Page 1

Installation

Operation

Maintenance

MCD/MWD

512-518-524-530-536-048-060

Ductable ceiling-suspended unit

SS-SVX07B-E4

Page 2

About the unit

MCD/MWD units are assembled,

pressure tested, dehydrated, charged

and run tested before shipment.

MCD units are designed to operate

in cooling mode only, whereas MWD

can operate in cooling or heating

modes. This unit with its mounted

accessories is in conformity with the

provisions of the low voltage

directive 73/23/EEC and

electromagnetic compatibility

directive 89/336/EEC as amended,

and in conformity with nation

implementing legislation.

Reception

On arrival, inspect the unit before

signing the delivery note. Specify

any damage on the delivery note,

and send a registered letter of

protest to the last carrier of the

goods within 72 hours of delivery.

Notify the local sales office at the

same time. The unit should be totally

inspected within 7 days of delivery.

If any concealed damage is

discovered, send a registered letter

of protest to the carrier within 7 days

of delivery and notify the local sales

office. Units are shipped with the

refrigerant operating or holding

charge and should be examined with

an electronic leak detector to

determine the hermetic integrity of

the unit. The refrigerant charge is not

included in the standard Warranty

Cover.

Refrigerant

The refrigerant provided by the

constructor meets all the

requirements of our units. When

using recycled or reprocessed

refrigerant, it is advisable to ensure

its quality is equivalent to that of a

new refrigerant. For this, it is

necessary to have a precise analysis

made by a specialized laboratory. If

this condition is not respected, the

constructor warranty could be

cancelled. Do not release refrigerant

into the atmosphere.

Foreword

These Installation Operation and

Maintenance instructions are given

as a guide to good practice in the

installation, start-up, operation and

periodic maintenance by the user of

MCD/MWD. They do not contain the

full service procedures necessary for

the continued successful operation

of this equipment. The services of a

qualified service technician should

be employed, through the medium

of a maintenance contract with a

reputable service company.

Warranty

Warranty is based on the general

terms and conditions of the

constructor. The warranty is void if

the equipment is modified or

repaired without the written

approval of the constructor, if the

operating limits are exceeded, or if

the control system or the electrical

wiring is modified. Damage due to

misuse, lack of maintenance, or

failure to comply with the

manufacturer's instructions, is not

covered by the warranty obligation.

If the user does not conform to the

rules of chapter "Maintenance", it

may entail cancellation of warranty

and liabilities by the constructor.

About this manual

The information contained in this

manual applies to units designated

MCD/MWD. Cautions appear at

appropriate places in this instruction

manual. Your personal safety and the

proper operation of this machine

require that you follow them

carefully. The constructor assumes

no liability for installations or

servicing performed by unqualified

personnel. Read this manual

carefully and the manual on the

installation of the outdoor unit

before starting to install the system.

© 2008 Trane

SS-SVX07B-E4

General information

Page 3

SS-SVX07B-E4 3

Contents

General information

2 droweroF

2 ytnarraW

2noitamrofni lareneG

2 noitpeceR

2tnaregirfeR

Installation

4gnitrats erofeB

5atad lareneG

31stimil gnitarepO

41gniriw lortnoc dna rewoP

51noitisop noitallatsni fo eciohC

61snoitcennoc tnaregirfeR

81snoitcennoc etasnednoC

81snoitcennoc lacirtcelE

91stcud eht gnitcennoC

91gniretliF

91rellortnoc deriw eht gnillatsnI

Operation

02muucav a gnitaerC

02egrahc tnaregirfer lanoitiddA

12deeps naF

12noitarepo dna noitarugifnoC

12naicinhcet deifilauq a yb pu-trats erofeB

12noitarepo hctiws ycnegreme dna yalpsid tinU

12noitarepo rellortnoc deriW

12noitarepo rellortnoc sseleriW

Maintenance

32ecnanetniam cidoireP

42gnitoohselbuorT

62gnitoohselbuort rellortnoC

82snoitadnemmocer ytefaS

82tcartnoc ecnanetniaM

82gniniarT

Page 4

4 SS-SVX07B-E4

Before starting

Creation of refrigerant lines

To create the refrigerant lines you

will need refrigeration quality

annealed copper tubing. These tubes

are available on the local market

together with the insulation and

mounting equipment. These units

must be connected using screw

connections/flare type for unit sizes

512 to 536 and brazed connections

for unit sizes 048-060.

Electrical connections

Use insulated copper wire. The

section of the core varies depending

on the length required. Refer to

table 1 for the recommended

sections. The wiring and electrical

connections must comply with

national electricity regulations.

Check that the electrical

characteristics on the nameplate

correspond to those of the national

grid. The electrical installation shall

include a disconnect switch in

compliance with local electrical

regulations.

WARNING!

Never open the indoor or outdoor

unit without first disconnecting the

power supply. There is a risk of

electrocution.

Table 1 - Recommended sections of

electric wires (power link)

Unit size Section Maximum fuse size

512 2.5 mm² 16 aM

518 - 524 2.5 mm² 32 aM

530 - 536 RB/SB 4.0 mm² 40 aM

530 - 536 RB/SB 2.5 mm² 32 aM

048 - 060 2.5 mm² 32 aM

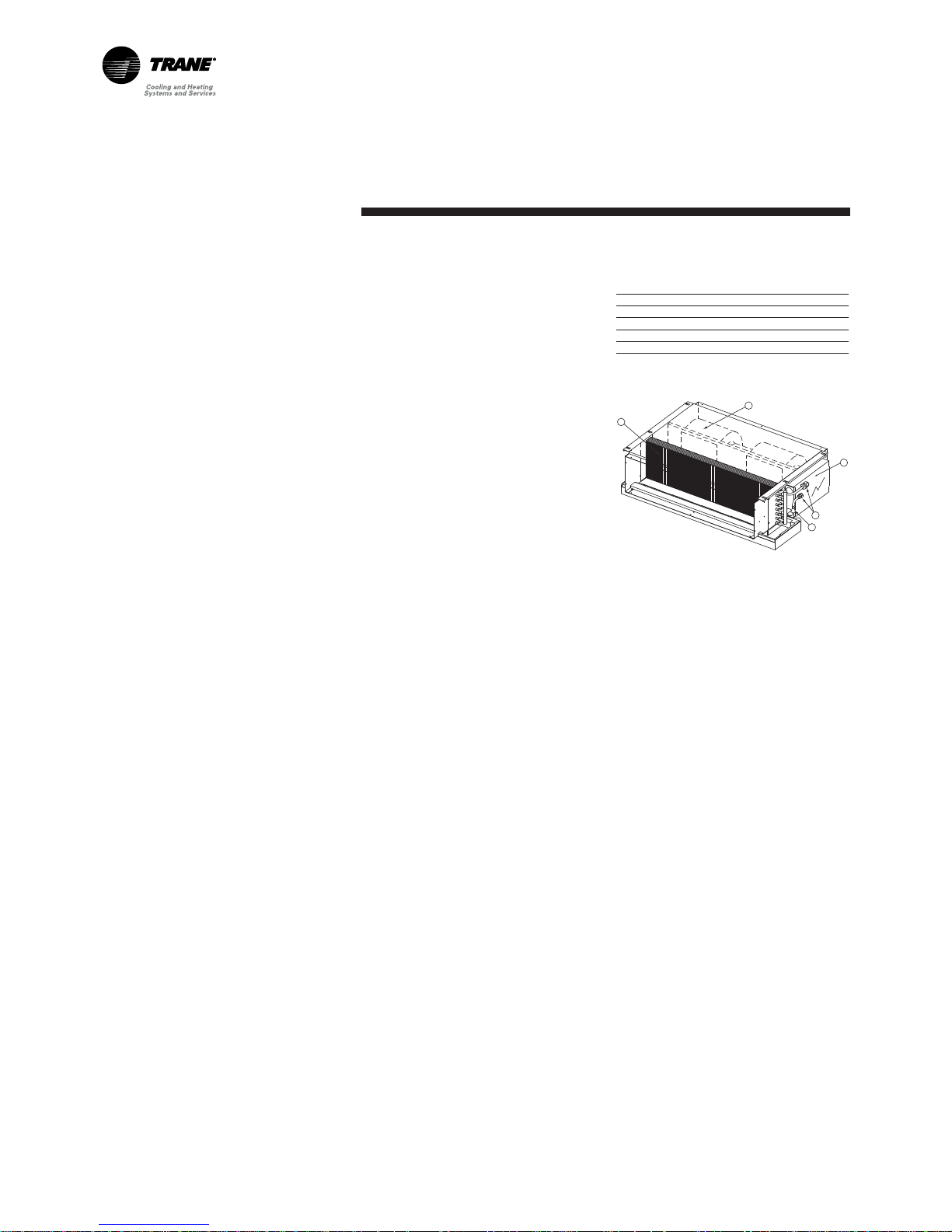

Figure 1 - Unit description

1 = Direct expansion coil

2 = Fan assembly

3 = Control panel

4 = Cooling mode expansion device

(sizes 530-060)

5 = Refrigerant connections

(screw connections/flare type for unit sizes

512 to 536 and brazed connections for unit

sizes 048-060)

