Trannergy PVI 1800, PVI 2300, PVI 4000, PVI 4600, PVI 5400TL User Manual

...

PVI 1800 / 2300 / 3200 / 4000 / 4600 / 5400TL

User Manual

Contents

Copyright Declaration ............................................................................................................... 3

1. Introduction ........................................................................................................................... 4

1.1. Introduction .................................................................................................................... 4

1.2. How to Use this manual ................................................................................................. 4

1.3. Applied Designations (Warning, Caution, Note) ........................................................... 4

1.4. Important Safety Information ......................................................................................... 4

1.5. General Safety Rules for Working on Electrical Equipment.......................................... 5

1.6. System Sizing ................................................................................................................. 6

1.7. DC-switch....................................................................................................................... 7

2. Technical Description of Inverters ........................................................................................ 8

2.1. Mechanical design .......................................................................................................... 8

2.2. Electrical system design ................................................................................................. 9

3. Operation Mode Definition ................................................................................................. 11

3.1. Waiting mode ............................................................................................................... 11

3.2. Connecting mode.......................................................................................................... 11

3.3. Normal mode................................................................................................................ 11

3.4. Fault mode.................................................................................................................... 11

4. Installation and startup ........................................................................................................ 13

4.1. Installation precaution .................................................................................................. 13

4.2. Installing the inverter.................................................................................................... 16

4.2.1. PVI1800TL/PVI2300TL ....................................................................................... 16

4.2.2. PVI3200/4000/4600/5400TL ................................................................................ 18

4.3. Electrical connection .................................................................................................... 21

4.4. Run the inverter ............................................................................................................ 27

5. Human Machine Interface ................................................................................................... 28

5.1. Control Panel................................................................................................................ 28

5.2. LCD Functions ............................................................................................................. 29

5.3. Language Settings ........................................................................................................ 29

1

User Manual

2

User Manual

6. Communication and Monitoring ......................................................................................... 32

6.1. Communication Interfaces............................................................................................ 32

6.2. Communication ............................................................................................................ 32

6.2.1. RS-232 Communication for single inverter type................................................... 32

6.2.2. RS-485 Communication for Several inverters....................................................... 33

6.2.3. Wireless ................................................................................................................. 34

6.3. Monitoring.................................................................................................................... 34

7. Service and repair ................................................................................................................ 35

7.1. Safety during service and repair ................................................................................... 35

7.2. Troubleshooting............................................................................................................ 35

8. Technique specification....................................................................................................... 37

8.1. Electrical Specification................................................................................................. 37

8.1.1. Input Specification................................................................................................. 37

8.1.2. Output Specification.............................................................................................. 37

8.1.3. General Data.......................................................................................................... 38

9. Qualification........................................................................................................................ 39

10. Contact Information .......................................................................................................... 40

Appendix A: FAQ (Frequently asked questions) .................................................................... 41

Appendix B: Abbreviation ...................................................................................................... 42

3

User Manual

Copyright Declaration

The copyright of this manual belongs to Shanghai Trannergy Power Electronics Co.,

Ltd. Any corporation or individual should not plagiarize, partially copy or fully copy

it (including software, etc.), and no reproduction or distribution of it in any form or by

any means. All rights reserved. Shanghai Trannergy reserves the right of final

interpretation. This manual is subject to change according to user’s or customer’s

feedback. Please check latest version at: http://www.trannergy.com.

1. Introduction

1.1. Introduction

This manual describes Trannergy solar inverters PVI1800TL , PVI2300TL,

PVI3200TL, PVI4000TL, PVI4600TL and PVI5400TL. These products are

among the most technologically advanced and efficient inverters on the market

and are designed to ensure a stable power supply for many years.

The PVI inverter is a transformerless based inverter.

1.2. How to Use this manual

Please read the safety instructions in this manual first. Throughout the manual it

is assumed that the reader is familiar with AC and DC installations and knows the

rules and regulations for electrical equipment and for connecting it to the utility

AC grid. It is especially important to be familiar with the general safety rules for

working with electrical equipment.

1.3. Applied Designations (Warning, Caution, Note)

Throughout the manual important information is shown at different levels

depending on the character of the information, as shown here:

Safety information important for human safety. Violation of

warnings may result in injury to persons or death.

