Page 1

Operators Guide

PN 100-11681 Rev A, October 2012

Page 2

This page intentionally left blank

Page 3

Change History

Rev A Initial version October 2012

100-TBD - Rev A Page i

Page 4

This page intentionally left blank

Page ii 100-TBD - Rev A

Page 5

adio Frequency Interference Statement

R

This device complies with Part 15 of the FCC Rules and Industry Canada

licence-exempt RSS standard(s) . Operation of the device is subject to

the following two conditions: (1) The device may not cause harmful interference,

and (2) The devices must accept any interference that may cause undesired

operation.

This unit has been tested and complies with limits for a Class A digital device

under Part 15 of the FCC Rules and Industry of Canada ICES-003. These limits

are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense..

Changes or modifications not expressly approved by TransAct Technologies,

Inc. could void the user's authority to operate the equipment.

The manufacturer declares that this product conforms to the following

standards or other normative documents:

EN 300 330-2 V1.5.1 (2010-02) Electomagnetic compatibility and Radio

spectrum Maters (ERM); Short-Range Devices (SRD); Radio equipment

in the frequency range 9 kHz to 25 MHz inductive loop system in the

frequency range 9 kHz and 30 MHz

EN 301 489-1 V1.9.2 (2011-09) Electomagnetic compatibility and Radio

spectrum Maters (ERM); ElectroMagnetic Compatibility (EMC) standard

for radio equipment and services; Part 1: Common technical requirements

EN 301 489-3 V1.4.1 (2002-08) Electomagnetic compatibility and Radio

spectrum Maters (ERM); ElectroMagnetic Compatibility (EMC) standard

for radio equipment and services; Part 3: Specific conditions for Short-Range

Devices (SRD) operating on frequencies between 9 kHz and 40 GHz

Safety: EN 60950-1:2006 Safety of information technology equipment

including electrical business equipment, including amendments A12:2011

100-TBD - Rev A _dp Page iii

Page 6

Disclaimer

NOTICE TO ALL PERSONS RECEIVING THIS DOCUMENT:

The information in this document is subject to change without notice. No part

of this document may be reproduced, stored or transmitted in any form or by

any means, electronic or mechanical, for any purpose, without the express

written permission of TransAct Technologies, Inc. ("TransAct"). This

document is the property of and contains information that is both confidential

and proprietary to TransAct. Recipient shall not disclose any portion of this

document to any third party.

TRANSACT DOES NOT ASSUME ANY LIABILITY FOR DAMAGES

INCURRED, DIRECTLY OR INDIRECTLY, FROM ANY ERRORS,

OMISSIONS OR DISCREPANCIES IN THE INFORMATION CONTAINED IN

THIS DOCUMENT.

TransAct cannot guarantee that changes in software and equipment made by

other manufacturers, and referred to in this publication, do not affect the

applicability of information in this publication.

Copyright

© 2012 TransAct Technologies, Inc. All rights reserved. Printed in USA

Revision Level A, October 2012

Trademarks

Some of the product names mentioned herein are used for identification

purposes only and may be trademarks and/or registered trademarks of their

respective companies.

TransAct, Printrex, and Atlantek are registered trademarks of TransAct

Technologies, Inc.

ZINK and Zero Ink are trademarks of Zink Imaging, LLC.

Microsoft and Windows are registered trademarks of Microsoft Corporation in

the United States and/or other countries.

Adobe and the Adobe logo are trademarks of Adobe Systems, Inc.

Page iv 100-TBD - Rev A

Page 7

able of Contents

T

Change History ................................................................................................ i

Federal Communications Commission Radio Frequency Interference

Statement ...................................................................................................... iii

Canadian Department of Communications Radio Interference Statement ...... iii

Disclaimer ...................................................................................................... iv

Copyright ....................................................................................................... iv

Trademarks .................................................................................................... iv

Table of Contents ............................................................................................ v

Introducing your Printrex® 920 Printer ......... 1

About your Printrex® 920 Printer ...................................................................... 3

Who Should Read This Guide? ....................................................................... 4

What Is Included in This Guide? ...................................................................... 4

Technical and Sales Support........................................................................... 5

On-line Technical Support .......................................................................... 5

Telephone Technical Support ..................................................................... 5

Warranty Information .................................................................................. 5

Return Materials Authorization and Return Policies .................................... 6

Sales Support ............................................................................................. 6

Contact Information .................................................................................... 7

Safety Precautions ..................................... 9

Important Safety Precautions ........................................................................ 11

General Precautions ................................................................................. 11

Grounding ................................................................................................ 11

Power Supply and Power Cord ................................................................. 11

Step-by-Step Installation Procedures ..........13

Unpack the Printer ........................................................................................ 15

Printer Part Names and Function .................................................................. 16

Front View ................................................................................................ 16

Back View ................................................................................................ 17

Inside the Printer ...................................................................................... 18

Operation Panel ....................................................................................... 19

Connecting the Communication Cable .......................................................... 20

