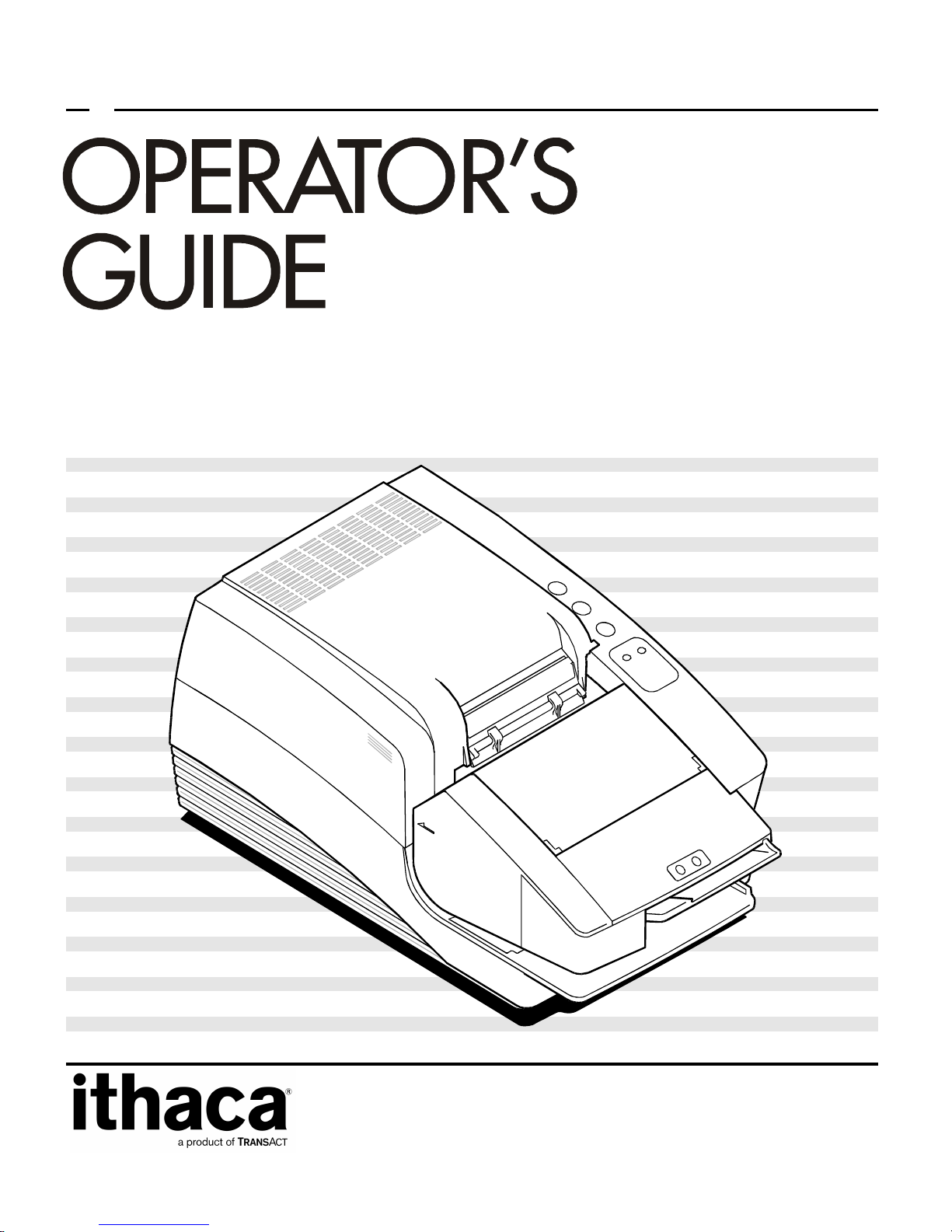

TransAct Ithaca 90PLUS Series, Ithaca 91PLUS, Ithaca 92PLUS, Ithaca 93PLUS, Ithaca 94PLUS Operator's Manual

Page 1

PCOS SERIES 90PLUS

Page 2

Page 3

WARNING: To prevent fire or shock hazard, do not expose this

printer to rain or moisture.

Page 4

Disclaimer

© 2003 TransAct Technologies, Inc. All rights reserved.

NOTICE TO ALL PERSONS RECEIVING THIS DOCUMENT:

The information in this document is subject to change without notice. No part of this document

may be reproduced, stored or transmitted in any form or by any means, electronic or mechanical,

for any purpose, without the express written permission of TransAct Technologies, Inc.

("TransAct"). This document is the property of and contains information that is both confidential

and proprietary to TransAct. Recipient shall not disclose any portion of this document to any third

party.

TRANSACT DOES NOT ASSUME ANY LIABILITY FOR DAMAGES INCURRED,

DIRECTLY OR INDIRECTLY, FROM ANY ERRORS, OMISSIONS OR DISCREPANCIES IN

THE INFORMATION CONTAINED IN THIS DOCUMENT.

Some of the product names mentioned herein are used for identification purposes only and may be

trademarks and/or registered trademarks of their respective companies.

TransAct, PowerPocket, Magnetec, Insta-Load, POSjet, Ithaca, 50Plus and "Made to Order. Built

to Last" are registered trademarks and BANKjet is a trademark of TransAct Technologies, Inc.

Copyright

© 2003 TransAct Technologies, Inc. All rights reserved.

Revision F, February 2003

Printed in the United States of America.

Page 5

Federal Communications Commission Radio Frequency Interference

Statement

The Series 90PLUS Printer complies with the limits for a Class A computing device in

accordance with the specifications in Part 15 of FCC rules, which are designed to minimize

radio frequency interference during installation; however, there is no guarantee that radio

or television interference will not occur during any particular installation. If this equipment

does cause interference to radio or television reception, which can be determined by

turning the equipment off and on while the radio or television is on, the user is encouraged

to try to correct the interference by one or more of the following measures:

♦ Reorient the radio or television receiving antenna;

♦ Relocate the printer with respect to the receiver;

♦ Plug the printer and receiver into different circuits.

If necessary the user should consult their dealer or an experienced radio/television

technician for additional suggestions. The user may find the following booklet prepared by

the Federal Communications Commission helpful: How to Identify and Resolve Radio/TV

Interference Problems.

This booklet is available from the US Government Printing Office, Washington, DC

20402. Ask for stock number 004-000-00345-4.

Canadian Department of Communications Radio Interference

Statement

The Series 90PLUS Printer does not exceed Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications.

UL, CSA, VDE, CE Statement

Ithaca Series 90PLUS Printers are UL and CSA Listed, VDE Certified, and carry the CE

Mark.

Page 6

Page 7

Table of Contents

i

TABLE OF CONTENTS

ABOUT THE SERIES 90PLUS PRINTER 1

About this Operator’s Guide..................................................................................... 1

Who should read this book?............................................................................ 1

What is covered in this book?......................................................................... 1

Where can you find more information?........................................................... 2

Contacting TransAct Technologies’ Ithaca Facility.................................................. 2

Warranty Information............................................................................................... 3

Options............................................................................................................ 3

Service Information......................................................................................... 3

Ordering Supplies..................................................................................................... 4

Paper ............................................................................................................... 4

Ribbon Cassettes............................................................................................. 5

Take-up Spools ............................................................................................... 5

Print Head ....................................................................................................... 5

Cables.............................................................................................................. 5

Description of the Series 90PLUS Printer................................................................ 6

Series 90PLUS Models................................................................................... 7

Standard Features............................................................................................ 9

Optional Features.......................................................................................... 10

Reliability...................................................................................................... 10

Print Characteristics...................................................................................... 11

SETTING UP THE PRINTER 15

Unpacking the Printer............................................................................................. 16

Page 8

Series 90PLUS Operator’s Guide

ii

Check That All Items Are Present................................................................. 18

Remove the Cantilever Restraint and the Print Head Carriage Restraint ...... 19

Remove the Paper Roll.................................................................................. 21

Choosing a Location for the Printer........................................................................ 23

Dimensions.................................................................................................... 23

Weight........................................................................................................... 23

Environmental Conditions............................................................................. 23

Airflow.......................................................................................................... 23

Installing a Ribbon Cassette ................................................................................... 24

Connecting the Power Cord.................................................................................... 26

Loading and Removing Paper................................................................................. 27

Installing the New Paper Roll ....................................................................... 27

Removing the Journal Take-up Roll.............................................................. 33

Cutter...................................................................................................................... 36

Loading and Removing Paper with the Cutter............................................... 36

Installing the New Paper Roll ....................................................................... 36

Removing the Journal Take-up Roll.............................................................. 40

MICR Reader.......................................................................................................... 42

Indicator LED’s............................................................................................. 42

Check Verification (MICR) .......................................................................... 43

Testing the Printer .................................................................................................. 44

Testing the Printer......................................................................................... 44

Testing the MICR Reader....................................................................................... 46

Testing the MICR Reader ............................................................................. 46

Connecting the Cables............................................................................................ 47

Connecting the Communication Cable.......................................................... 47

Connecting the Cash Drawer Cables............................................................. 49

Setup Checklist....................................................................................................... 50

OPERATING THE PRINTER 51

Operating the Keypad............................................................................................. 52

Page 9

Table of Contents

iii

Indicator Lights............................................................................................. 52

Buttons.......................................................................................................... 54

AC Power Switch.......................................................................................... 54

Printing on Forms................................................................................................... 55

Validating a Form ......................................................................................... 55

Slip Printing .................................................................................................. 57

Changing the Print Head......................................................................................... 58

Removing the Used Print Head..................................................................... 58

Installing the New Print Head....................................................................... 60

Adjusting the Platen Gap........................................................................................ 62

Cleaning the Printer................................................................................................ 63

Correcting Problems............................................................................................... 64

Indicator Lights............................................................................................. 64

READY Light Flashes Red........................................................................... 65

Printer Smears Characters............................................................................. 65

APPENDIX 67

Cash Drawer Pin Assignments................................................................................ 67

Serial Cable ............................................................................................................ 68

Cable Requirements ...................................................................................... 68

RS-232C Communication ............................................................................. 68

Pin Assignments for 9-pin Printer Connector................................................ 68

Serial Cable Configurations .......................................................................... 69

Parallel Cable.......................................................................................................... 70

Cable Requirements ...................................................................................... 70

Pin Assignments............................................................................................ 70

INDEX 71

Page 10

Page 11

About The Series 90PLUS Printer 1

ABOUT THE SERIES

90PLUS PRINTER

ABOUT THIS OPERATOR’S GUIDE

WHO SHOULD READ THIS BOOK?

This book is intended for new and experienced operators. If you are going to

set up, use, or maintain a Series 90PLUS Printer with any point-of-sale system,

then this book is for you.

WHAT IS COVERED IN THIS BOOK?

