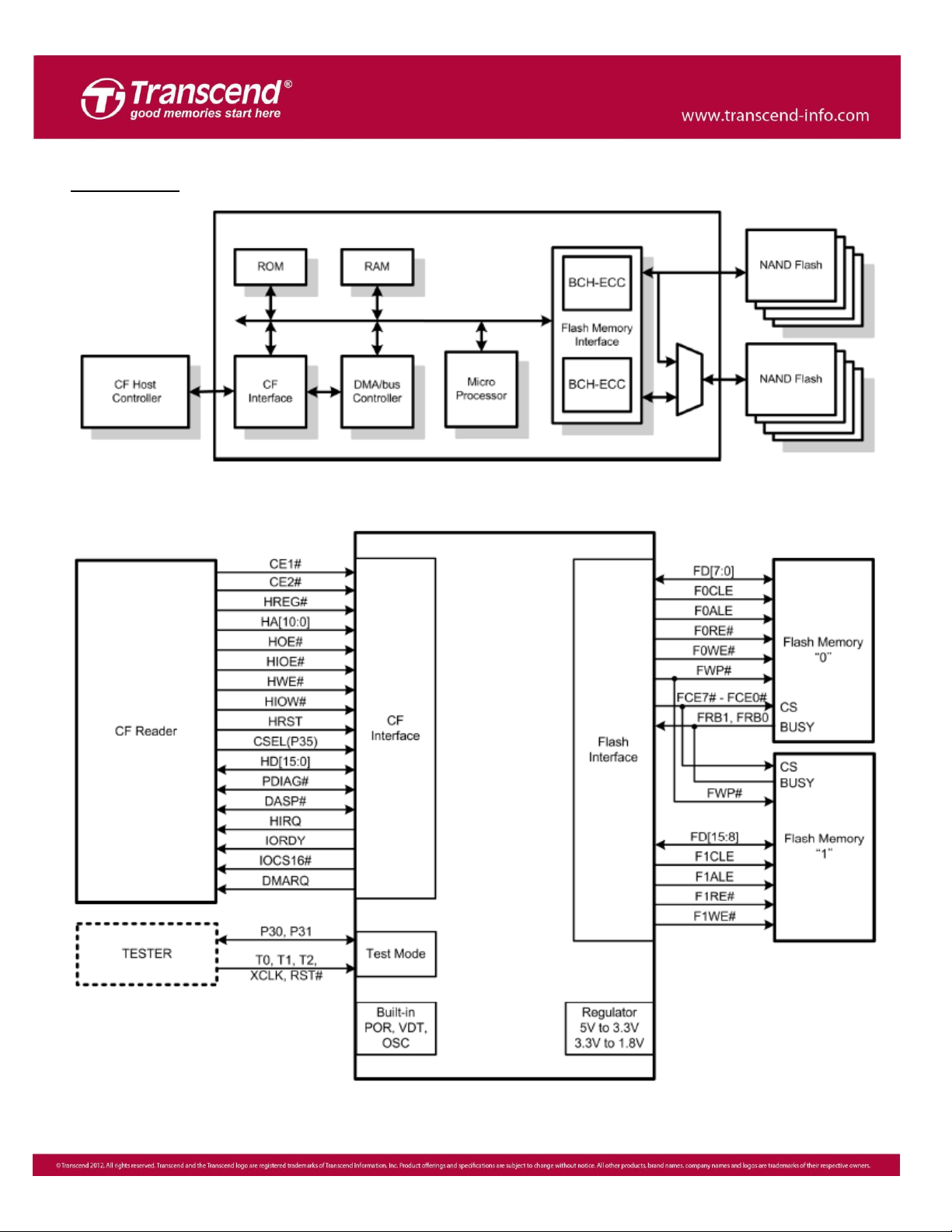

Block Diagram

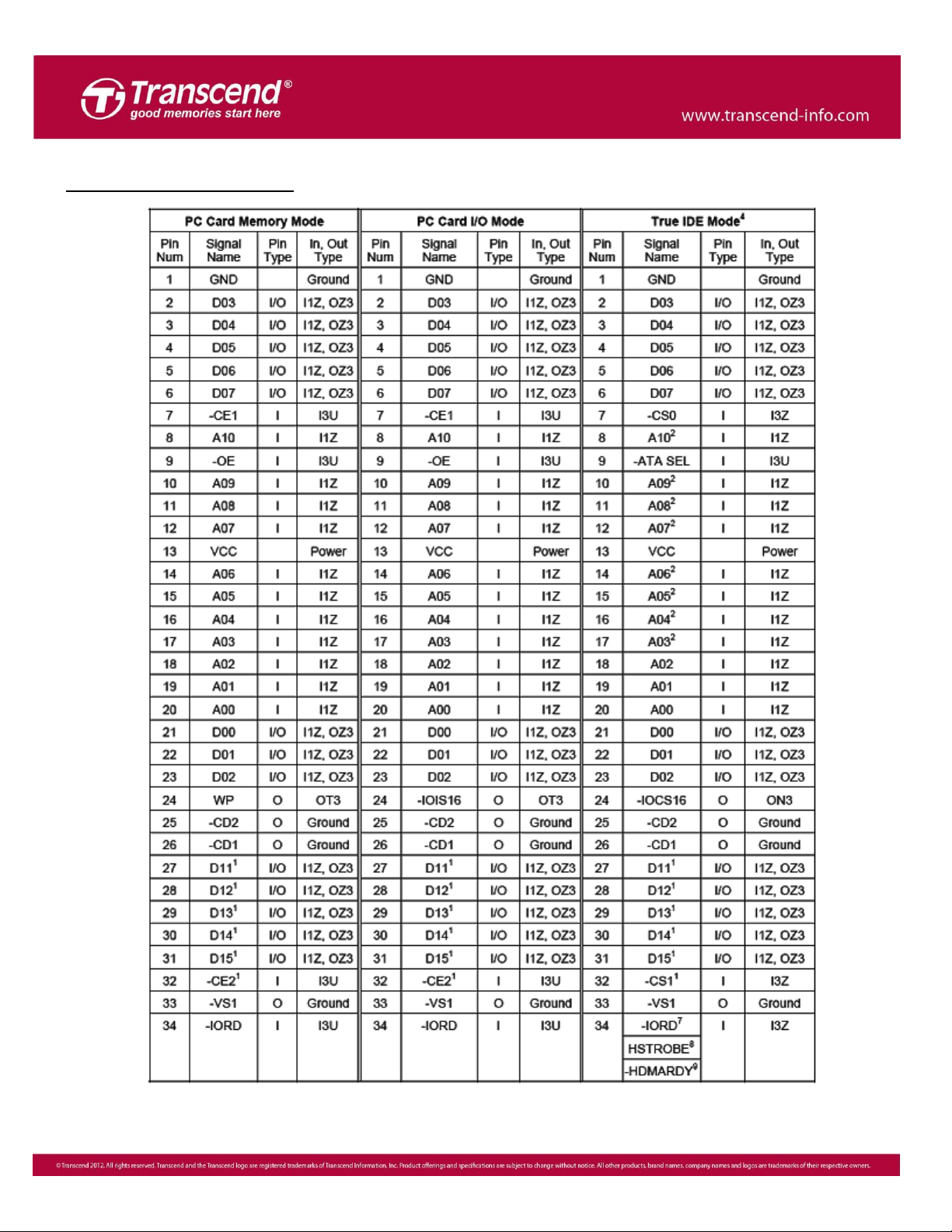

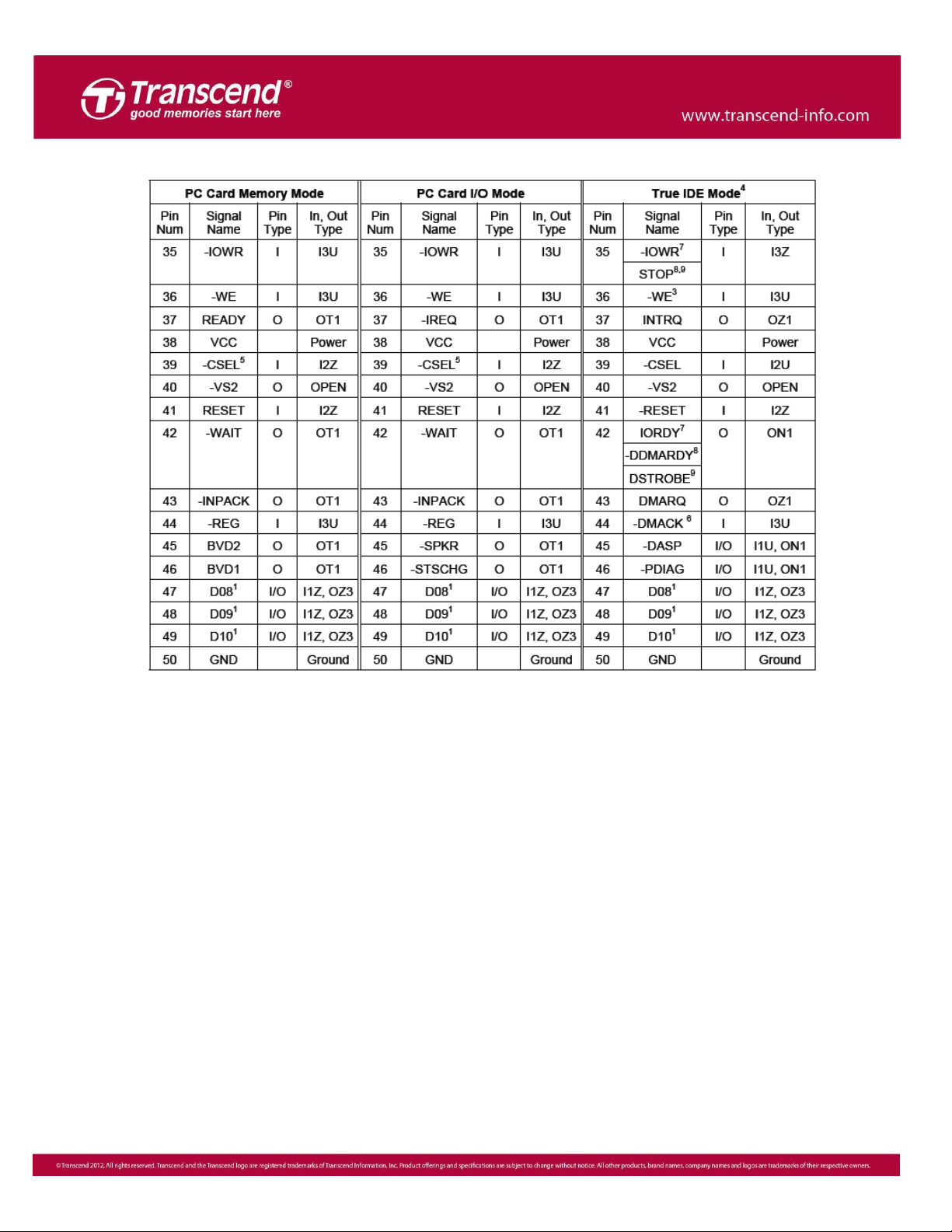

Pin Assignments and Pin Type

Note: 1) These signals are required only for 16 bit accesses and not required when installed in 8 bit

systems. Devices should allow for 3-state signals not to consume current.

2) The signal should be grounded by the host.

3) The signal should be tied to VCC by the host.

4) The mode is required for CompactFlash Storage Cards.

5) The -CSEL signal is ignored by the card in PC Card modes. However, because it is not

pulled upon the card in these modes, it should not be left floating by the host in PC Card

modes. In these modes, the pin should be connected by the host to PC Card A25 or

grounded by the host.

6) If DMA operations are not used, the signal should be held high or tied to VCC by the host. For

proper operation in older hosts: while DMA operations are not active, the card shall ignore

this signal,including a floating condition

7) Signal usage in True IDE Mode except when Ultra DMA mode protocol is active.

8) Signal usage in True IDE Mode when Ultra DMA mode protocol DMA Write is active.

9) Signal usage in True IDE Mode when Ultra DMA mode protocol DMA Read is active.

10) Signal usage in PC Card I/O and Memory Mode when Ultra DMA mode protocol DMA Write is active.

11) Signal usage in PC Card I/O and Memory Mode when Ultra DMA mode protocol DMA Read is active.

12) Signal usage in PC Card I/O and Memory Mode when Ultra DMA protocol is active.

Signal Name

Dir.

Pin

Description

A10 – A00

(PC Card Memory Mode)

A10 – A00

(PC Card I/O Mode)

A02 - A00

(True IDE Mode)

I

I

8,10,11,12,

14,15,16,17,

18,19,20

18,19,20

These address lines along with the -REG signal are used to select the following:

The I/O port address registers within the CompactFlash Storage Card , the

memory mapped port address registers within the CompactFlash Storage Card,

a byte in the card's information structure and its configuration control and status

registers.

This signal is the same as the PC Card Memory Mode signal.

In True IDE Mode, only A[02:00] are used to select the one of eight registers

in the Task File, the remaining address lines should be grounded by the host.

BVD1

(PC Card Memory Mode)

-STSCHG

(PC Card I/O Mode)

Status Changed

-PDIAG

(True IDE Mode)

I/O

46

This signal is asserted high, as BVD1 is not supported.

This signal is asserted low to alert the host to changes in the READY and Write

Protect states, while the I/O interface is configured. Its use is controlled by the

Card Config and Status Register.

In the True IDE Mode, this input / output is the Pass Diagnostic signal in the

Master / Slave handshake protocol.

BVD2

(PC Card Memory Mode)

-SPKR

(PC Card I/O Mode)

-DASP

(True IDE Mode)

I/O

45

This signal is asserted high, as BVD2 is not supported.