Paper Loading Procedure ............................................................................. 22

Printrex® 920 Specifications and Requirements

..............................................................29

Printrex® 920 Specifications and Requirements ............................................ 31

Standard Features ........................................................................................ 31

Physical Printer Specifications ...................................................................... 32

Environmental Conditions ......................................................................... 32

Electrical Specifications ................................................................................ 32

Media Specifications ..................................................................................... 33

Paper ....................................................................................................... 33

USB Interface ................................................................................................ 33

Printer Maintenance ..................................35

Cleaning the Printer ...................................................................................... 37

Protecting the Thermal Head......................................................................... 37

100-TBD - Rev A Page v

Page 8

Cleaning the Thermal Head .......................................................................... 37

Cleaning the Form ......................................................................................... 38

Clearing Paper Jams ..................................................................................... 39

Troubleshooting ........................................41

Appendix A: Ordering Supplies ...................45

Drivers Available ........................................................................................... 45

Index .......................................................47

Page vi 100-TBD - Rev A

Page 9

Chapter 1

Introducing your Printrex® 920 Printer

100-TBD - Rev A Page 1

Page 10

This page intentionally left blank

Page 2 100-TBD - Rev A

Page 11

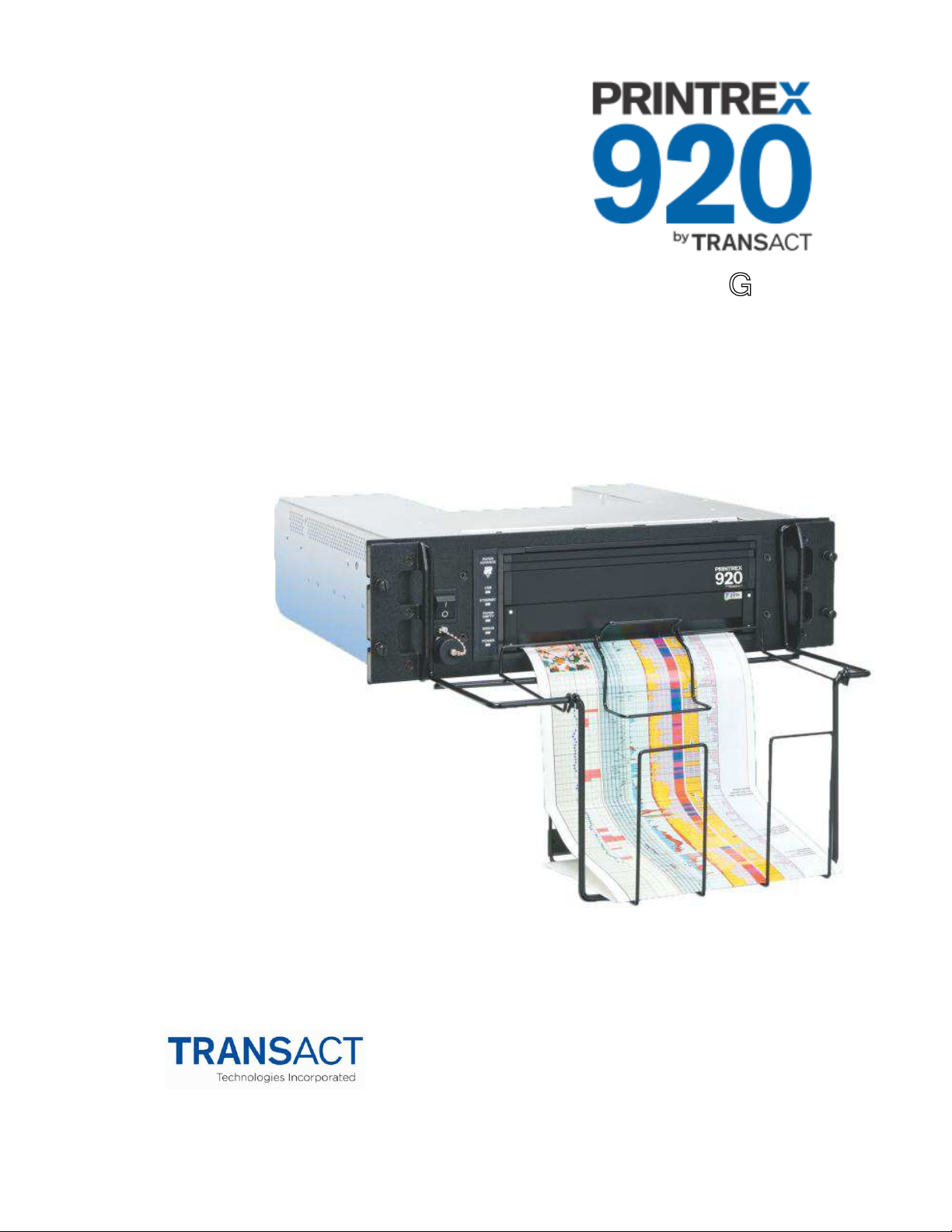

About Your Printrex® 920 Printer

About your Printrex® 920 Printer

The Printrex® 920 printer by TransAct® represents the very latest technology

for rack-mountable continuous form plotting, specifically designed to perform

in adverse environments such as logging trucks or offshore platforms. It builds

upon the experience of the Printrex® line of printers with a host of features

specifically designed to improve the performance of your plotting applications

in the field, including:

x Prints in full color without ink cartridges or ribbons using ZINK® (Zero Ink)

x Capable of printing black and white on standard thermal paper

x Designed and built with rugged reliability

x Available in both desktop and rack-mount configurations

x Easy path to upgrade existing logging systems to full color

x Print drivers for Windows ® and CUPS configurations for Linu[8QL[

x Low total cost of ownership

These features and more let you quickly and easily integrate the Printrex® 920

with your plotting applications, while giving you the quality, durability and

uptime you have come to expect from Printrex® by TransAct® printers.

100-TBD - Rev A Page 3

Page 12

About Your Printrex® 920 Printer

Who Should Read This Guide?

This document provides information useful for end users who will install,

configure, and operate the Printrex® 920 printer in their operations.

What Is Included in This Guide?

This Operators Guide includes information on the installation, specifications,

and operation of the Printrex® 920 printer. It provides the following information

to support your installation and operational efforts:

x Warranty and technical support information

x Specifications and functionality description

x Installation and operational procedures

x Configuration, testing, and troubleshooting procedures

We want you to have a trouble-free implementation with your TransAct®

printer. For any issues not covered in this guide, quality technical support is

available on-line at www.printrex.com, or by telephone or fax ± consult the

following pages for more details about our support services.

Page 4

100-TBD - Rev A

Page 13

About Your Printrex® 920 Printer

Technical and Sales Support

Your printer is backed by the resources of Printrex, a division of TransAct

Technologies, a global technology firm with dedicated technical support and

sales assistance. Here is how we can help you:

On-line Technical Support

Our web site at www.printrex.com is your on-line portal to obtaining technical

assistance with your Printrex® printer. Click on the Support link to find support

information for your Printrex® 920 printer, including online access to drivers

and documentation, or contact us via e-mail at support@printrex.com.

Telephone Technical Support

Live telephone support is available by contacting Printrex or one of its regional

affiliates via the contact information listed in this section. To help us serve you

faster, please have the following information ready when you call:

x The Model Number and Serial Number of the printer.

x A list of any other peripheral devices attached to the same port as the

printer.

x What application software, operating system, and network (if any) you are

using.

x What happened and what you were doing when the problem occurred.

x How you tried to solve the problem.

W

arranty Information

Printrex® 920 Printers come with a standard warranty that commences upon

shipment from factory, and covers parts and labor. An optional warranty,

covering both parts and labor, may be purchased separately.

100-TBD - Rev A Page 5

Page 14

About Your Printrex® 920 Printer

Return Materials Authorization and Return Policies

If a support technician determines that the printer should be serviced at a

Printrex facility, and you want to return the printer for repair, we will issue you

the Returned Materials Authorization (RMA) number that is required before

returning the printer. Please prepare the printer being returned for repair as

follows:

x Pack the printer to be returned in the original packing material.

x Do not return any accessories unless asked to do so by a support

technician.

x Write the RMA number clearly on the outside of the box.

Sales Support

To order supplies, receive information about other Printrex products, or obtain

information about your warranty, contact our Sales Department at the contact

telephone or fax numbers listed below or visit our web site at

www.printrex.com.

Page 6

100-TBD - Rev A

Page 15

About Your Printrex® 920 Printer

ontact Information

C

USA

Printrex Inc.

276 East Gish Road

San Jose, CA 95112-4703, USA

Telephone 408.573.1200

Fax 408.573.1600

Web Site: www.printrex.com

R ± Associates Inc.

6610 Gant Road

Houston, Texas 77066 USA

Telephone 713.973.1500

Fax 713.598.8311

Web Site: www.r-associates.com

United Kingdom

Trident Microsystems

Pilgrims Court

15 ± 17 West St.

Reigate, Surrey, RH2 9BL UK

Telephone (0845) 603 2770

Web Site: www.trident-uk.co.uk

Unicomp Limited

Unit 13 Bourne Estate

Borough Green, Kent, TN15 8DG UK

Telephone (01732) 781400

Fax (0172) 78064

Web Site:

Canada

Kesh Downhole Measurements, Inc.

P.O. Box 246

Clyde, Alberta T0G 0P0 Canada

Telephone 780.348.5278

Fax 780.348.5731

Email: kevindm@telusplanet.net

Germany

Elkutec Electronic GmbH

Postfach 11 33

D-85386 Eching bei München

Erfurter Straße 31 Germany

Telephone (49)-89-31-90-91-0

Fax (49)-89-31-90-91-91

Web Site:

Email: sales@elkutec.de

www.unicomp.co.uk

www.elkutec.de

100-TBD - Rev A Page 7

Page 16

About Your Printrex® 920 Printer

hina

C

Star-Luck Enterprises, Inc.