▲

1

2

3

5

4

Installation

Page 5

SS-SVX07B-E4 5

Installation

General data

Table 2 - Cooling only R407C (1/2)

Performances TTK 512 RB TTK 518 RB TTK 524 RB TTK 530 SB TTK 530 SC

Indoor unit

MCD 512 CB MCD 518 CB MCD 524 CB MCD 530 CB MCD 530 CB

Cooling Capacity (1) (kW) 3.16 4.56 6.76 8.60 8.60

Power Input (kW) 1.27 1.88 2.87 3.41 3.41

Main Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50 400/3/50

Sound Power Level in high speed (dB(A)) 36 43 40 44 44

Units Amps

Current (A) 6.4 9.6 12.8 19.8 7.7

Starting Amps (A) 28.7 44.0 72.0 97.0 45.5

Recommended Fuse size (AM) type gG 16 20 20 25 20

Recommended Power Wire nb wires x mm23 x 1.5 3 x 2.5 3 x 2.5 3 x 4 4 x 2.5

Recommended Control Interconnection Wire nb wires x mm22 x 1.5 2 x 1.5 2 x 1.5 2 x 1.5 2 x 1.5

Max wire length (2) (m) 50 50 50 50 50

Compressor

Number 11111

Type Rotary Rotary Rotary Scroll Scroll

Model RE 207 VHSMT PE 31 VNEMT NE 41 VNHMT ZR 40 K3E PFJ ZR 40 K3E TFD

Number of speeds 11111

Number of motors 11111

Maximum Continuous Current (A) 6.0 9.0 12.2 18.7 6.6

Locked Rotor Amps (A) 28 43 71 100 46

Motor RPM (rpm) 2850 2900 2900 2900 2900

Crankcase Heater (W) - - - - -

Outdoor Coil

Fin Type Wavy 3B Wavy 3B Wavy 3 B Wavy 3 B Wav y 3B

Tube size (mm) 9.52 9.52 9.52 9.52 9.52

Tube Type Inner Groove Inner Groove Inner Groove Inner Groove Inner Groove

Height (mm) 508 559 559 762 762

Length (mm) 420 755 755 855 855

Face Area (m2) 0.213 0.420 0.420 0.650 0.650

Number of rows 22222

Number of circuits 12244

Fins per feet (fpf) 180 180 180 180 180

Outdoor Fan

Type Axial Axial Axial Axial Axial

Number 11111

Diameter mm (inches) 406(16) 457(18) 457(18) 508(20) 508(20))

Number of speeds 11111

Airflow (3) (4) (m3/h) 1050 2020 2020 3400 3400

Number of motors 11111

Motor (4) (kW) 0.08 0.14 0.14 0.229 0.229

Rated Amps (4) (A) 0.35 0.60 0.60 1.05 1.05

Locked rotor Amps (4) (A) 0.70 1.00 1.00 2.04 2.04

Motor RPM (rpm) 930 930 930 900 900

Capacitor per fan (µF) 2.5 2 2 5 5

Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50 230/1/50

Indoor Fan

Airflow (3) (4) (m3/h) 550 820 1100 1370 1370

Expansion device

Cooling mode Orifice Orifice Orifice Orifice Orifice

Dimensions crated

Length (mm) 672 860 860 1045 1045

Width (mm) 357 340 340 380 380

Height (mm) 577 580 580 790 790

Dimensions uncrated

Length with feet (mm) 667 821 821 1100 1100

Length without feet (mm) 667 821 821 1003 1003

Width with feet (mm) 332 400 400 365 365

Width without feet (mm) 277 327 327 365 365

Height (mm) 517 567 567 790 790

Weight

Weight uncrated (kg) 36 54 58 87 87

Weight crated (kg) 37 56 60 89 89

Refrigerant Connections

Type Flare Flare Flare Flare Flare

Suction line (inches) 1/2 5/8 5/8 3/4 3/4

Liquid line (inches) 1/4 3/8 3/8 3/8 3/8

R407C Refrigerant Charge (kg) 1.1 1.6 2.2 2.5 2.5

Notes:

(1) at 27°C db /19°C wb indoor and 35°C outdoor

(2) Wire channel @ 35°C ambient max.

(3) at nominal airflow with standard drive

(4) for fan system

Page 6

6 SS-SVX07B-E4

Installation

Table 2 - Cooling only R407C (2/2)

Performances TTK 536 SB TTK 536 SC TTK 048 SC TTK 060 SC

Indoor unit

MCD 536 CB MCD 536 CB MCD 048 CB MCD 060 CB

Cooling Capacity (1) (kW) 9.42 9.42 13.14 14.90

Power Input (kW) 4.35 4.35 5.25 6.37

Main Power supply (V/Ph/Hz) 230/1/50 400/3/50 400/3/50 400/3/50

Sound Power Level in high speed (dB(A)) 44 44 53 63

Units Amps

Current (A) 24.6 11.1 11.3 12.7

Starting Amps (A) 116.0 52.0 64.0 72.5

Recommended Fuse size (AM) type gG 40 20 20 20

Recommended Power Wire nb wires x mm23 x 6 4 x 2.5 4 x 2.5 4 x 2.5

Recommended Control Interconnection Wire nb wires x mm22 x 1.5 2 x 1.5 2 x 1.5 2 x 1.5

Max wire length (2) (m) 50 50 50 50

Compressor

Number 1111

Type Scroll Scroll Scroll Scroll

Model ZR 48 K3E PFJ ZR 48 K3E TFD ZR 61 KCE TFD ZR 72 KCE TFD

Number of speeds 1 1 1 1

Number of motors 1111

Maximum Continuous Current (A) 23.5 10.0 10.0 11.4

Locked Rotor Amps (A) 114 50 65.5 74

Motor RPM (rpm) 2900 2900 2900 2900

Crankcase Heater (W) - - - -

Outdoor Coil

Fin Type Wavy 3B Wavy 3B Wav y 3B Wavy 3B

Tube size (mm) 9.52 9.52 9.52 9.52

Tube Type Inner Groove Inner Groove Inner Groove Inner Groove

Height (mm) 762 762 1219 1219

Length (mm) 855 855 855 855

Face Area (m2) 0.650 0.650 1.048 1.048

Number of rows 2222

Number of circuits 4466

Fins per feet (fpf) 180 180 240 240

Outdoor Fan

Type Axial Axial Axial Axial

Number 1122

Diameter mm (inches) 508(20) 508(20) 457(18) 457(18)

Number of speeds 1111

Airflow (3) (4) (m3/h) 3400 3400 4600 4600

Number of motors 1122

Motor (4) (kW) 0.229 0.229 0.29 0.29

Rated Amps (4) (A) 1.05 1.05 1.20 1.20

Locked rotor Amps (4) (A) 2.04 2.04 2.00 2.00

Motor RPM (rpm) 900 900 930 930

Capacitor per fan (µF) 5 5 4 4

Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50

Indoor Fan

Airflow (3) (4) (m3/h) 1650 1650 2190 2300

Expansion device

Cooling mode Orifice Orifice Orifice Orifice

Dimensions crated

Length (mm) 1045 1045 1045 1045

Width (mm) 380 380 390 390

Height (mm) 790 790 1389 1389

Dimensions uncrated

Length with feet (mm) 1100 1100 1030 1030

Length without feet (mm) 1003 1003 1030 1030

Width with feet (mm) 365 365 420 420

Width without feet (mm) 365 365 366 366

Height (mm) 790 790 1246 1246

Weight

Weight uncrated (kg) 89 89 105 108

Weight crated (kg) 91 91 108 111

Refrigerant Connections

Type Flare Flare Braze Braze

Suction line (inches) 3/4 3/4 1 1/8 1 1/8

Liquid line (inches) 3/8 3/8 3/8 3/8

R407C Refrigerant Charge (kg) 2.5 2.5 3.8 4.2

Notes:

(1) at 27°C db /19°C wb indoor and 35°C outdoor

(2) Wire channel @ 35°C ambient max.