Information important for the protection of property. Violation

of this type of information may cause damage and loss of

property.

Useful additional information or “Tips and Tricks" on specific

subjects.

1.4. Important Safety Information

Read this before installing, operating or maintaining the inverter.

4

User Manual

Before installation:

Check for damage to inverter and packaging. If you are in doubt,

please contact your supplier before installing the inverter. Check

the voltages of the solar modules and make sure they are within

the limits of the Trannergy inverter specifications before

connecting them to the inverter.

Installation:

Only trained and authorized personnel familiar with local

electrical codes may install the inverter. For optimum safety,

please follow the steps described in this manual. Keep in mind

that the inverter has two voltage carrying sides, the PV input and

the AC grid.

Disconnecting the inverter:

Always disconnect the AC line first! Afterwards disconnect the

PV lines. Note that the inverter can still be charged with very

high voltages at hazardous levels even when it is disconnected

from grid/mains and solar modules. Wait at least 15 min. before

proceeding, after having disconnected from grid and PV panels.

operating the inverter:

Before connecting the AC grid to the inverter, make sure that

the

installation cover is mounted again. The inverter must not be

open during operation.

Maintenance and modification:

Only authorized personnel are allowed to repair or modify the

inverter. To ensure optimum safety for user and environment,

only the original spare parts available from your supplier should

be used.

Functional safety parameters:

Unauthorized changes of functional safety parameters may cause

injury or accidents to people or inverter. Additionally it will lead

to the cancelling of all inverter operating approval certificates.

The Trannergy inverters in the PVI range are all designed

according to the German VDE0126-1-1standard.

If non-original spare parts are used, the compliance with CE

guidelines in respect of electrical safety, EMC and machine

safety is not guaranteed.

1.5. General Safety Rules for Working on Electrical Equipment

All persons installing, maintaining or servicing inverters should be trained in and

5

User Manual

have experience with the general safety rules to be observed when working on

electrical equipment.

Installation and service personnel should also be familiar with local requirements,

rules and regulations as well as safety requirements.

To provide a general guideline for safety precautions, five well-known and

widely accepted rules are repeated below. The list should by no means be

considered as exhaustive.

The person performing work on electrical equipment is

responsible for the safety of persons and property!

Disconnecting

Disconnect all cables supplying voltage to the working place

before starting any work. Please note that a lack of voltage is no

guarantee that disconnection has been performed.

Protecting against reconnection

Prevent the system from reconnecting by marking, closing or

locking off the work area. Unintentional reconnection may result

in severe accidents.

Checking that system is voltage free

Ascertain conclusively by means of a voltage tester that the

system is voltage free. Check all terminals to ensure that the

system is voltage free (on each individual conductor).

Covering adjacent voltage-carrying components and

preventing persons from gaining access to them

Cover up all voltage-carrying system compon

ents that can harm

you while working. Make sure that danger areas are clearly

marked.

1.6. System Sizing

When dimensioning a photovoltaic system, it must be ensured

that the open circuit voltage of the PV string never exceeds the

maximum permissible input voltage of 600V DC. The PV string

open circuit voltage during parallel string operation is 450V DC

(PVI1800TL), 500V (PVI2300TL) and 550V (PVI3200TL/

PVI4000TL/PVI4600TL/PVI5400TL) respectively. Higher

voltages may result in permanent damage to the inverter.

In Europe, the PV string open circuit voltage is normally calculated at a module

temperature of M10NC or M20NC depending on the location.

User Manual

6

The selection of PV string output should be based on the optimum utilization of

the invested capital compared to the expected annual energy yield from the

system. This optimization depends on local weather conditions and should be

considered in each individual case.

The inverter incorporates an input power limiting device, which automatically

keeps the power at levels that are safe for the inverter. The limitation depends

mainly on internal and ambient temperatures. The limitation is calculated

continuously and always allows the maximum possible amount of energy to be

produced.

Please use the tool supplied by Trannergy when dimensioning a photovoltaic

system.

1.7. DC-switch

On1y trained and authorized personnel familiar with local

electrical codes may perform service or maintenance on the

inverter. Before opening the inverter:

1) Disconnect AC grid.

2) Disconnect DC power.

3) Remove both AC and DC 1ines.

1) To switch OFF all power supply from the PV panels turn the DC-switch to

OFF (O).