Beijing Office

Room 328, Grand Vision Business Building,

No.2 Jiuxianqiao Road,

Chaoyang District

Beijing 100015 China

Telephone 86-10-51305677

Fax 86-10-51305658

Singapore

HABS Industries Pte Ltd.

2 Kensington Park Drive

#04-04

Singapore 557320

Telephone 65-967 32002 or 65 816 32322

Fax 65-234 3158

Email: habsindustries@gmail.com

Page 8

100-TBD - Rev A

Page 17

Chapter 2

Safety Precautions

100-TBD - Rev A Page 9

Page 18

This page intentionally left blank

Page 10

100-TBD - Rev A

Page 19

Safety Precautions

Important Safety Precautions

General Precautions

x Use this equipment only for the intended use described in this guide.

x Do not use power supplies outside the specified voltage/hertz range.

x Do not block any openings on the equipment.

x Do not use corrosive chemicals or vapors on or near the equipment.

x Do not expose equipment to rain, spills, or moisture.

Grounding

x This equipment must be grounded to conform with legal and safety

standards. Connect only to a properly grounded outlet.

Power Supply and Power Cord

To avoid the risk of fire, electrical shock, personal injury, or damage to the

printer:

x Always use the power cord provided with this printer. The power cord

supplied with the equipment is rated and approved for service to this

equipment.

x Make sure that the power plug is securely and completely inserted into the

power source.

x Do not cut, damage, or otherwise alter the power cord. Never place a

heavy object on the power cord, never expose it to heat, and never pull the

cord to disconnect it. If the power cord is damaged in any way

(condensation on exposed wires, broken wires, etc.) contact customer

service where you purchased the printer.

x Do not immerse the power cord or plug in water. Never handle the power

cord or plug when your hands are wet.

x Never knot the power cord or wrap it around itself.

x Turn off the main power before removing the power plug from the outlet.

x Check the power plug and cord for any problem (abnormal heat, rust,

bend, cracks, scratches, etc.) at least once a month.

x If any problem is found with the power plug or cord, contact customer

service regarding a replacement cord/

x Never pull on the power cord to unplug the cord from the power supply.

Always grip the plug to remove it from the power supply.

x Always keep the area around the power plug free of obstacles so that you

can unplug it easily. This allows you to unplug the power cord quickly in an

emergency.

100-TBD - Rev A Page 11

Page 20

Safety Precautions

x Never use any power source other than the one rated for the printer. This

printer is designed to be used in the region where you purchased. Also,

make sure that the power source can supply sufficient power for the

printer.

Supply Voltage:

AC 100-240 V, 50/60 Hz

Power Consumption:250 W (max.)

Page 12

100-TBD - Rev A

Page 21

Chapter 3

Step-by-Step Installation Procedures

100-TBD - Rev A Page 13

Page 22

This page intentionally left blank

Page 14

100-TBD - Rev A

Page 23

Step-by-Step Installation Procedures

Unpack the Printer

Be sure to save the box and packing materials in case you need to send the

printer in for service. TransAct Technologies is not responsible for damaged

return items that are not packaged in original shipping material. Refer to

³Return Materials Authorization and Return Policies´RQSDJH6 for information

on what to do if you have to return your printer for repair.

100-TBD - Rev A Page 15

Page 24

Step-by-Step Installation Procedures

[1]

[2]

[3]

[4]

[5]

Printer Part Names and Function

Front View

[1] Upper unit

Open this unit when set paper or removing the paper jammed in the paper

feed path or cleaning inside of the machine.

[2] Operation panel

This panel has the key switches necessary for printer operation and the lamps

that indicate printer status.

[3] Power switch

Use this switch when the printer is scheduled to be unused for a long period of

time or it is relocated.

[4] Front latches

These must both be flipped up to rotate open the upper unit to load paper or

for maintenance.

[5] Paper delivery slot

Paper is ejected through this slot.

Note: Never attempt to open the Upper unit by force or hit the door. This could

damage the printer or result in poor print quality. Always open and close the

Upper unit slowly.

Page 16 100-TBD - Rev A

Page 25

Step-by-Step Installation Procedures

[2]

[3]

[1]

Back View

[1] LAN port

Connect a LAN cable here to connect to the computer.

[2] USB port

Connect a USB cable here to connect to the computer.

[3] Power connector

Connect the power cord here.

100-TBD - Rev A Page 17

Page 26

Step-by-Step Installation Procedures

[1]

[2]

[3]

Inside the Printer

[1] Upper unit release levers

Push these levers up to release the upper unit.

[2] Paper tray

Load paper in this tray.

Note: Color thermal paper is loaded with a surrounding cartridge box, while

black and white paper is loaded directly as a fanfold stack of paper.

[3] Transport unit

Paper is fed by this unit. Clean it if soiled by paper dust or other foreign

material.