This book only covers the Series 90PLUS Printer, not the entire point-of-sale

system, but it will tell you all you need to know about using the printer

properly. You will learn what supplies you need to order, how to set up and

test the printer, and how to do the common tasks listed here:

♦ Change the paper with or without the optional cutter;

♦ Verify a check;

♦ Change the ribbon cassette;

♦ Change the print head;

♦ Use the MICR read test;

♦ Adjust the platen gap; and

♦ Clean the printer.

Page 12

Series 90PLUS Operator’s Guide

2

This book also provides some general and technical information about the

printer, so you will know what its features are, how reliable it is, and what its

printing capabilities are.

WHERE CAN YOU FIND MORE INFORMATION?

A Programmer’s Guide is available if you need to know how to program a

point-of-sale terminal or a personal computer to work with the printer. It

describes the commands the printer recognizes to perform its functions.

A MICR Programmer’s Guide describing the MICR reader operation and how

to program a point-of-sale terminal or personal computer to work with the

MICR reader is available.

A Maintenance Manual is also available. It shows how to repair the Series

90PLUS Printer and lists the replacement parts. The Maintenance Manual is

intended for trained, service technicians.

For information about ordering these books, refer to the next section.

CONTACTING TRANSACT TECHNOLOGIES’

ITHACA FACILITY

Contact the Ithaca facility for general information about the Series 90PLUS

Printer and how it works with your system. The Sales and Technical Support

Departments will be able to help you with most of your questions. Call the

Technical Support Department to receive technical support; order

documentation; receive additional information about the Series 90PLUS

Printer; or send in a printer for service. To order supplies; receive information

about other Ithaca products; or obtain information about your warranty, contact

the Sales Department.

Page 13

About The Series 90PLUS Printer 3

You may reach both the Sales and Technical Support Departments at the

following address and telephone or fax numbers:

TransAct Technologies Incorporated

Ithaca Facility

20 Bomax Drive

Ithaca, NY 14850 USA

Telephone (877) 7ithaca or (607) 257-8901

Main fax (607) 257-8922

Sales fax (607) 257-3868

Technical Support fax (607) 257-3911

Web site http://www.transact-tech.com

WARRANTY INFORMATION

OPTIONS

All Ithaca PcOS (personal computer, point-of-sale) Series 90PLUS Printers

come with a standard 24-month warranty covering both parts and labor that

starts upon shipment from the factory. An optional warranty, covering both

parts and labor for an additional 12 months, may be purchased separately.

For more information concerning the warranty options, please contact your

dealer or the Sales Department at TransAct’s Ithaca facility. See “Contacting

TransAct Technologies’ Ithaca Facility” on page 2.

SERVICE INFORMATION

TransAct Technologies is a full service organization designed to meet all

of your printer service and repair requirements. If your printer needs

service, please directly contact the Ithaca facility’s Technical Support

Department. See “Contacting TransAct Technologies’ Ithaca Facility” on

page 2. Please have the model and serial numbers of the printer

available. The numbers are on a decal located on the bottom of the

printer.

Page 14

Series 90PLUS Operator’s Guide

4

TransAct offers the following service programs to meet your needs: Extended

Warranties, Depot Repairs, Maintenance Contracts, and Internet Support.

ORDERING SUPPLIES

You may order supplies by calling TransAct Technologies or by faxing the

order form that was shipped in the box with the printer. The fax number is

(607) 257-3868. If you would like more forms, call TransAct Technologies’

Ithaca facility at (877) 7ithaca or (607) 257-8901, and ask for the Sales

Department.

The following items may be ordered:

♦ Paper,

♦ Ribbon cassettes,

♦ Take-up spools,

♦ Print heads, and

♦ Cables.

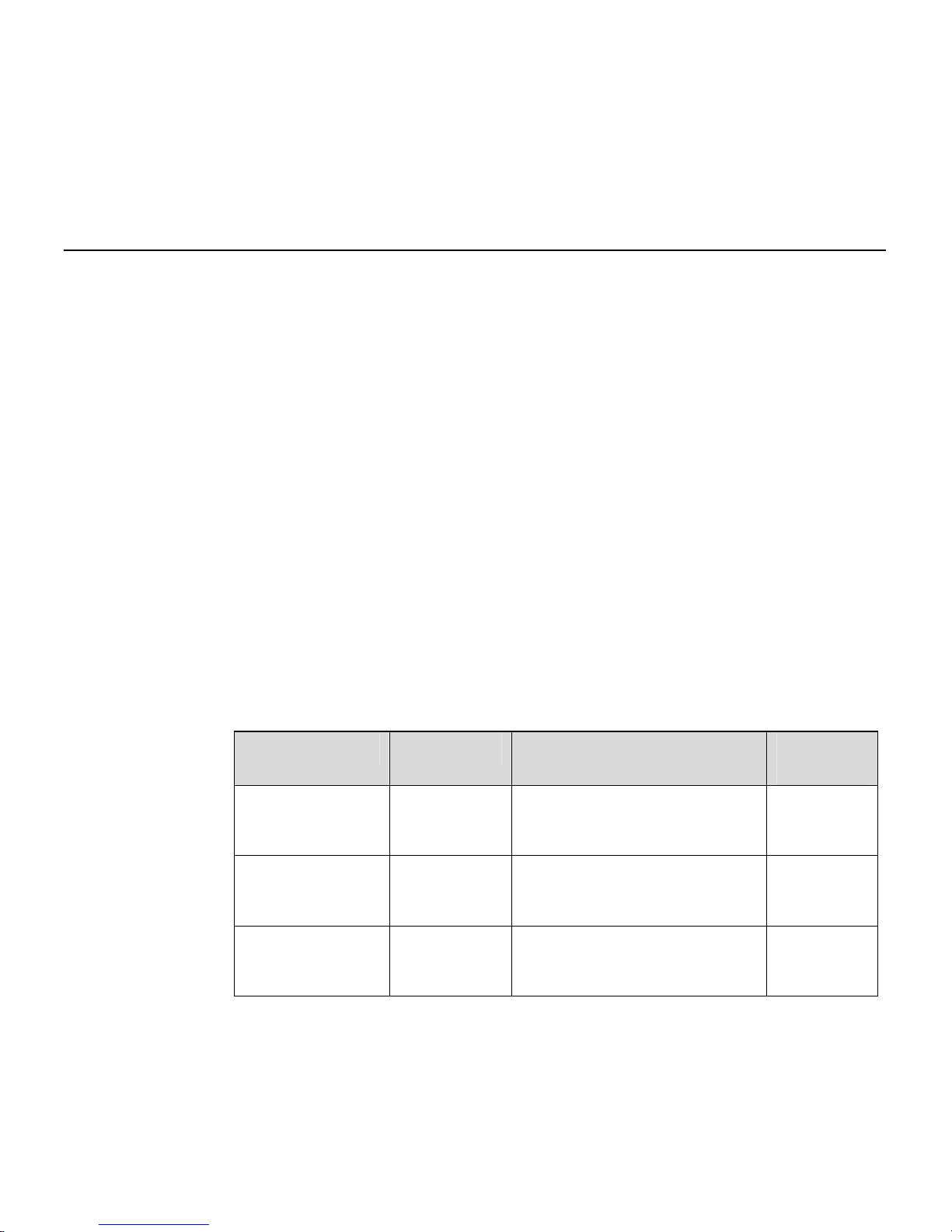

PAPER

Paper Type Dimensions Stock

Number

Receipt Paper Single-ply Width: 3.25 inches (82.6 mm)

Diameter: 3.5 inches (88.9 mm)

Length: 240 feet (73.2 m)

100-2203

Receipt-Journal

Paper

Double-ply Width: 3.25 inches (82.6 mm)

Diameter: 3.5 inches (88.9 mm)

Length: 125 feet (38.1 m)

100-2206

Receipt-Journal

Paper

Triple-ply Width: 3.25 inches (82.6 mm)

Diameter: 3.5 inches (88.9 mm)

Length: 85 feet (25.9 m)

100-2207

Page 15

About The Series 90PLUS Printer 5

RIBBON CASSETTES

Color Supplier Stock Number

Black TransAct Technologies 100-7565

Note: The warranty may be voided if other than genuine Ithaca ribbons are

used.