(3) at nominal airflow with standard drive

(4) for fan system

Page 7

SS-SVX07B-E4 7

Installation

Table 3 - Cooling only R22 (1/2)

Performances TTK 512 RB TTK 518 RB TTK 524 KB TTK 530 KB

Indoor unit

MCD 512 DB MCD 518 DB MCD 524 DB MCD 530 DB

Cooling Capacity (1) (kW) 3.30 5.00 6.40 8.30

Power Input (kW) 1.51 1.62 2.70 3.30

Main Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50

Sound Power Level in high speed (dB(A)) 36 43 40 44

Units Amps

Current (A) 6.0 8.0 11.3 19.1

Starting Amps (A) 28.7 44.0 72.0 97.0

Recommended Fuse size (AM) type gG 16 20 20 25

Recommended Power Wire nb wires x mm

2

3 x 1.5 3 x 2.5 3 x 2.5 3 x 4

Recommended Control Interconnection Wire nb wires x mm

2

2 x 1.5 2 x 1.5 2 x 1.5 2 x 1.5

Max wire length (2) (m) 50 50 50 50

Compressor

Number 11 11

Type Rotary Rotary Rotary Reciprocating

Model RH207 VHAT PH31 VNET CK32K3-PFZ CR37KQ-PFT

Number of speeds 11 11

Number of motors 11 11

Maximum Continuous Current (A) 5.5 7.0 11.0 18.5

Locked Rotor Amps (A) 31 43 75 85.5

Motor RPM (rpm) 2850 2900 2900 2900

Crankcase Heater (W) - - - -

Outdoor Coil

Fin Type Wavy 3B Wavy 3B Wavy 3B Wavy 3B

Tube size (mm) 9.52 10.52 11.52 12.52

Tube Type Inner Groove Inner Groove Inner Groove Inner Groove

Height (mm) 508 559 559 762

Length (mm) 420 755 755 855

Face Area (m2) 0.213 0.420 0.420 0.650

Number of rows 22 22

Number of circuits 24 44

Fins per feet (fpf) 180 180 180 180

Outdoor Fan

Type Axial Axial Axial Axial

Number 11 11

Diameter mm (inches) 406(16) 457(18) 457(18) 508(20)

Number of speeds 11 11

Airflow (3) (4) (m3/h) 1050 2020 2020 3400

Number of motors 11 11

Motor (4) (kW) 0.08 0.14 0.14 0.23

Rated Amps (4) (A) 0.35 0.60 0.60 1.05

Locked rotor Amps (4) (A) 0.70 1.00 1.00 2.04

Motor RPM (rpm) 930 930 930 900

Capacitor per fan (µF) 2.5 2 2 5

Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50

Indoor Fan

Airflow (3) (4) (m3/h) 550 820 1100 1370

Expansion device

Cooling mode Orifice Orifice Orifice Orifice

Dimensions crated

Length (mm) 672 860 860 1045

Width (mm) 357 340 340 380

Height (mm) 577 580 580 790

Dimensions uncrated

Length with feet (mm) 667 821 821 1100

Length without feet (mm) 667 821 821 1003

Width with feet (mm) 332 400 400 365

Width without feet (mm) 277 327 327 365

Height (mm) 517 567 567 790

Weight

Weight uncrated (kg) 36 54 58 87

Weight crated (kg) 37 56 60 89

Refrigerant Connections

Type Flare Flare Flare Flare

Suction line (inches) 1/2 5/8 5/8 3/4

Liquid line (inches) 1/4 3/8 3/8 3/8

R22 Refrigerant Charge (kg) 1.2 1.9 2.5 3.6

Notes:

(1) at 27°C db /19°C wb indoor and 35°C outdoor

(2) Wire channel @ 35°C ambient max.

(3) at nominal airflow with standard drive

(4) for fan system

Page 8

8 SS-SVX07B-E4

Installation

Table 3 - Cooling only R22 (2/2)

Performances TTK 536 KB TTK 048 KC TTK 060 KC

Indoor unit

MCD 536 DB MCD 048 DB MCD 060 DB

Cooling Capacity (1) (kW) 9.90 13.50 15.80

Power Input (kW) 4.20 5.10 5.90

Main Power supply (V/Ph/Hz) 230/1/50 400/3/50 400/3/50

Sound Power Level in high speed (dB(A)) 44 53 63

Units Amps

Current (A) 21.9 9.0 10.6

Starting Amps (A) 116.0 64.0 72.5

Recommended Fuse size (AM) type gG 40 20 20

Recommended Power Wire nb wires x mm

2

3 x 6 4 x 2.5 4 x 2.5

Recommended Control Interconnection Wire nb wires x mm

2

2 x 1.5 2 x 1.5 2 x 1.5

Max wire length (2) (m) 50 50 50

Compressor

Number 111

Type Reciprocating Reciprocating Reciprocating

Model CR47KQ-PFZ CRPQ-0450-TFD CRNQ-0500-TFD

Number of speeds 111

Number of motors 111

Maximum Continuous Current (A) 21.0 8.0 10.0

Locked Rotor Amps (A) 105 55 65

Motor RPM (rpm) 2900 2900 2900

Crankcase Heater (W) - 27 27

Outdoor Coil

Fin Type Wavy 3B Wavy 3B Wavy 3B

Tube size (mm) 13.52 14.52 15.52

Tube Type Inner Groove Inner Groove Inner Groove

Height (mm) 762 1219 1219

Length (mm) 855 855 855

Face Area (m2) 0.650 1.048 1.048

Number of rows 222

Number of circuits 466

Fins per feet (fpf) 180 240 240

Outdoor Fan

Type Axial Axial Axial

Number 122

Diameter mm (inches) 508(20) 457(18) 457(18)

Number of speeds 111

Airflow (3) (4) (m3/h) 3400 4600 4600

Number of motors 122

Motor (4) (kW) 0.23 0.29 0.29

Rated Amps (4) (A) 1.05 1.20 1.20

Locked rotor Amps (4) (A) 2.04 2.00 2.00

Motor RPM (rpm) 900 930 930

Capacitor per fan (µF) 5 4 4

Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50

Indoor Fan

Airflow (3) (4) (m3/h) 1650 2190 2300

Expansion device

Cooling mode Orifice TXV TXV

Dimensions crated

Length (mm) 1045 1045 1045

Width (mm) 380 390 390

Height (mm) 790 1389 1389

Dimensions uncrated

Length with feet (mm) 1100 1030 1030

Length without feet (mm) 1003 1030 1030

Width with feet (mm) 365 420 420

Width without feet (mm) 365 366 366

Height (mm) 790 1246 1246

Weight

Weight uncrated (kg) 89 105 108

Weight crated (kg) 91 108 111

Refrigerant Connections

Type Flare Flare Flare

Suction line (inches) 3/4 1 1/8 1 1/8

Liquid line (inches) 3/8 3/8 3/8

R22 Refrigerant Charge (kg) 3.8 3.5 4.5

Notes:

(1) at 27°C db /19°C wb indoor and 35°C outdoor

(2) Wire channel @ 35°C ambient max.

(3) at nominal airflow with standard drive

(4) for fan system

Page 9

SS-SVX07B-E4 9

Installation

Table 4 - Heat pump R407C (1/2)

Performances TWK 512 RB TWK 518 RB TWK 524 RB TWK 530 SB TWK 530 SC

Indoor unit

MWD 512 CB MWD 518 CB MWD 524 CB MWD 530 CB MWD 530 CB

Cooling Capacity (1) (kW) 2.97 4.28 6.08 7.95 7.95

Cooling mode power input (kW) 1.46 1.54 2.60 3.26 3.26

Heating Capacity (2) (kW) 3.40 4.61 6.78 8.82 8.82

Heating mode power input (kW) 1.16 1.30 2.13 2.83 2.83

Main Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50 400/3/50

Sound Power Level in high speed (dB(A)) 36 43 40 44 44

Units Amps

Current (A) 6.4 9.6 12.8 19.8 7.7

Starting Amps (A) 28.7 44.0 72.0 97.0 45.5

Recommended Fuse size(AM) type gG 16 20 20 25 20

Recommended Power Wire nb wires x mm23 x 1.5 3 x 2.5 3 x 2.5 3 x 4 4 x 2.5

Recommended Control Interconnection Wire nb wires x mm22 x 1.5 2 x 1.5 2 x 1.5 2 x 1.5 2 x 1.5

Max wire length (3) (m) 50 50 50 50 50

Compressor

Number 11 111

Type Rotary Rotary Rotary Scroll Scroll

Model RE 207 VHSMT PE 31 VNEMT NE 41 VNHMT ZR 40 K3E PFJ ZR 40 K3E TFD

Number of speeds 11 111

Number of motors 11 111

Maximum Continuous Current (A) 6.0 9.0 12.2 18.7 6.6

Locked Rotor Amps (A) 28.0 43.0 71.0 100.0 46.0

Motor RPM (rpm) 2850 2900 2900 2900 2900

Crankcase Heater (W) - - - - -

Outdoor Coil

Fin Type Wavy 3B Wavy 3B Wavy 3B Wavy 3B Wav y 3B

Tube size (mm) 9.52 9.52 9.52 9.52 9.52

Tube Type Inner Groove Inner Groove Inner Groove Inner Groove Inner Groove

Height (mm) 508 559 610 762 762

Length (mm) 420 755 855 855 855

Face Area (m2) 0.213 0.420 0.521 0.650 0.650

Number of rows 22 222

Number of circuits 24 233

Fins per feet (fpf) 180 180 240 180 180

Outdoor Fan

Type Axial Axial Axial Axial Axial

Number 11 111

Diameter mm (inches) 406(16) 457(18) 457(18) 508(20) 508(20)

Number of speeds 11 111

Airflow (4) (5) (m3/h) 1050 2020 2020 3400 3400

Number of motors 11 111

Motor (5) (kW) 0.08 0.14 0.14 0.229 0.229

Rated Amps (5) (A) 0.35 0.60 0.60 1.05 1.05

Locked rotor Amps (5) (A) 0.70 1.00 1.00 2.04 2.04

Motor RPM (rpm) 930 930 930 900 900

Capacitor per fan (µF) 2.5 2 2 5 5

Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50 230/1/50

Indoor Fan

Airflow (3) (4) (m3/h) 550 820 1100 1370 1370

Expansion device

Cooling mode Orifice Orifice Orifice Orifice Orifice

Dimensions crated

Length (mm) 672 860 1045 1045 1045

Width (mm) 357 340 390 380 380

Height (mm) 577 580 695 790 790

Dimensions uncrated

Length with feet (mm) 667 821 1030 1100 1100

Length without feet (mm) 667 821 1030 1003 1003

Width with feet (mm) 332 400 420 365 365

Width without feet (mm) 277 327 366 365 365

Height (mm) 517 567 623 790 790

Weight

Weight uncrated (kg) 36 54 58 87 87

Weight crated (kg) 37 56 60 89 89

Refrigerant Connections

Type Flare Flare Flare Flare Flare

Suction line (inches) 1/2 5/8 5/8 3/4 3/4

Liquid line (inches) 1/4 3/8 3/8 3/8 3/8

R407C Refrigerant Charge (kg) 1.0 1.7 2.3 2.4 2.4

Notes:

(1) at 27°C db /19°C wb indoor and 35°C outdoor

(2) at 7°C db /6°C wb outdoor and 20°C indoor

(3) Wire channel @ 35°C ambient max.