Page 18 100-TBD - Rev A

Page 27

Step-by-Step Installation Procedures

[1]

[2]

[3]

[4]

[5]

[6]

Operation Panel

[1] Power switch

Rocker switch that turns power on and off.

[2] SELF TEST key

Pressing this key down for about 1 second initiates an automated status

check.

[3] Status display

Displays error message codes (TBD) when the ERROR lamp is lit.

[4] PAPER ADVANCE key

Pressing this key in the offline mode feeds paper.

[5] PAPER EMPTY lamp

This lamp displays if the printer is out of paper.

[6] ERROR lamp

This lamp displays when there is an error within the printer.

100-TBD - Rev A Page 19

Page 28

Step-by-Step Installation Procedures

Connecting the Communication Cable

The Printrex® 920 is equipped with two interface ports. These interfaces are:

x USB 2.0 High Speed

x Ethernet 10/100 Base TX

Connect the appropriate communications cable to the corresponding port on

the printer as shown in the following figure. Cables are provided by your

dealer, the system installer or are available through Printrex.

Connect the cable to the printer first, as shown in the figure, and then to the

computer.

Note: You can disconnect the USB cable even while the printer and computer

are on, but do not disconnect the USB cable in the cases described below.

This could prevent the printer from operating normally.

x While the computer is starting up (until the desktop display appears).

x While the printer is printing.

x While you install the printer driver.

To disconnect the USB cable while the computer and the printer are on,

disconnect it at the computer or the USB hub. To reconnect the USB cable,

wait at least 5 seconds before you connect it again. If you reconnect it

immediately, the printer may not operate correctly.

Note: A USB cable is not provided with the printer. Please prepare a cable

that matches the port on your computer.

Note: Please consult your network administrator when connecting to an office

LAN using an Ethernet cable.

Note: If a printer driver has not been installed in the computer to which you

want to connect your printer, install it before connecting the USB cable or LAN

cable.

Page 20 100-TBD - Rev A

Page 29

Step-by-Step Installation Procedures

Ethernet port

USB port

100-TBD - Rev A Page 21

Page 30

Step-by-Step Installation Procedures

Paper Loading Procedure

This section describes how to load paper.

