Page 1

February 2003 MS-SVN004-EN

Installation Manual

ILLUSION

Split System

Concealed Type

MCD Series 50/60 Hz

Cooling Only/Cooling Heating

50 Hz Models

MCD 512 DB

MCD 518 DB

MCD 524 DB

MCD 530 DB

MCD 536 DB

MCD 048 DB

MCD 060 DB

Cooling Only/Cooling Heating

60 Hz Models

MCD 512 D1

MCD 518 D1

MCD 524 D1

MCD 530 D1

MCD 536 D1

MCD 048 D1

MCD 060 D1

L/O- 02091985TRA 21/4/03, 2:44 PM1

Page 2

General Information

Introduction

This Installation Manual is given as a

guide to good practice in the

installation by the installer of MCD

mini-split system. Installation

procedures should be performed in

the sequence that they appear in this

manual.

For installing the unit to operate

properly and reliably, it must be

installed in accordance with these

instructions. Also, the services of a

qualified service technician should be

employed, through the maintenance

contract with a reputable service

company.

Read these installation instructions

completely before installing the

air conditioning system.

About the Unit

These MCD units are assembled,

pressure tested, dehydrated, charged

and run tested before shipment.

The information contained in this

manual applies to MCD units are

designed to operate in cooling mode

only and in cooling or heating

modes.

Important

This document is customer property

and is to remain with unit. Please

place in service information pack upon

completion of work.

These instructions do not cover all

variations in systems, nor do they

provide for every possible contingency

to be met in connection with

installation.

Should further information be

desired or should particular

problems arise which are not

covered sufficiently in this manual,

the matter should be referred to

your authorized Trane dealer.

Reception

On arrival, inspect the unit before

signing the delivery note. Specify any

damage of the unit on the delivery

note, and send a registered letter of

protest to the last carrier of the goods

within 72 hours of delivery. Notify the

dealer at the same time.

The unit should be totally inspected

within 7 days of delivery. If any

concealed damage is discovered,

send a registered letter of protest to

the carrier within 7 days of delivery

and notify the dealer.

Warranty

Warranty is based on the general

terms and conditions by country.

The warranty is void if the equipment

is modified or repaired without the

written approval of

The Trane Company, if the

operating limits are exceeded or if

the control system or the electrical

wiring is modified.

Damage due to inappropriate

installation, lack of knowledge or

failure to comply with the

manufacturer’s instructions, is not

covered by the warranty obligation.

If the installation does not conform to

the rules described in Installation

Manual, it may entail cancellation of

warranty and liabilities by

The Trane Company.

About this Manual

Cautions appear at appropriate places

in this Installation Manual.

Your personal safety and the

proper operation of this machine

require that you follow them

carefully.

The Trane Company assumes no

liability for installations or servicing

performed by unqualified personnel.

All phases of the installation of this air

conditioning system must conform to

all national, provincial, state and local

codes.

Warning

Warnings are provided at appropriate

places in this manual to indicate to

installers, operators and service

personnel of potentially hazardous

situations which, if not avoided,

COULD result in death or serious

injury.

Caution

Cautions are provided at appropriate

places in this manual to indicate to

installers, operators, and service

personnel of potentially hazardous

situations which, if not avoided, MAY

result in minor or moderate injury or

malfunction of the unit.