TAKE-UP SPOOLS

Take-up Spool Stock Number

Journal Take-up Spool 90-6415

PRINT HEAD

Print Head and Clamp Stock Number

Print Head 90-7337

Print Head Clamp 06-0571

CABLES

Cables Stock Number

110V Power Cable 06-0561

230V Power Cable 06-0806

Parallel Communication Cable

25-pin male to 25-pin male

253-9800007

Serial Communication Cable

PC, 9-pin female to 9-pin female

PC, 9-pin female to 25-pin female

10-2020

10-2021

Page 16

Series 90PLUS Operator’s Guide

6

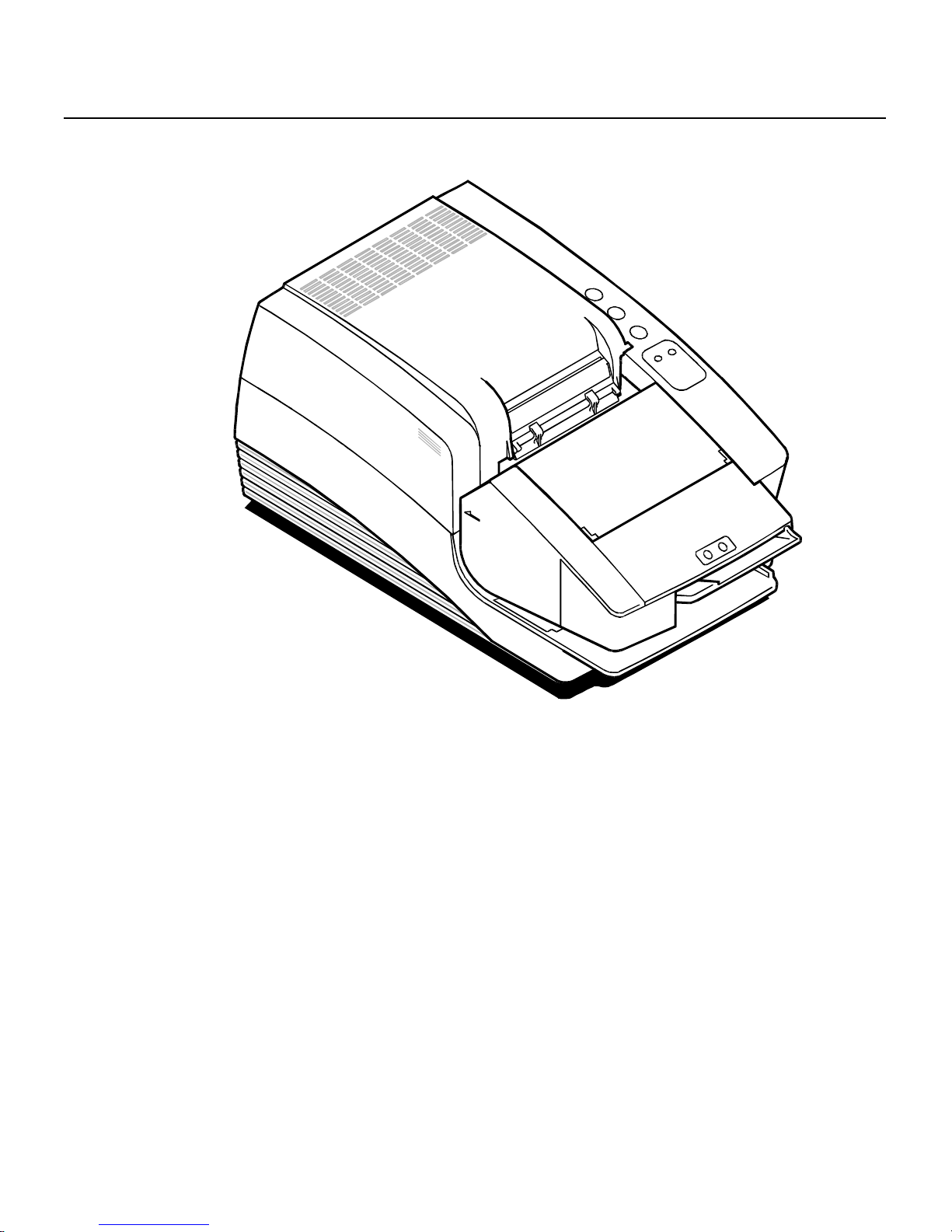

DESCRIPTION OF THE SERIES 90PLUS PRINTER

The PcOS Series 90PLUS Printer is a stand-alone, 42-column, high-speed

impact printer. The Series 90PLUS Printer performs a variety of functions in a

point-of-sale environment and is available in the following models:

♦ Model 91PLUS: Receipt only

♦ Model 92PLUS: Receipt and Journal

♦ Model 93PLUS: Receipt, Journal, and Slip/Validation

♦ Model 94PLUS: Receipt and Slip/Validation

Page 17

About The Series 90PLUS Printer 7

SERIES 90PLUS MODELS

Each of the four models in the Series 90PLUS line of printers has its own set

of features.

PcOS Model 91PLUS Receipt Printer

The Model 91PLUS is a receipt printer used for applications requiring highspeed printing of receipts and single-line validation. Its features include:

♦ 340 characters per second bidirectional printing at 17 characters per inch

and

♦ 42-column printing at 15 characters per inch.

PcOS Model 92PLUS Receipt and Journal Printer

The Model 92PLUS is a receipt and journal printer used for applications

requiring a transaction audit trail (journal) in addition to high-speed printing of

receipts and single-line validation. Its features include:

♦ 340 characters per second bidirectional printing,

♦ 42-column printing at 15 characters per inch, and

♦ Journal take-up.

Page 18

Series 90PLUS Operator’s Guide

8

PcOS Model 93PLUS Receipt, Journal, and Slip/Validation

Printer

The Model 93PLUS is a receipt, journal, and slip/validation printer used for

applications requiring printing of up to 17 lines on inserted forms such as

checks (for validation), charge slips, guest checks, or personal checks (slip

mode). In addition, it provides the same high-speed journal and receipt printing

as the Model 92PLUS. Its features include:

♦ 340 characters per second bidirectional printing at 17 characters per inch,

♦ 42-column printing at 15 characters per inch,

♦ Journal take-up,

♦ A form insertion sensor,

♦ 17-line validation, and

♦ Front slip insertion.

PcOS Model 94PLUS Receipt and Slip/Validation Printer

The Model 94PLUS is a receipt and slip/validation printer used for

applications requiring printing of up to 17 lines on inserted forms such as

checks (for validation), charge slips, guest checks, or personal checks (slip

mode). It does not include the journal take-up assembly. Its features include:

♦ 340 characters per second bidirectional printing at 17 characters per inch,

♦ 42-column printing at 15 characters per inch,

♦ A form insertion sensor,

♦ 17-line validation, and

♦ Front slip insertion.

Page 19

About The Series 90PLUS Printer 9

STANDARD FEATURES

The following features and items are standard on all Series 90PLUS Printers:

♦ Parallel interface - Centronics/IEEE 1284

♦ Internal Universal Power Supply (95 to 265 VAC)

♦ Operating controls and lights

Power On/Off switch and indicator

Paper FEED button

Forms RELEASE button

RESUME button

Alarm and forms LED’s

♦ Paper low sensor

♦ Operator controlled self-test

♦ Cash drawer connector (RJ12) and driver (24V, 1.0 amp pulse for

approximately 150 ms; drawer open/closed status reporting)

♦ Nine-pin stored energy print head

♦ Short line-seeking logic

♦ Characters and graphics

Lowercase characters with descenders

340 characters per second bidirectional printing at 17 characters per

inch

42-column printing at 15 characters per inch

Emphasized and enhanced print

IBM compatible all-points-addressable (APA) graphics

♦ Software controlled vertical spacing

♦ Snap-on ribbon cassette

♦ Steel receipt tear-off bar

Page 20

Series 90PLUS Operator’s Guide

10

OPTIONAL FEATURES

The optional features either replace a standard feature or enhance the operation

of the printer. All optional features are installed at the factory and must be

selected when the printer is ordered.

♦ RS-232C serial communication interface

♦ RS-422 serial communication interface

♦ Journal-cover lock

♦ Custom colors and logo

♦ Cutter (partial cut)

♦ MICR (Magnetic Ink Character Recognition) reads E13 style checks

(Models 93PLUS and 94PLUS only)

♦ USB (Universal Serial Bus) Serial Communication Interface

RELIABILITY

♦ Mean time between failure (except print head): 30,000 hours (Model

91PLUS)