2) To switch ON power supply from the PV panel turn the DC-switch to ON (I).

To ensure the functiona1ity of the DC-switch, a11 switches shou1d be switched

on and off (by turning the switch to on and off positions ten times) once a year, to

c1ean the contacts.

7

User Manual

2. Technical Description of Inverters

2.1. Mechanical design

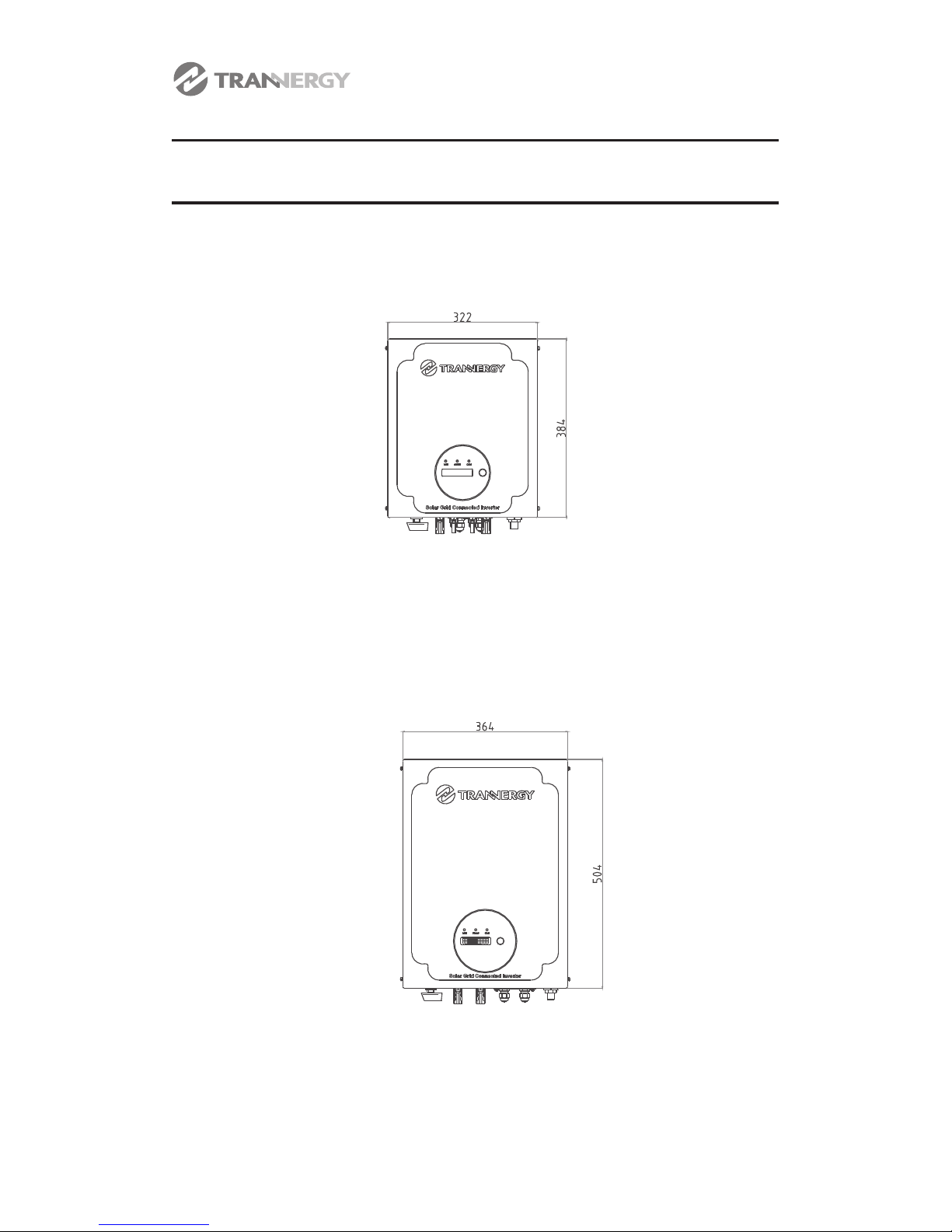

Figure 2-1 shows the outline dimensions of PVI1800TL&PVI2300TL:

Figure 2-1 Outline dimensions of PVI1800TL&PVI2300TL

Figure 2-2 shows the outline dimensions of PVI3200TL, PVI4000TL,

PVI4600TL and PVI5400TL:

Figure 2-2 Outline dimensions of PVI3200/4000/4600/5400TL

User Manual

8

Note: The AC output terminal is most length part at the bottom

of inverter, so take care of the AC output terminals, do not make

it stand on the ground or other materials while moving or lifting

the inverters otherwise will make terminal damaged.