MS-SVN004-EN© American Standard Inc.2000

L/O- 02091985TRA 21/4/03, 2:44 PM2

Page 3

3MS-SVN004-EN

Contents

General Information 2

System Appearance 4

Location and Preparation of Units 6

Units Installation 7

Connection of Refrigerant Tubing 9

Condensate Drain Piping 10

Electrical Installation 11

Wiring Diagram 12

Dimensional Data 15

Maintenance 18

L/O- 02091985TRA 21/4/03, 2:44 PM3

Page 4

4 MS-SVN004-EN

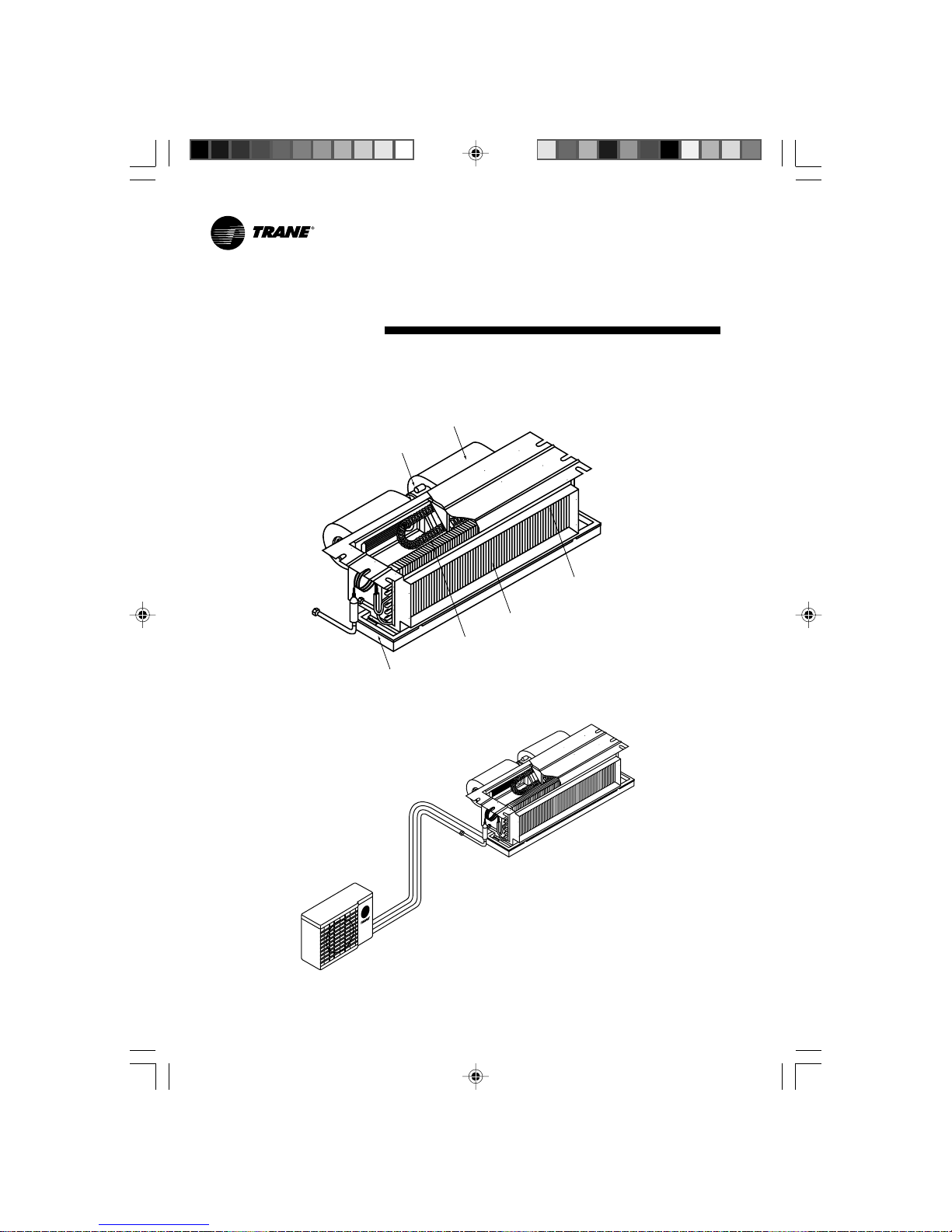

System Appearance

MCD 512-536 DB/D1

Condensate Drain Pan

Electric Heater

(Option)

Evaporator Coil

Outlet Collar

Motor

Blower

Outdoor Unit

Indoor unit

L/O- 02091985TRA 21/4/03, 2:44 PM4

Page 5

5MS-SVN004-EN

MCD 048-060 DB/D1

Blower

Return Air Plenum

(Standard)

Outdoor Unit

Indoor Unit

Electric Heater

(Option)

Condensate Drain Pan

Motor

Evaporator Coil

Outlet Collar

L/O- 02091985TRA 21/4/03, 2:44 PM5

Page 6

6 MS-SVN004-EN

Location and Preparation of Units

Indoor Unit

1. Select a convenient location that

allows the air to reach every corner

of the room and where it is easy to

route the refrigerant tubing, wiring

and drain to the outside.

