Page 1

6

7

32

May 2013 © 2013Trane RT-SVU03H-EN

All rights reserved

Model Number: YSC036E - YSC060E YHC036E - YHC072E

YSC072F - YSC120F YHC120E

YHC048F - YHC060F YHC072F - YHC102F

SAFETYWARNING

Only qualified personnel should installand service the equipment.The

installation, starting up, andservicing of heating, ventilating, and airconditioning equipment can be hazardousand requires specific

knowledge and training. Improperly installed,adjusted or altered

equipmentby anunqualified person couldresult indeath orserious injury.

When workingon the equipment,observe all precautionsin the literature

and on the tags, stickers, and labels that are attached to the equipment.

4 5

1

Owner Manual

Packaged Rooftop Air Conditioners

Precedent™- Gas/Electric

3-10Tons-60Hz

Cautions, Warnings and Notices

Important: Environmental Concerns! Scientific research hasshown

that certainman-made chemicals can affectthe earth's naturallyoccurring

stratospheric ozone layer whenreleased to the atmosphere. In particular,

several of the identified chemicals that may affectthe ozone layer are

refrigerants that contain Chlorine, Fluorineand Carbon (CFCs) and those

containing Hydrogen, Chlorine, Fluorine andCarbon (HCFCs). Not all

refrigerants containing these compoundshave the same potential impact

to the environment.Trane advocatesthe responsible handling of all

refrigerants-including industry replacements forCFCs such as HCFCs and

HFCs.

Important: Responsible Refrigerant Practices!Trane believes that

responsible refrigerant practices are importantto the environment, our

customers, and the air conditioningindustry. All technicians who handle

refrigerants must be certified.The Federal CleanAir Act (Section 608) sets

forththe requirementsfor handling,reclaiming, recoveringand recyclingof

certain refrigerants and theequipment that is used in these service

procedures. Inaddition, some statesor municipalities mayhave additional

requirements thatmust also beadhered to forresponsible managementof

refrigerants. Know the applicable lawsand follow them.

WARNING

Indicates a potentially hazardous situationwhich, if not avoided, could

result in death or seriousinjury

CAUTION

Indicates a potentially hazardous situationwhich, if not avoided, could

result in minor or moderateinjury. It may also be used toalert against

unsafe practices.

NOTICE

Indicates a situation that couldresult in equipment or property-damage

only accidents.

General Information

Important: Remember the following instructions atall times.

WARNING

Hazard of Explosion orFire!

Do notstore or usegasoline or otherflammable vapors and liquidsin the

vicinity of this or anyother appliance.

IFYOU SMELL GAS, follow instructions below:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Open windows and doors.

• Alert others and evacuate building immediately.

• From a phone outside of the building, immediatelycall your gas

supplier. Follow the gas supplier's instructions. If you can not reach

your gas supplier,call the fire department.

Failure to follow recommendationslisted above could result in death or

serious injury and equipment orproperty damage.

WARNING

Safety Hazards!

• Do not use thisfurnace if any portionhas been under wateras it may

have rendered the unit hazardousto operate. Immediately call a

qualified service technicianto inspect the furnace andto replace any

part orthe control system and anygas control whichhas been under

water.

• Should overheating occur, or theunit gas valve fail to shut off, close

the gas valve tothe furnace before shutting off the electrical supply.

Failure to follow recommendationscould result in death, serious injury

and equipment or propertydamage.

Yourunit is of complex design.Toensure that it performs safelyand gives

long lastingservices, someof themaintenance work mustbe performedby

a qualified service person.

When aservice person isreferred toin this manualit is describinga service

technicianwho has hadspecial training ora number ofyear sexperience in

servicingthis type ofequipment. Itis yourresponsibility toselect aqualified

service company that canprovide a service person of this caliber.

WARNING

Safety Hazards!

• Never perform anymaintenance proceduresuntil theelectrical power

to the unit is turnedoff.

• Never perform anymaintenance procedures untilthe gas valveis the

gas supply line isturned off.

• Never remove any panels from the unit whileit is operating.

• Never remove panels or partsfrom the unit that arenot discussed in

this manual.

• Never cover the unit since it is designedto operate year round.

Failure tofollow recommendations couldresult in deathor serious injury.

Thermostat

Room thermostats are delicatetemperature sensing controls. Theirmain

function is to energizeand de-energize the heating or cooling circuit to

maintain the temperature settingyou select.