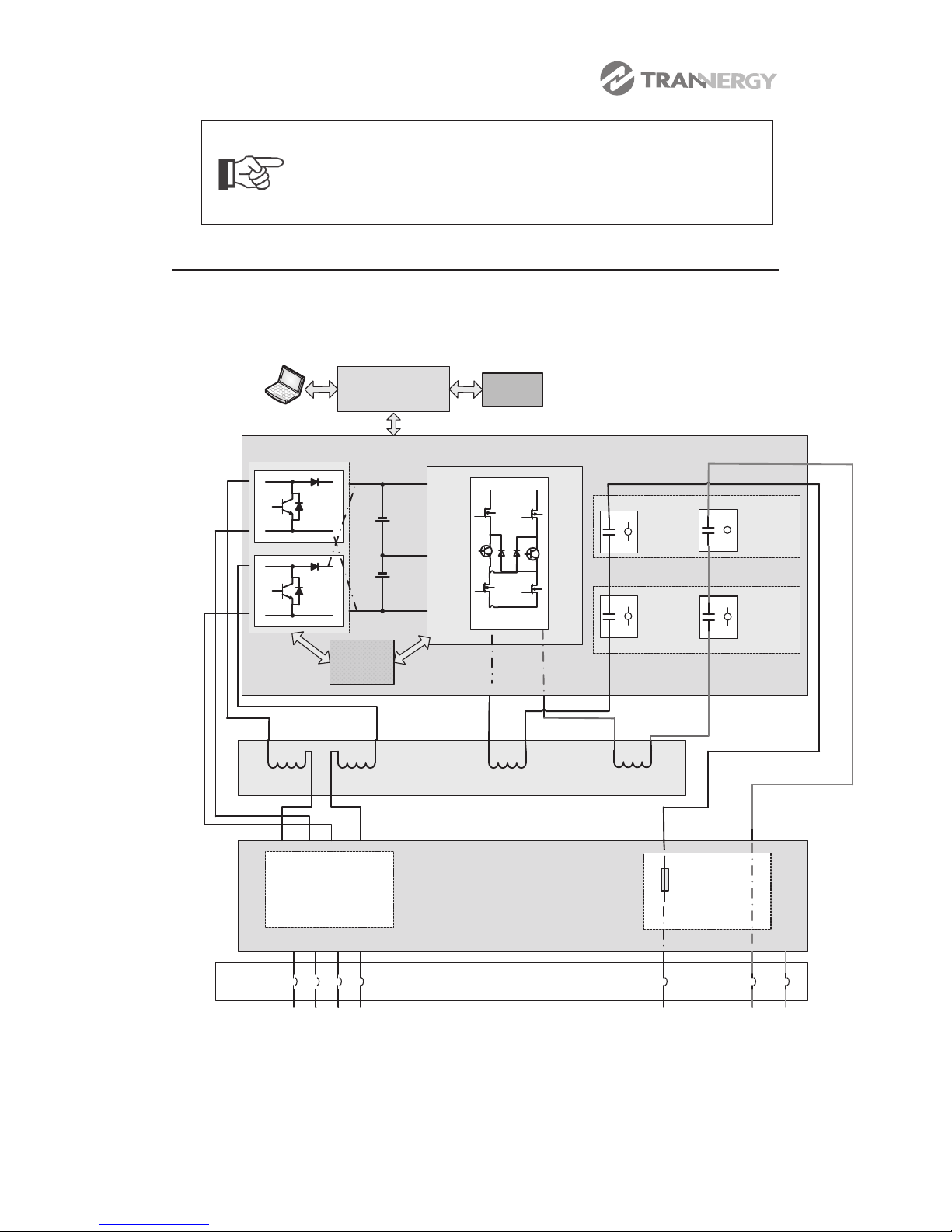

2.2. Electrical system design

Figure 2-3 shows the wiring diagram of the whole PVI1800/2300/3200/4000TL/

4600/5400TL systems.