(4) at nominal airflow with standard drive

(5) for fan system

Page 10

10 SS-SVX07B-E4

Installation

Table 4 - Heat pump R407C (2/2)

Performances TWK 536 SB TWK 536 SC TWK 048 SC TWK 060 SC

Indoor unit

MWD 536 CB MWD 536 CB MWD 048 CB MWD 060 CB

Cooling Capacity (1) (kW) 9.05 9.05 11.00 12.40

Cooling mode power input (kW) 3.99 3.99 4.86 5.73

Heating Capacity (2) (kW) 11.20 11.20 13.70 15.30

Heating mode power input (kW) 3.56 3.56 4.38 4.91

Main Power supply (V/Ph/Hz) 230/1/50 400/3/50 400/3/50 400/3/50

Sound Power Level in high speed (dB(A)) 44 44 53 63

Units Amps

Current (A) 6.24.6 11.1 11.3 12.7

Starting Amps (A) 116.0 52.0 64.0 72.5

Recommended Fuse size (AM) type gG 40 20 20 20

Recommended Power Wire nb wires x mm23 x 6 4 x 2.5 4 x 2.5 4 x 2.5

Recommended Control Interconnection Wire nb wires x mm22 x 1.5 2 x 1.5 2 x 1.5 2 x 1.5

Max wire length (3) (m) 50 50 50 50

Compressor

Number 1111

Type Scroll Scroll Scroll Scroll

Model ZR 48 K3E PFJ ZR 48 K3E TFD ZR 61 KCE TFD ZR 72 KCE TFD

Number of speeds 1111

Number of motors 1111

Maximum Continuous Current (A) 23.5 10.0 10.0 11.4

Locked Rotor Amps (A) 114.0 50.0 65.5 74.0

Motor RPM (rpm) 2900 2900 2900 2900

Crankcase Heater (W) - - - -

Outdoor Coil

Fin Type Wavy 3B Wavy 3B Wav y 3B Wavy 3B

Tube size (mm) 9.52 9.52 9.52 9.52

Tube Type Inner Groove Inner Groove Inner Groove Inner Groove

Height (mm) 762 762 1219 1219

Length (mm) 855 855 855 855

Face Area (m2) 0.650 0.650 1.048 1.048

Number of rows 2222

Number of circuits 2244

Fins per feet (fpf) 180 180 240 240

Outdoor Fan

Type Axial Axial Axial Axial

Number 1122

Diameter mm (inches) 508(20) 508(20) 457(18) 457(18)

Number of speeds 1111

Airflow (4) (5) (m3/h) 3400 3400 4600 4600

Number of motors 1122

Motor (5) (kW) 0.229 0.229 0.29 0.29

Rated Amps (5) (A) 1.05 1.05 1.20 1.20

Locked rotor Amps (5) (A) 2.04 2.04 2.00 2.00

Motor RPM (rpm) 900 900 930 930

Capacitor per fan (µF) 5 5 4 4

Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50

Indoor Fan

Airflow (3) (4) (m3/h) 1650 1650 2190 2300

Expansion device

Cooling mode Orifice Orifice Orifice Orifice

Dimensions crated

Length (mm) 1045 1045 1045 1045

Width (mm) 380 380 390 390

Height (mm) 790 790 1389 1389

Dimensions uncrated

Length with feet (mm) 1100 1100 1030 1030

Length without feet (mm) 1003 1003 1030 1030

Width with feet (mm) 365 365 420 420

Width without feet (mm) 365 365 366 366

Height (mm) 790 790 1246 1246

Weight

Weight uncrated (kg) 89 89 105 108

Weight crated (kg) 91 91 108 111

Refrigerant Connections

Type Flare Flare Braze Braze

Suction line (inches) 3/4 3/4 1 1/8 1 1/8

Liquid line (inches) 3/8 3/8 3/8 3/8

R407C Refrigerant Charge (kg) 2.6 2.6 3.3 3.75

Notes:

(1) at 27°C db /19°C wb indoor and 35°C outdoor

(2) at 7°C db /6°C wb outdoor and 20°C indoor

(3) Wire channel @ 35°C ambient max.

(4) at nominal airflow with standard drive

(5) for fan system

Page 11

SS-SVX07B-E4 11

Installation

Table 5 - Heat pump R22 (1/2)

Performances TWK 512 RB TWK 518 RB TWK 524 KB TWK 530 KB

Indoor unit

MWD 512 DB MWD 518 DB MWD 524 DB MWD 530 DB

Cooling Capacity (1) (kW) 3.30 5.00 6.40 8.30

Cooling mode power input (kW) 1.51 1.62 2.70 3.30

Heating Capacity (2) (kW) 3.50 5.90 7.50 9.30

Heating mode power input (kW) 1.20 1.35 2.21 2.92

Main Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50

Sound Power Level in high speed (dB(A)) 36 43 40 44

Units Amps

Current (A) 6.0 8.0 11.3 19.1

Starting Amps (A) 28.7 44.0 72.0 97.0

Recommended Fuse size (AM) type gG 16 20 20 25

Recommended Power Wire nb wires x mm

2

3 x 1.5 3 x 2.5 3 x 2.5 3 x 4

Recommended Control Interconnection Wire nb wires x mm

2

2 x 1.5 2 x 1.5 2 x 1.5 2 x 1.5

Max wire length (2) (m) 50 50 50 50

Compressor

Number 11 11

Type Rotary Rotary Rotary Reciprocating

Model RH207 VHAT PH31 VNET CK32K3-PFZ CR37KQ-PFT

Number of speeds 11 11

Number of motors 11 11

Maximum Continuous Current (A) 5.5 7.0 11.0 18.5

Locked Rotor Amps (A) 31.0 43.0 75.0 85.5

Motor RPM (rpm) 2850 2900 2900 2900

Crankcase Heater (W) - - - -

Outdoor Coil

Fin Type Wavy 3B Wavy 3B Wavy 3B Wavy 3B

Tube size (mm) 9.52 10.52 11.52 12.52

Tube Type Inner Groove Inner Groove Inner Groove Inner Groove

Height (mm) 508 559 559 762

Length (mm) 420 755 755 855

Face Area (m2) 0.213 0.420 0.420 0.650

Number of rows 22 22

Number of circuits 24 44

Fins per feet (fpf) 180 180 180 180

Outdoor Fan

Type Axial Axial Axial Axial

Number 11 11

Diameter mm (inches) 406(16) 457(18) 457(18) 508(20)

Number of speeds 11 11

Airflow (3) (4) (m3/h) 1050 2020 2020 3400

Number of motors 11 11

Motor (4) (kW) 0.08 0.14 0.14 0.23

Rated Amps (4) (A) 0.35 0.60 0.60 1.05

Locked rotor Amps (4) (A) 0.7 1 1 2.04

Motor RPM (rpm) 930 930 930 900

Capacitor per fan (µF) 2.5 2 2 5

Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50 230/1/50

Indoor Fan

Airflow (3) (4) (m3/h) 550 820 1100 1370

Expansion device

Cooling mode Orifice Orifice Orifice Orifice

Dimensions crated

Length (mm) 672 860 860 1045

Width (mm) 357 340 340 380

Height (mm) 577 580 580 790

Dimensions uncrated

Length with feet (mm) 667 821 821 1100

Length without feet (mm) 667 821 821 1003

Width with feet (mm) 332 400 400 365

Width without feet (mm) 277 327 327 365

Height (mm) 517 567 567 790

Weight

Weight uncrated (kg) 36 54 58 87

Weight crated (kg) 37 56 60 89

Refrigerant Connections

Type Flare Flare Flare Flare

Suction line (inches) 1/2 5/8 5/8 3/4

Liquid line (inches) 1/4 3/8 3/8 3/8

R22 Refrigerant Charge (kg) 1.2 1.4 1.7 2.4

Notes:

(1) at 27°C db /19°C wb indoor and 35°C outdoor

(2) at 7°C db /6°C wb outdoor and 20°C indoor

(3) Wire channel @ 35°C ambient max.