Manythermostats containa roomthermometer toindicate theapproximate

room temperature and atemperature scale at the adjustment indicator to

select the desired indoor airtemperature. In addition, most thermostats

have a selector mode switch with Heat, Offand Cool positions and a fan

switch with Onand Off positions.

When theswitch is positioned atOff your unitwill not operate ineither the

heat or cool modes. Ifthe selector switch is set at Heatthe unit will

automatically cycleon and offto maintain thedesired temperature setting.

The unit will also operateautomatically when the selector switch is

positioned at Cool.

The fanselector switch canbe used to operatethe indoor fancontinuously

by positioning it at On.When set to Autothe fan will only operate when

required during the heating orcooling cycles.

Toensure that the thermostat operates properly, it mustbe level and

positioned to avoid theinfluence of such external heat sources as lamps,

televisions or other heat producingappliances.

Air Filters

Filters are tobe used with this unit. Unitsship from the factory withfilters

installed.

It isvery important tok eepthe central ductsystem air filters clean.Be sure

to inspect them at leastonce each month when the system isin constant

operation. (Innew homes,check thefilters every weekfor thefirst 4 weeks.)

See Table 1for the required filter size(s).

If youhave disposabletype filters,replace themwith newfilters of thesame

type and size. Donot attempt to clean disposable filters.

Permanent type filters canbe cleaned by washing them with a mild

detergent and water.Ensure that the filters are thoroughly dry before

reinstalling them in the unit(or duct system).