This line is the Binary Audio output from the card. If the Card does not support the

Binary Audio function, this line should be held negated.

In the True IDE Mode, this input/output is the Disk Active/Slave Present signal in

the Master/Slave handshake protocol.

-CD1, -CD2

(PC Card Memory Mode)

-CD1, -CD2

(PC Card I/O Mode)

-CD1, -CD2

(True IDE Mode)

O

26,25

These Card Detect pins are connected to ground on the CompactFlash Storage

Card. They are used by the host to determine that the CompactFlash Storage

Card is fully inserted into its socket.

This signal is the same for all modes.

This signal is the same for all modes.

Signal Description

Signal Name

Dir.

Pin

Description

-CE1, -CE2

(PC Card Memory Mode)

Card Enable

-CE1, -CE2

(PC Card I/O Mode)

Card Enable

-CS0, -CS1

(True IDE Mode)

I

7,32

These input signals are used both to select the card and to indicate to the card

whether a byte or a word operation is being performed. -CE2 always accesses

the odd byte of the word.-CE1 accesses the even byte or the Odd byte of the

word depending on A0 and -CE2. A multiplexing scheme based on A0,-CE1,

-CE2 allows 8 bit hosts to access all data on D0-D7. See Table 27, Table 29,

Table 31, Table 35, Table 36 and Table 37.

This signal is the same as the PC Card Memory Mode signal.

In the True IDE Mode, -CS0 is the address range select for the task file

registers while -CS1 is used to select the Alternate Status Register and the

Device Control Register.

While –DMACK is asserted, -CS0 and –CS1 shall be held negated and the

width of the transfers shall be 16 bits.

-CSEL

(PC Card Memory Mode)

-CSEL

(PC Card I/O Mode)

-CSEL

(True IDE Mode)

I

39

This signal is not used for this mode, but should be connected by the host to PC

Card A25 or grounded by the host.

This signal is not used for this mode, but should be connected by the host to PC

Card A25 or grounded by the host.

This internally pulled up signal is used to configure this device as a Master or a

Slave when configured in the True IDE Mode.

When this pin is grounded, this device is configured as a Master.

When the pin is open, this device is configured as a Slave.

D15 - D00

(PC Card Memory Mode)

D15 - D00

(PC Card I/O Mode)

D15 - D00

(True IDE Mode)

I/O

31,30,29,28,

27,49,48,47,

6,5,4,3,2,

23, 22, 21

These lines carry the Data, Commands and Status information between the host

and the controller. D00 is the LSB of the Even Byte of the Word. D08 is the LSB of

the Odd Byte of the Word.

This signal is the same as the PC Card Memory Mode signal.

In True IDE Mode, all Task File operations occur in byte mode on the low order

bus D[7:0] while all data transfers are 16 bit using D[15:0].

GND

(PC Card Memory Mode)

GND

(PC Card I/O Mode)

GND

(True IDE Mode)

--

1,50

Ground.

This signal is the same for all modes.

This signal is the same for all modes.

Signal Name

Dir.