♦ Print head life: 200 million characters

♦ Mean time to repair: 15 minutes

♦ Cutter mean cuts before failure: 1,000,000 cuts

♦ MICR mean reads before failure: 290,000 reads

Page 21

About The Series 90PLUS Printer 11

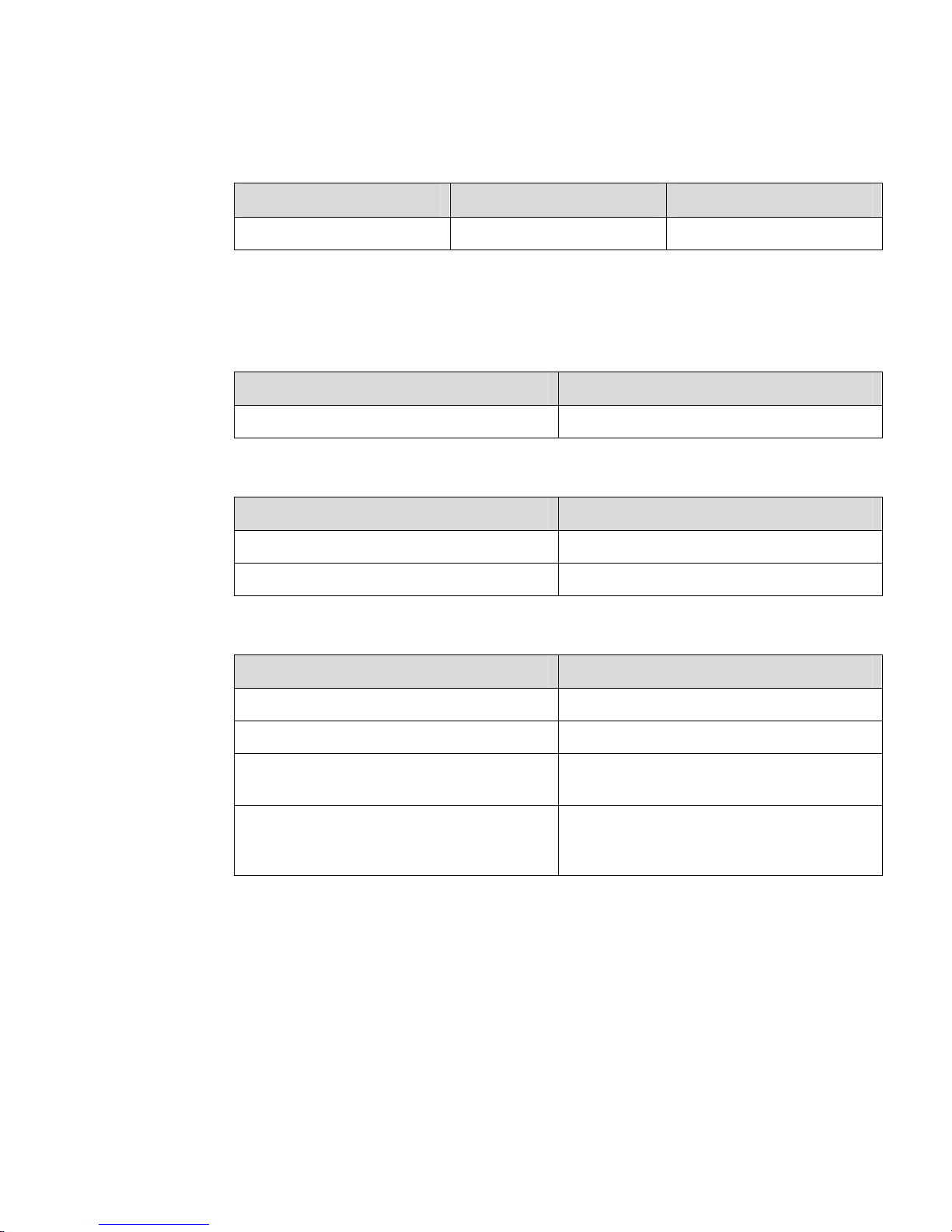

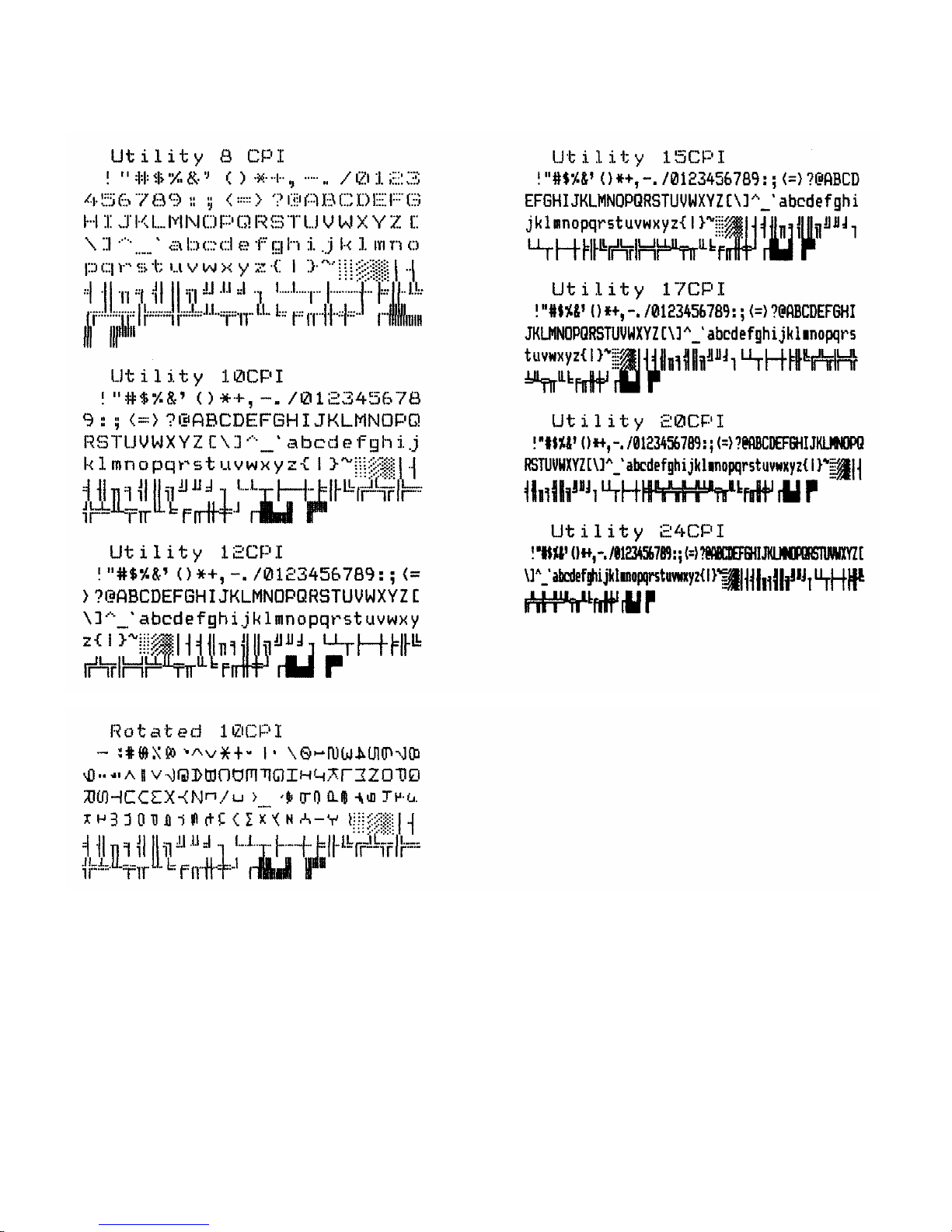

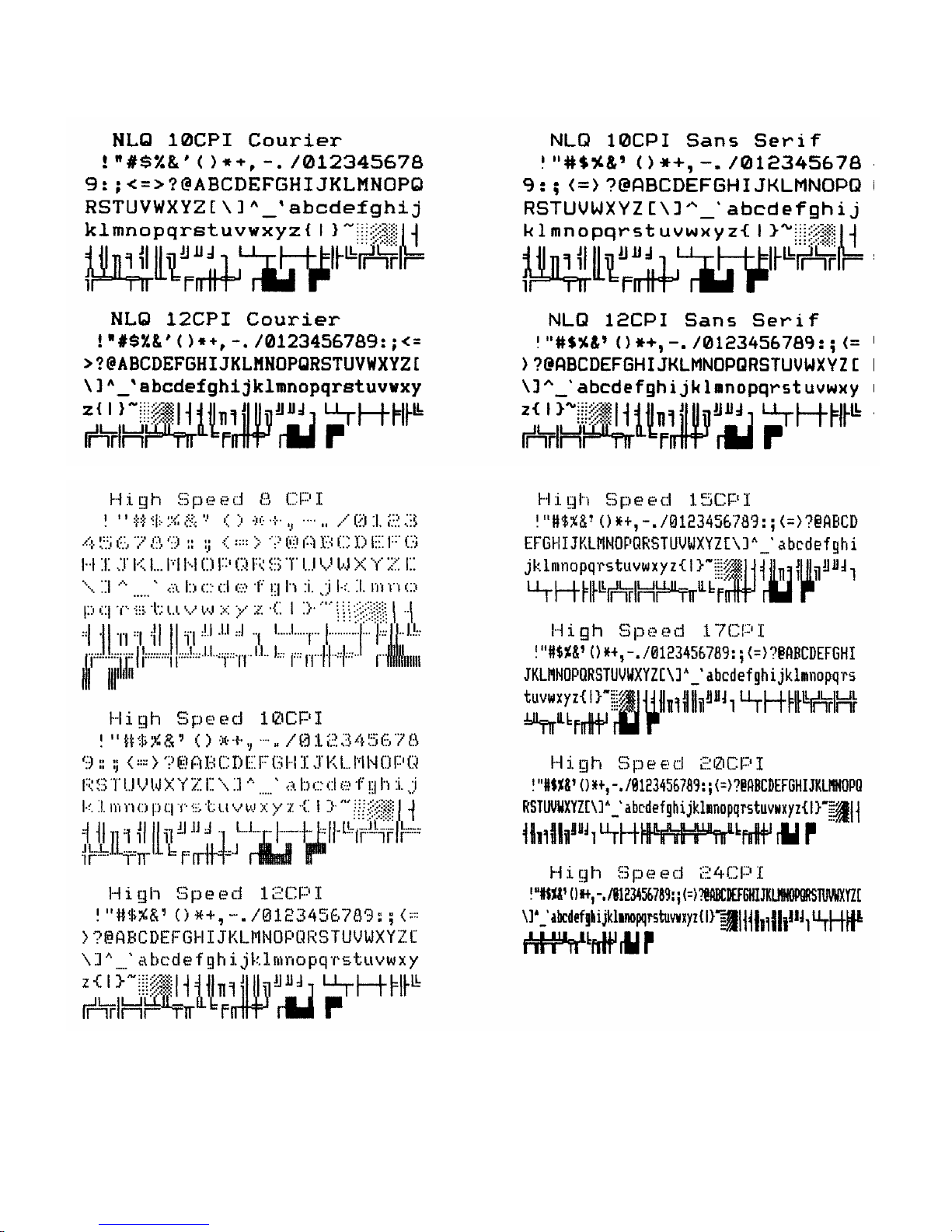

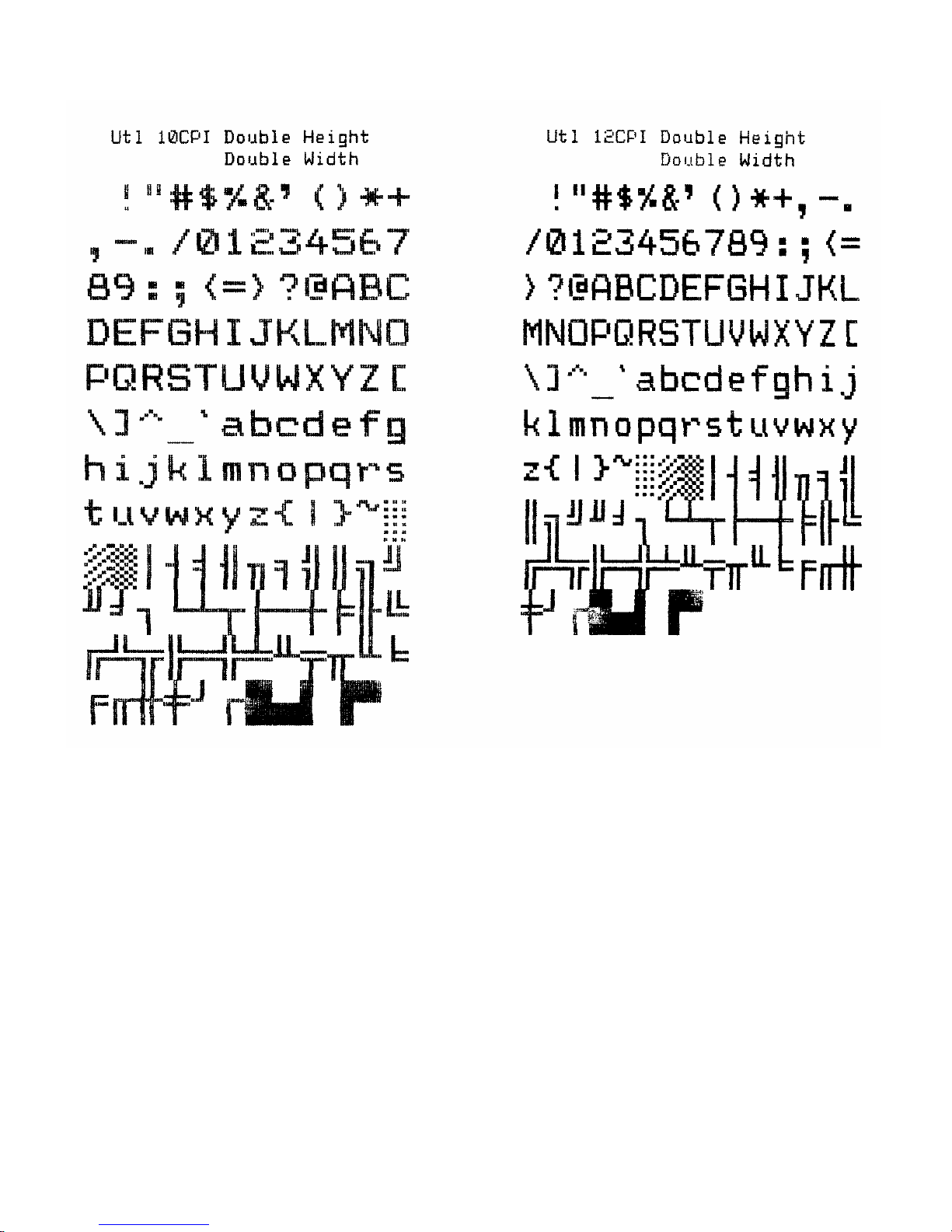

PRINT CHARACTERISTICS

The Series 90PLUS Printer prints characters in a variety of pitches as shown in

the following table and print samples. Each pitch can also be printed in a

variety of styles affecting the appearance of the characters and the speed of the

printer.

For information about programming the printer to print a particular pitch or

style, please refer to the Programmer’s Guide. You may order the

Programmer’s Guide from TransAct Technologies’ Ithaca Facility. See

“Contacting TransAct Technologies’ Ithaca Facility” on page 2.