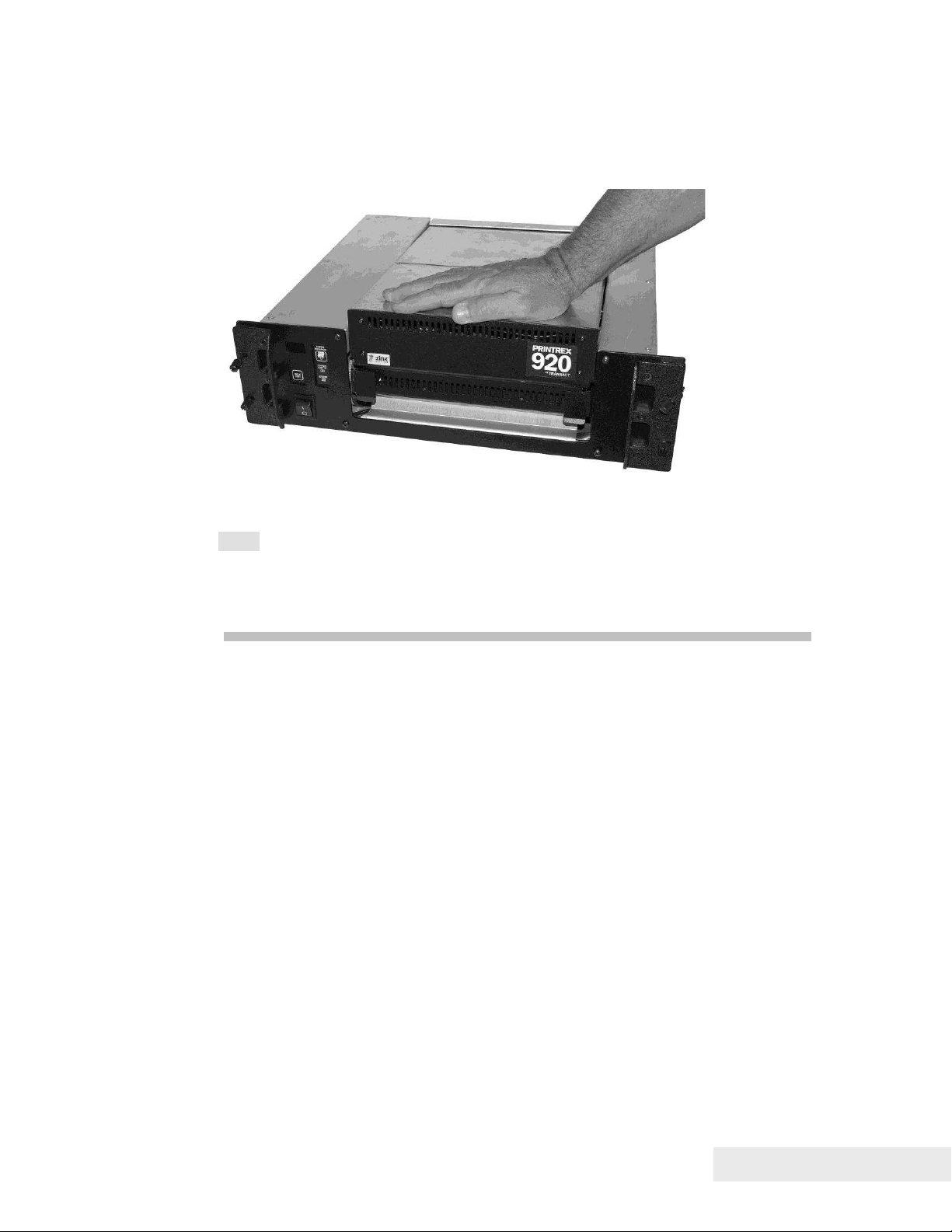

1. If the printer is installed in a rack-mounted configuration, slide the printer out

forward from the rack. Paper is loaded from the top of the printer.

2. Flip the two front latches upward to release the upper unit.

Page 22 100-TBD - Rev A

Page 31

Step-by-Step Installation Procedures

3. Rotate the upper unit upward to open the printer.

100-TBD - Rev A Page 23

Page 32

Step-by-Step Installation Procedures

4a. Color thermal paper stock is loaded from a plastic cartridge container.

Lower the container into the paper tray as shown. Ensure that the top of the

container is open and paper can feed out of it.

Page 24 100-TBD - Rev A

Page 33

Step-by-Step Installation Procedures

4b. Black and white thermal paper stock is loaded as a fanfold stack of paper.

Lower the stack into the paper tray as shown.

100-TBD - Rev A Page 25

Page 34

Step-by-Step Installation Procedures

Note: Load paper with the black mark located on the tip right side of the back

of the printing surface.

5. Unfold the top sheet of paper and lay it across the platen as shown in the

figure.

Page 26 100-TBD - Rev A

Page 35

Step-by-Step Installation Procedures

8. After loading paper, push the upper unit down until it clicks into place. Press

the PAPER ADVANCE button on the front console to advance the first sheet.

Slide the printer back into the rack if appropriate.

Note: Load paper in printer immediately after unpacking it. Paper remaining

after completion of printing may be held loaded in printer or stored in the paper

storage box. If printer is not used for an extended period of time, be sure to

store paper in the paper storage box.

100-TBD - Rev A Page 27

Page 36

Page 37

Chapter 4

Printrex® 920 Specifications and

Requirements

100-TBD - Rev A Page 29

Page 38

This page intentionally left blank

Page 30 100-TBD - Rev A

Page 39

Printrex® 920 Specifications and Requirements

Printrex® 920 Specifications and Requirements

Standard Features

The following features are standard for Printrex® 920 printers:

x Prints in full color without ink cartridges or ribbons using ZINK® (Zero Ink)

x Capable of printing black and white on standard thermal paper

x Color Printing: 18 inches per minute

x Black & White Printing: 120 inches per minute

x Resolution of 300 dots per inch horizontal/200 dots per inch vertical

x Extended operating and storage temperature ranges

x Available in both desktop and rack-mount (3U space) configurations

x Easy path to upgrade existing logging systems to full color

x USB 2.0 High Speed and Ethernet 10/100 Base TX

x Low total cost of ownership

Optional features:

x Output stacker for rack-mount configuration

x Combination input tray/output stacker for desktop configuration

100-TBD - Rev A Page 31

Page 40

Printrex® 920 Specifications and Requirements

Max Dimensions

W D

H

Desktop

19.0

20.0

5.0

Rack mount

12.0

20.0

5.0

20.0"

5.0"

(Rack mount configuration shown)

Physical Printer Specifications

Weight: approx. 18 lbs. (8.2 kg) desktop, 24 lbs. (10.9 kg) rack mount

Interface

USB 2.0 High Speed and Ethernet 10/100 Base TX

Environmental Conditions

The Printrex® 920 printer is designed for use in rugged environments, within

the temperature and humidity conditions described below.

Operating temperature (printing): -15°C to 40°C / 5°F to 104°F

Operating temperature (non-printing): -40°C to 70°C / -40°F to 158°F

Storage temperature: -55°C to 85°C / -67°F to 185°F

Electrical Specifications

Universal input (100/230 volts, 50/60 Hz)

250 watts maximum

Page 32 100-TBD - Rev A

Page 41

Printrex® 920 Specifications and Requirements

Media Specifications

Paper

ZINK ® Color Fan Fold Paper

Printrex p/n 2316-0027

Width: 8.5 inches (216 mm)

640 sheets/box

Black & White Fan Fold Paper

Printrex p/n 2316-0011

Width: 8.75 inches (222 mm)

800 sheets/box

USB Interface

The USB interface is a Version 2.0 interface card is implemented through a

standard Series "B" receptacle as defined in the USB Specification. The

printer is self-powered and does not draw power from the standard Type B

USB interface cable.