Pin

Description

-INPACK

(PC Card Memory Mode)

-INPACK

(PC Card I/O Mode)

Input Acknowledge

DMARQ

(True IDE Mode)

O

43

This signal is not used in this mode.

The Input Acknowledge signal is asserted by the CompactFlash Storage Card

when the card is selected and responding to an I/O read cycle at the address that

is on the address bus. This signal is used by the host to control the enable of any

input data buffers between the CompactFlash Storage Card and the CPU.

This signal is a DMA Request that is used for DMA data transfers between host

and device. It shall be asserted by the device when it is ready to transfer data to

or from the host. For Multiword DMA transfers, the direction of data transfer is

controlled by -IORD and -IOWR. This signal is used in a handshake manner with

-DMACK, i.e., the device shall wait until the host asserts -DMACK before

negating DMARQ, and reasserting DMARQ if there is more data to transfer.

DMARQ shall not be driven when the device is not selected.

While a DMA operation is in progress, -CS0 and –CS1 shall be held negated and

the width of the transfers shall be 16 bits.

If there is no hardware support for DMA mode in the host, this output signal is not

used and should not be connected at the host. In this case, the BIOS must report

that DMA mode is not supported by the host so that device drivers will not attempt

DMA mode.

A host that does not support DMA mode and implements both PCMCIA and

True-IDE modes of operation need not alter the PCMCIA mode connections

while in True-IDE mode as long as this does not prevent proper operation in any

mode.

-IORD

(PC Card Memory Mode)

-IORD

(PC Card I/O Mode)

-IORD

(True IDE Mode – Except

Ultra DMA Protocol Active)

-HDMARDY

(True IDE Mode – In Ultra

DMA Protocol DMA Read)

HSTROBE

(True IDE Mode – In Ultra

DMA Protocol DMA Write)

I

34

This signal is not used in this mode.

This is an I/O Read strobe generated by the host. This signal gates I/O data onto

the bus from the CompactFlash Storage Card when the card is configured to use

the I/O interface.

In True IDE Mode, while Ultra DMA mode is not active, this signal has the same

function as in PC Card I/O Mode.

In True IDE Mode when Ultra DMA mode DMA Read is active, this signal is

asserted by the host to indicate that the host is read to receive Ultra DMA data-in

bursts. The host may negate -HDMARDY to pause an Ultra DMA transfer.

In True IDE Mode when Ultra DMA mode DMA Write is active, this signal is the

data out strobe generated by the host. Both the rising and falling edge of

HSTROBE cause data to be latched by the device. The host may stop generating

HSTROBE edges to pause an Ultra DMA data-out burst.

Signal Name

Dir.

Pin

Description

-IOWR

(PC Card Memory Mode)

-IOWR

(PC Card I/O Mode)

-IOWR

(True IDE Mode – Except

Ultra DMA Protocol Active)

STOP

(True IDE Mode – Ultra DMA

Protocol Active)

I

35

This signal is not used in this mode.

The I/O Write strobe pulse is used to clock I/O data on the Card Data bus into the

CompactFlash Storage Card controller registers when the CompactFlash

Storage Card is configured to use the I/O interface.

The clocking shall occur on the negative to positive edge of the signal (trailing

edge).

In True IDE Mode, while Ultra DMA mode protocol is not active, this signal has

the same function as in PC Card I/O Mode. When Ultra DMA mode protocol is

supported, this signal must be negated before entering Ultra DMA mode protocol.

In True IDE Mode, while Ultra DMA mode protocol is active, the assertion of this

signal causes the termination of the Ultra DMA burst.

-OE

(PC Card Memory Mode)

-OE

(PC Card I/O Mode)

-ATA SEL

(True IDE Mode)

I

9

This is an Output Enable strobe generated by the host interface. It is used to read

data from the CompactFlash Storage Card in Memory Mode and to read the CIS

and configuration registers.

In PC Card I/O Mode, this signal is used to read the CIS and configuration

registers.

To enable True IDE Mode this input should be grounded by the host.

READY

(PC Card Memory Mode)

-IREQ

(PC Card I/O Mode)

INTRQ

(True IDE Mode)

O

37

In Memory Mode, this signal is set high when the CompactFlash Storage Card is

ready to accept a new data transfer operation and is held low when the card is

busy.

At power up and at Reset, the READY signal is held low (busy) until the

CompactFlash Storage Card has completed its power up or reset function. No

access of any type should be made to the CompactFlash Storage Card during

this time.

Note, however, that when a card is powered up and used with RESET

continuously disconnected or asserted, the Reset function of the RESET pin is

disabled. Consequently, the continuous assertion of RESET from the application

of power shall not cause the READY signal to remain continuously in the busy

state.

I/O Operation – After the CompactFlash Storage Card Card has been configured

for I/O operation, this signal is used as -Interrupt Request. This line is strobed low

to generate a pulse mode interrupt or held low for a level mode interrupt.

In True IDE Mode signal is the active high Interrupt Request to the host.

Signal Name

Dir.

Pin

Description

-REG

(PC Card Memory Mode)

Attribute Memory Select

-REG

(PC Card I/O Mode)

I

44

This signal is used during Memory Cycles to distinguish between Common

Memory and Register (Attribute) Memory accesses. High for Common Memory,

Low for Attribute Memory.

The signal shall also be active (low) during I/O Cycles when the I/O address is on

the Bus.

-DMACK

(True IDE Mode)

This is a DMA Acknowledge signal that is asserted by the host in response to

DMARQ to initiate DMA transfers.

While DMA operations are not active, the card shall ignore the -DMACK signal,

including a floating condition.

If DMA operation is not supported by a True IDE Mode only host, this signal

should be driven high or connected to VCC by the host.

A host that does not support DMA mode and implements both PCMCIA and

True-IDE modes of operation need not alter the PCMCIA mode connections

while in True-IDE mode as long as this does not prevent proper operation all

modes.

RESET

(PC Card Memory Mode)

RESET

(PC Card I/O Mode)

-RESET

(True IDE Mode)

I

41

The CompactFlash Storage Card is Reset when the RESET pin is high with the

following important exception:

The host may leave the RESET pin open or keep it continually high from the

application of power without causing a continuous Reset of the card. Under either

of these conditions, the card shall emerge from power-up having completed an

initial Reset.

The CompactFlash Storage Card is also Reset when the Soft Reset bit in the

Card Configuration Option Register is set.

This signal is the same as the PC Card Memory Mode signal.

In the True IDE Mode, this input pin is the active low hardware reset from the

host.

VCC

(PC Card Memory Mode)

VCC

(PC Card I/O Mode)

VCC

(True IDE Mode)

--

13,38

+5 V, +3.3 V power.

This signal is the same for all modes.

This signal is the same for all modes.

Signal Name

Dir.

Pin

Description

-VS1

-VS2

(PC Card Memory Mode)

-VS1

-VS2

(PC Card I/O Mode)

-VS1

-VS2

(True IDE Mode)

O

33

40

Voltage Sense Signals. -VS1 is grounded on the Card and sensed by the Host so

that the CompactFlash Storage Card CIS can be read at 3.3 volts and -VS2 is

reserved by PCMCIA for a secondary voltage and is not connected on the Card.

This signal is the same for all modes.

This signal is the same for all modes.

-WAIT

(PC Card Memory Mode)

-WAIT

(PC Card I/O Mode)

IORDY

(True IDE Mode – Except

Ultra DMA Mode)

-DDMARDY

(True IDE Mode – Ultra DMA

Write Mode)

DSTROBE

(True IDE Mode – Ultra

DMA Read Mode)

O

42

The -WAIT signal is driven low by the CompactFlash Storage Card to signal the

host to delay completion of a memory or I/O cycle that is in progress.

This signal is the same as the PC Card Memory Mode signal.

In True IDE Mode, except in Ultra DMA modes, this output signal may be used as

IORDY.

In True IDE Mode, when Ultra DMA mode DMA Write is active, this signal is

asserted by the host to indicate that the device is read to receive Ultra DMA

data-in bursts. The device may negate -DDMARDY to pause an Ultra DMA

transfer.

In True IDE Mode, when Ultra DMA mode DMA Write is active, this signal is the

data out strobe generated by the device. Both the rising and falling edge of

DSTROBE cause data to be latched by the host. The device may stop generating

DSTROBE edges to pause an Ultra DMA data-out burst.