(4) at nominal airflow with standard drive

(5) for fan system

Page 12

Installation

12 SS-SVX07B-E4

Table 5 - Heat pump R22 (2/2)

Performances TWK 536 KB TWK 048 KC TWK 060 KC

Indoor unit

MWD 536 DB MWD 048 DB MWD 060 DB

Cooling Capacity (1) (kW) 9.90 13.50 15.80

Cooling mode power input (kW) 4.2 5.10 5.90

Heating Capacity (2) (kW) 11.10 15.10 17.70

Heating mode power input (kW) 3.66 4.45 5.20

Main Power supply (V/Ph/Hz) 230/1/50 400/3/50 400/3/50

Sound Power Level in high speed (dB(A)) 44 53 63

Units Amps

Current (A) 21.9 9.0 10.6

Starting Amps (A) 116.0 64.0 72.5

Recommended Fuse size (AM) type gG 40 20 20

Recommended Power Wire nb wires x mm

2

3 x 6 4 x 2.5 4 x 2.5

Recommended Control Interconnection Wire nb wires x mm

2

2 x 1.5 2 x 1.5 2 x 1.5

Max wire length (2) (m) 50 50 50

Compressor

Number 111

Type Reciprocating Reciprocating Reciprocating

Model CR47KQ-PFZ CRPQ-0450-TFD CRNQ-0500-TFD

Number of speeds 111

Number of motors 111

Maximum Continuous Current (A) 21.0 8.0 10.0

Locked Rotor Amps (A) 105.0 55.0 65.0

Motor RPM (rpm) 2900 2900 2900

Crankcase Heater (W) - 27 27

Outdoor Coil

Fin Type Wavy 3B Wavy 3B Wavy 3B

Tube size (mm) 13.52 14.52 15.52

Tube Type Inner Groove Inner Groove Inner Groove

Height (mm) 762 1219 1219

Length (mm) 855 855 855

Face Area (m2) 0.650 1.048 1.048

Number of rows 222

Number of circuits 466

Fins per feet (fpf) 180 240 240

Outdoor Fan

Type Axial Axial Axial

Number 122

Diameter mm (inches) 508(20) 457(18) 457(18)

Number of speeds 111

Airflow (3) (4) (m3/h) 3400 4600 4600

Number of motors 122

Motor (4) (kW) 0.23 0.29 0.29

Rated Amps (4) (A) 1.05 1.20 1.20

Locked rotor Amps (4) (A) 2.04 2 2

Motor RPM (rpm) 900 930 930

Capacitor per fan (µF) 5 4 4

Power supply (V/Ph/Hz) 230/1/50 230/1/50 230/1/50

Indoor Fan

Airflow (3) (4) (m3/h) 1650 2190 2300

Expansion device

Cooling mode Orifice TXV TXV

Dimensions crated

Length (mm) 1045 1045 1045

Width (mm) 380 390 390

Height (mm) 790 1389 1389

Dimensions uncrated

Length with feet (mm) 1100 1030 1030

Length without feet (mm) 1003 1030 1030

Width with feet (mm) 365 420 420

Width without feet (mm) 365 366 366

Height (mm) 790 1246 1246

Weight

Weight uncrated (kg) 89 105 108

Weight crated (kg) 91 108 111

Refrigerant Connections

Type Flare Flare Flare

Suction line (inches) 3/4 1 1/8 1 1/8

Liquid line (inches) 3/8 3/8 3/8

R22 Refrigerant Charge (kg) 2.6 3.5 4.5

Notes:

(1) at 27°C db /19°C wb indoor and 35°C outdoor

(2) at 7°C db /6°C wb outdoor and 20°C indoor

(3) Wire channel @ 35°C ambient max.

(4) at nominal airflow with standard drive

(5) for fan system

Page 13

SS-SVX07B-E4 13

Installation

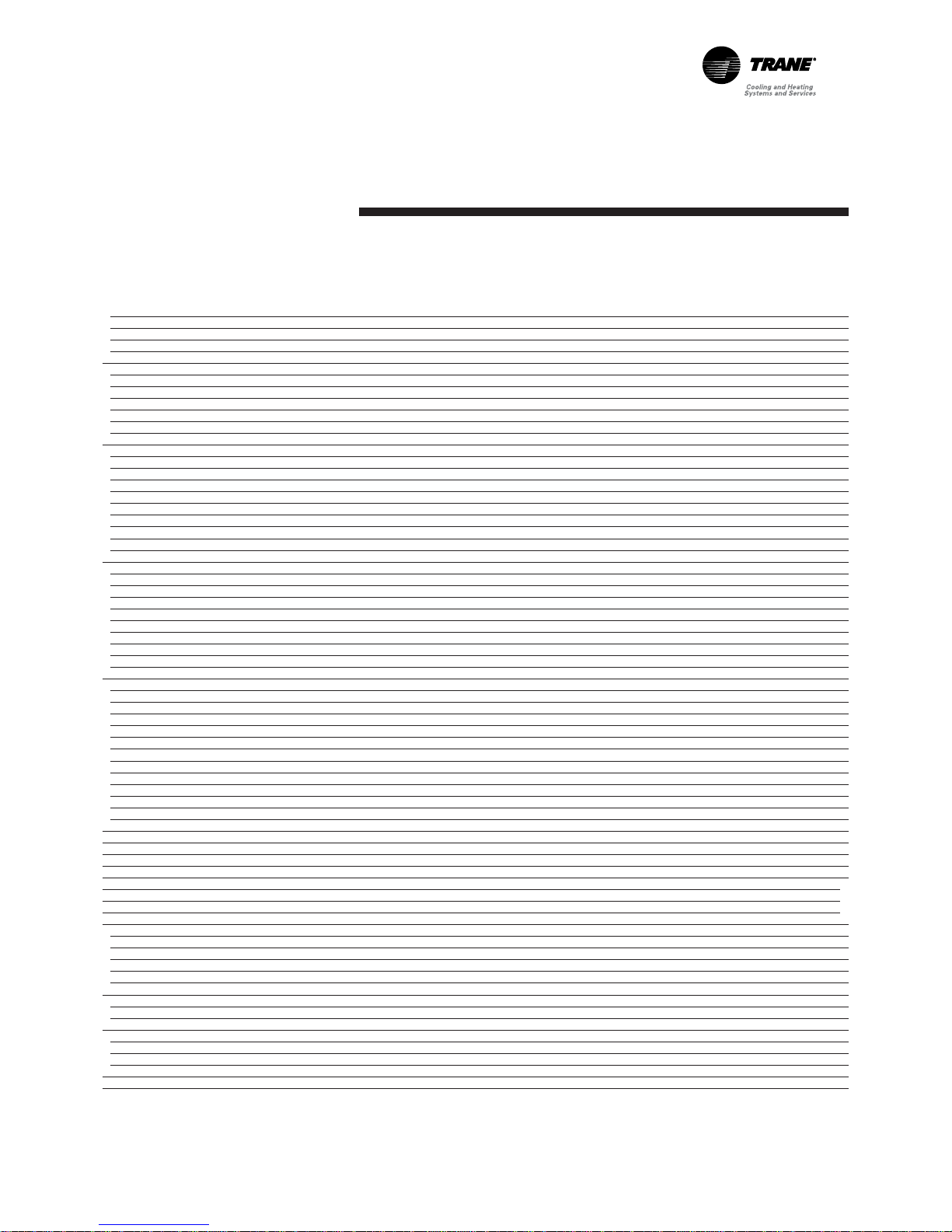

Table 6 - Unit dimensions (inch/mm)

ABCDEFGH

MCD/MWD 512 23 (578) 12 (305) 38.5 (980) 31.6 ( 803) 6.7 (170) 3.3 (87) 8.3 (210) 4.3 (110)

MCD/MWD 518 23 (578) 12 (305) 38.5 ( 980) 31.6 ( 803) 6.7 (170) 3.3 (87) 8.3 (210) 4.3 (110)

MCD/MWD 524 23 (578) 12 (305) 42.9 ( 1090) 36.1 (920) 6.7 (170) 3.3 (87) 8.3 (210) 4.3 (110)

MCD/MWD 530 23 (578) 12 (305) 48.3 ( 1228) 42.1 (1069) 6.7 (170) 3.3 (87) 8.3 (210) 4.3 (110)

MCD/MWD 536 23 (578) 12 (305) 48.3 ( 1228) 42.1 (1069) 6.7 (170) 3.3 (87) 8.3 (210) 4.3 (110)

MCD/MWD 048 27.7 (703) 15.4 ( 395) 43 ( 1091) 36 (920) 13.3 (337) 4.2 (110) 12.2 (310) 8.1 (205)

MCD/MWD 060 27.7 (703) 15.4 ( 395) 49 ( 1245) 42.1 (1070) 13.3 (337) 4.2 (110) 12.2 (310) 8.1 (205)

Dimensions

Figure 2 - Unit dimensions

Page 14

14 SS-SVX07B-E4

Installation

Power and control wiring

Table 7 - Control interconnection

Outdoor unit Number of wires x section area (mm²)

Including ground wire

TTK 512 3 x 2.5

TTK 518 2 x 1.5

TTK 524 2 x 1.5

TTK 530 2 x 1.5

TTK 536 2 x 1.5

TTK 048 2 x 1.5

TTK 060 2 x 1.5

TWK 512 5 x 1.5

TWK 518 5 x 1.5

TWK 524 5 x 1.5

TWK 530 6 x 1.5

TWK 536 6 x 1.5

TWK 048 6 x 1.5

TWK 060 6 x 1.5

Table 8 - Power supply outdoor unit (1)

Number of wires x section area (mm²)

Including ground wire

TTK/TWK 512 TTK/TWK 518 3 x 2.5

TTK/TWK 524 3 x 2.5

TTK/TWK 530 4 x 2.5

TTK/TWK 536 4 x 2.5

TTK/TWK 048 4 x 2.5

TTK/TWK 060 4 x 2.5

(1) Indoor and outdoor units are powered separately

(2) Number of wires and section area are given for a

maximum wire length of 50m. If the wire is longer

than 50m, these must be recalculated.