It maybe necessaryto replace permanentfilters annuallyif washing failsto

clean the filter,be sure to use the same type and sizeas was originally

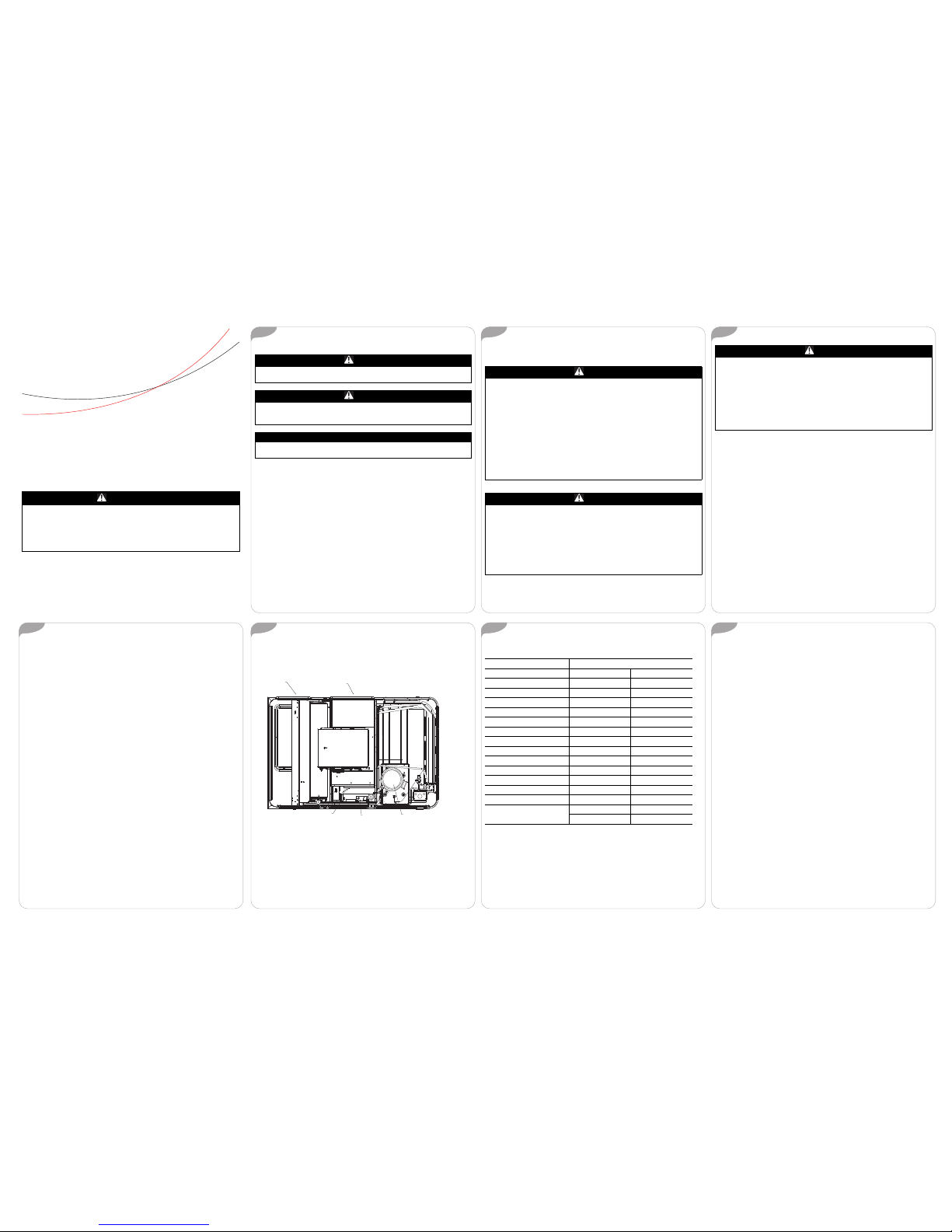

Figure 1. Gas unit overview

RETURN AIR

SUPPLY AIR

PRESSURE SWITCH

GAS VALVE

COMPRESSOR

installed.

Table1. Recommended standard filters

Unit Model Number Filter Size

Inches Millimeters

YH/SC036E*, YHC037E* (2) 20x30x2 (2) 508x762x50

YSC048E* (2) 20x30x2 (2) 508x762x50

YSC060E* (2) 20x30x2 (2) 508x762x50

YHC047E*, YHC048* (4) 16x25x2 (4) 406x635x50

YHC060*, YHC067E* (4) 16x25x2 (4) 406x635x50

YSC072F* (4) 16x25x2 (4) 406x635x50

YSC090F* (4) 16x25x2 (4) 406x635x50

YHC072F* (4) 20x25x2 (4) 508x635x50

YSC092F* (4) 20x25x2 (4) 508x635x50

YSC102F* (4) 20x25x2 (4) 508x635x50

YSC120F* (4) 20x25x2 (4) 508x635x50

YHC092F* (4) 20x25x2 (4) 508x635x50

YHC102F* (4) 20x25x2 (4) 508x635x50

YHC120E* (2) 20x30x2 (2) 508x762x50

(3) 20x25x2 (3) 508x635x50

Heating System

Heating Cycle Operation

Yourunit's heating system hasa solid-state electronic ignitioncontrol that

lights thefurnace burnerseach timethe thermostatcalls forheat. Atthe end

of each heatingcycle the furnace burners are extinguished.This type of

system is called Direct SparkIgnition (DSI).

A normal heating cyclebegins when the air temperature drops below the

thermostat setting.The thermostat then energizes theheating electrical

circuit thatstarts andcontrols thefurnace burners.Shortly afterthe burners

ignite theindoor fanstarts and circulateswarm airthrough the conditioned

space.

When theair temperature risesto the thermostatsetting thethermostat de-

energizes the heating electricalcircuit, which in turn extinguishes the

burners.The indoor fan continues to circulate warm airuntil most of the

heat is removed fromthe unit's combustion chamber.

Safety Controls

• Your unit is equipped with anautomatic reset safety limit control to

prevent overheating.When this control opens, it shuts down the

heating electrical circuit until theunit cools down sufficiently.

Inadequate airflow (i.e., caused bydirty filters or defective fan motor)

maycause theunit tocycle onand offas thelimit tripsand automatically

resets. If you suspect thatthe unit is cycling on its limit control,

immediately contact a service personfor instructions.

• If flames from the burner are not properly drawninto the heat

exchanger, aFlame Rollout Protection Control will open causing the

furnace to shut off.The cause mustbe investigated by a qualified

service person.

• If installed, the condensate overflow switch willshut down the unit

before a drain pan overflowoccurs.

Page 2

8 9 10 11

The manufacturer optimizesthe performance of homes andbuildings around the world. Abusiness of

Ingersoll Rand,the leader in creatingand sustainingsafe, comfortableand energyefficient environments,

the manufacturer offers a broad portfolio of advanced controls and HVAC systems, comprehensive

building services,and parts. Formore information, visitwww.IRCO.com.

The manufacturer hasa policyof continuous productand product dataimprovement andreserves the rightto change

design andspecifications withoutnotice.

© 2013Trane All rightsreserved

RT-SVU03H-EN 13 May2013

Supersedes RT-SVU03G-EN(18 July2012)

Weare committed tousing

environmentally consciousprint

practices thatreduce waste.

Heating System Start-Up

Because your unit has anautomatic ignition system, it is easy to startthe

heating cycle at the beginningof the heating season. In order for the unit

to operate properly andsafely, the furnace needs air forboth combustion

and ventilation. Check to makesure that all air openings areunobstructed

and there is adequate clearancearound the unit to provide good air flow.