-WE

(PC Card Memory Mode)

-WE

(PC Card I/O Mode)

-WE

(True IDE Mode)

I

36

This is a signal driven by the host and used for strobing memory write data to the

registers of the CompactFlash Storage Card when the card is configured in the

memory interface mode. It is also used for writing the configuration registers.

In PC Card I/O Mode, this signal is used for writing the configuration registers.

In True IDE Mode, this input signal is not used and should be connected to VCC

by the host.

WP

(PC Card Memory Mode)

Write Protect

-IOIS16

(PC Card I/O Mode)

-IOCS16

(True IDE Mode)

O

24

Memory Mode – The CompactFlash Storage Card does not have a write protect

switch. This signal is held low after the completion of the reset initialization

sequence.

I/O Operation – When the CompactFlash Storage Card is configured for I/O

Operation Pin 24 is used for the -I/O Selected is 16 Bit Port (-IOIS16) function. A

Low signal indicates that a 16 bit or odd byte only operation can be performed at

the addressed port.

In True IDE Mode this output signal is asserted low when this device is expecting

a word data transfer cycle.

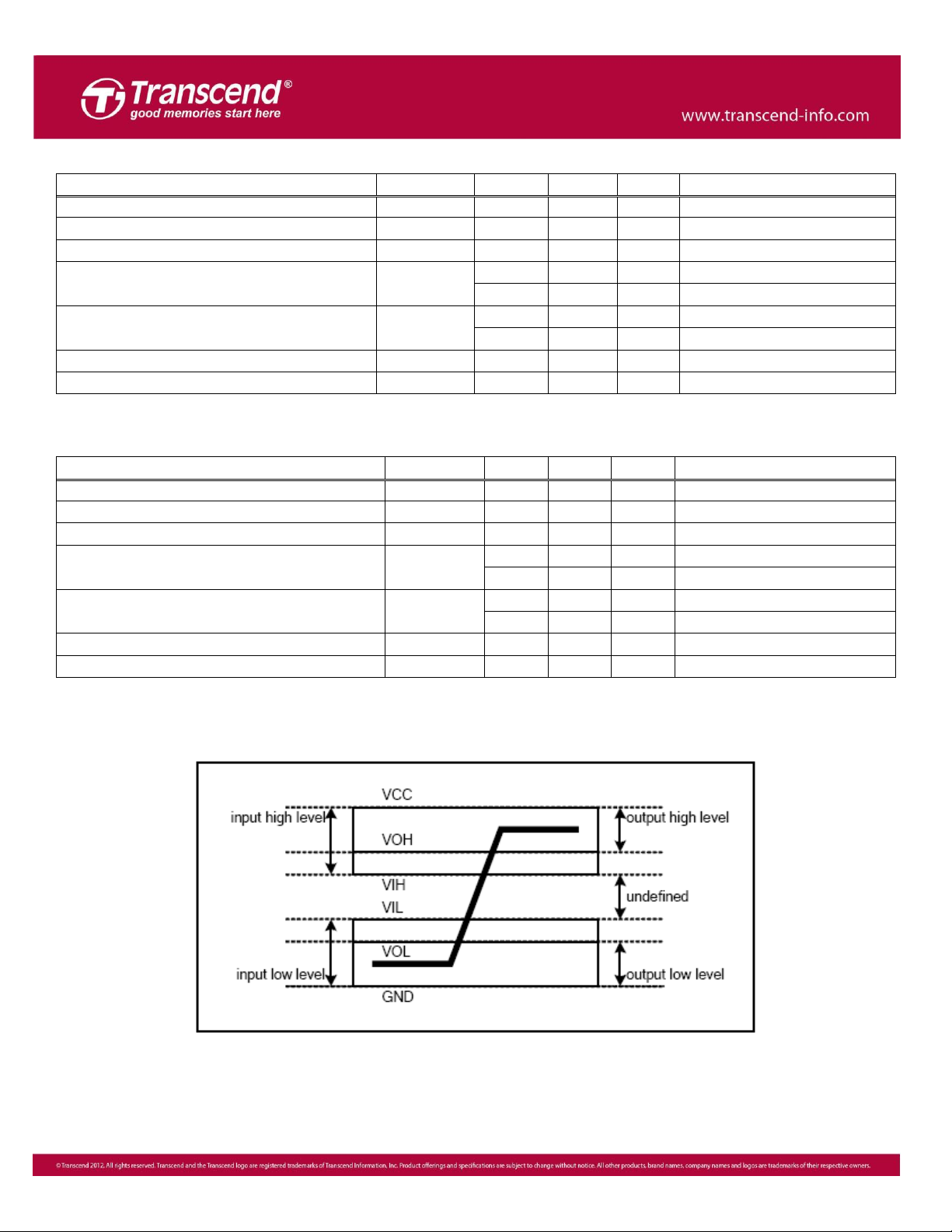

Parameter

Symbol

Min.

Max.

Unit

Remark

Supply Voltage

VCC

4.5

5.5

V

High level output voltage

VOH

VCC-0.8

V Low level output voltage

VOL

0.8

V

High level input voltage

VIH

4.0 V

Non-schmitt trigger

2.92 V

Schmitt trigger1

Low level input voltage

VIL

0.8 V Non-schmitt trigger

1.70 V Schmitt trigger1

Pull up resistance2

RPU

50.

73

kOhm Pull down resistance

RPD

50

97

kOhm

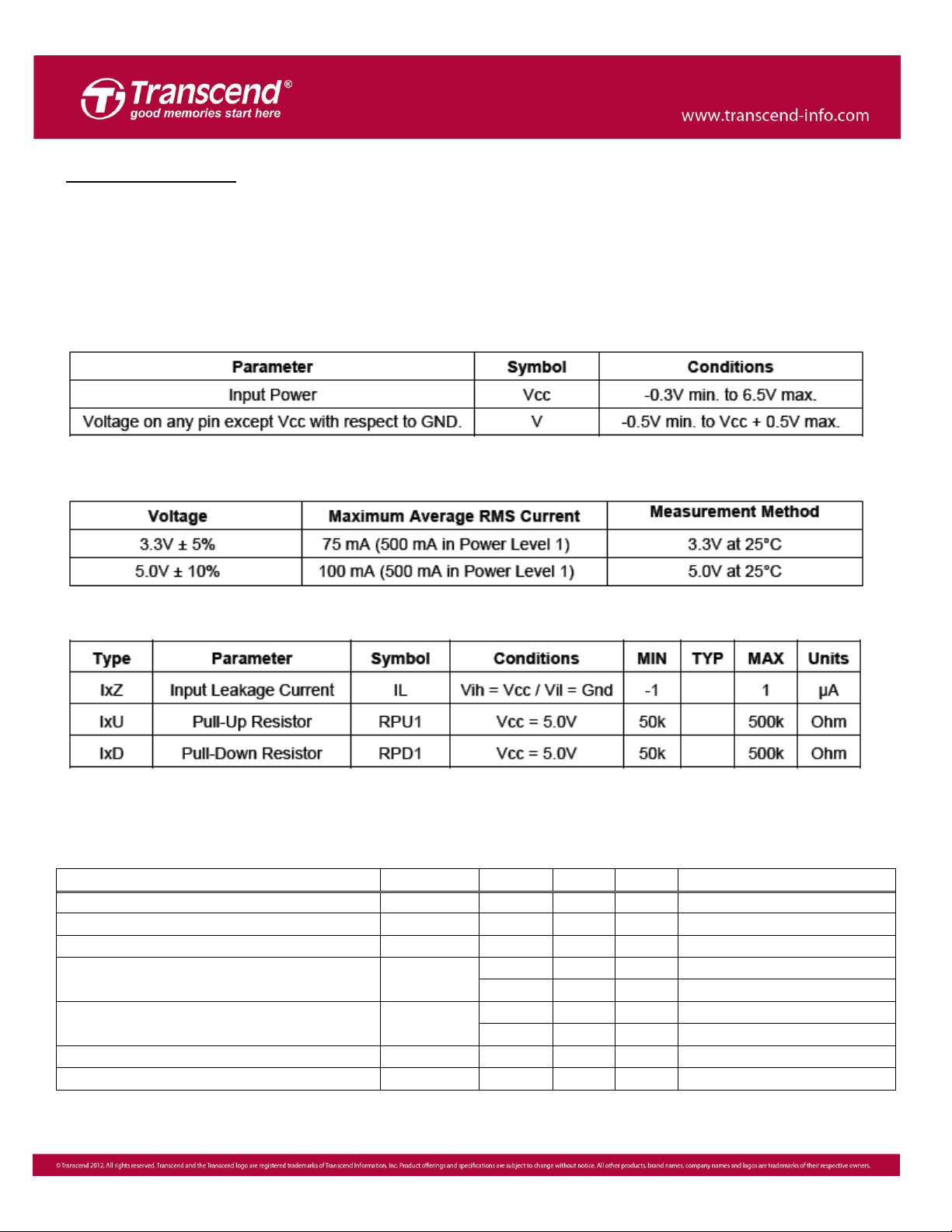

Electrical Specification

The following tables indicate all D.C. Characteristics for the CompactFlash Storage Card. Unless otherwise stated,

conditions are:

Vcc = 5V ±10%

Vcc = 3.3V ± 5%

Absolute Maximum Conditions

Input Power

Input Leakage Current

Input Characteristics

CompactFlash interface I/O at 5.0V

CompactFlash interface I/O at 3.3V

Parameter

Symbol

Min.