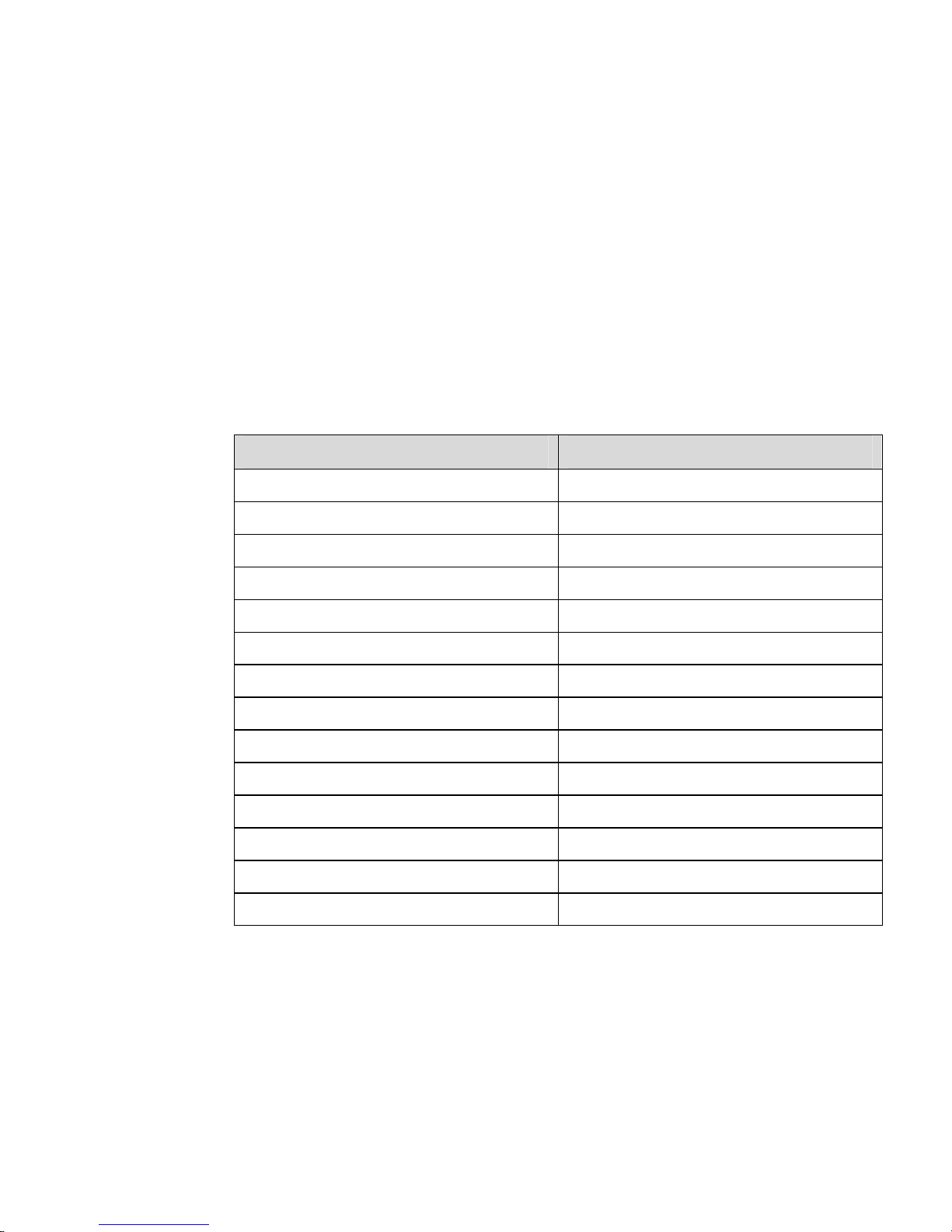

Pitch (characters per inch) Maximum Characters per Line

8 22

10 28

12 32

15 42

17.1 (condensed) 48

20 (super condensed) 56

24 (super condensed) 66

5 (double-wide) 14

6 (double-wide) 16

6.5 (double-wide) 18

7.5 (double-wide) 21

8.5 (condensed, double-wide) 24

10 (condensed, double-wide) 28

12 (super condensed, double-wide) 33

Page 22

Series 90PLUS Operator’s Guide

12

Page 23

About The Series 90PLUS Printer 13

Page 24

Series 90PLUS Operator’s Guide

14

Page 25

Setting Up the Printer 15

SETTING UP THE PRINTER

By following the instructions in this chapter, the Series 90PLUS Printer should

be ready to hook up to your system in just a few minutes.

Here is a list of what is covered in this chapter:

♦ Unpacking the printer,

♦ Removing the cantilever and print head carriage restraints,

♦ Choosing a location for the printer,

♦ Installing a ribbon cassette,

♦ Connecting the power cord,

♦ Loading paper without the cutter,

Loading receipt paper for the Model 91PLUS

Loading receipt-journal paper for Models 92PLUS and 93PLUS

♦ Loading and removing paper with cutter,

Installing a new paper roll

Removing the journal take-up roll

♦ Using the MICR reader,

LED indicators

Check verification

♦ Testing the printer,

♦ Testing the MICR reader, and

♦ Connecting the communication and cash drawer cables.

Page 26

Series 90PLUS Operator’s Guide

16

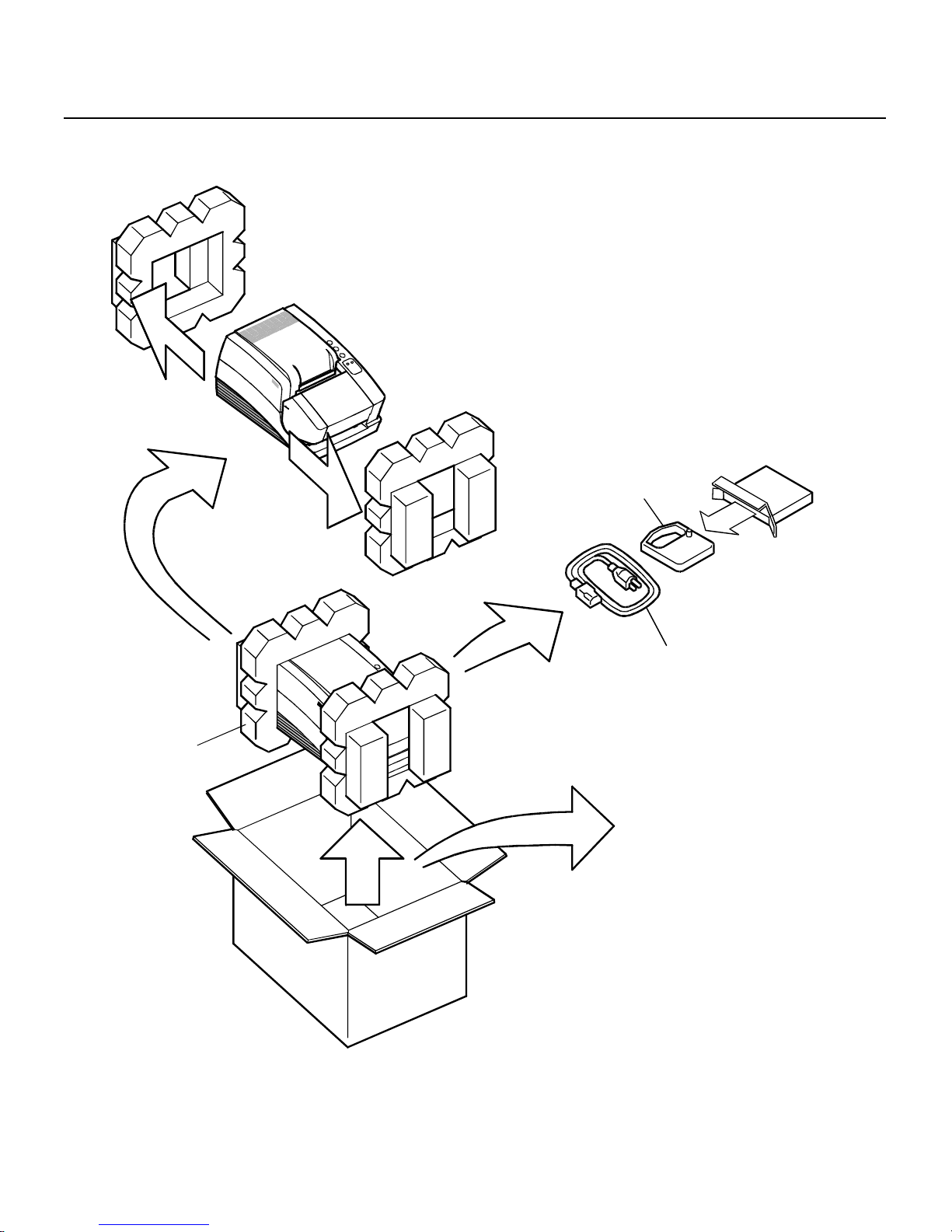

UNPACKING THE PRINTER

• Operator's Guide

• Supplies Order Form

• Journal Lock

Keys (Optional)

A

C Power

Cord

Print Ribbon

Cassette

Protective

Foam Pads

Page 27

Setting Up the Printer 17

Note: Be sure to save the box and packing materials in case you

need to send the printer in for service.

1. Before removing the printer, examine the outside of the box for signs of

damage.

If any damage has occurred to the box, carefully examine the printer and

accessories before setting up the printer. Report all evidence of damage or

abuse to your dealer and shipper.

2. Open the box, and remove the paper and supplies envelope.

3. Carefully lift the printer out of the box, and set it on a sturdy, flat surface.

4. Separate the printer from the packing material.

Simply reverse these steps if you need to repack the printer to send in for

service. (You will not need to repack the supplies).

5. Check the printer and accessories for any signs of damage.

If the printer or any parts are damaged, report this to your dealer and

shipper immediately.

Page 28

Series 90PLUS Operator’s Guide

18

CHECK THAT ALL ITEMS ARE PRESENT

The following items are packed in the box and supplies envelope. If any items

are missing, contact your dealer, or if you purchased the printer directly from

TransAct Technologies Incorporated, contact the Sales Department. Please

refer to “Contacting TransAct Technologies’ Ithaca Facility” on page 2.

♦ PcOS Series 90PLUS Operator’s Guide

♦ Warranty sheet

♦ Supplies order form

♦ Printer with the following items installed

Print head

Journal take-up spool assembly (Models 92PLUS or 93PLUS only)

♦ Journal lock keys (if journal lock was ordered)

♦ Supplies envelope

AC power cord

Ribbon cassette

♦ Paper roll

♦ Cantilever restraint

♦ Print head carriage restraint (located under the cassette cover)

Page 29

Setting Up the Printer 19

REMOVE THE CANTILEVER RESTRAINT AND THE PRINT

HEAD CARRIAGE RESTRAINT

Note: Do not remove the packing restraints if you will be moving

the printer to another location before installation.