The standard USB Type B connector has the following pin functions:

Pin Signal

1 Vbus (+5 V dc)

2 Minus data

3 Plus data

4 Ground

Note: The standard USB interface does not have sufficient power to run the

printer.

100-TBD - Rev A Page 33

Page 42

Page 43

Chapter 5

Printer Maintenance

100-TBD - Rev A Page 35

Page 44

This page intentionally left blank

Page 36

100-TBD - Rev A

Page 45

Printer Maintenance

leaning the Printer

C

There is no regular cleaning required for proper operation of the printer,

however the printer surfaces are designed and manufactured to permit

cleaning with the following cleaning agents:

x Isopropyl alcohol

x Ammonia

x Chlorine bleach (1:10 concentration with water)

x Hexachlorophene (PhisoHex)

x Glutaraldehyde (Cidex)

Use a soft cloth dampened with the cleaning agent to clean the surfaces of the

printer. Do NOT submerse the printer or allow spills onto or into it.

Note:

x Before cleaning the printer, switch it off and disconnect the power plug

from the power source. This can prevent personal injury or damage to the

printer if you make a mistake during cleaning.

Protecting the Thermal Head

The thermal head incorporates a protective glaze coating and is generally

resistant to harsh environments, but follow these guidelines to protect it:

x Do not allow the thermal head to come into contact with sharp or hard

objects.

x Do not allow thermal paper debris to accumulate on the thermal head. See

below.

x Do not allow condensation to accumulate on the thermal head.

x Use only Printrex approved thermal paper.

x Do not use abrasive cleaning substances on the thermal head. See below.

Cleaning the Thermal Head

Paper dust or other foreign material may occasionally accumulate on the

thermal print head. This will be indicated by light printing or no printing in a

narrow band down the length of the paper. In order to eliminate the thermal

paper debris buildup, use a soft cloth moistened with one of the following

cleaning agents:

x Isopropyl alcohol

x Ethanol

A light wiping along the length of the print head is adequate. Allow the print

head to dry before resuming printing. It can be wiped dry with a soft, clean

cloth. Do NOT submerse the print head or allow spills onto it.

100-TBD - Rev A Page 37

Page 46

Printer Maintenance

Cleaning the Form

Sensor paper dust or other foreign material may occasionally accumulate on

the form sensor. This will be indicated by paper advances missing the top of

form position (some time after it has been correctly stopping at the top of

form). The form sensor can be cleaned with an aerosol air spray or soft

bristled brush. It is located just under the form sensor window.

Page 38

100-TBD - Rev A

Page 47

Printer Maintenance

learing Paper Jams

C

If paper has been loaded askew, has been torn off forcefully, or is damp, the

paper may feed abnormally and wrap around the platen roller. These

occurrences are extremely rare, but it is important to know how to clear the

jam:

1. Turn off power to the printer.

2. Open the printer door and remove the paper holder.

3. Tear off the incoming paper (either from the roll, or fanfold supply).

4. Pull on the free end of paper with one hand, while turning the platen roller

with the other hand to unroll paper from the platen.

5. Do not use a razor, knife or sharp object of any kind to cut the paper off of

the platen roller. Nicking or cutting the roller surface will result in progressive

damage to the platen with continued use of the printer.

6. Be very careful not to damage the print head exposed on the underside of

the door. Use bare hands to free the paper to avoid accidental contact with

metal or hard surfaces

100-TBD - Rev A Page 39

Page 48

Page 49

Chapter 6

Troubleshooting

100-TBD - Rev A Page 41

Page 50

This page intentionally left blank

Page 42 100-TBD - Rev A

Page 51

Troubleshooting

This section lists a few common questions that are received by Printrex

support staff and the answers most likely to fix the problem. For further

LQIRUPDWLRQVHHWKH3ULQWUH[6\VWHP$GPLQLVWUDWRU¶V*XLGH

he printer seems to be working, but nothing is printed.

T

The thermal paper has one side that has a thermal sensitive coating while the

other side is not coated. Be sure the thermally coated side is facing upward

(as the paper is exiting the printer).

,¶PXVLQJIDQIROGSDSHUZLWKIRUPPDUNHUs, but the printer stops in the

wrong place. What driver settings should I use?

%HVXUHWRVHW3DSHU6L]HWRWKHDFWXDOVL]HRIWKHSDSHUHJ´[´

and enable End-of-Job Form Feed.

Also, see that the Form Marker setting (in the Windows XP/Vista driver)

matches the actual printed location of the marker.

Check that the paper is loaded correctly: looking at the front of the printer, the

marker should be on the right side, on the bottom of the paper.

,¶PWU\LQJWRSULQW7,))ILOHVEXWWKHSULQWed output is clipped off. How do

I print the whole log?