Max.

Unit

Remark

Supply Voltage

VCC

2.97

3.63

V

High level output voltage

VOH

VCC-0.8

V Low level output voltage

VOL

0.8

V

High level input voltage

VIH

2.4 V

Non-schmitt trigger

2.05 V

Schmitt trigger1

Low level input voltage

VIL

0.6 V Non-schmitt trigger

1.25 V Schmitt trigger1

Pull up resistance2

RPU

52.7

141

kOhm Pull down resistance

RPD

47.5

172

kOhm

Parameter

Symbol

Min.

Max.

Unit

Remark

Supply Voltage

VCC

2.7

3.6

V

High level output voltage

VOH

2.4 V

Low level output voltage

VOL

0.4

V

High level input voltage

VIH

2.0 V

Non-schmitt trigger

1.4

2.0 V Schmitt trigger

Low level input voltage

VIL

0.8 V Non-schmitt trigger

0.8

1.2 V Schmitt trigger

Pull up resistance

RPU

40 kOhm

Pull down resistance

RPD

40 kOhm

The I/O pins other than CompactFlash interface

1. Include CE1, CE2, HREG, HOE. HIOE, HWE, HIOW pins.

2. Include CE1, CE2, HREG, HOE. HIOE, HWE, HIOW, CSEL, PDIAG, DASP pins.

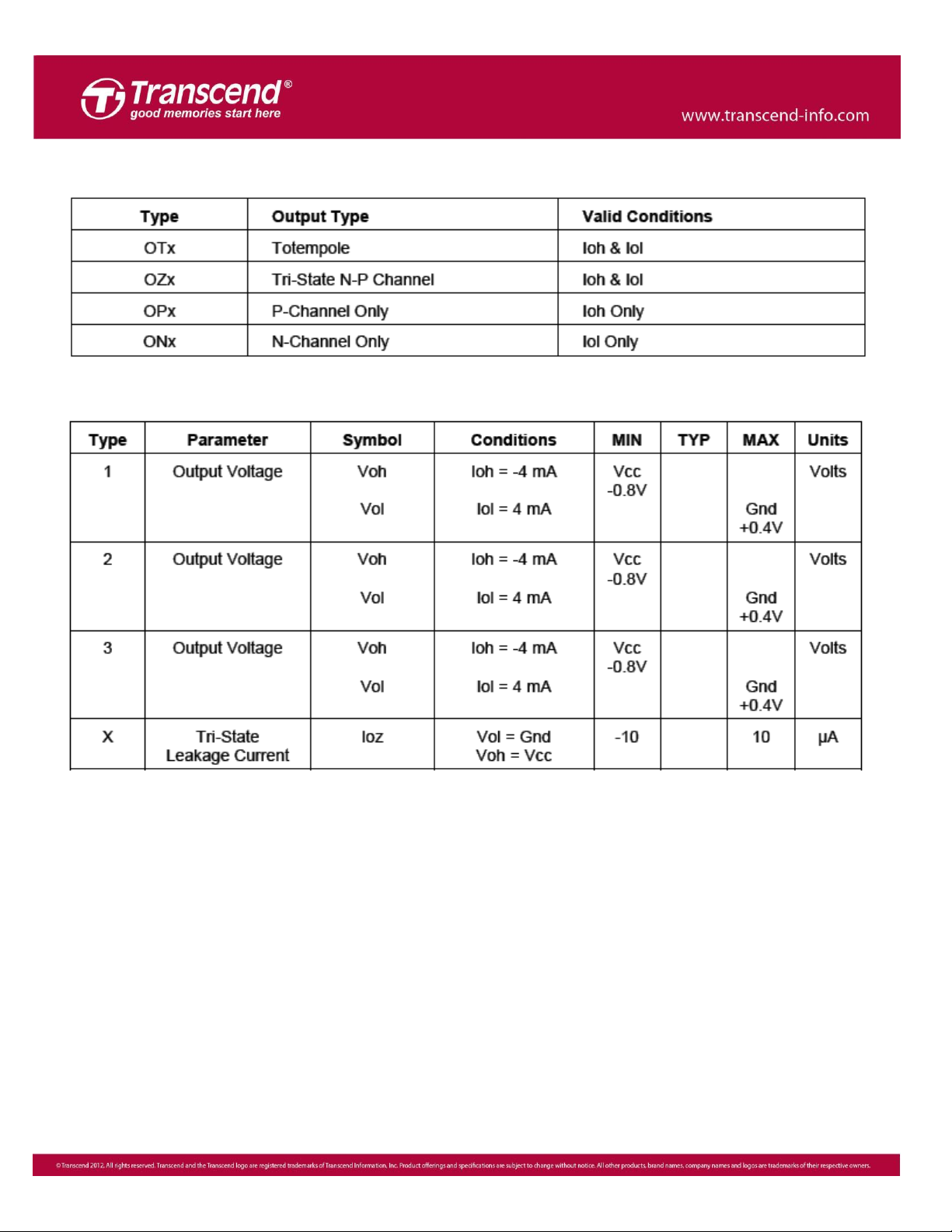

Output Drive Type

Output Drive Characteristics

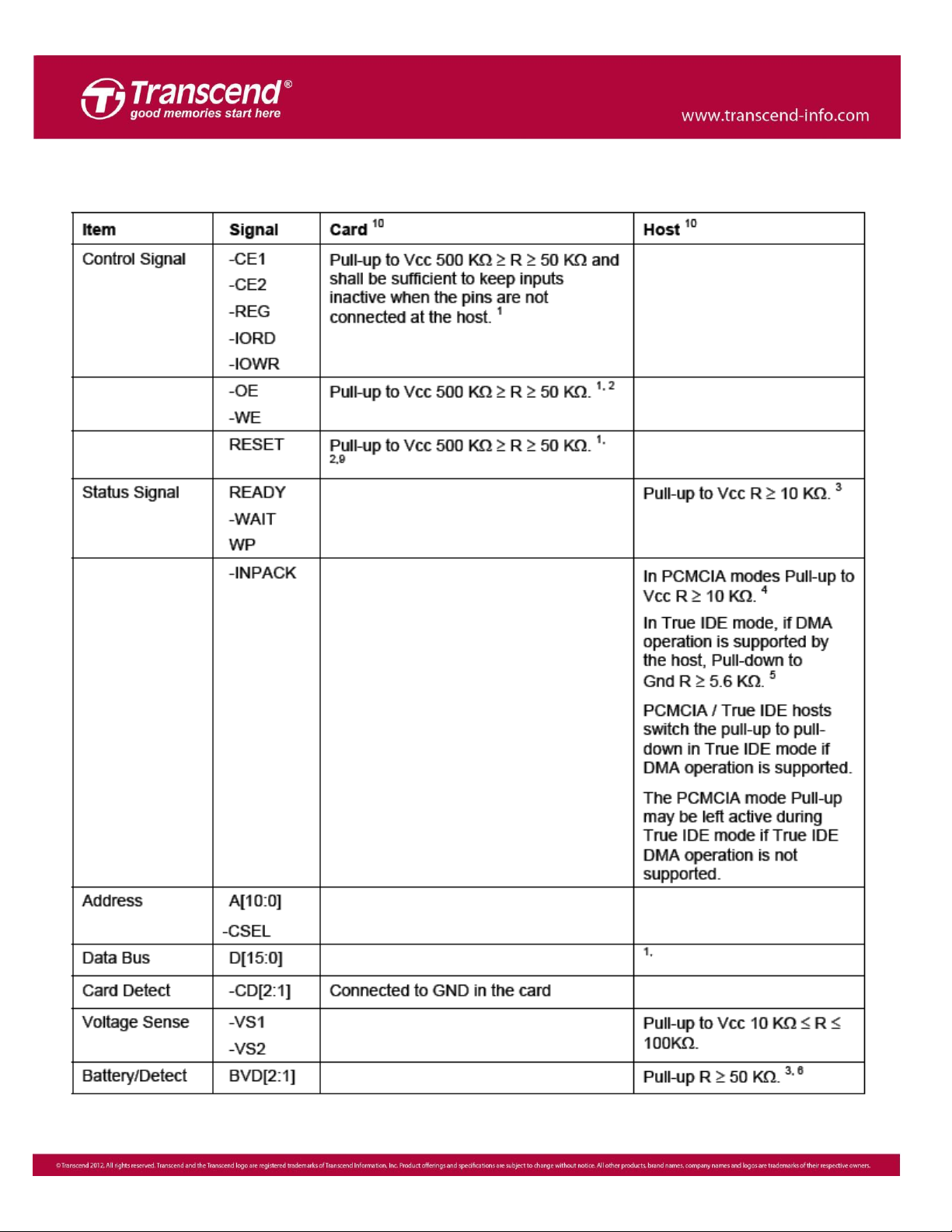

Signal Interface

Notes: 1) Control Signals: each card shall present a load to the socket no larger than 50 pF 10 at a DC current of 700 μ A low

state and 150 μ A high state, including pull-resistor. The socket shall be able to drive at least the following load

10 while meeting all AC timing requirements: (the number of sockets wired in parallel) multiplied by (50 pF with

DC current 700 μ A low state and 150 μ A high state per socket).

2) Resistor is optional.

3) Status Signals: the socket shall present a load to the card no larger than 50 pF 10 at a DC current of 400 μ A low

state and 100 μ A high state, including pull-up resistor. The card shall be able to drive at least the following load

10 while meeting all AC timing requirements: 50 pF at a DC current of 400 μ A low state and 100 μ A high state.

4) Status Signals: the socket shall present a load to the card no larger than 50 pF 10 at a DC current of 400 μ A low

state and 100 μ A high state, including pull-up resistor. The card shall be able to drive at least the following load

10 while meeting all AC timing requirements: 50 pF at a DC current of 400 μ A low state and 100 μ A high state.

5) Status Signals: the socket shall present a load to the card no larger than 50 pF 10 at a DC current of 400 μ A low

state and 100 μ A high state, including pull-up resistor. The card shall be able to drive at least the following load

10 while meeting all AC timing requirements: 50 pF at a DC current of 400 μ A low state and 1100 μ A high state.

6) BVD2 was not defined in the JEIDA 3.0 release. Systems fully supporting JEIDA release 3 SRAM cards shall

pull-up pin 45 (BVD2) to avoid sensing their batteries as “Low.”