2. The ceiling construction should be

strong enough to support the

weight of the unit.

3. The refrigerant tubing, drain piping

and wiring conduit are connected

through the wall.

4. Refrigerant tubes between the

indoor and the outdoor units and

drain pipes should be as short as

possible (Figure 1).

5. If a refrigerant charge adjustment is

necessary, follow the Installation

Manual for the Outdoor Unit.

Outdoor Unit

See instructions for location and

preparation of the unit in the Installation

Manual for the Outdoor Unit.

Installation Method:

Indoor Unit

After selecting the location to place

the unit, follow these steps:

1. Make a hole in the wall to route

tubing and wiring through a locally

purchased PVC pipe. The hole

should slope downwards slightly,

towards the outside (Figure 2).

Figure 1

2. Before cutting, check that no pipes

or studs are directly behind the

place to be cut. Avoid areas where

electrical wiring or conduits are

located.

3. Hang the unit on a solid and level

roof. Noise, vibration or leakage

could occur on and unstable

foundation (Figure 3,4).

For correct installation of duct

work see (Figure 6).

4. Support the unit solidly.

5. To have access to electrical

terminals, remove the right side

junction box (Figure 2).

6. Note that refrigerant tubing,

interconnecting wiring and drain

hose should go through the wall.

Shape these items so that they will

easily fit through the wall.

Figure 2

Outdoor Unit

See the proper installation method

provided in the Installation Manual

for the Outdoor Unit.

Installation Requirements

Important

- Read the Installation Manual

completely before installing and

operating the system.

-Turn on the mains power at least

five (5) hours before operating

the system.

Installation Requirements

Following is a brief outline of where

and how to install the unit. Please read

over the entire set of instructions for

indoor and outdoor units and make

sure all accessory parts list are with

the unit before beginning.

1. Tools Required for Installation

(not supplied)

- Level

- Hole saw or saw

- Core bits

- Hammer

- Drill

-Torque wrench

- Adjustable wrench

- Standard screwdriver

- Phillips head screwdriver

- Knife or wire stripper

-Tape measure

-4 Anchor bolts for ceiling

mounting

2. Refrigerant Piping and Insulation

Material

- See the Installation Manual

included with the Outdoor Unit.

- The length of wiring will determine

the wire size. See local codes and

refer to Section Electrical

Installation.

Caution

Check local electrical codes and

regulations before buying any wire.

Also check for any specitic wiring

instructions or limitations.

3. Additional Materials Required

for Installation

- Saddles or clamps to secure

refrigerant tubing.

- Insulated clamps or staples for

connecting wire. See local codes.

- Ceiling mount: Use nuts and bolts

as required to mount the unit on the

ceiling. Use 4 (3/8) fasteners or

closest standard metric with nuts

and lock washers. The length will

vary with application.

- Refrigerant oil and tape

(insulation).

- Putty or similar filler.

L/O- 02091985TRA 21/4/03, 2:44 PM6

Page 7

7MS-SVN004-EN

J

K

F

E

E

H

G

C

D

D

A

B

K

Min.750 Min. 800 100 150 50 200 Min. 100 Min. 50Min. 200 Min. 300 Min. 300

NOTE: FOR DUCT LENGTH PLEASE SEE PAGE 15, 16 AND 17

IJHABCDEFG

DISTANCE (M.M.)

I

CELING

WALL

DRAIN PIPE

DRAIN PIPE

RETURN PLENUM

WITH FILTER

DETAIL "X"

FLEXIBLE CONNECTER

CHAMBER

CHAMBER

FILTER

FILTER

RETURN AIR GRILLE

SLANT 1 : 50

SUPPLY

DUCT

SUPPLY DUCT

FIGURE 3 (SIDE VIEW)

FIGURE 4 (TOP VIEW)

Unit Installation

L/O- 02091985TRA 21/4/03, 2:44 PM7

Page 8

8 MS-SVN004-EN

Units Installation

6

L/O- 02091985TRA 21/4/03, 2:44 PM8

Page 9

9MS-SVN004-EN

Connection of Refrigerant Tubing

Proper installation prodecure is

recommended in the Installation

Manual Package, usually provided

together with the outdoor unit. It is

advisable to read bofore installing.