1. Set the thermostat's heating adjustmentlever at its lowest setting.

2. Move the selector switchto the Off position.

3. Turn offall electric power to the unit.

4. This unit isequipped with an ignition devicewhich automatically lights

the burners.

5. Remove the access panel thatcontains the following label:

6. Change the ON/OFF switchto the OFF position.

WARNING

HazardousVoltage w/ Capacitors!

Disconnectall electricpower, includingremote disconnectsand discharge

all motor start/run capacitors beforeservicing. Follow proper

lockout/tagout procedures toensure the power cannot be inadvertently

energized.Verify with an appropriate voltmeter that allcapacitors have

discharged. Failureto disconnect power anddischarge capacitors before

servicing could result in deathor serious injury.

WARNING

Risk of Burn!

NEVER attempt to manuallylight the burner! Failure to follow this

recommendation could result in seriousinjury.

Figure 2. Label

REMOVE THIS PANEL

TO GAIN ACCESS TO

THE GAS VALVE

Note: Somevalves requirethe knobto be pushedin slightlybefore turning.

7. Wait (5) minutesto clear outany gas. If youthen smell gas,STOP! Refer

to thewarnings providedin the “GeneralInformation” section.If you do

not smell gas, goto the next step.

8. Change the ON/OFF switchto the ON position.

9. Replace panel removed in step5 above.

10.Turnon all electric power to unit.

11.Set thermostat to desired temperatureand move the selector switchto

the ON position.The unit will now operate automatically.

12.If the unit willnot operate, follow the instructions "ToTurnOff Gas To

Unit" (underHeating SystemShutdown) andcall your servicetechnician

or gas supplier.

Important: The unit is to be adjustedto obtain an air rise within that

specified on the nameplate.

Heating System Shutdown

Toshut down theheating system forbrief periodsof time simplyadjust the

thermostat selector switchto the "Off" position.

NOTICE

Property Damage!

If theunit is shut downduring the cold weathermonths, provisions must

be taken to prevent freeze-upof all water pipes and water receptacles.

Whenever your house or buildingis to be vacant, arrange to have

someone inspect your structure forproper temperature. This isvery

importantin below freezingweather.If for any reason yourfurnace should

fail to operate, damage such as frozen waterpipes could result.

HowToTurn Off GasTo Unit

1. Set the thermostat to lowestsetting.

2. Turn offall electric power to the unit if service isto be performed.

3. Remove the access panel thatcontains the label shown in Figure 2.

4. Change ON/OFF switch tothe "OFF" position.

5. Replace panel removed in step3 above.

WARNING

HazardousVoltage w/ Capacitors!

Disconnectall electricpower, includingremote disconnectsand discharge

all motor start/run capacitors beforeservicing. Follow proper

lockout/tagout procedures toensure the power cannot be inadvertently

energized.Verify with an appropriate voltmeter that allcapacitors have

discharged. Failureto disconnect power anddischarge capacitors before

servicing could result in deathor serious injury.

Heating System Maintenance

Complete the following unit inspectionsand service routines at the

beginning of eachheating season.

Refer to the warningsin “General Information” regarding combustible

materials and what to doif you smell gas.

Important: These steps should only be performedby a qualified service

technician.

1. Inspect the control panel wiring andheating controls to make sure

connections are tight and wiringinsulation is intact.

2. Turnthe unit on and offat the thermostatto be sure the ignitioncontrol

and spark electrode are operatingproperly.

3. Turn offthe gas supply with the unit operating toverify that the gas

valves closes and that are-ignition cycle is initiated by the ignition

control.

4. Check the operation ofthe gas ignition system.

5. Check the burnermanifold pressure. A 1/8inch pipe plug is providedin

the gas valve forthis purpose.

6. Visually inspect allof the unit'sflue product passageways for excessive

deposit build up and corrosion.If build up or corrosion is apparent,

perform the necessary repairs.

7. Arrange fora qualifiedserviceman toinspect theunit everyother heating

season to maintain safe andefficient operation.

8. Visually checkthe mainburner flames.Theyshould bebright blueflames

extending into the heat exchanger sections.

9. Never storeanything flammable orcombustible around ornear the unit.

Condensate Overflow Sensor (Optional)

If installed,the Condensate overflow switchwill shut down theunit before

a drain pan overflowoccur s.

Loading...

Loading...