EMCA

DC EMI/EMC Filter

L N PE

30Vac

Grid

PV1+ PV1- PV2- PV2+

125-550Vdc

Solar Array

DC Circuit Breaker

AC Circuit Breaker

LB1

3IL1IL2BL

Inductors Box

PSDA

INVERTER

N

R

N

PV1+ PV2+

+2VP+1VP

PV2-PV1-

BOOST1 & 2

Communication

COMA

RS232/485

LCD&indicator

HMI

PC

Detection/Control

/Protection

CNTA

Relay Control by Master DSP

Relay Control by Slave DSP

AC EMI/EMC Filter & GFCI

F1 F2 F3

Shanghai Trannergy Power Electronics Co.,Ltd.

H6

Figure 2-3 wiring diagram

of the whole PVI1800/2300/3200/4000/4600/5400TL system

9

User Manual

We recommend a 32A DC Breaker located at the input of the DC input, and a

32A AC Breaker located at the output of the AC part.

Notes:

When choose the breaker, please call your installer for technique

support

For the input and output wire selection, we recommend UL1015 wire, please see

the following table.

Model PVI1800TL PVI2300TL PVI3200TL PVI4000TL PVI4600TL PVI5400TL

DC input 14AWG 14AWG 14AWG 12AWG 12AWG 12AWG

AC output 14AWG 14AWG 14AWG 12AWG 12AWG 12AWG

Notes:

Before install the inverter, please firstly check the polarity of the

PV side, and a wrong polarity to the inverter may lead to a

permanent damage

The above recommended wire already consider the maximum

work current and degrading

User Manual

10

3. Operation Mode Definition

The inverter has four standard operation modes.

3.1. Waiting mode

In waiting mode, the inverter is ready to switch into connecting mode. As

decision variable the input voltage of the PV generator is used. Inverter is waiting

to checking when output DC voltage from PV panels is greater than 100V (lowest

start-up voltage) but less than 150V (lowest operating voltage). If the input

voltage exceeds 150V, the inverter shifts from "standby" to "connecting", or

continues into the operation model OFF" if the PV voltage drops.

3.2. Connecting mode

After performing the system tests, which check whether all connection conditions

are met, the inverter goes from waiting mode to connecting mode. During the

specified cut-in time, the inverter continues testing the system values and

connects the inverter to the grid if the system tests are okay. The minimum cut-in

time is specified by the supplier and authorities and can vary from region to

region.

3.3. Normal mode

In this mode, the inverter is connected to the grid and supplies power to the grid.

Inverter begins to operate normally with green light on. Meanwhile, feedback

energy to grid, LCD displays present output power, and inverter will stop

feedbacks power to grid when PV power is not enough. The inverter is only

disconnected from the grid in case of abnormal grid conditions or when PV

power is not available.