The indoor unit refrigerant connections

are located on the left hand side when

facing the unit (Figure 7).

Figure 7

Connecting the Units with

Flaring Procedure.

1. Cut the copper tube to the required

length with a tube cutter. It is

recommended to cut approx.

20-30 cm. longer than the tubing

length.

2. Remove burrs at the end of the

copper tube with a tube reamer

or file, as shown in Figure 8.

Figure 8

Copper

Tubing

Reamer

When reaming, hold the tube end

downward and be sure that no copper

scraps fall into the tube (Figure 9).

Deburring

Before

After

Figure 9

3. Remove the flare nut from the unit

and be sure to insert on the copper

tube.

4. Make a flare at the end of the copper

tube with a flare tool (Figure 10).

Flare Nut

Copper Tubing

Flare Tool

Figure 10

A good flare should have the

following characteristics:

• Inside surface is glossy and smooth.

• Edge is smooth.

•Tapered sides are of uniform

length.

Cautions Before Connecting

Tightly

1. Be sure to apply a sealing cap or

water-proof tape to prevent dust or

water from getting into the tubes

before they are used.

2. Be sure to apply refrigerant

lubricant to the matching surfaces

of the flare and union before

connecting them together. This is

effective for reducing gas leaks

(Figure 11).

Figure 11

Apply refrigerant lubricant here

3. For proper connection, align the

union tube and flare tube straight

with each other, then screw in the

flare nut lightly at first to obtain a

smooth match (Figure 12).

Union Flare Nut

Figure 12

4. Tighten the flare nuts, using the

appropriate wrench.

Connecting the Unit with

Brazing Prodecure

1. Cut the copper tube to the required

length with a tube cutter. It is

recommended to cut approx.

20-30 cm. longer than the tube length.

2. Remove burrs at the end of the

copper tube with a tube reamer

(Figure 8).

3. There are 2 ways to connect the

copper tube

- Use a coupling between the

copper tube of Fan Coil Unit and

the copper tube used for

installation (Figure 13).

Copper Tube

of Fan Coil

Unit

Solder Coupling

Copper Tube of

Condensing Unit

Figure 13

- Expand the copper tube by

using a swaging tool set as in

Figure 14.

Swaging Tool

Tube Holder

(Clamp)

Copper Tube

Figure 14

4. To braze the copper tube, before

brazing a copper tube to a solder

coupling or a copper tube to an

expanded tube, do not forget to

keep them tight as shown in

Figure 15.

COMMET 3

Torch

Solder Coupling

Copper Tube from

Condensing Unit

Solder Rod

Figure 15

Copper Tube

from Fan

Coil Unit

L/O- 02091985TRA 21/4/03, 2:44 PM9

Page 10

10 MS-SVN004-EN

Condensate Drain Piping

Condensate Drain Piping

1. The drain hose should run straight

down the wall to a level where the

run off will not stain the wall.

2. These should have water traps.

Avoid putting the end of the hose in

water.

3. To conveniently drain the system,

the drain piping must slant

downward, with a slope of at least

1:50 to prevent leakage.

4. When the drain hose is placed in

the room, insulate the hose with

foam polyethylene to avoid damage

to the ceiling or furniture.

5. After completing installation of

refrigerant lines, wiring and drain

connections, bind the tubing,

wiring and drain piping (check if

local codes permit binding) into a

bundle by using tape at 100 or 200

mm (4" to 8") intervals. Make sure

the drain tube is at the bottom of

the bundle (Figure 16).

Figure 16

P.V.C.

Conduit

Control Wiring

Power Wiring with

Ground Wiring

Suction Line Tube

Insulation Tube

P.V.C. Tape

Liquid Line Tube

Water Condensated

Drain Tube

(P.V.C. Tube)

L/O- 02091985TRA 21/4/03, 2:44 PM10

Page 11

11MS-SVN004-EN

Electrical Installation

Electrical Installation

All wiring and grounding must comply

with local electrical codes.