Table 9 - Power supply indoor unit (1)

Without electric heater With electric heater

Number of wires x section area (mm²) Number of wires x section area (mm²)

MCD/MWD 512 3 x 1.5 3 x 2.5 / 3 x 4

MCD/MWD 518 3 x 1.5 3 x 4

MCD/MWD 524 3 x 1.5 3 x 4

MCD/MWD 530 3 x 1.5 4 x 4

MCD/MWD 536 3 x 1.5 4 x 4

MCD/MWD 048 3 x 1.5 4 x 4

MCD/MWD 060 3 x 1.5 4 x 4

(1) Indoor and outdoor units are powered separately

(2) Number of wires and section area are given for a

maximum wire length of 50m. If the wire is longer

than 50m, these must be recalculated.

Page 15

SS-SVX07B-E4 15

Installation

Table 10 - Recommended piping R407C/R22

D3 D2 D1 Line diameter (inches)

Outdoor unit Indoor unit (m) (m) (m) Gas Liquid

TTK/TWK 512 MCD/MWD 512 20 12 15 1/2 1/4

TTK/TWK 518 MCD/MWD 518 24 18 24 5/8 3/8

TTK/TWK 524 MCD/MWD 524 24 18 24 5/8 3/8

TTK/TWK 530 MCD/MWD 530

12 12 12 5/8

3/8

40 18 24 7/8

TTK/TWK 536 MCD/MWD 536

18

18

18 3/4

3/8

40 24 7/8

TTK/TWK 048 MCD/MWD 048

24

18 24

7/8

3/8

40 1 1/8

TTK/TWK 060 MCD/MWD 060

18 12 18 7/8 3/8

40 18 24 1 1/8 1/2

Choice of installation

position

To ensure correct installation, the

following points must be

considered.

- The ceiling must be strong enough

to support the weight of the unit.

- Choose a place where it will be

easy to comply with the

recommended clearances, taking

into account the additional space

required due to external

accessories.

- Take into consideration the drilling

of the holes in the walls to connect

the unit.

- Make sure the maximum distances

between the two units are not

exceeded. See Figure 3 and

Table 10.

Figure 3- Recommended clearances and

maximum lengths used between two

units

Preparing the ceiling and installing

the unit

Drill holes in the ceiling to fix the

threaded rods according to the

dimensions given the Dimensions

section. The angle brackets can also

be used to space the drill holes.

Access is necessary on the

refrigerant connection side to

facilitate installation, maintenance

and access to the cabinet.

Four 8 mm diameter threaded rods

must be securely fixed into the

ceiling. Introduce the other end of

the rods through the slots of the unit

suspension brackets. Position the

shock absorbers, add washers and

screw the nuts down until the unit is

correctly supported. The unit must

be perfectly level in both directions

to ensure correct evacuation of the

condensates. If there is enough

space, a rubber or neoprene sheet

can be placed between the ceiling

and the unit.

Page 16

16 SS-SVX07B-E4

Installation

Refrigerant connections

It is possible to remove the electrical

cabinet to facilitate access to the

refrigerant connection.

Installation procedure

- Make sure the route taken by your

refrigerant lines is as short as

possible.

- Limit pressure losses in the lines

which may be caused by crushing

of the lines, a large number of

bends or bending radii that are too

small.

- Slope all the gas lines leaving the

indoor unit so that oil can return to

the compressor by gravity.

· Prevent any possibility of oil

trapped in the gas lines.

CAUTION!

An insufficiently lubricated

compressor may break down.

If the vertical difference in level

between the units is greater than

2.5 m, an oil trap must be positioned

at the bottom of the vertical line, and

an additional trap must be

positioned every 7.5 m of vertical

elevation to allow oil return to the

compressor. There are no special

technical recommendations for

liquid lines because of the wellbalanced mixture of refrigerant and

oil. Movement of the liquid

refrigerant also causes the oil to

move.

Passage of the tube and cable

bundle

Before drilling into the wall

- make sure there are no pipes or

electrical cables in the wall at the

place where you are going to drill

provide a protective sleeve for the

bundle of tubes and cables at the

point where it passes through the

hole (Figure 4). If permitted by

legislation, the condensate

drainage line can also be included

in the bundle. Wrap tape around

all the lines and cables from the

bottom of the outside unit to the

point where the piping enters the

wall. Carry out the same operation

for each circuit.

Figure 4 - Protective sleeve

A = Cable bundle

1 = Wall

2 = Inside

3 = Outside

A

Page 17

SS-SVX07B-E4 17

Installation

Brazed connections

These lines will be created on the

installation site. They will be

installed according to normal trade

practice by qualified personnel, in

compliance with local legislation.

1. Remove the plugs from the units'

refrigerant connections just before

connecting the piping, when all

the connections on the refrigerant

lines have been terminated. This

will prevent contamination by

humidity. Remove the rubber

plugs from the ends of the tubes.

2.Use a clean dry copper tube for

refrigeration installations.

3.Use silver brazing alloy only. Do

not overheat the welds and carry

out nitrogen scavenging inside the

tubes to prevent oxidization during

brazing.

4.Once all the other connections

have been made, debraze or cut

the plug on the outdoor unit's

refrigerant line connections.

Proceed in the same way as for

brazing of the indoor unit's lines.

Line insulation

To prevent heat losses and

condensation, both liquid and gas

lines must be thoroughly insulated.

Unscrew the Flare nuts which are

placed on the beginnings of the

indoor unit lines. Put the Flare nut

onto the tube. Splay the tube.

Connect the refrigerant tubes to the

indoor unit. Tighten the Flare nuts

using the recommended tightening

torques in Table 11. Insufficient

tightening will cause refrigerant

leaks. Use flat wrenches only (see

Figure 6). Repeat the operation for

each circuit.

Figure 6 - Tightening flare nuts

Table 11 -Recommended tightening

torques

Line diameter Tightening torque (kg/cm)

1/4'' 150-200

3/8'' 350-400

1/2'' 500-550

5/8'' 600-650

3/4'' 700-750

Screw/flare connections

CAUTION!

When cutting, deburring and

splaying the tubes, keep the end of

the tube down to make sure that

copper waste does not fall into the

lines.

Cut the copper tube using a pipecutter only (do not use a metalsaw).

Hold the tube downwards when

deburring it.

Figure 5 - Deburring recommendations

Page 18

18 SS-SVX07B-E4

Installation

Condensate connections

The unit must be perfectly level in

both directions. Connect the indoor

unit's condensate tray to a

condensate drainage line. The unit is

equipped with a 20 mm diameter

smooth tube connection. To ensure

correct condensate flow, the

drainage tube must be given a

10° slope. There must not be a

condensate trap at any point in the

line. However, a trap can be

provided to prevent outside air from

being taken in by the indoor unit. If

the tube enters a room, insulate it to

prevent condensation damage.

Figure 7 - Condensate drainage

connections

Electrical connections

All the wiring and earthing

arrangements must comply with

local legislation.

WARNING!

Never open the indoor or outdoor

unit without first disconnecting the

power supply. There is a risk of

electrocution.

CAUTION!

1. Check the electrical characteristics

on the unit's nameplate. Make

sure the wiring complies with the

manufacturer's electrical diagram

and local legislation.

2. Connect the units using one or

more lines protected by an

electrical disconnect device.

3. Ground each unit.

4. The cables must not touch the

refrigerant lines, the motors or

other moving parts and metal

edges.

5. The manufacturer does not

assume any liability for problems

caused by modifications made to

the unit's internal wiring.

6. Tighten the terminals securely.

7. For the electrical connections,

refer to the interconnection

diagrams attached with the

machine.

Page 19

SS-SVX07B-E4 19

Installation

Connecting the ducts

Units can be equipped with

rectangular discharge and/or intake

from the bottom or intake from the

back ducts.

WARNING!

The pressure loss in the network and

the accessories must not exceed the

unit's available static pressure given

in the selection data. The design and

installation shall be done by a

qualified technician and according to

local regulations.

Figure 8 - Discharge and intake duct

possibilities

A = Discharge

B = Intake from the bottom

C = Intake from the back

Table 12 - Duct connection dimensions

Unit size Length (mm) Height (mm)

512/518 748 198

524/530/536 948 248

048/060 1148 298

Filtering

Filtering the air is necessary to

ensure the unit's correct operation.