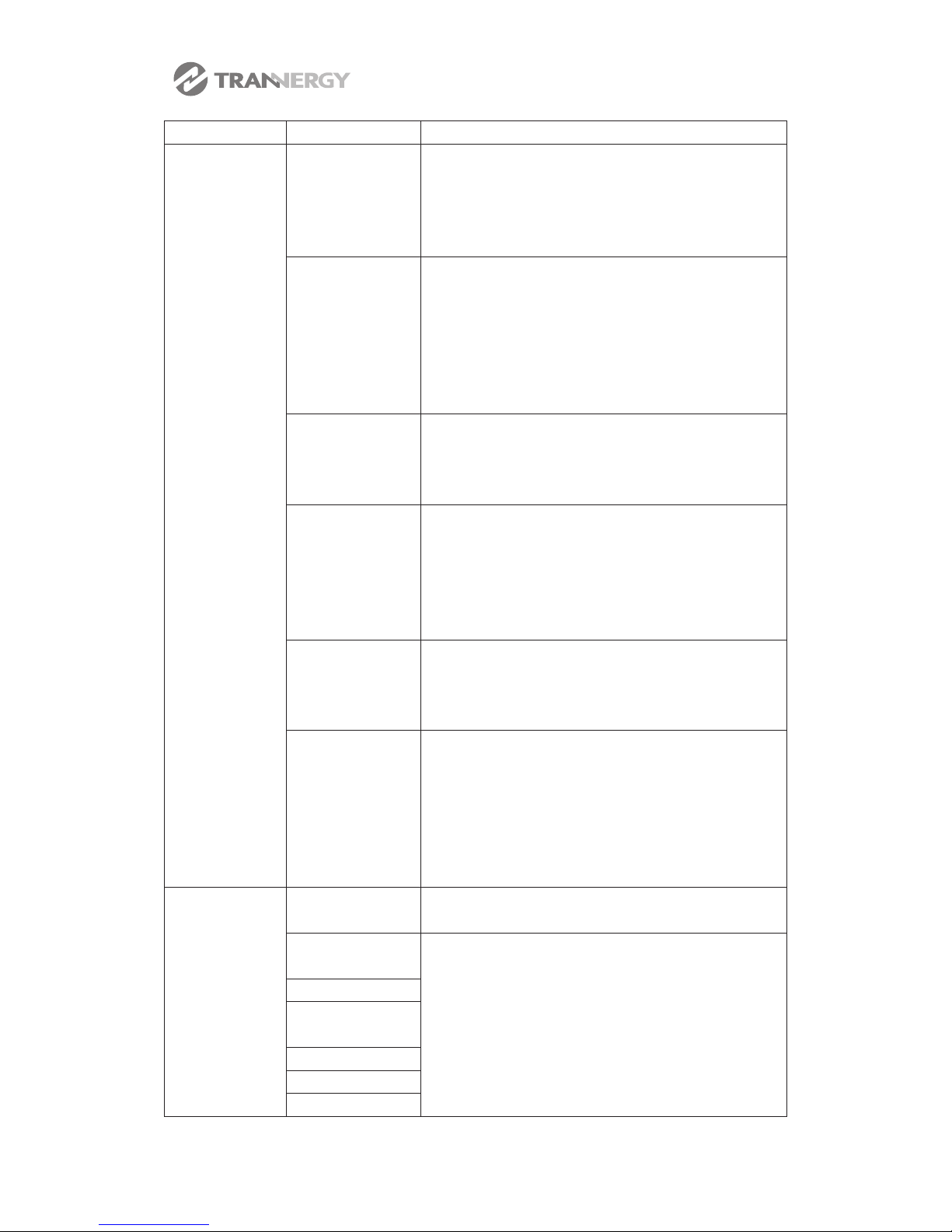

3.4. Fault mode

If the red LED on the front panel light up, the inverter enters the fault mode. The

following solutions for trouble shooting are recommended:

11

User Manual

LCD display Possible actions

Resumable

Fault

Isolation Fault 1. Check the impedance between PV (+)&PV(-)

and the inverter is earthed. The impedance

must be greater than 2MΩ

2. Check whether the AC end has contacted with

earth

Ground Fault 1. The ground current is too high

2. After cutting off the AC end connection,

unplug the inputs from the PV generator and

check the peripheral AC system.

3. After the cause is cleared, re-plug the PV

generator and AC connection, and check

PV-Inverter status.

Grid Fault

Fac Over Range

Vac Over Range

1. Wait for a moment, if the grid returns to

normal, PV-Inverter automatically restarts.

2. Make sure grid voltage and frequency meet the

specifications.

Utility Loss 1. Grid is not connected.

2. Check grid connection cables.

3. Check grid usability.

4. If grid is ok, the problem persists, maybe the

fuse in the inverter is open, please call the

service.

Over

Temperature

1. The internal temperature is higher than

specified normal value.

2. Find a way to reduce the ambient temperature

or move the inverter to cooler environment.

PV over voltage 1. Check the open circuit voltage of the PV

generator, see if it is greater than or too close

to 450VDC (for PVI1500TL) or 500VDC

(for PVI2000TL)

2. If PV voltage is less than 450VDC or

500VDC, and the problem still occurs, please

call the service.

Permanent

Fault

Consistent Fault Disconnect PV (+) or PV(-) from the input,

restart the inverter.

Relay-Check

Fail

1. Disconnect all PV (+) or PV (-)

2. Wait for a few seconds.

3. After the LCD switches off, reconnect and

check again.

4. If the problems remain, please call the service.

DC INJ High

EEPROM R/W

Fail

SCI Failure

AC HCT Fault

GFCI Failure

User Manual

12

Loading...

Loading...