Wiring Important Safeguards:

- Check the unit nameplate for

electrical rating. Be sure wiring is

done according to local codes and

wiring diagram.

- Use a separate power line with

circuit breaker for each air

conditioning unit.

- Connect electrical ground to all

units.

- Wiring should not touch refrigerant

tubing, compressor, motors or

moving parts.

- The manufacturer will accept no

responsibility for problems caused

by unauthorized changes in the

internal wiring.

- Connect the wiring firmly.

Indoor Unit

Remove the right side junction box

(see previous instructions) to access

the terminal base.

System Wiring Routing

- Pass the system wiring through the

PVC pipe, referred to in the Section

of Installation Method (both power

and control lines) to interconnect

indoor and outdoor units.

- Connect the wire terminals to the

terminal base. See connection

indication on system wiring

diagram.

- Make sure all connections are tight.

Outdoor Unit

See the electrical installation

instructions in the Installation Manual

for the Outdoor Unit.

L/O- 02091985TRA 21/4/03, 2:44 PM11

Page 12

12 MS-SVN004-EN

Wiring Diagram

CONCEALED FAN COIL UNITS

COOLING ONLY

MCD 512-536 DB/D1

MCD 048-060 DB/D1

Remove HI-BR wire from TB-1 and replace

with EXTRA HI-BLK wire when high speed/cfm

is required in the field.

EXTRA–HI

BLK

HI

MED

LOW

COM

BR

BL

RD

WH

BLOWER

MOTOR

1

2

3

4

L2 L1 C1 C2

THERMOSTAT

3 SPEED SWITCH

POWER SUPPLY

200-240V/1PH/60Hz

220-240V/1PH/50Hz

200-240 VAC

CONTROL WIRING

TO CONDENSING

UNIT.

NOTE :

1. Power wiring and grounding of equipment

must comply with local codes.

2. Ensure that power supply agrees with

equipment nameplate.

3. Use only copper conductors.

LEGEND :

FIELD WIRING

FACTORY WIRING

LOW MEDHI

L/O- 02091985TRA 21/4/03, 2:44 PM12

Page 13

13MS-SVN004-EN

CONCEALED DX AIR HANDLER

COOLING-HEATING

MCD 512-524 DB/D1

EXTRA–HI

BLK

HI

MED

LOW

COM

BR

BL

RD

WH

BLOWER

MOTOR

BLK

RD

RD

1

2

3

4

5

6

REMOVE HI-BR WIRE FROM TB-1 AND REPLACE

WITH EXTRA HI-BLK WIRE WHEN HI SPEED/CFM

IS REQUIRED IN THE FIELD.

HEATER THERMAL OVERLOAD

PROTECTOR (MANUAL RESET)

(MAX.20AMP. NON-INDUCTIVE

FULL LOAD CURRENT)

HEATER THERMAL OVERLOAD

PROTECTOR (AUTO RESET)

(MAX.20AMP. NON-INDUCTIVE

FULL LOAD CURRENT)

HEATER

HC HC

10

2468

HEAT

COOL

TO HEATING

TO COOLING

THERMOSTAT

COOLING-HEATING

SWITCH

3 SPEED

SWITCH

h

OFF

LOWMED HI

POWER SUPPLY

200-240V/1PH/60Hz

220-240V/1PH/50Hz

200-240 VAC

CONTROL WIRING

TO CONDENSING UNIT.

LEGEND:

FIELD WIRING

FACTORY WIRING

1. POWER WIRING AND GROUDING OF

EQUIPMENT MUST COMPLY WITH LOCAL

CODE.

2. ENSURE THAT POWER SUPPLY AGREES

WITH EQUIPMENT NAME PLATE.

3. USE ONLY COPPER CONDUCTORS.

NOTE:

LNC1C2

Wiring Diagram

L/O- 02091985TRA 21/4/03, 2:44 PM13

Page 14

14 MS-SVN004-EN

CONCEALED FAN COIL UNITS

COOLING-HEATING

MCD 530-536 DB/D1

MCD 048-060 DB/D1

Wiring Diagram

C

C

H

H

HEATER

HEATER

CH

HC

NOTES :

THERMOSTAT

3 SPEED

SWITCH

1. POWER WIRING AND GROUDING OF

EQUIPMENT MUST COMPLY WITH

LOCAL CODES.