The unit is supplied with a filter.

Installing the wired

controller

Location

- Do not install thermostats near or

above a source of heat (i.e. direct

sunlight, hot lamps or radiator).

- Do not expose the controller to the

indoor unit discharge air stream.

- Do not place in a confined space.

Wiring

Electrical interconnection between

units must be in accordance with

national, state and local codes.

Units must be grounded. Refer to

the wiring diagrams that are shipped

with the unit.

Page 20

20 SS-SVX07B-E4

Operation

Creating a vacuum

For this operation, use a pump

capable of creating a vacuum of

1 mm Hg (1.3mbar) or less. To create

the vacuum you must connect the

pump to the Schrader pressure

connection on service valve

A located on the outdoor unit (gas

line). To use the vacuum pump,

follow the pump manufacturer's

instructions. Create a vacuum up to

2 mm Hg (2.6mbar) or less. Once the

value of 2mm Hg or less has been

reached, an increase in pressure will

be observed after a certain time. The

maximum permissible increase is

1 mm Hg after 15 minutes. If the

increase is greater and remains at a

constant value, this means there is

too much humidity in the system.

In this case, break the vacuum using

dry nitrogen and start the vacuum

creation procedure again.

A continuous increase in pressure

means there is a leak in the system.

WARNING!

Valves A and B must not be opened

before the installation of the

refrigerant circuit has been

completely finished, or the

refrigerant charge will be lost.

Figure 9 - Refrigerant circuit

1 = Outdoor unit

2 = Vacuum pump

3 = Indoor unit

4 = Gas line

5 = Liquid line

6 = TTK/TWK cooling mode

Additional refrigerant

charge

Once the system has been vacuum

pumped and is in operation and if

the distance between the units is

greater than 6m, it may be

necessary to add an additional

charge. Table 13 indicates the

amounts of refrigerant to add per

additional meter of line. Once the

appropriate amount of refrigerant

has been added, fully open liquid

line valve and check the operating

pressure.

Figure 10 - Adding refrigerant charge

1 = Outdoor unit

2 = Gas line

3 = Indoor units

4 = Liquid line

5 = For sizes 512 to 524

6 = For sizes 530 to 060

A

R22 Refrigerant

While the unit is operating, charge

the unit with gas through the service

Schraeder valve located at the

compressor suction. R22 refrigerant

can also be added in liquid phase in

the liquid line: see method used for

R407C. Never add liquid in the

suction line of the compressor.

R407C Refrigerant

WARNING! add only R407C

refrigerant in liquid state. Never add

liquid in the suction line of the

compressor period. Use service

Schraeder valve located on the liquid

line to charge the unit. While the unit

is operating, close partially the

service valve in order to create a

lower pressure downstream the

service valve. Add the refrigerant

necessary. Control the added weight

with a scale.

Table 13 - Additional refrigerant charge

Liquid line Gas line Additional

R22/R407C charge (g)

1/4'' 1/2'' 26

5/16" 5/8" 36

3/8'' 5/8'' 60

3/8'' 3/4'' 60

3/8'' 7/8'' 63

3/8'' 1 1/8'' 68

Page 21

SS-SVX07B-E4 21

Operation

Fan speed

Refer to the selection data to select

the static pressure according to the

flow rate. From this it is possible to

deduce a fan rotation speed. Once

you have chosen the speed, refer to

the interconnection diagram to

connect the room thermostat to the

unit electric cabinet in order to

power the correct selected speed.

Configuration and

operation

The unit is equipped with a control

board that manages operation of the

split system. It is fitted with 4

switches, SW1-1 to SW1-4.

Before start-up by a

qualified technician

Once the system has been installed,

it is recommend to carry out the

following checks.

1. Make sure no tools or debris

have been left inside, around or

on top of the unit.

2. Unit is perfectly level in both

directions.

3. Check the electrical connections

have been correctly done. Check

the electric power supply

corresponds to the units'

nameplates.

4. Make sure the disconnect

switches have been disengaged.

5. Check the refrigerant lines are

fixed securely.

6. Check if the condensate drain

pan is correctly installed.

7. Check the piping connections

and the water-tightness of the

connectors using an appropriate

leak detection method. Check

the connections on the site have

been tightened.

8. Make sure the gas piping and

the condensate drainage tube

are insulated properly to prevent

problems with trickling of

condensation water.

9. Check the fan turns freely.

10. Make sure the intake and

discharge ducts are not blocked.

11. Check the filters are correctly

positioned. Show the user how

to change the filters.

12. Power up the system and

observe operation carefully:

make any necessary

adjustments.

13. Explain to the user how to

operate the unit.

Unit display and

emergency switch

operation

Four lamps on the unit display show

operating status. In case of loss of

the remote control unit, the system

can be operated temporarily by the

emergency switch. The emergency

switch changes the system mode of

operation by cycling through the

following modes:

➠ FAN ➠ COOL ➠ HEAT ➠ AUTO ➠

OFF ➠.

COOL, HEAT and AUTO operation

are at fixed setting of 24°C. Fan

speed is controlled by the AUTO

mode. FAN only operation is at

HIGH fan speed.

Figure 11 - Unit display

1 = Remote control receiver - this picks up the

infrared signals from the wireless controller

2 = Fan lamp- lit when the fan is operating

3 = Cooling lamp - lit when the unit is

operating in COOL mode (or COMP ON in

AUTO mode)

4 = Heating lamp - lit when the unit is

operating in HEAT mode (or heater ON in

the HEAT mode of AUTO mode)

5 = Timer lamp - lit when the system is being

controlled by the timer

6 = Emergency switch

Wired controller operation

Figure 12 - Wired controller

1 = Press to turn on or off the unit, passing

through the different modes: OFF à COOL à

HEAT.

2 = Press TEMP + to increase the setting

temperature. Press TEMP - to decrease the

setting temperature. The setting

temperature will blink for 4 seconds, then

the current room temperature will display.

3 = Press to select the required fan speed. The

speed will be shown by LED indicators:

AUTO ➠ HIGH ➠ MEDIUM ➠ LOW ➠

AUTO

HIGH

MED

LOW

HEAT

COOL

POWER FAN

TEMP+

TEMP-

Page 22

22 SS-SVX07B-E4

Operation

Auto (optional)

The unit can be put into 5 different

modes (FAN, COOL, DRY, HEAT and

AUTO). The cycling will be:

➠ FAN ➠ COOL ➠ DRY ➠ HEAT ➠

HEAT ➠AUTO ➠

When the system is in AUTO mode,

the display on the remote controller

will show COOL and HEAT modes at

the same time.

Louver (optional)

To change the angle of the louver: if

the button is pressed and released,

the angle of the louver is changed

one step at a time. If the button is

pressed and held, the angle of the

louver is changed until the button is

released.

Sleep mode

For COOL mode, the setting

temperature will be automatically

raised 1°C after 1 hour. For HEAT

mode, the setting temperature will

be automatically lowered 1°C after 1

hour.

When the system is in SLEEP mode,

pressing the SLEEP button will

cancel the SLEEP function. When

the system is in SLEEP mode,

pressing the TEMP button will raise

the setting temperature 1°C from the

last setting.

When the system is in SLEEP mode

and the unit is stopped by a power

failure or is turned off, the SLEEP

function will be canceled.

Wireless controller

operation

To use the wireless controller, point

the transmitter head directly towards

the unit receiver to emit infrared

signals.

Figure 13 - Wireless controller

1. Operating mode

2. Fan speed

3. Fan button

4. Sleep button

5. Mode button

6. Sweep button - to turn on/off the sweep

motor

7. Louver button

8. Timer (start) button

9. Send button - to transmit all parameters

shown on the LCD to the main control

board

10. Clock

11. Timer (start/stop)

12. Transmit mode (lit when remote is being

used)

13. Sleep mode

14. Temperature (range: 16-30°C)

15. Power button

16. Temperature setting button

17. Stop button

18. Clock setting button

19. Minute setting button

20. Hour setting button

SLEEP MODE

SWEEP LOUVER

HOUR

START

SEND

TEMP

STOP

MIN

FAN

COOL

DRY

HEAT

10:14

18:40

6:30

START

STOP

HIGH

MED

LOW

AUTO

Clock

To set the clock:

- Press the clock setting button

(Figure 13, 18). The time display

will blink.

- Press the HOUR button to set the

hour. (Figure 13, 20)

- Press the MIN button to set the

minutes. (Figure 13, 19)

- Press the clock setting button

again. The time display will stop

blinking.

Auto start

The unit can be programmed to start

automatically. To program:

- Press the START button. (Figure

13, 8) The time display will blink.

- Press the HOUR button to set the

hour. (Figure 13, 20)

- Press the MIN button to set the

minutes. (Figure 13, 19)

- Press the START button again. The

time display will stop blinking.

Auto stop

The unit can be programmed to stop

automatically. To program:

- Press the STOP button. (Figure 13,

17) The time display will blink.

- Press the HOUR button to set the

hour. (Figure 13, 20)

- Press the MIN button to set the

minutes. (Figure 13, 19)

- Press the STOP button again. The

time display will stop blinking.