Commonly, users view TIFF logs in Windows Imaging, the free viewer

provided in the Accessories folder. Unfortunately, this is a single-page

application. It is designed for simple photograph-size viewing and printing.

In addition, the Windows printing subsystem formerly limited printer pages to

32,766 raster lines (approximately 163 inches long for 200 dpi Printrex

printers, or 109 inches for 300 dpi Printrex printers), so the longest log that

could be printed from Windows Imaging was just 13 feet long.

In Windows XP, the Imaging applet was replaced by a new Paint applet that

uses multiple printer pages. In this case, set the printer page size to the

SDSHU¶VSDJHVL]HHJ´[´KDOISDJHDQd Paint will generate as

many printer pages as needed to print the log.

In most of the larger geotechnical organizations, proprietary viewers have

been written for internal use by staff and customers. There are very few

options for users of TIFF log files who are not using Windows XP, or who find

the XP Paint application too primitive.

Printrex welcomes comments regarding requirements and features for log

viewing tools, to help us evaluate customer viewer application needs.

E

very time I start my program, I have to change printer settings. How do I

change the default driver settings?

Changes to the printer settings done from within an application are generally

not saved unless some unusual program coding is done.

Self test prints out OK but when I print from the computer I get garbage.

The most common culprits for this symptom are the printer cable or printer

GULYHU%HVXUHWKHFDEOHLVDSSURSULDWHO\FRQQHFWHGVHH³&RQQHFWLQJWKH86%

100-TBD - Rev A Page 43

Page 52

Troubleshooting

&DEOH´$OVREHVXUHWKHSULQWHUGULYHULVIRUWKHVSHFLILFPRGHORISUinter in

use.

ometimes the fan-fold paper skews to one side or the other. How do I correct

S

this?

The Printrex printers work with a wide variety of media. A paper skewing

problem is normally corrected by realigning the paper manually, by opening

the door, straightening the paper, and closing the door.

In some cases (generally with very thin paper) the problem may persist. If this

is the case, thread the paper over a full internal roll of paper (as shown) to

remedy the situation.

Page 44

100-TBD - Rev A

Page 53

Appendix A: Ordering Supplies

Appendix A: Ordering Supplies

Printrex® 920 supplies can be ordered easily direct from the Printrex website

(www.printrex.com) or our telephone number within the US: 408.573.1200.

When calling by phone, pleDVHDVNIRUWKH6DOHV'HSDUWPHQW6HH³Contact

Information´in the first section of this document for more details.

Drivers Available

(TBD)

100-TBD - Rev A Page 45

Page 54

Page 55

Index

Index

Canadian Radio Interference

Statement, iii

Cleaning the printer, 37

Clearing paper jams, 39

Communication cable, 20

Connecting communiation

cables, 20

Contact information, 7

Federal Communications

Commission Radio Frequency

Interference Statement, iii

Overview, 3

Paper loading, 22

Part names and function, 16

Printer maintenance, 35

Product information

Warranty information, 5

Return Materials Authorization, 6

Safety precautions, 11

Specifications

Electrical, 32

Environmental conditions, 32

Interface, 32

Media, 33

Printer dimensions, 32

Specifications and

Requirements, 31

Supplies, ordering, 45

Technical support, 5

Troubleshooting, 41

Unpacking the printer, 15

100-TBD - Rev A Page 47

Page 56

adio Frequency Interference Statement

R

This device complies with Part 15 of the FCC Rules and Industry Canada

licence-exempt RSS standard(s) . Operation of the device is subject to

the following two conditions: (1) The device may not cause harmful interference,

and (2) The devices must accept any interference that may cause undesired

operation.

This unit has been tested and complies with limits for a Class A digital device

under Part 15 of the FCC Rules and Industry of Canada ICES-003. These limits

are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense..

Changes or modifications not expressly approved by TransAct Technologies,

Inc. could void the user's authority to operate the equipment.

The manufacturer declares that this product conforms to the following

standards or other normative documents:

EN 300 330-2 V1.5.1 (2010-02) Electomagnetic compatibility and Radio

spectrum Maters (ERM); Short-Range Devices (SRD); Radio equipment

in the frequency range 9 kHz to 25 MHz inductive loop system in the

frequency range 9 kHz and 30 MHz

EN 301 489-1 V1.9.2 (2011-09) Electomagnetic compatibility and Radio

spectrum Maters (ERM); ElectroMagnetic Compatibility (EMC) standard

for radio equipment and services; Part 1: Common technical requirements

EN 301 489-3 V1.4.1 (2002-08) Electomagnetic compatibility and Radio

spectrum Maters (ERM); ElectroMagnetic Compatibility (EMC) standard

for radio equipment and services; Part 3: Specific conditions for Short-Range

Devices (SRD) operating on frequencies between 9 kHz and 40 GHz

Safety: EN 60950-1:2006 Safety of information technology equipment

including electrical business equipment, including amendments A12:2011

100-TBD - Rev A _dp Page iii

Loading...

Loading...