7) Address Signals: each card shall present a load of no more than 100pF 10 at a DC current of 450μ A low state and

150μ A high state. The host shall be able to drive at least the following load 10 while meeting all AC timing

requirements: (the number of sockets wired in parallel) multiplied by (100pF with DC current 450μ A low state

and 150μ A high state per socket).

8) Data Signals: the host and each card shall present a load no larger than 50pF 10 at a DC current of 450μ A and

150μ A high state. The host and each card shall be able to drive at least the following load 10 while meeting all

AC timing requirements: 100pF with DC current 1.6mA low state and 300μ A high state. This permits the host to

wire two sockets in parallel without derating the card access speeds.

9) Reset Signal: This signal is pulled up to prevent the input from floating when a CFA to PCMCIA adapter is used in

a PCMCIA revision 1 host. However, to minimize DC current drain through the pull-up resistor in normal

operation the pull-up should be turned off once the Reset signal has been actively driven low by the host.

Consequently, the input is specified as an I2Z because the resistor is not necessarily detectable in the input

current leakage test.

10) Host and card restrictions for CF Advanced Timing Modes and Ultra DMA modes: Additional Requirements for

CF Advanced Timing Modes and Ultra DMA Electrical Requirements for additional required limitations on the

implementation of CF Advanced Timing modes and Ultra DMA modes respectively.

Additional Requirements for CF Advanced Timing Modes

The CF Advanced Timing modes include PCMCIA I/O and Memory modes that are 100ns or faster and True

IDE PIO Modes 5,6 and Multiword DMA Modes 3,4.

When operating in CF Advanced timing modes, the host shall conform to the following requirements:

1) Only one CF device shall be attached to the CF Bus.

2) The host shall not present a load of more than 40pF to the device for all signals, including any cabling.

3) The maximum cable length is 0.15 m (6 in). The cable length is measured from the card connector to the host

controller. 0.46 m (18 in) cables are not supported.

4) The -WAIT and IORDY signals shall be ignored by the host.

Devices supporting CF Advanced timing modes shall also support slower timing modes, to ensure operability with

systems that do not support CF Advanced timing modes

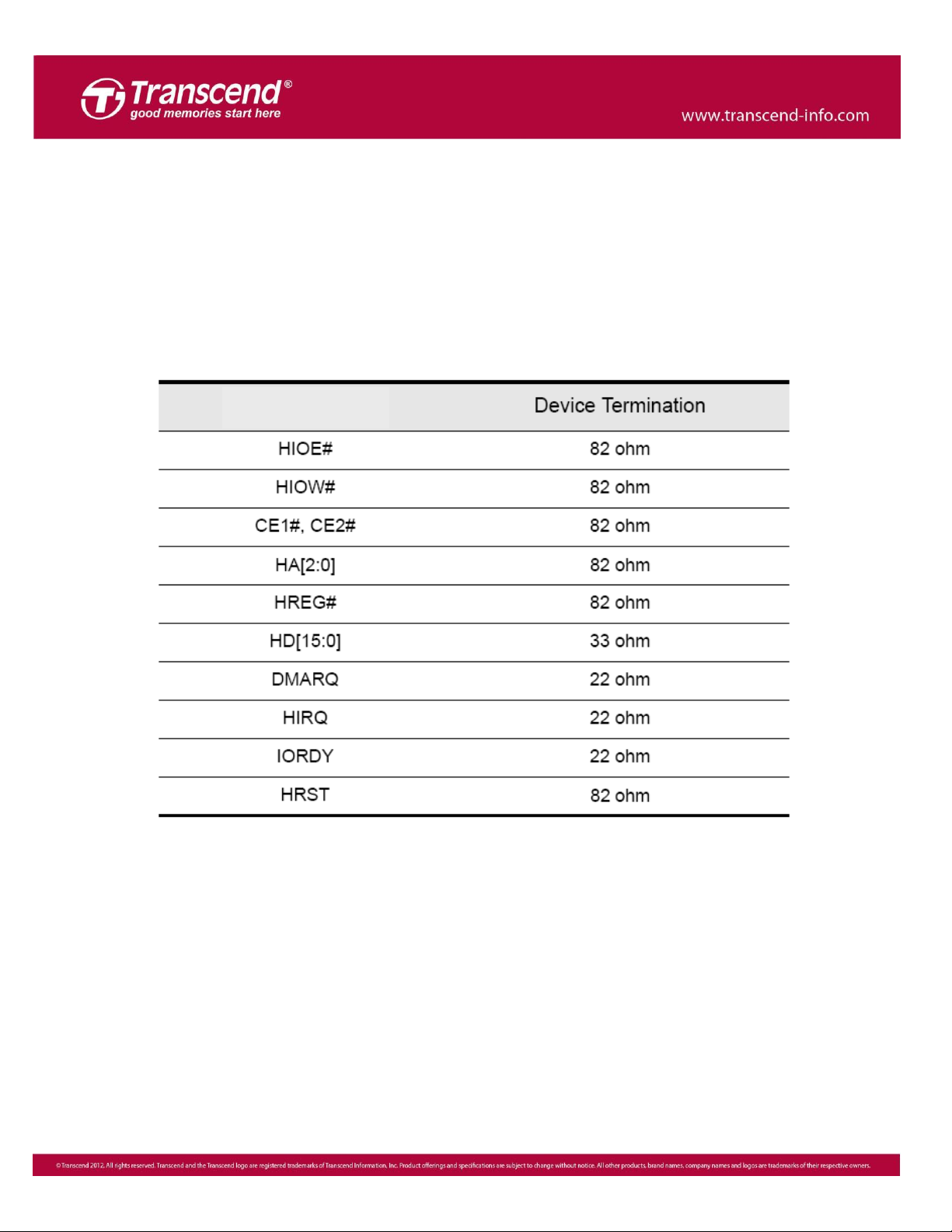

Table: Typical Series Termination for Ultra DMA

Signal

Ultra DMA Electrical Requirements

Host and Card signal capacitance limits for Ultra DMA operation

The host interface signal capacitance at the host connector shall be a maximum of 25 pF for each signal as measured at

1 MHz. The card interface signal capacitance at the card connector shall be a maximum of 20 pF for each signal as

measured at 1 MHz.