Page 23

SS-SVX07B-E4 23

Maintenance

WARNING!

Disconnect the unit's power supply

before servicing the unit. When

servicing the units, make sure that

the air passages through the coils

(both internal and external) are

clean, and free of dirt and debris.

Periodic maintenance

CAUTION!

Failure to follow these instructions

may cause damage to the unit. The

frequency of servicing will depend

on the conditions for use of the unit,

and will be determined by regular

inspections.

1. Check the condensate piping is

not blocked.

2. Turn the fan blades manually and

make sure they are not damaged.

Clean them if necessary and

verify their alignment.

3. Motor - check the wiring, and

ensure the commutators are

operating correctly. Replace any

damaged components.

4. Disconnection of power and

electrical components - check for

correct operation.

5. Refrigerant circuit - use an

appropriate leak detection method

to check for leaks.

6. Tighten all the screws and bolts.

7. Make sure that the air passages

through the coils (both internal

and external) are clean, and free

of dirt and debris.

8. Clean the filter by beating it and

applying suction in the opposite

direction to the airflow.

Handling the filter

1. To remove the filter, slightly push

the 4 clips down.

2. Remove the filter.

3. To put the filter back, just clip the

filter back into place

Page 24

24 SS-SVX07B-E4

Maintenance

Table 14 - Troubleshooting

Symptoms Possible causes Checks Corrective action

No cooling or

heating

A. Compressor or fan is not operating.

1. Loose electrical connections. 1. Tighten the connections if necessary.

2. Check the fuses and wiring. 2. Replace the fuses if necessary.

B. The fan is operating but the compressor

does not start.

1. Check the compressor's wiring and

winding resistors.

1. If the check shows the motor windings

are broken or earthed, replace the

compressor.

2. Check the capacitor 2. Replace if necessary.

C. The compressor is operating but the fan

does not start.

1. Check the fan motor, the capacitor or

the wiring.

1. Repair or replace

D. Control switch is defective, incorrectly

wired or adjusted.

1. Check the control switch connections

and the temperature setting.

1. Change the setting. Replace if defective.

Insufficient heating

or cooling

A. Lack of refrigerant fluid. 1. Check there are no leaks. 1. Drain, repair and recharge.

B. Insufficient air volume.

1. Check the air filter. 1. Clean and replace.

2. Check the fin assemblies are clean. 2. Clean if obstructed.

3. Check the fan.

3. If the fan is loose on its shaft, tighten the

fixing bolts.

4. Check the wiring and capacitors. 4. Repair or replace

C. Obstructed capillaries or blocked orifice.

1. Check there is no humidity in the

system.

1. Drain and recharge.

Page 25

SS-SVX07B-E4 25

Maintenance

Symptoms Possible causes Checks Corrective action

The system operates

for too long or

continuously.

A. Control switch no longer responds to the

ambient temperature.

1. Check operation and connections of

the control switch.

1. Replace the control switch if it is defective.

B. Loss of refrigerant fluid. 1. Check there are no leaks in the system. 1. Repair and recharge.

C. Insufficient ventilation.

1. Check the air circulation in the

condenser.

1. Make sure air circulation is satisfactory.

Move the outdoor unit if necessary.

D. Incorrectly adjusted control switch. 1. Check the set point. 1. Adjust or replace if defective.

System operates in

short cycles.

A. Defective control switch 1. Check operation of the control switch. 1. Replace if defective.

B. Insufficient air circulation.

1. Check air circulation in the indoor and

outdoor units.

1. Clean the coil and filter if necessary.

C. Insufficient or excess refrigerant fluid.

1. Check if there are leaks or excess

pressure.

1. Repair if there are leaks. Add or remove

refrigerant fluid.

D. Incorrect electric power supply. 1. Check the electric power supply. 1. Find cause and stabilise the power supply.

Internal coil frozen.

A. Insufficient refrigerant fluid. 1. Check if there are leaks in the system. 1. Repair the leak and recharge.

B. Insufficient air circulation.

1. Check the filter. 1. Clean and put back in position.

2. Check the fin block.

2. Clean the fins. If the filter is missing, install

one.

3. Check the fan.

3. Fan free on the bearing, tighten the fixing

screws - connection fault, find the cause

and repair.

C. Defective anti-frost sensor. 1. Check the sensor. 1. Replace if necessary.

Unit is noisy

A. Defective installation.

1. Check installation of the compressor

and motor.

1. Tighten any loose components.

2. Check the fan position.

2. If the fan is rubbing against a part, re-align

it.

3. Check for vibrations of piping and

crankcase.

3. Find the cause and repair.

4. Check positioning of unit concerning

noise and vibrations.

4. Find the cause and repair.

B. Motor bearings are worn. 1. Check the motor. 1. Replace the motor if necessary.

C. Noisy compressor. 1. Check if the compressor is losing oil. 1. Locate the leak, repair and add oil.

D. Excess refrigerant fluid or oil. 1. Remove the excess charge.

Page 26

26 SS-SVX07B-E4

Table 15 - Trouble-shooting (electric heating only)

Trouble-shooting

(electric heating only)

Controller troubleshooting

The controller has a built-in selfdiagnostic function. The following

LEDs are used to indicate the

problem or status.

Auto/High/Medium/Low LEDs

show fan speed setting.

Cool LED shows the COOL operating

mode.

- If the cooling fail protection is

active, this LED will be blinking

with the signal as per Figure 14, A.

- If anti-overheat or low ambient

protection is active, this LED will

be blinking with the signal as per

Figure 14, B.

Heat LED shows the HEAT

operating mode.

- If the heating fail protection is

active, this LED will be blinking

with the signal as per Figure 14, A.

- If the compressor overload

protection is active, this LED will

be blinking with the signal as per

Figure 14, B.

7-segment LED (2 digits) shows the

room temperature if lit, and the

setting temperature while blinking.

Dot LED after the first digit of

7-segment LED, if blinking indicates

any of the room, freeze or defrost

sensor is open or short circuit.

Dot LED after the second digit of

7-segment LED, indicates that the

compressor is on if lit, and indicates

either the freeze or defrost

protection is active if blinking.

Figure 14 - LEDs blinking signals

On-board setting

There is 1 jumper location on the

main control board which is related

to this setting. If the jumper is put at

OP4 location, both heat pump and

heater can be operated. If not, only

heat pump can be operated.

No heating. A. Incorrect control switch setting. 1. Check the thermostat's set points and

operation.

1. Change the settings.

B. Defective control switch. 1. Check operation and the signal to the

heating device.

1. Repair or replace.

C. Defective heater temp. limit switch. 1. Check the heater temp. limit switch. 1. Replace the defective switch.

D. Unit wiring is incorrect. 1. Check the wiring. 1. Modify the wiring as indicated on

the wiring diagram.

E. The heater temperature limit switch

has opened.

1. Check tightness of the indoor unit's

fan on its shaft.

1. Tighten the fixing screws.

F. Dirty air filter. 1. Check the filter. 1. Clean the filter.

G. Indoor unit coil fins obstructed. 1. Check the filter is not missing. 1. Fix the filter.

H. Defective electrical component. 1. Check all the components are correct.

2. Check the fin block.

1. Replace the defective component.

2. Clean the fins.

Page 27

SS-SVX07B-E4 27

Notes

Page 28

Safety recommendations

To avoid accidents and damage, the

following recommendations should

be observed during maintenance

and service visits :

1. Never apply pressure higher than

7 bar for tests.

2. Disconnect the main supply

before any servicing on the unit.

3. Service work on the refrigeration

system and the electrical system

should be carried out only by

qualified and experienced

personnel.

Maintenance contract

It is strongly recommended that you

sign a maintenance contract with

your local Service Agency. This

contract provides regular

maintenance of your installation by

a specialist in our equipment.

Regular maintenance ensures that

any malfunction is detected and

corrected in good time and

minimizes the possibility that

serious damage will occur. Finally,

regular maintenance ensures the

maximum operating life of your

equipment. We would remind you

that failure to respect these

installation and maintenance

instructions may result in immediate

cancellation of the warranty.

Training

The equipment described in this

manual is the result of many years

of research and continuous

development. To assist you in

obtaining the best use of it, and

maintaining it in perfect operating

condition over a long period of time,

the constructor has at your disposal

a refrigeration and air conditioning

service school. The principal aim of

this is to give operators and

maintenance technicians a better

knowledge of the equipment they

are using, or that is under their

charge. Emphasis is particularly

given to the importance of periodic

checks on the unit operating

parameters as well as on preventive

maintenance, which reduces the cost

of owning the unit by avoiding

serious and costly breakdown.

Trane has a policy of continuous product and product data improvement and reserves the right to

change design and specifications without notice.

Only qualified technicians should perform the installation and servicing of equipment referred to in

this publication..

Literature Order Number SS-SVX07B-E4

Date 0808

Supersedes SS-SVX07A-E4_0606

Stocking Location Europe

www.trane.com

For more information contact your local

district office or e-mail us at comfort@trane.com

Trane bvba

Chaussée de Wavre 1789 - 1160 Brussels, Belgium

ON 0888.048.262 - RPR BRUSSELS

Loading...

Loading...