2. ENSURE THAT POWER SUPPLY

AGREES WITH EQUIPMENT NAME

PLATE.

3. USE ONLY COPPER CONDUCTORS.

HEATER THERMAL OVERLOAD

PROTECTOR (MANUAL RESET)

(MAX.20AMP. NON-INDUCTIVE

FULL LOAD CURRENT)

HEATER THERMAL OVERLOAD

PROTECTOR (AUTO RESET)

(MAX.20AMP. NON-INDUCTIVE

FULL LOAD CURRENT)

FIELD WIRING

FACTORY WIRING

COOLING - HEATING

LEGEND :

MOTOR

BLOWER

EXTRA-HI

RD

RD

WH

LOW

COM

BLK

MED

HI

RD

BL

BR

BLK

TO HEATING

TO COOLING

COOL

SWITCH

h

HEAT

OFF

LOW MED HI

LNC1

5

2 4

6 8

0 1

6

4

3

2

1

C2

POWER SUPPLY

200-240V/1pH/60Hz

220-240V/1pH/50Hz

200-240 VAC

CONTROL WIRING

TO CONDENSING UNIT.

Remove HI-BR wire FROM TB-1 and replace

with EXTRA HI-BLK wire when high speed/cfm

is required in the field.

L/O- 02091985TRA 21/4/03, 2:44 PM14

Page 15

15MS-SVN004-EN

Dimensional Data

Model

MCD 536

MCD 518

MCD 524

MCD 530

MCD 512

External Dimensions (No Plenum)

Refrig. Line Conn. Size Number OfAll External Dimensions are in inch (mm.)

AB CSuction Liquid Fan(s) Motor(s)

2

2

2

2

2

1

1

1

1

1

30"(762) 34 3/4"(882) 37 1/4"(946) 1/4"(6.35) 1/2"(12.7)

30"(762) 34 3/4"(882) 37 1/4"(946) 1/4"(6.35) 1/2"(12.7)

36"(914) 40 1/4"(1034) 43 1/4"(1098) 3/8"(9.52) 5/8"(15.87)

30"(762) 34 3/4"(882) 37 1/4"(946) 3/8"(9.52) 5/8"(15.87)

42"(1067) 34 7/8"(1087) 49 1/4"(1251) 3/8"(9.52) 3/4"(19.05)

VIEW "A"

Ø16

32

111127

63.5

HANGER HOLES - X6

SEE VIEW "A"

A

B

C

C

SUCTION CONNECTION

LIQUID CONNECTION

284

252

166

254

17440

DRAIN CONN. Ø22.5 MPT

210

234

Note: From the experience of our Trane technician, based on the design condition, at velocity at supply air grille of 300 ft/min for bedroom and 400

ft/min for office (based on free face area), the length of the air duct should be more than 3 meters.

L/O- 02091985TRA 21/4/03, 2:44 PM15

Page 16

16 MS-SVN004-EN

VIEW "A"

Ø16

32

E

D

111127

63.5

A

B

C

Ø20

HANGER HOLES - X6

SEE VIEW "A"

C

SUCTION CONNECTION

LIQUID CONNECTION

625

490

300

266

17440

DRAIN CONN. Ø22.5 MPT

254

165

External Dimensions (Return Air Plenum is option)

All External Dimensions are in inch (mm.) Refrig. Line Conn. Sizes

AB CD ESuction Liquid Fan(s) Motor(s)

MCD 512

30"(762) 34 3/4"(882) 37 1/4"(946) 30"(762) 33 15/16"(862) 1/4"(6.35) 1/2"(12.7) 2 1

MCD 518 30"(762) 34 3/4"(882) 37 1/4"(946) 30"(762) 33 15/16"(862) 1/4"(6.35) 1/2"(12.7) 2 1

MCD 524 30"(762) 34 3/4"(882) 37 1/4"(946) 30"(762) 33 15/16"(862) 3/8"(9.52) 5/8"(15.87) 2 1

MCD 530 36"(914) 40 1/4"(1034) 43 1/4"(1098)