Cantilever

Restraint

1. Remove the cantilever restraint, as shown in the illustration.

Page 30

Series 90PLUS Operator’s Guide

20

Cassette

Cover

2. Open the cassette cover.

Print Head

Carriage

Restraint

3. Remove the print head carriage restraint.

The foam restraint keeps the print head from moving during shipment. Be

sure to remove the restraint before operating the printer.

Page 31

Setting Up the Printer 21

4. Close the cassette cover.

Note: Save both restraints with the box and packing materials in

case you need to send the printer in for service.

REMOVE THE PAPER ROLL

Paper

Cover

1. Open the paper cover.

Page 32

Series 90PLUS Operator’s Guide

22

Paper Roll

Rubber Band

2. Remove the paper roll and the rubber band around it.

3. Close the paper cover.

Page 33

Setting Up the Printer 23

CHOOSING A LOCATION FOR THE PRINTER

The Series 90PLUS Printer is designed to be placed on point-of-sale terminals,

counter tops, or any other flat, stable surface that can support the weight of the

printer (about 10 pounds or 4.5 kilograms). Please refer to the dimensions

when selecting the best possible location. Be aware of the environmental

conditions of the location where you place the printer. Generally, the

environment in any store is suitable for operating the printer.

DIMENSIONS

♦ Width: 7.3 inches (185 mm)

♦ Length: 12.25 inches (311 mm)

♦ Height: 6.0 inches (152 mm)

WEIGHT

♦ Approximate weight: 10 pounds (4.5 kg)

♦ Approximate shipping weight: 13 pounds (5.9 kg)

ENVIRONMENTAL CONDITIONS

The printer will run at its best when stored and operated in an environment that

meets the following temperature and humidity conditions:

♦ Operating temperature: 0° to 50°C (32° to 122°F)

♦ Storage temperature: -10° to +60°C (-14° to +140°F)

♦ Operating relative humidity: 10% to 90% (noncondensing)

♦ Storage relative humidity: 5% to 90%

AIRFLOW

Make sure the printer is in a location where it will receive plenty of airflow.

Do not block any passages or place anything on top of the printer.

Page 34

Series 90PLUS Operator’s Guide

24

INSTALLING A RIBBON CASSETTE

Note: If you are installing the printer, a ribbon cassette is located

in the supplies envelope.

Follow these steps to install or change the ribbon cassette.

Power

Switch

On Off

Back of

Printer

1. Turn off the printer (if already on), and open the cassette cover.

Note: If you are removing a used ribbon cassette, grasp both sides

of the cassette. Lift and rock the cassette towards you. Do

not pull the cassette straight up.

Cassette

Carriage

Groove

Tabs

Print head

2. Holding the ribbon cassette with the Mylar guide facing away from you,

insert the front of the cassette into the carriage. See the following

illustration.

Page 35

Setting Up the Printer 25

Note: It is important to fit the front edge of the ribbon cassette

into the carriage first. Do not place the ribbon cassette

flat on the carriage.

Ribbon

Cassette

Clamp

Carriage

Tab

Print head

3. Rock the ribbon cassette forward, toward the print head, and then press

down on it until the tabs on the cassette snap into the clamps on the

carriage.

Cassette

Knob

4. Tighten the ribbon by turning the knob on the cassette clockwise.

5. Close the cassette cover.

6. Turn the printer back on (if already installed).

If you are setting up the printer, go to the next section.

Page 36

Series 90PLUS Operator’s Guide

26

CONNECTING THE POWER CORD

Caution: The printer must be grounded through the three-prong

power connector. Do not use a ground-defeating adapter.

Power

Switch

On Off

Back of

Printer

1. Turn off the power switch.

Back of

Printer

Power

Cord

2. Connect the power cord to the power socket located on the back of the

printer and the external AC power source.

The power cord is in the supplies envelope.

3. Turn on the printer. The READY light turns green indicating the printer is

functioning.

Note: The printer takes about 1.5 seconds to begin operation.

Page 37

Setting Up the Printer 27

LOADING AND REMOVING PAPER

This section describes how to load and remove paper. Change the paper when

the READY light flashes orange and green. This indicates that the paper is

low. The printer will stop. You must change the paper for the printer to resume

operation.

INSTALLING THE NEW PAPER ROLL

Follow these instructions for loading either single- or multiple-ply paper.

Note: If this is a new installation, a receipt roll is supplied with the

printer. If you are changing multiple-ply paper, remove the

journal take-up roll before loading the new roll. See

“Removing the Journal Take-up Roll” on page 33.

1. Open the paper cover.

If you are changing the paper, remove the used supply roll. Do not pull on

the paper to remove unused paper from the printer. Instead, hold the FEED

and RESUME buttons simultaneously. This removes unused paper from

the printer safely.

2. Tear off a clean edge on the new roll and fold the paper straight.

This makes it easier to load the paper.

Page 38

Series 90PLUS Operator’s Guide

28

3. Place the roll in the printer, so the paper unwinds from the bottom (front).

Receipt

Roller

4. Slide the edge of the paper over the receipt roller and into the paper load

throat.

Page 39

Setting Up the Printer 29

FEED

Button

5. Turn on the printer, and press the FEED button until 12 inches of paper is

loaded.

With slight downward pressure, the receipt paper feeds into the throat and

around the platen assembly.

Page 40

Series 90PLUS Operator’s Guide

30

Take-up

Spool

6. If you are loading multiple-ply paper, place the take-up spool into the

printer, lining up the gears.

If you are loading single-ply paper, continue with Step 10.

7. Separate the paper plies. The white ply is always used for the receipt.

Page 41

Setting Up the Printer 31

8. Fold the edge of the journal ply, and insert it into the slot on the take -up

spool.

9. Press the FEED button to wind two or three turns of the journal ply onto

the take-up spool.

Page 42

Series 90PLUS Operator’s Guide

32

10. Thread the receipt paper through the slot in the paper cover. Close the

paper cover, and then tear off any excess receipt paper.

If at any time the paper does not feed, repeat the steps. If this does not

work, remove the paper and restart.

Page 43

Setting Up the Printer 33

REMOVING THE JOURNAL TAKE-UP ROLL

If you are changing multiple-ply paper, you must remove the journal take-up

roll before installing the supply roll.

Paper

Cover

1. Open the paper cover.

2. Press the FEED button to advance the journal paper past the last journal

entry.

Page 44

Series 90PLUS Operator’s Guide

34

3. Lift the take-up spool from the printer, and cut the paper below the last

journal entry. Be sure that all entries are included.

4. Slide the printed journal off the take-up core, and put it in a safe place.

If the paper sticks on the core, hold the paper and twist the core in the

direction opposite the way the paper is wound.

Page 45

Setting Up the Printer 35

FEED

Button

RESUME

Button

5. Remove the journal supply roll. Do not pull on the paper to remove unused

paper from the printer. Instead, hold the FEED and the RESUME buttons

simultaneously. This removes unused paper from the printer safely.

Page 46

Series 90PLUS Operator’s Guide

36

CUTTER

The cutter is a factory installed option on the Series 90PLUS Printer. The

cutter performs a partial cut that slices the receipt paper when the receipt is

finished printing.

LOADING AND REMOVING PAPER WITH THE CUTTER

This section describes how to load and remove paper with the optional cutter

installed, if your printer does not have the optional cutter installed refer to

“Loading and Removing Paper” on page 27. Change the paper when the

READY light flashes orange and green. This indicates that the paper is low.

The printer will stop. You must change the paper for the printer to resume

operation.

INSTALLING THE NEW PAPER ROLL

Follow these instructions for loading either single- or multiple-ply paper.

Note: If this is a new installation, a receipt roll is supplied with the

printer.

If you are changing multiple-ply paper, remove the journal

take-up roll before loading the new roll. See “Removing the

Journal Take-up Roll” on page 40.

1. Open the paper cover.

If you are changing the paper, remove the used supply roll. Do not pull on

the paper to remove unused paper from the printer. Instead, hold the FEED

and the RESUME buttons simultaneously. This removes unused paper

from the printer safely.

2. Tear off a clean edge on the new roll, and fold the paper straight.

This makes it easier to load the paper.

Page 47

Setting Up the Printer 37

3

4

2

Cutter

Unit

3. Place the roll in the printer, so the paper unwinds from the bottom (front).

4. Open the cutter unit.

5

6

5. Slide the edge of the paper under the cutter unit, and insert the paper

between the receipt roller and the paper load throat.

6. Turn on the printer, and press the FEED button until 12 inches of paper is

loaded.

With slight downward pressure, the paper feeds into the throat and around

the platen assembly.

Page 48

Series 90PLUS Operator’s Guide

38

7

7. If you are loading single-ply paper, continue with Step 8.

If you are loading multiple-ply paper, separate the paper plies. The white

ply is always used for the receipt. Thread the journal ply (yellow) under

the cutter unit.

8. Insert the receipt paper through the slot in the cutter unit. The slot is

marked with a series of arrows.

1

0

9

9. Close the cutter unit.

10. Tear off the excess receipt paper.

If you are loading single-ply paper, continue with Step 14.

Page 49

Setting Up the Printer 39

11

12

13

11. Place the take-up spool into the printer, lining up the gears.

12. Fold the edge of the journal ply, and insert it into the slot on the take-up

spool.

13. Press the FEED button to wind two or three turns of the journal ply onto

the take-up spool.

14. Close the paper cover, and tear off any excess receipt paper.

If at any time the paper does not feed, repeat the steps. If this does not

work, remove the paper and restart.

Page 50

Series 90PLUS Operator’s Guide

40

REMOVING THE JOURNAL TAKE-UP ROLL

If you are changing multiple-ply paper, you must remove the journal take-up

roll before installing the supply roll.

1. Open the paper cover.

3

2

2. Press the FEED button to advance the journal paper past the last journal

entry.

3. Lift the take-up spool from the printer, and cut the paper below the last

journal entry. Be sure that all entries are included.

4

4. Slide the printed journal off the take-up core, and put it in a safe place.

If the paper sticks on the core, hold the paper, and twist the core in the

direction opposite the way the paper is wound.

Page 51

Setting Up the Printer 41

5

6

6

5. Remove the used paper core. If there is still unused paper on the core, tear

the paper out of the printer. Do not pull on the paper to remove unused

paper from the printer. Hold the FEED and the RESUME buttons

simultaneously. This removes unused paper from the printer safely.

Page 52

Series 90PLUS Operator’s Guide

42

MICR READER

The MICR (Magnetic Ink Character Recognition) reader is an option on the

Series 90PLUS Printer. The reader is attached to the front of the printer and

allows a document with MICR data, such as a check, to be read and positioned

for printing.

The MICR reader will read the MICR code, transmit the information to the

host, and be ready to load or reject the document. If the host decides to load

the document, it will be positioned ready to print on the face of the document.