Series termination required for Ultra DMA operation

Series termination resistors are required at both the host and the card for operation in any of the Ultra DMA modes. Table

13 describes typical values for series termination at the host and the device.

Table: Ultra DMA Termination with Pull-up or Pull down Example

Printed Circuit Board (PCB) Trace Requirements for Ultra DMA

On any PCB for a host or device supporting Ultra DMA:

The longest D[15:00] trace shall be no more than 0.5" longer than either STROBE trace as measured from the

IC pin to the connector.

The shortest D[15:00] trace shall be no more than 0.5" shorter than either STROBE trace as measured from

the IC pin to the connector.

Ultra DMA Mode Cabling Requirement

Operation in Ultra DMA mode requires a crosstalk suppressing cable. The cable shall have a grounded line

between each signal line.

For True IDE mode operation using a cable with IDE (ATA) type 40 pin connectors it is recommended that the

host sense the cable type using the method described in the ANSI INCITS 361-2002 AT Attachment - 6

standard, to prevent use of Ultra DMA with a 40 conductor cable.

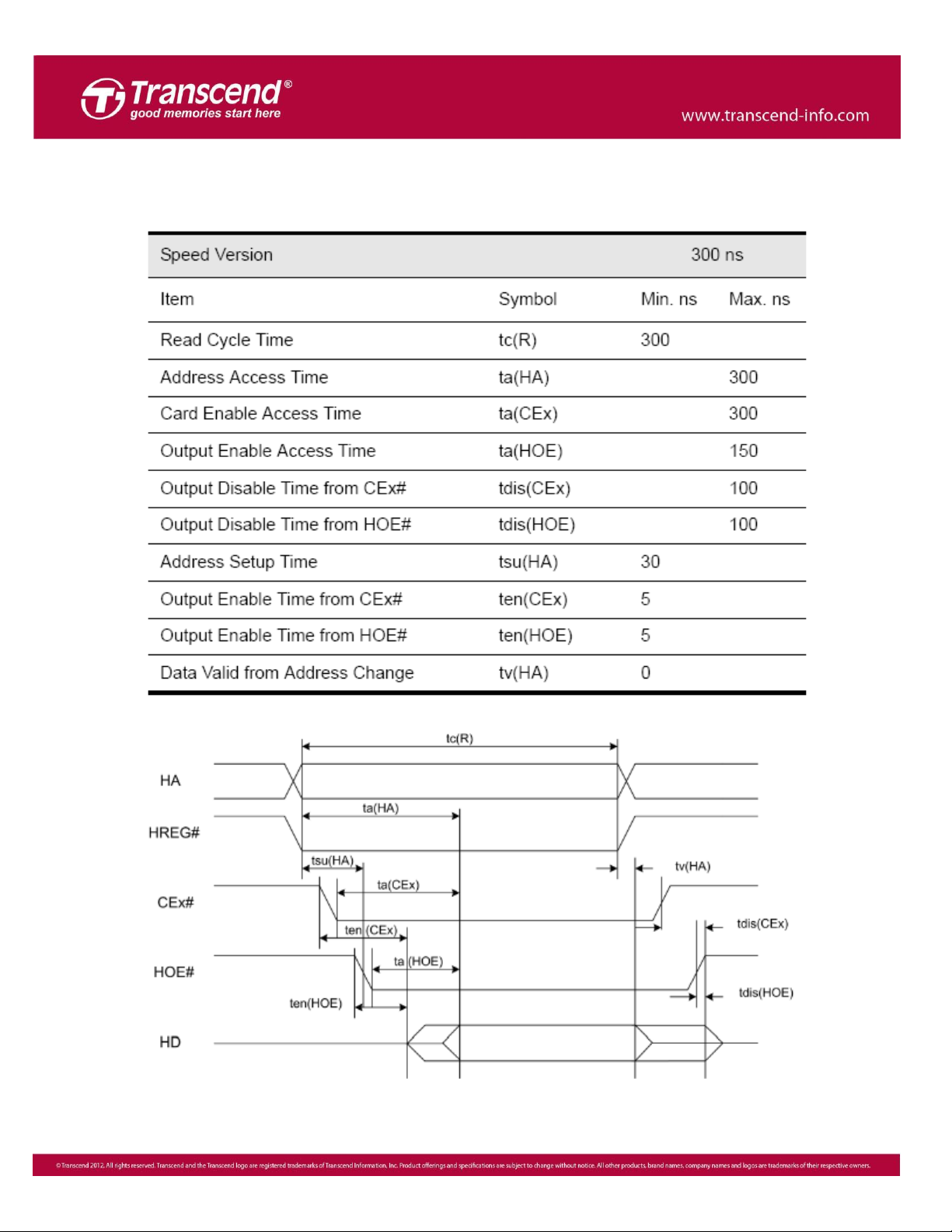

Attribute Memory Read Timing Specification

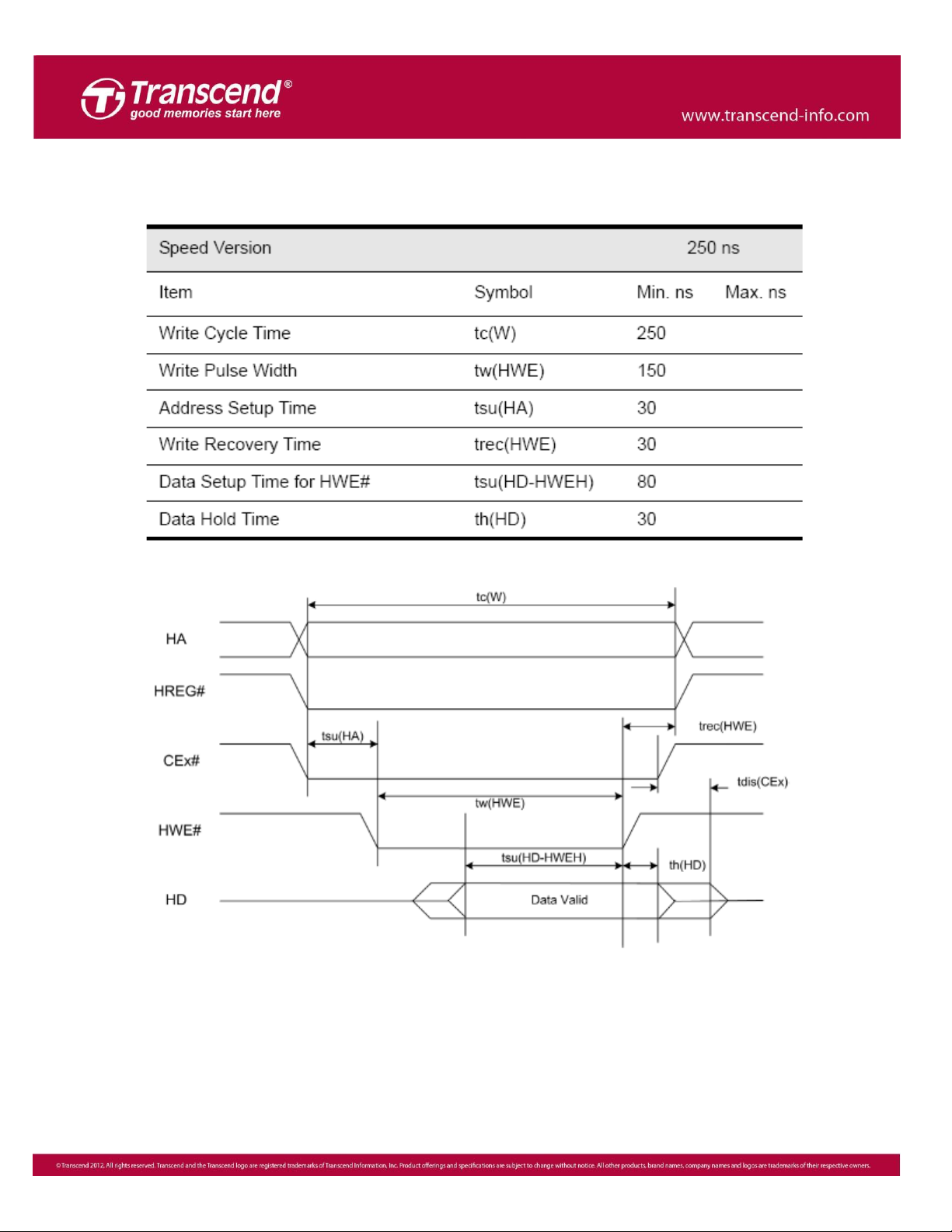

Configuration Register (Attribute Memory) Write Timing Specification

Common Memory Read Timing Specification

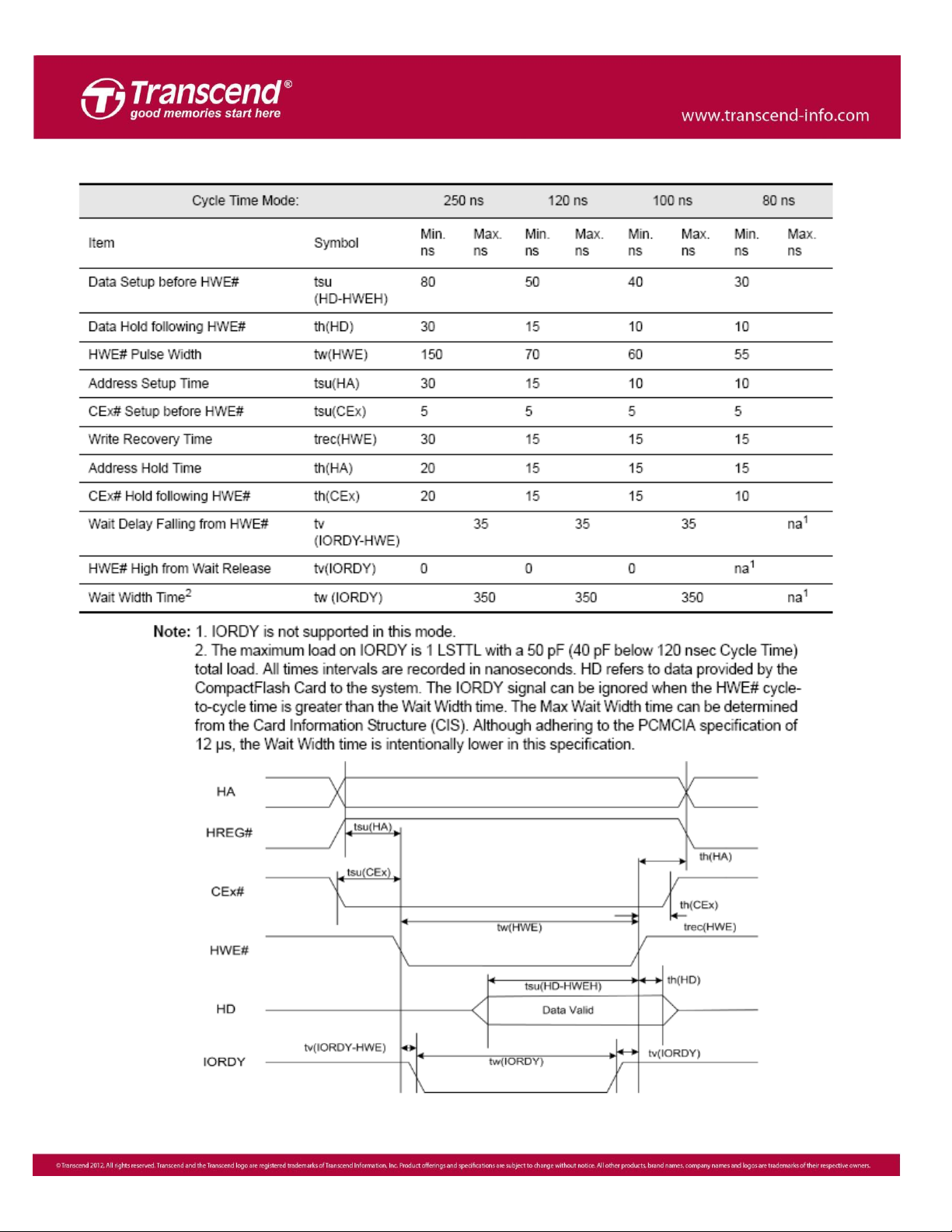

Common Memory Write Timing Specification

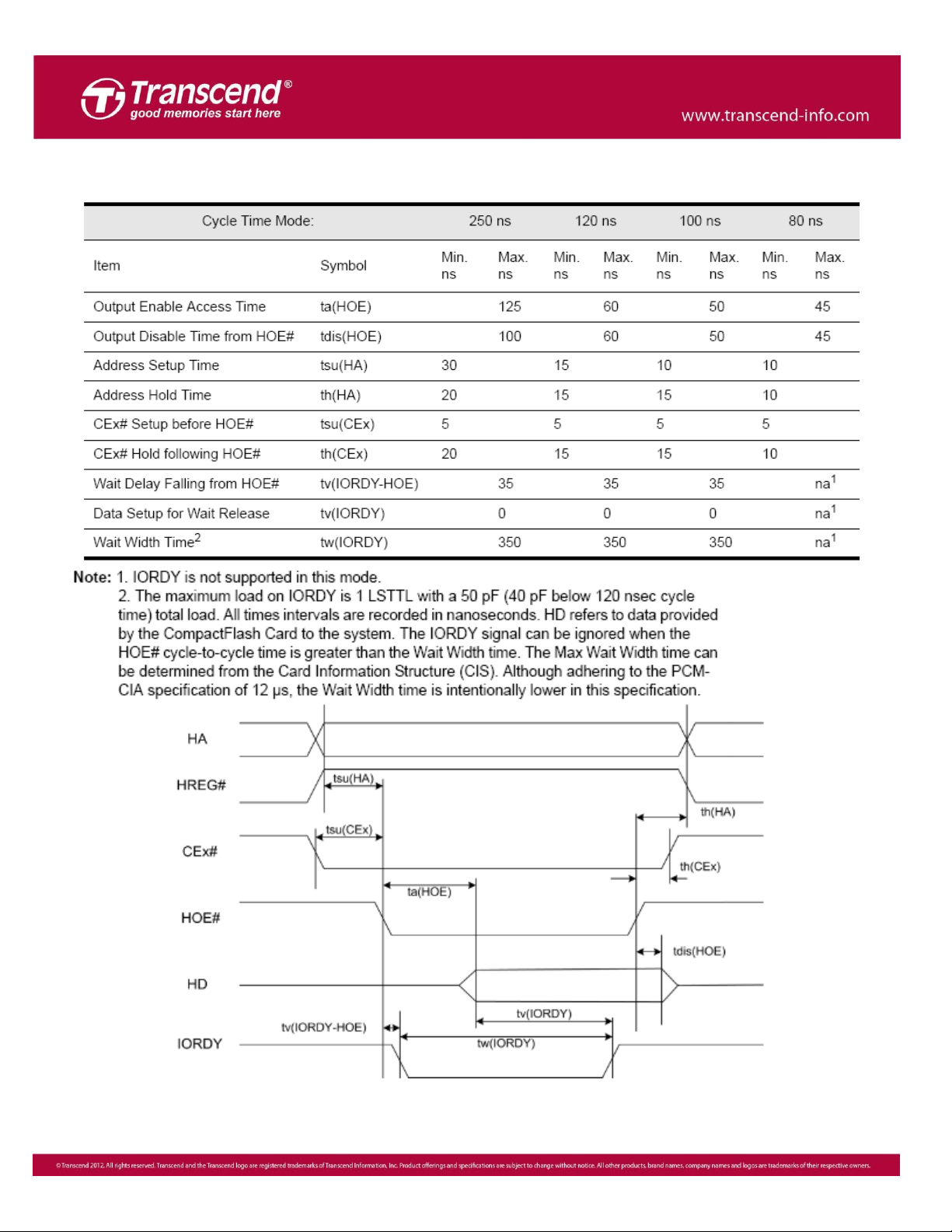

Loading...

Loading...