36"(914) 39 15/16"(1014) 3/8"(9.52) 5/8"(15.87) 2

1

MCD 536 42"(1067) 42 7/8"(1087) 49 1/4"(1251) 42"(1067)

45 15/16"(1167) 3/8"(9.52) 3/4"(19.05) 2 1

Number Of

Model

Note: From the experience of our Trane technician, based on the design condition, at velocity at supply air grille of 300 ft/min for bedroom and 400

ft/min for office (based on free face area), the length of the air duct should be more than 3 meters.

Dimensional Data

L/O- 02091985TRA 21/4/03, 2:44 PM16

Page 17

17MS-SVN004-EN

VIEW "A"

Ø16

32

Ø20

HANGER HOLES - X6

SEE VIEW "A"

A

B

C

E

D

111

139

75

SUCTION CONNECTION

408

352

180

30

DRAIN CONN. Ø21 MPT

LIQUID CONNECTION

394

354

615

759

C

ABCDESuction Liquid Fan(s) Motor(s)

MCD048 36.06"(916) 40.70"(1034) 43.58"(1107) 35.70"(907) 39.88"(1013) 1-1/8"(28.57) 3/8"(9.52) 2 1

MCD060 42.08"(1069) 46.73"(1187) 49.21"(1250) 41.73"(1060) 45.90"(1166) 1-1/8"(28.57) 3/8"(9.52) 2 1

External Dimensions (Return Air Plenum is Standard)

All External Dimensions are in inch (mm.) Refrig. Line Conn. Size Number Of

Model

Note: From the experience of our Trane technician, based on the design condition, at velocity at supply air grille of 300 ft/min for bedroom and 400

ft/min for office (based on free face area), the length of the air duct should be more than 3 meters.

Dimensional Data

L/O- 02091985TRA 21/4/03, 2:44 PM17

Page 18

18 MS-SVN004-EN

Regular Maintenance

Be sure to disconnect the power

before inspection or maintenance of

air conditioner.

1. Cleaning the air filter

Air flow is reduced and cooling

efficiency impaired if the filter is

clogged. Be sure to clean the filter

every two weeks during the cooling

season.

1.1 How to remove the air filters

- Loose screws located under

the filter in return air plenum

set.

- Remove air filter frame from

return air plenum set.

1.2 How to clean the air filter.

-Wash away dust from the air

filter with clean water or

vacuum it with an electric

vacuum cleaner.

Note:

Once the air filter is washed,

dry it completely before returning it to

its original position.

After cleaning be sure to return it to its

original position.

Cautions

- Do not wash the air filter in water

that is over 40ºC or it may shrink.

- Do not expose the air filter to fire.

- Do not expose the air filter to direct

sunlight for a long time.

- Clean the air filter more frequently

Figure 8

when the air is very dirty.

Maintenance

L/O- 02091985TRA 21/4/03, 2:44 PM18

Page 19

19MS-SVN004-EN

Notes

L/O- 02091985TRA 21/4/03, 2:44 PM19

Page 20

Literature Order Number MS-SVN004-EN 0200

New MCD-SV1801-EN 0698

Stocking Location Bangkok, Thailand

∫√‘…—∑ ·Õ¡·Õ√å ®”°—¥ 35 À¡Ÿà 8 ∂.ªŸÉ‡®â“¡‘ßæ√“¬ µ.”‚√ß„µâ Õ.æ√–ª√–·¥ß ®.¡ÿ∑√ª√“°“√ 10130

Since The Trane Company has a policy of continuous product and product data improvement,

it reserves the right to change design and specifications without notice.

Trane Thailand

7th Floor, Ploenchit Center Building

2 Sukhumvit Road, Klongtoey

Bangkok 10110

Amair Limited

35 Mu 8, Poochaosamingprai Road

Samrong Tai, Samutprakarn 10130

http://www.trane.com

An American Standard Company

L/O- 02091985TRA 21/4/03, 2:45 PM20

Loading...

Loading...