If the document is rejected, it will be fed out of the top of the printer.

The MICR reader can also be used to load a document for endorsement. In this

case, the MICR reader is only used as a loading aid, and the MICR characters

are not read.

INDICATOR LED’S

There are two LED indicators on the MICR reader. These LED’s indicate that

the reader is ready or a read failure has occurred. When the green LED is lit,

the printer is ready to accept a document. The green LED turns off after a

document is read correctly. The red LED indicates a read failure.

Page 53

Setting Up the Printer 43

CHECK VERIFICATION (MICR)

MICR

Characters

Check

Green

LED

Red

LED

1. The host system sends a MICR read request to the printer. The green LED

lights up indicating the printer is ready to verify a check.

2. Be sure the check is face up with the MICR characters on the right.

Position the check against the right side of the MICR reader table, and

slide the check into the MICR reader. The printer will automatically load

and read the check.

3. Remove the check.

Page 54

Series 90PLUS Operator’s Guide

44

TESTING THE PRINTER

Test the printer to ensure that it is running properly. The sample on the

following page shows what a printout of the test may look like. The test pattern

varies depending on the printer model and the character set selected when the

printer was ordered.

Run the test after loading the paper, but before connecting it to a host system.

If the characters do not print properly or ink is smudged on the paper, check to

make sure the paper and ribbon are installed correctly. If you are still having

problems, please refer to “Correcting Problems” on page 64.

If the printer is still not working correctly, contact your dealer or the Technical

Support Department at TransAct Technologies’ Ithaca facility. For more

information, see “Contacting TransAct Technologies’ Ithaca Facility” on page

2.

TESTING THE PRINTER

1. Turn off the printer.

2. Press and hold the RESUME button while turning on the printer.

When the printer starts printing, let go of the RESUME button.

Some technical information is printed before the character set. This

information identifies the part number and date of the printer’s firmware.

If the character set is incomplete or does not look at all like the sample,

contact your dealer or the Technical Support Department at TransAct

Technologies’ Ithaca facility. Please refer to “Contacting TransAct

Technologies’ Ithaca Facility” on page 2.

Page 55

Setting Up the Printer 45

The menu shown on the sample above provides different modes for running

the printer. These modes are described in the Programmer’s Guide. To order a

Programmer’s Guide, see “Contacting TransAct Technologies’ Ithaca

Facility” on page 2. If you have accidentally entered this menu mode, turn the

printer off and then back on again.

Page 56

Series 90PLUS Operator’s Guide

46

TESTING THE MICR READER

You may test the MICR reader to ensure that it is running properly. The next

section describes how to enter the Test Mode and verify that the MICR reader

is correctly reading the MICR characters.

TESTING THE MICR READER

1. Turn off the printer.

2. Press and hold the RESUME button while turning on the printer.

When the printer starts printing, let go of the RESUME button.

The model number and other information about the printer are printed.

When the printer stops printing, the first selectable test is printed at the

bottom of the receipt.

3. Press and let go of the RELEASE button until the test you would like to

run is printed, in this case the MICR Read Test.

4. Press the RESUME button to start the test.

5. The printer prints “Insert Check to Read,” and the green LED is lit. Insert a

check with MICR characters printed on it.

6. After the check is read, press the RESUME button to print the MICR data.

The numbers at the bottom of the receipt should correspond with the

MICR numbers on the check.

7. To exit the Test Mode, turn the printer off and back on again.

The other test modes are described in the Programmer’s Guide. If you have

accidentally entered this menu mode, turn the printer off and back on again.

Page 57

Setting Up the Printer 47

CONNECTING THE CABLES

Now that you have set up and tested the printer, you are ready to connect it to

the point-of-sale system.

CONNECTING THE COMMUNICATION CABLE

Depending on the interface your system uses, either connect the serial or

parallel communication cable to the appropriate connector on the back of the

printer.

Cables are provided by your dealer or system installer. If cables are

unavailable, contact TransAct Technologies. See “Contacting TransAct

Technologies’ Ithaca Facility” on page 2.

Connect the Serial Cable

Back of

Printer

9-pin Serial

Interface Connector

1. Turn off the printer and host system or personal computer.

2. Connect the 9-pin serial interface cable to the connector located on the

back of the printer.

Refer to the Appendix for information on the serial cable requirements.

3. Tighten the two mounting screws on each side of the cable connector.

Page 58

Series 90PLUS Operator’s Guide

48

Connect the Parallel Cable

Back of

Printer

25-pin Parallel

Interface Connector

1. Turn off the printer and host system or personal computer.

2. Connect the 25-pin parallel interface cable to the connector located on the

back of the printer.

Refer to the Appendix for information on the parallel cable requirements.

3. Tighten the two mounting screws on each side of the cable connector.

Page 59

Setting Up the Printer 49

CONNECTING THE CASH DRAWER CABLES

Back of

Printer

Cash Drawer

Connector 1

Cash Drawer

Connector 2

1. Turn off the printer.

2. Connect the cash drawer cables to the connectors located on the back of

the printer.

Adapters are available for connecting cash drawers equipped with BNC

style connectors (the standard is a modular, telephone style connector).

If you need an adapter, contact the Technical Support Department at

TransAct Technologies. See “Contacting TransAct Technologies’ Ithaca

Facility” on page 2.

Page 60

Series 90PLUS Operator’s Guide

50

SETUP CHECKLIST

Did you follow all of the steps required to setup the printer? Here they are

again for you to check.

q Unpack the printer.

q Remove the cantilever restraint and the print head carriage restraint.

q Choose a location for the printer.

q Check the environmental conditions and airflow around the printer.

q Install the ribbon cassette.

q Connect the power cord.

q Load the paper: single-ply paper on the 91PLUS model, multiple-ply paper

on the 92PLUS and 93PLUS models.

q Verify a check (if your printer has a MICR reader).

q Test the printer.

q Test the MICR reader.

q Connect the communication and cash drawer cables.

Page 61

Operating the Printer 51

OPERATING THE PRINTER

Once the printer has been setup, there is little that you need to do during daily

operation because most functions are controlled by the host system. This

chapter describes the following few tasks that you will need to perform, some

more often than others:

♦ Operating the keypad,

♦ Validating a form or slip,

♦ Changing the print head,

♦ Adjusting the platen gap,

♦ Cleaning the printer, and

♦ Correcting problems.

Note: For instructions on changing the ribbon cassette and the

paper, the following sections will be helpful:

♦ “Installing a Ribbon Cassette,” on page 24 and

♦ “Loading and Removing Paper” on page 27.

Page 62

Series 90PLUS Operator’s Guide

52

OPERATING THE KEYPAD

READYFORM

RESUME

RELEASE

FEED

Series 90PLUS

The keypad contains three buttons and two indicator lights for easy operation

of the printer. The AC power switch is on the left rear side of the printer. Take

a few minutes to become familiar with the keypad so that if something

unexpected happens, you will be prepared.

INDICATOR LIGHTS

There are two indicator lights: READY and FORM. The READY light may be

red, green, or orange. The FORM light is green.

Page 63

Operating the Printer 53

READY Light FORM Light Condition Printer State

Green OFF Printer is ready to print. READY

Flashing Green OFF Paper cover is open. NOT READY

Form Status Conditions

READY

Orange Slow flash Insert slip form.

Orange Fast flash Insert validation form.

Green OFF Form is inserted.

Flashing Orange Slow flash Remove form or slip misfeed.

Flashing Orange

and Green

OFF Printer is low on receipt paper.

Error Conditions

ERROR

Flashing Orange OFF Printer is out of paper.

Flashing Red OFF Printer has faulted.

Page 64

Series 90PLUS Operator’s Guide

54

BUTTONS

The printer includes three buttons and a power switch which have the

following functions:

FEED Button

The FEED button advances receipt/journal paper.

Note: To reverse the feed, press and hold the RESUME and FEED

buttons simultaneously. Reverse feed is useful to get the end

of a used paper roll out of the printer safely.

RELEASE Button

The RELEASE button is used on printers with slip/validation capability. This

button opens and closes the carrier assembly, allowing forms to be removed if

a jam occurs.

RESUME Button

The RESUME button restarts the printer after a form load failure.

Note: When the printer is reinitialized, all printer functions return

to their default settings (as if the printer were just turned on)

and any data stored in the print buffer is lost. In this case,

you may need to reenter the current transaction.

AC POWER SWITCH

The AC power switch turns the printer on and puts it on-line (READY light

On, FORM light Off).

Note: The printer takes about 1.5 seconds to begin operation.

Page 65

Operating the Printer 55

PRINTING ON FORMS

The Series 90PLUS Printer can print on inserted forms in two ways by:

♦ Inserting the form in the top of the printer, referred to as validation, which

allows up to 17 lines of print on a form, or

♦ Inserting the form in the front of the printer, referred to as slip printing,

which allows many more lines of print on a form.

Validation and slip printing are described in the following two sections.

VALIDATING A FORM

Forms can be validated with either a single line or multiple lines of

information. Depending on the host system and software used, either the host

system or the printer controls the procedure. In most cases, the only difference

is whether you are prompted by the host system or the printer.

Validation Controlled by the Host System

When the host system controls the validation procedure, the area on the printer

where forms are inserted is opened by the host.

1. The host system indicates that a form is to be inserted for validation.

2. Insert the form into the printer.

3. The host system closes the validation clamp and prints on the form.

When printing is complete, the host releases the form.

4. Remove the form.

Page 66

Series 90PLUS Operator’s Guide

56

Validation Controlled by the Printer

1. The host system sends a validation transaction to the printer.

2. The printer opens the validation clamp, so the form can be inserted. The

FORM light flashes, and the READY light shines orange.

Green

Forms Guide

READY

Light

3. Insert the form into the printer.

Use the green form guide on the right side of the validation slot to align the

form. Push the form all the way down until the READY light turns green.

When the READY light changes from orange to green, the form is

properly positioned, and the printer clamps the form automatically.

4. The printer prints on the form.

When printing is complete, the host releases the form.

5. Remove the form.

Page 67

Operating the Printer 57

SLIP PRINTING

During slip printing, the form to be printed on is inserted into the front of the

printer. Slip printing is controlled by the printer.

1. The host system sends a slip transaction to the printer.

2. The printer opens the slip clamp, so a form can be inserted. The FORM

light flashes, and the READY light shines orange.

Slip

Guide

Rail

READY

Light

3. Insert the form into the printer.

Use the right slip guide rail to align the form. Then push the form all the

way in until the READY light turns green.

When the READY light changes from orange to green, the form is

properly positioned, and the printer clamps the form automatically.

Page 68

Series 90PLUS Operator’s Guide

58

4. The printer automatically positions the form to the top line.

If the form is not positioned correctly, the printer generates an error. The

READY light flashes orange. The FORM light flashes green, and the form

clamp is released. Remove the form, and press the RESUME button. Start

again at Step 2 above.

5. When the form is positioned properly, printing begins.

When printing is complete, the host releases the form.

5. Remove the form.

CHANGING THE PRINT HEAD

Replace the print head when characters are consistently misprinting.

REMOVING THE USED PRINT HEAD

Caution: The print head can get very hot.

Power

Switch

On Off

Back of

Printer

1. Turn off the printer, and allow the print head to cool for at least three

minutes before replacing it.

Page 69

Operating the Printer 59

Cassette

Cover

1. Open the cassette cover.

2. Remove the ribbon cassette.

4. Open the print head clip by grasping the tab on the right side of the clip

and rotating it from right to left.

Page 70

Series 90PLUS Operator’s Guide

60

Note: In the following illustrations, the heat sink is not shown

for clarity.

5. Lift the print head straight up out of the carriage.

INSTALLING THE NEW PRINT HEAD

1. Slide the black wire guide on the back of the print head into the slot on the

carriage. Make sure the tabs on the wire guide hold the print head against

the carriage.

2. Align the PC board on the bottom of the print head with the receptacle on

the carriage.

3. Press the print head into the carriage. Do not force the PC board into the

receptacle. Make sure it is lined up properly.

Page 71

Operating the Printer 61

4. Close the print head clip by rotating it from left to right and latching it into

place.

5. Replace the ribbon cassette, and then close the cassette cover.

6. Turn on the printer.

After the print head has been replaced, test the printer to make sure it is

printing properly.

Page 72

Series 90PLUS Operator’s Guide

62

ADJUSTING THE PLATEN GAP

Blue

Lever

The gap between the print head and the platen can be adjusted to accommodate

the thickness of different paper. If the gap is not set properly, the characters

can smudge, the print head can jam, and the density of the characters will be

less than ideal.

Adjust the print head gap by moving the blue lever, located to the left of the

ribbon cassette, to one of three positions. Open the cassette cover to reach the

lever.

Set the gap to one of the following:

♦ Position 1: One-ply paper,

♦ Position 2: Two-ply paper, or

♦ Position 3: Three-ply paper.

Page 73

Operating the Printer 63

CLEANING THE PRINTER

Cleaning the printer occasionally and keeping it well maintained will help it

last longer and run better.

Caution: Do not use rubbing alcohol or any kind of cleaner on internal parts

of the printer, as this may cause some parts to crack or break.

None of the internal parts of the printer require lubrication or routine

maintenance. Apply a common cleaner such as fantastik® or Formula 409® to a

damp cloth and gently wipe the surface of the printer and keypad.

Page 74

Series 90PLUS Operator’s Guide

64

CORRECTING PROBLEMS

INDICATOR LIGHTS

There are two indicator lights on the right side of the printer: READY and

FORM. The READY light may be red, green, or orange. The FORM light is

green.

READY Light FORM Light Condition Printer State

Green OFF The printer is ready to print. READY

Flashing Green OFF The paper cover is open. NOT READY

Form Status Conditions

READY

Orange Slow Flash Insert a slip form.

Orange Fast Flash Insert a validation form.

Green OFF Form is inserted.

Flashing Orange Slow Flash A slip or check is jammed or

skewed. Remove the slip or

check, and press the

RESUME button.

Flashing Orange

and Green

OFF Printer is low on receipt paper.

Error Conditions

ERROR

Flashing Orange OFF The printer is out of paper.

Flashing Red OFF Printer fault or knife fault has

occurred.

The MICR reader has two LED’s: green and red. The green LED indicates the

MICR reader is ready to accept a check for verification. The red LED indicates

a MICR misread.

Page 75

Operating the Printer 65

READY LIGHT FLASHES RED

Any time the READY light is flashing red, the printer has failed.

You should first find out the code for the error that has occurred and then

attempt to correct the problem.

Press the RESUME button to display the error code. The number of times the

FORM light blinks indicates the error code. Count the blinks and write down

the number. If you lose count, push the RESUME button again to redisplay the

code. You must find out the error code before turning off the printer.

After you have written down the error code, complete the following steps to

correct the problem.

1. Turn off the power switch.

2. Open the paper cover and the cassette cover.

3. Do the following.

Remove or clear any jams or obstructions, such as misfed paper.

Turn the knob on the ribbon cassette to be sure it is operating

correctly.

Move the print head from side-to-side to be sure that it slides easily.

4. Close both covers.

5. Turn on the power switch.

If you are unable to correct the problem, contact your dealer or the Technical

Support Department at TransAct Technologies. Please refer to “Contacting

TransAct Technologies’ Ithaca Facility” on page 2. Have the error code

available when you call.

PRINTER SMEARS CHARACTERS

Adjust the platen gap. For step-by-step instructions, see “Adjusting the Platen

Gap” on page 62. If this does not correct the problem, contact your dealer or

the Technical Support Department at TransAct Technologies. Please refer to

“Contacting TransAct Technologies’ Ithaca Facility” on page 2.

Page 76

Page 77

Appendix 67

APPENDIX

CASH DRAWER PIN ASSIGNMENTS

Function Drawer 1 Drawer 2

Drawer Drive + Pin 4 Pin 4

Drawer Drive - Pin 5 Pin 1

Status Signal Pin 2 Pin 2

Status Ground Pin 3 Pin 3

Frame Ground Pin 6 Pin 6

Pin 1

Page 78

68 Series 90PLUS Operator’s Guide

SERIAL CABLE

CABLE REQUIREMENTS

The PcOS Series 90PLUS Printer requires an RS-232C shielded cable, no

more than 50 feet long. The cable must be UL and CSA approved.

RS-232C COMMUNICATION

The RS-232C interface uses the following protocol and communication

characteristics:

♦ Up to 19.2K baud;

♦ Up to 6K buffer;

♦ Ready/Busy or XON/XOFF protocol; and

♦ Communication Diagnostic Mode.

PIN ASSIGNMENTS FOR 9-PIN PRINTER CONNECTOR

Pin Name Description

1 DCD Data Carrier Detect

2 RX Receive Data

3 TX Transmit Data

4 DTR Data Terminal Ready

5 GND Signal Ground

6 DSR Data Set Ready

7 RTS Request To Send

8 CTS Clear To Send

9 SSD Secondary Data

Page 79

Appendix 69

SERIAL CABLE CONFIGURATIONS

The following cable configurations are for different host requirements.

Serial PC to Series 90PLUS

Ithaca part number 10-2020, 9-pin to 9-pin female cable, should be used to

connect PcOS Series 90PLUS Printers to personal computers or PS/2’s with 9pin serial ports.

DTR

DSR

DCD

TXD

RXD

GND

RTS

CTS

4

6

1

3

2

5

7

8

DTR

DSR

DCD

TXD

RXD

GND

RTS

CTS

4

6

1

3

2

5

7

8

Nine-pin

Female

PC

Nine-pin

Female

Printer

PN 10-2020

Serial AT to Series 90PLUS

Ithaca part number 10-2021, 9-pin to 25-pin female cable, should be used to

connect PcOS Series 90PLUS Printers to personal computers or PS/2’s with

25-pin serial ports.

DTR

DSR

DCD

TXD

RXD

GND

RTS

CTS

20

6

8

2

3

7

4

5

DTR

DSR

DCD

TXD

RXD

GND

RTS

CTS

4

6

1

3

2

5

7

8

Twenty-five-pin

Female

PC

Nine-pin

Female

Printer

PN 10-2021

Page 80

70 Series 90PLUS Operator’s Guide

PARALLEL CABLE

CABLE REQUIREMENTS

The PcOS Series 90PLUS Printer requires a 25-pin male D-shell connector at

the printer. To connect the printer to most personal computers, use Ithaca part

number, 253-9800007, which is a 25-pin male to 25-pin male parallel

interconnect cable.

PIN ASSIGNMENTS

Pin(s) Signal Description Direction

1 STROBE Clock data to printer Host to printer

2-9 D0 - D7 Data Host to printer

10 ACK\ Printer accepted data Printer to host

11 BUSY Printer busy Printer to host

12 PE Paper out/status Printer to host

13 SLCT Printer selected Printer to host

14 AUTOFD Autofeed paper Host to printer

15 ERR\ Printer error Printer to host

16 INIT\ Initialize printer Host to printer

17 SLIN Select printer Host to printer

18-25 GND Ground

Page 81

INDEX

A

AC power switch, 55

airflow around printer, 24

B

buttons, 55

C

cables

connecting, 50

ordering, 5

cantilever restraint

removing, 19

cash drawer cable

connecting, 50

cash drawer connector

pin assignments, 67

character pitch, 11

character set

sample printout, 45

checks

verification, 43

cleaning, 64

cutter

cutter, 37

D

dimensions of printer, 23

documentation

ordering. See TransAct Technologies.

E

environment of printer, 23

F

features, 9

options, 10

FEED button, 55

forms

printing, 56

I

indicator lights, 53

MICR reader, 43

K

keypad

buttons, 55

indicator lights, 53

operating, 53

M

MICR reader

MICR reader, 43

testing, 47

O

options, 10

ordering documentation. See TransAct Technologies.

ordering supplies, 5

Page 82

72 Series 90PLUS Operator’s Guide

P

paper

loading, 28, 37

ordering, 4

removing, 35–36, 35–36

reverse feed, 37

reverse feed, 28, 55

paper roll

removing, 21

parallel cable

connecting, 49

requirements, 70

parallel cable connector

pin assignments, 70

pin assignments

cash drawer connector, 67

parallel cable connector, 70

serial cable connector, 68

pitch, 11

platen gap

adjusting, 63

power cord

connecting, 27

power switch, 55

print characteristics, 11

print head

changing, 59

ordering, 5

print head carriage restraint

removing, 19

printer

cleaning, 64

dimensions, 23

environment, 23

features, 9

keypad, 53

models, 7

options, 10

reliability, 10

repacking, 17

testing, 45, 47

unpacking, 17

warranty, 3

weight, 23

printing

forms, 56

problems

correcting, 65

R

RELEASE button, 55

reliability, 10

repacking the printer, 17

RESUME button, 55

ribbon cassette

installing, 24

removing, 24

RS-232C communication, 68

S

serial cable

configurations, 69

connecting, 48

requirements, 68

serial cable connector

pin assignments, 68

Series 90PLUS models, 7

service information, 3

slip printing, 56

supplies, 5

cables, 5

paper, 4

print head, 5

take-up spools, 5

T

take-up spools

ordering, 5

test printout, 45

testing the printer, 45, 47

Transact technologies

contacting, 2

troubleshooting, 65

Page 83

U

unpacking the printer, 17

V

validation, 56

W

warranty information, 3

weight of printer, 23

Page 84

PN: 90-7478 Rev. F 02/03

Loading...

Loading...